A Review on Replacing Food Packaging Plastics with Nature-Inspired Bio-Based Materials

Abstract

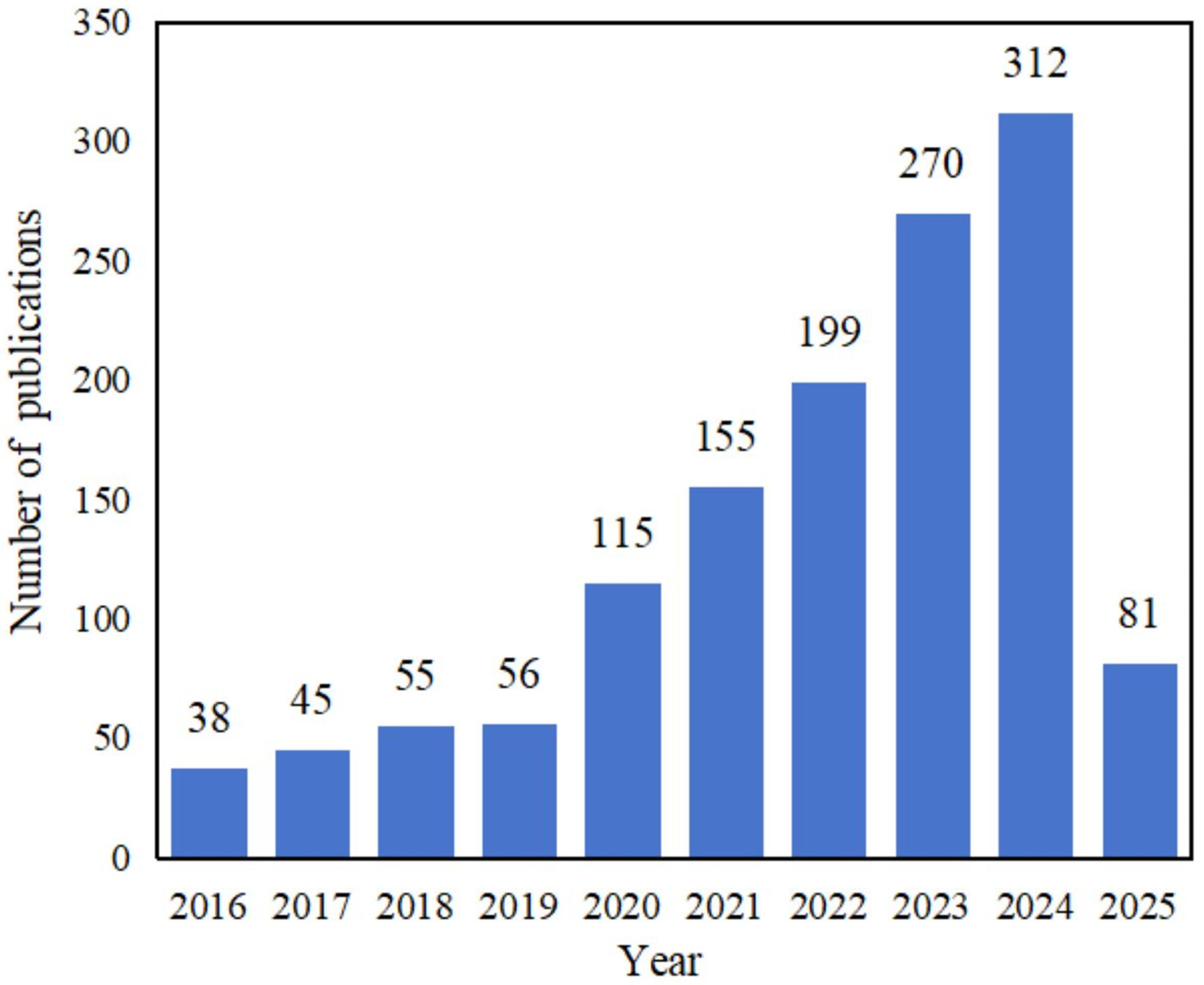

1. Introduction

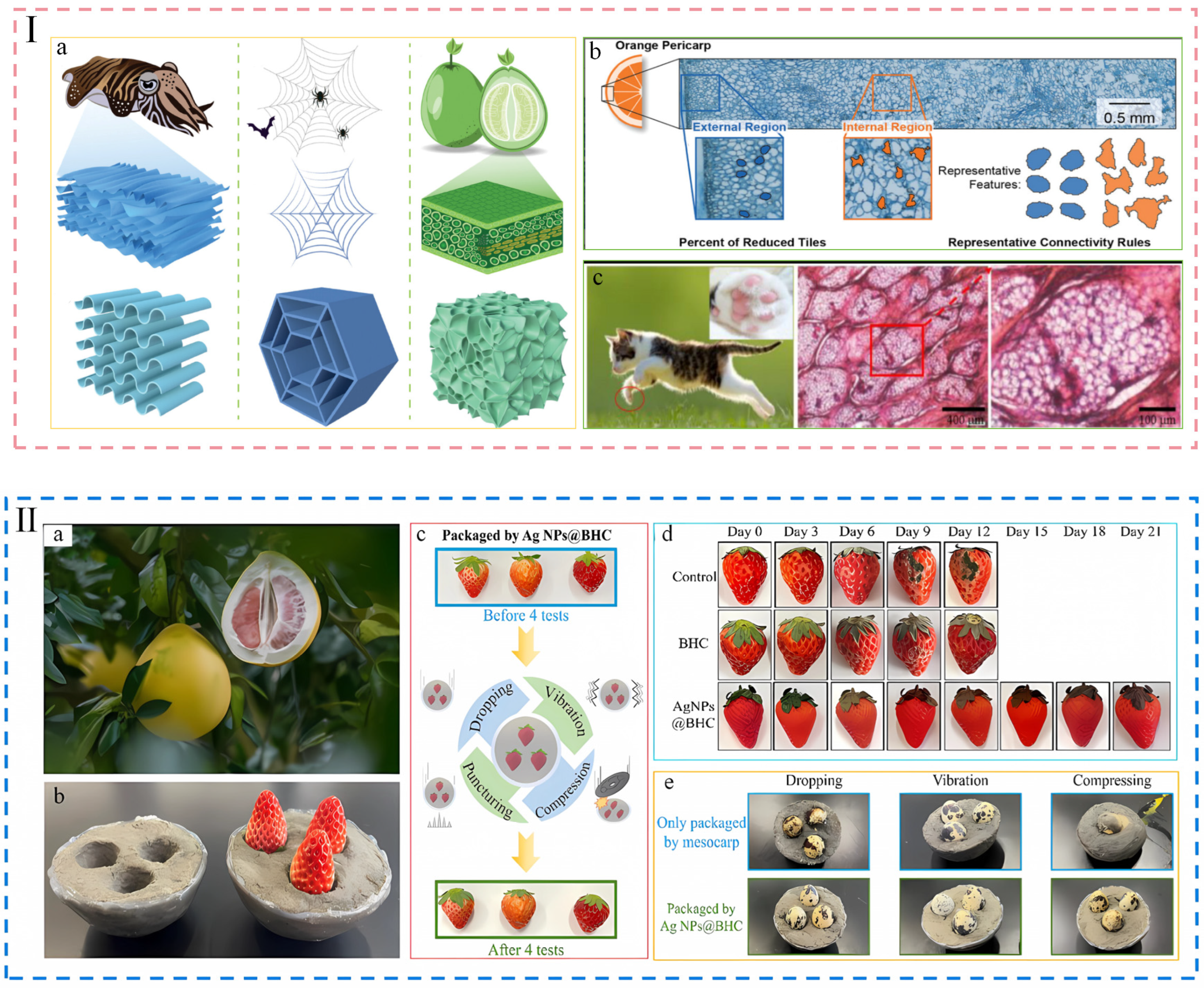

2. Anti-Mechanical Damage Packaging

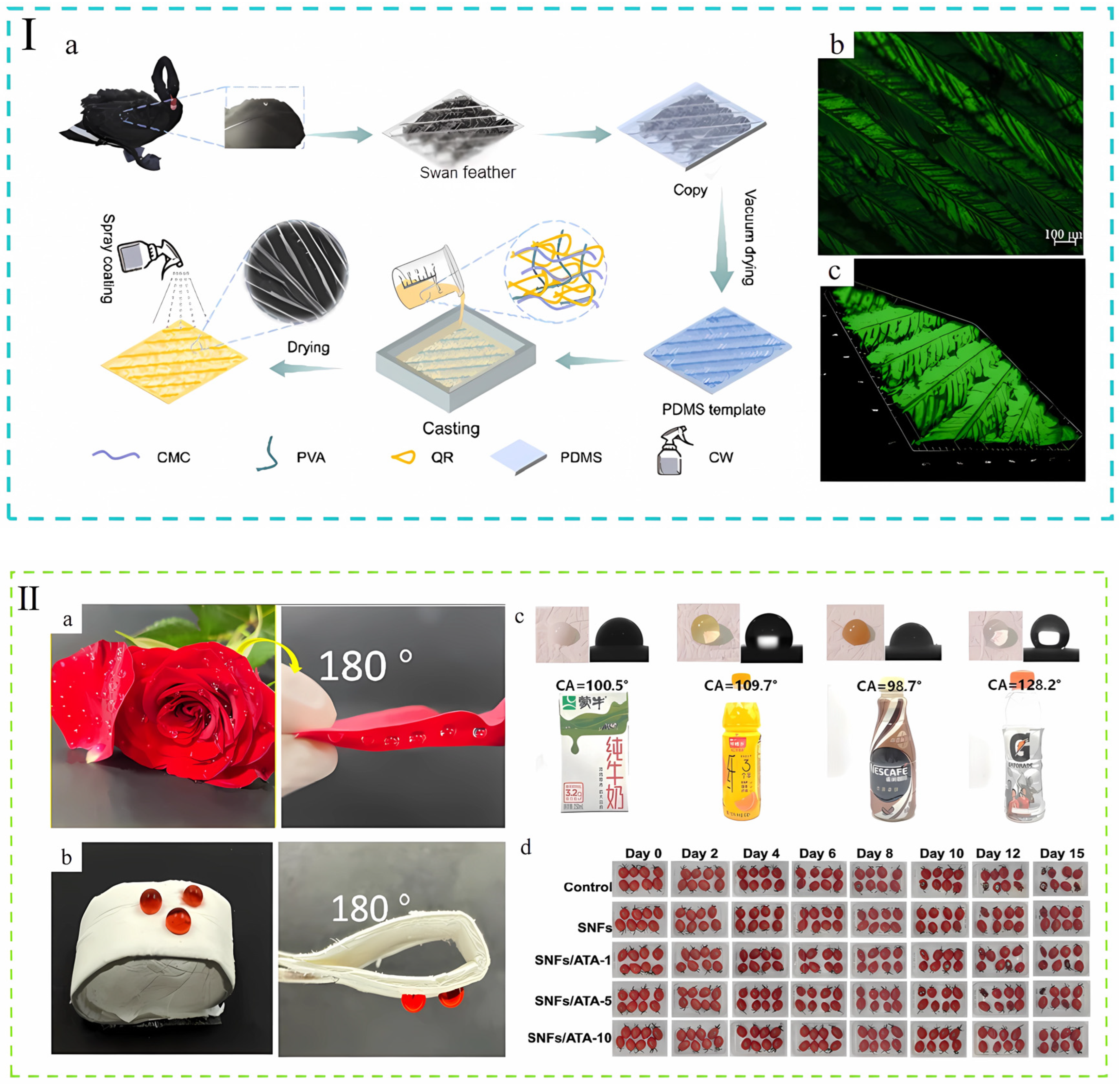

3. Application of Superhydrophobicity in Food Packaging

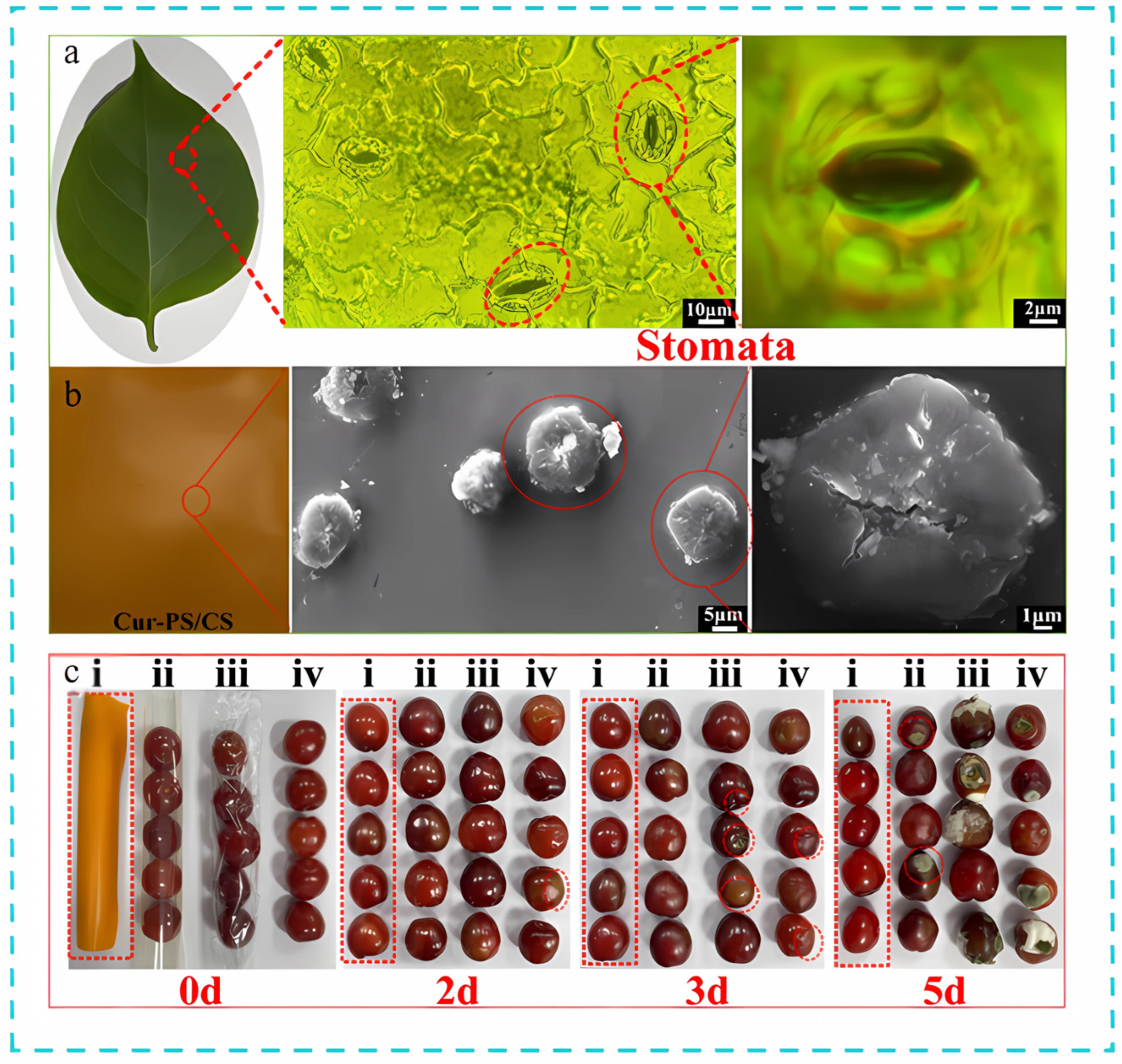

3.1. Superhydrophobic-Preservation

| Bionic Object | Main Material | Main Conclusion | References |

|---|---|---|---|

| Swan feather | Carboxymethyl cellulose, polyvinyl alcohol, Brazilian carnauba wax | The film has a water contact angle of 138°, similar to feathers, and extends pork shelf life to 5 days, better than the 2 days of regular packaging. | [48] |

| Rose petal | Starch nanofiber membrane, acylated tannins | The film had a water contact angle of approximately 134.1° and was also able to extend the shelf life of cherry tomatoes to 15 days compared to 8 days for the control. | [49] |

| Duck feather | Carboxymethyl cellulose, gelatin, candelilla wax | The film features a water contact angle of 142.57° and increases the shelf life of beef to 5 days, providing an additional 2 days compared to standard polyethylene packaging. | [56] |

| Lotus leaf | Konjac glucomannan, polylactic acid, tea polyphenols | The fiber boasts a water contact angle exceeding 150°, enabling self-cleaning properties and prolonging the shelf life of cabbage to 6 days and potatoes to 10 days. | [57] |

