Hemp-Based Meat Analogs: An Updated Review on Extraction Technologies, Nutritional Excellence, Functional Innovation, and Sustainable Processing Technologies

Abstract

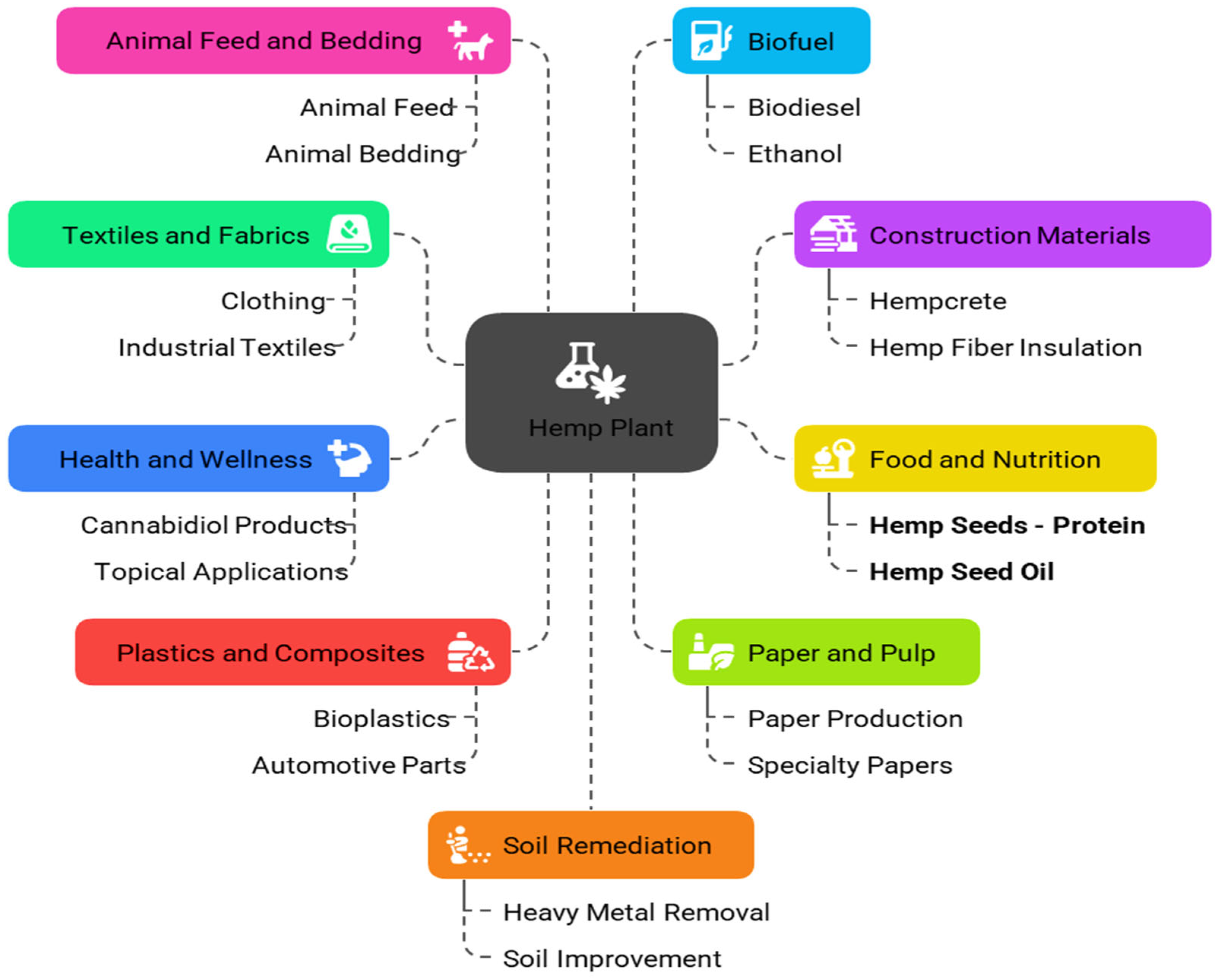

1. Introduction

2. Methodology

3. Comparative Analysis of Hemp Protein Extraction Technologies

4. Nutritional Profile and Health Benefits

5. Textural and Sensory Properties with Protein Blends

6. Techno-Functional Properties

6.1. Protein Structure and Functionality

6.2. Impact of Processing

7. Applications in Food Products

7.1. Nutritional and Health Implications

7.2. Technological Innovations

- •

- Harnessing precision fermentation via specific microbial strains to develop natural flavor compounds—such as heme analogs, savory peptides, and aroma volatiles—can impart authentic meaty notes and mask any lingering off-notes typical of plant proteins. This approach allows the creation of “fermented hemp bases” that deliver elevated umami and complexity, enhancing consumer acceptance [95]. Also, the use of 3D printing technology enables the creation of customizable fibrous structures and marbling patterns that mimic muscle tissue and fat in animal meat. By controlling deposition and layering of hemp protein-based pastes, it is possible to reproduce the heterogeneity of real meat, catering to various culinary traditions and consumer preferences [37].

- •

- Regrading fortification with functional bioactives, incorporating functional ingredients such as plant-derived omega-3 fatty acids, antioxidants (e.g., polyphenols, tocopherols), dietary fibers (e.g., beta-glucans), and natural iron salts can boost the nutritional profile of HBMAs, aligning with trends for health and functional foods [115]. Additionally, applying pulsed electric field (PEF) or ultrasound during hemp protein processing can modify protein structure, enhance hydration, improve emulsifying properties, and promote better integration of fats and flavors. This leads to superior textural outcomes, reduced ingredient usage, and an enhanced mouthfeel [52].

- •

- On the other hand, innovative use of by-products such as hemp hulls, press cake, or microgreens as ingredients in meat analogs can close resource loops, enhance dietary fiber content, and add unique flavors. Integrating these fractions supports sustainability and zero-waste initiatives in food production [116]. Moreover, encapsulating natural colorants, flavors, or micronutrients using techniques like microencapsulation or liposomal delivery can provide targeted release during cooking or eating, helping to stabilize sensitive components and further mimic the sensory experience of animal meats [117].

7.3. Market and Consumer Trends

- •

- Product Diversification: The market is shifting from soy-dominated analogs to diversified products incorporating hemp, pea, chickpea, and other regional proteins [20].

- •

- Environmental Sustainability: Hemp cultivation requires less water, pesticides, and land compared with many other crops, making it a sustainable ingredient for future food systems [13].

