Technological Advancements of Insoluble Dietary Fiber from Food By-Product Processing: A Review

Abstract

1. Introduction

2. Definition of Insoluble Dietary Fibers (IDFs): Regulatory and Scientific Background

3. Source, Composition, and Functionalities of IDFs

4. IDFs as Rheological Modifiers in Food Systems

4.1. Stability of Food Systems Structured with IDFs

4.2. Investigation Tools in the Rheology of Food Systems Structured with IDFs

4.3. Viscosifying Ability of IDFs

4.4. Gelling Ability of IDFs

5. Processing of Food Systems Containing IDFs

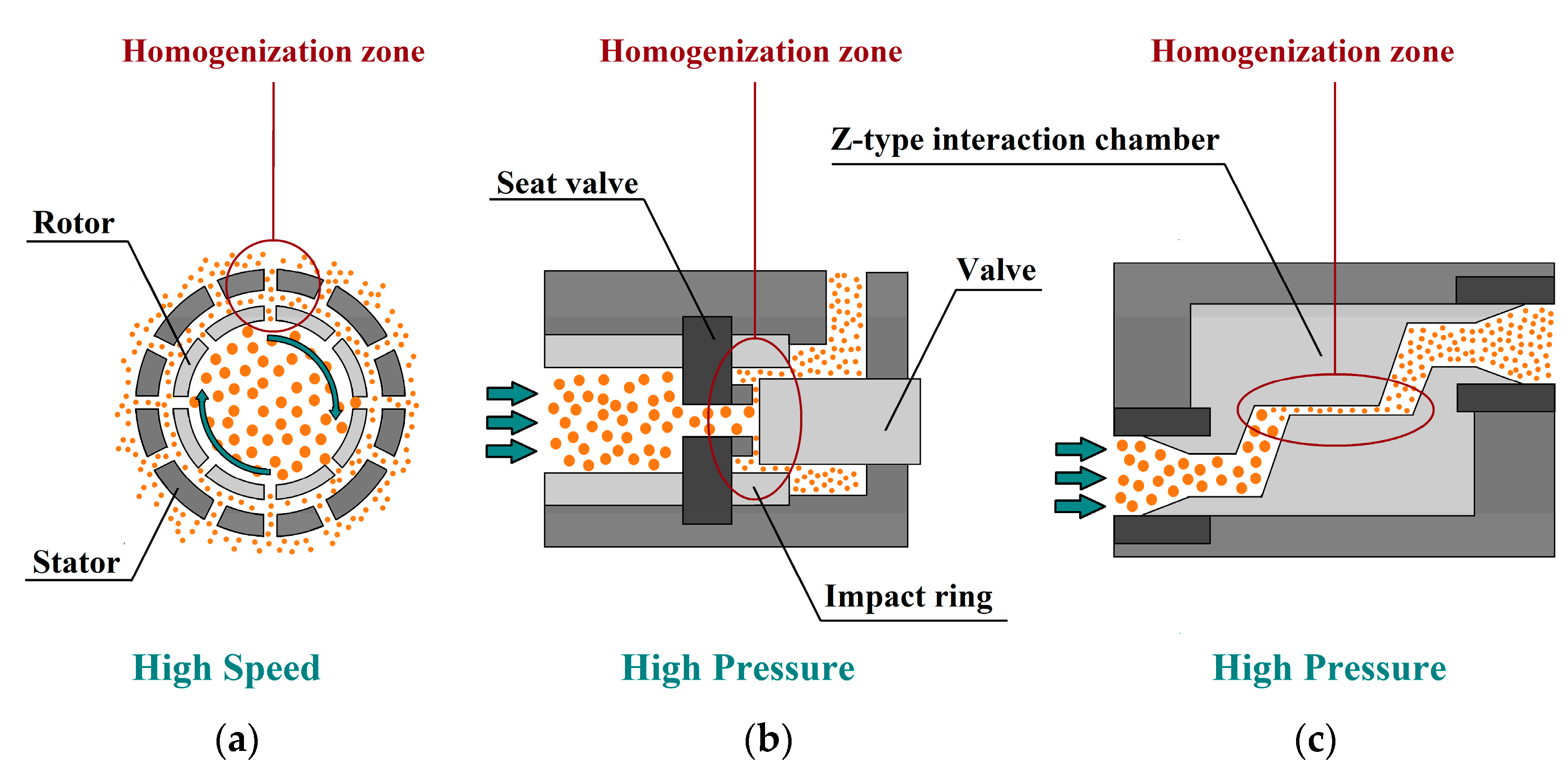

5.1. High-Speed Homogenization (HSH)

5.2. High-Pressure Homogenization (HPH)

5.3. Dynamic High-Pressure Microfluidization (DHPM)

5.4. Extrusion Cooking

5.5. Novel Processing Methods

6. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Payling, L.; Fraser, K.; Loveday, S.M.; Sims, I.; Roy, N.; McNabb, W. The Effects of Carbohydrate Structure on the Composition and Functionality of the Human Gut Microbiota. Trends Food Sci. Technol. 2020, 97, 233–248. [Google Scholar] [CrossRef]

- Quin, W.; Sun, L.; Miao, M.; Zhang, G. Plant-Sourced Intrinsic Dietary Fiber: Physical Structure and Health Function. Trends Food Sci. Technol. 2021, 118, 341–355. [Google Scholar] [CrossRef]

- He, Y.; Wang, B.; Wen, L.; Wang, F.; Yu, H.; Chen, D.; Su, X.; Zhang, C. Effects of Dietary Fiber on Human Health. Food Sci. Hum. Wellness 2022, 11, 1–10. [Google Scholar] [CrossRef]

- McCleary, B.V. Dietary Fibre Analysis. Proc. Nutr. Soc. 2003, 62, 3–9. [Google Scholar] [CrossRef]

