Characterization of Key Factors Associated with Flavor Characteristics in Lager Beer Based on Flavor Matrix

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Chemicals

2.3. Pretreatment with LLE, SAFE, and HS-SPME

2.4. Identification and Analysis of the Flavor Compounds

2.5. Odor-Specific Magnitude Estimation (Osme)

2.6. Quantification and Odor Active Values (OAVs)

2.7. Descriptive Sensory Analysis (DSA)

2.8. Recombination and Omission Experiments

2.9. Validation Experiments

2.10. Statistical Analysis

3. Results

3.1. Chemical Analysis

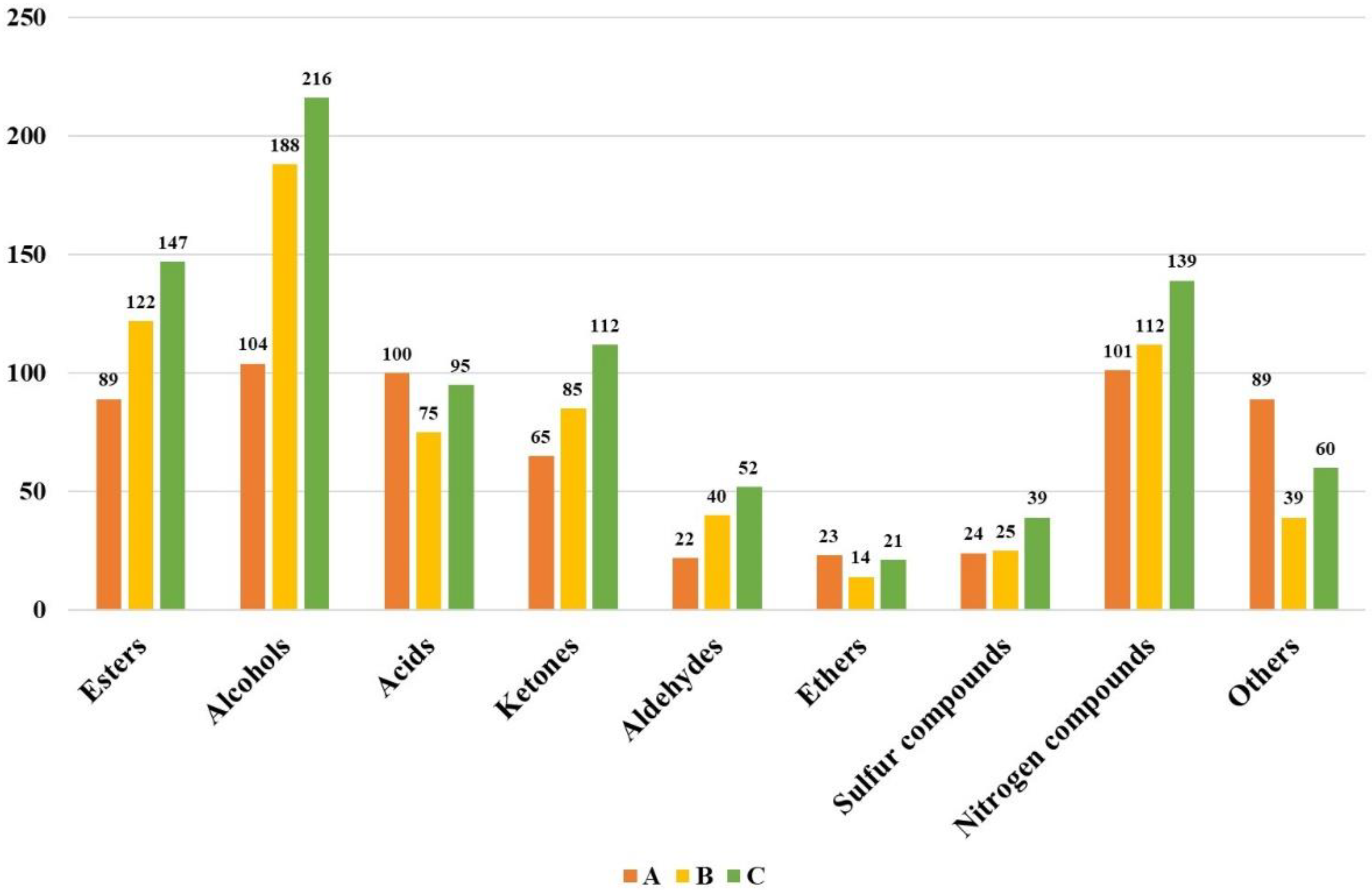

3.1.1. Characterization and Expression Analysis of the Flavor Compounds

3.1.2. Quantification and OAVs of the Flavor Compounds

3.2. Sensory Evaluation

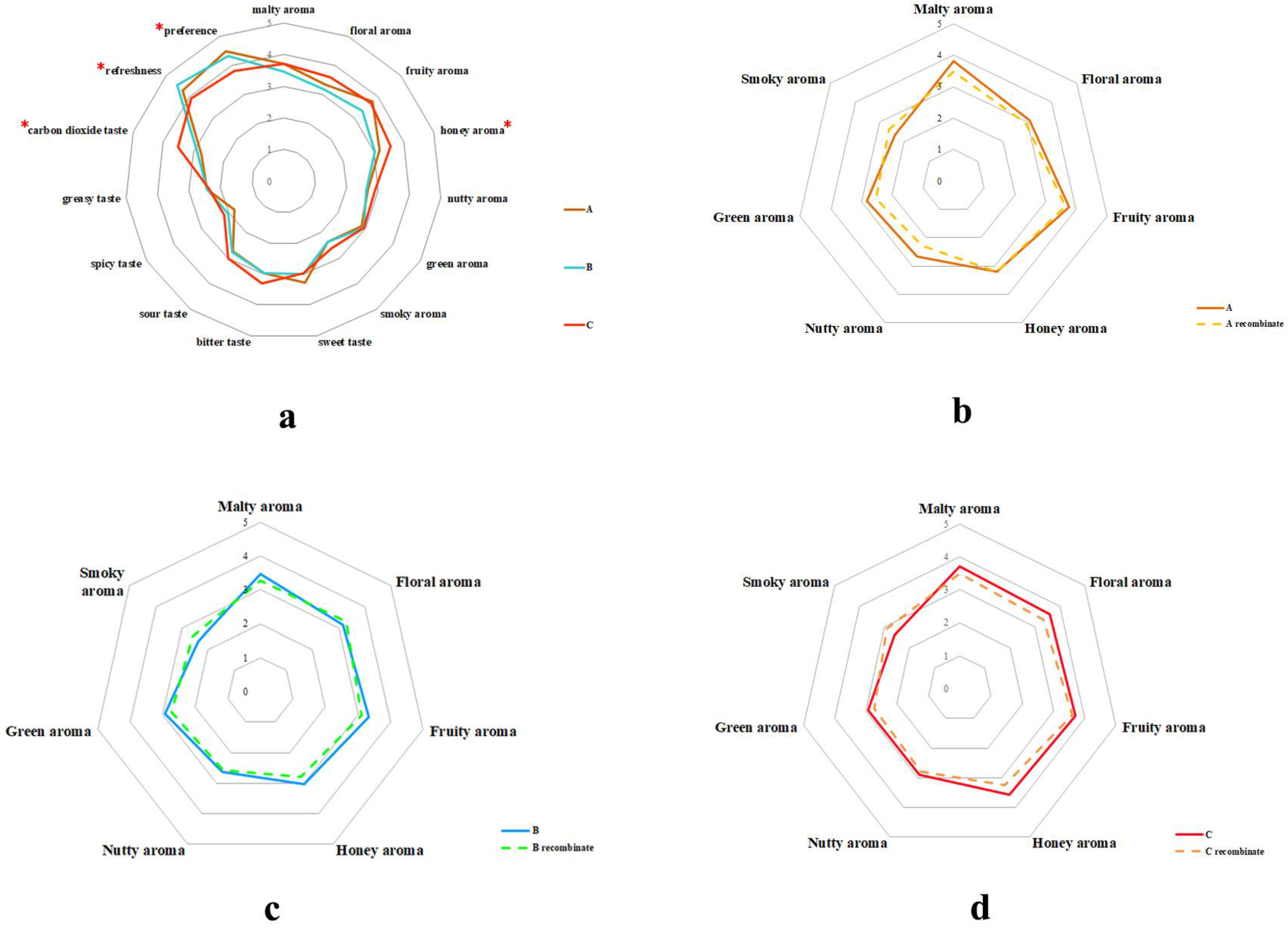

3.2.1. Overall Sensory Evaluation

3.2.2. Recombination Experiments

3.2.3. Omission Experiments

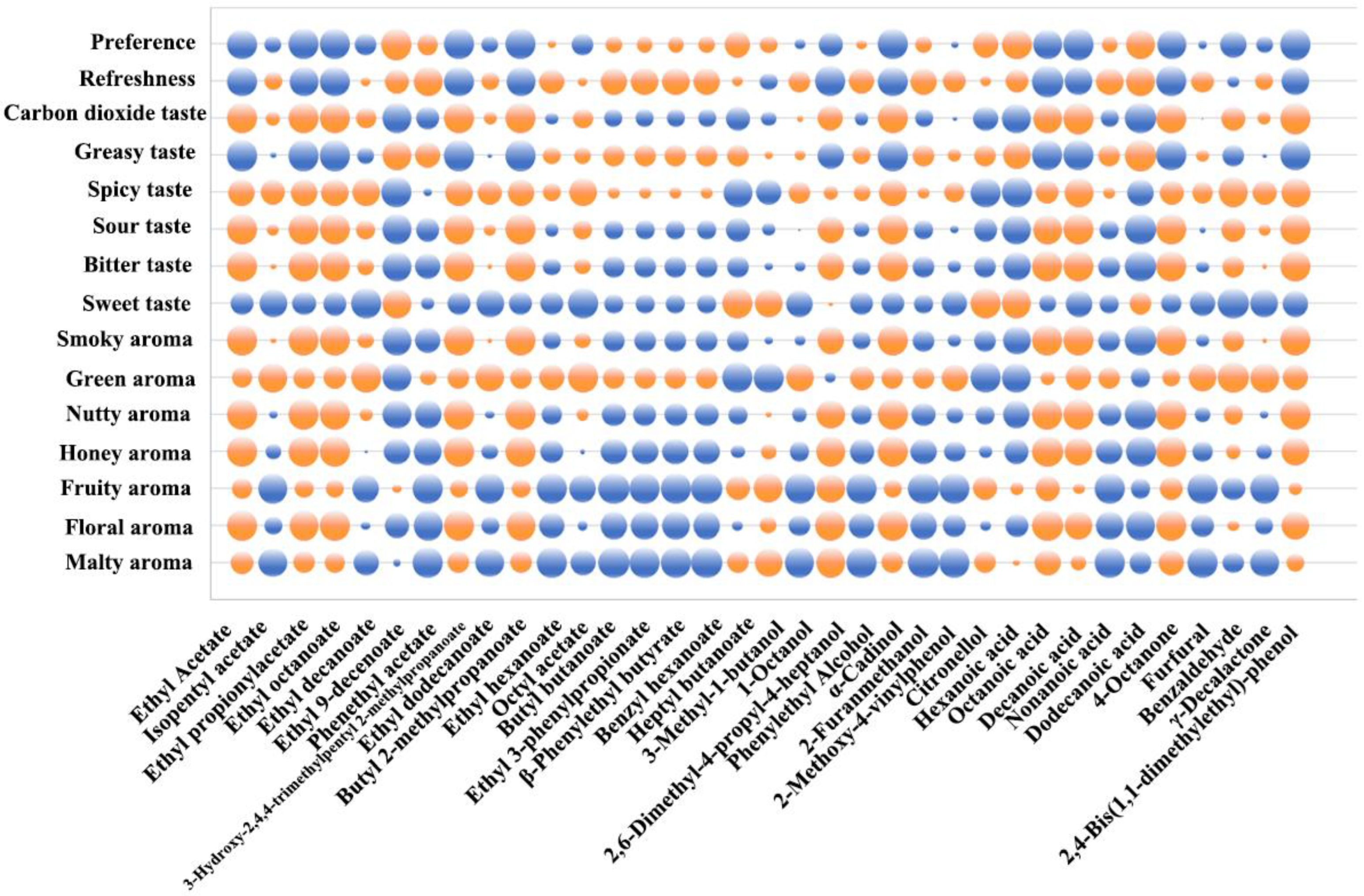

3.2.4. Correlation Analysis of Flavor Compounds and Flavor Profile of Lager Beer by Using a Flavor Matrix

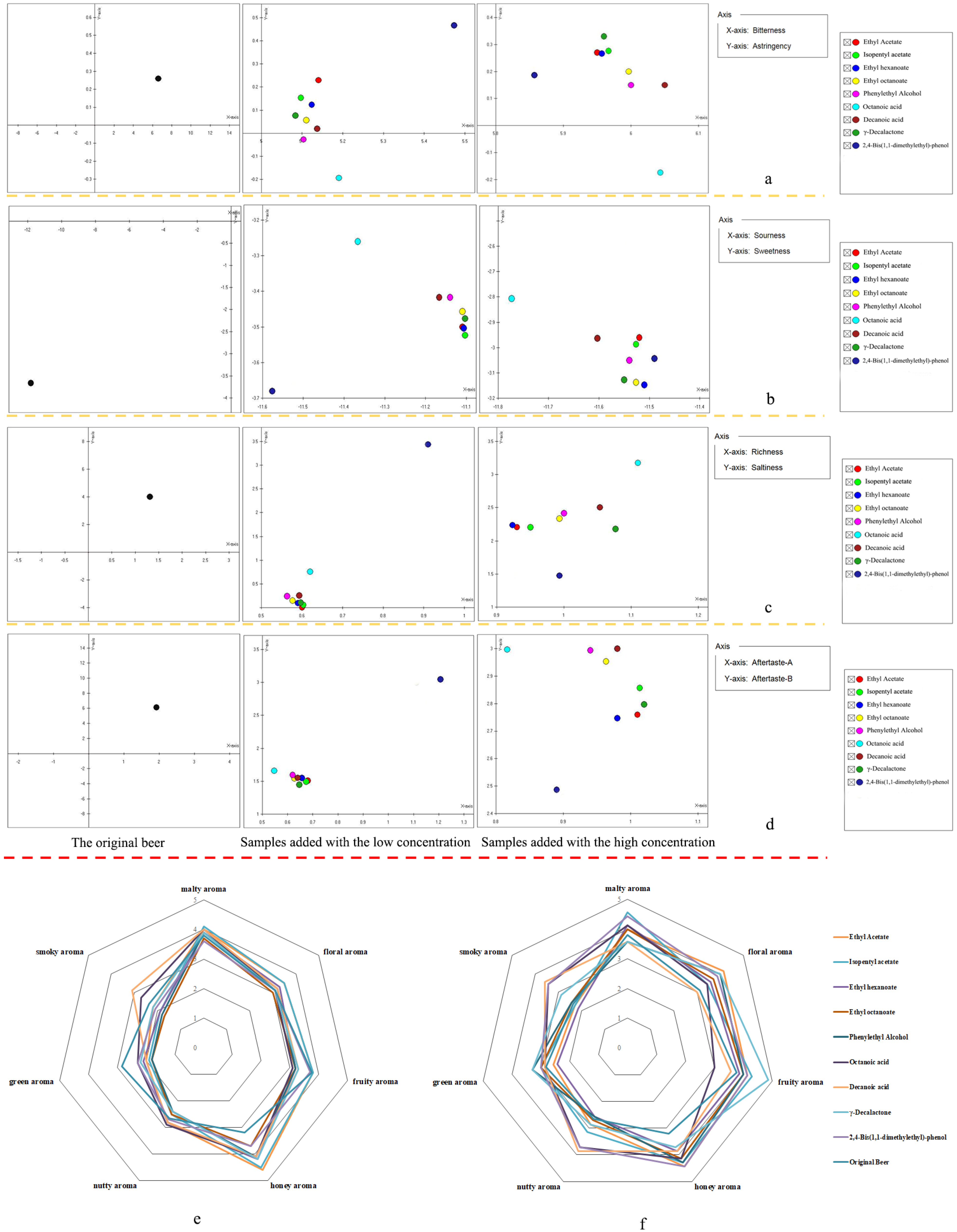

3.2.5. The Validation Experiment for the Flavor Compounds

