Optimization of Cassava Starch/Onion Peel Powder-Based Bioplastics: Influence of Composition on Mechanical Properties and Biodegradability Using Central Composite Design

Abstract

1. Introduction

2. Materials and Methods

2.1. Standards and Materials

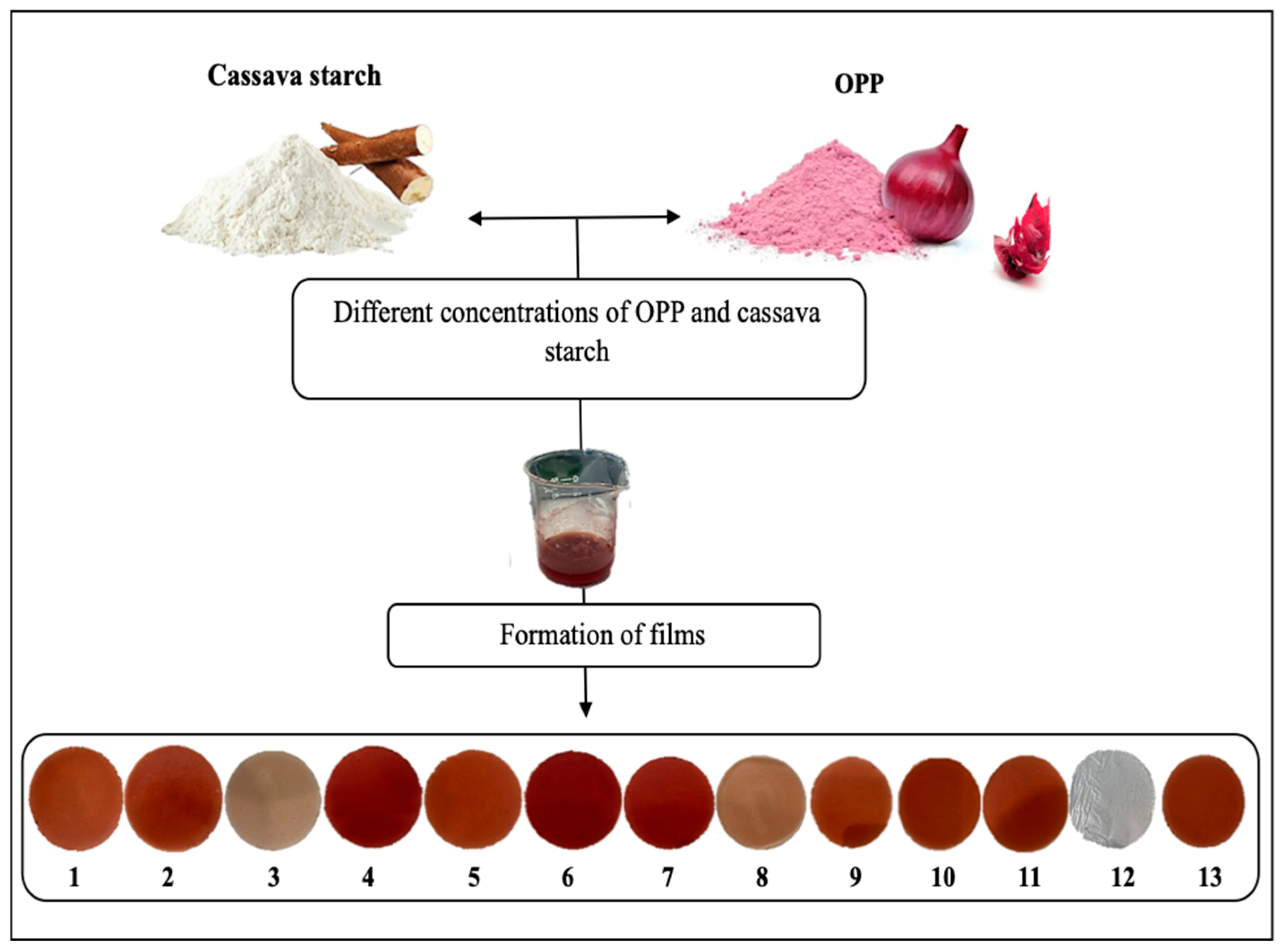

2.2. OPP Preparation

2.3. OPP Extraction

2.4. Quantitative Analysis by UHPLC-UV

2.5. Starch–OPP Film Preparation

2.6. Experimental Design

2.7. Mechanical Test

2.8. Biodegradability Test

2.9. Statistical Analysis

3. Results

3.1. Identification and Quantification of Phenolic Compounds by UHPLC-UV

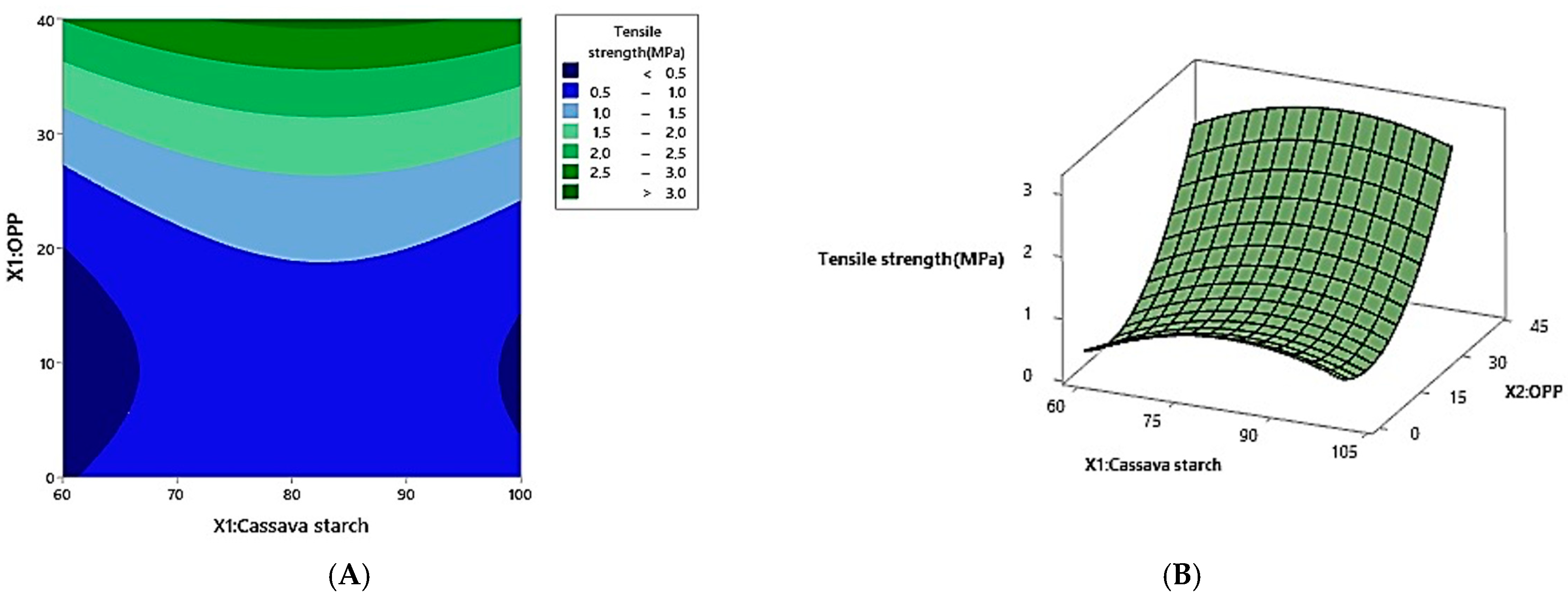

3.2. Effect of Cassava Starch and Onion Peel Powder on Tensile Strength of Film

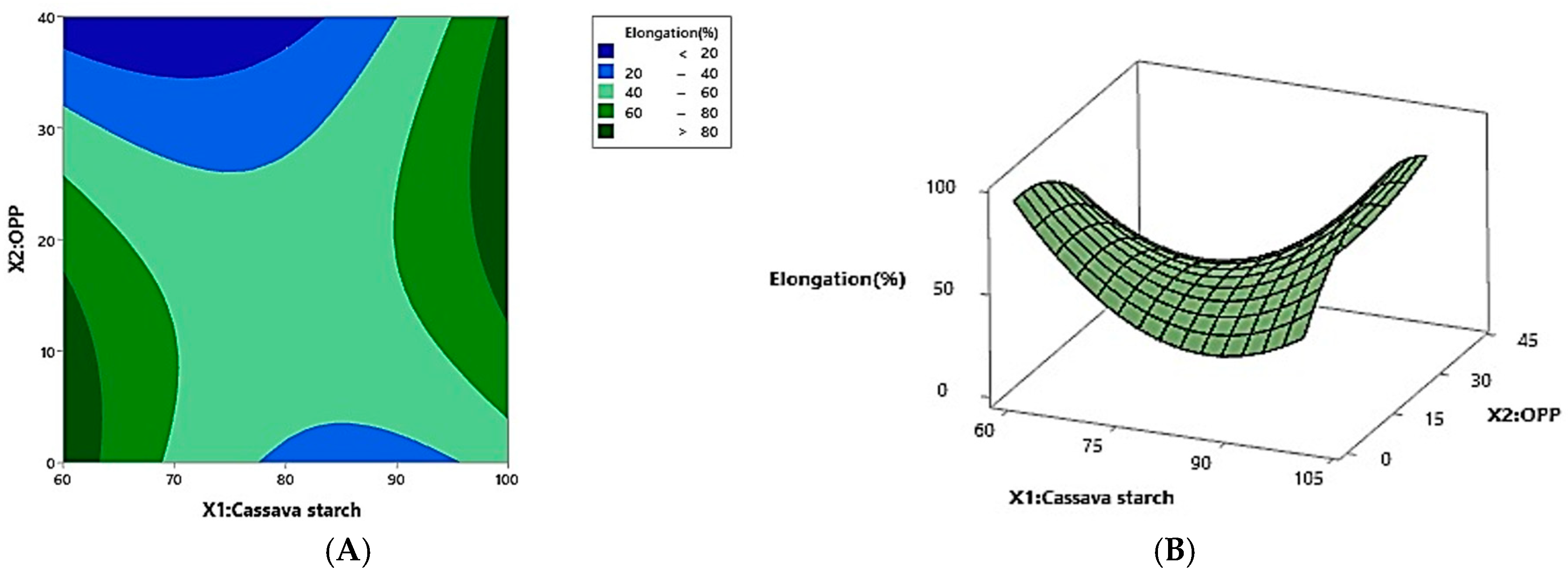

3.3. Effect of Cassava Starch and Onion Peel Powder on Elongation of Film