- Fernández-Fernández, A.M.; Dellacassa, E.; Medrano-Fernandez, A.; Castillo, M.D. Citrus Waste Recovery for Sustainable Nutrition and Health. In Food Wastes and By-Products: Nutraceutical and Health Potential; Campos-Vega, R., Oomah, B.D., Vergara-Castañeda, H.A., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 193–222. [Google Scholar]

- Yang, X.; Li, A.; Li, X.; Sun, L.; Guo, Y. An Overview of Classifications, Properties of Food Polysaccharides and Their Links to Applications in Improving Food Textures. Trends Food Sci. Technol. 2020, 102, 1–15. [Google Scholar] [CrossRef]

- Pathania, S.; Kaur, N. Utilization of Fruits and Vegetable By-Products for Isolation of Dietary Fibres and Its Potential Application as Functional Ingredients. Bioact. Carbohydr. Diet. Fibre 2022, 27, 100295. [Google Scholar] [CrossRef]

- European Parliament and Council Commission Regulation (EU). No. 1129/2011 of 11 November 2011 Amending Annex II to Regulation (EC) No. 1333/2008 of the European Parliament and of the Council by Establishing a Union List of Food Additives. Off. J. Eur. Union 2011, L295, 1–177. [Google Scholar] [CrossRef]

- CFR Part 172. Food Additives Permitted for Direct Addition to Food for Human Consumption. 2024. Available online: https://www.ecfr.gov/current/title-21/chapter-I/subchapter-B/part-172 (accessed on 18 December 2024).

- Alexandri, M.; Kachrimanidou, V.; Papapostolou, H.; Papadaki, A.; Kopsahelis, N. Sustainable Food Systems: The Case of Functional Compounds towards the Development of Clean Label Food Products. Foods 2022, 11, 2796. [Google Scholar] [CrossRef]

- Cui, J.; Lian, Y.; Zhao, C.; Du, H.; Han, Y.; Gao, W.; Xiao, H.; Zheng, J. Dietary Fibers from Fruits and Vegetables and Their Health Benefits via Modulation of Gut Microbiota. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1514–1532. [Google Scholar] [CrossRef]

- O’Shea, N.; Arendt, E.K.; Gallagher, E. Dietary Fibre and Phytochemical Characteristics of Fruit and Vegetable By-Products and Their Recent Applications as Novel Ingredients in Food Products. Innov. Food Sci. Emerg. Technol. 2012, 16, 1–10. [Google Scholar] [CrossRef]

- Gan, J.; Xie, L.; Peng, G.; Xie, J.; Chen, Y.; Yu, Q. Systematic Review on Modification Methods of Dietary Fiber. Food Hydrocoll. 2021, 119, 106872. [Google Scholar] [CrossRef]

- Keskin, S.O.; Ali, T.M.; Ahmed, J.; Shaikh, M.; Siddiq, M.; Uebersax, M.A. Physico-Chemical and Functional Properties of Legume Protein, Starch, and Dietary Fiber—A Review. Legum. Sci. 2022, 4, e117. [Google Scholar] [CrossRef]

- Kaur, A.; Singh, B.; Yadav, M.P.; Bhinder, S.; Singh, N. Isolation of Arabinoxylan and Cellulose-Rich Arabinoxylan from Wheat Bran of Different Varieties and Their Functionalities. Food Hydrocoll. 2021, 112, 106287. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Liu, J.; Zheng, T.; Li, Y.; He, S.; Jiang, M.; Wu, L.; Wang, S. Extraction Methods of Dietary Fiber and Effect on Bioactivity: A Review. Process Biochem. 2024, 146, 451–461. [Google Scholar] [CrossRef]

- Zannini, E.; Núñez, Á.B.; Sahin, A.W.; Arendt, E.K. Arabinoxylans as Functional Food Ingredients: A Review. Foods 2022, 11, 1026. [Google Scholar] [CrossRef]

- Hipsley, E.H. Dietary “Fibre” and Pregnancy Toxaemia. Br. Med. J. 1953, 2, 420–422. [Google Scholar] [CrossRef]

- Lupton, J.R. Codex Definition of Dietary Fibre and Issues Requiring Resolution; Wageningen Academic: Leiden, The Netherlands, 2010; pp. 13–24. ISBN 9789086866922. [Google Scholar]

- Board of Directors of the American Association of Cereal Chemists. The Definition of Dietary Fiber; American Association of Cereal Chemists (AACC): St. Paul, MN, USA, 2001; Volume 46. [Google Scholar]

- EFSA Panel on Dietetic Products, Nutrition, and Allergies (NDA). Scientific Opinion on Dietary Reference Values for Carbohydrates and Dietary Fibre. EFSA J. 2016, 8, 1462. [Google Scholar] [CrossRef]

- Codex Alimentarius. Guidelines on Nutrition Labelling, CXG 2-1985; FAO: Rome, Italy, 2021. [Google Scholar]

- Tejada-Ortigoza, V.; Garcia-Amezquita, L.E.; Serna-Saldívar, S.O.; Welti-Chanes, J. Advances in the Functional Characterization and Extraction Processes of Dietary Fiber. Food Eng. Rev. 2016, 8, 251–271. [Google Scholar] [CrossRef]

- Figuerola, F.; Hurtado, M.L.; Estévez, A.M.; Chiffelle, I.; Asenjo, F. Fibre Concentrates from Apple Pomace and Citrus Peel as Potential Fibre Sources for Food Enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Martínez, R.; Torres, P.; Meneses, M.A.; Figueroa, J.G.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, Technological and in Vitro Antioxidant Properties of Mango, Guava, Pineapple and Passion Fruit Dietary Fibre Concentrate. Food Chem. 2012, 135, 1520–1526. [Google Scholar] [CrossRef]

- Ajila, C.M.; Prasada Rao, U.J.S. Mango Peel Dietary Fibre: Composition and Associated Bound Phenolics. J. Funct. Foods 2013, 5, 444–450. [Google Scholar] [CrossRef]

