1. Introduction

The world population is increasing rapidly and, according to the United Nations, it is projected to reach approximately 9.8 billion by 2050 [

1,

2]. As the world’s population rises, the demand for food resources increases, along with other challenges, such as food shortages, less available land, low resources, and climate change [

3]. This review aims to explore the current state of microbial protein production, its environmental and nutritional benefits, and the technological advancements necessary to overcome the scalability challenges. By examining these critical aspects, this review seeks to offer insights that will aid policymakers, researchers, and industry stakeholders in navigating the future of microbial proteins as a key element in global food security. Sustainable and innovative, environmentally friendly ideas are needed to handle these problems. Food security seriously needs attention [

4]. Animal products like meat are very important; the main challenge in regard to food security now is to ensure that enough of these products are supplied. The demand for meat is increasing with the increasing population [

5]. Meat alternatives can be a promising solution for the growing demand [

6]. Plant-based meat [

7,

8], cultured meat [

9,

10], hybrid cultured meat [

11], restructured meat [

12], and microbial protein-based meat [

13] are considered to be potential meat alternatives.

Bacteria, fungi, yeast, and algae-based approaches to producing microbial proteins are considered to be a sustainable method to develop meat analogs [

14]. Companies that produce microbial protein need less space and water, and provide a nutritious diet to consumers [

15]. These microbial proteins can also match the desired nutritional profile, using restructuring production technology to form meat analogs [

12]. Microbial proteins as a food are a good choice for the circular economy, which values resource efficiency and reductions in waste. Microbes can convert food waste into proteins [

16], and that protein can be utilized to make microbial protein-based meat alternatives. Traditional meat production, reliant on extensive land and water resources, is becoming increasingly unsustainable, instigating the search for innovative alternatives that meet both the nutritional needs and environmental goals of the future. While microbial proteins present an innovative solution to these challenges, their integration into global food systems faces several barriers, including high production costs, limited consumer awareness, and regulatory hurdles. Despite the promising environmental and nutritional benefits, a thorough understanding of microbial protein production, its scaling potential, and consumer perceptions is still needed.

The consumption of meat alternatives (e.g., plant-based meat) is growing rapidly [

17]. Still, there are several challenges in regard to producing microbial protein-based meat analogs, e.g., cost, taste, and the final product’s appearance. It is essential to address these challenges to enhance the microbial protein-based meat analogs market. The use of restructuring technology can be a sustainable method to make restructured hybrid meat, which involves improving the texture, taste, and decreasing the cost [

12]. This hybrid meat may contain plant-based proteins, animal-based proteins, or microbial proteins. Furthermore, this technology can be used to specify the nutritional profile of hybrid meat [

12].

This review highlights all the significant aspects of microbial proteins and addresses the impact of microbial proteins on global food security and health, as well as the environmental benefits of microbial protein-based meat analogs. This review points out the importance of microbial proteins in achieving several UN Sustainable Development Goals, including SDG 2, SDG 12, SDG 13, SDG 15, and SDG 9. This review is conducted to share insights on microbial proteins with policymakers, researchers, and industry stakeholders, to shed light on the possibilities and difficulties of using microbial proteins in the global food system.

3. Common Sources of Microbial Proteins

Microbial proteins, called single-cell proteins (SCPs), are biomass, protein extracts, or protein-rich products derived from microorganisms, such as bacteria, fungi, yeasts, and algae [

23]. These microorganisms have a high protein content and can be cultivated using fermentation technologies, often on sustainable and low-cost substrates [

24]. Microbial proteins offer an efficient and scalable solution for alternative protein production, addressing food security and environmental challenges [

25]. Furthermore, microbes are rich in protein, while

Table 2 presents a comparison of the protein ratios among various microbial protein sources. Microbial proteins can be derived from various microorganisms, including bacteria, fungi, yeasts, and algae. Each group has distinct characteristics that make it suitable for food applications. Among the different microbial proteins, bacteria have the highest protein content, ranging from 50 to 80%, making them ideal for high-yield production [

26]. Algae come second with 50–70% protein, offering additional benefits like omega-3 fatty acids and antioxidants [

27]. Yeasts provide moderate protein content (45–65%) and are also rich in B-vitamins [

28], while fungi, with 40–60% protein, are valued for their meat-like texture and high fiber content, especially beta-glucans. All these microbial sources are complete proteins, containing all the essential amino acids, which makes them nutritionally valuable compared to other protein sources [

29].

