Heat Pump Technology in the Field of Fruit and Vegetable Drying: A Review

Abstract

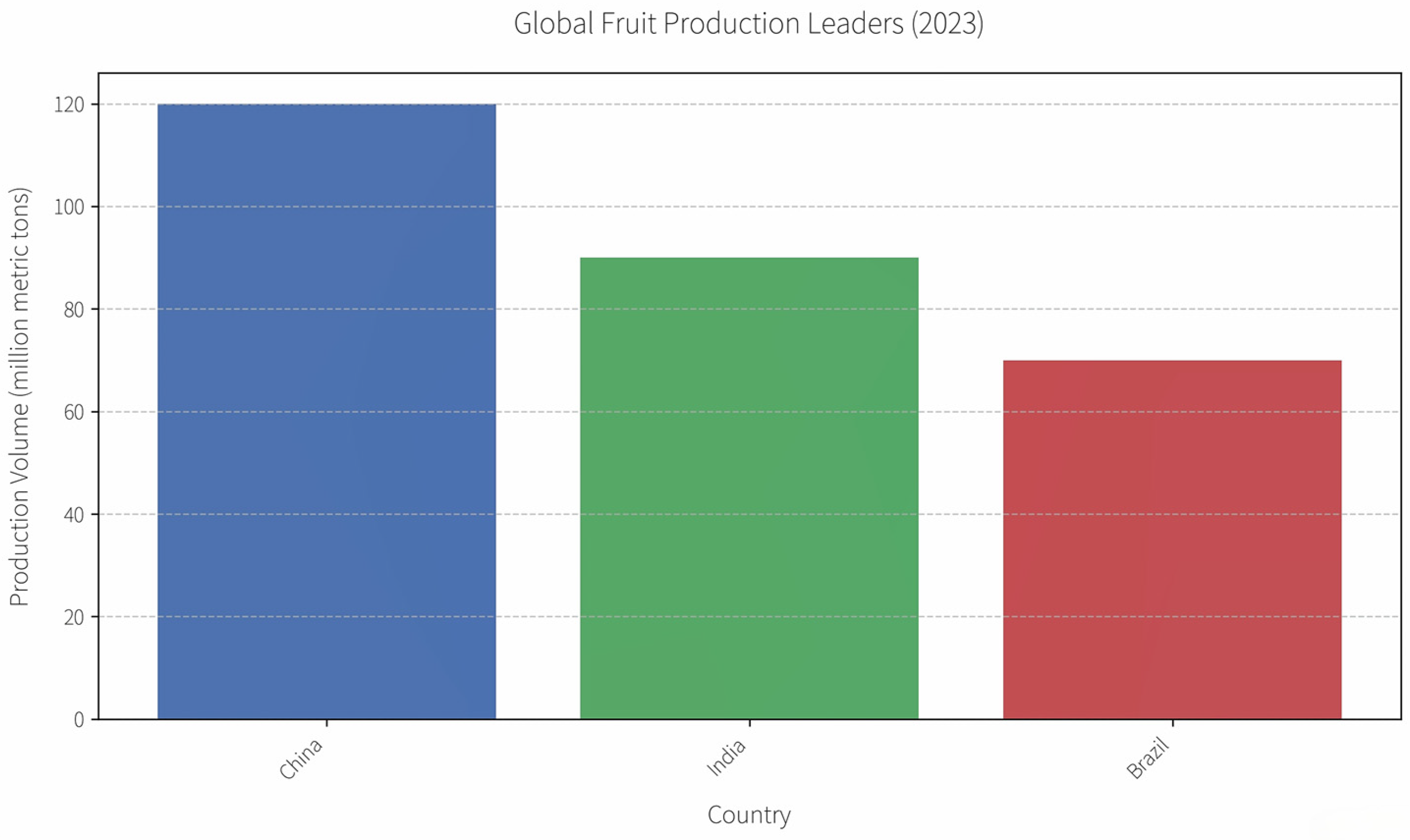

1. Introduction

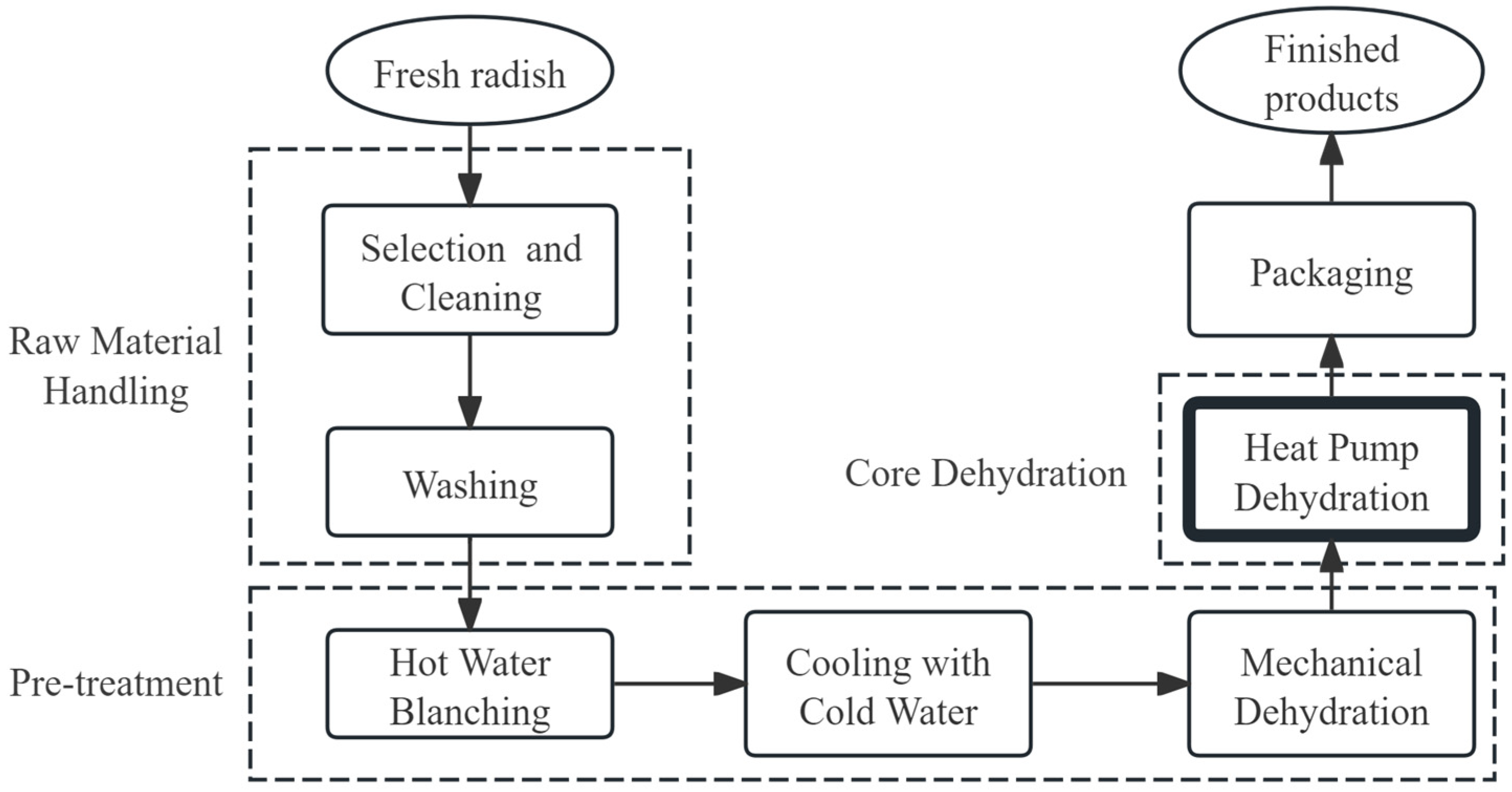

2. Single-Stage Heat Pump Drying Technologies

2.1. Current Status of Single Heat Pump Drying Technologies

2.2. Limitations of Single Heat Pump Drying Technologies

2.2.1. Automation Limitations

2.2.2. Production Requirement Limitations

2.2.3. Challenges in Market Application

2.2.4. Limitations in Drying Quality

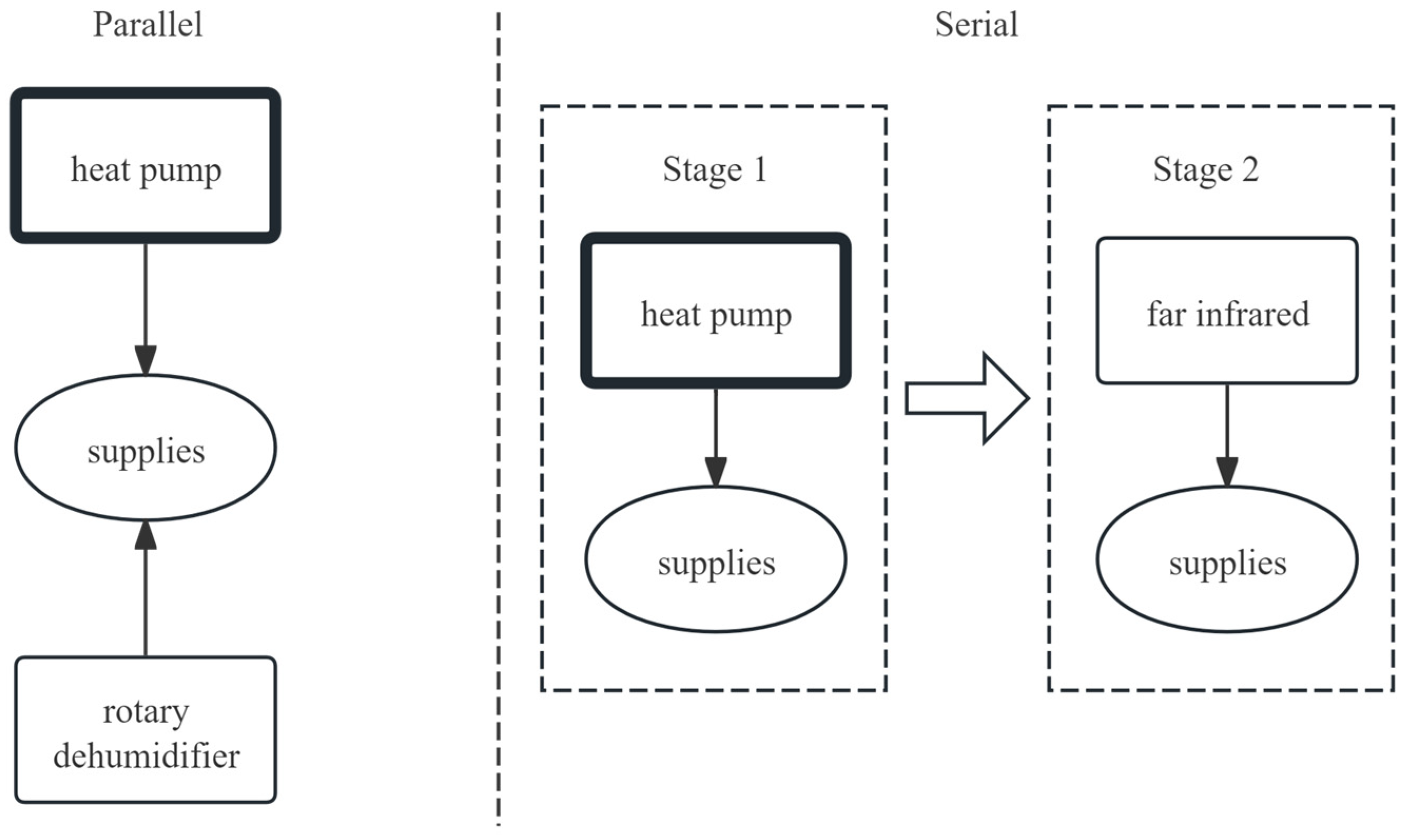

3. Combined Heat Pump Drying Technologies

3.1. Principles, Configuration Selection, and Comparative Merits of Series vs. Parallel Combined Drying

3.1.1. Fundamental Principles and Rationale

3.1.2. Criteria for Selecting Series vs. Parallel Configuration

3.1.3. Advantages and Disadvantages of Each Configuration

3.2. Combined Heat Pump Drying Technology in Parallel

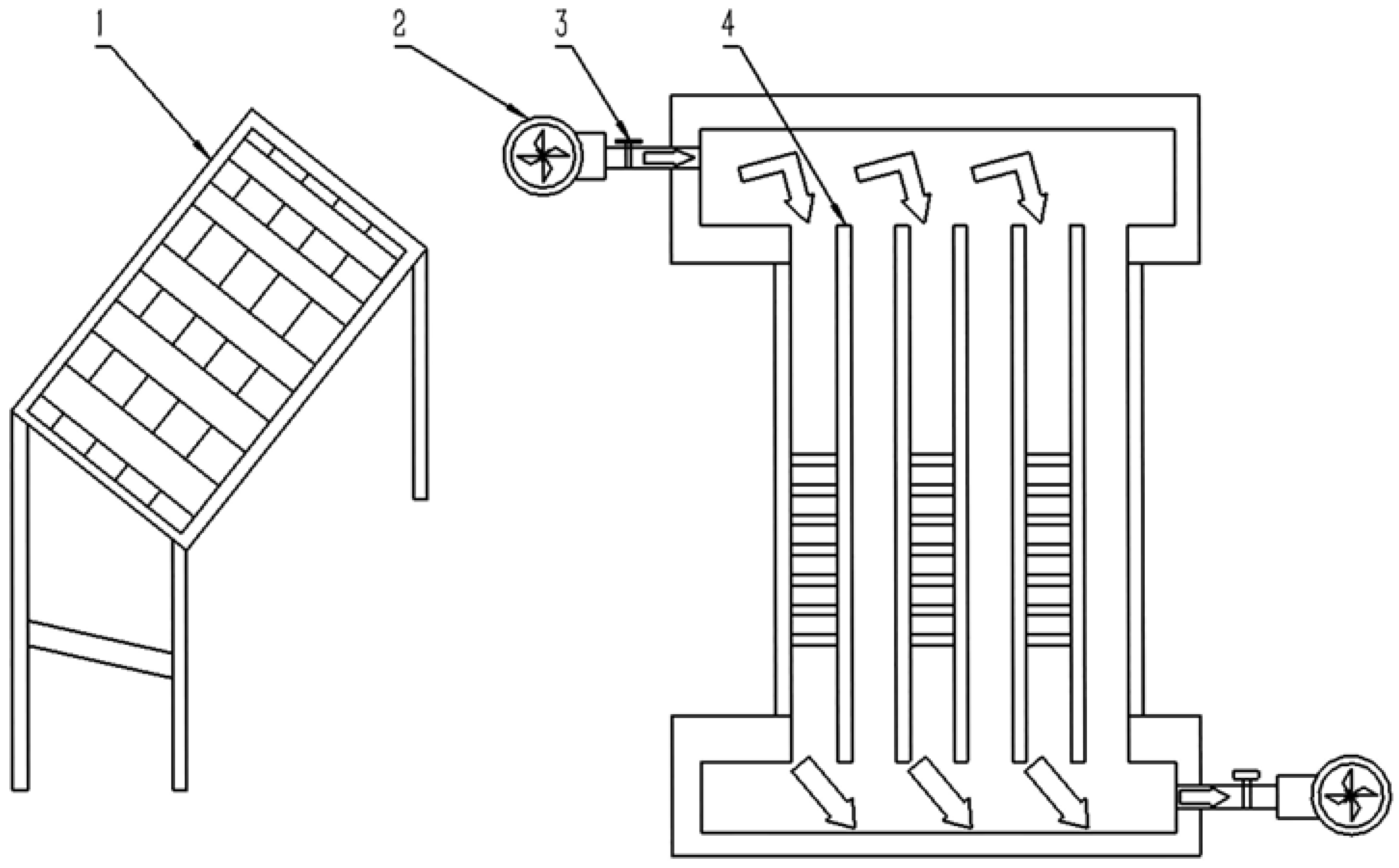

3.2.1. Heat Pump Combined with Fluidized Bed Drying

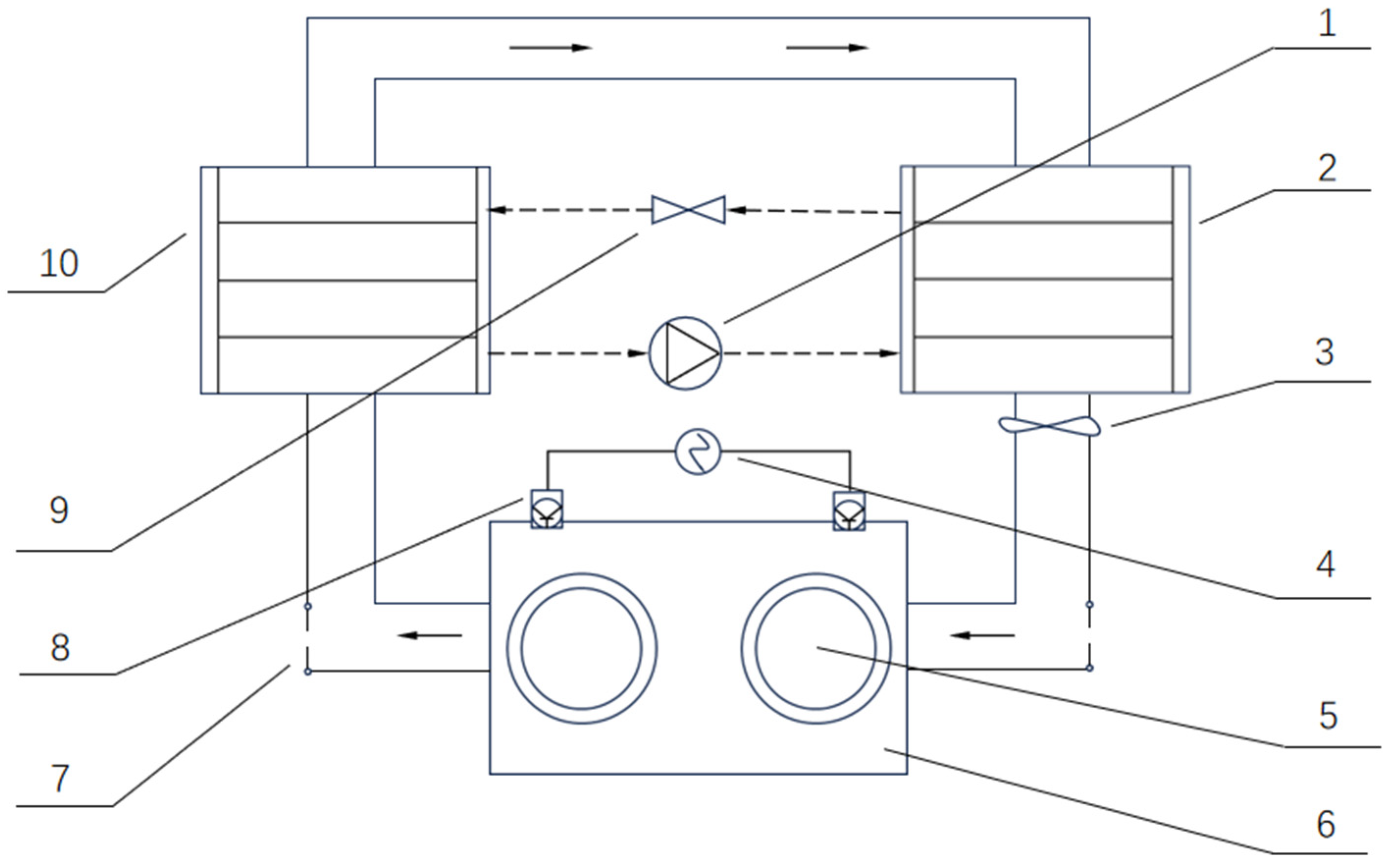

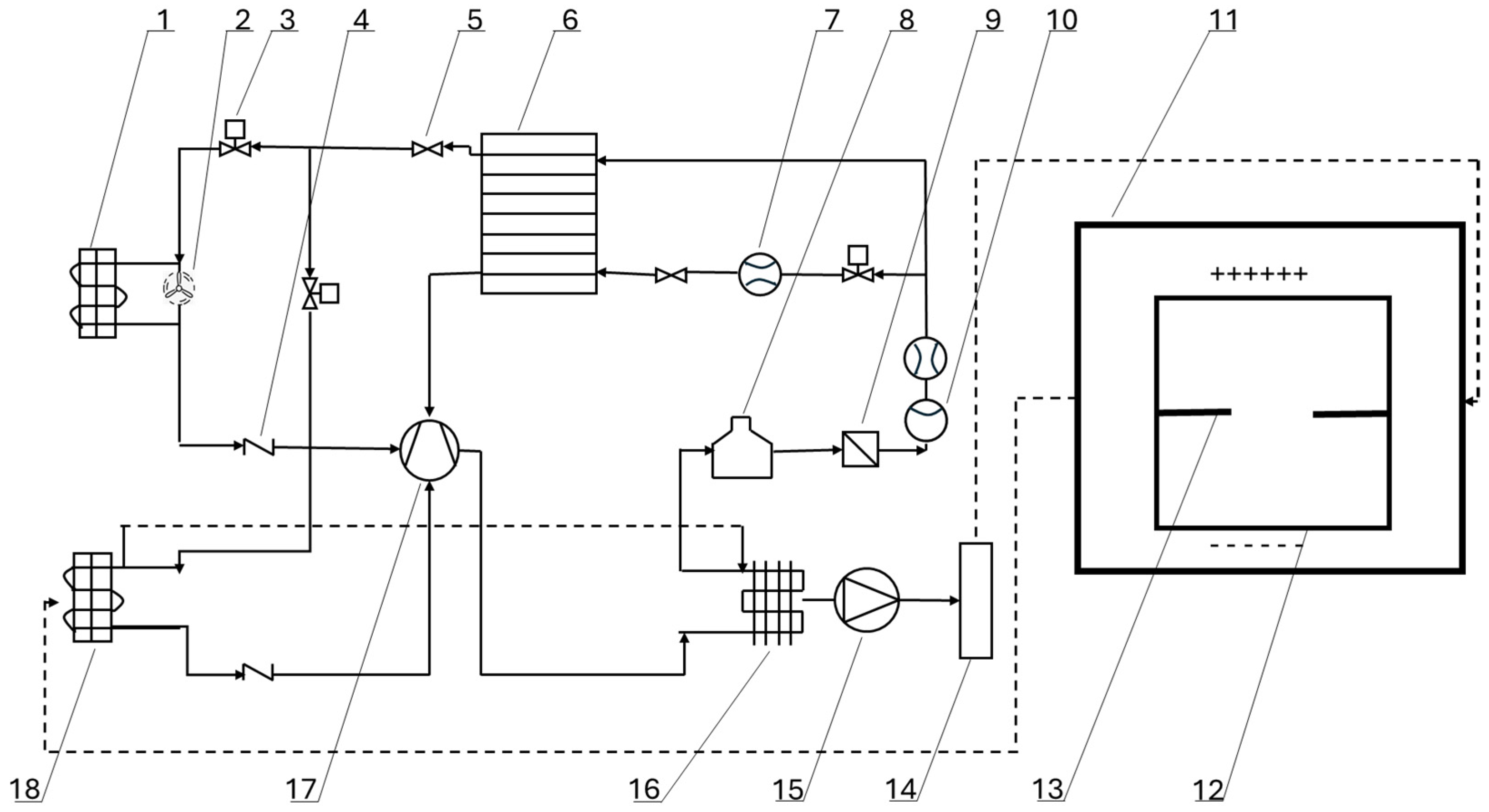

3.2.2. Heat Pump Combined with Dehumidification Drying

3.2.3. Heat Pump Combined with Vacuum Freeze-Drying

3.2.4. Heat Pump Combined with High-Voltage Electric Field Drying

3.3. Combined Heat Pump Drying Technology in Series

3.3.1. Heat Pump Combined with Hot Air Drying