8. Challenges and Future Directions

8.1. Product Diversification

8.2. Environmental Sustainability

8.3. Future Prospects

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boukid, F. Plant-Based Meat Analogues: From Niche to Mainstream. Eur. Food Res. Technol. 2021, 247, 297–308. [Google Scholar] [CrossRef]

- Yano, H.; Fu, W. Hemp: A Sustainable Plant with High Industrial Value in Food Processing. Foods 2023, 12, 651. [Google Scholar] [CrossRef]

- Górski, K.; Kowalczyk, T.; Gładys, A.; Glica, M.; Muskała, M.; Picot, L.; Mori, M.; Hatziantoniou, S.; Sitarek, P. Industrial Applications of Cannabis sativa (L.): Exploring Its Biological and Nanotechnological Potential. Ind. Crops Prod. 2025, 225, 120566. [Google Scholar] [CrossRef]

- MarketsandMarkets. Industrial Hemp Market Worth $30.24 Billion by 2029; MarketsandMarkets Inc.: Delray Beach, FL, USA, 2025. [Google Scholar]

- Research, E.M. Industrial Hemp Market Size, Share & Yoy Growth Rate 2034; Emergen Research: Surrey, BC, Canada, 2025. [Google Scholar]

- Astute Analytica. Hemp Fiber Market Set to Surpass Valuation of Us$ 30.13 Billion by 2033; Astute Analytica: Chicago, IL, USA, 2025. [Google Scholar]

- USDA. Overview of the Market of Industrial Hemp in the Netherlands and Its Potential as Bio-Based Material; USDA: Washington, DC, USA, 2025.

- Axentii, M.; Codină, G.G. Exploring the Nutritional Potential and Functionality of Hemp and Rapeseed Proteins: A Review on Unveiling Anti-Nutritional Factors, Bioactive Compounds, and Functional Attributes. Plants 2024, 13, 1195. [Google Scholar] [CrossRef]

- Eckhardt, L.; Bu, F.; Franczyk, A.; Michaels, T.; Ismail, B.P. Hemp (Cannabis sativa L.) Protein: Impact of Extraction Method and Cultivar on Structure, Function, and Nutritional Quality. Curr. Res. Food Sci. 2024, 8, 100746. [Google Scholar] [CrossRef]

- Lanzoni, D. Nutritional and Functional Characterisation of Alternative Feed and Food Ingredients: Emphasis on Hemp-Based Products, Co-Products, Microalgae and Cultured Meat. Ph.D. Thesis, Università degli Studi di Milano, Milan, Italy, 2025. [Google Scholar]

- Karabulut, G.; Kahraman, O.; Pandalaneni, K.; Kapoor, R.; Feng, H. A Comprehensive Review on Hempseed Protein: Production, Functional and Nutritional Properties, Novel Modification Methods, Applications, and Limitations. Int. J. Biol. Macromol. 2023, 253, 127240. [Google Scholar] [CrossRef] [PubMed]

- Benković, M.; Jurinjak Tušek, A.; Sokač Cvetnić, T.; Jurina, T.; Valinger, D.; Gajdoš Kljusurić, J. An Overview of Ingredients Used for Plant-Based Meat Analogue Production and Their Influence on Structural and Textural Properties of the Final Product. Gels 2023, 9, 921. [Google Scholar] [CrossRef] [PubMed]

- Jang, J.; Lee, D.-W. Advancements in Plant Based Meat Analogs Enhancing Sensory and Nutritional Attributes. NPJ Sci. Food 2024, 8, 50. [Google Scholar] [CrossRef] [PubMed]

- Nasrollahzadeh, F.; Roman, L.; Swaraj, V.S.; Ragavan, K.; Vidal, N.P.; Dutcher, J.R.; Martinez, M.M. Hemp (Cannabis sativa L.) Protein Concentrates from Wet and Dry Industrial Fractionation: Molecular Properties, Nutritional Composition, and Anisotropic Structuring. Food Hydrocoll. 2022, 131, 107755. [Google Scholar] [CrossRef]

- Dapčević-Hadnađev, T.; Hadnađev, M.; Dizdar, M.; Lješković, N.J. Functional and Bioactive Properties of Hemp Proteins. In Sustainable Agriculture Reviews 42: Hemp Production and Applications; Springer: Berlin/Heidelberg, Germany, 2020; pp. 239–263. [Google Scholar]

- Chen, H.; Xu, B.; Wang, Y.; Li, W.; He, D.; Zhang, Y.; Zhang, X.; Xing, X. Emerging Natural Hemp Seed Proteins and Their Functions for Nutraceutical Applications. Food Sci. Hum. Wellness 2023, 12, 929–941. [Google Scholar] [CrossRef]

- Liu, X.; Xue, F.; Adhikari, B. Recent Advances in Plant Protein Modification: Spotlight on Hemp Protein. Sustain. Food Technol. 2024, 2, 893–907. [Google Scholar] [CrossRef]

- Hertzler, S.R.; Lieblein-Boff, J.C.; Weiler, M.; Allgeier, C. Plant Proteins: Assessing Their Nutritional Quality and Effects on Health and Physical Function. Nutrients 2020, 12, 3704. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, W.; Zhang, F.; Chiu, I.; Li, D.; Wu, X.; Yang, T.; Gao, Y.; Zheng, H. Physicochemical Modulation of Soy-Hemp-Wheat Protein Meat Analogues Prepared by High-Moisture Extrusion Using Transglutaminase. Food Res. Int. 2025, 208, 116229. [Google Scholar] [CrossRef] [PubMed]

- Papatzimos, G.; Mitlianga, P.; Basdagianni, Z.; Kasapidou, E. Hemp Flour as a Functional Ingredient for the Partial Replacement of Nitrites in a Minced Meat Model: Effect on Nutrient Composition, Antioxidant Profile and Sensory Characteristics. Appl. Sci. 2024, 14, 3925. [Google Scholar] [CrossRef]

- Günal-Köroğlu, D.; Karabulut, G.; Ozkan, G.; Yılmaz, H.; Gültekin-Subaşı, B.; Capanoglu, E. Allergenicity of Alternative Proteins: Reduction Mechanisms and Processing Strategies. J. Agric. Food Chem. 2025, 73, 7522–7546. [Google Scholar] [CrossRef]

- Aimutis, W.R.; Shirwaiker, R. A Perspective on the Environmental Impact of Plant-Based Protein Concentrates and Isolates. Proc. Natl. Acad. Sci. USA 2024, 121, e2319003121. [Google Scholar] [CrossRef]

- Banskota, A.H.; Tibbetts, S.M.; Jones, A.; Stefanova, R.; Behnke, J. Biochemical Characterization and in Vitro Digestibility of Protein Isolates from Hemp (Cannabis sativa L.) by-Products for Salmonid Feed Applications. Molecules 2022, 27, 4794. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, M.; Fan, H.; Wu, J. Emerging Proteins as Precursors of Bioactive Peptides/Hydrolysates with Health Benefits. Curr. Opin. Food Sci. 2022, 48, 100914. [Google Scholar] [CrossRef]

- Tănase Apetroaei, V.; Pricop, E.M.; Istrati, D.I.; Vizireanu, C. Hemp Seeds (Cannabis sativa L.) as a Valuable Source of Natural Ingredients for Functional Foods—A Review. Molecules 2024, 29, 2097. [Google Scholar] [CrossRef]

- Zaky, A.A.; Simal-Gandara, J.; Eun, J.-B.; Shim, J.-H.; Abd El-Aty, A. Bioactivities, Applications, Safety, and Health Benefits of Bioactive Peptides from Food and by-Products: A Review. Front. Nutr. 2022, 8, 815640. [Google Scholar] [CrossRef]

- Su, T.; Le, B.; Zhang, W.; Bak, K.H.; Soladoye, P.O.; Zhao, Z.; Zhao, Y.; Fu, Y.; Wu, W. Technological Challenges and Future Perspectives of Plant-Based Meat Analogues: From the Viewpoint of Proteins. Food Res. Int. 2024, 186, 114351. [Google Scholar] [CrossRef] [PubMed]

