Effects of Isomaltulose and Gamma-Irradiated Taro Flour on Selected Physicochemical Properties and Consumer Acceptance of Pudding

Abstract

1. Introduction

2. Materials and Methods

2.1. Pudding Preparation

2.2. Gamma Irradiation and Proximate Chemical Composition of Taro Flour

2.3. Determination of Physicochemical Properties of Puddings

2.4. Microbial Analysis of Pudding Samples

2.5. Consumer Acceptance Test

2.6. Volatile Profile Analysis by GC-MS

2.7. Statistical Analysis

3. Results and Discussion

3.1. The Effects of Different Types of Sugar on the Physicochemical Properties and Consumer Acceptance of Puddings

3.2. The Effects of Gamma Irradiation on the Proximate Composition of Taro Flour

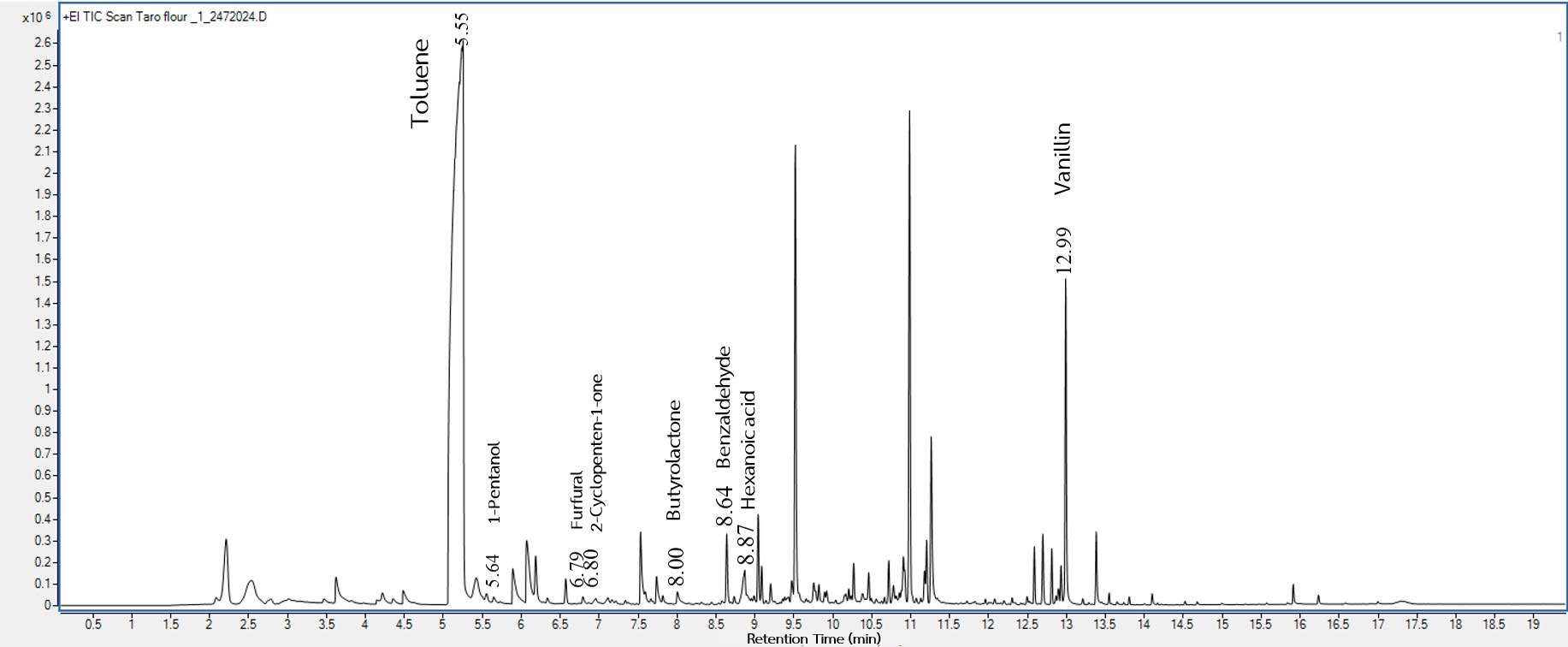

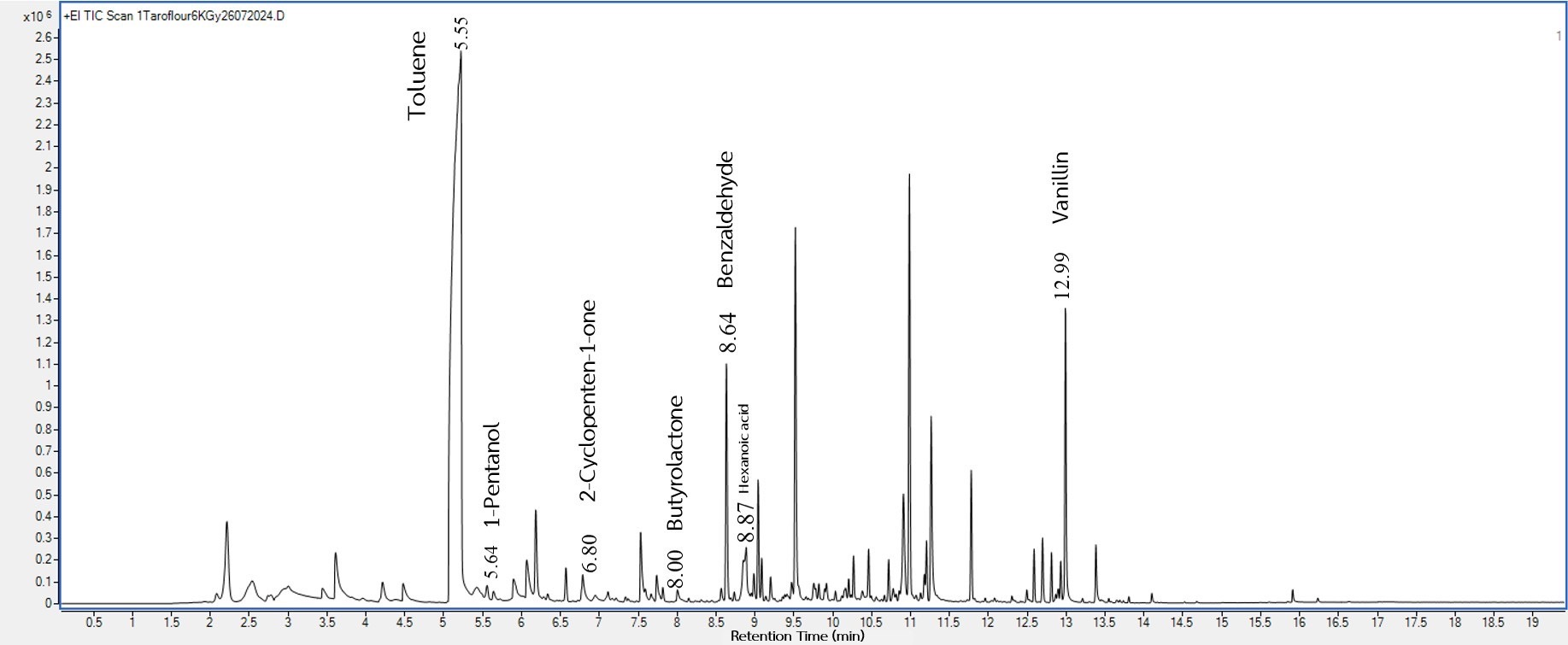

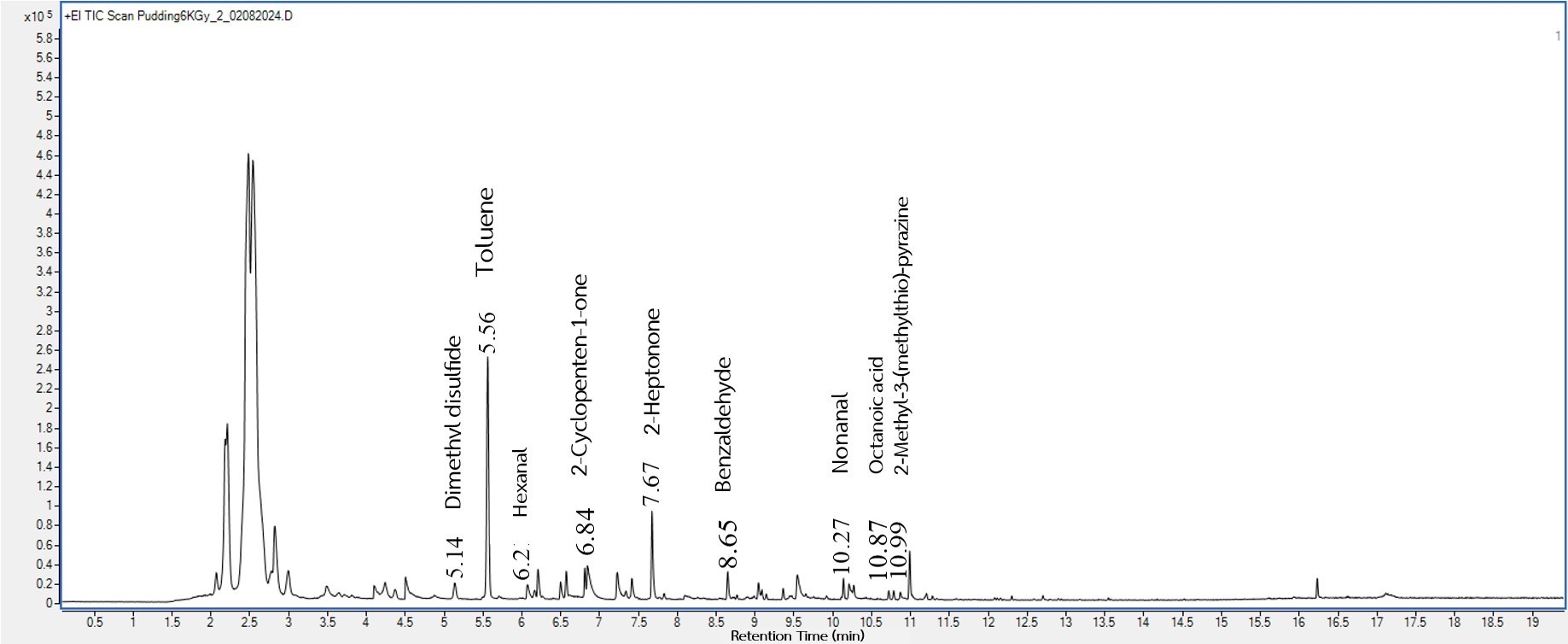

3.3. The Effects of Gamma Irradiation on the Volatile Profile of Taro Flour and Puddings

| Compound | RT | Peak Area | Odor Description | References | |

|---|---|---|---|---|---|

| 0 kGy | 6 kGy | ||||

| Dimethyl disulfide | 5.14 | 7.8 × 104 | 6.3 × 104 | Onion | [23] |

| Toluene | 5.56 | 3.5 × 105 | 4.3 × 105 | Sweet | [21] |

| Hexanal | 6.21 | 4.6 × 104 | 3.1 × 104 | Grass, Tallow, Fat | [23] |

| 2-Cyclopenten-1-one | 6.84 | ND | 1.2 × 105 | Jasmine, Sweet | [24] |

| 2-Heptonone | 7.67 | 1.0 × 105 | 1.3 × 105 | Fruity | [23] |

| Benzaldehyde | 8.65 | 2.2 × 104 | 3.9 × 104 | Almond, Nutty | [23] |

| Nonanal | 10.27 | 2.6 × 104 | 1.5 × 104 | Fat, Green | [23] |

| Octanoic acid | 10.87 | 3.1 × 104 | 1.4 × 104 | Sweat, Cheese | [23] |

| 2-Methyl-3-(methylthio)-pyrazine | 10.99 | 3.8 × 104 | 6.3 × 104 | Nutty | [27] |

3.4. The Effects of Gamma-Irradiated Taro Flour on the Physicochemical Properties, Microbial Safety, and Consumer Acceptance of Puddings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Department of Agricultural Extension. Taro. Available online: https://esc.doae.go.th/wp-content/uploads/2015/02/taro.pdf (accessed on 15 June 2024).