3.3.2. Heat Pump Combined with Far-Infrared Drying

3.3.3. Heat Pump Combined with Microwave Drying

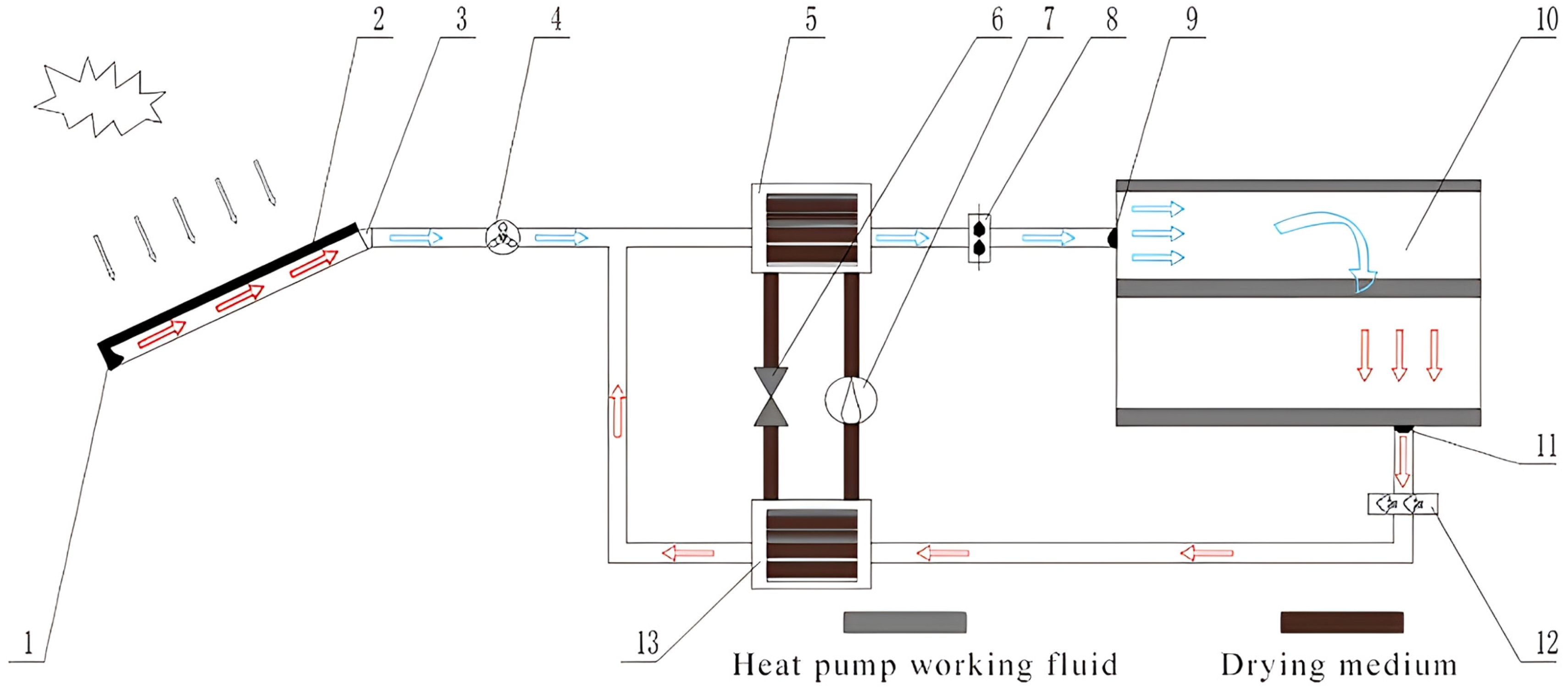

3.3.4. Solar-Assisted Heat Pump Drying

3.3.5. Ultrasound-Enhanced Heat Pump Drying

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, F. Statistical analysis of fruit production in China in 2020. China Fruit Ind. Inf. 2021, 38, 29–39. [Google Scholar]

- Xiong, T. Key technology and industrialization application of probiotic fermentation in fruits and vegetables. Beverage Ind. 2016, 19, 71–73. [Google Scholar]

- Botelho, V.R.; Monte, M.L.; Pereira Filho, R.D.; Pinto, L.A.A. Internet of Things (IoT): Operational automation in experimental and computational analyses of hop residues drying. J. Food Eng. 2025, 401, 112662. [Google Scholar] [CrossRef]

- Yao, J.; Chen, W.; Fan, K. Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review. Foods 2023, 12, 4321. [Google Scholar] [CrossRef] [PubMed]

- Zou, L.G.; Liu, Y.; Yu, M.Q.; Yu, J.L. A review of solar assisted heat pump technology for drying applications. Energy 2023, 283, 129215. [Google Scholar] [CrossRef]

- Zheng, X.Z. Drying Theory and Technology of Agricultural Products; China Light Industry Press: Beijing, China, 2009; Volume 1, pp. 11–22. [Google Scholar]

- Zhu, W.X. Principle and Technology of Food Drying; Science Press: Beijing, China, 2009; Volume 7–21. [Google Scholar]