4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| GC-MS | gas chromatography–mass spectrometry |

| GC–O–MS | gas chromatography-olfactometry–mass spectrometry |

| GC×GC-MS | comprehensive two-dimensional gas chromatography–mass spectrometry |

| HS-SPME | headspace solid-phase microextraction |

| LLE | liquid–liquid extraction |

| SAFE | solvent-assisted flavor evaporation |

| Osme | Odor-specific magnitude estimation |

| SD | the standard deviation |

| OAVs | odor active values |

| DSA | descriptive sensory analysis |

References

- Liu, L.; Wang, J.; Rosenberg, D.; Zhao, H.; Lengyel, G.; Nadel, D. Fermented beverage and food storage in 13,000 y-old stone mortars at Raqefet Cave, Israel: Investigating Natufian ritual feasting. J. Archaeol. Sci. Rep. 2018, 21, 783–793. [Google Scholar] [CrossRef]

- Jeff, A. The Beer Bible; Gao, H., Ed.; China Machine Press: Beijing, China, 2018. [Google Scholar]

- Gonzalez Viejo, C.; Fuentes, S.; Torrico, D.; Godbole, A.; Dunshea, F. Chemical characterization of aromas in beer and their effect on consumers liking. Food Chem. 2019, 293, 479–485. [Google Scholar] [CrossRef]