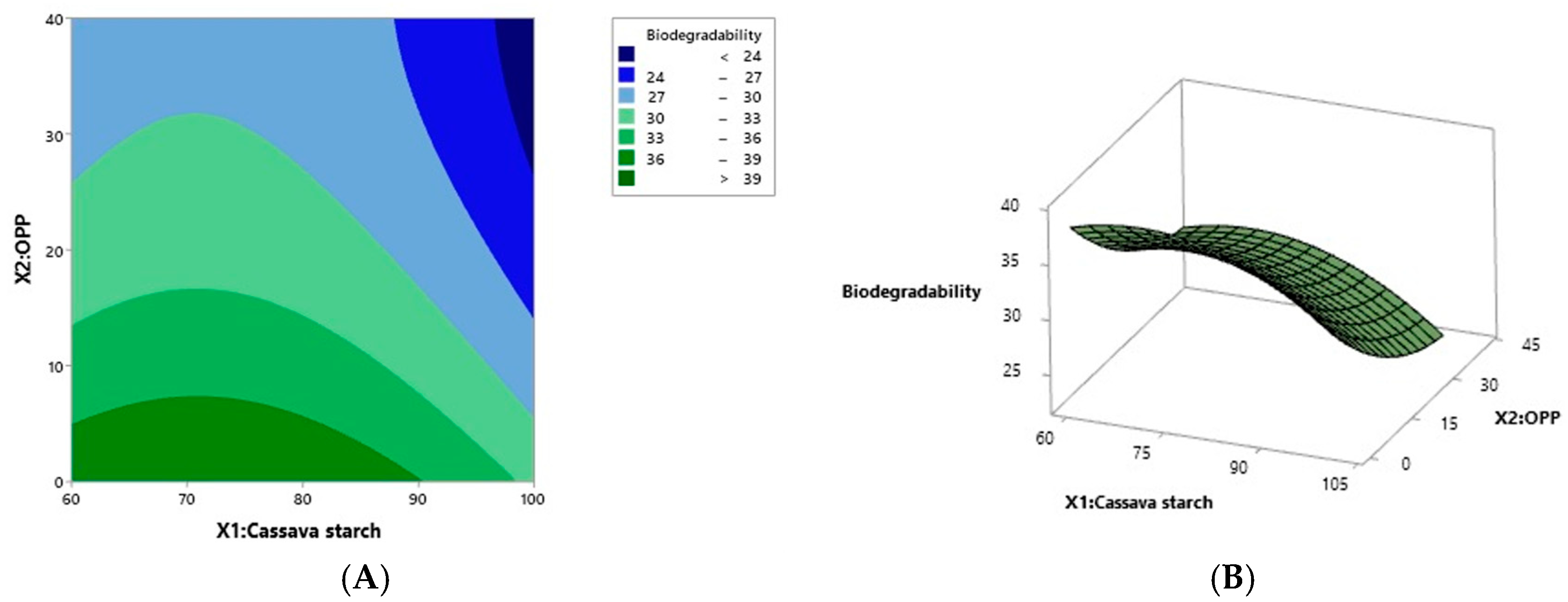

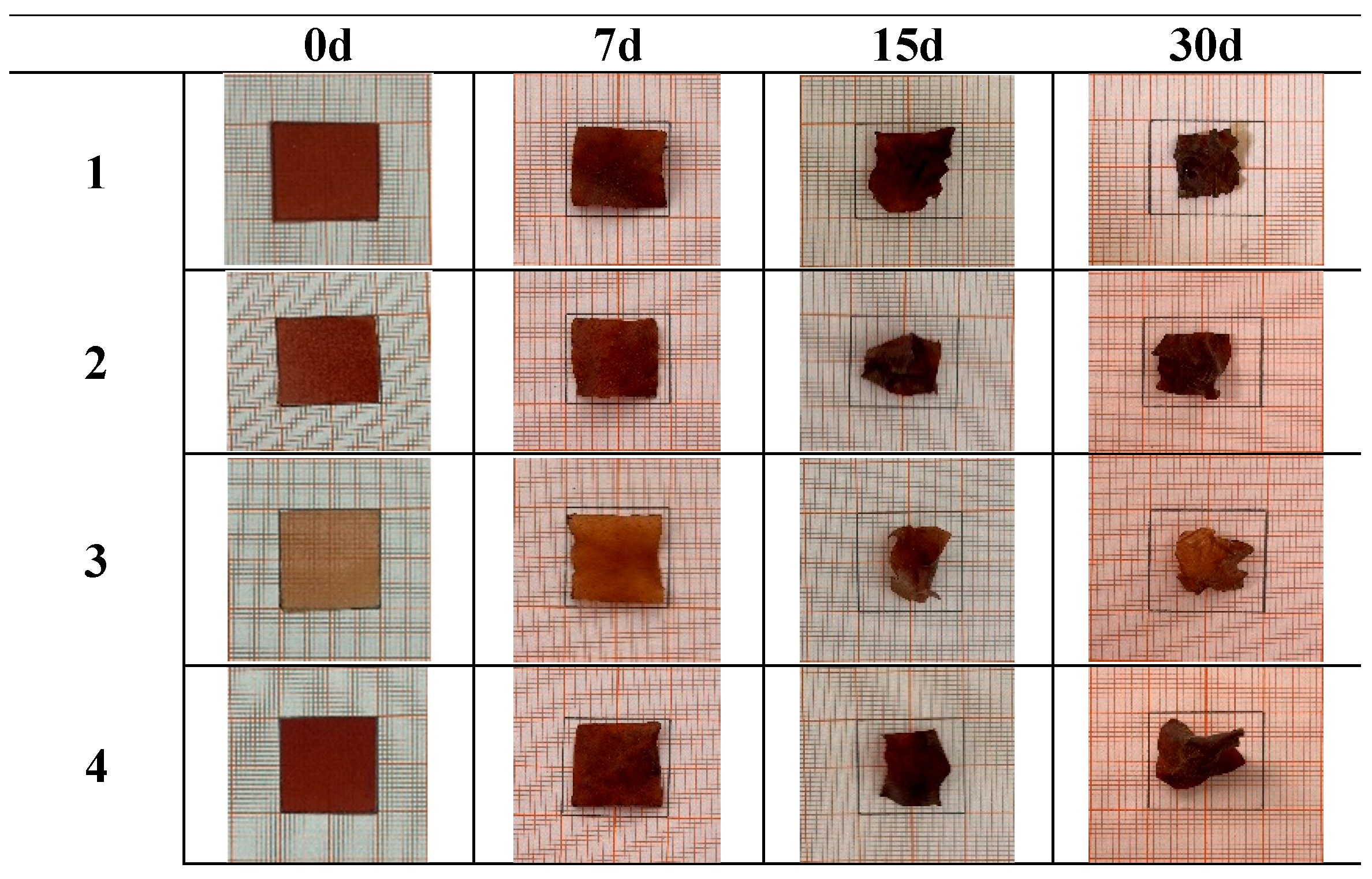

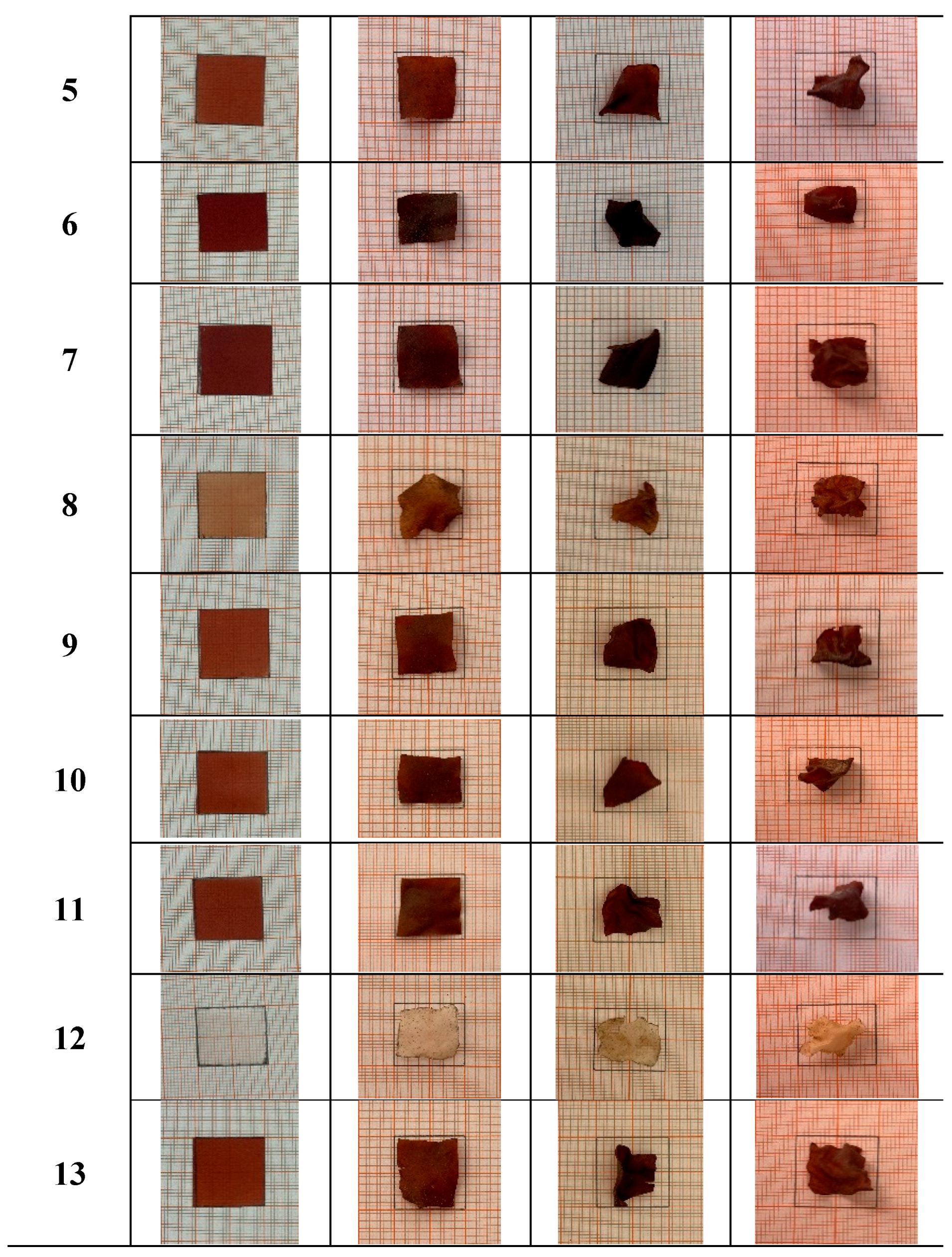

3.4. Effect of Cassava Starch and Onion Peel Powder on the Biodegradability of Film

3.5. Optimization and Model Validation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Drishya, P.K.; Reddy, M.V.; Mohanakrishna, G.; Sarkar, O.; Isha; Rohit, M.V.; Patel, A.; Chang, Y.-C. Advances in Microbial and Plant-Based Biopolymers: Synthesis and Applications in Next-Generation Materials. Macromol 2025, 5, 21. [Google Scholar]

- Barkoula, N.M.; Alcock, B.; Cabrera, N.O.; Peijs, T. Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene. Polym. Polym. Compos. 2008, 16, 101–113. [Google Scholar]