- Li, X.G. Current situation and development trend of dry processing technology of agricultural products in China. Agric. Eng. Technol. Agric. Process. Ind. 2014, 2, 16–21. [Google Scholar]

- Slim, R.; Zoughaib, A.; Clodic, D. Modeling of a solar and heat pump sludge drying system. Int. J. Refrig. 2008, 31, 1156–1168. [Google Scholar] [CrossRef]

- Xu, C.; Ma, H.T.; Wang, S. Thermal digestion characteristics of kitchen waste based on high temperature heat pump combined with vacuum drying. Appl. Therm. Eng. 2024, 244, 122703. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Kheir Abadi, M.; Asadi, M.; Khutornaya, J.; Sergienko, O. Investigation of a new solar-wind energy-based heat pump dryer for food waste drying based on different weather conditions. Energy 2024, 290, 130328. [Google Scholar] [CrossRef]

- Lou, Z.; Liu, Q.; Zhao, Y.Q.; Shao, G.; Shi, S.R.; Xie, Q.Z. Application of air source heat pump drying technology in postnatal treatment of agricultural products. Agric. Eng. 2017, 7, 68–72. [Google Scholar]

- Sun, Z.H. Research on the application of heat pump drying technology in the processing of dehydrated fruits and vegetables. Food Saf. Guide 2015, 36, 151. [Google Scholar]