- Jiménez-Aguilar, D.M.; López-Martínez, J.M.; Hernández-Brenes, C.; Gutiérrez-Uribe, J.A.; Welti-Chanes, J. Dietary Fiber, Phytochemical Composition and Antioxidant Activity of Mexican Commercial Varieties of Cactus Pear. J. Food Compos. Anal. 2015, 41, 66–73. [Google Scholar] [CrossRef]

- Navarro-González, I.; García-Valverde, V.; García-Alonso, J.; Periago, M.J. Chemical Profile, Functional and Antioxidant Properties of Tomato Peel Fiber. Food Res. Int. 2011, 44, 1528–1535. [Google Scholar] [CrossRef]

- Yadav, M.P.; Kale, M.S.; Hicks, K.B.; Hanah, K. Isolation, Characterization and the Functional Properties of Cellulosic Arabinoxylan Fiber Isolated from Agricultural Processing by-Products, Agricultural Residues and Energy Crops. Food Hydrocoll. 2017, 63, 545–551. [Google Scholar] [CrossRef]

- Grigelmo-Miguel, N.; Martín-Belloso, O. Characterization of Dietary Fiber from Orange Juice Extraction. Food Res. Int. 1998, 31, 355–361. [Google Scholar] [CrossRef]

- de Moraes Crizel, T.; Jablonski, A.; de Oliveira Rios, A.; Rech, R.; Flôres, S.H. Dietary Fiber from Orange Byproducts as a Potential Fat Replacer. LWT 2013, 53, 9–14. [Google Scholar] [CrossRef]

- Ubando-Rivera, J.; Navarro-Ocaña, A.; Valdivia-López, M.A. Mexican Lime Peel: Comparative Study on Contents of Dietary Fibre and Associated Antioxidant Activity. Food Chem. 2005, 89, 57–61. [Google Scholar] [CrossRef]

- Vitaglione, P.; Napolitano, A.; Fogliano, V. Cereal Dietary Fibre: A Natural Functional Ingredient to Deliver Phenolic Compounds into the Gut. Trends Food Sci. Technol. 2008, 19, 451–463. [Google Scholar] [CrossRef]

- Gidley, M.J.; Yakubov, G.E. Functional Categorisation of Dietary Fibre in Foods: Beyond ‘soluble’ vs ‘Insoluble’. Trends Food Sci. Technol. 2019, 86, 563–568. [Google Scholar] [CrossRef]

- Bruno, E.; Lupi, F.R.; Martin-Piñero, M.J.; Girimonte, R.; Baldino, N.; Muñoz, J.; Gabriele, D. Influence of Different Dispersing Systems on Rheological and Microstructural Properties of Citrus Fiber Suspensions. LWT 2021, 152, 112270. [Google Scholar] [CrossRef]

- Wang, H.; Wang, P.; Kasapis, S.; Truong, T. Pomelo (Citrus grandis L.) Peels as Effective Sorbents for Diverse Gel Matrices: The Influence of Particle Size and Powder Concentration. J. Food Eng. 2024, 370, 111966. [Google Scholar] [CrossRef]

- Bruno, E.; Lupi, F.R.; Mammolenti, D.; Baldino, N.; Gabriele, D. Development and Rheological Modeling of Dietary Fiber and Policosanol Plant-Based Bigels for Potential Food Applications. Food Hydrocoll. 2024, 150, 109733. [Google Scholar] [CrossRef]

- Bruno, E.; Lupi, F.R.; Mammolenti, D.; Mileti, O.; Baldino, N.; Gabriele, D. Emulgels Structured with Dietary Fiber for Food Uses: A Rheological Model. Foods 2022, 11, 3866. [Google Scholar] [CrossRef]

- Qi, J.; Song, L.; Zeng, W.; Liao, J. Citrus Fiber for the Stabilization of O/W Emulsion through Combination of Pickering Effect and Fiber-Based Network. Food Chem. 2021, 343, 128523. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Li, Y.; Li, B.; Liu, S. Water-Insoluble Dietary-Fibers from Flammulina Velutiper Used as Edible Stabilizers for Oil-in-Water Pickering Emulsions. Food Hydrocoll. 2020, 101, 105519. [Google Scholar] [CrossRef]

- Du, H.; Wang, X.; Yang, H.; Zhu, F.; Cheng, J.; Peng, X.; Lin, Y.; Liu, X. Effects of Mulberry Pomace Polysaccharide Addition before Fermentation on Quality Characteristics of Yogurt. Food Control 2023, 153, 109900. [Google Scholar] [CrossRef]

- Chen, B.; Zhao, X.; Cai, Y.; Jing, X.; Zhao, M.; Zhao, Q.; Van der Meeren, P. Incorporation of Modified Okara-Derived Insoluble Soybean Fiber into Set-Type Yogurt: Structural Architecture, Rheological Properties and Moisture Stability. Food Hydrocoll. 2023, 137, 108413. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, P.; Li, H.; Adhikari, B.P.; Li, D. Rheological Behavior of Tomato Fiber Suspensions Produced by High Shear and High Pressure Homogenization and Their Application in Tomato Products. Int. J. Anal. Chem. 2018, 2018, 5081938. [Google Scholar] [CrossRef]

- Dickinson, E. Stabilising Emulsion-Based Colloidal Structures with Mixed Food Ingredients. J. Sci. Food Agric. 2013, 93, 710–721. [Google Scholar] [CrossRef]

- Moelants, K.R.N.; Cardinaels, R.; Van Buggenhout, S.; Van Loey, A.M.; Moldenaers, P.; Hendrickx, M.E. A Review on the Relationships between Processing, Food Structure, and Rheological Properties of Plant-Tissue-Based Food Suspensions. Compr. Rev. Food Sci. Food Saf. 2014, 13, 241–260. [Google Scholar] [CrossRef]

- McClements, D.J. Food Emulsions-Principles, Practices, and Techniques, 3rd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2016; ISBN 9781498726696. [Google Scholar]

- Guo, X.; McClements, D.J.; Chen, J.; He, X.; Liu, W.; Dai, T.; Liu, C. The Nutritional and Physicochemical Properties of Whole Corn Slurry Prepared by a Novel Industry-Scale Microfluidizer System. LWT 2021, 144, 111096. [Google Scholar] [CrossRef]

