Brewing with Whole Wheat Bread to Produce Different Beer Styles

Abstract

:1. Introduction

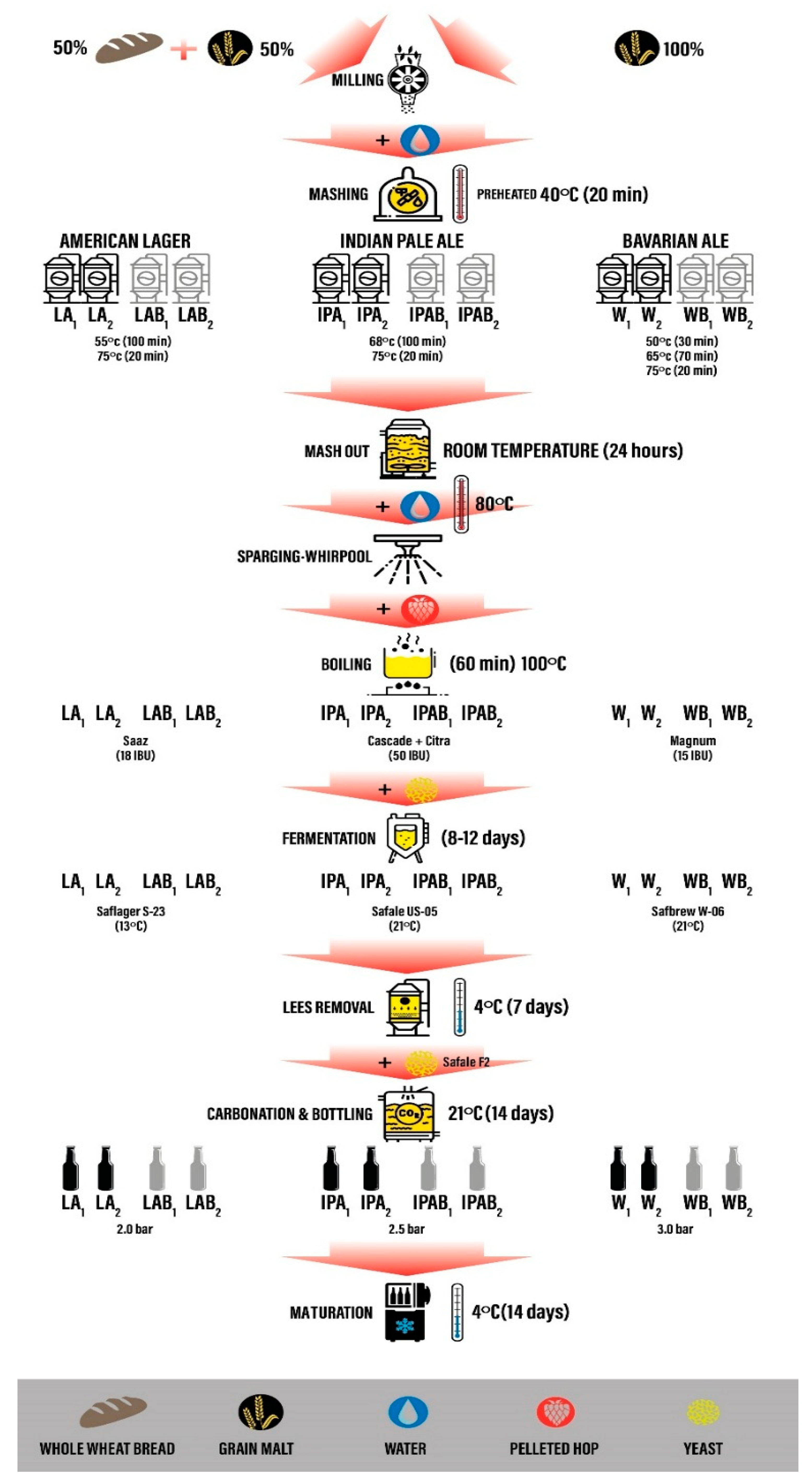

2. Materials and Methods

2.1. Reagents and Standards

2.2. Raw Materials

2.3. Brewing Procedure

2.4. Physicochemical Analysis

- pH was measured with a pH-meter (HACH-LANGE, calibrated sensiON™+ pH3 model, Hospitalet, Spain).

- Acidity: pH-meter measurements were taken continuously. An acid–base titration was performed until a pH of 7 was reached. Then, the results were expressed in terms of lactic acid percentage.

- Turbidity was measured with a turbidimeter (Hanna Instruments, HI 98703 model, Eibar, Spain). The different samples were placed in a transparent glass container with a lid, and then each container was placed in the turbidity meter to obtain NTU turbidity values (Nephelometric Turbidity Units).

- Alcohol By Volume (ABV) was measured with an ebulliometer (GAB system, 1010006 model, Moja, Spain). First, it was calibrated with distilled water as a standard. Subsequently, the boiling temperatures of the standard (water) and the test sample (beer) were compared, and the volumetric alcohol content was calculated to the nearest 0.1 ABV using a ruler scale. Full attenuation of each batch was verified by three consecutive daily density readings at 20 ± 0.1 °C (stable FG = 1.010–1.012 SG) using a calibrated densimeter. The ebulliometric values were then validated by comparing the resulting % ABV with those calculated from the original and final gravities according to the EBC reference equation.

- Real Extract was determined in accordance with the principles of Analytica-EBC (Real Extract of Beer) by direct gravimetry. After degassing each beer at 20 ± 0.1 °C, an accurately weighed 1.000 ± 0.005 g aliquot was transferred to a pre-dried, tared pan in a thermobalance (Gibertini Eurotherm, Novate Milanese, Italy). The sample was dried at 105 °C until the rate of mass loss was <0.1 mg per 30 s, guaranteeing constant weight. The residue represents the real extract, expressed as % (m/m).