- Wang, R.G.; Wu, Z.H.; Hu, Q.S.; Wu, S.B.; Mao, Z.H.; Wu, J.L.; Wu, W.J.; Li, Z.Q. Application and Practice of Heat Pump Drying Technology in the Production Process of Edible Fungi and Other Agricultural Products/Electrical Engineering (Electric Power) Society of Six Provinces and One City in East China; Zhejiang Electric Power Society 2017 Outstanding Papers; China Electric Power Press: Beijing, China, 2017; Volume 1, pp. 314–322. [Google Scholar]

- Ding, J.X.; Wu, X.H.; Wang, P.; Zang, Z.T. Application of drying technology in fruits and vegetables. Refrig. Air Cond. 2019, 19, 23–27+58. [Google Scholar]

- Zhang, P.; Wu, X.H.; Zhang, Z.T.; Yue, Y.K.; Yang, J.L. Heat pump drying technology and its application in agricultural special products. Refrig. Air Cond. 2019, 19, 65–71. [Google Scholar]

- Song, W. Advantages and development prospects of air energy heat pump for drying technology of agricultural products. Agric. Mach. Use Maint. 2022, 11, 134–136. [Google Scholar]

- Ma, C.Y.; Yang, K.M.; Wang, Y.C. Application of heat pump technology in drying agricultural products. Dist. Heat. 2019, 4, 1–8. [Google Scholar]

- Duan, S.; Wang, L.; Nie, D. Performance analysis of a two-stage evaporation heat pump drying system for graded cooling/dehumidification. Appl. Therm. Eng. 2024, 247, 122965. [Google Scholar] [CrossRef]

- Conte, R.; Tancon, M.; Mozafarivanani, M.; Zanetti, E.; Azzolin, M.; Del Col, D. Investigation on a direct expansion multisource carbon dioxide heat pump to maximize the use of renewable energy sources. Appl. Therm. Eng. 2025, 274, 126533. [Google Scholar] [CrossRef]