| Lotus leaf | Nanoparticles of chitosan, sodium alginate, and zeinolysin | The water contact angle of the outer layer of the membrane exceeds 130° and significantly reduces the rate of deterioration of apple rosettes. | [58] |

| Lotus leaf | Soybean polysaccharide, carnauba wax | The film has a water contact angle of 157.2°, and freshness tests have shown that grapes packed in this film can still be eaten at 7 days. | [59] |

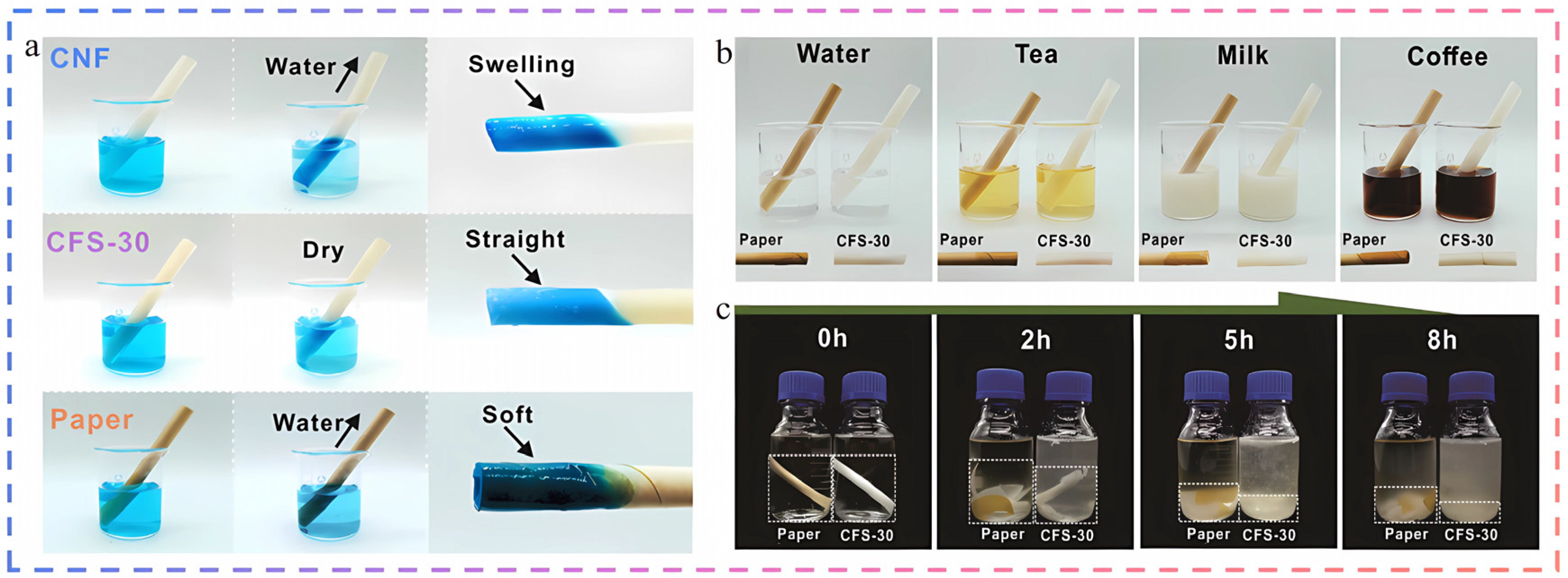

| Lotus leaf | Nano-silica, chitosan, acrylic acid, rosin | Paper with this coating has a water contact angle of 155.8° and an oil contact angle of 92°. In a 6 h storage test, the residue rate of water/soda/tea/milk/coffee was only 0.5–2.0%, significantly lower than that of commercial paper cups, which effectively reduces liquid residue. | [60] |

| Mussel | Chitosan, curcumin, hydrophobic SiO2 | The composite film, exhibiting a water contact angle of 130.43°, extends the shelf life of pork by two days when stored at both 25 °C and 4 °C. | [61] |

| Taro leaf | Alkyl ketene dimer, cellulose nanofiber, cellulose powder, TiO2 nanoparticles | The superhydrophobic coating creates a waterproof barrier by boosting the surface hydrophobicity angle (e.g., filter paper up to 173°), keeping tomatoes fresh for 14 days, while uncoated ones mold. | [62] |