- Med Thai. Taro Properties and Benefits. Available online: https://medthai.com (accessed on 15 June 2024).

- Ferdaus, M.J.; Chukwu-Munsen, E.; Foguel, A.; da Silva, R.C. Taro Roots: An Underexploited Root Crop. Nutrients 2023, 15, 3337. [Google Scholar] [CrossRef]

- Alcantara, R.M.; Hurtada, W.A.; Dizon, E.I. The Nutritional Value and Phytochemical Components of Taro [Colocasia esculenta (L.) Schott] Powder and its Selected Processed Foods. J. Nutr. Food Sci. 2013, 3, 207. [Google Scholar] [CrossRef]

- Ertop, M.H.; Atasoy, R.; Akın, Ş.S. Evaluation of Taro [Colocasia Esculenta (L.) Schott] Flour as a Hydrocolloid on the Physicochemical, Rheological, and Sensorial Properties of Milk Pudding. J. Food Process. Preserv. 2020, 44, e14103. [Google Scholar] [CrossRef]

- Xie, J.; Li, J.; Qin, Q.; Ning, H. Effect of Isomaltulose on Glycemic and Insulinemic Responses: A Systematic Review and Meta-analysis of Randomized Controlled Trials. Adv. Nutr. 2022, 13, 1901–1913. [Google Scholar] [CrossRef]

- Kobayashi, R.; Sakazaki, M.; Nagai, Y.; Asaki, K.; Hashiguchi, T.; Negoro, H. Effects of Different Types of Carbohydrates on Arterial Stiffness: A Comparison of Isomaltulose and Sucrose. Nutrients 2021, 13, 4493. [Google Scholar] [CrossRef]

- Theprugsa, P.; Vatthanakul, S.; Limroongreungrat, K.; Khwansakool, P.; Wongmaneepratip, W.; Sajjabut, S.; Prinyawiwatkul, W. Selected Physico-Chemical and Morphological Properties of Gamma-Irradiated Tapioca Flour, Rice Flour, and Pea Flours. Int. J. Food Sci. Technol. 2024, 59, 2592–2602. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Majzoobi, M.; Ghiasi, F.; Eskandari, M.H.; Farahnaky, A. Roasted Wheat Germ: A Natural Plant Product in Development of Nutritious Milk Pudding; Physicochemical and Nutritional Properties. Foods 2022, 11, 1815. [Google Scholar] [CrossRef]

- Eadmusik, S.; Chaiya, D.; Soichuen, S. Utilization of Egg Albumen: Application and Optimization of Gelatin and Carrageenan for Pudding Production via Response Surface Methodology (RSM). E3S Web Conf. 2020, 141, 02004. [Google Scholar] [CrossRef]

- U.S. Food and Drug Administration. Chapter 3: Aerobic plate count. In Bacteriological Analytical Manual Online; U.S. Department of Health and Human Services: Washington, DC, USA, 2001. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 21st ed.; AOAC: Gaithersburg, MD, USA, 2019. [Google Scholar]

- Hadjikinova, R.D. Comparative characteristics of instant creams with sugar and isomaltulose. IOP Conf. Ser. Mater. Sci. Eng. 2020, 1031, 012102. [Google Scholar] [CrossRef]

- Bakó, I.; Pusztai, L.; Pothoczki, S. Outstanding Properties of the Hydration Shell around β-D-Glucose: A Computational Study. ACS Omega 2024, 9, 20331–20337. [Google Scholar] [CrossRef]

- Sawale, P.D.; Shendurse, A.M.; Mohan, M.S.; Patil, G.R. Isomaltulose (Palatinose)—An emerging carbohydrate. Food Biosci. 2017, 18, 46–52. [Google Scholar] [CrossRef]

- Khemakhem, M.; Attia, H.; Ayadi, M.A. The effect of pH, sucrose, salt and hydrocolloid gums on the gelling properties and water holding capacity of egg white gel. Food Hydrocoll. 2019, 87, 11–19. [Google Scholar] [CrossRef]

- Hadjikinova, R.; Petrova, I. Effect of sucrose replacement on nutritional parameters and sensory characteristics of the lollipops with isomaltulose. BIO Web Conf. 2023, 58, 01013. [Google Scholar] [CrossRef]