- Xia, Y.; Jin, L.; Liu, T.; Cao, F. Research progress of heat pump technology applied to fruit and vegetable drying. Res. Agric. Sci. 2014, 35, 60–67. [Google Scholar]

- Liu, J.; Wu, X.; Zhao, Y.; Shi, Q.L. Research progress of heat pump combined drying technology for fruits and vegetables. China Fruits Veg. 2022, 42, 8–15. [Google Scholar]

- Bei, X.; Yu, X.; Li, D.; Sun, Q.; Yu, Y.; Wang, Y.; Okonkwo, C.E.; Zhou, C. Heat source replacement strategy using catalytic infrared: A future for energy saving drying of fruits and vegetables. J. Food Sci. 2023, 88, 4827–4839. [Google Scholar] [CrossRef] [PubMed]

- Jokiel, M.; Bantle, M.; Kopp, C.; Verpe, E.H. Modelica-based modelling of heat pump-assisted apple drying for varied drying temperatures and bypass ratios. Therm. Sci. Eng. Prog. 2020, 19, 100575. [Google Scholar] [CrossRef]

- Dong, X.; Zhao, H.; Kong, F.; Han, J.; Xu, Q. Parameter optimization of multistage closed series heat pump drying system. Appl. Therm. Eng. 2022, 216, 119124. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, M.; Feng, M.; Semenov, G.; Yu, D. Artificial intelligence-based multi-objective optimization in fruit and vegetable drying systems: A comprehensive review. Food Res. Int. 2025, 218, 0963–9969. [Google Scholar] [CrossRef]