- Kyoya, O.; Masahiro, F.; Asuka, M.; Eiichiro, F. New insights into the characteristic flavor components of traditional sour beers such as Lambic and Flanders Red Ale beers. J. Biosci. Bioeng. 2024, 138, 54–62. [Google Scholar] [CrossRef]

- Krebs, G.; Mueller, M.; Becker, T.; Martina, G. Characterization of the macromolecular and sensory profile of non-alcoholic beers produced with various methods. Food Res. Int. 2019, 116, 508–517. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Xue, L.; Wu, Z.; Hu, Z. Research Progress on Beer Volatile Flavor Components. Food Res. Dev. 2021, 42, 210–219. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.; Zhang, Z.; Yuan, Y.; Geng, C.; Wu, R.; Deng, J. Research progress on beer volatile compounds. J. Food Saf. Qual. 2023, 14, 44–51. [Google Scholar] [CrossRef]

- Richter, T.; Eyres, G.; Silcock, P.; Bremer, P. Comparison of four extraction methods for analysis of volatile hop-derived aroma compounds in beer. J. Sep. Sci. 2017, 40, 4366–4376. [Google Scholar] [CrossRef]

- Humia, B.; Santos, K.; Barbosa, A.; Sawata, M.; Mendonca, M.; Padilha, F. Beer molecules and its sensory and biological properties: A review. Molecules 2019, 24, 1568. [Google Scholar] [CrossRef]