- Heydari, A.; Alemzadeh, I.; Vossoughi, M. Functional properties of biodegradable corn starch nanocomposites for food packaging applications. Mater Des. 2013, 50, 954–961. [Google Scholar]

- Celano, R.; Docimo, T.; Piccinelli, A.L.; Gazzerro, P.; Tucci, M.; Di Sanzo, R.; Carabetta, S.; Campone, L.; Russo, M.; Rastrelli, L. Onion Peel: Turning a Food Waste into a Resource. Antioxidants 2021, 10, 304. [Google Scholar] [CrossRef]

- Manohar, M.; Joseph, J.; Selvaraj, T.; Sivakumar, D. Application of desirability-function and RSM to optimise the multi-objectives while turning Inconel 718 using coated carbide tools. Int. J. Manuf. Technol. Manag. 2013, 27, 218–237. [Google Scholar]

- Filho, J.G.d.O.; Bertolo, M.R.V.; Rodrigues, M.Á.V.; Silva, G.d.C.; de Mendonça, G.M.N.; Junior, S.B.; Ferreira, M.D.; Egea, M.B. Recent advances in the development of smart, active, and bioactive biodegradable biopolymer-based films containing betalains. Food Chem. 2022, 390, 133149. [Google Scholar]

- Ibrahim, H.M.; Yusoff, W.M.W.; Hamid, A.A.; Illias, R.M.; Hassan, O.; Omar, O. Optimization of medium for the production of β-cyclodextrin glucanotransferase using Central Composite Design (CCD). Process Biochem. 2005, 40, 753–758. [Google Scholar]

- Santos, L.G.; Silva, G.F.A.; Gomes, B.M.; Martins, V.G. A novel sodium alginate active films functionalized with purple onion peel extract (Allium cepa). Biocatal Agric. Biotechnol. 2021, 35, 102096. [Google Scholar]

- Afshar, S.; Baniasadi, H. Investigation the effect of graphene oxide and gelatin/starch weight ratio on the properties of starch/gelatin/GO nanocomposite films: The RSM study. Int. J. Biol. Macromol. 2018, 109, 1019–1028. [Google Scholar]

- Kechichian, V.; Ditchfield, C.; Veiga-Santos, P.; Tadini, C.C. Natural antimicrobial ingredients incorporated in biodegradable films based on cassava starch. LWT 2010, 43, 1088–1094. [Google Scholar]

- dos Santos Caetano, K.; Lopes, N.A.; Costa, T.M.H.; Brandelli, A.; Rodrigues, E.; Flôres, S.H.; Cladera-Olivera, F. Characterization of active biodegradable films based on cassava starch and natural compounds. Food Packag. Shelf Life 2018, 16, 138–147. [Google Scholar]

- Pirsa, S.; Bener, M.; Şen, F.B. Biodegradable film of carboxymethyl cellulose modified with red onion peel powder waste and boron nitride nanoparticles: Investigation of physicochemical properties and release of active substances. Food Chem. 2024, 445, 138721. [Google Scholar] [PubMed]