- Aryal, K.; Maraseni, T.; Kretzschmar, T.; Chang, D.; Naebe, M.; Neary, L.; Ash, G. Knowledge Mapping for a Secure and Sustainable Hemp Industry: A Systematic Literature Review. Case Stud. Chem. Environ. Eng. 2024, 9, 100550. [Google Scholar] [CrossRef]

- Yao, S.; Li, W.; Martin, G.J.O.; Ashokkumar, M. An Investigation into the Mechanism of Alkaline Extraction-Isoelectric Point Precipitation (Ae-Iep) of High-Thiol Plant Proteins. Appl. Sci. 2023, 13, 6469. [Google Scholar] [CrossRef]

- Chen, B.; Pangloli, P.; Dia, V.P. Comparative Physicochemical and Functional Analyses of Protein Ingredients and Their Enzymatic Hydrolysates from Industrial Hempseed (Cannabis sativa L.) Hearts. ACS Food Sci. Technol. 2024, 4, 1480–1489. [Google Scholar] [CrossRef]

- Tang, C.-H.; Wang, X.-S.; Yang, X.-Q. Enzymatic Hydrolysis of Hemp (Cannabis sativa L.) Protein Isolate by Various Proteases and Antioxidant Properties of the Resulting Hydrolysates. Food Chem. 2009, 114, 1484–1490. [Google Scholar] [CrossRef]

- Yao, S.; Li, W.; Wu, Y.; Martin, G.J.; Ashokkumar, M. The Impact of High-Intensity Ultrasound-Assisted Extraction on the Structural and Functional Properties of Hempseed Protein Isolate (Hpi). Foods 2023, 12, 348. [Google Scholar] [CrossRef]

- Navaf, M.; Sunooj, K.V.; Aaliya, B.; Sudheesh, C.; Akhila, P.P.; Mir, S.A.; Nemtanu, M.R.; George, J.; Lackner, M.; Khaneghah, A.M. Contemporary Insights into the Extraction, Functional Properties, and Therapeutic Applications of Plant Proteins. J. Agric. Food Res. 2023, 14, 100861. [Google Scholar] [CrossRef]

- Yildiz, S.; Karabulut, G.; Sıçramaz, H. High-Intensity Ultrasound-Assisted Extraction for Functionalized Pistachio Meal Protein Concentrate. J. Food Sci. 2025, 90, e70031. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhou, W.; Qin, X.; Hou, C.; Yang, X. Preparation, Modification, Food Application, and Health Effects of Protein and Peptide from Hemp (Cannabis sativa L.) Seed: A Review of the Recent Literature. Foods 2025, 14, 1149. [Google Scholar] [CrossRef]

- Corigliano, O.; Morrone, P.; Algieri, A. Navigating the Challenges of Sustainability in the Food Processing Chain: Insights into Energy Interventions to Reduce Footprint. Energies 2025, 18, 296. [Google Scholar] [CrossRef]

- Zahari, I.; Ferawati, F.; Helstad, A.; Ahlström, C.; Östbring, K.; Rayner, M.; Purhagen, J.K. Development of High-Moisture Meat Analogues with Hemp and Soy Protein Using Extrusion Cooking. Foods 2020, 9, 772. [Google Scholar] [CrossRef]

- Wang, Y.; Tuccillo, F.; Lampi, A.M.; Knaapila, A.; Pulkkinen, M.; Kariluoto, S.; Coda, R.; Edelmann, M.; Jouppila, K.; Sandell, M. Flavor Challenges in Extruded Plant-Based Meat Alternatives: A Review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 2898–2929. [Google Scholar] [CrossRef]

- Zahari, I.; Rinaldi, S.; Ahlstrom, C.; Östbring, K.; Rayner, M.; Purhagen, J. High Moisture Meat Analogues from Hemp–the Effect of Co-Extrusion with Wheat Gluten and Chickpea Proteins on the Textural Properties and Sensorial Attributes. LWT-Food Sci. Technol. 2023, 189, 115494. [Google Scholar] [CrossRef]

- Nasrollahzadeh, F.; Alexi, N.; Skov, K.B.; Roman, L.; Sfyra, K.; Martinez, M.M. Texture Profiling of Muscle Meat Benchmarks and Plant-Based Analogues: An Instrumental and Sensory Design Approach with Focus on Correlations. Food Hydrocoll. 2024, 151, 109829. [Google Scholar] [CrossRef]

- Immonen, M.; Chandrakusuma, A.; Sibakov, J.; Poikelispää, M.; Sontag-Strohm, T. Texturization of a Blend of Pea and Destarched Oat Protein Using High-Moisture Extrusion. Foods 2021, 10, 1517. [Google Scholar] [CrossRef] [PubMed]

- Krause, M.; Sørensen, J.C.; Petersen, I.L.; Duque-Estrada, P.; Cappello, C.; Tlais, A.Z.A.; Di Cagno, R.; Ispiryan, L.; Sahin, A.W.; Arendt, E.K. Associating Compositional, Nutritional and Techno-Functional Characteristics of Faba Bean (Vicia faba L.) Protein Isolates and Their Production Side-Streams with Potential Food Applications. Foods 2023, 12, 919. [Google Scholar] [CrossRef] [PubMed]

- Cermeno, M.; Silva, J.V.; Arcari, M.; Denkel, C. Foaming Properties of Plant Protein Blends Prepared Using Commercial Faba Bean and Hemp Protein Concentrates at Different Faba Bean/Hemp Protein Ratios. LWT-Food Sci. Technol. 2024, 198, 115948. [Google Scholar] [CrossRef]

- Amyoony, J.; Dabas, T.; Gorman, M.; Moss, R.; McSweeney, M.B. Sensory Properties of Thickened Tomato Soup Enhanced with Different Sources of Protein (Whey, Soy, Hemp, and Pea). J. Texture Stud. 2024, 55, e12807. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Sun, L.; Zhuang, Y.; Gu, Y.; Cheng, G.; Fan, X.; Ding, Y.; Liu, H. Protein-Stabilized Emulsion Gels with Improved Emulsifying and Gelling Properties for the Delivery of Bioactive Ingredients: A Review. Foods 2023, 12, 2703. [Google Scholar] [CrossRef]

- Yang, J.; Meng, D.; Wu, Z.; Chen, J.; Xue, L. Modification and Solubility Enhancement of Rice Protein and Its Application in Food Processing: A Review. Molecules 2023, 28, 4078. [Google Scholar] [CrossRef]

- Webb, D.; Dogan, H.; Li, Y.; Alavi, S. Physico-Chemical Properties and Texturization of Pea, Wheat and Soy Proteins Using Extrusion and Their Application in Plant-Based Meat. Foods 2023, 12, 1586. [Google Scholar] [CrossRef]