- Liu, Q.; Jia, J.; Bai, Y.; Xiao, L.; Qiu, R. Research progress on flavor substances in beer and the analysis techniques. China Brew. 2023, 42, 20–27. [Google Scholar]

- Seo, S.; Kim, E.; Park, S.; Park, D.; Park, K.; Na, C.; Son, H. GC/MS-based metabolomics study to investigate between ale and lager beers differential metabolites. Food Biosci. 2020, 36, 100671. [Google Scholar] [CrossRef]

- Ocvirk, M.; Mlinarič, N.K.; Košir, I.J. Comparison of sensory and chemical evaluation of lager beer aroma by gas chromatography and gas chromatography/mass spectrometry. J. Sci. Food Agric. 2018, 98, 3627–3635. [Google Scholar] [CrossRef] [PubMed]

- Witrick, K.; Pitts, E.; O’Keefe, S. Analysis of Lambic Beer Volatiles during Aging Using Gas Chromatography-Mass Spectrometry (GCMS) and Gas Chromatography-Olfactometry (GCO). Beverages 2020, 6, 31. [Google Scholar] [CrossRef]

- Yu, M.; Yang, P.; Song, H.; Guan, X. Research progress in comprehensive two-dimensional gas chromatography-mass spectrometry and its combination with olfactometry systems in the flavor analysis field. J. Food Compos. Anal. 2022, 114, 1–15. [Google Scholar] [CrossRef]