- Wang, C.; Wang, Y.; Wang, N.; Ren, J. Influence of Onion Peel Extract on the Dough Characteristics of High-Gluten Wheat Flour and the Quality of Bread. Foods 2025, 14, 1618. [Google Scholar] [CrossRef]

- Pirsa, S.; Mohtarami, F. Biodegradable film based on barley sprout powder/pectin modified with quercetin and V2O5 nanoparticles: Investigation of physicochemical and structural properties. Heliyon 2024, 3, e25448. [Google Scholar]

- Karmakar, B.; Sarkar, S.; Chakraborty, R.; Saha, S.P.; Thirugnanam, A.; Roy, P.K.; Roy, S. Starch-based biodegradable films amended with nano-starch and tannic acid-coated nano-starch exhibit enhanced mechanical and functional attributes with antimicrobial activity. Carbohydr. Polym. 2024, 341, 122321. [Google Scholar] [PubMed]

- Alqahtani, N.; Alnemr, T.; Ali, S. Development of low-cost biodegradable films from corn starch and date palm pits (Phoenix dactylifera). Food Biosci. 2021, 42, 101199. [Google Scholar]

- Ayyubi, S.N.; Purbasari, A. The effect of composition on mechanical properties of biodegradable plastic based on chitosan/cassava starch/PVA/crude glycerol: Optimization of the composition using Box Behnken Design. Mater. Today Proc. 2022, 63, S78–S83. [Google Scholar]

- Adilah, A.N.; Jamilah, B.; Noranizan, M.A.; Hanani, Z.N. Utilization of mango peel extracts on the biodegradable films for active packaging. Food Packag. Shelf Life 2018, 16, 1–7. [Google Scholar]

- Piñeros-Hernandez, D.; Medina-Jaramillo, C.; López-Córdoba, A.; Goyanes, S. Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll. 2017, 63, 488–495. [Google Scholar]

- Črnivec, I.G.O.; Skrt, M.; Šeremet, D.; Sterniša, M.; Farčnik, D.; Štrumbelj, E.; Poljanšek, A.; Cebin, N.; Pogačnik, L.; Možina, S.S.; et al. Waste streams in onion production: Bioactive compounds, quercetin and use of antimicrobial and antioxidative properties. Waste Manag. 2021, 126, 476–486. [Google Scholar]

- Martelli, M.R.; Barros, T.T.; de Moura, M.R.; Mattoso, L.H.; Assis, O.B. Effect of chitosan nanoparticles and pectin content on mechanical properties and water vapor permeability of banana puree films. J. Food Sci. 2013, 78, N98–N104. [Google Scholar] [PubMed]

- Romero-Bastida, C.A.; Flores-Huicochea, E.; Martin-Polo, M.O.; Velazquez, G.; Torres, J.A. Compositional and moisture content effects on the biodegradability of zein/ethylcellulose films. J. Agric. Food Chem. 2004, 52, 2230–2235. [Google Scholar] [PubMed]

- Datta, R. Enzymatic degradation of cellulose in soil: A review. Heliyon 2024, 10, e24022. [Google Scholar]

- Rodriguez, O.T.; Valero, M.F.; Gómez-Tejedor, J.A.; Diaz, L. Performance of Biodegradable Active Packaging in the Preservation of Fresh-Cut Fruits: A Systematic Review. Polymers 2024, 16, 3518. [Google Scholar] [CrossRef]

- Bayram, B.; Ozkan, G.; Kostka, T.; Capanoglu, E.; Esatbeyoglu, T. Valorization and application of fruit and vegetable wastes and by-products for food packaging materials. Molecules 2021, 26, 4031. [Google Scholar] [CrossRef] [PubMed]

- Akachat, B.; Himed, L.; Merniz, S.; D’Elia, M.; Rastrelli, L.; Barkat, M. Development of Pectin-Based Films with Encapsulated Lemon Essential Oil for Active Food Packaging: Improved Antioxidant Activity and Biodegradation. Foods 2025, 14, 353. [Google Scholar] [CrossRef]

- Djerri, R.; Merniz, S.; D’elia, M.; Aissani, N.; Khemili, A.; Mustapha, M.A.; Rastrelli, L.; Himed, L. Ultrasound-Enhanced Ionotropic Gelation of Pectin for Lemon Essential Oil Encapsulation: Morphological Characterization and Application in Fresh-Cut Apple Preservation. Foods 2025, 14, 1968. [Google Scholar]

- Akachat, B.; Himed, L.; Salah, M.; D’eLia, M.; Zomorroda, S.; Ali, R.; Rastrelli, L.; Barkat, M. Optimization of Pectin Extraction from Lemon Peels Using Hydrochloric Acid and Response Surface Methodology. Appl. Food Res. 2025, 5, 100948. [Google Scholar]

- Joković, N.; Matejić, J.; Zvezdanović, J.; Stojanović-Radić, Z.; Stanković, N.; Mihajilov-Krstev, T.; Bernstein, N. Onion peel as a potential source of antioxidants and antimicrobial agents. Agronomy 2024, 14, 453. [Google Scholar] [CrossRef]