4. Sensory Properties of Microbial Proteins

Texture: Microbial proteins, particularly the mycoprotein of

Fusarium venenatum, have a fibrous texture, which can be identical to meat [

30]. It has been demonstrated that these proteins can be made to be meat-like in texture under the influence of extrusion or restructuring methods, which make them suitable for use as meat analogs [

30]. Other proteins are produced by microbes, such as yeast and bacteria, including

Saccharomyces cerevisiae and

Methylophilus methylotrophus, which can also be used as an alternative to meat after processing. Humpenöder et al. [

31] stated that mycoprotein offers a similar texture and protein quality to beef, with up to 96% lower CO

2 emissions. Furthermore Elhalis et al. [

32] stated that fermentation can be used to improve the sensory quality of plant-based meat analogs using fungi like

Fusarium venenatum and bacteria like

Lactobacillus plantarum.

Color: Microbial proteins occur in natural colors, dependent on their origin [

33]. Protein sources like

Fusarium venenatum are frequently beige [

34], and algae sources like

Spirulina provide a natural green color [

35]. Beet juice and other natural colorants are occasionally added when making meat analogs using microbial proteins. Yeast and fungi, along with red yeast, are important in terms of the color and visual appeal of meat alternatives. Yeast, such as

Saccharomyces cerevisiae, typically has a light beige or yellowish color, which may not naturally resemble the rich tones of meat. However, this can be adjusted with natural colorants like beetroot powder or caramel coloring to achieve a more meat-like appearance. On the other hand, fungi, such as

Fusarium venenatum (used in Quorn) [

36], generally have a pale off-white or ivory color, and, like yeast, they often require color modification to replicate the red, brown, or pink hues of meat, especially when used in products like vegan burgers [

28]. Wu et al. [

37] stated that red yeast, from

Monascus species, naturally provides a red or reddish color, mimicking the pinkish hues of meat and is particularly beneficial in creating realistic meat analogs. The combination of yeast and fungi with natural colorants can help produce a realistic, appetizing appearance of meat substitutes, while color adjustments also ensure consumer appeal and acceptance.

Flavor: Yeast and other fungal microbial proteins contain high amounts of glutamic acid, which is responsible for generating an umami taste [

38], and they can offer a taste similar to meat. For example, Quorn*(TM), a popular product manufactured using mycoprotein, has over the years enhanced its taste in order to enhance its acceptability in the meat alternatives market. Borthakur et al. [

39] stated that

Fusarium venenatum produces esters, aldehydes, ketones, and sulfur compounds that mimic savory, umami, and meaty notes; furthermore, Sharma et al. [

40] have also reviewed the effect of microbes on flavor.

6. Technologies for Microbial Protein Production

Microbial protein production relies on biotechnological advancements that optimize growth conditions, maximize yield, and ensure sustainability [

50]. Various fermentation-based techniques and substrate utilization strategies are employed to enhance the efficiency and scalability of microbial protein production [

51].

6.1. Fermentation-Based Approaches

Fermentation is the primary method for producing microbial proteins [

52]. It involves cultivating microorganisms in a controlled environment to maximize biomass production [

43]. Several types of fermentation, explained below, are used to produce microbial protein.

Through fermentation, these substrates can yield a range of high-value products, such as single-cell proteins (SCPs), enzymes, organic acids (e.g., lactic acid, citric acid, succinic acid), bioethanol, bioplastics (e.g., PHAs), bioactive peptides, and natural colorants. For example, orange peels can be used to produce pectinase and citric acid, while wheat bran can be used to support the production of xylanase, an enzyme used in food processing and animal feed.

These fermentation products have significant economic value, finding applications in the food and beverage industry, animal feed, pharmaceuticals, cosmetics, biofuel, and biodegradable packaging sectors. For instance, Danone and Unilever have explored microbial protein production from food processing waste, while companies like Cargill and ADM are using corn stover and molasses in fermentation to produce organic acids and amino acids.

Moreover, utilizing waste materials not only reduces raw material costs, but also contributes to a circular bioeconomy by converting low-value or polluting residues into valuable, marketable products. This waste valorization approach supports both environmental sustainability and economic efficiency, providing a dual benefit of reducing waste disposal issues, while generating profit [

53].

6.1.1. Submerged Fermentation (SmF)

Submerged Fermentation is the most widely used technique for the production of microbial protein. Microorganisms grow in liquid nutrient media, where the temperature, pH, aeration, and agitation are controlled to optimize the biomass yield [

54]. This type of fermentation is mainly used for

Fusarium venenatum (Quorn),

Saccharomyces cerevisiae, and

Methylobacterium methylotrophus.