2.5. Spectrophotometric Analysis

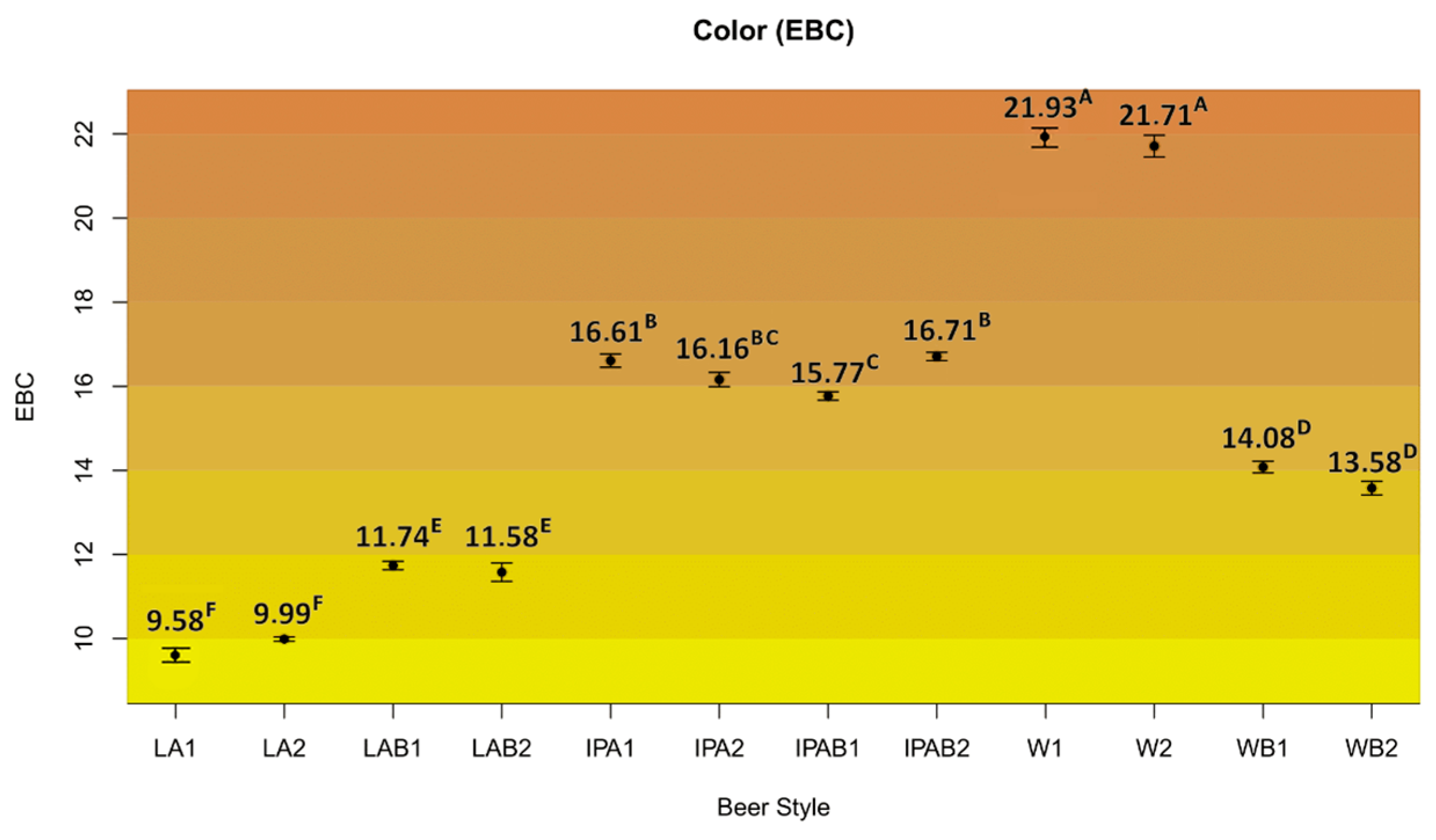

- Color (EBC): Beer color was determined according to the standard method of the European Brewery Convention (EBC).

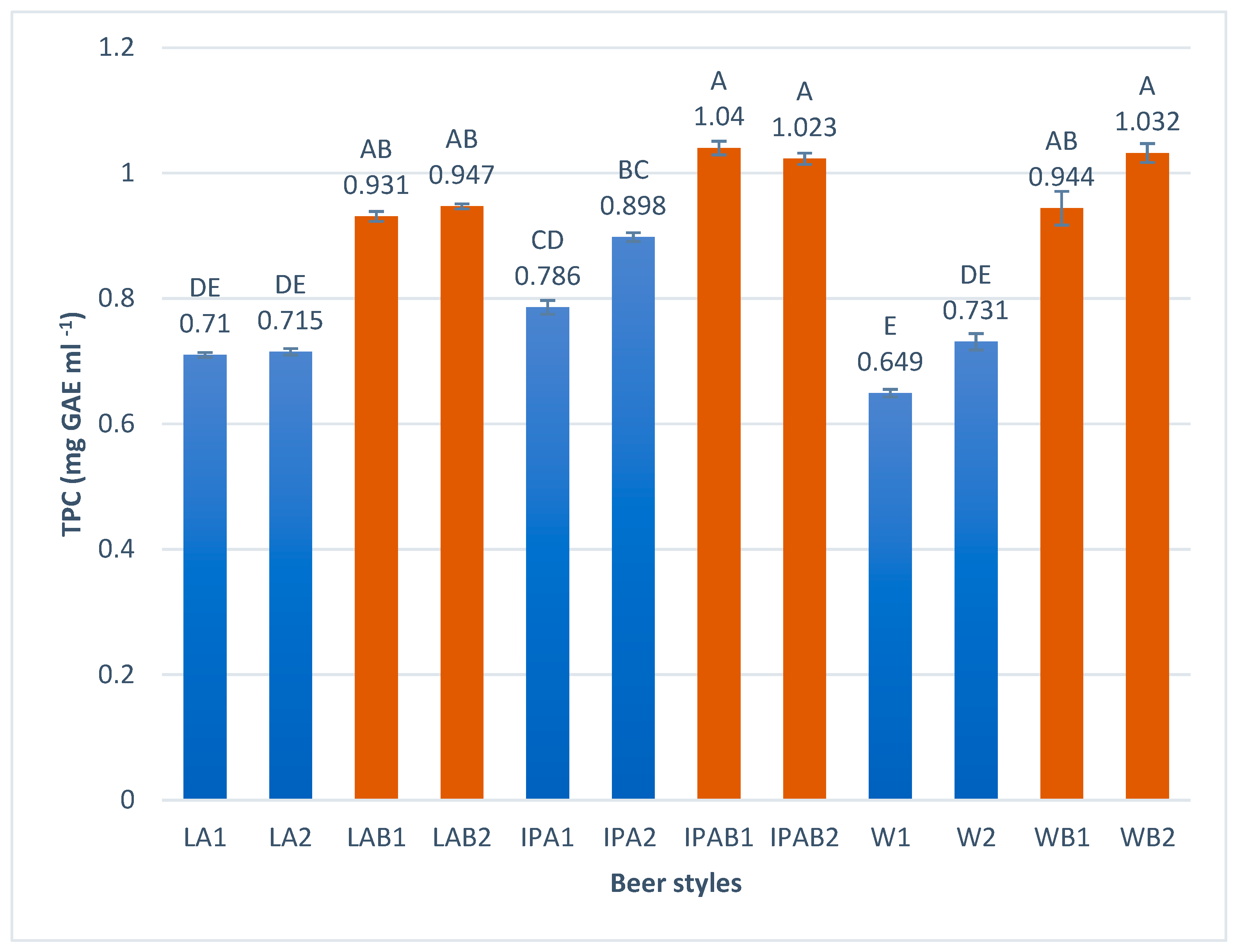

- Total polyphenol content (TPC): The total polyphenol content was determined by the Folin–Ciocalteu method by measuring absorbance at 760 nm [23], using the spectrophotometer mentioned above. A calibration line was performed using different concentrations (0.0–30 mg L−1) of standard solutions of gallic acid, resulting in the following equation: Y = 0.0243x + 0.0209, R = 0.9959. The concentration of total phenols is expressed as mg of GAE mL−1 of the sample.