3.2. Superhydrophobic—Paper Straws

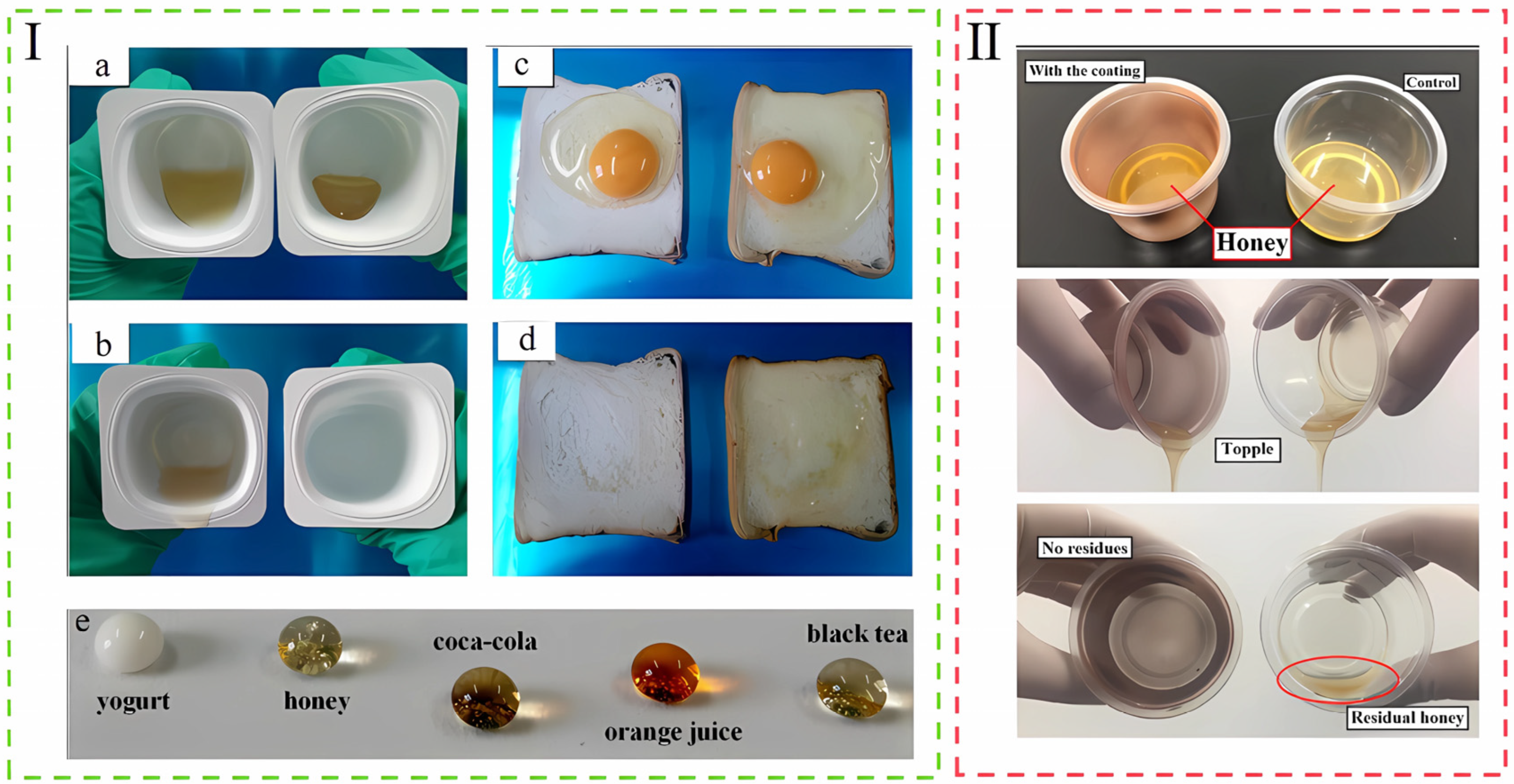

3.3. Superhydrophobicity—Reducing Food Waste

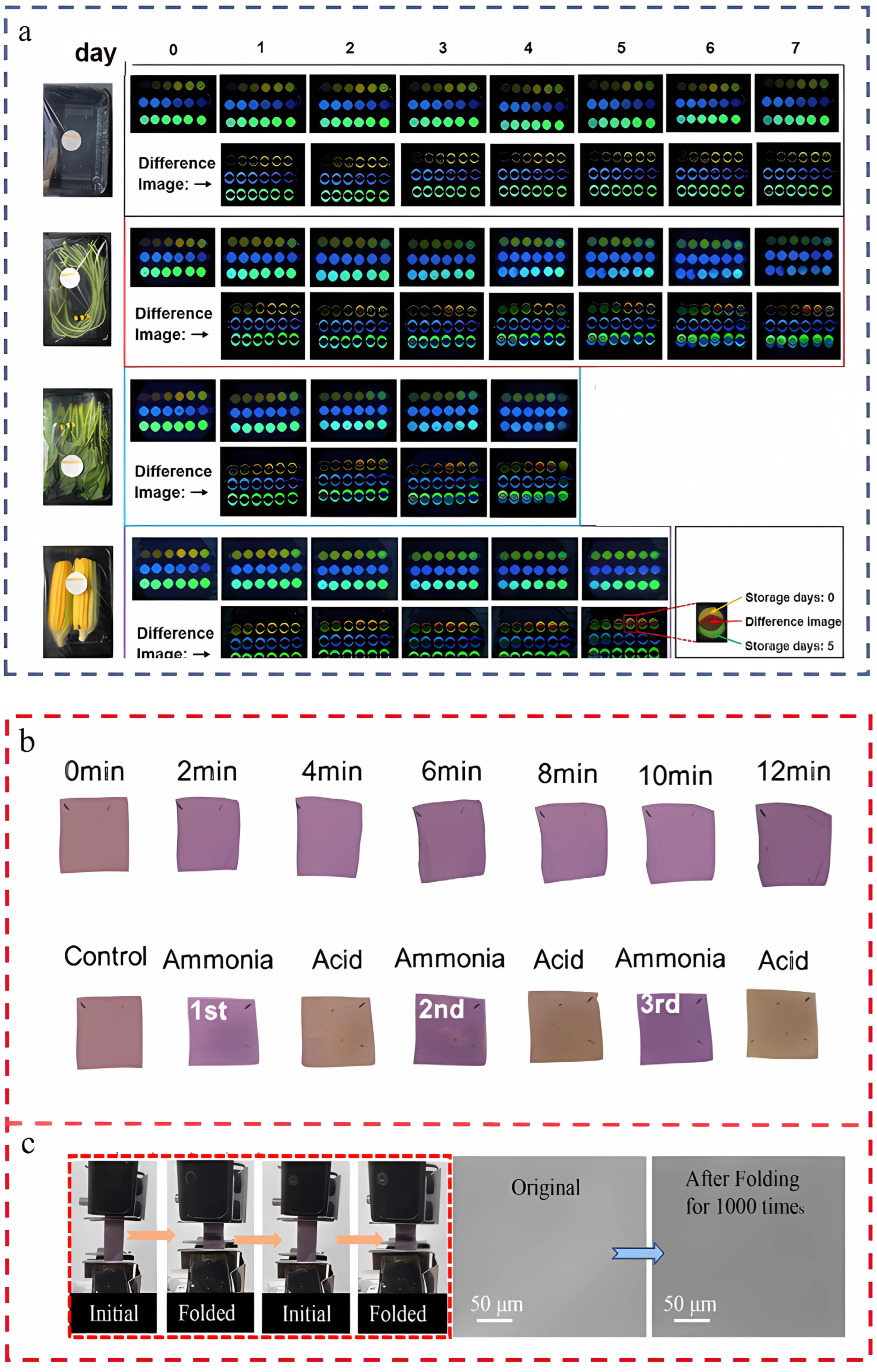

4. Air-Conditioned Packaging

5. Controlled Release Packaging

| Main Material | Response Object | Main Conclusion | References |

|---|---|---|---|

| Thymol, ZIF-8,κ-carrageenan, zein | pH | By 36 h, the cumulative release of thymol was approximately 92% at pH 4.5 and 39.3% at pH 7.4. When practically applied to freshness, the shelf life of blueberries was extended by 9 days. | [78] |

| Starch, polyvinyl alcohol, essential oil of clove, Trichoderma mycelium | pH | Trichoderma mycelium film reaches release equilibrium 33 h later than ordinary films. The film keeps shrimp quality stable for 8 days. | [79] |

| Gelatin, beta-cyclodextrin, oregano essential oil | pH | Tested at 105 °C, the cumulative release of essential oils in 12 h was only 15%, much lower than the unencapsulated 60%. This film can extend the shelf life of grass carp filets by 2–3 days when refrigerated at 4 °C. | [80] |

| Corn Alcohol Soluble Protein/β-Cyclodextrin-Metal–Organic Framework/carvacrol | humidity | Thymol-loaded ZIF-8-based films exhibited 96.3 ± 1.5% cumulative release at 100% RH (36 h) vs. 12.0 ± 0.8% at 43% RH, enabling 7-day preservation of strawberries at 21 °C/50% RH (vs. 3-day spoilage in controls). | [81] |

| Nanofiber film, zein, polyethylene oxide, thyme essential oil, sodium bicarbonate, citric acid | humidity | The film maintained 64% thymol release at 60 h under high humidity (vs. 25% under low humidity), sustaining superior strawberry preservation quality over 6 days compared to control films. | [82] |

| CeCDs, folic acid, ZnCl2 | light | The hydrogel releases a high concentration of Zn2+ for more than 15 days, resulting in a sustained antimicrobial effect that effectively extends shelf life and ensures food quality by controlling microbial contamination when applied to cabbages, apples, and cooked meats. | [83] |

| Polyvinylidene fluoride, rose Bengal, N-N-dimethylformamide | light | Rose Bengal generates reactive oxygen species for sterilization when exposed to light and stabilizes the encapsulation to avoid reactive oxygen species leakage in the absence of light; the film extends the shelf life of pork at 4 °C by 3 days. | [84] |

| Polylactic acid, lemon essential oil, polyvinyl alcohol, poly(N-isopropylacrylamide) | temperature | The release rate of lemon essential oil was low at 20 °C for 24 h, and the release rate increased to 47.16% at 40 °C. In strawberry preservation experiments at 25 °C/80% RH and 35 °C/80% RH, the decay rate was significantly lower than the control. | [85] |

| Tea polyphenol, chitosan, polyaspartic acid, polyvinyl alcohol | Enzyme and pH | The nanofiber film achieved 56.22% cumulative release of lemon essential oil at pH 5.0 over 120 h, with a 25.31% enhancement in the presence of protease (1 mg/mL), and exhibited complete suppression of strawberry mildew growth for 6 days, significantly exceeding the 4-day mildew onset observed in the control group. | [86] |