- Rossi, S.; Sileoni, V.; Perretti, G.; Marconi, O. Characterization of the volatile profiles of beer using headspace solid-phase microextraction and gas chromatography–mass spectrometry. J. Sci. Food Agric. 2014, 94, 919–928. [Google Scholar] [CrossRef]

- Dong, L.; Hou, Y.; Li, F.; Piao, Y.; Zhang, X.; Zhang, X.; Li, C.; Zhao, C. Characterization of volatile aroma compounds in different brewing barley cultivars. J. Sci. Food Agric. 2015, 95, 915–921. [Google Scholar] [CrossRef]

- Olayide, O.; Sue, J.; Trevor, C.; Frieda, D.; Katherine, S.; Joanne, H.; David, C. Perceived bitterness character of beer in relation to hop variety and the impact of hop aroma. Food Chem. 2017, 230, 215–224. [Google Scholar] [CrossRef]

- Bettenhausen, H.; Barr, L.; Broeckling, C.; Chaparro, J.; Holbrook, C.; Sedin, D.; Heuberger, A. Influence of malt source on beer chemistry, flavor, and flavor stability. Food Res. Int. 2018, 113, 487–504. [Google Scholar] [CrossRef] [PubMed]

- Pokrivcak, J.; Supekova, S.; Lancaric, D.; Savov, R.; Toth, M.; Vasina, R. Development of beer industry and craft beer expansion. J. Food Nutr. Res. 2019, 58, 63–74. [Google Scholar]

- Michael, F.; Klaas, R.; Veronika, M.; Jens, V.; Martin, S. Molecular Insights into the Contribution of Specialty Barley Malts to the Aroma of Bottom-Fermented Lager Beers. J. Agric. Food Chem. 2021, 69, 8190–8199. [Google Scholar] [CrossRef]

- Dusart, A.; Ryckaert, J.; Collin, S. Comparative investigation of flavors in red and Brown flemish beers: Key-role of Brettanomyces and torrefied malts in ethylphenols occurrence. J. Am. Soc. Brew. Chem. 2023, 81, 357–365. [Google Scholar] [CrossRef]

- Marcos Edgar, H.; Oliver, B.; Marcus, F. Hops across Continents: Exploring How Terroir Transforms the Aromatic Profiles of Five Hop (Humulus lupulus) Varieties Grown in Their Countries of Origin and in Brazil. Plants 2024, 13, 2675. [Google Scholar] [CrossRef] [PubMed]

- Klaas, R.; Michael, F.; Veronika, M.; Jens, V.; Martin, S. The impact of caramel and roasted wheat malts on aroma compounds in top-fermented wheat beer. J. Inst. Brew. 2022, 128, 138–149. [Google Scholar] [CrossRef]

- Herkenhoff, M.E.; Battistini, C.; Praia, A.B.; Rossini, B.C.; Dos Santos, L.D.; Brödel, O.; Frohme, M.; Saad, S.M.I. The combination of omics strategies to evaluate starter and probiotic strains in the Catharina sour Brazilian-style beer. Food Res. Int. 2023, 167, 112704. [Google Scholar] [CrossRef]

- Marcos Edgar, H.; Oliver, B.; Marcus, F. Aroma component analysis by HS-SPME/GC–MS to characterize Lager, Ale, and sour beer styles. Food Res. Int. 2024, 194, 114763. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Shi, D.; Sun, J.; Li, A.; Sun, B.; Zhao, M.; Chen, F.; Sun, X.; Li, H.; Huang, M.; et al. Characterization of key aroma compounds in Gujinggong Chinese Baijiu by gas chromatography-olfactometry, quantitative measurements, and sensory evaluation. Food Res. Int. 2018, 105, 616–627. [Google Scholar] [CrossRef]

- Chen, P.; Liu, Y.; Wu, J.; Yu, B.; Zhao, H.; Huang, M.; Zheng, F. Sensory-directed decoding of key aroma compounds from Jiugui-series Baijiu, the representative of Fuyu-flavor-type Baijiu (FFTB). J. Food Compos. Anal. 2022, 114, 104799. [Google Scholar] [CrossRef]

- Fan, W.L.; Xu, Y. Current practice and future trends of aroma and flavor of Chinese liquor (baijiu). J. Food Saf. Qual. 2014, 5, 3073–3078. [Google Scholar]

- Liu, H.; Sun, B. Effect of Fermentation Processing on the Flavor of Baijiu. J. Agric. Food Chem. 2018, 66, 5425–5432. [Google Scholar] [CrossRef]

- Wang, J.S.; Chen, H.; Wu, Y.S.; Zhao, D.R. Uncover the flavor code of strong aroma baijiu: Research progress on the revelation of aroma compounds in strong aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499–104516. [Google Scholar] [CrossRef]

- Hong, J.; Huang, H.; Zhao, D.; Sun, J.; Huang, M.; Sun, X.; Sun, B. Investigation on the key factors associated with flavor quality in northern strong aroma type of Baijiu by flavor matrix. Food Chem. 2023, 426, 136576–136587. [Google Scholar] [CrossRef]

- van Gemert, L.J. Compilations of Odour Threshold Values in Air, Water and Other Media, 2nd ed.; Science Press: Beijing, China, 2011. [Google Scholar]

- Gamero, A.; Ferreira, V.; Pretorius, I.S.; Querol, A. Wine, Beer and Cider: Unraveling the Aroma Profile in Molecular Mechanisms in Yeast Carbon Metabolism; Piskur, J., Compagno, C., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 261–297. [Google Scholar]