- He, K.; Li, Q.; Li, Y.; Li, B.; Liu, S. Water-Insoluble Dietary Fibers from Bamboo Shoot Used as Plant Food Particles for the Stabilization of O/W Pickering Emulsion. Food Chem. 2020, 310, 125925. [Google Scholar] [CrossRef] [PubMed]

- Gao, K.; Liu, T.; Cao, L.; Liu, Y.; Zhang, Q.; Ruan, R.; Feng, S.; Wu, X. Feasibility of Pomelo Peel Dietary Fiber as Natural Functional Emulsifier for Preparation of Pickering-Type Emulsion. J. Sci. Food Agric. 2022, 102, 4491–4499. [Google Scholar] [CrossRef]

- Wallecan, J.R.P.; McCrae, C.H.; Debon, S.J.J.; Dong, J.; Mazoyer, J. Emulsifying and Stabilizing Properties of Functionalized Orange Pulp Fibers. Food Hydrocoll. 2015, 47, 115–123. [Google Scholar] [CrossRef]

- Barnes, H.A.; Hutton, J.F.; Walters, K. An Introduction to Rheology, 1st ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Huang, X.; Liu, Q.; Yang, Y.; He, W.Q. Effect of High Pressure Homogenization on Sugar Beet Pulp: Rheological and Microstructural Properties. LWT 2020, 125, 109245. [Google Scholar] [CrossRef]

- Su, D.; Zhu, X.; Adhikari, B.; Li, D.; Wang, L. Effect of High-Pressure Homogenization on the Rheology, Microstructure and Fractal Dimension of Citrus Fiber-Oil Dispersions. J. Food Eng. 2020, 277, 109899. [Google Scholar] [CrossRef]

- Lupi, F.R.; Puoci, F.; Bruno, E.; Baldino, N.; Marino, R.; Gabriele, D. The Effects of Process Conditions on Rheological Properties of Functional Citrus Fibre Suspensions. Food Bioprod. Process. 2020, 121, 54–64. [Google Scholar] [CrossRef]

- Gabriele, D.; de Cindio, B.; D’Antona, P. A Weak Gel Model for Foods. Rheol. Acta 2001, 40, 120–127. [Google Scholar] [CrossRef]

- Tang, D.; Marangoni, A.G. Microstructure and Fractal Analysis of Fat Crystal Networks. JAOCS J. Am. Oil Chem. Soc. 2006, 83, 377–388. [Google Scholar] [CrossRef]

- Bayod, E.; Bolmstedt, U.; Innings, F.; Tornberg, E. Rheological Characterization of Fiber Suspensions Prepared from Vegetable Pulp and Dried Fiber: A Comparative Study. Annu. Trans. Nord. Rheol. Soc. 2005, 13, 249–253. [Google Scholar]

- Moelants, K.R.N.; Cardinaels, R.; Jolie, R.P.; Verrijssen, T.A.J.; Van Buggenhout, S.; Zumalacarregui, L.M.; Van Loey, A.M.; Moldenaers, P.; Hendrickx, M.E. Relation Between Particle Properties and Rheological Characteristics of Carrot-Derived Suspensions. Food Bioprocess Technol. 2013, 6, 1127–1143. [Google Scholar] [CrossRef]

- Redgwell, R.J.; Curti, D.; Robin, F.; Donato, L.; Pineau, N. Extrusion-Induced Changes to the Chemical Profile and Viscosity Generating Properties of Citrus Fiber. J. Agric. Food Chem. 2011, 59, 8272–8279. [Google Scholar] [CrossRef]

- Van Buggenhout, S.; Wallecan, J.; Christiaens, S.; Debon, S.J.J.; Desmet, C.; Van Loey, A.; Hendrickx, M.; Mazoyer, J. Influence of High-Pressure Homogenization on Functional Properties of Orange Pulp. Innov. Food Sci. Emerg. Technol. 2015, 30, 51–60. [Google Scholar] [CrossRef]

- Liu, J.; Wang, R.; Wang, X.; Yang, L.; Shan, Y.; Zhang, Q.; Ding, S. Effects of High-Pressure Homogenization on the Structural, Physical, and Rheological Properties of Lily Pulp. Foods 2019, 8, 472. [Google Scholar] [CrossRef]

- Daou, C.; Zhang, H. Functional and Physiological Properties of Total, Soluble, and Insoluble Dietary Fibres Derived from Defatted Rice Bran. J. Food Sci. Technol. 2014, 51, 3878–3885. [Google Scholar] [CrossRef] [PubMed]

- Bengtsson, H.; Tornberg, E. Physicochemical Characterization of Fruit and Vegetable Fiber Suspensions. I: Effect of Homogenization. J. Texture Stud. 2011, 42, 268–280. [Google Scholar] [CrossRef]

- Willemsen, K.L.D.D.; Panozzo, A.; Moelants, K.; Debon, S.J.J.; Desmet, C.; Cardinaels, R.; Moldenaers, P.; Wallecan, J.; Hendrickx, M.E.G. Physico-Chemical and Viscoelastic Properties of High Pressure Homogenized Lemon Peel Fiber Fraction Suspensions Obtained after Sequential Pectin Extraction. Food Hydrocoll. 2017, 72, 358–371. [Google Scholar] [CrossRef]

- Su, D.; Zhu, X.; Wang, Y.; Li, D.; Wang, L. Effect of High-Pressure Homogenization on Rheological Properties of Citrus Fiber. LWT 2020, 127, 109366. [Google Scholar] [CrossRef]

- Liu, T.; Lei, H.; Zhen, X.; Liu, J.; Xie, W.; Tang, Q.; Gou, D.; Zhao, J. Advancements in Modifying Insoluble Dietary Fiber: Exploring the Microstructure, Physicochemical Properties, Biological Activity, and Applications in Food Industry—A Review. Food Chem. 2024, 458, 140154. [Google Scholar] [CrossRef]