- Guidi, S.; Formica, F.A.; Denkel, C. Mixing Plant-Based Proteins: Gel Properties of Hemp, Pea, Lentil Proteins and Their Binary Mixtures. Food Res. Int. 2022, 161, 111752. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, J.; Xu, Y.; Mi, H.; Yi, S.; Gao, R.; Li, X.; Li, J. Effects of Chickpea Protein-Stabilized Pickering Emulsion on the Structure and Gelling Properties of Hairtail Fish Myosin Gel. Food Chem. 2023, 417, 135821. [Google Scholar] [CrossRef]

- Zahari, I.; Purhagen, J.K.; Rayner, M.; Ahlström, C.; Helstad, A.; Landers, M.; Müller, J.; Eriksson, J.; Östbring, K. Extrusion of High-Moisture Meat Analogues from Hempseed Protein Concentrate and Oat Fibre Residue. J. Food Eng. 2023, 354, 111567. [Google Scholar] [CrossRef]

- Zang, Y.; Wang, S.; Gao, Y.; Sun, C.; Zhao, Y.; Cao, Y.; Lu, W.; Zhang, Y.; Fang, Y. High Moisture Extrusion of Pulse Proteins: Texture, Structure, and in Vitro Digestion Characteristics of Extrudates. Food Hydrocoll. 2025, 159, 110676. [Google Scholar] [CrossRef]

- San, Y.; Xing, Y.; Li, B.; Zheng, L. Effect of Transglutaminase Cross-Linking on the Structure and Emulsification Performance of Heated Black Bean Protein Isolate. J. Sci. Food Agric. 2025, 105, 2382–2389. [Google Scholar] [CrossRef]

- Jyothi, I.; Sashidevi, G.; Kanchana, S.; Geethapadmanaban, P.; Parimalam, P.; Meenakshisundaram, P. Plant-Based Meat Analogues-Green Technologies in Protein Extraction and Production Technologies of Plant-Based Meat Analogues. Plant Sci. Today 2025, 12, 1–14. [Google Scholar] [CrossRef]

- Rahaman, A.; Ahsan, S.; Kumari, A.; Khaliq, A.; Mehmood, T.; Chughtai, M.F.J.; Farooq, M.A.; Khalifa, I.; Wali, M.; Zeng, X.-A. Application of Plant-Based Proteins in the Development of Fish and Meat Analogues Products. J. Texture Stud. 2025, 56, e70025. [Google Scholar] [CrossRef]

- Boachie, R.T.; Aluko, R.E. Plant-Based Meat Analogues: Processing, Product Safety, Protein Quality, and Contributions to Environmental Sustainability. Sustain. Food Protein 2025, 3, e70018. [Google Scholar] [CrossRef]

- Romão, B.; Sommo, M.; Zandonadi, R.P.; de Holanda, M.E.M.; Borges, V.R.P.; Saraiva, A.; Raposo, A. Sustainability of Key Proteins in Plant-Based Meat Analogs Production: A Worldwide Perspective. Sustainability 2025, 17, 382. [Google Scholar] [CrossRef]

- Arango, S.; Kojić, J.; Perović, L.; Đermanović, B.; Stojanov, N.; Sikora, V.; Tomičić, Z.; Raffrenato, E.; Bailoni, L. Chemical Characterization of 29 Industrial Hempseed (Cannabis sativa L.) Varieties. Foods 2024, 13, 210. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Androsova, N.V.; Toshev, A.D.; El Enshasy, H.A. Nutritional Quality, Chemical, and Functional Characteristics of Hemp (Cannabis sativa ssp. sativa) Protein Isolate. Plants 2022, 11, 2825. [Google Scholar] [CrossRef]

- Lu, Z.; Lee, P.-R.; Yang, H. Using Hpmc to Improve Sensory Properties of Vegan Omelet Analogue: Effect of Hpmc on Water Retention, Oil Adsorption, and Thermal Gelation. Food Hydrocoll. 2023, 144, 108938. [Google Scholar] [CrossRef]

- Dinani, S.T.; Broekema, N.L.; Boom, R.; van der Goot, A.J. Investigation Potential of Hydrocolloids in Meat Analogue Preparation. Food Hydrocoll. 2023, 135, 108199. [Google Scholar] [CrossRef]

- Cornet, S.H.; Snel, S.J.; Lesschen, J.; van der Goot, A.J.; van der Sman, R.G. Enhancing the Water Holding Capacity of Model Meat Analogues through Marinade Composition. J. Food Eng. 2021, 290, 110283. [Google Scholar] [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Ajibola, C.F.; Aluko, R.E. Physicochemical and Functional Properties of 2s, 7s, and 11s Enriched Hemp Seed Protein Fractions. Molecules 2022, 27, 1059. [Google Scholar] [CrossRef]

- Pihlanto, A.; Nurmi, M.; Pap, N.; Mäkinen, J.; Mäkinen, S. The Effect of Processing of Hempseed on Protein Recovery and Emulsification Properties. Int. J. Food Sci. 2021, 2021, 8814724. [Google Scholar] [CrossRef]

- Kornet, R.; Yang, J.; Venema, P.; van der Linden, E.; Sagis, L.M. Optimizing Pea Protein Fractionation to Yield Protein Fractions with a High Foaming and Emulsifying Capacity. Food Hydrocoll. 2022, 126, 107456. [Google Scholar] [CrossRef]

- Ma, K.K.; Greis, M.; Lu, J.; Nolden, A.A.; McClements, D.J.; Kinchla, A.J. Functional Performance of Plant Proteins. Foods 2022, 11, 594. [Google Scholar] [CrossRef]

- Wittek, P.; Zeiler, N.; Karbstein, H.P.; Emin, M.A. High Moisture Extrusion of Soy Protein: Investigations on the Formation of Anisotropic Product Structure. Foods 2021, 10, 102. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, T.; Chen, Q.; Liu, H.; Kaplan, D.L.; Wang, Q. Application of Transglutaminase Modifications for Improving Protein Fibrous Structures from Different Sources by High-Moisture Extruding. Food Res. Int. 2023, 166, 112623. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, J.; Liu, H.; Li, T.; Wang, Q. Mechanism of High-Moisture Extruded Protein Fibrous Structure Formation Based on the Interactions among Pea Protein, Amylopectin, and Stearic Acid. Food Hydrocoll. 2023, 136, 108254. [Google Scholar] [CrossRef]

- Wittek, P.; Karbstein, H.P.; Azad Emin, M.; José, M.; Apesteguía, B. Blending Proteins in High Moisture Extrusion to Design Meat Analogues: Rheological Properties, Morphology Development and Product Properties. Foods 2021, 10, 1509. [Google Scholar] [CrossRef]

- Schreuders, F.K.; Schlangen, M.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Structure Formation and Non-Linear Rheology of Blends of Plant Proteins with Pectin and Cellulose. Food Hydrocoll. 2022, 124, 107327. [Google Scholar] [CrossRef]

- See, X.Y.; Chiang, J.H.; Law, L.M.; Osen, R. High Moisture Extrusion of Plant Proteins: Advances, Challenges, and Opportunities. Crit. Rev. Food Sci. Nutr. 2025, 65, 143–164. [Google Scholar] [CrossRef] [PubMed]

- Stanišić, N.; Kurćubić, V.S.; Stajić, S.B.; Tomasevic, I.D.; Tomasevic, I. Integration of Dietary Fibre for Health Benefits, Improved Structure, and Nutritional Value of Meat Products and Plant-Based Meat Alternatives. Foods 2025, 14, 2090. [Google Scholar] [CrossRef]