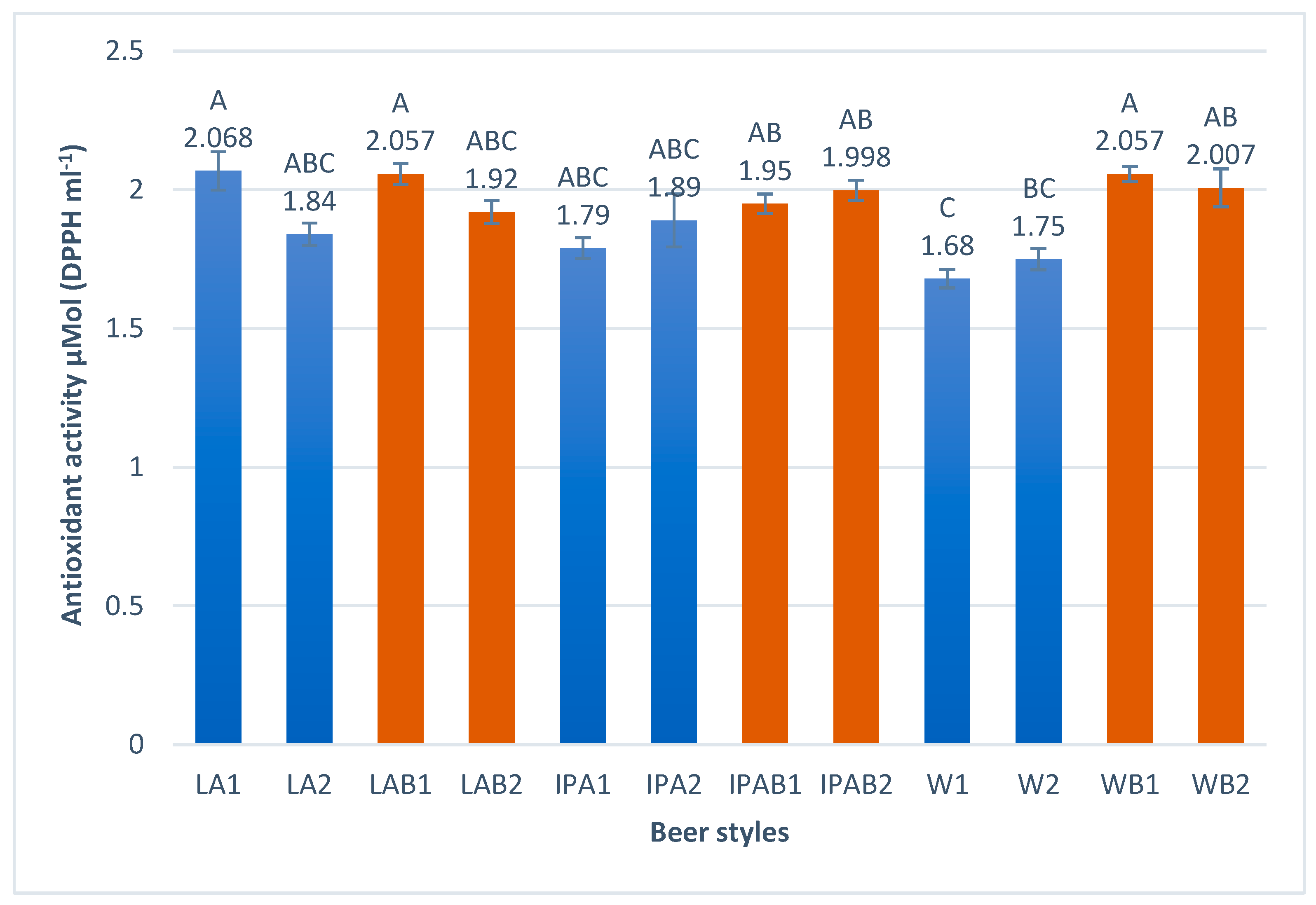

- Antioxidant capacity (DPPH): The antioxidant capacity of the beer samples was determined according to the method described by Abderrahim et al. [24]. Beer samples, once filtered and diluted (the 50 μL sample or the blank control), were introduced and mixed with 1000 μL of DPPH (60 μMol L−1 dissolved in methanol 1: 1/10 mMol L−1 Tris-HCl buffer pH 7.5) in a 5 mL volumetric flask. At 0 min, and after 20 min of incubation at room temperature in the laboratory (21 ± 2 °C), a small volume was introduced into 10 mm quartz cuvettes, and absorbance was measured at 520 nm with the spectrophotometer mentioned above. The antioxidant capacity of the beer, expressed in μMol DPPH mL−1, was calculated using the following mathematical formula:where A0: control absorbance (DPPH diluted in methanol); At: sample absorbance; Vt: total reaction volume in liters; [DPPH]: DPPH concentration; FD: dilution factor; and mL: sample milliliters used in the reaction.

