Development of a Multifunctional Chitosan-Based Composite Film from Crab Shell (Portunus segnis) and Algae (Ulva lactuca) with Enhanced Antioxidant and Antimicrobial Properties for Active Food Packaging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

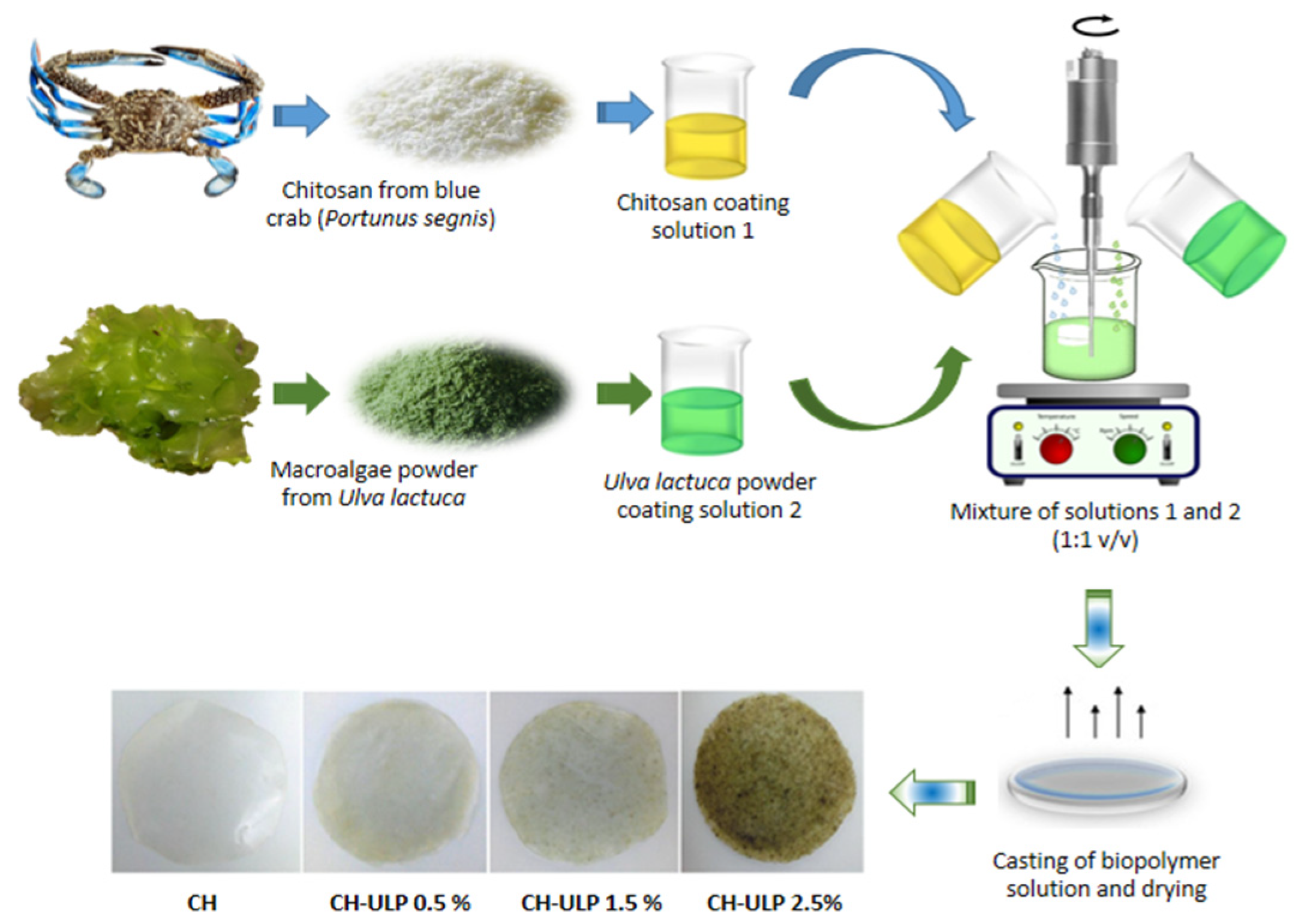

2.2. Composite Films Preparation via the Casting Method

2.2.1. Preparation of Chitosan and Algae Coating Solutions

2.2.2. Preparation of Composite Films

2.3. Characterization of Films

2.3.1. Moisture Content

2.3.2. Water Solubility (WS)