6.1.2. Solid-State Fermentation (SSF)

Solid-state fermentation (SSF) involves the growth of microorganisms on solid substrates in the absence of free-flowing water [

55]. This technique is highly sustainable as it utilizes agro-industrial waste (e.g., wheat bran, corn stover). Solid-state fermentation is frequently employed in the cultivation of filamentous fungi like

Aspergillus oryzae and

Rhizopus oligosporus.

6.1.3. Gas Fermentation

Certain bacteria, such as

Cupriavidus necator, can convert gases like CO

2, CH

4, or H

2 into proteins. Gas fermentation is a promising approach for sustainable, large-scale protein production, with minimal environmental impact [

56]. For example, Calysta’s FeedKind uses methane as a feedstock to produce microbial protein for animal feed.

6.2. Single-Cell Protein (SCP) Production

SCP production refers to microbial biomass used directly as a protein source for food or feed [

57]. The efficiency of SCP production depends on the microorganism used and the fermentation conditions. Furthermore, the advantages of SCP production are graphically explained in

Figure 2, and the commonly used microbes for SCP production are presented in

Table 4. In addition to this, a comparison of the different fermentation types that are being used in the production of microbial protein-based meat analogs is presented in

Table 5.

6.3. Bioprocessing Using Waste Streams and Renewable Substrates

Using alternative feedstocks, such as agricultural residues, industrial byproducts, and renewable substrates, enhances the sustainability of microbial protein production [

60].

6.3.1. Agricultural and Food Waste

Agro-industrial waste materials, such as wheat straw, sugarcane bagasse, fruit peels, corn cobs, potato peels, spent coffee grounds, and brewery spent grains are rich in carbohydrates, proteins, fibers, and micronutrients, making them promising substrates for microbial fermentation [

61]. These materials can be hydrolyzed into fermentable sugars, amino acids, and other nutrients that support the growth of various microorganisms, including bacteria (

Bacillus subtilis, Lactobacillus spp.), fungi (

Aspergillus niger, Fusarium venenatum), and yeasts (

Saccharomyces cerevisiae, Yarrowia lipolytica). Several industries and companies have already transformed agro-industrial waste materials into valuable products using microbial fermentation.

Waste materials, such as wheat straw, sugarcane bagasse, fruit peels, and spent grains, can serve as nutrient sources for microbial growth [

61]. For example,

Aspergillus oryzae can ferment food waste into protein-rich biomass. Quorn foods use

Fusarium venenatum grown on glucose derived from starch waste to produce mycoprotein, a meat alternative [

36]. Unilever and Danone have invested in startups exploring microbial protein production from food processing byproducts like potato peels and molasses.

6.3.2. Industrial Byproducts

Waste streams from bioethanol production, dairy processing, and brewery industries contain valuable nutrients that support microbial growth [

62]. For example,

Yarrowia lipolytica can utilize glycerol (a byproduct of biodiesel production) to produce SCP.

6.3.3. Methanotrophic and Photosynthetic Pathways

Bacteria like

Methylococcus capsulatus can convert methane into microbial protein, reducing greenhouse gas emissions [

63]. Microalgae, such as Chlorella vulgaris, use CO

2 for protein biosynthesis, contributing to carbon sequestration. The microbial fermentation of agricultural and food waste offers a sustainable and economically viable solution for protein production.

Table 6 compares different agricultural and food waste substrates, including the types of microorganisms used, conversion rates, protein content, and the economic potential of each substrate for producing microbial protein.

7. Scaling Up Microbial Protein Production

For microbial proteins to compete with conventional proteins, large-scale production and cost effectiveness must be achieved [

64].