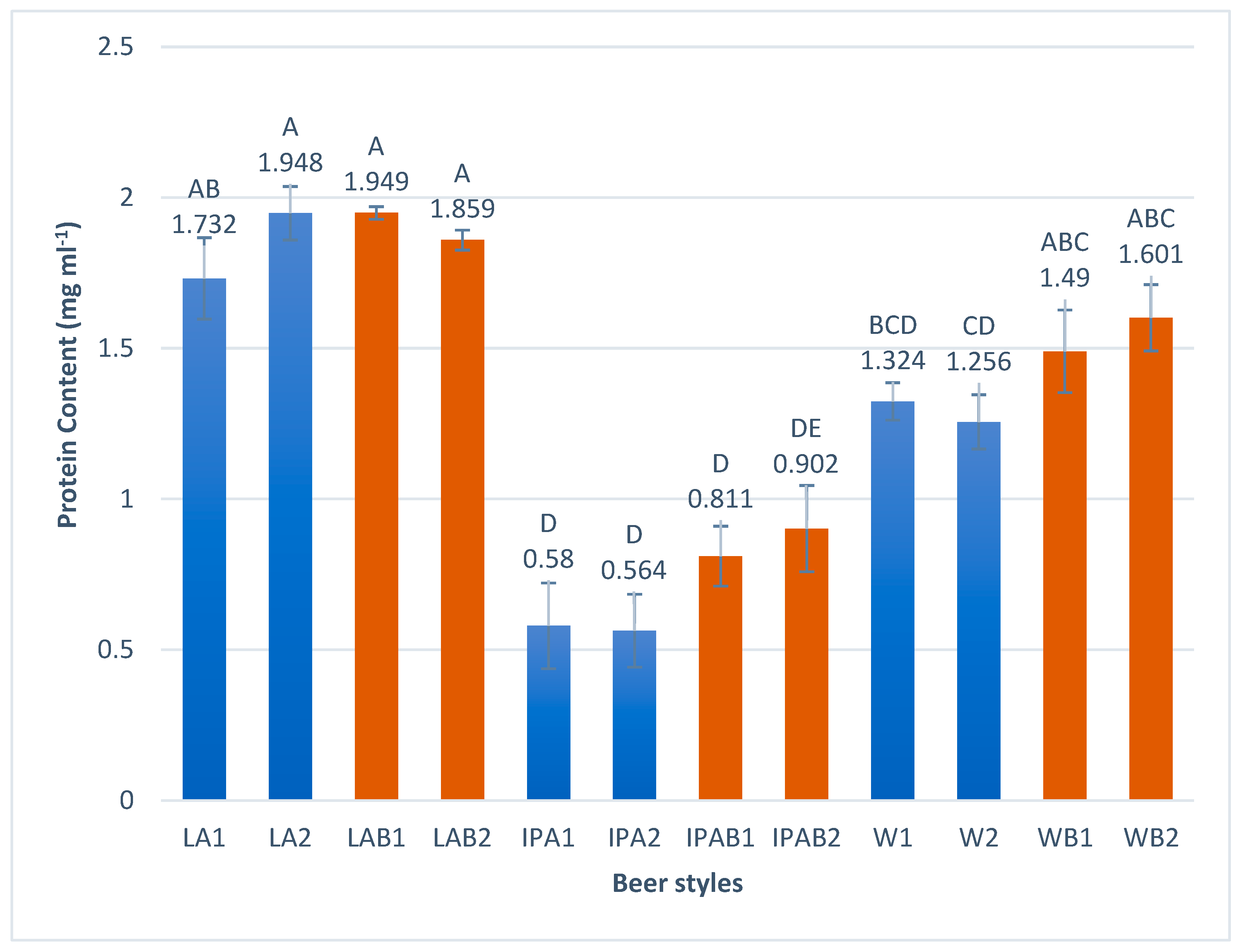

- Protein content: A method based on the Bradford test [25] was followed, according to which the quantification of proteins is based on the union of the Coomassie blue dye G-250 (Bradford reagent) with the proteins available from the analyzed beer samples. In these analyses, 3140 μL of distilled water and 200 μL of the Bradford reagent were added to 60 μL of the beer sample in a test tube. A calibration line from 1 to 40 μL was also constructed using serum albumin (0.1 μg μL−1). Finally, samples were measured at 595 nm.