2.3.3. Color

2.3.4. Opacity

2.3.5. Fourier Transform Infrared (FTIR) Spectroscopy

2.3.6. Mechanical Properties

2.3.7. Antioxidant Activity: DPPH Radical Scavenging Assay

2.3.8. Antimicrobial Activity

2.3.9. Biodegradability

2.4. Statistical Analysis

3. Results and Discussion

3.1. Moisture Content

3.2. Water Solubility (WS)

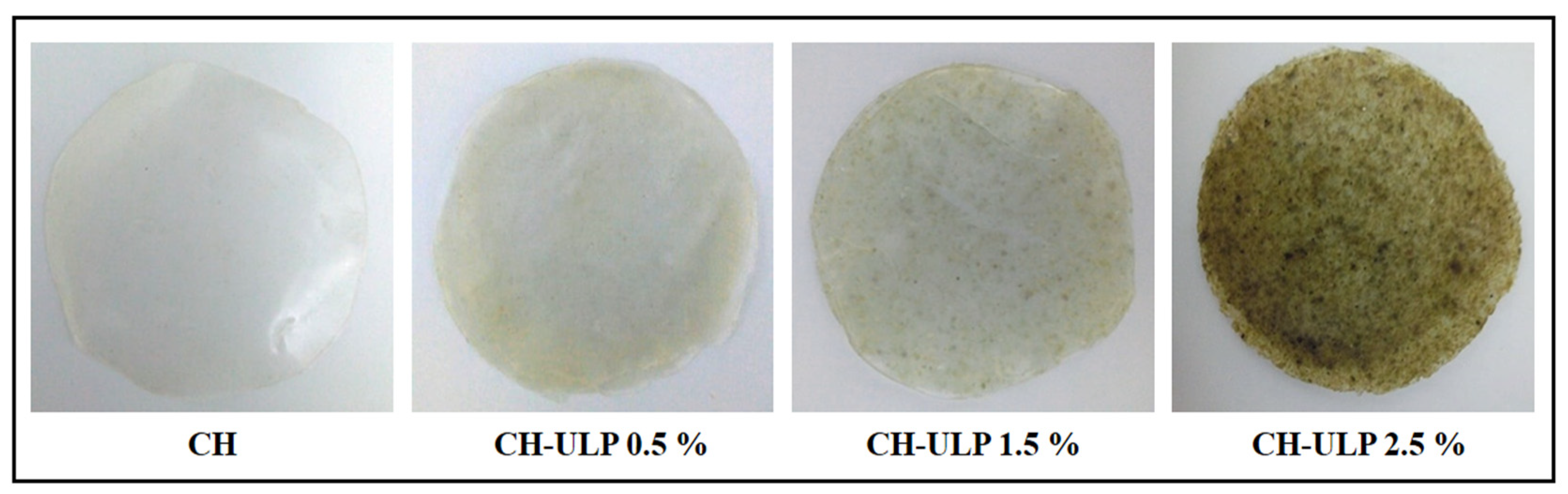

3.3. Visual Observations and Color Measurements

3.4. Opacity

3.5. Fourier-Transform Infrared (FTIR) Spectroscopy

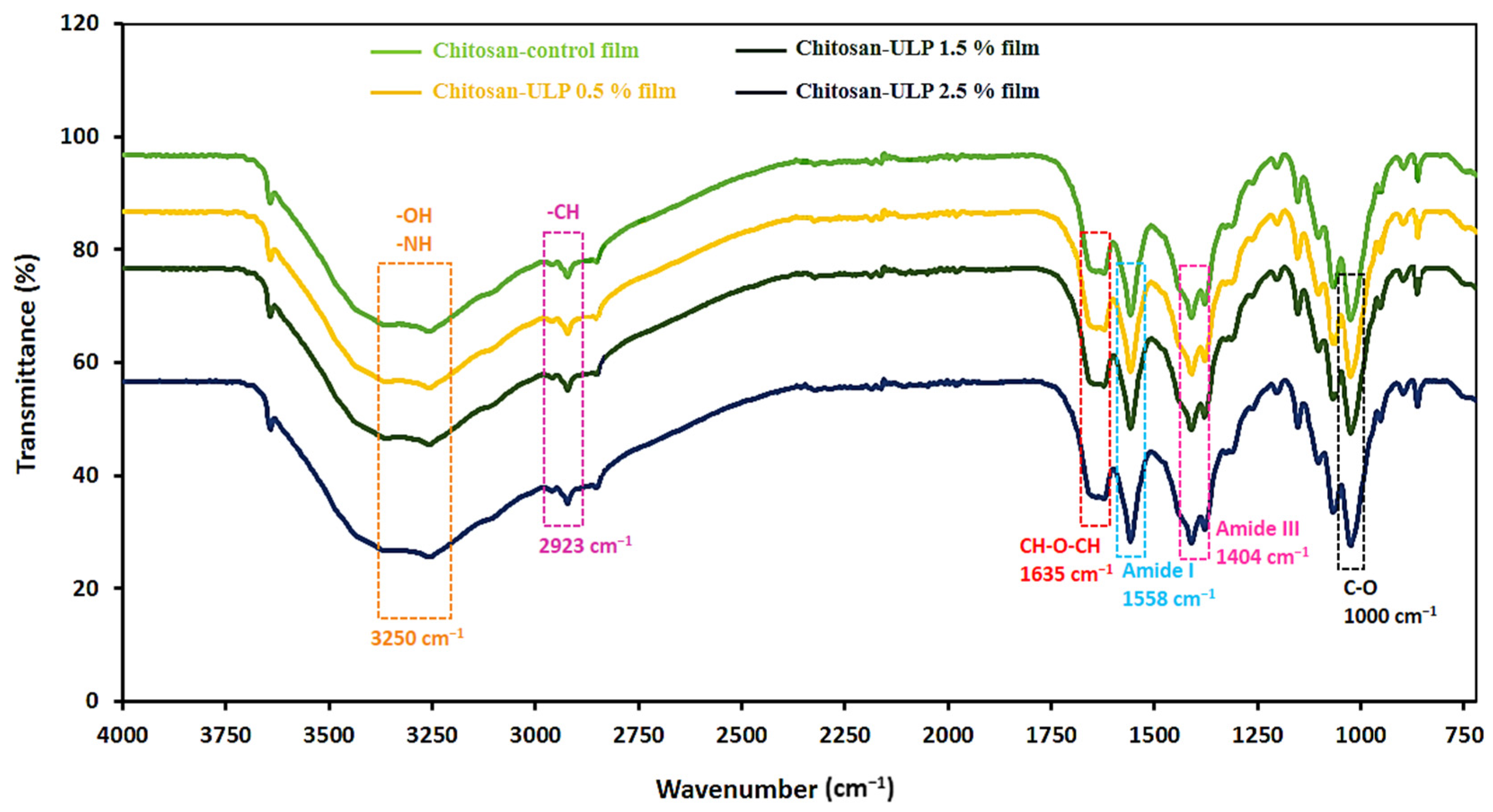