6. Packaging with Smart Indicator

7. Self-Healing Packaging

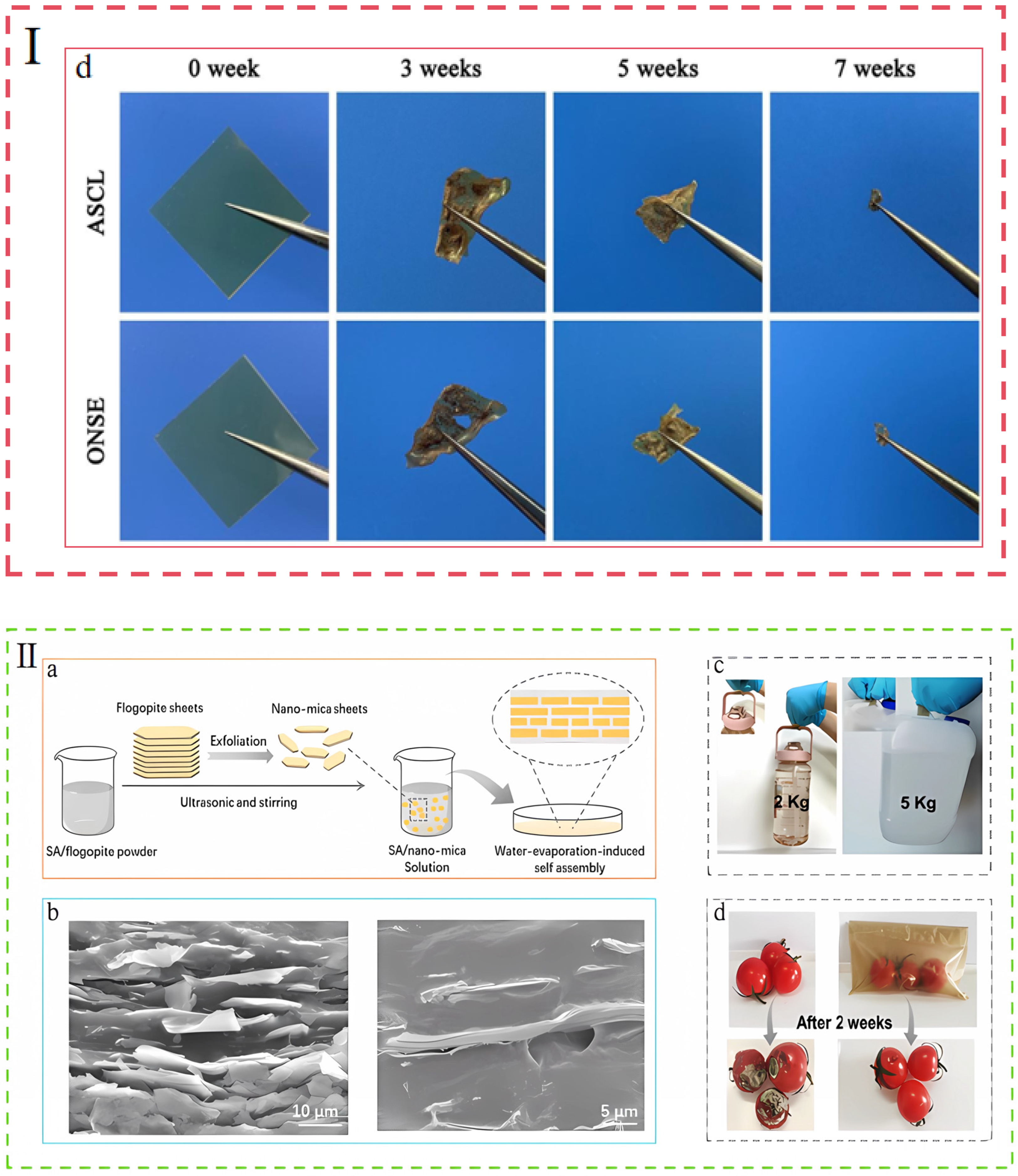

8. High-Strength Food Packaging

| Main Material | Bionic Object | Main Conclusion | References |

|---|---|---|---|

| Polylactic acid-coated mica nanosheets | Nacre | The film’s tensile strength saw a notable increase to 97 MPa, marking an 86.5% enhancement. The Young’s modulus also rose to 8 GPa, representing a 116% improvement. Additionally, its toughness climbed to 1.5 MJ/m3, a 25% boost, surpassing that of pure polylactic acid film by a considerable margin. | [118] |

| Oxidized nanocellulose, silver nanoparticles, MXene | Nacre | The film has a Young’s modulus of 4.4 GPa, which is 6.2 times higher than that of polyethylene, and a tensile strength that is 17.7 times higher, capable of supporting a weight of 1 kg, and is foldable and flexible. | [121] |

| Polypropylene carbonate, cellulose nanocrystals | Pearl layer | The maximum mechanical strength of the composite film was 12.6 MPa in the longitudinal direction, while the maximum tensile strength in the cross-section reached 9.1 MPa. | [122] |

| Catechol-functionalized chitosanPolyvinyl Alcohol | Mussel | The composite film exhibits a maximum tensile strength of 45.2 MPa and an elongation at break of 153%, representing an increase of 46.3% and 25.4% compared to pure polyethylene film, respectively. | [123] |

| Pullulan starch nanosheets | Vein network | The composite film demonstrates enhanced tensile strength, Young’s modulus, and toughness values of 51.05 MPa, 2.37 GPa, and 69.65 MJ/m3, respectively. These values represent significant improvements of 86.11%, 30.22%, and 223.36% compared to the pure Pullulan polysaccharide film. Moreover, these properties rival or surpass the strength of commercial plastic packaging films commonly utilized in the food industry. | [124] |

| Polylactic acid composite impregnated with hydroxyapatite nanocrystalline whisker | Pea pod | The yield strength of the composite material is 71.6 MPa, an increase of 54%. The elastic modulus of 2547 MPa was increased by nearly 72%, which was better than pure polylactic acid. | [125] |

| Collagen, nano zinc oxide, anthocyanidin | Pangolins | The film exhibits excellent tensile strength (78.64 MPa) and elongation at break approaching 50%. | [126] |

| Polyvinyl alcohol, cellulose micro-, nanofibers, calcium phosphate oligomers | Bone | The tensile strength of the bionic composite film was 145.57 MPa, and the toughness was 183.1 MJ/m3. | [127] |

9. Future Outlook

9.1. Emergence of More Functional Bionic Packaging

9.2. Multimodal Nature-Inspired Bionic Cling Film Design Prospects

9.3. Combined with 3D Printing Technology

9.4. Overcoming Current Limitations

10. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Knorr, D.; Augustin, M.A. From Food to Gods to Food to Waste. Crit. Rev. Food Sci. Nutr. 2022, 64, 5379–5397. [Google Scholar] [CrossRef]

- Ishangulyyev, S.; Kim, S.; Lee, S.H. Understanding Food Loss and Waste-Why Are We Losing and Wasting Food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- Tchonkouang, R.D.; Onyeaka, H.; Miri, T. From Waste to Plate: Exploring the Impact of Food Waste Valorisation on Achieving Zero Hunger. Sustainability 2023, 15, 10571. [Google Scholar] [CrossRef]

- Brennan, L.; Francis, C.; Jenkins, E.L.; Schivinski, B.; Jackson, M.; Florence, E.; Parker, L.; Langley, S.; Lockrey, S.; Verghese, K.; et al. Consumer Perceptions of Food Packaging in Its Role in Fighting Food Waste. Sustainability 2023, 15, 1917. [Google Scholar] [CrossRef]

- Brennan, L.; Langley, S.; Verghese, K.; Lockrey, S.; Ryder, M.; Francis, C.; Phan-Le, N.T.; Hill, A. The role of packaging in fighting food waste: A systematised review of consumer perceptions of packaging. J. Clean. Prod. 2021, 281, 125276. [Google Scholar] [CrossRef]

- Navarre, N.; Mogollón, J.M.; Tukker, A.; Barbarossa, V. Recycled plastic packaging from the Dutch food sector pollutes Asian oceans. Resour. Conserv. Recycl. 2022, 185, 106508. [Google Scholar] [CrossRef]

- Muncke, J. Tackling the toxics in plastics packaging. PLoS. Biol. 2021, 19, e3000961. [Google Scholar] [CrossRef]

- Golwala, H.; Zhang, X.Y.; Iskander, S.M.; Smith, A.L. Solid waste: An overlooked source of microplastics to the environment. Sci. Total Environ. 2021, 769, 144581. [Google Scholar] [CrossRef]

- Kadac-Czapska, K.; Knez, E.; Gierszewska, M.; Olewnik-Kruszkowska, E.; Grembecka, M. Microplastics Derived from Food Packaging Waste-Their Origin and Health Risks. Materials 2023, 16, 674. [Google Scholar] [CrossRef]

- Meng, W.K.; Chen, Q.Y.; Zhang, Y.Y.; Sun, H.; Li, J.H.; Sun, H.; Liu, C.S.; Fang, M.L.; Su, G.Y. Tracking chemical feature releases from plastic food packaging to humans. J. Hazard. Mater. 2024, 480, 135897. [Google Scholar] [CrossRef]

- Teixeira, S.C.; de Oliveira, T.V.; Soares, N.D.F.; Raymundo-Pereira, P.A. Sustainable and biodegradable polymer packaging: Perspectives, challenges, and opportunities. Food Chem. 2025, 470, 142652. [Google Scholar] [CrossRef] [PubMed]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-sourced polymers as alternatives to conventional food packaging materials: A review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Halonen, N.; Pálvölgyi, P.S.; Bassani, A.; Fiorentini, C.; Nair, R.; Spigno, G.; Kordas, K. Bio-Based Smart Materials for Food Packaging and Sensors—A Review. Front. Mater. 2020, 7, 82. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Barrow, C.J.; Adhikari, B. The future of bioplastics in food packaging: An industrial perspective. Food Packag. Shelf Life 2024, 43, 101279. [Google Scholar] [CrossRef]