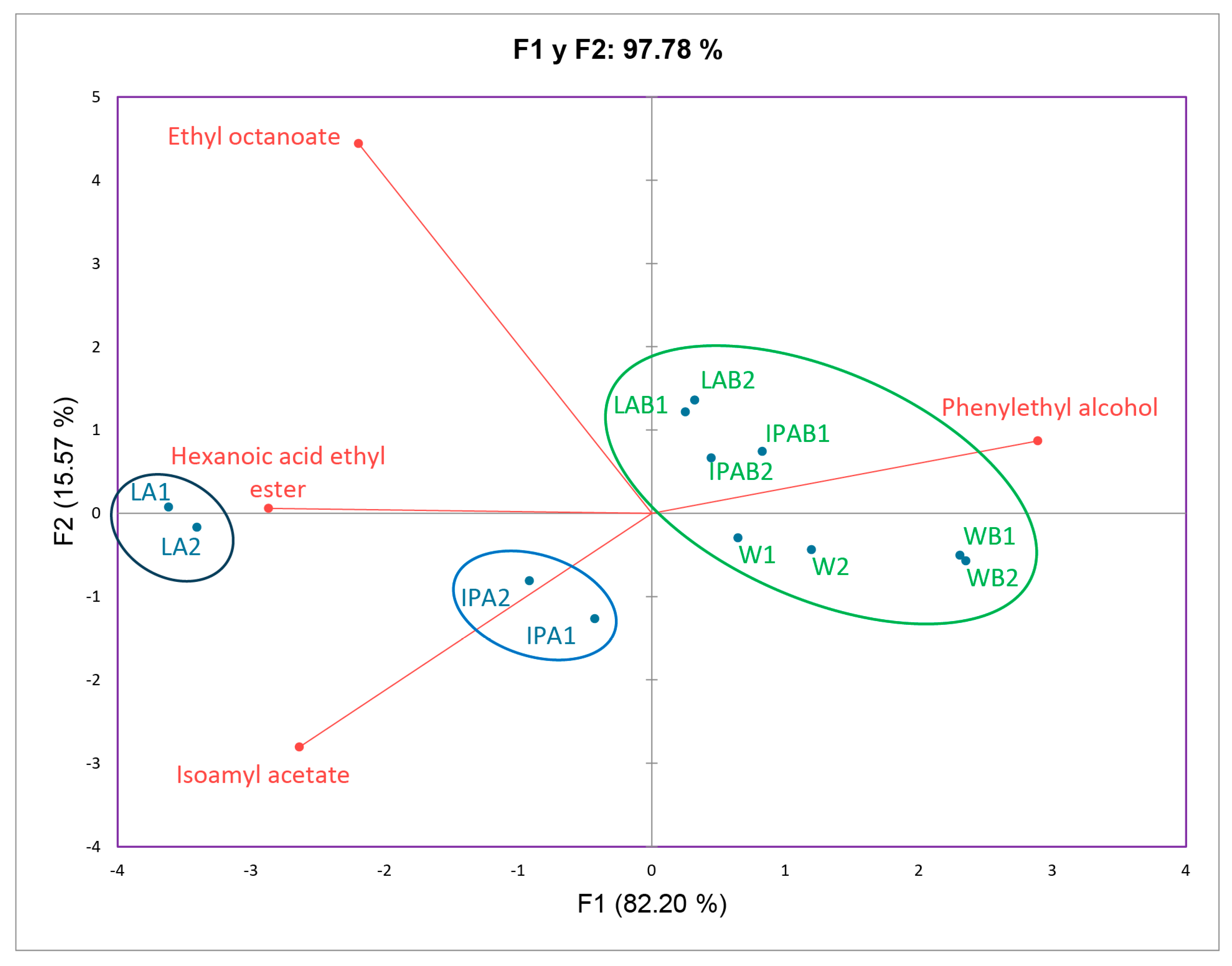

2.6. Headspace Gas Chromatography–Mass Spectrometry Analysis (HS-GC-MS)

2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Analysis

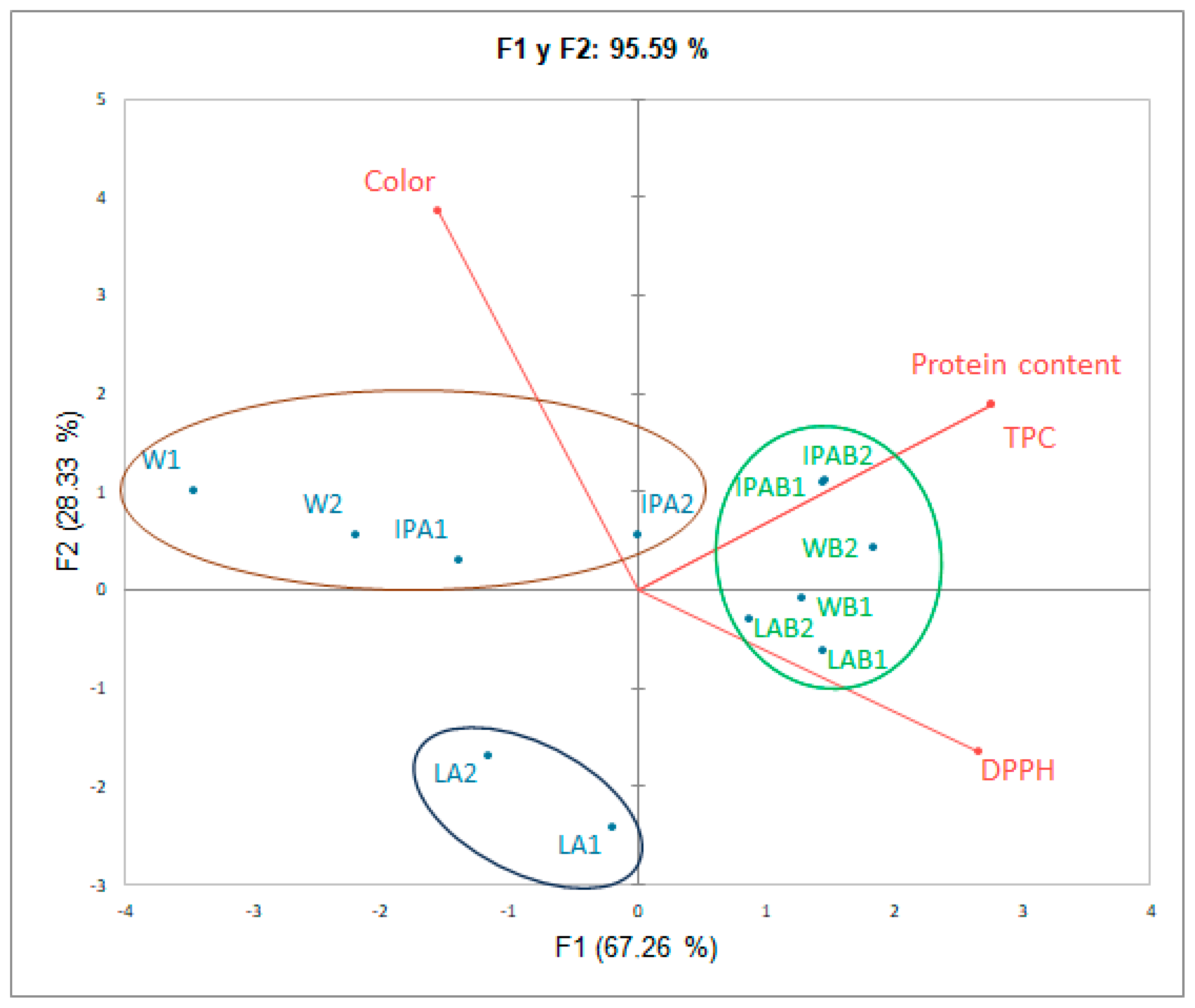

3.2. Spectrophotometric Properties

3.2.1. Color (EBC)

3.2.2. Total Polyphenol Content (TPC)

3.2.3. Antioxidant Activity by DPPH

3.2.4. Protein Content

3.3. Headspace Gas Chromatography-Mass Spectrometry (HS-GC-MS) Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Investing in Food Loss and Waste; FAO: Rome, Italy, 2022. [Google Scholar] [CrossRef]

- UNEP. UNEP Food Waste Index Report 2021; UNEP—UN Environment Programme. 2021. Available online: http://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 6 March 2025).

- Yusufoğlu, B.; Yaman, M.; Karakuş, E. Glycemic evaluation of some breads from different countries via in vitro gastrointestinal enzymatic hydrolysis system. Food Sci. Technol. 2021, 42, e34920. [Google Scholar] [CrossRef]

- Kumar, V.; Brancoli, P.; Narisetty, V.; Wallace, S.; Charalampopoulos, D.; Dubey, B.K.; Kumar, G.; Bhatnagar, A.; Bhatia, S.K.; Taherzadeh, M.J. Bread waste—A potential feedstock for sustainable circular biorefineries. Bioresour. Technol. 2023, 369, 128449. [Google Scholar] [CrossRef] [PubMed]

- Hafyan, R.; Mohanarajan, J.; Uppal, M.; Kumar, V.; Narisetty, V.; Maity, S.; Sadhukhan, J.; Gadkari, S. Bread waste valorization: A review of sustainability aspects and challenges. Front. Sustain. Food Syst. 2024, 8, 1334801. [Google Scholar] [CrossRef]

- Iakovlieva, M. Food Waste in Bakeries—Quantities, Causes and Treatment. Master’s Thesis, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2021. Available online: https://stud.epsilon.slu.se/17180/ (accessed on 6 March 2025).

- European Commission. Brief on Food Waste in the European Union. Knowledge for Policy. European Commission. 2020. Available online: https://knowledge4policy.ec.europa.eu/publication/brief-food-waste-european-union_en (accessed on 6 March 2025).

- Brancoli, P.; Bolton, K.; Eriksson, M. Environmental impacts of waste management and valorisation pathways for surplus bread in Sweden. Waste Manag. 2020, 117, 136–145. [Google Scholar] [CrossRef]

- Statista. Worldwide Beer Production 2022. Available online: https://www.statista.com/statistics/270275/worldwide-beerproduction/ (accessed on 6 March 2025).