- Lin, R.; Wu, D.; Peng, Z.; Xie, G.; Lu, J. Effect of different tea addition methods on flavor of Taiping Houkui green tea beer. Food Ferment. Ind. 2024, 1–14. [Google Scholar] [CrossRef]

| Flavor Compounds | CAS | Aroma Characteristics | Aroma Intensity | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | ||||||||||||

| SPME | SD | LLE | SD | SPME | SD | LLE | SD | SPME | SD | LLE | SD | |||

| Ethyl Acetate | 141-78-6 | Fruity | 1 | 0.24 | 1 | 0.24 | 2 | 0.24 | 2 | 0.24 | ||||

| Isopentyl acetate | 123-92-2 | Banana | 1 | 0.24 | 3 | 0.47 | 2 | 0.24 | 3 | 0.24 | ||||

| Ethyl propionylacetate | 4949-44-4 | Sweet | 1 | 0.24 | 1 | 0.24 | ||||||||

| Ethyl hexanoate | 123-66-0 | Pineapple, Peach | 1 | 0.24 | 2 | 0.24 | 2 | 0.24 | 2 | 0.24 | 2 | 0.24 | 1 | 0.24 |

| Ethyl octanoate | 106-32-1 | Pear | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | 3 | 0.41 | 2 | 0.24 |

| Octyl acetate | 112-14-1 | Mushroom | 2 | 0.24 | 1 | 0.24 | ||||||||

| Ethyl decanoate | 110-38-3 | Fruity, Peach | 2 | 0.24 | 2 | 0.41 | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | ||

| Ethyl 9-decenoate | 67233-91-4 | Fruity, Fatty | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | ||||||

| 2-Phenethylformate | 104-62-1 | Green, Floral | 2 | 0.24 | ||||||||||

| Phenethyl acetate | 103-45-7 | Rose, Honey | 4 | 0.24 | 4 | 0.41 | 3 | 0.24 | 3 | 0.24 | 4 | 0.41 | 4 | 0.47 |

| Ethylene glycol | 107-21-1 | Sweet | 3 | 0.41 | ||||||||||

| 2-Furanmethanol | 98-00-0 | Bready | 1 | 0.24 | ||||||||||

| 1-Octanol | 111-87-5 | Coconut | 1 | 0.24 | 2 | 0.24 | ||||||||

| 3-Methyl-1-butanol | 123-51-3 | Sugarcane, Fruity | 4 | 0.24 | 2 | 0.24 | 3 | 0.41 | 2 | 0.24 | 1 | 0.24 | 1 | 0.24 |

| 2,3-Butanediol | 513-85-9 | Buttery, Creamy | 1 | 0.24 | 2 | 0.24 | 2 | 0.24 | 1 | 0.24 | ||||

| 3-Methylthiopropanol | 505-10-2 | Vegetable | 2 | 0.24 | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | ||||

| Phenylethyl Alcohol | 60-12-8 | Floral | 4 | 0.47 | 5 | 0.41 | 3 | 0.41 | 4 | 0.24 | 5 | 0.47 | 4 | 0.24 |

| 2-Ethylbutyric acid | 88-09-5 | Dairy | 2 | 0.24 | 2 | 0.24 | 2 | 0.24 | 1 | 0.24 | 2 | 0.24 | 3 | 0.24 |

| 2-(Aminooxy)valeric acid | 5699-55-8 | Earthy | 1 | 0.24 | ||||||||||

| Hexanoic acid | 142-62-1 | Cheesy, Fruity | 1 | 0.24 | 3 | 0.24 | 1 | 0.24 | 1 | 0.24 | 3 | 0.24 | 3 | 0.24 |

| 2-Methyl-2-pentenoic acid | 3142-72-1 | Jammy | 1 | 0.24 | ||||||||||

| Octanoic acid | 124-07-2 | Cheesy | 2 | 0.24 | 1 | 0.24 | 3 | 0.24 | 2 | 0.24 | 1 | 0.24 | 3 | 0.24 |

| Decanoic acid | 334-48-5 | Fatty | 2 | 0.24 | 4 | 0.24 | 3 | 0.24 | 1 | 0.24 | 3 | 0.41 | ||

| Benzaldehyde | 100-52-7 | Nutty, Fruity | 2 | 0.41 | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | 1 | 0.24 | ||

| Cinnamaldehyde | 104-55-2 | Honey, Sweet | 1 | 0.41 | 2 | 0.24 | 1 | 0.24 | ||||||

| Furfural | 98-01-1 | Woody, Nutty | 1 | 0.24 | 2 | 0.24 | 1 | 0.24 | ||||||

| Naphthalene | 91-20-3 | Fatty | 3 | 0.47 | 3 | 0.24 | ||||||||

| Benzothiazole | 95-16-9 | Vegetable | 3 | 0.41 | ||||||||||

| 4-Hydroxy-2,5-Furaneol | 3658-77-3 | Caramel | 3 | 0.47 | 2 | 0.24 | 2 | 0.24 | ||||||