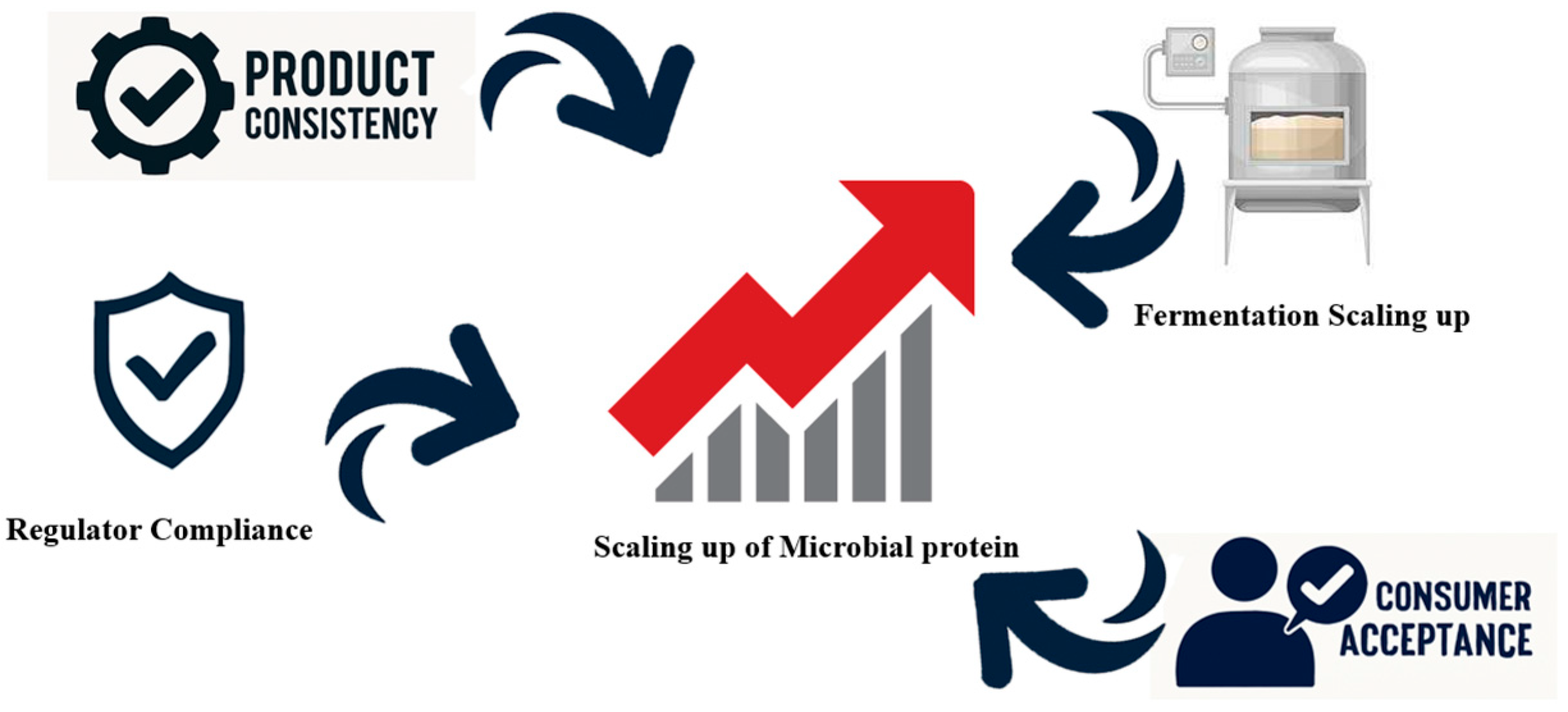

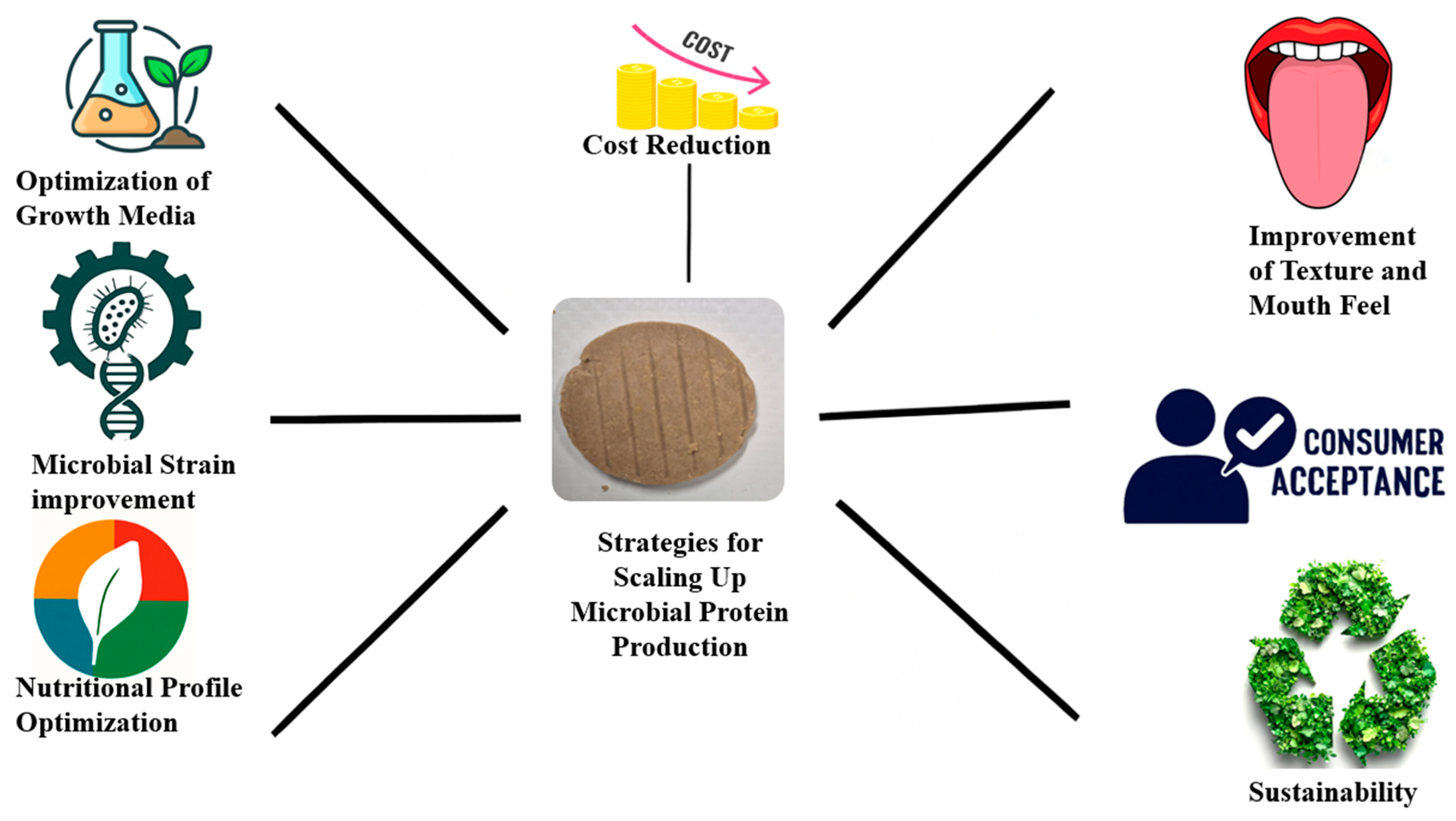

Figure 3 presents the challenges associated with scaling up microbial protein production, along with potential solutions. Furthermore, there are several strategies to improve the scaling up of microbial protein production, which are presented in

Figure 4. Several companies are leading in terms of large-scale microbial protein production, as shown in

Table 7. Scaling up microbial protein production involves transitioning from laboratory-scale processes to industrial-scale operations, while maintaining product consistency, regulatory compliance, and consumer acceptance, as illustrated in the diagram. The main methods include batch fermentation, fed-batch fermentation, and continuous fermentation. Batch fermentation is simple and easy to control, making it ideal for early-stage production; however, it has lower productivity and longer downtimes. Fed-batch fermentation enables better control over the nutrient supply, leading to higher cell densities and protein yields, but it requires more complex monitoring and can be costly to scale. Continuous fermentation offers the highest productivity and efficient use of equipment, making it suitable for large-scale operations, but it poses challenges in regard to maintaining long-term sterility and consistent product quality. Other innovations like precision fermentation (e.g., using genetically engineered microbes) and solid-state fermentation (using agro-waste as a substrate) are gaining attention for their sustainability and substrate flexibility benefits, although they may face regulatory hurdles or technical limitations in terms of process control.

8. Sustainability and Environmental Benefits of Microbial Proteins

Producing microbial proteins presents a sustainable alternative to conventional animal agriculture, offering significant environmental advantages [

15]. Compared to livestock farming, microbial protein production requires less land and water, generates lower greenhouse gas (GHG) emissions, and contributes to a circular bioeconomy by utilizing waste streams as feedstocks [

65].

One of the most significant advantages of microbial protein production is its minimal land and water footprint compared to conventional meat production [

15]. Microbial proteins require 10–100 times less land than traditional livestock farming [

15]. Unlike animal agriculture, which depends on extensive pastureland and feed crop cultivation, microbial proteins can be produced in bioreactors, significantly reducing deforestation and habitat loss [

65].