- Iqbal, S.; Tirpanalan-Staben, Ö.; Franke, K. Modification of Dietary Fibers to Valorize the By-Products of Cereal, Fruit and Vegetable Industry—A Review on Treatment Methods. Plants 2022, 11, 3466. [Google Scholar] [CrossRef]

- Yang, Y.Y.; Ma, S.; Wang, X.X.; Zheng, X.L. Modification and Application of Dietary Fiber in Foods. J. Chem. 2017, 2017, 9340427. [Google Scholar] [CrossRef]

- Wolf, B. Polysaccharide Functionality through Extrusion Processing. Curr. Opin. Colloid Interface Sci. 2010, 15, 50–54. [Google Scholar] [CrossRef]

- Ağar, B.; Gençcelep, H.; Saricaoğlu, F.T.; Turhan, S. Effect of Sugar Beet Fiber Concentrations on Rheological Properties of Meat Emulsions and Their Correlation with Texture Profile Analysis. Food Bioprod. Process. 2016, 100, 118–131. [Google Scholar] [CrossRef]

- Liu, Y.; Yi, S.; Ye, T.; Leng, Y.; Alomgir Hossen, M.; Sameen, D.E.; Dai, J.; Li, S.; Qin, W. Effects of Ultrasonic Treatment and Homogenization on Physicochemical Properties of Okara Dietary Fibers for 3D Printing Cookies. Ultrason. Sonochem. 2021, 77, 105693. [Google Scholar] [CrossRef] [PubMed]

- Szafrańska, J.O.; Sołowiej, B.G. Effect of Different Fibres on Texture, Rheological and Sensory Properties of Acid Casein Processed Cheese Sauces. Int. J. Food Sci. Technol. 2020, 55, 1971–1979. [Google Scholar] [CrossRef]

- Yildiz, E.; Ozcan, T. Functional and Textural Properties of Vegetable-Fibre Enriched Yoghurt. Int. J. Dairy Technol. 2019, 72, 199–207. [Google Scholar] [CrossRef]

- Rosa-Sibakov, N.; de Oliveira Carvalho, M.J.; Lille, M.; Nordlund, E. Impact of Enzymatic Hydrolysis and Microfluidization on the Techno-Functionality of Oat Bran in Suspension and Acid Milk Gel Models. Foods 2022, 11, 228. [Google Scholar] [CrossRef]

- Oladiran, D.A.; Emmambux, N.M. Nutritional and Functional Properties of Extruded Cassava-Soy Composite with Grape Pomace. Starch/Staerke 2018, 70, 1700298. [Google Scholar] [CrossRef]

- Issar, K.; Sharma, P.C.; Gupta, A. Utilization of Apple Pomace in the Preparation of Fiber-Enriched Acidophilus Yoghurt. J. Food Process. Preserv. 2017, 41, e13098. [Google Scholar] [CrossRef]

- Cepeda, E.; Collado, I. Rheology of Tomato and Wheat Dietary Fibers in Water and in Suspensions of Pimento Purée. J. Food Eng. 2014, 134, 67–73. [Google Scholar] [CrossRef]

- Håkansson, A. Rotor-Stator Mixers: From Batch to Continuous Mode of Operation-A Review. Processes 2018, 6, 32. [Google Scholar] [CrossRef]

- Kamble, M.G.; Singh, A.; Prabhakar, P.K.; Meghwal, M.; Singh, S.V.; Chinchkar, V.A. Effect of High Shear Homogenization on Quality Characteristics of Bael Fruit Pulp. Food Qual. Saf. 2022, 6, fyac011. [Google Scholar] [CrossRef]

- Betoret, E.; Betoret, N.; Rocculi, P.; Dalla Rosa, M. Strategies to Improve Food Functionality: Structure-Property Relationships on High Pressures Homogenization, Vacuum Impregnation and Drying Technologies. Trends Food Sci. Technol. 2015, 46, 1–12. [Google Scholar] [CrossRef]

- Castro, A.; Céspedes, G.; Carballo, S.; Bergenståhl, B.; Tornberg, E. Dietary Fiber, Fructooligosaccharides, and Physicochemical Properties of Homogenized Aqueous Suspensions of Yacon (Smallanthus sonchifolius). Food Res. Int. 2013, 50, 392–400. [Google Scholar] [CrossRef]

- Su, D.; Zhu, X.; Wang, Y.; Li, D.; Wang, L. Effects of High-Pressure Homogenization on Physical and Thermal Properties of Citrus Fiber. LWT 2019, 116, 108573. [Google Scholar] [CrossRef]

- Willemsen, K.L.D.D.; Panozzo, A.; Moelants, K.; Cardinaels, R.; Wallecan, J.; Moldenaers, P.; Hendrickx, M. Effect of PH and Salts on Microstructure and Viscoelastic Properties of Lemon Peel Acid Insoluble Fiber Suspensions upon High Pressure Homogenization. Food Hydrocoll. 2018, 82, 144–154. [Google Scholar] [CrossRef]

- Jurić, S.; Ferrari, G.; Velikov, K.P.; Donsì, F. High-Pressure Homogenization Treatment to Recover Bioactive Compounds from Tomato Peels. J. Food Eng. 2019, 262, 170–180. [Google Scholar] [CrossRef]

- Colletti, A.C.; Delgado, J.F.; Cabezas, D.M.; Wagner, J.R.; Porfiri, M.C. Soybean Hull Insoluble Polysaccharides: Improvements of Its Physicochemical Properties Through High Pressure Homogenization. Food Biophys. 2020, 15, 173–187. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, Z.; He, Z.; Zeng, M.; Qin, F.; Chen, J. Effect of Particle Size and Microstructure on the Physical Properties of Soybean Insoluble Dietary Fiber in Aqueous Solution. Food Biosci. 2021, 41, 100898. [Google Scholar] [CrossRef]