- Cheng, J.; Gao, R.; Zhu, Y.; Lin, Q.B. Applications of biodegradable materials in food packaging: A review. Alex. Eng. J. 2024, 91, 70–83. [Google Scholar] [CrossRef]

- Zhao, P.P.; Zheng, D.P.; Li, T.; Peng, H.Y.; He, J.Q.; Shi, J.Y.; Zhao, J.Z.; Li, P.; Zhang, W.X. Maillard reaction based chitosan-monosaccharide films and the application in fruit preservation. Food Hydrocoll. 2025, 166, 111269. [Google Scholar] [CrossRef]

- Chen, C.; Deng, S.Y.; Tian, H.X.; Yu, H.Y.; Huang, J.; Lou, X.M.; Yuan, H.B. Enhanced fresh walnut preservation using chitosan films reinforced with cinnamon essential oil and bacterial cellulose pickering emulsion. Food Hydrocoll. 2025, 165, 111267. [Google Scholar] [CrossRef]

- Li, N.N.; Jiang, D.Y.; Zhou, Z.G.; Lu, Y.Y.; Lei, Z.; Law, W.C.; Tang, C.Y. Development of carboxymethyl cellulose/starch films enriched with ZnO-NPs and anthocyanins for antimicrobial and pH-indicating food packaging. Int. J. Biol. Macromol. 2024, 282, 136814. [Google Scholar] [CrossRef]

- Jose, A.; Mathew, M.; Mathew, A.S.; Aswani, R.; Vimal, J.; Premnath, M.; Kanoth, B.P.; Reshmy, R.; Radhakrishnan, E.K. Cinnamon essential oil induced microbial stress metabolome indicates its active food packaging efficiency when incorporated into poly vinyl alcohol, engineered with zinc oxide nanoparticles and nanocellulose. Int. J. Biol. Macromol. 2024, 278, 134115. [Google Scholar] [CrossRef]

- Jiang, Z.L.; Ngai, T. Recent Advances in Chemically Modified Cellulose and Its Derivatives for Food Packaging Applications: A Review. Polymers 2022, 14, 1533. [Google Scholar] [CrossRef]

- Król, A.; Pomastowski, P.; Rafinska, K.; Railean-Plugaru, V.; Buszewski, B. Zinc oxide nanoparticles: Synthesis, antiseptic activity and toxicity mechanism. Adv. Colloid Interface Sci. 2017, 249, 37–52. [Google Scholar] [CrossRef] [PubMed]

- Stalder, T.; Zaiter, T.; El-Basset, W.; Cornu, R.; Martin, H.; Diab-Assaf, M.; Beduneau, A. Interaction and toxicity of ingested nanoparticles on the intestinal barrier. Toxicology 2022, 481, 153353. [Google Scholar] [CrossRef]

- Tao, L.N.; Shi, C.P.; Zi, Y.; Zhang, H.B.; Zhong, J.; Wang, X.C. A review on the chemical modification of alginates for food research: Chemical nature, modification methods, product types, and application. Food Hydrocoll. 2024, 147, 109338. [Google Scholar] [CrossRef]

- Lei, Z.W.; Sun, X.T.; Zhu, S.F.; Dong, K.; Liu, X.Q.; Wang, L.L.; Zhang, X.S.; Qu, L.J.; Zhang, X.J. Nature Inspired MXene-Decorated 3D Honeycomb-Fabric Architectures Toward Efficient Water Desalination and Salt Harvesting. Nano-Micro Lett. 2022, 14, 10. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.; Zhou, Z.H.; Song, Q.C.; Chen, K.Y.; Su, G.H.; Zhou, T.; Zheng, Z.; Lu, C.H.; Zhang, X.X. Ultrarobust Ti3C2Tx MXene-Based Soft Actuators via Bamboo-Inspired Mesoscale Assembly of Hybrid. ACS Nano 2020, 14, 7055–7065. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.H.; Valenzuela, C.; Zhang, X.; Yang, X.; Wang, L.; Feng, W. Light-driven dandelion-inspired microfliers. Nat. Commun. 2023, 14, 10. [Google Scholar] [CrossRef]

- Katiyar, N.K.; Goel, G.; Hawi, S.; Goel, S. Nature-inspired materials: Emerging trends and prospects. NPG Asia Mater. 2021, 13, 56. [Google Scholar] [CrossRef]

- Lin, M.H.; Fawole, O.A.; Saeys, W.; Wu, D.; Wang, J.; Opara, U.L.; Nicolai, B.; Chen, K.S. Mechanical damages and packaging methods along the fresh fruit supply chain: A review. Crit. Rev. Food Sci. Nutr. 2023, 63, 10283–10302. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Opara, U.L. Mechanical damage of fresh produce in postharvest transportation: Current status and future prospects. Trends Food Sci. Technol. 2022, 124, 195–207. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Al-Mahdouri, A. Effect on physiological properties of banana fruit based on pendulum impact test and storage. Curr. Res. Food Sci. 2023, 7, 100640. [Google Scholar] [CrossRef]

- Dagdelen, C.; Aday, M.S. The effect of simulated vibration frequency on the physico-mechanical and physicochemical properties of peach during transportation. LWT 2021, 137, 110497. [Google Scholar] [CrossRef]

- Lu, F.; Xu, F.X.; Li, Z.; Liu, Y.F.; Wang, J.W.; Zhang, L. Effect of vibration on storage quality and ethylene biosynthesis-related enzyme genes expression in harvested apple fruit. Sci. Hortic. 2019, 249, 1–6. [Google Scholar] [CrossRef]

- Fan, X.; Wang, H.; Kong, L.S.; Huang, J.R. Advanced ethylene-absorbing and cushioning depending on the 3D porous-structured fruit packaging: Toward polyurethane foam manipulation using zein and soybean oil polyol substrates. Food Res. Int. 2024, 186, 114340. [Google Scholar] [CrossRef] [PubMed]

- Ingrole, A.; Aguirre, T.G.; Fuller, L.; Donahue, S.W. Bioinspired energy absorbing material designs using additive manufacturing. J. Mech. Behav. Biomed. Mater. 2021, 119, 104518. [Google Scholar] [CrossRef]

- Siddique, S.H.; Hazell, P.J.; Wang, H.X.; Escobedo, J.P.; Ameri, A.A.H. Lessons from nature: 3D printed bio-inspired porous structures for impact energy absorption-A review. Addit. Manuf. 2022, 58, 103051. [Google Scholar] [CrossRef]

- Shi, S.S.; Han, H.B.; Yang, B.; Zhou, X.; Chen, B.Z.; Sun, Z. Compression performance of a bio-inspired locally densified aluminum honeycomb structure. Thin-Walled Struct. 2025, 209, 112927. [Google Scholar] [CrossRef]

- Li, T.T.; Zhang, C.W.; Wang, H.Y.; Shiu, B.C.; Ren, H.T.; Huo, J.L.; Lou, C.W.; Lin, J.H. Pomelo-inspired sandwich composites: Manufacturing and cushioning property. Text. Res. J. 2022, 92, 3844–3856. [Google Scholar] [CrossRef]

- Xie, Y.; Bai, H.L.; Liu, Z.H.; Chen, N.N. A Novel Bionic Structure Inspired by Luffa Sponge and Its Cushion Properties. Appl. Sci. 2020, 10, 2584. [Google Scholar] [CrossRef]

- Zhuang, Z.Q.; Qian, Z.H.; Wang, X.; Xu, X.L.; Chen, B.Y.; Song, G.S.; Liu, X.Y.; Ren, L.; Ren, L.Q. Bioinspired Structural Composite Flexible Material with High Cushion Performance. Adv. Sci. 2024, 11, 2304947. [Google Scholar] [CrossRef]

- Fox, C.; Chen, K.Y.; Antonini, M.; Magrini, T.; Daraio, C. Extracting Geometry and Topology of Orange Pericarps for the Design of Bioinspired Energy Absorbing Materials. Adv. Mater. 2024, 36, 2405567. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, Q.; Qin, F.; Xu, P.; Chen, Q.; Wang, H.; Scarpa, F.; Peng, H.-X. Hierarchical network structural composites for extraordinary energy dissipation inspired by the cat paw. Appl. Mater. Today 2021, 25, 101222. [Google Scholar] [CrossRef]

- Hu, R.Z.; Liu, L.; Liu, E.J.; Tu, J.; Yao, X.H.; Song, P.; Zhang, D.Y.; Huang, Z.H.; Chen, T. Biomimetic hierarchical composites inspired by natural pomelo peel for mechanical-damage resistance and storage of fruits. Chem. Eng. J. 2024, 485, 149853. [Google Scholar] [CrossRef]

- Hu, R.Z.; Yang, J.X.; Zhang, Z.F.; Huang, J.X.; Shen, Y.S.; Yao, X.H.; Zhang, D.Y.; Chen, T.; Fu, Y.J. An all-cellulose sponge with a nanofiller-assisted hierarchical cellular structure for fruit maintaining freshness. Int. J. Biol. Macromol. 2023, 225, 1361–1373. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Yang, J.X.; Liu, E.J.; Hu, R.Z.; Yao, X.H.; Chen, T.; Zhao, W.G.; Liu, L.; Fu, Y.J. Soft and elastic silver nanoparticle-cellulose sponge as fresh-keeping packaging to protect strawberries from physical damage and microbial invasion. Int. J. Biol. Macromol. 2022, 211, 470–480. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.L.; Kong, N.; Hou, Z.Y.; Men, L.B.; Yang, P.; Wang, Z.J. Sponge-like porous polyvinyl alcohol/chitosan-based hydrogel with integrated cushioning, pH-indicating and antibacterial functions. Int. J. Biol. Macromol. 2024, 272, 132904. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Peng, Y.; You, H.; Guan, X.Y.; Lv, J.; Yang, C. Recent Developments in the Fabrication and Application of Superhydrophobic Suraces. Chem. Rec. 2024, 24, e202400065. [Google Scholar] [CrossRef]

- Farzam, M.; Beitollahpoor, M.; Solomon, S.E.; Ashbaugh, H.S.; Pesika, N.S. Advances in the Fabrication and Characterization of Superhydrophobic Surfaces Inspired by the Lotus Leaf. Biomimetics 2022, 7, 196. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, S.; Li, Z.; Chen, L.; Mo, H.; Liu, X. Swan-feathers inspired smart-responsive sustainable carboxymethyl cellulose/polyvinyl alcohol based food packaging film for robustly integrated Intelligent and Active Packaging. Nano Today 2024, 56, 102272. [Google Scholar] [CrossRef]