- Tunçkal, C.; Direk, M.; Doymaz, İ.; Göksel, Z.; Atak, A. Drying kinetics and energy-exergy analysis of an experimental heat pump dryer utilized horseshoe heat recovery heat pipes for drying different grapes. Therm. Sci. Eng. Prog. 2022, 36, 101487. [Google Scholar] [CrossRef]

- Sun, X.F. Research on Drying and β-Carotene Degradation of Carrot with CO2 Gas-Modulated Heat Pump; Jiangsu University: Zhenjiang, China, 2019; Volume 10. [Google Scholar]

- Lee, H.Y.; Chin, K.S.; Chung, K.S. Drying characteristics and product quality of lemon slices dried with hot air circulation oven and hybrid heatpump dryers. Int. J. Sci. Eng. 2015, 8, 69–74. [Google Scholar]

- Ruan, H.P.; Zhu, J.W.; Chen, J.L. Design and development of small agricultural heat pump drying equipment. Agric. Technol. Equip. 2017, 5, 62–63+66. [Google Scholar]

- Yao, M.; Li, M.; Zhang, Y.; Wang, Y.; Li, G.; Zhang, Y.; Deng, Z.; Xing, T.; Zhu, Y. Performance, energy and exergy analysis of solar-assisted heat pump drying system with heat recovery: A comprehensive experimental study. Renew. Energy 2025, 244, 122665. [Google Scholar] [CrossRef]

- Qiao, J.L. Application of Heat Pump Drying Technology in Fruit and Vegetable Dehydration; Fujian Agriculture and Forestry University: Fuzhou, China, 2014; Volume 22. [Google Scholar]

- Wang, H.; Li, S.; Lei, K.; Zhang, J. Performance analysis of cross seasonal thermal storage solar soil source heat pump drying system. Renew. Energy 2025, 241, 122202. [Google Scholar] [CrossRef]

- Lu, X.C.; Yuan, J.; Li, G.J.; Yang, F.S.; Zhang, W.; Hong, S.; Zhang, Z.X. Application progress of heat pump technology in drying common fruits and vegetables. Chem. Mach. 2022, 49, 589–597+658. [Google Scholar]

- Sehrawat, R.; Nema, P.K.; Kaur, P.B. Quality evaluation and drying characteristics of mango cubes dried using low-pressure superheated steam, vacuum and hot air drying methods. LWT 2018, 92, 548–555. [Google Scholar] [CrossRef]

- Huang, Y.F. Heat Pump Drying Characteristics and Changes of Flavor Components of Whole Fruit and Pulp of Litchi; South China Agricultural University: Guangzhou, China, 2020; pp. 23–35. [Google Scholar]

- Yao, N.N. Effects of Pretreatment and Drying Methods on Drying Characteristics and Quality of Sea Buckthorn; Xinjiang Agricultural University: Ürümqi, China, 2020; pp. 17–37. [Google Scholar]

- Azadbakht, M.; Aghili, H.; Ziaratban, A.; Vahedi Torshizi, M. Application of artificial neural network method to exergy and energy analyses of fluidized bed dryer for potato cubes. Energy 2017, 120, 947–958. [Google Scholar] [CrossRef]

- Bai, S.; Xiao, K.; Liu, Q.; Mariga, A.M.; Yang, W.; Fang, Y.; Hu, Q.; Gao, H.; Chen, H.; Pei, F. Prediction of moisture content of Agaricus bisporus slices as affected by vacuum freeze drying using hyperspectral imaging. Food Control 2024, 159, 110290. [Google Scholar] [CrossRef]

- Raj, G.V.S.B.; Dash, K.K. Microwave vacuum drying of dragon fruit slice: Artificial neural network modelling, genetic algorithm optimization, and kinetics study. Comput. Electron. Agric. 2020, 178, 105814. [Google Scholar] [CrossRef]

- Chakravartula, S.S.N.; Bandiera, A.; Nardella, M.; Bedini, G.; Ibba, P.; Massantini, R.; Moscetti, R. Computer vision-based smart monitoring and control system for food drying: A study on carrot slices. Comput. Electron. Agric. 2023, 206, 107654. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z. Research progress of fruit and vegetable drying technology. China Fruits Veg. 2020, 40, 9–17. [Google Scholar]

- Li, S.P.; Zhang, X.Y.; Liu, R.Y.; Guo, Y.L.; Li, Z.H.; Zhao, Q.L. Research progress of microwave combined drying technology for agricultural products. Food Res. Dev. 2022, 43, 207–212. [Google Scholar]

- Shi, Y.F. Research on Drying Process of Closed Circulation Heat Pump Fluidized Bed; Zhejiang University of Technology: Hangzhou, China, 2017; Volume 22. [Google Scholar]

- Wu, Q.R.; Wang, G.M.; Zeng, E.; Liu, S.P.; Zhang, X.K.; Xu, G.; Xu, J.G. Research progress of heat pump combined drying of agricultural products. Food Sci. Technol. 2016, 41, 88–92. [Google Scholar]

- Zhang, X.K.; Mao, Z.H.; Li, H.D.; Xu, G.; Xiong, K.M.; Gu, Z. Experiment on drying diced carrot with heat pump fluidized bed combination. Trans. Chin. Soc. Agric. Mach. 2006, 37, 608–671. [Google Scholar]

- Zielinska, M.; Zapotoczny, P.; Alves-Filho, O.; Eikevik, T.M.; Blaszczak, W. A multi-stage combined heat pump and microwave vacuum drying of green peas. J. Food Eng. 2013, 115, 347–356. [Google Scholar] [CrossRef]

- Xie, H.; Liu, X.Y.; Yang, S.C.; Bai, W.D. Application of heat pump combined drying technology in fruit and vegetable drying process. Agric. Prod. Process. 2022, 16, 75–78+83. [Google Scholar]

- Wang, J.L.; Song, W.D.; Jin, C.Q.; Ding, T.H.; Wang, M.Y. Structure design and process parameter optimization of rotary dehumidification heat pump drying system for Pleurotus eryngii. Trans. Chin. Soc. Agric. Eng. 2019, 35, 273–280. [Google Scholar]

- Wang, Y.M. Research on Characteristics of Dried Yam Combined With Heat Pump and High Voltage Electric Field; Zhongyuan University of Technology: Zhengzhou, China, 2022; Volume 23. [Google Scholar]

- Han, L.-c.; Jin, T.-x. Effects of combined vacuum and heat pump drying on drying characteristics and physicochemical properties of pineapple. LWT 2024, 192, 115727. [Google Scholar] [CrossRef]