- Ali, A.; Basit, A.; Hussain, A.; Sammi, S.; Wali, A.; Goksen, G.; Muhammad, A.; Faiz, F.; Trif, M.; Rusu, A.; et al. Starch-based environment friendly, edible and antimicrobial films reinforced with medicinal plants. Front. Nutr. 2023, 9, 1066337. [Google Scholar]

- Gomes, Á.V.R.; Leite, R.H.D.L.; Silva, M.Q.D.; Santos, F.K.G.D.; Aroucha, E.M.M. Influence of composition on mechanical properties of cassava starch, sisal fiber and carnauba wax biocomposites. Mater. Res. 2019, 22, e20180887. [Google Scholar]

- Tafa, K.D.; Satheesh, N.; Abera, W. Mechanical properties of tef starch based edible films: Development and process optimization. Heliyon 2023, 9, e13160. [Google Scholar] [PubMed]

- Gavande, V.; Jeong, M.; Lee, W.K. On the Mechanical, Thermal, and Rheological Properties of Polyethylene/Ultra-High Molecular Weight Polypropylene Blends. Polymers 2023, 15, 4236. [Google Scholar] [PubMed]

| Run | Coded Value X1 (Cassava Starch) | Coded Value X2 (OPP) | Uncoded X1 (%) | Uncoded X2 (%) |

|---|---|---|---|---|

| 1 | 0.000 | 0.000 | 80.000 | 20.000 |

| 2 | −1.414 | 0.000 | 60.000 | 20.000 |

| 3 | 1.000 | −1.000 | 94.142 | 5.858 |

| 4 | 1.000 | 1.000 | 94.142 | 34.142 |

| 5 | 0.000 | 0.000 | 80.000 | 20.000 |

| 6 | 0.000 | 1.414 | 80.000 | 40.000 |

| 7 | −1.000 | 1.000 | 65.858 | 34.142 |

| 8 | −1.000 | −1.000 | 65.858 | 5.858 |

| 9 | 0.000 | 0.000 | 80.000 | 20.000 |

| 10 | 1.414 | 0.000 | 100.000 | 20.000 |

| 11 | 0.000 | 0.000 | 80.000 | 20.000 |

| 12 | 0.000 | −1.414 | 80.000 | 0.000 |

| 13 | 0.000 | 0.000 | 80.000 | 20.000 |

| N° | Compound Name | R(t) (min) | RDS (%) | mg/100 g DM ± RDS |

|---|---|---|---|---|

| 1 | Protocatechuic acid | 1.2 | 1.8 | 135.8 ± 6 |

| 2 | 2-(3,4-Dihydroxybenzoyl)-2,4,6-trihydroxy-3(2H)-benzofuranone | 6.0 | 3.9 | 116.5 ± 4 |

| 3 | Quercetin-7,4′-diglycoside | 6.5 | 7.0 | 63.5 ± 8 |

| 4 | Quercetin-3,4′-diglycoside | 6.9 | 5.5 | 74.3 ± 12 |

| 5 | Quercetin-4′-glycoside | 10.3 | 6.4 | 351.3 ± 8 |

| 6 | Isorhamnetin-4′-glycoside | 12.5 | 6.6 | nq |

| 7 | Quercetin | 13.5 | 7.6 | 510.4 ± 12 |

| 8 | Kaempferol | 16.4 | 2.0 | nq |

| 9 | Isorhamnetin | 16.7 | 2.6 | nq |

| 10 | Quercetin dimer 4′-glycoside | 17.1 | 1.9 | 44.1 ± 4 |

| 11 | Quercetin dimer 4′-glycoside | 18.2 | 0.8 | 43.3 ± 6 |

| 12 | Quercetin dimer hexoside | 18.5 | 2.5 | nq |

| 13 | Quercetin dimer | 19.4 | 0.8 | 110.3 ± 2 |

| 14 | Quercetin trimer | 20.7 | 2.4 | 62.8 ± 6 |

| Run | Cassava Starch (%) | Onion Peel Powder (%) | Tensile Strength (Mpa) | Elongation (%) | Biodegradability (%) |