| Phenol | 108-95-2 | Rubbery | 2 | 0.24 | 1 | 0.24 | 2 | 0.24 | 1 | 0.24 | ||||

| 2-Acetyl pyrrole | 1072-83-9 | Nutty | 2 | 0.41 | ||||||||||

| γ-Nonanolactone | 104-61-0 | Floral | 3 | 0.47 | 4 | 0.24 | 2 | 0.24 | 1 | 0.24 | 3 | 0.24 | 3 | 0.24 |

| 2-Methoxy-4-vinylphenol | 7786-61-0 | Smoky | 1 | 0.24 | 3 | 0.24 | 1 | 0.24 | 2 | 0.24 | ||||

| Flavor Compounds | CAS | Odor Threshold (μg/L) | Concentration (μg/L) | OAV | ||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | |||

| Ethyl Acetate | 141-78-6 | 32,552 b | 262.81 ± 14.32 | 250.88 ± 19.60 | 457.99 ± 14.00 | 0 | 0 | 0 |

| Isopentyl acetate | 123-92-2 | 94 b | 164.21 ± 3.20 | 595.02 ± 14.25 | 394.83 ± 13.02 | 2 | 6 | 4 |

| Ethyl propionylacetate | 4949-44-4 | 0 | 0 | 13.70 ± 4.14 | ||||

| Ethyl octanoate | 106-32-1 | 13 b | 640.7 ± 10.52 | 657.43 ± 9.43 | 1358.35 ± 11.71 | 49 | 51 | 104 |

| Ethyl decanoate | 110-38-3 | 1120 b | 83.40 ± 1.71 | 228.26 ± 7.92 | 194.20 ± 7.27 | 0 | 0 | 0 |

| Ethyl 9-decenoate | 67233-91-4 | 24.16 ± 4.01 | 21.77 ± 1.80 | 18.79 ± 2.90 | ||||

| Phenethyl acetate | 103-45-7 | 407 b | 2113.72 ± 18.82 | 2782.11 ± 19.07 | 1910.71 ± 5.49 | 5 | 7 | 5 |

| 3-Hydroxy-2,4,4-trimethylpentyl 2-methylpropanoate | 74367-34-3 | 0 | 0 | 18.05 ± 4.40 | ||||

| Ethyl dodecanoate | 106-33-2 | 500 b | 0 | 26.81 ± 5.34 | 14.11 ± 5.84 | 0 | 0 | |

| Butyl 2-methylpropanoate | 97-87-0 | 22,000 a | 0 | 0 | 24.65 ± 6.96 | 0 | ||

| Ethyl hexanoate | 123-66-0 | 55 b | 317.02 ± 9.67 | 362.94 ± 4.93 | 326.62 ± 14 | 6 | 7 | 6 |

| Octyl acetate | 112-14-1 | 450 d | 0 | 11.31 ± 4.92 | 8.52 ± 0.48 | 0 | 0 | |

| Butyl butanoate | 109-21-7 | 110 b | 0 | 27.47 ± 3.54 | 0 | 0 | ||

| Ethyl 3-phenylpropionate | 2021-28-5 | 125 b | 0 | 19.20 ± 1.35 | 0 | 0 | ||

| β-Phenylethyl butyrate | 103-52-6 | 0 | 10.64 ± 1.81 | 0 | ||||

| Benzyl hexanoate | 6938-45-0 | 0 | 10.67 ± 2.98 | 0 | ||||

| Heptyl butanoate | 5870-93-9 | 18.24 ± 3.63 | 0 | 0 | ||||

| 3-Methyl-1-butanol | 123-51-3 | 10,000 c | 302.95 ± 2.43 | 249.06 ± 5.35 | 272.20 ± 13.27 | 0 | 0 | 0 |

| 1-Octanol | 111-87-5 | 1100 c | 20.10 ± 1.01 | 26.28 ± 1.95 | 22.55 ± 0.33 | 0 | 0 | 0 |

| 2,6-Dimethyl-4-propyl-4-heptanol | 54774-83-3 | 22.50 ± 1.98 | 0 | 36.96 ± 1.69 | ||||

| Phenylethyl Alcohol | 60-12-8 | 47,900 a | 2854.20 ± 14.93 | 3255.28 ± 15.28 | 2921.54 ± 8.18 | 0 | 0 | 0 |

| α-Cadinol | 481-34-5 | 0 | 0 | 7.56 ± 0.31 | ||||

| 2-Furanmethanol | 98-00-0 | 1400 c | 0 | 7.00 ± 1.24 | 0 | 0 | ||

| 2-Methoxy-4-vinylphenol | 7786-61-0 | 500 a | 0 | 44.04 ± 4.78 | 14.66 ± 6.27 | 0 | 0 | |

| Citronellol | 106-22-9 | 700 c | 8.03 ± 2.13 | 0 | 0 | 0 | ||

| Hexanoic acid | 142-62-1 | 2517 b | 1415.51 ± 10.11 | 1362.31 ± 18.46 | 1317.68 ± 11.32 | 1 | 1 | 1 |

| Octanoic acid | 124-07-2 | 2701 b | 25,627.31 ± 12.53 | 23,553.12 ± 18.06 | 30,402.23 ± 10.11 | 9 | 9 | 11 |

| Decanoic acid | 334-48-5 | 13,737 b | 5277.46 ± 17.35 | 6660.27 ± 14.87 | 11,151.89 ± 19.68 | 0 | 0 | 1 |