- Maung, T.-T.; Gu, B.-Y.; Ryu, G.-H. Influence of Extrusion Process Parameters on Specific Mechanical Energy and Physical Properties of High-Moisture Meat Analog. Int. J. Food Eng. 2021, 17, 149–157. [Google Scholar] [CrossRef]

- Xia, S.; Song, J.; Ma, C.; Hao, T.; Hou, Y.; Shen, S.; Li, K.; Ma, L.; Xue, Y.; Xue, C. Effects of Moisture Content and Processing Temperature on the Strength and Orientation Regulation of Fibrous Structures in Meat Analogues. Food Hydrocoll. 2023, 145, 109113. [Google Scholar] [CrossRef]

- Ozturk, O.K.; Hamaker, B.R. Texturization of Plant Protein-Based Meat Alternatives: Processing, Base Proteins, and Other Constructional Ingredients. Future Foods 2023, 8, 100248. [Google Scholar] [CrossRef]

- Dinali, M.; Liyanage, R.; Silva, M.; Newman, L.; Adhikari, B.; Wijesekara, I.; Chandrapala, J. Fibrous Structure in Plant-Based Meat: High-Moisture Extrusion Factors and Sensory Attributes in Production and Storage. Food Rev. Int. 2024, 40, 2940–2968. [Google Scholar] [CrossRef]

- De Angelis, D.; Latrofa, V.; Caponio, F.; Pasqualone, A.; Summo, C. Techno-Functional Properties of Dry-Fractionated Plant-Based Proteins and Application in Food Product Development: A Review. J. Sci. Food Agric. 2024, 104, 1884–1896. [Google Scholar] [CrossRef]

- Fang, B.; Chang, L.; Ohm, J.-B.; Chen, B.; Rao, J. Structural, Functional Properties, and Volatile Profile of Hemp Protein Isolate as Affected by Extraction Method: Alkaline Extraction–Isoelectric Precipitation Vs Salt Extraction. Food Chem. 2023, 405, 135001. [Google Scholar] [CrossRef]

- Vogelsang-O’Dwyer, M.; Sahin, A.W.; Arendt, E.K.; Zannini, E. Enzymatic Hydrolysis of Pulse Proteins as a Tool to Improve Techno-Functional Properties. Foods 2022, 11, 1307. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Li, H.; Selomulya, C. Effect of Hydrolysis on the Emulsification and Antioxidant Properties of Plant-Sourced Proteins. Curr. Opin. Food Sci. 2022, 48, 100949. [Google Scholar] [CrossRef]

- Montserrat-de la Paz, S.; Rivero-Pino, F.; Villanueva, A.; Toscano-Sanchez, R.; Martin, M.E.; Millan, F.; Millan-Linares, M.C. Nutritional Composition, Ultrastructural Characterization, and Peptidome Profile of Antioxidant Hemp Protein Hydrolysates. Food Biosci. 2023, 53, 102561. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, Z.; Cao, Y.; Ming, Y.; Wu, M. Improving the Solubility and Interfacial Absorption of Hempseed Protein Via a Novel High Pressure Homogenization-Assisted Ph-Shift Strategy. Food Chem. 2024, 442, 138447. [Google Scholar] [CrossRef]

- Opazo-Navarrete, M.; Burgos-Díaz, C.; Garrido-Miranda, K.A.; Acuña-Nelson, S. Effect of Enzymatic Hydrolysis on Solubility and Emulsifying Properties of Lupin Proteins (Lupinus luteus). Colloids Interfaces 2022, 6, 82. [Google Scholar] [CrossRef]

- Karabulut, G.; Yemiş, O. Modification of Hemp Seed Protein Isolate (Cannabis sativa L.) by High-Intensity Ultrasound Treatment. Part 1: Functional Properties. Food Chem. 2022, 375, 131843. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Wang, M.; Xue, F.; Adhikari, B. Application of Ultrasound Treatment to Improve the Technofunctional Properties of Hemp Protein Isolate. Future Foods 2022, 6, 100176. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, T.; Huang, X.; Lian, Y.; Yang, F.; Yu, D. Hemp Seed Protein and Chlorogenic Acid Complex: Effect of Ultrasound Modification on Its Structure and Functional Properties. Int. J. Biol. Macromol. 2023, 233, 123521. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, O.; Petersen, G.E.; Fields, C. Physicochemical and Functional Modifications of Hemp Protein Concentrate by the Application of Ultrasonication and Ph Shifting Treatments. Foods 2022, 11, 587. [Google Scholar] [CrossRef] [PubMed]

- Karabulut, G.; Kapoor, R.; Yemis, O.; Feng, H. Manothermosonication, High-Pressure Homogenization, and Their Combinations with Ph-Shifting Improve the Techno-Functionality and Digestibility of Hemp Protein. Food Hydrocoll. 2024, 150, 109661. [Google Scholar] [CrossRef]

- Cabral, E.M.; Zhu, X.; Garcia-Vaquero, M.; Pérez-Vila, S.; Tang, J.; Gómez-Mascaraque, L.G.; Poojary, M.M.; Curtin, J.; Tiwari, B.K. Recovery of Protein from Industrial Hemp Waste (Cannabis sativa, L.) Using High-Pressure Processing and Ultrasound Technologies. Foods 2023, 12, 2883. [Google Scholar] [CrossRef]

- Yuliarti, O.; Kovis, T.J.K.; Yi, N.J. Structuring the Meat Analogue by Using Plant-Based Derived Composites. J. Food Eng. 2021, 288, 110138. [Google Scholar] [CrossRef]

- Sha, L.; Xiong, Y.L. Plant Protein-Based Alternatives of Reconstructed Meat: Science, Technology, and Challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Lee, J.-S.; Kim, S.; Jeong, Y.J.; Choi, I.; Han, J. Impact of Interactions between Soy and Pea Proteins on Quality Characteristics of High-Moisture Meat Analogues Prepared Via Extrusion Cooking Process. Food Hydrocoll. 2023, 139, 108567. [Google Scholar] [CrossRef]

- Milcarz, A.; Harasym, J. Solid State Fermentation—A Promising Approach to Produce Meat Analogues. Foods 2025, 14, 1820. [Google Scholar] [CrossRef]

- Canoy, T.S.; Wiedenbein, E.S.; Bredie, W.L.; Meyer, A.S.; Wösten, H.A.; Nielsen, D.S. Solid-State Fermented Plant Foods as New Protein Sources. Annu. Rev. Food Sci. Technol. 2024, 15, 189–210. [Google Scholar] [CrossRef]

- Abbaspour, N. Fermentation’s Pivotal Role in Shaping the Future of Plant-Based Foods: An Integrative Review of Fermentation Processes and Their Impact on Sensory and Health Benefits. Appl. Food Res. 2024, 4, 100468. [Google Scholar] [CrossRef]

- Karabulut, G.; Kapoor, R.; Feng, H. Biotransformation Approaches Using Solid-State Fermentation and Germination with High-Intensity Ultrasound to Produce Added-Value Hemp Protein Nanoaggregates. Food Biosci. 2023, 56, 103400. [Google Scholar] [CrossRef]