- Xie, F.; Feng, X.; Wang, Z.; Zhang, D.; Chen, Q.; He, Z.; He, S.; Wang, X.; Wu, Y.; Cai, J. Bioinspired starch nanofibrous films with tunable hydrophobicity and water adhesion via tannic acid-interfacial self-assembly for food packaging. Chem. Eng. J. 2024, 496, 154113. [Google Scholar] [CrossRef]

- Gao, T.; Yuan, C.; Cui, B.; Liu, P.F.; Wu, Z.Z.; Fang, Y.S.; Lu, L. Effect of soybean peptides on structure and functional properties of soluble soybean polysaccharide edible films. Food Hydrocoll. 2025, 167, 111405. [Google Scholar] [CrossRef]

- Xu, L.J.; Chen, R.Q.; Ren, T. Fabrication of gelatin-based photodynamic food packaging with dual-antimicrobial activity for enhanced pork preservation. Food Hydrocoll. 2025, 166, 111361. [Google Scholar] [CrossRef]

- Dardari, O.; Benzaouia, M.A.; El Idrissi, A.; Channab, B.-E.; Benjellound, G.R.; El Gharrak, A.; El Ouardi, M.; El Kadib, A. Anthocyanin and thyme oil embedded carrageenan-PVA towards bioactive and pH-sensitive food-packaging materials. Int. J. Biol. Macromol. 2025, 310, 143213. [Google Scholar] [CrossRef] [PubMed]

- He, J.T.; Peng, Q.; Wang, J.J.; Deng, J.; Li, W.; Lin, Q.L.; Zhong, F.F.; Xia, X. An intelligent thymol/alizarin-loaded polycaprolactone/gelatin/zein nanofibrous film with pH-responsive and antibacterial properties for shrimp freshness monitoring and preservation. Food Chem. 2025, 471, 142812. [Google Scholar] [CrossRef]

- Wu, X.L.; Yan, X.X.; Zhang, J.W.; Wu, X.X.; Zhang, Q.; Zhang, B.Q. Intelligent films based on dual-modified starch and microencapsulated Aronia melanocarpa anthocyanins: Functionality, stability and application. Int. J. Biol. Macromol. 2024, 275, 134076. [Google Scholar] [CrossRef]

- Feng, Z.R.; Sun, P.D.; Zhao, F.Y.; Li, M.; Ju, J. Advancements and challenges in biomimetic materials for food preservation: A review. Food Chem. 2025, 463, 141119. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Jiang, L.W.; Liu, T.T.; Qin, R.R.; Xue, J.Y.; Wang, L.Y.; Ren, L.L. Duck feather inspired hydrophobic carboxymethyl cellulose/gelatin film for intelligent and active food packaging. Int. J. Biol. Macromol. 2025, 301, 140424. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.Z.; Wang, L.; Chen, X.R.; Bu, N.T.; Duan, J.; Liu, W.; Ma, C.; Pang, J. Enhancing Waterproof Food Packaging with Janus Structure: Lotus Leaf Biomimicry and Polyphenol Particle Technology for Vegetable Preservation. ACS Appl. Mater. Interfaces 2025, 17, 8248–8261. [Google Scholar] [CrossRef]

- Wei, Z.C.; Xue, W.H.; Chai, X.H.; Fan, Q.Q.; Zhu, J.X.; Wu, H. Development and preservative applications of polysaccharide-based bilayer packaging films: Enhanced functional properties through metal-phenolic network-coated zein nanoparticles and biomimetic hydrophobic surfaces. Food Hydrocoll. 2025, 160, 110726. [Google Scholar] [CrossRef]

- Ma, Z.X.; Xing, Z.Y.; Zhao, Y.; Zhang, H.B.; Xin, Q.W.; Liu, J.; Qin, M.; Ding, C.M.; Li, J.S. Lotus leaf inspired sustainable and multifunctional Janus film for food packaging. Chem. Eng. J. 2023, 457, 141279. [Google Scholar] [CrossRef]

- Lu, M.Z.; Lu, P.; Liu, S.; Peng, Y.Y.; Yang, Z.M.; Chu, Z.Z.; Hong, Z.Y.; Yang, Z.H.; Hu, Y. Chitosan/acrylic rosin-based superhydrophobic coatings inspired by Pickering emulsion template and lotus leaf surface structure for paper-based food packaging. Int. J. Biol. Macromol. 2025, 308, 142375. [Google Scholar] [CrossRef]

- Liu, T.T.; Xue, J.Y.; Qin, R.R.; Jiang, L.W. Bioinspired hydrophobic chitosan-based films for monitoring the visual freshness of pork. Food Hydrocoll. 2025, 162, 110932. [Google Scholar] [CrossRef]

- Rahman, M.M.; Zhu, L.H.; Yao, R.T.; Wang, C.; Tamer, T.M.; Habib, M.A.; Wu, M. Taro leaf inspired micro/nanocellulose-based hierarchical structural coating and its application on O/W separation and food preservation. Carbohydr. Polym. 2025, 358, 123493. [Google Scholar] [CrossRef]

- Wang, X.Z.; Xia, Q.Q.; Jing, S.S.; Li, C.; Chen, Q.Y.; Chen, B.; Pang, Z.Q.; Jiang, B.; Gan, W.T.; Chen, G.; et al. Strong, Hydrostable, and Degradable Straws Based on Cellulose-Lignin Reinforced Composites. Small 2021, 17, 2008011. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.Y.; Li, T.T.; Wu, C.E.; Zhou, D.D.; Fan, G.J.; Li, X.J. Paper-based material with hydrophobic and antimicrobial properties: Advanced packaging materials for food applications. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13373. [Google Scholar] [CrossRef]

- Qin, L.L.; Liu, Z.Q.; Liu, T.; Liu, S.J.; Zhang, J.; Wu, J.H.; Liang, X.Q. A bioinspired, strong, all-natural, superhydrophobic cellulose-based straw. Int. J. Biol. Macromol. 2022, 220, 910–919. [Google Scholar] [CrossRef]

- Li, Y.; Bi, J.R.; Wang, S.Q.; Zhang, T.; Xu, X.M.; Wang, H.T.; Cheng, S.S.; Zhu, B.W.; Tan, M.Q. Bio-inspired Edible Superhydrophobic Interface for Reducing Residual Liquid Food. J. Agric. Food Chem. 2018, 66, 2143–2150. [Google Scholar] [CrossRef]

- Liu, B.Y.; Xue, C.H.; An, Q.F.; Jia, S.T.; Xu, M.M. Fabrication of superhydrophobic coatings with edible materials for super-repelling non-Newtonian liquid foods. Chem. Eng. J. 2019, 371, 833–841. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Bi, J.R.; Wang, S.Q.; Cao, Q.P.; Li, Y.; Zhou, J.H.; Zhu, B.W. Functional food packaging for reducing residual liquid food: Thermo-resistant edible super-hydrophobic coating from coffee and beeswax. J. Colloid Interface Sci. 2019, 533, 742–749. [Google Scholar] [CrossRef]

- Zhou, Z.Q.; Ma, J.J.; Li, K.; Zhang, W.W.; Li, K.; Tu, X.H.; Liu, L.X.; Xu, J.; Zhang, H. A Plant Leaf-Mimetic Membrane with Controllable Gas Permeation for Efficient Preservation of Perishable Products. ACS Nano 2021, 15, 8742–8752. [Google Scholar] [CrossRef]

- Xie, D.H.; Huang, G.H.; Yang, M.H.; Yi, S.M.; Zheng, X.G.; Zhu, M.G.; Zhai, H.Y. Bionic modified atmosphere film Inspired by plant stomata with curcumin as controllable gas “Switches” for fruit preservation. Chem. Eng. J. 2024, 500, 156741. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, Z.L.; Lu, P.; Wu, M. Leaf porous structure Inspired packaging film for fruits preservation and monitoring CO2 concentration of package. Chem. Eng. J. 2023, 464, 142660. [Google Scholar] [CrossRef]

- Ma, J.J.; Liu, Y.P.; Xu, J.; Chen, Y.Q.; Liu, L.X.; Zhang, H. An insect lac blanket-mimetic and degradable shellac hydrogel/chitosan packaging film with controllable gas permeation for fresh-cut vegetables preservation. Int. J. Biol. Macromol. 2024, 275, 133131. [Google Scholar] [CrossRef] [PubMed]

- Peng, L.; Chen, J.; Chen, Y.; Nilghaz, A.; Yun, X.; Wan, X.; Zhan, H.; Tian, J. Eggshell-inspired heterogeneous bilayer paper window with selective gas permeability for preserving fresh produce. Chem. Eng. J. 2025, 512, 162407. [Google Scholar] [CrossRef]

- Lou, W.; Huang, Z.; Shao, Q.; Shan, Y.; Shi, D.; Chen, Z.; Zhang, J.; Yu, W.; Wang, J.; Yang, H.; et al. Recent advances in active packaging: Insights into novel functional elements, response strategies and applications for food preservation. Food Packag. Shelf Life 2025, 49, 101489. [Google Scholar] [CrossRef]

- Hou, T.M.; Ma, S.F.; Wang, F.J.; Wang, L.Q. A comprehensive review of intelligent controlled release antimicrobial packaging in food preservation. Food Sci. Biotechnol. 2023, 32, 1459–1478. [Google Scholar] [CrossRef] [PubMed]

- García-Anaya, M.C.; Sepúlveda, D.R.; Acosta-Muñiz, C.H. Contributing factors to the migration of antimicrobials in active packaging films. Food Res. Int. 2025, 200, 115514. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, B.; Zhang, W.; Zhang, L.; Zhao, H.; Wang, S.; Huang, C. Recent Advances in Sustainable Antimicrobial Food Packaging: Insights into Release Mechanisms, Design Strategies, and Applications in the Food Industry. J. Agric. Food Chem. 2023, 71, 11806–11833. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Chen, J.; Sun, M.; Tang, H. Preparation and characterization of thymol-loaded ZIF-8/κ-carrangeenan/Zein composite film as active food packaging with enhanced functional properties for blueberry preservation. Carbohydr. Polym. 2025, 356, 123406. [Google Scholar] [CrossRef]