Table 8 presents a comparison of land use per kilogram of protein across various protein sources.

8.1. Water Conservation

The water footprint of microbial proteins is significantly lower than beef and poultry. Microbial fermentation is conducted in closed systems, minimizing water loss and contamination.

Table 9 compares the water conversion efficiency per kilogram of protein among various protein sources.

8.2. Lower Greenhouse Gas Emissions Compared to Conventional Meat

Livestock farming is a major contributor to greenhouse gas (GHG) emissions, particularly methane (CH

4) from ruminant digestion and carbon dioxide (CO

2) from feed production and land use changes [

70]. In contrast, microbial protein production generates significantly lower emissions. Microbial protein production can reduce GHG emissions compared to beef production [

15]. Fermentation-based protein production emits less than 1 kg of CO

2 equivalent per kg of protein, whereas beef production emits up to 33.30 kg of CO

2 equivalent per kg of protein [

71]. Unlike ruminant livestock, mycoprotein (

Fusarium venenatum) and bacterial SCP (

Methylococcus capsulatus) produce minimal methane emissions. Specific microbial fermentation systems can utilize CO

2 as a feedstock, directly converting waste gases into protein [

72].

12. Future Perspectives

There are several studies that have been conducted on microbial protein-based meat over the last 10 years, as shown in

Figure 6. As global food demand increases, microbial proteins have emerged as a sustainable and scalable alternative to conventional protein sources [

13]. However, their widespread adoption depends on advances in synthetic biology, precision fermentation, regulatory policies, and investment in large-scale production. Synthetic biology and genetic engineering are transforming microbial protein production by enhancing the protein yield, and enabling functional customization [

82].

Moreover, genetic modifications have the potential to enhance biomass growth rates, thereby increasing protein production efficiency. Through metabolic engineering, microbes can be optimized to utilize low-cost feed stocks such as CO

2, methane, or agricultural waste, which can significantly reduce production costs [

83]. Additionally, genetic engineering can improve the essential amino acid profiles of microbial proteins, making them more comparable in nutritional quality to animal-derived proteins.

Figure 6.

A keyword co-occurrence network, which is generated from the literature published over the past ten years on microbial protein-based meat (derived using the keyword microbial protein in PubMed in the literature published in the last 10 years).

Figure 6.

A keyword co-occurrence network, which is generated from the literature published over the past ten years on microbial protein-based meat (derived using the keyword microbial protein in PubMed in the literature published in the last 10 years).

Precision bioengineering allows for the customization of protein structures to improve its texture, digestibility, and taste [

84]. Precision fermentation is a revolutionary technology that enables the targeted production of specific proteins, peptides, and functional compounds using microbial systems [

85]. Unlike traditional fermentation, precision fermentation inserts specific genes into microorganisms to produce targeted proteins identical to those found in animal or plant sources. Perfect Day uses precision fermentation to produce animal-free dairy proteins (whey and casein) from engineered microbes.

The production of meat-like textures is accomplished by engineering fungal and bacterial proteins to develop enhanced fibrous structures. The creation of hybrid proteins involves combining microbial proteins with plant-based ingredients to improve both taste and functional properties. Additionally, research is focused on generating bioactive peptides from these proteins, which may offer potential health benefits such as anti-inflammatory and immune-modulating effects.

13. Conclusions

This review underscores the significance of microbial proteins as a sustainable alternative to meet the increasing global demand for meat, emphasizing their potential to substantially reduce the environmental impact associated with conventional animal-based meat production.

Microbial protein-based meat offers high nutritional value and can be produced with little space compared to animal-based meat production. These advantages make microbial proteins an essential component of future food systems. However, key challenges, such as limited public awareness, high production costs, and regulatory complexities, must be addressed for microbial proteins to achieve large-scale integration. Technological innovations, supportive policy frameworks, and efforts to improve consumer perceptions are crucial to overcoming these limitations. Additionally, restructuring technologies and hybrid formulations that blend microbial and plant-based proteins could help reduce costs and enhance the product’s taste and texture, making microbial protein-based meat analogs more acceptable and economically feasible. Ultimately, microbial proteins represent more than a protein source, they embody a strategic approach to achieving multiple United Nations Sustainable Development Goals, including food security, climate action, and sustainable industry. With continued advancement and collaboration across sectors, microbial proteins could play a transformative role in building a resilient and equitable global food system.