- Jiang, Z.; Mu, S.; Ma, C.; Liu, Y.; Ma, Y.; Zhang, M.; Li, H.; Liu, X.; Hou, J.; Tian, B. Consequences of Ball Milling Combined with High-Pressure Homogenization on Structure, Physicochemical and Rheological Properties of Citrus Fiber. Food Hydrocoll. 2022, 127, 107515. [Google Scholar] [CrossRef]

- Van Audenhove, J.; Bernaerts, T.; Putri, N.I.; Van Rooy, L.; Van Loey, A.M.; Hendrickx, M.E. The Role of Mechanical Collapse by Cryogenic Ball Milling on the Effect of High-Pressure Homogenization on the Microstructural and Texturizing Properties of Partially Pectin-Depleted Tomato Cell Wall Material. Food Res. Int. 2022, 155, 111033. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Chen, M.; Li, Y.; Dai, T.; Shuai, X.; Chen, J.; Liu, C. Modification of Food Macromolecules Using Dynamic High Pressure Microfluidization: A Review. Trends Food Sci. Technol. 2020, 100, 223–234. [Google Scholar] [CrossRef]

- Zhu, X.; Lundberg, B.; Cheng, Y.; Shan, L.; Xing, J.; Peng, P.; Chen, P.; Huang, X.; Li, D.; Ruan, R. Effect of High-Pressure Homogenization on the Flow Properties of Citrus Peel Fibers. J. Food Process Eng. 2018, 41, e12659. [Google Scholar] [CrossRef]

- Serial, M.R.; Velichko, E.; Nikolaeva, T.; den Adel, R.; Terenzi, C.; Bouwman, W.G.; van Duynhoven, J.P.M. High-Pressure Homogenized Citrus Fiber Cellulose Dispersions: Structural Characterization and Flow Behavior. Food Struct. 2021, 30, 100237. [Google Scholar] [CrossRef]

- Chen, J.; Gao, D.; Yang, L.; Gao, Y. Effect of Microfluidization Process on the Functional Properties of Insoluble Dietary Fiber. Food Res. Int. 2013, 54, 1821–1827. [Google Scholar] [CrossRef]

- Morales-Medina, R.; Dong, D.; Schalow, S.; Drusch, S. Impact of Microfluidization on the Microstructure and Functional Properties of Pea Hull Fibre. Food Hydrocoll. 2020, 103, 105660. [Google Scholar] [CrossRef]

- He, X.; Dai, T.; Sun, J.; Liang, R.; Liu, W.; Chen, M.; Chen, J.; Liu, C. Disintegrating the Structure and Improving the Functionalities of Pea Fiber by Industry-Scale Microfluidizer System. Foods 2022, 11, 418. [Google Scholar] [CrossRef]

- Wu, Q.; Wu, J.; Ren, M.; Zhang, X.; Wang, L. Modification of Insoluble Dietary Fiber from Rice Bran with Dynamic High Pressure Microfluidization: Cd(II) Adsorption Capacity and Behavior. Innov. Food Sci. Emerg. Technol. 2021, 73, 102765. [Google Scholar] [CrossRef]

- Tejada-Ortigoza, V.; Garcia-Amezquita, L.E.; Campanella, O.H.; Hamaker, B.R.; Welti-Chanes, J. Extrusion Effect on in Vitro Fecal Fermentation of Fruit Peels Used as Dietary Fiber Sources. LWT 2022, 153, 112569. [Google Scholar] [CrossRef]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Pérez-Carrillo, E.; Serna-Saldívar, S.O.; Campanella, O.H.; Welti-Chanes, J. Functional and Compositional Changes of Orange Peel Fiber Thermally-Treated in a Twin Extruder. LWT 2019, 111, 673–681. [Google Scholar] [CrossRef]

- Tabibloghmany, F.S.; Mazaheri Tehrani, M.; Koocheki, A. Optimization of the Extrusion Process through Response Surface Methodology for Improvement in Functional and Nutritional Properties of Soybean Hull. J. Food Sci. Technol. 2020, 57, 4054–4064. [Google Scholar] [CrossRef]

- Schmid, V.; Steck, J.; Mayer-Miebach, E.; Behsnilian, D.; Bunzel, M.; Karbstein, H.P.; Emin, M.A. Extrusion Processing of Pure Chokeberry (Aronia melanocarpa) Pomace: Impact on Dietary Fiber Profile and Bioactive Compounds. Foods 2021, 10, 518. [Google Scholar] [CrossRef] [PubMed]

- Balasubramaniam, V.M.B.; Martínez-Monteagudo, S.I.; Gupta, R. Principles and Application of High Pressure-Based Technologies in the Food Industry. Annu. Rev. Food Sci. Technol. 2015, 6, 435–462. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Niu, L.; Song, J.; Liu, C.; Zhang, Z.; Liu, C.; Li, D.; Xiao, L. Effect of Pretreatment and High Hydrostatic Pressure on Soluble Dietary Fiber in Lotus Root Residues. J. Food Qual. 2022, 2022, 5565538. [Google Scholar] [CrossRef]

- Mateos-Aparicio, I.; Mateos-Peinado, C.; Rupérez, P. High Hydrostatic Pressure Improves the Functionality of Dietary Fibre in Okara By-Product from Soybean. Innov. Food Sci. Emerg. Technol. 2010, 11, 445–450. [Google Scholar] [CrossRef]

- Xie, F.; Li, M.; Lan, X.; Zhang, W.; Gong, S.; Wu, J.; Wang, Z. Modification of Dietary Fibers from Purple-Fleshed Potatoes (Heimeiren) with High Hydrostatic Pressure and High Pressure Homogenization Processing: A Comparative Study. Innov. Food Sci. Emerg. Technol. 2017, 42, 157–164. [Google Scholar] [CrossRef]

- Wu, C.; McClements, D.J.; He, M.; Zheng, L.; Tian, T.; Teng, F.; Li, Y. Preparation and Characterization of Okara Nanocellulose Fabricated Using Sonication or High-Pressure Homogenization Treatments. Carbohydr. Polym. 2021, 255, 117364. [Google Scholar] [CrossRef]