- Marcos, A.; Serra-Majem, L.; Pérez-Jiménez, F.; Pascual, V.; Tinahones, F.J.; Estruch, R. Moderate Consumption of Beer and Its Effects on Cardiovascular and Metabolic Health: An Updated Review of Recent Scientific Evidence. Nutrients 2021, 13, 879. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Gao, X. Research progress on the antioxidant biological activity of beer and strategy for applications. Trends Food Sci. Technol. 2021, 110, 754–764. [Google Scholar] [CrossRef]

- Ceccaroni, D.; Sileoni, V.; Marconi, O.; De Francesco, G.; Lee, E.G.; Perretti, G. Specialty Rice Malt Optimization and Improvement of Rice Malt Beer Aspect and Aroma. LWT 2019, 99, 299–305. [Google Scholar] [CrossRef]

- Martinez-Gomez, A.; Caballero, I.; Blanco, C.A. Phenols and Melanoidins as Natural Antioxidants in Beer. Structure, Reactivity and Antioxidant Activity. Biomolecules 2020, 10, 400. [Google Scholar] [CrossRef]

- Krofta, K.; Mikyška, A.; Hašková, D. Antioxidant Characteristics of Hops and Hop Products. J. Inst. Brew. 2008, 114, 160–166. [Google Scholar] [CrossRef]

- Habschied, K.; Košir, I.J.; Krstanović, V.; Kumrić, G.; Mastanjević, K. Beer Polyphenols—Bitterness, Astringency, and Off-Flavors. Beverages 2021, 7, 38. [Google Scholar] [CrossRef]

- Šibalić, D.; Planinić, M.; Jurić, A.; Bucić-Kojić, A.; Tišma, M. Analysis of Phenolic Compounds in Beer: From Raw Materials to the Final Product. Chem. Pap. 2021, 75, 67–76. [Google Scholar] [CrossRef]

- Mikyška, A.; Jurková, M.; Horák, T.; Slabý, M. Study of the Influence of Hop Polyphenols on the Sensory Stability of Lager Beer. Eur. Food Res. Technol. 2022, 248, 533–542. [Google Scholar] [CrossRef]

- Almeida, J.; Thomas, J.; Murphy, K.; Griffiths, R.; Bengtsson, J. Circular Brew: Life Cycle Assessment of Waste Bread-Based Beer. In Proceedings of the 11th International Conference Life Cycle Assessment of FOOD, Bangkok, Thailand, 17–19 October 2018; Beer Style Guidelines. Available online: https://www.researchgate.net/publication/328576546_Circular_Brew_life_cycle_assessment_of_waste_bread-based_beer (accessed on 9 May 2025).

- Narisetty, V.; Cox, R.; Willoughby, N.; Aktas, E.; Tiwari, B.; Singh Matharu, A.; Salonitis, K.; Kumar, V. Recycling Bread Waste into Chemical Building Blocks Using a Circular Biorefining Approach. Sustain. Energy Fuels 2021, 5, 4842–4849. [Google Scholar] [CrossRef] [PubMed]

- McDonagh, K.; Zhang, R.; Merkouri, L.-P.; Arnell, M.; Hepworth, A.; Duyar, M.S.; Short, M. Lowering the Carbon Footprint of Beer through Waste Breadcrumb Substitution for Malted Barley: Life Cycle Assessment and Experimental Study. Clean. Environ. Syst. 2024, 15, 100241. [Google Scholar] [CrossRef]

- Dall’Acqua, L.; Silva, E.K.; Betim Cazarin, C.B.; Maróstica Junior, M.R. Understanding the Utilization of Wasted Bread as a Brewing Adjunct for Producing a Sustainable Wheat Craft Beer. Microorganisms 2025, 13, 66. [Google Scholar] [CrossRef] [PubMed]

- Martin-Lobera, C.; Aranda, F.; Lozano-Martinez, P.; Caballero, I.; Blanco, C.A. Bread as a Valuable Raw Material in Craft Ale Beer Brewing. Foods 2022, 11, 3013. [Google Scholar] [CrossRef]

- Magalhães, L.M.; Santos, F.; Segundo, M.A.; Reis, S.; Lima, J.L.F.C. Rapid microplate high-throughput methodology for assessment of Folin-Ciocalteu reducing capacity. Talanta 2010, 83, 441–447. [Google Scholar] [CrossRef]

- Abderrahim, F.; Arribas, S.M.; Gonzalez, M.C.; Condezo-Hoyos, L. Rapid high-throughput assay to assess scavenging capacity index using DPPH. Food Chem. 2013, 141, 788–794. [Google Scholar] [CrossRef]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Liu, M.; Zeng, Z.; Xiong, B. Preparation of novel solid-phase microextraction fibers by sol-gel technology for headspace solid-phase microextraction-gas chromatographic analysis of aroma compounds in beer. J. Chromatogr. A 2005, 1065, 287–299. [Google Scholar] [CrossRef]

- He, L.; Gao, Y.; Zhao, L. Online coupling of bubbling extraction with gas chromatography-mass spectrometry for rapid quantitative analysis of volatiles in beer. J. Chromatogr. A 2022, 1665, 462800. [Google Scholar] [CrossRef] [PubMed]

- Habschied, K.; Ćosić, I.; Šarić, G.; Krstanović, V.; Mastanjević, K. Sensory Analysis Coupled with Gas Chromatography/Mass Spectrometry Analysis in Craft Beer Evaluation. Fermentation 2023, 9, 747. [Google Scholar] [CrossRef]

- Pai, T.V.; Sawant, S.Y.; Ghatak, A.A.; Chaturvedi, P.A.; Gupte, A.M.; Desai, N.S. Characterization of Indian beers: Chemical composition and antioxidant potential. J. Food Sci. Technol. 2015, 52, 1414–1423. [Google Scholar] [CrossRef]

- Silva, S.; Oliveira, A.I.; Cruz, A.; Oliveira, R.F.; Almeida, R.; Pinho, C. Physicochemical Properties and Antioxidant Activity of Portuguese Craft Beers and Raw Materials. Molecules 2022, 27, 8007. [Google Scholar] [CrossRef] [PubMed]

- Beer Style Guidelines. Available online: https://cdn.brewersassociation.org/wp-content/uploads/2023/07/10124402/2023_BA_Beer_Style_Guidelines-updated.pdf (accessed on 6 March 2025).