3.6. Mechanical Properties

3.7. Antioxidant Activity

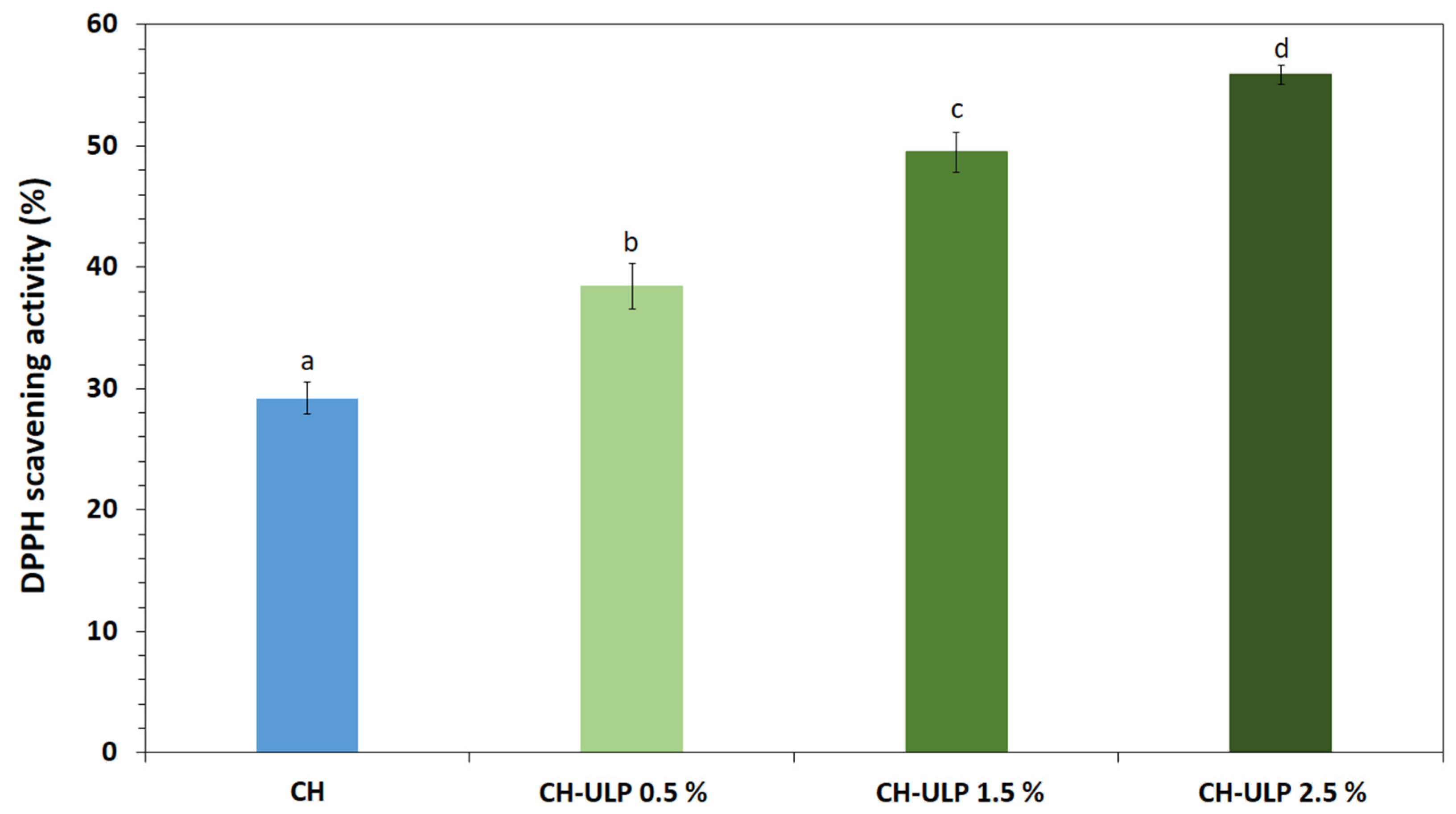

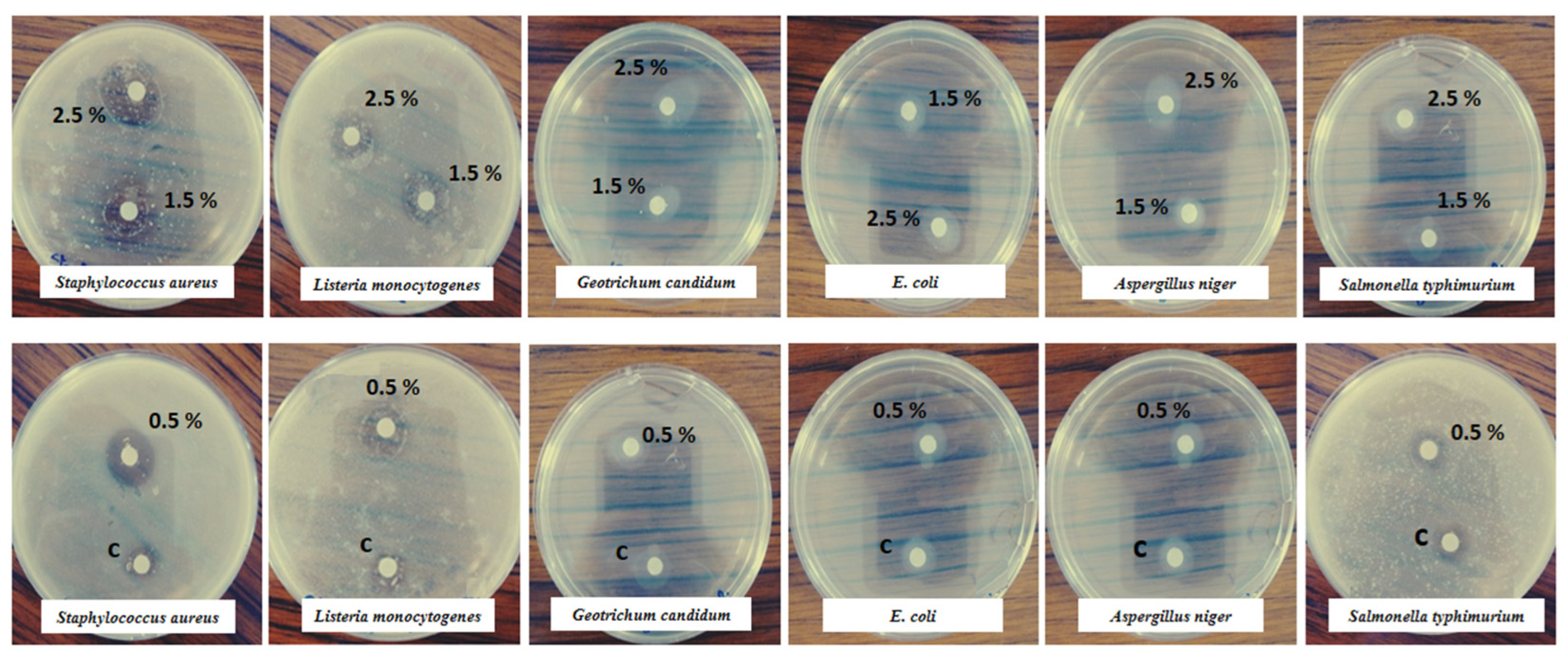

3.8. Antimicrobial Activity

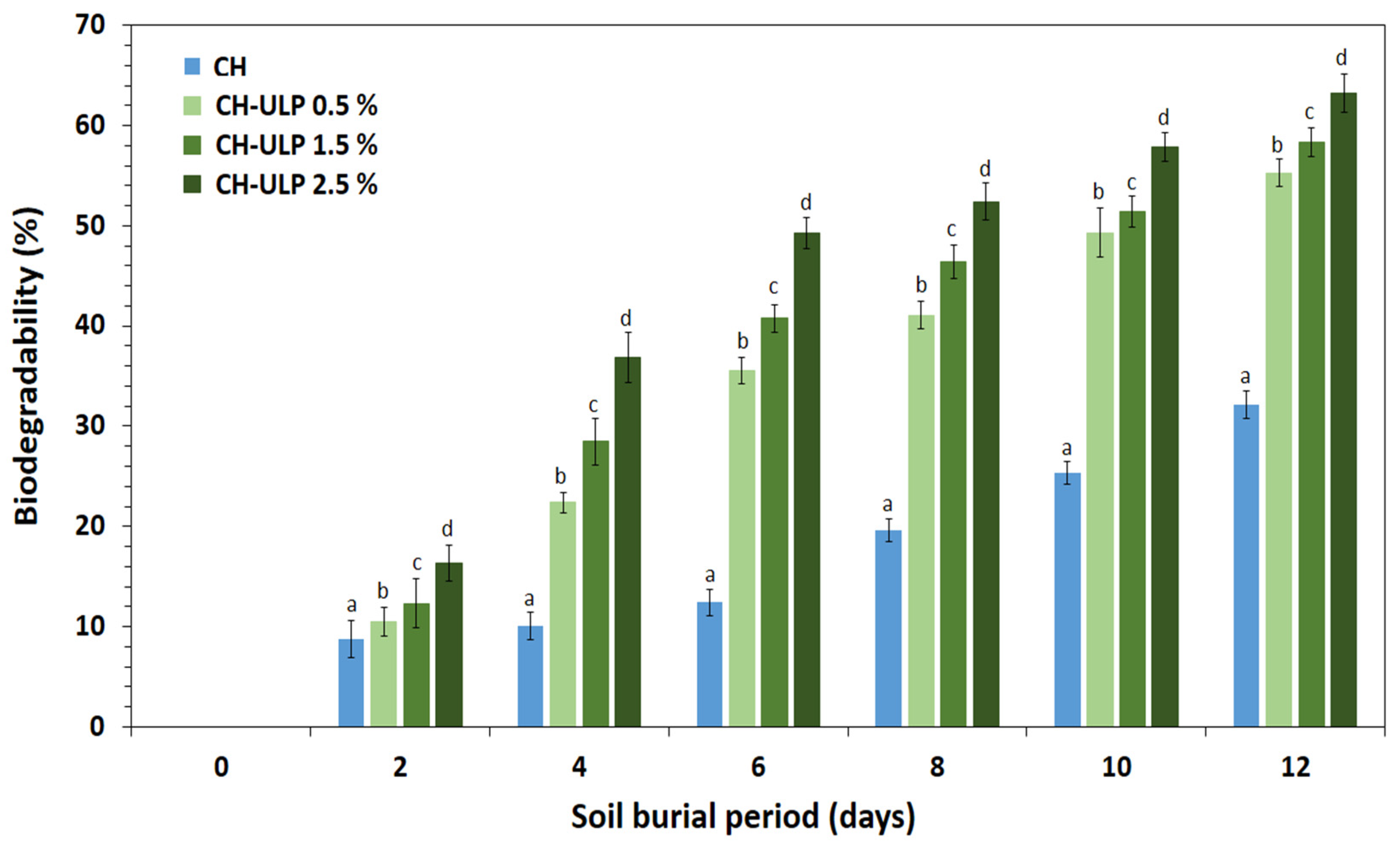

3.9. Biodegradability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nguyen, T.T.T.; Tran, N.T.K.; Le, T.Q.; Nguyen, T.T.A.; Nguyen, L.T.M.; Tran, T. Van Passion fruit peel pectin/chitosan based antibacterial films incorporated with biosynthesized silver nanoparticles for wound healing application. Alex. Eng. J. 2023, 69, 419–430. [Google Scholar] [CrossRef]