- Feng, X.; Ng, K.; Ajlouni, S.; Zhang, P.; Fang, Z. Effect of Solid-State Fermentation on Plant-Sourced Proteins: A Review. Food Rev. Int. 2024, 40, 2580–2617. [Google Scholar] [CrossRef]

- Elhalis, H.; See, X.Y.; Osen, R.; Chin, X.H.; Chow, Y. Significance of Fermentation in Plant-Based Meat Analogs: A Critical Review of Nutrition, and Safety-Related Aspects. Foods 2023, 12, 3222. [Google Scholar] [CrossRef] [PubMed]

- Iftikhar, A.; Zafar, U.; Ahmed, W.; Shabbir, M.A.; Sameen, A.; Sahar, A.; Bhat, Z.F.; Kowalczewski, P.Ł.; Jarzębski, M.; Aadil, R.M. Applications of Cannabis sativa L. In Food and Its Therapeutic Potential: From a Prohibited Drug to a Nutritional Supplement. Molecules 2021, 26, 7699. [Google Scholar] [CrossRef]

- Aloo, S.O.; Mwiti, G.; Ngugi, L.W.; Oh, D.-H. Uncovering the Secrets of Industrial Hemp in Food and Nutrition: The Trends, Challenges, and New-Age Perspectives. Crit. Rev. Food Sci. Nutr. 2024, 64, 5093–5112. [Google Scholar] [CrossRef] [PubMed]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of Hemp in Textiles, Paper Industry, Insulation and Building Materials, Horticulture, Animal Nutrition, Food and Beverages, Nutraceuticals, Cosmetics and Hygiene, Medicine, Agrochemistry, Energy Production and Environment: A Review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Magalhães, P.; Domingues, R.M.; Alves, E. Hemp Seeds, Flaxseed, and Açaí Berries: Health Benefits and Nutritional Importance with Emphasis on the Lipid Content. Curr. Nutr. Food Sci. 2022, 18, 4–14. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in Food Industry: Nutritional Value, Health Benefits, and Industrial Applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 282–308. [Google Scholar] [CrossRef]

- Nevara, G.A.; Giwa Ibrahim, S.a.; Syed Muhammad, S.K.; Zawawi, N.; Mustapha, N.A.; Karim, R. Oilseed Meals into Foods: An Approach for the Valorization of Oilseed by-Products. Crit. Rev. Food Sci. Nutr. 2023, 63, 6330–6343. [Google Scholar] [CrossRef]

- Sumara, A.; Stachniuk, A.; Montowska, M.; Kotecka-Majchrzak, K.; Grywalska, E.; Mitura, P.; Saftić Martinović, L.; Kraljević Pavelić, S.; Fornal, E. Comprehensive Review of Seven Plant Seed Oils: Chemical Composition, Nutritional Properties, and Biomedical Functions. Food Rev. Int. 2023, 39, 5402–5422. [Google Scholar] [CrossRef]

- Barsby, J.P.; Cowley, J.M.; Leemaqz, S.Y.; Grieger, J.A.; McKeating, D.R.; Perkins, A.V.; Bastian, S.E.; Burton, R.A.; Bianco-Miotto, T. Nutritional Properties of Selected Superfood Extracts and Their Potential Health Benefits. PeerJ 2021, 9, e12525. [Google Scholar] [CrossRef]

- Prajapati, R. New Protein Rich Plant Diet in 21st Century. Res. Rev. Int. J. Multidiscip. 2025, 10, 236–241. [Google Scholar] [CrossRef]

- Pellinen, T.; Päivärinta, E.; Isotalo, J.; Lehtovirta, M.; Itkonen, S.T.; Korkalo, L.; Erkkola, M.; Pajari, A.-M. RePlacing Dietary Animal-Source Proteins with Plant-Source Proteins Changes Dietary Intake and Status of Vitamins and Minerals in Healthy Adults: A 12-Week Randomized Controlled Trial. Eur. J. Nutr. 2022, 61, 1391–1404. [Google Scholar] [CrossRef]

- Tso, R.; Forde, C.G. Unintended Consequences: Nutritional Impact and Potential Pitfalls of Switching from Animal-to Plant-Based Foods. Nutrients 2021, 13, 2527. [Google Scholar] [CrossRef]

- Pasichnyi, V.; Shevchenko, O.; Tischenko, V.; Bozhko, N.; Marynin, A.; Strashynskyi, I.; Matsuk, Y. Substantiating the Feasibility of Using Hemp Seed Protein in Cooked Sausage Technology. East.-Eur. J. Enterp. Technol. 2024, 4, 56–66. [Google Scholar]

- Maizhanova, A.; Amirkhanov, K.; Zhakupbekova, S.; Nurymkhan, G.; Baytukenova, S.; Dautova, A.; Spanova, A.; Ashakayeva, R. Effect of Flax and Hemp Flour on the Nutritional Value of Turkey-Duck Meat Pate. Slovak J. Food Sci. 2024, 18, 874–886. [Google Scholar] [CrossRef] [PubMed]

- Başkaya, B.; Çelik, M.; Kadak, A.E.; Küçükgülmez, A. Comparison of Nutritional Composition, Mineral and Heavy Metal Content of Rainbow Trout from Different Aquaculture Systems. J. Anatol. Environ. Anim. Sci. 2023, 8, 547–553. [Google Scholar] [CrossRef]

- Wilson, J.W.; Thompson, T.W.; Wei, Y.; Chaparro, J.M.; Stull, V.J.; Nair, M.N.; Weir, T.L. Comparison of the in Vitro Iron Bioavailability of Tempeh Made with Tenebrio Molitor to Beef and Plant-Based Meat Alternatives. Nutrients 2024, 16, 2756. [Google Scholar] [CrossRef]

- Amagliani, L.; Fanesi, B.; de Oliveira Reis, G.; Bovay, C.; Affolter, M.; Schmitt, C. High Moisture Extrusion Processing of Hemp Protein Ingredients as Influenced by Their Composition and Physicochemical Properties. Sci. Talks 2023, 8, 100250. [Google Scholar] [CrossRef]

- Feddern, V.; Langone, M.G.S.; Fortunato, G.d.S.; Bonan, C.I.D.G.; Ienczak, J.L.; Feltes, M.M.C. Plant-Based Protein Sources Applied as Ingredients in Meat Analogues Sustainable Production. Braz. J. Food Technol. 2024, 27, e2024001. [Google Scholar] [CrossRef]

- Duque-Estrada, P.; Hardiman, K.; Dam, A.B.; Dodge, N.; Aaslyng, M.D.; Petersen, I.L. Protein Blends and Extrusion Processing to Improve the Nutritional Quality of Plant Proteins. Food Funct. 2023, 14, 7361–7374. [Google Scholar] [CrossRef]

- Flory, J.; Xiao, R.; Li, Y.; Dogan, H.; Talavera, M.J.; Alavi, S. Understanding Protein Functionality and Its Impact on Quality of Plant-Based Meat Analogues. Foods 2023, 12, 3232. [Google Scholar] [CrossRef]