| Nonanoic acid | 112-05-0 | 2400 c | 0 | 365.00 ± 11.93 | 0 | 0 | ||

| Dodecanoic acid | 143-07-7 | 10,000 c | 143.30 ± 18.22 | 154.69 ± 7.85 | 0 | 0 | 0 | |

| 4-Octanone | 589-63-9 | 82 d | 124.09 ± 9.29 | 122.09 ± 5.08 | 132.24 ± 7.30 | 2 | 1 | 2 |

| Furfural | 98-01-1 | 15,000 a | 81.06 ± 7.85 | 115.50 ± 10.00 | 93.21 ± 17.46 | 0 | 0 | 0 |

| Benzaldehyde | 100-52-7 | 5000 c | 0 | 25.94 ± 3.46 | 26.44 ± 1.89 | 0 | 0 | |

| γ-Decalactone | 706-14-9 | 1000 c | 15.02 ± 1.71 | 32.58 ± 1.37 | 24.31 ± 5.80 | 0 | 0 | 0 |

| 2,4-Bis(1,1-dimethylethyl)-phenol | 96-76-4 | 500 d | 9.67 ± 0.69 | 10.56 ± 1.22 | 13.90 ± 1.13 | 0 | 0 | 0 |

| NO. | Flavor Compounds Omitted | n | Significance | ||||

|---|---|---|---|---|---|---|---|

| A | B | C | A | B | C | ||

| 1 | Ethyl acetate | 14 | 13 | 14 | *** | *** | *** |

| 2 | Isopentyl acetate | 12 | 12 | 13 | *** | *** | *** |

| 3 | Ethyl hexanoate | 11 | 6 | 14 | ** | *** | |

| 4 | Ethyl propionylacetate | —— | —— | 11 | ** | ||

| 5 | Ethyl octanoate | —— | 11 | 10 | ** | * | |

| 6 | Octyl acetate | —— | 11 | 11 | ** | ** | |

| 7 | Ethyl decanoate | 10 | 9 | 11 | * | * | ** |

| 8 | Phenethyl acetate | 10 | 4 | 11 | * | ** | |

| 9 | Ethyl dodecanoate | —— | 10 | 13 | * | *** | |

| 10 | Butyl butanoate | —— | 8 | 14 | *** | ||

| 11 | β-Phenylethyl butyrate | —— | 9 | —— | * | ||

| 12 | All esters | 12 | 11 | 11 | *** | ** | ** |

| 13 | 3-Methyl-1-butanol | 9 | 9 | 7 | * | ||

| 14 | Citronellol | 10 | —— | —— | * | ||

| 15 | Phenylethyl alcohol | 13 | 14 | 11 | *** | *** | ** |

| 16 | 1-Octanol | —— | 12 | 10 | *** | * | |

| 17 | 2-Furanmethanol | —— | 15 | —— | *** | ||

| 18 | All alcohols | 12 | 14 | 11 | *** | *** | ** |

| 19 | Hexanoic acid | —— | 14 | 11 | *** | ** | |

| 20 | Octanoic acid | 11 | 13 | 10 | ** | *** | * |

| 21 | Nonanoic acid | —— | 10 | —— | * | ||

| 22 | Decanoic acid | 11 | 14 | 14 | ** | *** | *** |

| 23 | Dodecanoic acid | 11 | 9 | —— | ** | * | |

| 24 | All acids | 14 | 12 | 13 | *** | *** | *** |

| 25 | Furfural | 10 | 9 | 6 | * | * | |

| 26 | γ-Decalactone | 11 | 14 | —— | ** | *** | |

| 27 | 2,4-Bis(1,1-dimethylethyl)-phenol | 11 | 11 | 11 | ** | ** | ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, J.; Wei, H.; Yin, R.; Xie, J.; Huang, H.; Guo, L.; Zhao, D.; Song, Y.; Sun, J.; Huang, M.; et al. Characterization of Key Factors Associated with Flavor Characteristics in Lager Beer Based on Flavor Matrix. Foods 2025, 14, 1702. https://doi.org/10.3390/foods14101702

Hong J, Wei H, Yin R, Xie J, Huang H, Guo L, Zhao D, Song Y, Sun J, Huang M, et al. Characterization of Key Factors Associated with Flavor Characteristics in Lager Beer Based on Flavor Matrix. Foods. 2025; 14(10):1702. https://doi.org/10.3390/foods14101702

Chicago/Turabian StyleHong, Jiaxin, Huayang Wei, Ruiyang Yin, Jiang Xie, He Huang, Liyun Guo, Dongrui Zhao, Yumei Song, Jinyuan Sun, Mingquan Huang, and et al. 2025. "Characterization of Key Factors Associated with Flavor Characteristics in Lager Beer Based on Flavor Matrix" Foods 14, no. 10: 1702. https://doi.org/10.3390/foods14101702

APA StyleHong, J., Wei, H., Yin, R., Xie, J., Huang, H., Guo, L., Zhao, D., Song, Y., Sun, J., Huang, M., & Sun, B. (2025). Characterization of Key Factors Associated with Flavor Characteristics in Lager Beer Based on Flavor Matrix. Foods, 14(10), 1702. https://doi.org/10.3390/foods14101702