- Shen, L.; Chen, C.; Xie, J. Development and characterization of starch/polyvinyl alcohol active films with slow-release property by utilizing Mucorracemosus Fresenius mycelium to load with clove essential oil. Int. J. Biol. Macromol. 2025, 295, 139610. [Google Scholar] [CrossRef]

- Ying, T.; Jiang, C.; Munir, S.; Liu, R.; Yin, T.; You, J.; Rong, J.; Xiong, S.; Hu, Y. Synthesis and application of gelatin-based controlled-release antibacterial films containing oregano essential oil/β-cyclodextrin microcapsules for chilling preservation of grass carp fillets. Food Chem. 2024, 451, 139465. [Google Scholar] [CrossRef]

- Nong, W.; Luo, H.; Wang, G.; Chen, Q.; Zou, X.; Miao, W.; Wu, J.; Guan, W.; Qu, S. β-CD-MOF-based edible antimicrobial packaging film with humidity-controlled carvacrol release for preserving fresh strawberry. Carbohydr. Polym. 2025, 351, 123133. [Google Scholar] [CrossRef] [PubMed]

- Jiao, X.; Chong, X.; Du, H.; Bian, X.; Yang, M.; Liu, X.; Zhu, Z.; Wen, Y. Leveraging gas generation for Humidity-Responsive release of Thyme essential oil via nanofiber film for fresh fruits. Chem. Eng. J. 2024, 487, 150606. [Google Scholar] [CrossRef]

- Wang, M.; Zeng, L.; Chen, H.; Hu, S.; Huang, C.; Zhen, S.; Zhan, L. Antibacterial properties of folic acid-based hydrogel loaded with CeCDs and its potential application in food preservation. Food Chem. 2025, 481, 144031. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, J.; Zhang, R.; Huang, X.; Li, Z.; Zhai, X.; Shen, T.; Shi, J.; Zou, X. Preparation of photodynamic-controlled release packaging for pork preservation and its visualization. Food Chem. 2025, 473, 143005. [Google Scholar] [CrossRef]

- Xia, S.; Bian, M.; Li, H.; Shi, C.; Xu, M.; Lyu, L.; Wu, Y.; Cao, F.; Wang, Y.; Li, W.; et al. Development of poly(lactic acid)/polyvinyl alcohol-based temperature-responsive shell-core nanofibers: Controlled release, biosafety evaluation, and application in raspberry preservation. Int. J. Biol. Macromol. 2025, 307, 142084. [Google Scholar] [CrossRef]

- Jiao, X.; Chong, X.; Du, H.; Yang, M.; Zhu, Z.; Ma, Z.; Wen, Y. Development of pH and enzyme dual responsive chitosan/polyaspartic acid nanoparticle-embedded nanofibers for fruit preservation. Int. J. Biol. Macromol. 2025, 297, 139903. [Google Scholar] [CrossRef]

- Lu, W.; Si, M.Q.; Le, X.X.; Chen, T. Mimicking Color-Changing Organisms to Enable the Multicolors and Multifunctions of Smart Fluorescent Polymeric Hydrogels. Acc. Chem. Res. 2022, 55, 2291–2303. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.T.; Fan, J.R.; Zhao, H.; Song, X.M.; Ji, Z.; Xie, C.X.; Chen, F.S.; Meng, Y. Biomimetic Robust Starch Composite Films with Super-Hydrophobicity and Vivid Structural Colors. Int. J. Mol. Sci. 2022, 23, 5607. [Google Scholar] [CrossRef]

- Sun, M.X.; Meng, W.H.; Yin, H.W.; Fan, L.J.; Shi, L.; Watson, G.S.; Watson, J.A.; Wang, J.X.; Jiang, L.; Liang, A.P. Dynamic Color Regulation of the Lycaenid Butterfly Wing Scales. J. Bionic Eng. 2024, 21, 2395–2408. [Google Scholar] [CrossRef]

- Shao, P.; Liu, L.M.; Yu, J.H.; Lin, Y.; Gao, H.Y.; Chen, H.J.; Sun, P.L. An overview of intelligent freshness indicator packaging for food quality and safety monitoring. Trends Food Sci. Technol. 2021, 118, 285–296. [Google Scholar] [CrossRef]

- Yun, D.W.; Yong, H.M.; Xu, F.F.; Li, N.; Guan, T.Z.; Liu, J. Purple sweet potato anthocyanin-g-dialdehyde locust bean gum: An innovative polymeric colorant with good stability and application potential in food intelligent packaging. Food Hydrocoll. 2025, 163, 111121. [Google Scholar] [CrossRef]

- Tao, Q.L.; Xiao, Y.W.; Hu, X.; Pang, H.T.; Xiao, F.; Li, L.L.; Chen, M.M.; Wang, H.L. Intelligent multi-colorimetric cellulose acetate/cobalt-based metal-organic framework antibacterial film and its application to pork preservation. Food Packag. Shelf Life 2024, 45, 101339. [Google Scholar] [CrossRef]

- Cheng, R.; Niu, B.; Fang, X.J.; Chen, H.J.; Chen, H.Z.; Wu, W.J.; Gao, H.Y. Preparation and characterization of water vapor-responsive methylcellulose-polyethylene glycol-400 composite membranes and an indication of freshness of shiitake mushrooms. Int. J. Biol. Macromol. 2024, 270, 132189. [Google Scholar] [CrossRef]

- Xia, S.; Fang, X.J.; Wu, W.J.; Wang, G.N.; Chen, H.Z.; Hu, Z.W.; Wang, L.S.; Liu, R.L.; Gao, H.Y. Preparation and characterization of novel natural pigment-indicating film: Application in kiwifruit freshness monitoring. Food Chem. 2025, 463, 141491. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhang, M.; Zhu, Q.B.; Adhikari, B. Intelligent vegetable freshness monitoring system developed by integrating eco-friendly fluorescent sensor arrays with deep convolutional neural networks. Chem. Eng. J. 2024, 488, 150739. [Google Scholar] [CrossRef]

- Li, S.Q.; Liu, L.; Yang, S.L.; Wang, X.N.; Yuan, Y.H.; Yue, T.L.; Cai, R.; Wang, Z.L. Designing double-layer smart packaging with sustained-release antibacterial and antioxidant activities for efficient preservation and high-contrast monitoring. Food Hydrocoll. 2025, 158, 110559. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Li, C.; Xia, X.D.; Tan, M.Q.; Wang, H.S.; Lv, Y.N.; Cheng, Y.; Tao, Y.H.; Lu, J.; Li, D.M.; et al. Eco-friendly and intelligent cellulosic fibers-based packaging system for real-time visual detection of food freshness. Chem. Eng. J. 2023, 474, 146013. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Sun, F.Y.; Xu, J.H.; Zhao, Z.H.; Fu, J.J. Research Progress of Human Biomimetic Self-Healing Materials. Small 2025, 21, 2408199. [Google Scholar] [CrossRef]

- Li, X.K.; Wang, Y.Y.; Zhang, X.X. Strong, healable materials with bio-like ordered architectures and versatile functionality. SusMat 2024, 4, e248. [Google Scholar] [CrossRef]

- Wang, P.; Lv, Y.; Duan, J.L.; Sun, G.F.; Meng, C.Z.; Li, Y.; Guo, S.J.; Zhang, T. A thermally responsive phase-change hydrogel for skin-mountable multifunctional sensors. Nano Energy 2025, 136, 110722. [Google Scholar] [CrossRef]

- Chhillar, A.; Jaiswal, A. Hyaluronic Acid-Based Self-Healing Hydrogels for Diabetic Wound Healing. Adv. Healthc. Mater. 2025, 14, 2404255. [Google Scholar] [CrossRef]

- Guo, K.N.; Ou, K.K.; Newton, M.A.A.; Zhang, J.; Xu, H.; Li, J.Y.; Xin, B.J.; Huang, Y.J. Multifunctional Janus nanofibrous membrane with unidirectional water transport and pH-responsive color-changing for wound dressing. J. Colloid Interface Sci. 2025, 679, 723–736. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.H.; Wang, Y.X. Recent advances in self-healing materials for food packaging. Packag. Technol. Sci. 2023, 36, 157–169. [Google Scholar] [CrossRef]

- Wang, J.D.; Gao, Q.C.; Zhao, F.Y.; Ju, J. Repair mechanism and application of self-healing materials for food preservation. Crit. Rev. Food Sci. Nutr. 2024, 64, 11113–11123. [Google Scholar] [CrossRef] [PubMed]

- Tavassoli, M.; Zhang, W.L.; Assadpour, E.; Zhang, F.Y.; Jafari, S.M. Self-healing packaging films/coatings for food applications; an emerging strategy. Adv. Colloid Interface Sci. 2025, 339, 103423. [Google Scholar] [CrossRef]

- Deng, P.P.; Zhang, Y.S.; Niu, Z.Y.; Li, Y.W.; Wang, Z.H.; Jiang, F.T. Multifunctional konjac glucomannan/xanthan gum self-healing coating for bananas preservation. Int. J. Biol. Macromol. 2024, 270, 132287. [Google Scholar] [CrossRef] [PubMed]

- Deng, P.P.; Zhang, Y.X.; Deng, Q.X.; Sun, Y.F.; Li, Y.W.; Wang, Z.H.; Jiang, F.T. Multifunctional sodium alginate-based self-healing edible cross-linked coating for banana preservation. Food Hydrocoll. 2024, 151, 109753. [Google Scholar] [CrossRef]

- Wang, D.F.; Cui, F.C.; Xi, L.Q.; Tan, X.Q.; Li, J.R.; Li, T.T. Preparation of a multifunctional non-stick tamarind polysaccharide-polyvinyl alcohol hydrogel immobilized with a quorum quenching enzyme for maintaining fish freshness. Carbohydr. Polym. 2023, 302, 120382. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Wang, F.; Lu, C.; Liu, Y.; Zhang, S.; Ma, S.; Wang, L. Development of cellulose-based self-healing hydrogel smart packaging for fish preservation and freshness indication. Carbohydr. Polym. 2025, 348, 122806. [Google Scholar] [CrossRef]

- Yu, K.J.; Yang, L.N.; Zhang, S.Y.; Zhang, N.; Liu, H. Strong, tough self-healing multi-functional sodium alginate-based edible composite coating for banana preservation. Int. J. Biol. Macromol. 2024, 281, 136191. [Google Scholar] [CrossRef]