- Kalla-Bertholdt, A.-M.; Nguyen, P.-V.; Baier, A.K.; Rauh, C. Influence of Dietary Fiber on In-Vitro Lipid Digestion of Emulsions Prepared with High-Intensity Ultrasound. Innov. Food Sci. Emerg. Technol. 2021, 73, 102799. [Google Scholar] [CrossRef]

- Wu, C.; Teng, F.; McClements, D.J.; Zhang, S.; Li, Y.; Wang, Z. Effect of Cavitation Jet Processing on the Physicochemical Properties and Structural Characteristics of Okara Dietary Fiber. Food Res. Int. 2020, 134, 109251. [Google Scholar] [CrossRef]

- Tian, X.-Y.; Liu, J.-F.; Cheng, Z.; Wu, N.-N.; Tan, B. Structure, Thermal Stability, Physicochemical and Functional Characteristics of Insoluble Dietary Fiber Obtained from Rice Bran with Steam Explosion Treatment: Effect of Different Steam Pressure and Particle Size of Rice Bran. Food Res. Int. 2024, 187, 114310. [Google Scholar] [CrossRef]

- Yan, J.; Li, Y.; Bai, S.; Zheng, J.; Hassan, N.A.; Lu, B.; Hu, A. Comparison of Structural, Physicochemical and Functional Properties of Dried Coconut Dietary Fiber by Steam Explosion and Extrusion Modification. Ind. Crops Prod. 2024, 218, 118916. [Google Scholar] [CrossRef]

- Qin, S.; Li, M.; Yang, Y.; Zhang, Y.; Guo, B.; Li, W.; Zhang, B. Effect of Induced Electric Field Treatment on Structural and Physicochemical Properties of Wheat Bran to Enhance Soluble Dietary Fiber Content. Food Res. Int. 2025, 201, 115618. [Google Scholar] [CrossRef]

| Food By-Products | TDF% | SDF% | IDF% | SDF%/IDF% Ratio | WHC (g/g) | WSC (mL/g) | Reference |

|---|---|---|---|---|---|---|---|

| Fruits processing | |||||||

| Apple pomace var. Royal Gala | 78.20 | 14.33 | 63.90 | 1:4.5 | 1.62 | 6.59 | [24] |

| Apple pomace var. Granny Smith | 60.70 | 4.14 | 56.50 | 1:12.9 | 1.78 | 6.89 | |

| Apple pomace var. Liberty | 89.8 | 8.20 | 81.60 | 1:9.9 | 1.87 | 6.87 | |

| Passion fruit | 81.50 | 35.50 | 46.00 | 1:1.3 | 13.5 | 7.2 | [25] |

| Pineapple | 75.80 | 0.60 | 75.20 | 1:125.3 | 14.6 | 6.6 | |

| Guava | 69.10 | 11.10 | 57.70 | 1:5.2 | 10.2 | 1.4 | |

| Mango | 70.00 | 28.20 | 41.50 | 1:1.5 | 6.4 | 4.6 | |

| Mango peel var. Raspuri | 54.90 | 17.20 | 37.70 | 1:2.2 | - | - | [26] |

| Mango peel var. Badami | 72.50 | 23.00 | 49.50 | 1:2.2 | - | - | |

| Cactus pear peel var. Rojo San Martìn | 45.20 | 10.60 | 35.2 | 1:3.3 | - | - | [27] |

| Cactus pear peel var. Verde Villanueva | 58.1 | 17.2 | 40.9 | 1:2.4 | - | - | |

| Cactus pear peel var. Rojo Cenizo | 50.90 | 19.3 | 31.6 | 1:1.6 | - | - | |

| Cactus pear seed var. Rojo San Martìn | 93.8 | 2.60 | 91.3 | 1:35 | - | - | |

| Cactus pear seed var. Verde Villanueva | 91.2 | 2.7 | 88.5 | 1:33 | - | - | |

| Cactus pear seed var. Rojo Cenizo | 86.7 | 2.4 | 84.3 | 1:35 | - | - | |

| Vegetable processing | |||||||

| Tomato peel | 86.10 | 14.30 | 71.80 | 1:5.0 | 6.86 | 0.11 | [28] |

| Carrot pomace | 96.20 | 1.4 | 94.70 | 1:67 | 22.9 | - | [29] |

| Sugarcane bagasse | 90.82 | 0.00 | 90.82 | - | 17.3 | - | |

| Citrus processing | |||||||

| Orange bagasse var. Navel | 35.40 | 12.60 | 22.80 | 1:1.8 | 10.02 | - | [30] |

| Orange bagasse var. Salustiana | 35.90 | 13.00 | 22.90 | 1:1.8 | 10.32 | - | |

| Orange bagasse var. Valencia | 36.90 | 11.30 | 25.50 | 1:2.3 | 7.30 | - | |

| Orange peel, bagasse, and seed | 63.60 | 17.40 | 46.20 | 1:2.7 | 8.71 | - | [31] |

| Orange peel | 63.70 | 15.60 | 48.20 | 1:3.1 | 9.63 | - | |

| Lime peel var. C. Aurantifolia | 70.40 | 21.89 | 48.67 | 1:2.2 | 12.84 | 13.64 | [32] |