- Bashir, K.; Swer, T.L.; Prakash, K.S.; Aggarwal, M. Physico-chemical and functional properties of gamma irradiated whole wheat flour and starch. Food Sci. Technol. 2017, 76, 131–139. [Google Scholar] [CrossRef]

- Bashir, K.; Aggarwal, M. Effects of gamma irradiation on the physicochemical, thermal and functional properties of chickpea flour. Food Sci. Technol. 2016, 69, 614–622. [Google Scholar] [CrossRef]

- Hong, X.; Wang, C.; Jiang, R.; Hu, T.; Zheng, X.; Huang, J.; Liu, Z.; Li, Q. Characterization of the Key Aroma Compounds in Different Aroma Types of Chinese Yellow Tea. Foods 2023, 12, 27. [Google Scholar] [CrossRef]

- Ajarayasiri, J.; Chaiseri, S. Aroma Active Compounds of Thai Taro (Colocasia esculenta L.); Department of Food Science and Technology, Kasetsart University: Bangkok, Thailand, 2008. [Google Scholar]

- Terry, A.; Heinrich, A. Flavornet and Human Odor Space. 2004. Available online: https://www.flavornet.org/flavornet.html (accessed on 15 August 2024).

- Liu, Y.; Li, W.; Tan, Q.; Li, Z.; Wang, H.; Suo, H. Characterization and comparison of key aroma compounds in traditional and rapid Yongchuan douchi by molecular sensory science. Food Sci. Technol. 2024, 191, 115607. [Google Scholar] [CrossRef]

- Huang, X.; You, Y.; Liu, Q.; Dong, H.; Bai, W.; Lan, B.; Wu, J. Effect of gamma irradiation treatment on microstructure, water mobility, flavor, sensory and quality properties of smoked chicken breast. Food Chem. 2023, 421, 136174. [Google Scholar] [CrossRef]

- Wang, H.; Yang, R.; Liu, Y.; Zhang, W.; Zhao, W.; Zhang, Y.; Hua, X. Effects of Low Dose Gamma Irradiation on Microbial Inactivation and Physicochemical Properties of Fried Shrimp (Penaeus vannamei). Int. J. Food Sci. Technol. 2010, 45, 1088–1096. [Google Scholar] [CrossRef]

- Puvipirom, J.; Chaiseri, S. Volatile Compounds in Thai Robusta Coffee. In Proceedings of the 41st Kasetsart University Annual Conference: Agro-Industry; Kasetsart University: Bangkok, Thailand, 2000; pp. 124–131. [Google Scholar]

- Barkaoui, S.; Mankai, M.; Miloud, N.B.; Kraïem, M.; Madureira, J.; Verde, S.C.; Boudhrioua, N. Effect of gamma radiation coupled to refrigeration on antioxidant capacity, sensory properties and shelf life of strawberries. Food Sci. Technol. 2021, 150, 112088. [Google Scholar] [CrossRef]

- Liu, D.; Liu, Z.; Lan, B.; Ma, L.; Huang, H.; Xiao, G.; Wang, Q.; Wang, F. 60Co γ-radiation at low-dose level alters volatile compounds of blueberry during storage. Int. J. Food Sci. Technol. 2024, 59, 4081–4092. [Google Scholar] [CrossRef]

- Hussain, P.R.; Suradkar, P.P. Low dose irradiation of plum peel anthocyanins: Impact on stability and antioxidant activity. J. Food Saf. Hyg. 2020, 6, 205–220. [Google Scholar] [CrossRef]

- Gani, A.; Gazanfar, T.; Jan, R.; Wani, S.M.; Masoodi, F.A. Effect of gamma irradiation on the physicochemical and morphological properties of starch extracted from lotus stem harvested from Dal Lake of Jammu and Kashmir, India. J. Saudi Soc. Agric. Sci. 2013, 12, 109–115. [Google Scholar] [CrossRef]

- Bhat, S.A.; Singla, M.; Goraya, R.K.; Kumar, Y.; Jan, K.; Bashir, K. Dose-Dependent Effects of Gamma Irradiation on Microbiological, Antioxidant, and Functional Properties of Buckwheat, Cowpea, Oat, and Brown Rice Flour. J. Food Process. Preserv. 2024, 48, e17325. [Google Scholar] [CrossRef]