- Halloub, A.; Nekhlaoui, S.; Raji, M.; Essabir, H.; Bensalah, M.O.; Bouhfid, R.; Qaiss, A. UV-activated self-healing food packaging: ω-3 based microcapsules in hemicellulose/chitosan blend film for cashew nut preservation. Food Biosci. 2024, 60, 104313. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Zhou, S.Y.; Xia, X.D.; Tan, M.Q.; Lv, Y.N.; Cheng, Y.; Tao, Y.H.; Lu, J.; Du, J.; Wang, H.S. High-performance carboxymethyl cellulose-based hydrogel film for food packaging and preservation system. Int. J. Biol. Macromol. 2022, 223, 1126–1137. [Google Scholar] [CrossRef] [PubMed]

- Ding, F.Y.; Fu, L.; Huang, X.W.; Shi, J.Y.; Povey, M.; Zou, X.B. Self-healing carboxymethyl chitosan hydrogel with anthocyanin for monitoring the spoilage of flesh foods. Food Hydrocoll. 2025, 165, 111270. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, L.Z.; Guan, Q.B.; Guo, Y.F.; Lou, J.M.; Lei, D.; Wang, S.L.; Chen, S.; Sun, L.J.; Xuan, H.X.; et al. Biomimetic Materials with Multiple Protective Functionalities. Adv. Funct. Mater. 2019, 29, 1901058. [Google Scholar] [CrossRef]

- Su, Y.P.; Shi, S.; Wang, C.; Wang, Z.; Li, P.S.; Zhang, S.T.; Fei, B.; Yang, Z.H.; Hu, J.L. Spider silk-inspired tough materials: Multi-pathway synthesis, advanced processing, and functional applications. Nano Today 2024, 55, 102188. [Google Scholar] [CrossRef]

- Chang, Z.; Shen, Y.; Xue, J.; Sun, Y.; Zhang, S. Fabrication of spider silk-inspired bio-based polymeric materials under dynamic nanoconfinement as high-strong, ultra-tough, and multifunctional plastic substitutes. Chem. Eng. J. 2023, 457, 140984. [Google Scholar] [CrossRef]

- Sharma, A.; Shukla, N.K.; Belarbi, M.O.; Abbas, M.; Garg, A.; Li, L.; Bhutto, J.; Bhatia, A. Bio-inspired nacre and helicoidal composites: From structure to mechanical applications. Thin-Walled Struct. 2023, 192, 111146. [Google Scholar] [CrossRef]

- Han, Z.M.; Li, D.H.; Yang, H.B.; Zhao, Y.X.; Yin, C.H.; Yang, K.P.; Liu, H.C.; Sun, W.B.; Ling, Z.C.; Guan, Q.F.; et al. Nacre-Inspired Nanocomposite Films with Enhanced Mechanical and Barrier Properties by Self-Assembly of Poly(Lactic Acid) Coated Mica Nanosheets. Adv. Funct. Mater. 2022, 32, 2202221. [Google Scholar] [CrossRef]

- Zhong, J.Q.; Cheng, H.; McClements, D.J.; Zhang, Z.P.; Zhang, R.J.; Zhou, H.; Wang, W.; Zhao, J.W.; Jin, Z.Y.; Chen, L. Pearl-inspired functional biomaterials: Review of their preparation, characterization, and application in food packaging. Trends Food Sci. Technol. 2024, 154, 104774. [Google Scholar] [CrossRef]

- Wu, D.; Wang, J.; Zhao, Y.; Li, S.; Yang, H.; Tan, R.; Zhang, T. Bio-inspired seaweed-based nanocomposite materials with excellent degradability and multifunctional barrier properties for green packaging. Chem. Eng. J. 2024, 479, 147285. [Google Scholar] [CrossRef]

- Tang, S.W.; Wu, Z.G.; Li, X.Y.; Xie, F.W.; Ye, D.D.; Ruiz-Hitzky, E.; Wei, L.S.; Wang, X.Y. Nacre-inspired biodegradable nanocellulose/MXene/AgNPs films with high strength and superior gas barrier properties. Carbohydr. Polym. 2023, 299, 120204. [Google Scholar] [CrossRef] [PubMed]

- Alebachew, A.W.; Abdalkarim, S.Y.H.; Zhu, J.L.; Wu, S.P.; Zhang, Y.H.; Yu, H.Y.; Yunusov, K.E. Two-directions mechanical strength and high-barrier mechanisms of cellulose nanocrystal-based hybrids reinforced packaging with nacre-mimetic structure. Carbohydr. Polym. 2025, 348, 122910. [Google Scholar] [CrossRef]

- Lei, Y.Z.; Mao, L.; Yao, J.; Zhu, H.P. Improved mechanical, antibacterial and UV barrier properties of catechol-functionalized chitosan/polyvinyl alcohol biodegradable composites for active food packaging. Carbohydr. Polym. 2021, 264, 117997. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Q.; Dai, M.Q.; Huang, M.; Lim, L.T. Bioinspired pullulan-starch nanoplatelets nanocomposite films with enhanced mechanical properties. Carbohydr. Polym. 2024, 329, 121769. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Ke, L.; Tang, M.K.; Shang, H.; Zhang, Z.L.; Xu, W.X.; Fu, Y.N.; Wang, Y.Q.; Tang, D.Y.; Huang, D.H.; et al. Pea pod-mimicking hydroxyapatite nanowhisker-reinforced poly(lactic acid) composites with bone-like strength. Int. J. Biol. Macromol. 2022, 216, 114–123. [Google Scholar] [CrossRef]

- Shi, X.; Ju, F.X.; Wang, R.X.; Xu, J.; Li, T.D.; Wei, T.; Lv, A.; Yang, H. Brilliant fabrication of multifunctional collagen-based packaging films with rigid-flexible coupling structure bio-inspired by pangolins. Food Chem. 2025, 479, 143814. [Google Scholar] [CrossRef]

- Zhang, C.; Bi, H.; Wei, Y.; Zhou, Y.; Wang, C.; He, Y.; Ao, J.; Kang, S.; Chen, G. High-strength, high-toughness, and high-barrier composite films based on bionic multi-scale fiber reinforcement and organic–inorganic interface hybridization for flexible food packaging. Chem. Eng. J. 2025, 510, 161663. [Google Scholar] [CrossRef]

- Yang, Z.; Qin, Z.; Wu, M.; Hu, H.; Nie, P.; Wang, Y.; Li, Q.; Wu, D.; He, Y.; Chen, K. A wearable conductive hydrogel with triple network reinforcement inspired by bio-fibrous scaffolds for real-time quantitatively sensing compression force exerted on fruit surface. J. Adv. Res. 2024, in press. [CrossRef]

- He, Z.K.; Wang, N.; Mu, L.P.; Wang, Z.; Su, J.; Chen, Y.K.; Luo, M.D.; Wu, Y.; Lan, X.R.; Mao, J.Y. Porous polydimethylsiloxane films with specific surface wettability but distinct regular physical structures fabricated by 3D printing. Front. Bioeng. Biotechnol. 2023, 11, 1272565. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, M.; Bhandari, B.; Deng, D.W. 3D printed cinnamon essential oil/banana peel carbon dots loaded corn starch/gelatin bilayer film with enhanced functionality for food packaging application. Food Chem. 2024, 448, 139176. [Google Scholar] [CrossRef]

| Main Material | Self-Healing Mechanism | Repair Effect | References |

|---|---|---|---|

| Konjac glucomannan, Xanthan gum, gallic acid | Hydrogen bond | When water droplets contacted the scratches on the composite film, the scratches vanished entirely within 15 min, demonstrating the film’s remarkable self-healing capabilities. Additionally, this film extended the banana’s shelf life by over six days. | [106] |

| Sodium alginate, gluconolactone, whey isolate protein | Electrostatic force | Film scratches drip water after 20 min of self-healing, after repairing the mechanical properties of the composite film reaches more than 75% of the undamaged state, and can extend the banana freshness for 6 days. | [107] |

| Tamarind polysaccharide, polyvinyl alcohol | Hydrogen bond | The hydrogels were placed next to each other, and the edges blurred in 20 min and completely healed in 60 min. The hydrogel effectively retarded the rotting of red snapper filets at 4 °C and maintained the quality of the fillets. | [108] |

| Nanocellulose, polyvinyl alcohol, curcumin, borax | Borate and hydrogen bonding | The broken hydrogel film heals quickly within 1 s without external stimulation, and the film extends the shelf life of the fish to 9 days. | [109] |

| Sodium alginate, gluconolactone, wheat gluten | Electrostatic force | Scalpel scrapes the film and then drops of deionized water, the scratch heals itself in 60 s, demonstrating self-repairing properties while extending the freshness of the banana up to 7 days. | [110] |

| Hemicellulose, chitosan | Exogenous restoratives and ultraviolet light | When the film is scratched, the microcapsules break to release free radicals and polymerize and cross-link under UV light to achieve self-repair. This film keeps the quality of cashew nuts fresh for 60 days. | [111] |

| Sodium carboxymethyl cellulose, polyethyleneimine, polyvinyl alcohol | Possible dynamically reversible Physical bonds | The hydrogel film is self-repairing at room temperature, can support 500 g of weight after healing, and extends strawberry freshness for 7 days. | [112] |

| Oxidized alginate, carboxymethyl chitosan, anthocyanin | Schiff base linkages and hydrogen bonds | The severed hydrogel heals completely within one hour with a self-healing efficiency of approximately 93%, and Schiff base bonds have a significant impact on the self-repairing capability of the hydrogel. | [113] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Han, L.; Yu, C.; Pan, L.; Tu, K. A Review on Replacing Food Packaging Plastics with Nature-Inspired Bio-Based Materials. Foods 2025, 14, 1661. https://doi.org/10.3390/foods14101661

Hu S, Han L, Yu C, Pan L, Tu K. A Review on Replacing Food Packaging Plastics with Nature-Inspired Bio-Based Materials. Foods. 2025; 14(10):1661. https://doi.org/10.3390/foods14101661

Chicago/Turabian StyleHu, Shengsi, Lu Han, Chenfeng Yu, Leiqing Pan, and Kang Tu. 2025. "A Review on Replacing Food Packaging Plastics with Nature-Inspired Bio-Based Materials" Foods 14, no. 10: 1661. https://doi.org/10.3390/foods14101661

APA StyleHu, S., Han, L., Yu, C., Pan, L., & Tu, K. (2025). A Review on Replacing Food Packaging Plastics with Nature-Inspired Bio-Based Materials. Foods, 14(10), 1661. https://doi.org/10.3390/foods14101661