| Lime peel var. C. Latifolia | 66.70 | 20.26 | 46.45 | 1:2.3 | 6.96 | 11.34 | |

| Lemon peel var. Eureka | 60.10 | 9.20 | 50.90 | 1:5.5 | 1.85 | 7.32 | [24] |

| Lemon peel vat. Fino 49 | 68.30 | 6.25 | 62.00 | 1:9.9 | 1.74 | 9.19 | |

| Orange peel var. Valencia | 64.30 | 10.28 | 54.00 | 1:5.3 | 1.65 | 6.11 | |

| Cereal processing | |||||||

| Wheat bran | 45.50 | 2.80 | 41.7 | 1:14.9 | - | - | [33] |

| Rye bran | 35.80 | 5.30 | 30.50 | 1:5.8 | - | - | |

| Oat bran | 21.70 | 4.30 | 17.40 | 1:4.0 | - | - | |

| Corn bran | 96.54 | 4.09 | 92.44 | 1:22.6 | 32.8/74.3 | - | [29] |

| Wheat bran | 92.03 | 0.00 | 92.03 | - | 13.9 | - | |

| Wheat straw | 97.55 | 0.00 | 97.55 | - | 23.7 | - | |

| Rice fiber | 98.63 | 0.00 | 98.63 | - | 6.4 | - | |

| Barley hulls | 102.65 | 4.15 | 98.51 | 1:23.7 | 13.8 | - | |

| Barley straw | 104.41 | 6.84 | 97.57 | 1:14.3 | 21.4 | - | |

| Legume processing | |||||||

| Bean hull | 77.35 | 5.56 | 71.79 | 1:12.9 | 3.4 | - | [14] |

| Chickpea hull | 84.18 | 6.50 | 77.61 | 1:11.9 | 3.7 | - | |

| Cowpea hull | 70.86 | 1.08 | 69.78 | 1:64.6 | 3.8 | - | |

| Stability Parameter | Symbol | Technique Used | References |

|---|---|---|---|

| Surface diameters, over time | D3,2 | Laser diffraction/Indirect methods | [40,48,49] |

| Volume diameter, over time | D4,3 | Laser diffraction/Indirect methods | [39] |

| Emulsion index | EI% | Visual inspection | [40,48] |

| Theoretical surface coverage | C | Coupling different methods | [40,48] |

| ζ-potential | ζ | Electrophoretic laser Doppler | [39] |

| Emulsion stability index | ESI | Laser diffraction/Indirect methods | [50] |

| Interfacial tension | γ | Contact angle/Pendent drop | [38,49] |

| IDFs | Food Product | Technological and Physiological Assessments | Processing Methods | Reference |

|---|---|---|---|---|

| Sugar beet fiber | Meat emulsion model | Viscosity, viscoelasticity, rheological modeling, texture analysis | HSH (2250 rpm, 10 s + addition of oil, 5 s) | [70] |

| Okara fiber | 3D-printed cookies | Viscosity, viscoelasticity, texture analysis, functional properties, stability studies | Ultrasound (400–600 W, 30 min) + HPH (5000–15,000 rpm, 10 min) + 3D-printing | [71] |

| Sweet corn fiber | Whole sweet corn suspension | Viscosity, physical stability, phenolic compounds, in-vitro antioxidant activity | Industry-scale microfluidization (60, 09, 120 MPa) | [47] |

| Bamboo, acacia, potato, and citrus fiber | Processed cheese sauces | Viscosity, viscoelasticity, texture analysis | HSH (1118 g, 2 + 10 min) | [72] |

| Pumpkin, carrot, green pea, and zucchini purees | Fiber-enriched yogurt | Physical-chemical profile, in-vitro antioxidant activity, texture analysis | Homogenization + homogenization for yogurt production (60 °C, 50 bar) | [73] |

| Soybean fibers | Fiber-enriched yogurt | Viscosity, viscoelasticity, microstructure | HPH (20–22 MPs) + yogurt production | [42] |

| Mulberry pomace | Fiber-enriched yogurt | Physical chemical properties, viscosity, viscoelasticity, microstructure, and texture analysis | Yogurt production | [41] |

| Oat bran | Acid-milk gel model | Microstructure, functional properties, viscosity, texture analysis | Enzymatic reaction + extrusion cooking + microfluidization + mixing | [74] |

| Grape pomace fiber | Cassava–soy–grape pomace fiber composite food model | Viscosity, in vitro digestibility studies, phenolic compounds, in vitro antioxidant activity | Extrusion cooking (60–140 °C, 200 rpm) | [75] |

| Apple pomace fiber | Fiber-enriched yogurt | Soluble/insoluble fraction | Mixing/homogenization (conditions not specified) | [76] |

| Orange fiber | Ice cream | Physical and functional properties, chemical profile | Homogenization in batch processing plant (conditions not specified) | [31] |

| Citrus fiber | O/W food emulgel model | Viscoelasticity, interfacial properties, modeling of viscoelastic properties | HSH (5000–10,000 rpm, 180–800 s) | [38] |

| Citrus fiber | O/W food bigel model | Viscoelasticity, modeling of the viscoelastic properties | HSH (2000 rpm, 120–240 s) + HSH (5000 rpm, 180–360 s) | [37] |

| Tomato fiber | Ketchup-like tomato sauce | Viscosity, viscoelasticity | HSH (3400–14,000 rpm, 12 min), HPH (0–10 MPa, 0–10 cycles) | [43] |

| Tomato fiber/wheat fiber | Pimento purée | Viscosity, thixotropy, texture analysis, functional properties | HSH (1500 rpm) | [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mammolenti, D.; Lupi, F.R.; Baldino, N.; Gabriele, D. Technological Advancements of Insoluble Dietary Fiber from Food By-Product Processing: A Review. Foods 2025, 14, 1822. https://doi.org/10.3390/foods14101822

Mammolenti D, Lupi FR, Baldino N, Gabriele D. Technological Advancements of Insoluble Dietary Fiber from Food By-Product Processing: A Review. Foods. 2025; 14(10):1822. https://doi.org/10.3390/foods14101822

Chicago/Turabian StyleMammolenti, Domenico, Francesca Romana Lupi, Noemi Baldino, and Domenico Gabriele. 2025. "Technological Advancements of Insoluble Dietary Fiber from Food By-Product Processing: A Review" Foods 14, no. 10: 1822. https://doi.org/10.3390/foods14101822

APA StyleMammolenti, D., Lupi, F. R., Baldino, N., & Gabriele, D. (2025). Technological Advancements of Insoluble Dietary Fiber from Food By-Product Processing: A Review. Foods, 14(10), 1822. https://doi.org/10.3390/foods14101822