|---|---|---|---|---|---|

| 1 | 80.000 | 20.000 | 1.07 ± 0.017 e f | 47.63 ± 0.010 g | 30.83 ± 0.051 e f |

| 2 | 60.000 | 20.000 | 0.75 ± 0.005 i | 60.37 ± 0.015 d | 30.04 ± 0.040 f |

| 3 | 94.142 | 5.858 | 0.58 ± 0.010 j | 47.24 ± 0.045 h | 32.08 ± 0.060 c |

| 4 | 94.142 | 34.142 | 1.52 ± 0.011 b | 14.09 ± 0.030 l | 26.00 ± 0.50 h |

| 5 | 80.000 | 20.000 | 0.97 ± 0.015 g | 24.11 ± 0.051 k | 31.43 ± 0.030 c d e |

| 6 | 80.000 | 40.000 | 3.87 ± 0.011 a | 73.46 ± 0.060 b | 27.43 ± 0.015 g |

| 7 | 65.858 | 34.142 | 1.41 ± 0.020 c | 47.68 ± 0.026 g | 31.00 ± 1.15 d e f |

| 8 | 65.858 | 5.858 | 0.52 ± 0.015 k | 97.06 ± 0.065 a | 36.96 ± 0.015 b |

| 9 | 80.000 | 20.000 | 1.08 ± 0.010 d e | 52.85 ± 0.025 e | 30.69 ± 0.035 e f |

| 10 | 100.000 | 20.000 | 1.11 ± 0.015 d | 38.15 ± 0.035 j | 25.21 ± 0.020 h |

| 11 | 80.000 | 20.000 | 1.11 ± 0.015 d | 43.73 ± 0.015 i | 32.04 ± 0.037 c d |

| 12 | 80.000 | 0.000 | 0.88 ± 0.015 h | 47.63 ± 0.010 g | 38.38 ± 0.170 a |

| 13 | 80.000 | 20.000 | 1.03 ± 0.005 f | 60.37 ± 0.015 d | 32.20 ± 0.10 c |

| Response | Equation | R2 | |

|---|---|---|---|

| Y1: Tensile Strength (Mpa) | Y1 = −6.56 + 0.184 X1 – 0.051 X2 + 0.002494 X22 | Equation (3) | 0.8153 |

| Y2: Elongation (%) | Y2 = 681.3 – 14.97 X1 – 4.44 X2 + 0.08638 X12 – 0.05974 X22 + 0.0776 X1X2 | Equation (4) | 0.9723 |

| Y3: Biodegradability (%) | Y3 = −1.1 + 1.132 X1 – 0.440 X2 – 0.00798 X12 + 0.00522 X22 | Equation (5) | 0.9542 |

| Variables | Tensile Strength (Mpa) | Elongation (%) | Biodegradability (%) |

|---|---|---|---|

| Coefficient | 1.055 | 48.04 | 31.439 |

| p-value | 0.002 | 0.000 | 0.000 |

| X1 (Cassava Starch) | 0.085 | 5.72 | −2.089 |

| p-value | 0.629 | 0.010 | 0.001 |

| X2 (Onion Peel Powder) | 0.757 | −8.83 | −3.440 |

| p-value | 0.003 | 0.001 | 0.000 |

| X12 (Cassava Starch2) | −0.224 | 17.28 | −1.596 |

| p-value | 0.254 | 0.000 | 0.005 |

| X22 (Onion Peel Powder2) | 0.499 | −11.95 | 1.045 |

| p-value | 0.028 | 0.000 | 0.033 |

| X1X2 (Interaction) | 0.012 | 15.52 | −0.030 |

| p-value | 0.959 | 0.000 | 0.956 |

| Formula | Cassava Starch (%) | Onion Peel Powder (%) | Tensile Strength (MPa) | Elongation (%) | Biodegradability (%) | |

|---|---|---|---|---|---|---|

| 1 | Prediction | 72.066 | 21.0563 | 0.99579 | 48.8895 | 31.8590 |

| Verification | 72.066 | 21.0563 | 0.9754 ± 0.020 | 48.732 ± 0.253 | 31.835 ± 0.076 | |

| 2 | Prediction | 77.2803 | 37.6878 | 2.7547 | 14.1122 | 29.1211 |

| Verification | 77.2803 | 37.6878 | 2.713 ± 0.015 | 14.103 ± 0.015 | 29.114 ± 0.022 | |

| 3 | Prediction | 84.5616 | 27.7373 | 1.62493 | 46.0143 | 29.0246 |

| Verification | 84.5616 | 27.7373 | 1.619 ± 0.070 | 46.001 ± 0.002 | 29.018 ± 0.009 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torche, A.; Toufik, C.; Djeghim, F.; Sanah, I.; Arhab, R.; D’Elia, M.; Rastrelli, L. Optimization of Cassava Starch/Onion Peel Powder-Based Bioplastics: Influence of Composition on Mechanical Properties and Biodegradability Using Central Composite Design. Foods 2025, 14, 2414. https://doi.org/10.3390/foods14142414

Torche A, Toufik C, Djeghim F, Sanah I, Arhab R, D’Elia M, Rastrelli L. Optimization of Cassava Starch/Onion Peel Powder-Based Bioplastics: Influence of Composition on Mechanical Properties and Biodegradability Using Central Composite Design. Foods. 2025; 14(14):2414. https://doi.org/10.3390/foods14142414

Chicago/Turabian StyleTorche, Assala, Chouana Toufik, Fairouz Djeghim, Ibtissem Sanah, Rabah Arhab, Maria D’Elia, and Luca Rastrelli. 2025. "Optimization of Cassava Starch/Onion Peel Powder-Based Bioplastics: Influence of Composition on Mechanical Properties and Biodegradability Using Central Composite Design" Foods 14, no. 14: 2414. https://doi.org/10.3390/foods14142414

APA StyleTorche, A., Toufik, C., Djeghim, F., Sanah, I., Arhab, R., D’Elia, M., & Rastrelli, L. (2025). Optimization of Cassava Starch/Onion Peel Powder-Based Bioplastics: Influence of Composition on Mechanical Properties and Biodegradability Using Central Composite Design. Foods, 14(14), 2414. https://doi.org/10.3390/foods14142414