- Zhu, B.L.; Zhang, X.K. Development of heat pump fluidized bed dryer. Grain Oil Process. 2006, 06, 70–73. [Google Scholar]

- Tellab, N.; Hemis, M.; Panigrahi, S.S.; Singh, C.B. Influence of rewetting method on soybean behaviour during fluidized bed drying, experimental and simulation study. J. Stored Prod. Res. 2025, 111, 102548. [Google Scholar] [CrossRef]

- Rajendran, B.; Pattabi, T.; Sudalaimani, A.; Mohankumar, A.; Mariappan, M. A Study of the Comparison of Fluidized Bed Drying of Turkey Berries and Open-Sun Drying. Braz. Arch. Biol. Technol. 2024, 67, e24220397. [Google Scholar] [CrossRef]

- Liu, E.H.; Liu, Y.; Fan, Z.Y.; Wang, X.L.; Li, S.; Fang, B.J. Experimental study on storage effect of heat pump fluidized bed intermittent drying of wheat. Grain Oil Food Sci. Technol. 2016, 24, 101–103+110. [Google Scholar]

- Han, W.L.; Yan, J.H.; Wu, F.J.; Liu, Y.; Li, S.Q.; Li, S.M.; Gao, L. Effect of combined heat pump-low temperature regeneration rotor dehumidification on drying characteristics of white radish slices. Food Ferment. Ind. 2024, 50, 256–264. [Google Scholar]

- Wu, F.J.; Gao, L.; Yan, J.H.; Liu, Y.; Han, W.N.; Zhou, D.D.; Li, S.M.; Li, S.Q. Drying characterization of carrot slices by combined heat pump-rotor dehumidification. Food Sci. Technol. 2024, 49, 65–73. [Google Scholar]

- Sun, Z.; Wang, Q.; Yuan, Y.; Wang, D.; Zhou, Q.; Xu, C.; Meng, K.; Peng, H.; Yan, L.; Jin, R.; et al. Experimental analysis of a CO2 closed heat pump drying system combined with rotary dehumidification for drying banana slices drying. Int. J. Refrig. 2024, 160, 76–87. [Google Scholar] [CrossRef]

- Sun, Z.H. Research on the Application of Dehumidification Drying Technology in Fruit and Vegetable Drying; Northwest Agriculture and Forestry University: Xianyang, China, 2016; Volume 24. [Google Scholar]

- Song, J.; Zhang, H.Y.; Zeng, C.Z.; Yuan, J.; Mu, Y.W.; Kang, S.J.; Wen, P.C. Effect of drying method on quality characteristics and flavor of dried apple. Food Ind. Sci. Technol. 2024, 45, 221–231. [Google Scholar]

- Zheng, L.J. Experimental Study on Vacuum Freeze-Drying and Heat Pump-Microwave Combined Drying Process; Guangdong Ocean University: Zhanjiang, China, 2010; Volume 6. [Google Scholar]

- Cheng, H.; Ji, C.Y.; Zhang, B.; Jiang, S.J. Optimization of combined heat pump-vacuum drying process for shiitake mushrooms. J. South China Agric. Univ. 2019, 40, 125–132. [Google Scholar]

- Wang, L.Y.; Li, C.H.; Liu, M.Z.; Li, K.; Ye, X.R.; Wang, Z.W.; Fan, L.Z.; Wang, R.K.; Zhao, H.Y.; Kan, Z.; et al. Current status of research on drying technology and equipment for Chinese herbal medicines. J. Agric. Eng. 2024, 40, 1–28. [Google Scholar]

- Meng, Z.; Ding, C.; Liu, Y.; Zhang, Z.; Zhang, W.; Xu, P.; Zhang, Z.; Huo, Z. Analysis of the interaction between airflow and high-voltage electric fields on drying characteristics of carrots using heat pump-electrohydrodynamics combined drying. Case Stud. Therm. Eng. 2024, 63, 105241. [Google Scholar] [CrossRef]

- Wang, Y.M.; Liu, Y.; Meng, Z.F.; Du, C.Y.; Hu, R.S.; Cui, X.N.; Wang, H. Characterization and kinetics of high-voltage electric field-heat pump combined drying of banana chips. Food Ind. Sci. Technol. 2022, 43, 261–270. [Google Scholar]

- Gao, X.; Liu, R.; Wu, L.; Gong, X.; Li, L.; Wang, T. Moisture migration pattern and quality changes during far-infrared-assisted heat pump drying of Agaricus bisporus based on LF-NMR. J. Chin. Inst. Food Sci. Technol. 2024, 24, 403–413. [Google Scholar]

- Bai, H.; Liu, R.; Niu, B.; Gao, X.; Wu, L.; Wang, T. Effects of far-infrared combined heat pump drying on the quality and antioxidant activity of millet pepper. Food Ferment. Ind. 2025, 51, 1–12. [Google Scholar]

- Yang, F.; Qing, S.T.; Wang, C.X.; Xu, J.; Yue, J. Application of far-infrared assisted heat pump drying technology in food processing. Food Sci. Technol. 2021, 46, 75–80. [Google Scholar]

- Wu, K.; Liu, R.; Fang, X. Heat pump combined with far-infrared backward drying of wild rice and its rehydration characteristics. Zhejiang J. Agric. 2025, 37, 909–919. [Google Scholar]

- Wang, Y. Research on the Drying Characteristics of Squid Slices with Far-Infrared-Assisted Heat Pump and Its Quality Change; Shanghai Jiaotong University: Shanghai, China, 2014; Volume 8. [Google Scholar]

- Yao, L.; Fan, L.; Duan, Z. Effect of different pretreatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and microstructure of mango slices. Food Chem. 2020, 305, 125477. [Google Scholar] [CrossRef] [PubMed]

- Li, C.X. Research on the Parameters of Combined Drying Process of Anise with Microwave Heat Pump; Yunnan Agricultural University: Kunming, China, 2023; Volume 28. [Google Scholar]

- You, X.M.; Li, Y.Z.; Mo, G.B.; Hong, Y.; Zeng, D. Application of heat pump, microwave and solar drying technologies in food processing/Guangdong Food Society. In Proceedings of the Sixth General Meeting and Symposium of Guangdong Food Society, Guangzhou, China, 30 March 2012; pp. 159–162. [Google Scholar]

- Zhou, L.C. Application practice of microwave, far-infrared and heat pump technology integration in new dehydration and drying process of agricultural products. Agric. Equip. Technol. 2009, 35, 20–21. [Google Scholar]

- Chien, H.; Adam, F.; Chung, L.; Wojdylo, A. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food Bioprocess Technol. 2014, 7, 975–989. [Google Scholar]

- Zhang, B.G.; Zhao, Z.X.; Huo, G.Q.; Yi, S.L. Solar heating system for wood drying. For. Ind. 1998, 02, 29–32. [Google Scholar]