- Gargano, D.; Appanna, R.; Santonicola, A.; De Bartolomeis, F.; Stellato, C.; Cianferoni, A.; Casolaro, V.; Iovino, P. Food Allergy and Intolerance: A Narrative Review on Nutritional Concerns. Nutrients 2021, 13, 1638. [Google Scholar] [CrossRef] [PubMed]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- Juhrich, L.C.; Grosse, M.; Mörlein, J.; Bergmann, P.; Zorn, H.; Gand, M. Nutritional and Sensory Properties of Meat Analogues: A Current Overview and Future Considerations. J. Agric. Food Chem. 2025, 73, 2236–2248. [Google Scholar] [CrossRef]

- Maciejewska, M.; Dąbrowska, A.; Cano-Lamadrid, M. Sustainable Protein Sources: Functional Analysis of Tenebrio Molitor Hydrolysates and Attitudes of Consumers in Poland and Spain toward Insect-Based Foods. Foods 2025, 14, 333. [Google Scholar] [CrossRef]

- Lu, D.; Roy, D.; Acevedo-Fani, A.; Singh, H.; Ye, A. Investigation of Various Plant Protein Ingredients for Processed Cheese Analogues: Physical Properties and Microstructure Compared with Milk Proteins. Int. J. Food Sci. Technol. 2025, 60, vvae018. [Google Scholar] [CrossRef]

- Khezerlou, A.; Yekta, R.; Abedi-Firoozjah, R.; Alizadeh-Sani, M.; McClements, D.J. Advances in Sensory and Nutritional Innovation for Sustainable Plant-Based Meat Analogs: A Comprehensive Review. Food Rev. Int. 2025, 1–26. [Google Scholar] [CrossRef]

- Campiglia, E.; Gobbi, L.; Marucci, A.; Rapa, M.; Ruggieri, R.; Vinci, G. Hemp Seed Production: Environmental Impacts of Cannabis sativa L. Agronomic Practices by Life Cycle Assessment (Lca) and Carbon Footprint Methodologies. Sustainability 2020, 12, 6570. [Google Scholar] [CrossRef]

- Kabato, W.; Getnet, G.T.; Sinore, T.; Nemeth, A.; Molnár, Z. Towards Climate-Smart Agriculture: Strategies for Sustainable Agricultural Production, Food Security, and Greenhouse Gas Reduction. Agronomy 2025, 15, 565. [Google Scholar] [CrossRef]

- Moscariello, C.; Matassa, S.; Pirozzi, F.; Esposito, G.; Papirio, S. Valorisation of Industrial Hemp (Cannabis sativa L.) Biomass Residues through Acidogenic Fermentation and Co-Fermentation for Volatile Fatty Acids Production. Bioresour. Technol. 2022, 355, 127289. [Google Scholar] [CrossRef] [PubMed]

- Huser, B. Industrial Hemp: A Review of the Growing Industry. Drake J. Agric. Law 2020, 25, 249. [Google Scholar]

| Attribute | Hemp Protein | Soy Protein | Pea Protein | Meat Protein | Ref. |

|---|---|---|---|---|---|

| Protein Content | ~51% (in hemp protein powder) | 61–91% (varies by source) | 77–81% | 25–30% | [9] |

| Amino Acid Profile | Complete protein with all 9 essential amino acids but relatively low in lysine; rich in sulfur-containing amino acids and arginine | Complete protein that meets essential amino acid requirements; higher lysine content | Complete protein that meets essential amino acid requirements; higher lysine content | Complete with optimal proportions of all essential amino acids and notably high in lysine, methionine, and leucine. | [16] |

| PDCAAS Score | Scores 49–53% | Scores 98–100% | Scores 83–91% | 100% | [18] |

| DIAAS Score | Scores 60 ≤ 75 | Scores > 75 | - | >100 | |

| Fiber Content | High fiber content that aids digestion and gut health | Low fiber (typically isolated protein) | Low fiber (typically isolated protein) | No dietary fiber | [19] |

| Digestibility | Naturally easy to digest with less kidney stress | Good digestibility but may cause allergies in some cases | Good digestibility; hypoallergenic | Easily digested and absorbed with minimal anti-nutritional factors | [11,16] |

| Functional Properties | Good emulsification and gelation; unique cysteine-rich composition aids food processing | Widely used for emulsification and gelation; versatile | Good emulsification and gelation; popular in meat analogs | Superior water-holding, emulsification, and gelation used in processed meats | [16,20] |

| Additional Nutrients | Rich in omega-3 fatty acids, magnesium, iron, zinc, and anti-inflammatory properties | Contains isoflavones and minerals | Contains iron and other minerals | Sources of vitamin B12, heme iron, zinc, creatine, and taurine | [8] |

| Allergenicity | Low allergenicity; soy and dairy-free | Potential allergen (soy) | Generally low allergenicity | Allergies are rare vs. plant protein allergens | [21] |

| Environmental Impact | Cultivation stands out for its minimal water and pesticide requirements, soil remediation capabilities, and low environmental footprint, making it an environmentally friendly protein source | While nutritionally valuable, it has sustainability challenges related to pesticide use, GMO crops, deforestation, and processing intensity | It offers sustainability advantages through nitrogen fixation and has a moderate environmental impact, though it generally requires more water and pesticides than hemp | Highest resource use—significant greenhouse gas emissions and land and water use compared with plant proteins | [22] |

| Parameters | Extraction Method | ||||

|---|---|---|---|---|---|

| AE-IP | EE | UAE | MAE | SFE | |

| Yield (% w/w) | 45–60 | 55–70 | 60–75 | 58–68 | 40–55 |

| Purity (%) | 75–85 | 80–90 | 85–92 | 80–88 | 90–95 |

| Processing Time (h) | 2–4 | 4–8 | 0.5–1.5 | 0.17–0.5 | 1–3 |

| Energy Cost ($/kg) | 0.15–0.25 | 0.20–0.30 | 0.25–0.40 | 0.18–0.28 | 0.50–0.80 |

| Equipment Cost ($/MT capacity) | 50,000–150,000 | 80,000–200,000 | 120,000–250,000 | 100,000–220,000 | 300,000–800,000 |

| Total Cost ($/kg protein) | 2.50–3.20 | 3.80–4.50 | 3.20–4.00 | 3.00–3.80 | 5.50–7.20 |

| Solubility (%) | 45–60 | 75–85 | 75–85 | 70–80 | 80–90 |

| Consumer Acceptance (%) | 45–50 | 65–70 | 60–65 | 55–60 | 70–75 |

| Functional Properties Score * | 6.5/10 | 8.5/10 | 8.0/10 | 7.5/10 | 9.0/10 |

| Environmental Impact ** | Moderate | Low | Low | Low | Very Low |

| Refs. | [9,29] | [30,31] | [32] | [33] | [34] |

| Protein Blend and Ratio | Technological Changes and Processing Notes | Nutritional Impact | Mechanical and Rheological Properties | Sensory (Appearance and flavor Attributes) | Ref. |

|---|---|---|---|---|---|

| Hemp + Wheat Gluten (90:10, 50:50) | Improved texturization, water retention, and extrusion stability | Complements lysine deficiency in hemp; balanced amino acids | Increased hardness, chewiness, resilience, and fibrous texture | Uniform brown color, visible fibers, juiciness, earthy, nutty, slight beany, meaty, some off-notes | [19,39] |