- Bhat, N.A.; Wani, I.A.; Sultan, N. Effect of Gamma-irradiation on the Physicochemical, Functional, and Antioxidant Properties of Unpigmented Brown Whole Rice Flour. Food Sci. Technol. Int. 2023, 29, 228–242. [Google Scholar] [CrossRef]

- Singh, S.; Habib, M.; Mondal, D.; Kumar, Y.; Jan, S.; Bashir, K.; Rao, E.S.; Jan, K. Gamma Irradiation–Induced Structural Modification of Sorghum Flour and Its Impact on the Physicofunctional, Rheological and Thermal Properties of Extracted Starch. J. Food Process. Preserv. 2024, 48, e17325. [Google Scholar] [CrossRef]

- Boshevska, M.; Sandeva, I.; Verde, S.C.; Spasevska, H.; Jankuroski, Z. Effects of different irradiation doses and storage period on microbiological characteristics of wheat (Triticum aestivum L.). Food Control 2024, 158, 107063. [Google Scholar] [CrossRef]

- Zheng, Q.; Tian, W.; Yue, L.; Wang, S.; Zhang, Y.; Chen, Z.; Qi, W.; Zhang, C.; Yan, W.; Kong, Q. Effect of gamma irradiation on sensory and aroma compounds of soaked bayberry jiu. Radiat. Phys. Chem. 2024, 208, 111990. [Google Scholar] [CrossRef]

| Ingredient (%) | Pudding Samples | ||

|---|---|---|---|

| Sucrose (S) | 5% Isomaltulose (5I) | 10% Isomaltulose (10I) | |

| Lactose-free milk | 65 | 65 | 62 |

| Water | 26 | 26 | 24 |

| Sucrose | 5 | 0 | 0 |

| Isomaltulose | 0 | 5 | 10 |

| Taro flour | 3 | 3 | 3 |

| Agar | 1 | 1 | 1 |

| Pudding Samples | TSS (°Brix) | pH |

|---|---|---|

| S (sugar) | 16.50 b ± 0.71 | 6.54 a ± 0.01 |

| 5I (5% isomaltulose) | 15.50 b ± 0.71 | 6.13 a ± 0.65 |

| 10I (10% isomaltulose) | 21.50 a ± 0.71 | 6.51 a ± 0.06 |

| Pudding Samples | L* (Lightness) | a* (Redness) | b* (Yellowness) |

|---|---|---|---|

| S (sugar) | 71.06 ± 1.41 ns | 3.34 ± 0.50 ns | 4.47 ± 0.73 ns |

| 5I (5% isomaltulose) | 71.84 ± 0.01 | 3.34 ± 0.33 | 3.35 ± 0.23 |

| 10I (10% isomaltulose) | 70.86 ± 1.12 | 3.08 ± 0.69 | 3.10 ± 1.08 |

| Pudding Samples | Day 1 | Day 15 |

|---|---|---|

| S (sugar) | 4.28 ± 1.30 ns | 11.77 a ± 0.25 |

| 5I (5% isomaltulose) | 4.11 ± 0.66 | 11.00 b ± 0.73 |

| 10I (10% isomaltulose) | 4.48 ± 0.61 | 10.61 b ± 0.34 |

| Pudding Samples | Hardness (g) | Springiness | Cohesiveness | Gumminess (g) |

|---|---|---|---|---|

| S (sugar) | 793.64 b ± 79.48 | 0.55 ± 0.07 ns | 0.13 a ± 0.01 | 106.56 ± 10.27 ns |

| 5I (5% isomaltulose) | 804.10 b ± 58.47 | 0.54 ± 0.10 | 0.13 a ± 0.01 | 104.25 ± 10.63 |

| 10I (10% isomaltulose) | 915.93 a ± 54.56 | 0.54 ± 0.08 | 0.12 b ± 0.01 | 109.21 ± 10.08 |

| Pudding Samples | Appearance | Color | Flavor | Texture | Taste | Overall Liking |