- Balti, R.; Mansour, M.B.; Sayari, N.; Yacoubi, L.; Rabaoui, L.; Brodu, N.; Massé, A. Development and characterization of bioactive edible films from spider crab (Maja crispata) chitosan incorporated with Spirulina extract. Int. J. Biol. Macromol. 2017, 105, 1464–1472. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Z.; Feng, Y.; Zhao, J.; Qiao, M.; Jin, Q. Valorization of Seafood Waste for Food Packaging Development. Foods 2024, 13, 2122. [Google Scholar] [CrossRef]

- Rodríguez-Félix, F.; Corte-Tarazón, J.A.; Rochín-Wong, S.; Fernández-Quiroz, J.D.; Garzón-García, A.M.; Santos-Sauceda, I.; Plascencia-Martínez, D.F.; Chan-Chan, L.H.; Vásquez-López, C.; Barreras-Urbina, C.G.; et al. Physicochemical, structural, mechanical and antioxidant properties of zein films incorporated with no-ultrafiltered and ultrafiltered betalains extract from the beetroot (Beta vulgaris) bagasse with potential application as active food packaging. J. Food Eng. 2022, 334, 111153. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Saurabh, C.K.; Tye, Y.Y.; Lai, T.K.; Easa, A.M.; Rosamah, E.; Fazita, M.R.N.; Syakir, M.I.; Adnan, A.S.; Fizree, H.M.; et al. Seaweed based sustainable films and composites for food and pharmaceutical applications: A review. Renew. Sustain. Energy Rev. 2017, 77, 353–362. [Google Scholar] [CrossRef]

- Li, S.; Ren, Y.; Hou, Y.; Zhan, Q.; Jin, P.; Zheng, Y.; Wu, Z. Polysaccharide-Based Composite Films: Promising Biodegradable Food Packaging Materials. Foods 2024, 13, 3674. [Google Scholar] [CrossRef]