- Gu, X.H.; Peng, Q.X. Current research status of combined heating with solar collectors and air source heat pumps. J. Dalian Univ. 2020, 41, 24–27. [Google Scholar]

- Zhang, B.Y.; Xuan, C.Z.; Qian, S.Z.; Gao, X.Y.; Hong, B.D. Progress of solar-heat pump drying technology and its application to straw materials. J. Inn. Mong. Agric. Univ. (Nat. Sci. Ed.) 2024, 45, 89–100. [Google Scholar]

- Ou, Y.H. Joint application of solar energy + heat pump hot water system in large hotel project. In Proceedings of the 16th Conference on Building Water Supply and Drainage (2024), Hangzhou, China, 24 October 2024; China Architectural Design and Research Institute Co. Ltd.: Shanghai, China; Building Water Supply and Drainage Research Branch of Architectural Society of China: Beijing, China; Shanghai Panda Machinery (Group) Co. Ltd.: Shanghai, China; Beijing Dake Culture Exhibition Service Co.: Beijing, China; Zhejiang University Architectural Design and Research Institute Co.: Hangzhou, China, 2024; pp. 362–366. [Google Scholar]

- Liu, J.; Chen, A.J.; Zhang, J. Performance study and heating test of new solar air collector. Sci. Technol. Eng. 2022, 22, 9623–9629. [Google Scholar]

- Qin, B.; Lu, H.X.; Chen, S.J.; Chen, T.W.; Wu, C.J. Effect of different drying methods on quality characteristics of purple potato. Packag. Food Mach. 2014, 32, 6–10. [Google Scholar]

- Shen, W.Q.; Liu, X.L.; Tian, X.; Xiamuxi, R. Experimental study on drying walnuts with solar heat pump combined drying equipment for fruits and vegetables. Chin. Agric. Mech. 2012, 107–108, 116. [Google Scholar]

- Mortezapour, H.; Ghobadian, B.; Minaei, S.; Minaei, S.; Khoshtaghaza, M.H. Saffron drying with a heat pump-assisted hybrid photovoltaic-thermal solar dryer. Dry. Technol. 2012, 30, 560–566. [Google Scholar] [CrossRef]

- Rulazi, E.L.; Marwa, J.; Kichonge, B.; Kivevele, T.T. Techno-economic analysis of a solar-assisted heat pump dryer for drying agricultural products. Energy 2024, 12, 952–970. [Google Scholar] [CrossRef] [PubMed]

- Cárcel, J.; García-Pérez, J.; Riera, E. Mechanisms and applications of ultrasound-assisted drying. Dry. Technol. 2021, 39, 621–634. [Google Scholar]

- Cárcel, J.; García-Pérez, J.; Riera, E. Enhancement of the drying process by ultrasonics. Ultrasonochemistry 2019, 38, 503–516. [Google Scholar]

- Zhang, Y.X.; Liu, J.; Wu, X.T.; Zhao, Y.; Shi, Q.L. Research progress on drying technology of edible fungi. Chin. J. Fruit Veg. 2022, 42, 24–33. [Google Scholar]

- Xue, Y.; Zhang, L.; Wang, T.; Li, X. Research on the combined drying technology of fruits and vegetables by direct contact ultrasound and heat pump. J. Food Eng. 2023, 337, 111234. [Google Scholar]

- Schössler, K.; Jäger, H.; Knorr, D. Ultrasound penetration depth studies in food matrices. Innov. Food Sci. Emerg. Technol. 2012, 15, 49–54. [Google Scholar]

- Kowalski, S.; Pawłowski, A. Intensification of apple drying due to ultrasound enhancement. J. Food Eng. 2015, 156, 1–9. [Google Scholar] [CrossRef]

- Rojas, M.; Augusto, P. Optimization strategies for ultrasound-assisted drying. Trends Food Sci. Technol. 2021, 110, 304–316. [Google Scholar]

- Xue, Y.; Liu, E.C.; Geng, M.Y. Study on quality characteristics of ultrasonic enhanced heat pump drying of Iron rod yam. Food Ferment. Ind. 2023, 49, 234–242. (In Chinese) [Google Scholar]

- Wang, X.Q.; Han, M.; Peng, C.N.; Xie, A.G.; Fan, X.Y.; Liu, Y.H. Moisture distribution change and quality characteristics of ultrasound enhanced heat pump drying on carrot. Int. J. Food Eng. 2024, 20, 583–600. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, Y.; Wang, J. Synergistic effect of ultrasound and heat pump drying on product quality. Food Bioprocess. Technol. 2022, 15, 589–602. [Google Scholar]

- Xue, Y.; Zhang, W.; Li, Q. Application of ultrasound-enhanced heat pump drying (CU-HPD) technology in fruit and vegetable processing. Food Sci. 2022, 43, 1–8. [Google Scholar]

- Chen, Y.F. Automatic drying equipment of fruit and vegetable products and application analysis of adaptive technology. Equip. Manuf. Technol. 2022, 12, 84–86+126. [Google Scholar]

- Liu, J.; Zhao, Y.; Shi, Q.L. Correlation of viscoelastic properties with water status of scallop adductors during heat pump drying: Effects of ultrasound pretreatment and drying conditions. Food Bioprocess Technol. 2024, 17, 5097–5118. [Google Scholar] [CrossRef]

- Li, X.; Ding, Y.; Jiao, J.; Gong, X.; Li, L.; Wang, T. Research progress of ultrasound-assisted heat pump drying technology for agricultural products. Packag. Eng. 2024, 45, 53–61. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Ji, X.; Yang, H.; Cao, X.; Wang, W.; Liang, M.; Li, J.; Zhang, Q.; Yang, X.; Geng, Z. Heat Pump Technology in the Field of Fruit and Vegetable Drying: A Review. Foods 2025, 14, 2569. https://doi.org/10.3390/foods14152569

Zhu L, Ji X, Yang H, Cao X, Wang W, Liang M, Li J, Zhang Q, Yang X, Geng Z. Heat Pump Technology in the Field of Fruit and Vegetable Drying: A Review. Foods. 2025; 14(15):2569. https://doi.org/10.3390/foods14152569

Chicago/Turabian StyleZhu, Lichun, Xinyu Ji, Hao Yang, Xinze Cao, Wenchao Wang, Mengke Liang, Jiapin Li, Qian Zhang, Xuhai Yang, and Zhihua Geng. 2025. "Heat Pump Technology in the Field of Fruit and Vegetable Drying: A Review" Foods 14, no. 15: 2569. https://doi.org/10.3390/foods14152569

APA StyleZhu, L., Ji, X., Yang, H., Cao, X., Wang, W., Liang, M., Li, J., Zhang, Q., Yang, X., & Geng, Z. (2025). Heat Pump Technology in the Field of Fruit and Vegetable Drying: A Review. Foods, 14(15), 2569. https://doi.org/10.3390/foods14152569