|---|---|---|---|---|---|---|

| S (sugar) | 7.17 c ± 1.3 | 7.50 ± 1.4 ns | 6.57 ± 1.6 ns | 6.17 b ± 1.6 | 6.83 a ± 1.4 | 6.93 b ± 1.3 |

| 5I (5% isomaltulose) | 7.23 b ± 1.3 | 7.47 ± 1.5 | 6.90 ± 1.7 | 5.37 c ± 1.8 | 4.90 b ± 2.0 | 5.63 c ± 1.6 |

| 10I (10% isomaltulose) | 7.70 a ± 1.5 | 7.70 ± 1.3 | 6.37 ± 1.9 | 7.60 a ± 1.5 | 7.00 a ± 1.8 | 7.40 a ± 1.3 |

| Dose (kGy) | Moisture (%) | Fat (%) | Protein (%) | Ash (%) | Total Carbohydrate (%) |

|---|---|---|---|---|---|

| 0 | 5.55 ± 0.06 ns | 0.37 ± 0.01 ns | 0.74 ± 0.04 ns | 1.14 ± 0.06 ns | 92.20 |

| 2 | 5.40 ± 0.04 | 0.37 ± 0.01 | 0.73 ± 0.04 | 1.19 ± 0.01 | 92.31 |

| 4 | 5.35 ± 0.19 | 0.38 ± 0.01 | 0.73 ± 0.04 | 1.12 ± 0.11 | 92.42 |

| 6 | 5.36 ± 0.16 | 0.40 ± 0.01 | 0.78 ± 0.01 | 1.16 ± 0.07 | 92.30 |

| Compound | RT | Peak Area | Odor Description | References | |||

|---|---|---|---|---|---|---|---|

| 0 kGy | 2 kGy | 4 kGy | 6 kGy | ||||

| Toluene | 5.55 | 7.3 × 104 | 6.5 × 104 | 9.1 × 104 | 9.8 × 104 | Sweet | [21] |

| 1-Pentanol | 5.64 | 5.3 × 104 | 5.1 × 104 | 5.7 × 104 | 7.3 × 104 | Taro, Sweet | [22] |

| Furfural | 6.79 | 6.6 × 104 | 5.7 × 104 | ND | ND | Bread, Almond, Sweet | [23] |

| 2-Cyclopenten-1-one | 6.80 | 1.2 × 104 | 1.1 × 105 | 2.6 × 105 | 2.9 × 105 | Jasmine, Sweet | [24] |

| Butyrolactone | 8.00 | 9.7 × 104 | 1.9 × 105 | 1.6 × 105 | 1.4 × 105 | Caramel, Sweet | [23] |

| Benzaldehyde | 8.64 | 3.7 × 105 | 5.4 × 105 | 7.5 × 105 | 1.4 × 106 | Almond, Nutty | [23] |

| Hexanoic acid | 8.87 | 7.7 × 105 | 5.6 × 105 | 4.9 × 105 | 2.9 × 105 | Sweat, Cheese | [23] |

| Vanillin | 12.99 | 2.2 × 106 | 1.9 × 106 | 9.1 × 105 | 1.9 × 106 | Vanilla, Sweet | [23] |