| Hemp + Chickpea Protein (50:50) | Enhanced emulsification and gelation; soy-free formulation | Improved lysine and sulfur amino acid profile | Good chewiness and firmness; stable gel formation | Light brown-tan color, glossy, retains structure, beany, slightly grassy, mild nuttiness | [39] |

| Soy + Hemp + Wheat + Transglutaminase (TGase) | TGase cross-linking increases protein network strength and water holding capacity | Improved protein digestibility and quality | Pronounced fibrous structure; improved mouthfeel and juiciness | Browns, develops grill-marks, and has fiber alignment; flavor has enhanced umami, reduced off-notes, and is rich | [19] |

| Hemp Protein Concentrate (HPC) alone (up to 60%) | Requires a higher denaturation temperature; lower water absorption than soy | Complete protein but lower lysine than soy | Moderate hardness and chewiness; less fibrous than blends | Natural brown color with mild nutty flavor; less gloss, strong earthy, grassy, and mild nutty | [37,39] |

| Hemp + Soy Protein Isolate (SPI) | Improved gelation and emulsification; better processing stability | Enhanced essential amino acid profile; increased digestibility | Increased elasticity and firmness; improved texture uniformity | Brown shade, surface gloss, umami, mild earthy, soy masking ability | [15,37] |

| Hemp + Pea Protein (4:1 with maize starch) | Improved solubility, emulsification, and foaming properties | Complementary amino acid profile; increased lysine content | Balanced texture with improved chewiness and cohesiveness | Generally well accepted, mild flavor profile, uniform pale color, smooth surface, mild earthy, subdued beany, less bitterness | [12] |

| Hemp + Oat Fiber | Produces fibrous structure and brown color; influences texture via moisture | Adds dietary fiber and healthy fats | Fibrous texture; moisture content affects hardness and chewiness | Positive texture; natural color regulation, visible fibers, irregular surface, mild earthy, faint grassy | [41] |

| Hemp + Faba Bean Protein | Complementary amino acids; improved emulsification | Balanced amino acids; enhanced protein quality | Good gelation and foam stability | Improved sensory profile, matte beige color, marbling simulation, earthy, faint bean, masks hemp flavor | [42,43] |

| Hemp + Yellow Pea Protein | Synergistic effects on texture and nutrition | Improved lysine and sulfur amino acid content | Enhanced fibrousness and chewiness | High consumer acceptance, good red-brown, surface shine, minimal beany, mild earthy notes, balanced flavor | [44] |

| Hemp + Buckwheat Protein | Improved emulsification and gelling properties | Enhanced mineral and amino acid profile | Moderate gel strength; improved water holding | Mild flavor, acceptable texture, slightly brown color | [45] |

| Hemp + Rice Protein | Improved solubility and emulsification | Complementary amino acids; hypoallergenic | Balanced texture; moderate hardness | Mild flavor; good acceptance, mild earthy, subdued beany, less bitterness | [46] |

| Hemp + Pea + Wheat Gluten (Ternary blend) | Synergistic effects on extrusion and texture | Balanced amino acid profile (abundant in arginine and sulfur-containing amino acids); improved digestibility | Enhanced fibrous texture; improved chewiness | High consumer acceptance, brown color, earthy, nutty, slight beany flavor | [47] |

| Hemp + pea + Chickpea Protein (Ternary blend) | Improved gelation, emulsification, and texture | Enhanced amino acid balance; soy-free option | Increased hardness and chewiness | Positive sensory evaluation, beany flavor | [48,49] |

| Hemp + Soy + Pea Protein | Improved protein network formation and texture | Enhanced essential amino acids; increased digestibility | Increased firmness and elasticity | Good sensory acceptance, robust meaty, umami, slightly nutty, and beany | [44] |

| Hemp + Wheat Gluten + Chickpea Protein | Improved extrusion behavior and texture | Balanced amino acid profile (low in lysine and tryptophan); improved fiber content | Increased hardness, chewiness, and resilience | Browning, grill surface, structural fidelity, balanced, mild earthy, meaty | [39] |

| Hemp + Pea + Oat Fiber | Improved fiber content and texture | Increased dietary fiber and balanced amino acids | Fibrous texture; improved water retention | Deep, uniform brown color, earthy, mild nutty, light oat undertone, subtle beany notes | [50] |

| Hemp + Pea + Soy + Wheat Gluten + TGase | Enzymatic cross-linking enhances texture and water holding | Enhanced protein quality and digestibility | Pronounced fibrous structure; improved juiciness | Excellent sensory acceptance, rich, dark brown hue; robust meaty, pronounced umami, slightly nutty and beany; minimal off-notes | [14,19] |

| Hemp + Pea + Chickpea + Wheat Gluten | Improved extrusion and texturization | Balanced amino acid and fiber content | Enhanced chewiness and texture uniformity | Brown color, faint golden tint from chickpea, balanced earthy, light nutty and chickpea flavor, mild beany tones | [39] |

| Category | Details | Refs. |

|---|---|---|

| Nutritional Content |

| [103,104,105] |

| Health Benefits |

| [106,107] |

| Functional Properties in Meat Analogs |

| [104,105] |

| Sustainability |

| [108] |

| Consumer Acceptance |

| [105,108] |

| Regulatory Challenges |

| [104,105,108] |

| Nutrients | Meat (e.g., Turkey, Fish) | Hemp-Enriched Meat Analogs/Hemp Protein | Impact on Nutrition and Health Benefits | Refs |

|---|---|---|---|---|

| Minerals |

|

|

| [112,113] |

| Vitamins |

|

|

| [112] |

| Bioactive Compounds |

|

|

| [112] |

| Consumer Health Implications |

|

|

| [114] |

| Sustainability and Diet Support |

|

|

| [112] |

| Application Area | Description | Benefits | Refs. |

|---|---|---|---|

| Enzyme-Assisted Structuring |

|

| [19] |

| Regional Adaptation |

|

| [37] |

| Sustainable Processing |

|

| [14] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barakat, H.; Aljutaily, T. Hemp-Based Meat Analogs: An Updated Review on Extraction Technologies, Nutritional Excellence, Functional Innovation, and Sustainable Processing Technologies. Foods 2025, 14, 2835. https://doi.org/10.3390/foods14162835

Barakat H, Aljutaily T. Hemp-Based Meat Analogs: An Updated Review on Extraction Technologies, Nutritional Excellence, Functional Innovation, and Sustainable Processing Technologies. Foods. 2025; 14(16):2835. https://doi.org/10.3390/foods14162835

Chicago/Turabian StyleBarakat, Hassan, and Thamer Aljutaily. 2025. "Hemp-Based Meat Analogs: An Updated Review on Extraction Technologies, Nutritional Excellence, Functional Innovation, and Sustainable Processing Technologies" Foods 14, no. 16: 2835. https://doi.org/10.3390/foods14162835

APA StyleBarakat, H., & Aljutaily, T. (2025). Hemp-Based Meat Analogs: An Updated Review on Extraction Technologies, Nutritional Excellence, Functional Innovation, and Sustainable Processing Technologies. Foods, 14(16), 2835. https://doi.org/10.3390/foods14162835