- Byeon, Y.S.; Lim, S.-T.; Kim, H.-J.; Kwak, H.S.; Kim, S.S. Quality Characteristics of Wheat Malts with Different Country of Origin and Their Effect on Beer Brewing. J. Food Qual. 2021, 2021, 2146620. [Google Scholar] [CrossRef]

- da Costa Fulgêncio, A.C.; Resende, G.A.P.; Teixeira, M.C.F.; Botelho, B.G.; Sena, M.M. Determination of Alcohol Content in Beers of Different Styles Based on Portable Near-Infrared Spectroscopy and Multivariate Calibration. Food Anal. Methods 2022, 15, 307–316. [Google Scholar] [CrossRef]

- Nardini, M. An Overview of Bioactive Phenolic Molecules and Antioxidant Properties of Beer: Emerging Trends. Molecules 2023, 28, 3221. [Google Scholar] [CrossRef]

- Habschied, K.; Lončarić, A.; Mastanjević, K. Screening of Polyphenols and Antioxidative Activity in Industrial Beers. Foods 2020, 9, 238. [Google Scholar] [CrossRef]

- Bertuzzi, T.; Mulazzi, A.; Rastelli, S.; Donadini, G.; Rossi, F.; Spigno, G. Targeted healthy compounds in small and large-scale brewed beers. Food Chem. 2020, 310, 125935. [Google Scholar] [CrossRef]

- Nardini, M.; Foddai, M.S. Phenolics Profile and Antioxidant Activity of Special Beers. Molecules 2020, 25, 2466. [Google Scholar] [CrossRef]

- Piazzon, A.; Forte, M.; Nardini, M. Characterization of phenolics content and antioxidant activity of different beer types. J. Agric. Food Chem. 2010, 58, 10677–10683. [Google Scholar] [CrossRef] [PubMed]

- Iannone, M.; Ovidi, E.; Vitalini, S.; Laghezza Masci, V.; Marianelli, A.; Iriti, M.; Tiezzi, A.; Garzoli, S. From Hops to Craft Beers: Production Process, VOCs Profile Characterization, Total Polyphenol and Flavonoid Content Determination and Antioxidant Activity Evaluation. Processes 2022, 10, 517. [Google Scholar] [CrossRef]

- Adebo, O.A.; Medina-Meza, I.G. Impact of Fermentation on the Phenolic Compounds and Antioxidant Activity of Whole Cereal Grains: A Mini Review. Molecules 2020, 25, 927. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, T.; Zhang, Y.; Chen, Y.; Ge, X.; Sui, W.; Zhu, Q.; Geng, J.; Zhang, M. Release of bound polyphenols from wheat bran soluble dietary fiber during simulated gastrointestinal digestion and colonic fermentation in vitro. Food Chem. 2023, 402, 134111. [Google Scholar] [CrossRef]

- Mitić, S.S.; Paunović, D.Đ.; Pavlović, A.N.; Tošić, S.B.; Stojković, M.B.; Mitić, M.N. Phenolic Profiles and Total Antioxidant Capacity of Marketed Beers in Serbia. Int. J. Food Prop. 2014, 17, 908–922. [Google Scholar] [CrossRef]

- Hu, X.; Jin, Y.; Du, J. Differences in protein content and foaming properties of cloudy beers based on wheat malt content. J. Inst. Brew. 2019, 125, 235–241. [Google Scholar] [CrossRef]

- Devolli, A.; Dara, F.; Stafasani, M.; Shahinasi, E.; Kodra, M. The Influence of Protein Content on Beer Quality and Colloidal Stability. Int. J. Innov. Approaches Agric. Res. 2018, 2, 391–407. [Google Scholar] [CrossRef]

- Mastanjević, K.; Krstanović, V.; Lukinac, J.; Jukić, M.; Vulin, Z.; Mastanjević, K. Beer–The Importance of Colloidal Stability (Non-Biological Haze). Fermentation 2018, 4, 91. [Google Scholar] [CrossRef]

- Wang, S.-H.; Huang, S.-Y. Perturbation theory for cross data matrix-based PCA. J. Multivar. Anal. 2022, 190, 104960. [Google Scholar] [CrossRef]

- Gorinstein, S.; Caspi, A.; Libman, I.; Leontowicz, H.; Leontowicz, M.; Tashma, Z.; Katrich, E.; Jastrzebski, Z.; Trakhtenberg, S. Bioactivity of beer and its influence on human metabolism. Int. J. Food Sci. Nutr. 2007, 58, 94–107. [Google Scholar] [CrossRef]

- Ferreira, I.M.; Freitas, F.; Pinheiro, S.; Mourão, M.F.; Guido, L.F.; Gomes da Silva, M. Impact of temperature during beer storage on beer chemical profile. LWT 2022, 154, 112688. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.; Dong, G.; Bian, M.; Liu, X.; Dong, X.; Xia, T. Multi-omics study revealed the genetic basis of beer flavor quality in yeast. LWT 2022, 168, 113932. [Google Scholar] [CrossRef]

- Giannetti, V.; Boccacci Mariani, M.; Torrelli, P.; Marini, F. Flavour component analysis by HS-SPME/GC–MS and chemometric modeling to characterize Pilsner-style Lager craft beers. Microchem. J. 2019, 149, 103991. [Google Scholar] [CrossRef]

- da Silva, G.C.; da Silva, A.A.S.; da Silva, L.S.N.; Godoy, R.L.O.; Nogueira, L.C.; Quitério, S.L.; Raices, R.S.L. Method development by GC–ECD and HS-SPME–GC–MS for beer volatile analysis. Food Chem. 2015, 167, 71–77. [Google Scholar] [CrossRef]

- Gao, Y.-F.; Li, X.-Y.; Wang, Q.-L.; Li, Z.-H.; Chi, S.-X.; Dong, Y.; Guo, L.; Zhang, Y.-H. Discrimination and quantification of volatile compounds in beer by FTIR combined with machine learning approaches. Food Chem. X 2024, 22, 101300. [Google Scholar] [CrossRef]

- Coelho, P.; Prista, C.; Sousa, I. Brewing Mainly from Stale Bread: A Pale Ale Case Study. Beverages 2024, 10, 23. [Google Scholar] [CrossRef]

| Raw Material | American Lager Beer | IPA Beer | Bavarian Weiss Beer |

|---|---|---|---|

| Grain malt and flakes (% by weight) | Pale Ale EBC 7 (Castle Malting, Beloeil, Belgium) (85%) | Pilsner EBC 3 (Weyermann, Bamberg, Germany) (81%) | Pilsner EBC 3 (Weyermann, Bamberg, Germany) (50%) |

| Corn flakes EBC 3.5 (Castle Malting, Beloeil, Belgium) (10%) | Munich Type I EBC 12 (Weyermann, Bamberg, Germany) (15%) | Pale Wheat malt EBC 5 (Weyermann, Bamberg, Germany) (50%) | |

| Rice flakes EBC 2.5 (Castle Malting, Beloeil, Belgium) (5%) | Cara amber EBC 60 (Weyermann, Bamberg, Germany) (4%) | ||