| Dose (kGy) | TSS (°Brix) | pH |

|---|---|---|

| 0 | 21.67 ± 0.52 ns | 6.50 ± 0.03 ns |

| 2 | 22.00 ± 0.00 | 6.50 ± 0.02 |

| 4 | 21.67 ± 0.52 | 6.52 ± 0.03 |

| 6 | 22.00 ± 0.63 | 6.48 ± 0.03 |

| Dose (kGy) | L* | a* | b* |

|---|---|---|---|

| 0 | 71.88 ± 1.36 ns | 3.78 a ± 0.17 | 3.78 b ± 0.22 |

| 2 | 71.71 ± 2.13 | 3.26 b ± 0.26 | 4.14 a ± 0.13 |

| 4 | 71.84 ± 0.86 | 3.28 b ± 0.39 | 4.41 a ± 0.31 |

| 6 | 71.52 ± 0.94 | 3.86 a ± 0.53 | 4.33 a ± 0.20 |

| Dose (kGy) | Day 1 | Day 15 |

|---|---|---|

| 0 | 5.58 a ± 0.68 | 11.64 a ± 0.22 |

| 2 | 5.13 b ± 0.72 | 9.45 b ± 0.41 |

| 4 | 5.03 b ± 0.59 | 9.39 b ± 0.31 |

| 6 | 4.89 b ± 0.25 | 9.03 b ± 0.41 |

| Dose (kGy) | Hardness (g) | Springiness | Cohesiveness | Gumminess (g) |

|---|---|---|---|---|

| 0 | 890.43 c ± 141.01 | 0.51 ± 0.07 ns | 0.14 a ± 0.02 | 121.82 b ± 12.12 |

| 2 | 1004.56 b ± 111.20 | 0.53 ± 0.08 | 0.13 ab ± 0.02 | 126.82 b ± 12.15 |

| 4 | 1025.89 b ± 94.54 | 0.52 ± 0.06 | 0.13 ab ± 0.02 | 128.63 b ± 7.22 |

| 6 | 1134.31 a ± 48.53 | 0.52 ± 0.06 | 0.12 b ± 0.01 | 137.56 a ± 13.85 |

| Dose (kGy) | Total Plate Count (CFU/g) | Yeasts and Molds (CFU/g) | ||

|---|---|---|---|---|

| Day 0 | Day 7 | Day 0 | Day 7 | |

| 0 | 45 a ± 3 | 120 a ±10 | <10 ns | <10 ns |

| 6 | 30 b ± 4 | <10 b | <10 | <10 |

| Dose (kGy) | Appearance | Color | Flavor | Texture | Taste | Overall Liking |

|---|---|---|---|---|---|---|

| 0 | 7.73 ± 1.2 ns | 7.60 ± 1.0 ns | 6.97 ab ± 1.5 | 6.73 ± 1.4 ns | 6.83 ± 1.7 ns | 6.90 b ± 1.3 |

| 2 | 7.83 ± 1.2 | 7.53 ± 1.1 | 6.80 b ± 1.1 | 6.83 ± 1.5 | 6.77 ± 1.4 | 6.70 b ± 1.1 |

| 4 | 8.03 ± 1.0 | 7.83 ± 1.02 | 6.87 ab ± 1.2 | 6.87 ± 1.4 | 6.70 ± 1.3 | 6.83 b ± 1.3 |

| 6 | 7.97 ± 1.0 | 7.90 ± 1.0 | 7.30 a ± 1.0 | 7.07 ± 1.2 | 7.20 ± 1.2 | 7.30 a ± 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vatthanakul, S.; Salamun, N.; Cheersomsuk, T.; Chuenchomrat, P.; Suthipibul, P.; Sajjabut, S.; Prinyawiwatkul, W. Effects of Isomaltulose and Gamma-Irradiated Taro Flour on Selected Physicochemical Properties and Consumer Acceptance of Pudding. Foods 2025, 14, 3350. https://doi.org/10.3390/foods14193350

Vatthanakul S, Salamun N, Cheersomsuk T, Chuenchomrat P, Suthipibul P, Sajjabut S, Prinyawiwatkul W. Effects of Isomaltulose and Gamma-Irradiated Taro Flour on Selected Physicochemical Properties and Consumer Acceptance of Pudding. Foods. 2025; 14(19):3350. https://doi.org/10.3390/foods14193350

Chicago/Turabian StyleVatthanakul, Suteera, Napassorn Salamun, Tatcha Cheersomsuk, Pumnat Chuenchomrat, Philipda Suthipibul, Surasak Sajjabut, and Witoon Prinyawiwatkul. 2025. "Effects of Isomaltulose and Gamma-Irradiated Taro Flour on Selected Physicochemical Properties and Consumer Acceptance of Pudding" Foods 14, no. 19: 3350. https://doi.org/10.3390/foods14193350

APA StyleVatthanakul, S., Salamun, N., Cheersomsuk, T., Chuenchomrat, P., Suthipibul, P., Sajjabut, S., & Prinyawiwatkul, W. (2025). Effects of Isomaltulose and Gamma-Irradiated Taro Flour on Selected Physicochemical Properties and Consumer Acceptance of Pudding. Foods, 14(19), 3350. https://doi.org/10.3390/foods14193350