| Pelleted hops | Saaz 3.80% a.a. (Laguilhoat, Fuenlabrada, Spain) | Cascade 6.80% a.a. (Laguilhoat, Fuenlabrada, Spain) | Magnum 13.10% a.a. (Laguilhoat, Fuenlabrada, Spain) |

| Citra 12.70% a.a. (Laguilhoat, Fuenlabrada, Spain) | |||

| Bread | Whole wheat | Whole wheat | Whole wheat |

| Yeast | Saflager S-23 (Fermentis, Marcq-en-Baroeul, France) | Safale US-05 (Fermentis, Marcq-en-Baroeul, France) | Safbrew W-06 (Fermentis, Marcq-en-Baroeul, France) |

| Safale F-2 (Fermentis, Marcq-en-Baroeul, France) | Safale F-2 (Fermentis, Marcq-en-Baroeul, France) | Safale F-2 (Fermentis, Marcq-en-Baroeul, France) | |

| Water | Monte Pinos (Carbónicas Navalpotro S.A, Almazán, Spain) | ||

| Sample | Turbidity (NTU) | pH | Acidity (% Lactic Acid) | ABV (%) | Real Extract (%) |

|---|---|---|---|---|---|

| LA1 | 620.33 ± 52.29 CD | 3.92 ± 0.01 D | 0.03 ± 0.02 A | 5.52 ± 0.10 B | 5.65 ± 0.24 DE |

| LA2 | 684.33 ± 16.01 D | 3.94 ± 0.01 D | 0.04 ± 0.01 A | 5.56 ± 0.04 B | 5.65 ± 0.13 DE |

| LAB1 | 542.00 ± 18.73 DE | 4.16 ± 0.01 BC | 0.04 ± 0.01 A | 5.25 ± 0.10 B | 6.15 ± 0.21 BC |

| LAB2 | 462.00 ± 9.00 E | 4.12 ± 0.01 C | 0.04 ± 0.01 A | 5.43 ± 0.15 B | 5.73 ± 0.30 CD |

| IPA1 | 675.67 ± 26.5 D | 4.42 ± 0.02 A | 0.04 ± 0.01 A | 6.98 ± 0.13 A | 6.74 ± 0.16 A |

| IPA2 | 627.33 ± 29.19 CD | 4.31 ± 0.09 AB | 0.04 ± 0.01 A | 7.00 ± 0.10 A | 6.48 ± 0.09 AB |

| IPAB1 | 620.00 ± 5.29 CD | 4.31 ± 0.02 AB | 0.04 ± 0.01 A | 6.70 ± 0.22 A | 5.93 ± 0.13 CD |

| IPAB2 | 671.67 ± 37.07 D | 4.20 ± 0.04 BC | 0.04 ± 0.01 A | 6.72 ± 0.19 A | 5.99 ± 0.15 CD |

| W1 | 1023.67 ± 39.70 A | 3.85 ± 0.03 D | 0.05 ± 0.01 A | 5.37 ± 0.15 B | 5.46 ± 0.11 DEF |

| W2 | 1017.33 ± 30.35 A | 3.84 ± 0.02 D | 0.05 ± 0.01 A | 5.23 ± 0.15 B | 5.21 ± 0.16 EF |

| WB1 | 807.67 ± 27.50 B | 3.78 ± 0.01 D | 0.05 ± 0.01 A | 5.22 ± 0.10 B | 5.17 ± 0.12 EF |

| WB2 | 867.67 ± 16.44 B | 3.82 ± 0.01 D | 0.05 ± 0.01 A | 5.40 ± 0.10 B | 5.06 ± 0.05 F |

| Sample | Isoamyl Acetate | Butyl Alcohol | Hexanoic Acid Ethyl Ester | Glycine Benzoil | Phenylethyl Alcohol | Ethyl Octanoate | Phenethyl Acetate | Decanoic Acid Ethyl Ester |

|---|---|---|---|---|---|---|---|---|

| Retention Time (min.) | 5.33 | 7.39 | 7.55 | 9.23 | 9.53 | 10.87 | 11.84 | 13.92 |

| LA1 | 54.00 | 3.09 | 8.78 | 1.19 | 12.18 | 15.79 | 1.78 | 3.19 |

| LA2 | 52.90 | 2.89 | 8.99 | 1.56 | 13.77 | 14.31 | 1.63 | 3.96 |

| LAB1 | 24.19 | 2.17 | 4.93 | 5.70 | 47.54 | 12.57 | 1.89 | 0.99 |

| LAB2 | 22.98 | 1.80 | 5.01 | 5.45 | 49.42 | 12.87 | 1.80 | 0.67 |

| IPA1 | 41.19 | 4.70 | 5.42 | 5.60 | 32.85 | 5.60 | 2.58 | 2.06 |

| IPA2 | 40.97 | 3.94 | 6.05 | 6.50 | 29.54 | 7.84 | 2.78 | 2.38 |

| IPAB1 | 25.73 | 2.21 | 3.07 | 6.18 | 47.69 | 10.75 | 2.06 | 2.31 |

| IPAB2 | 27.72 | 1.89 | 4.12 | 5.34 | 46.97 | 10.86 | 1.33 | 1.77 |

| W1 | 29.94 | 2.29 | 4.95 | 4.54 | 49.12 | 6.75 | 1.78 | 0.64 |

| W2 | 28.23 | 3.02 | 4.00 | 4.87 | 52.43 | 5.55 | 1.34 | 0.56 |

| WB1 | 26.68 | 1.67 | 1.52 | 1.75 | 62.03 | 4.47 | 1.52 | 0.36 |

| WB2 | 26.14 | 1.08 | 1.81 | 2.33 | 63.15 | 3.98 | 1.17 | 0.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martin-Lobera, C.; Fermoso, J.; Blanco, C.A.; Caballero, I. Brewing with Whole Wheat Bread to Produce Different Beer Styles. Foods 2025, 14, 1697. https://doi.org/10.3390/foods14101697

Martin-Lobera C, Fermoso J, Blanco CA, Caballero I. Brewing with Whole Wheat Bread to Produce Different Beer Styles. Foods. 2025; 14(10):1697. https://doi.org/10.3390/foods14101697

Chicago/Turabian StyleMartin-Lobera, Carlos, Jose Fermoso, Carlos A. Blanco, and Isabel Caballero. 2025. "Brewing with Whole Wheat Bread to Produce Different Beer Styles" Foods 14, no. 10: 1697. https://doi.org/10.3390/foods14101697

APA StyleMartin-Lobera, C., Fermoso, J., Blanco, C. A., & Caballero, I. (2025). Brewing with Whole Wheat Bread to Produce Different Beer Styles. Foods, 14(10), 1697. https://doi.org/10.3390/foods14101697