- Nur Amila Najwa, I.S.; Guerrero, P.; de la Caba, K.; Nur Hanani, Z.A. Physical and antioxidant properties of starch/gelatin films incorporated with Garcinia atroviridis leaves. Food Packag. Shelf Life 2020, 26, 100583. [Google Scholar] [CrossRef]

- Kumar, N.; Neeraj; Ojha, A.; Singh, R. Preparation and characterization of chitosan–pullulan blended edible films enrich with pomegranate peel extract. React. Funct. Polym. 2019, 144, 104350. [Google Scholar] [CrossRef]

- Uranga, J.; Etxabide, A.; Guerrero, P.; de la Caba, K. Development of active fish gelatin films with anthocyanins by compression molding. Food Hydrocoll. 2018, 84, 313–320. [Google Scholar] [CrossRef]

- Zaghbib, I.; Arafa, S.; Hassouna, M. Biological, Functional and Physico-Chemical Characterization of Chitosan Extracted From Blue Crab (Portunus segnis) Shell Waste by Chemical Method. Am. Acad. Sci. Res. J. Eng. 2022, 85, 100–115. [Google Scholar]

- Mondal, M.I.H. Recent Advancement of PVA/Chitosan-Based Composite Biofilm for Food Packaging. Biomed. J. Sci. Tech. Res. 2022, 46, 36982–36986. [Google Scholar] [CrossRef]

- Vadalà, R.; De Maria, L.; De Pasquale, R.; Di Salvo, E.; Lo Vecchio, G.; Di Bella, G.; Costa, R.; Cicero, N. Development of a Chitosan-Based Film from Shellfish Waste for the Preservation of Various Cheese Types during Storage. Foods 2024, 13, 2055. [Google Scholar] [CrossRef] [PubMed]

- Samani, M.A.; Babaei, S.; Naseri, M.; Majdinasab, M.; Nafchi, A.M. Development and characterization of a novel biodegradable and antioxidant film based on marine seaweed sulfated polysaccharide. Food Sci. Nutr. 2023, 11, 3767–3779. [Google Scholar] [CrossRef] [PubMed]

- Barik, M.; BhagyaRaj, G.V.S.; Dash, K.K.; Shams, R. A thorough evaluation of chitosan-based packaging film and coating for food product shelf-life extension. J. Agric. Food Res. 2024, 16, 101164. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Jiménez-Rosado, M.; Benítez, J.J.; Guerrero, A.; Romero, A. Biopolymer-Based Films Reinforced with FexOy-Nanoparticles. Polymers 2022, 14, 4487. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Jiménez-Rosado, M.; Guerrero, A.; Romero, A. Biopolymer-Based Films Reinforced with Green Synthesized Zinc Oxide Nanoparticles. Polymers 2022, 14, 5202. [Google Scholar] [CrossRef]

- Galus, S.; Arik Kibar, E.A.; Gniewosz, M.; Kraśniewska, K. Novel Materials in the Preparation of Edible Films and Coatings—A Review. Coatings 2020, 10, 674. [Google Scholar] [CrossRef]

- Kumar, L.; Ramakanth, D.; Akhila, K.; Gaikwad, K.K. Edible films and coatings for food packaging applications: A review. Environ. Chem. Lett. 2022, 20, 875–900. [Google Scholar] [CrossRef]

- Ediyilyam, S.; George, B.; Shankar, S.S.; Dennis, T.T.; Wacławek, S.; Černík, M.; Padil, V.V.T. Chitosan/Gelatin/Silver Nanoparticles Composites Films for Biodegradable Food Packaging Applications. Polymers 2021, 13, 1680. [Google Scholar] [CrossRef]

- Torres, M.D.; Kraan, S.; Domínguez, H. Seaweed biorefinery. Rev. Environ. Sci. Bio/Technol. 2019, 18, 335–388. [Google Scholar] [CrossRef]

- Armeli Minicante, S.; Bongiorni, L.; De Lazzari, A. Bio-Based Products from Mediterranean Seaweeds: Italian Opportunities and Challenges for a Sustainable Blue Economy. Sustainability 2022, 14, 5634. [Google Scholar] [CrossRef]

- Zaghbib, I.; Arafa, S.; Hassouna, M. Functional Properties and Biological Potentials of the Tunisian Green Seaweed Ulva lactuca. Am. Sci. Res. J. Eng. Technol. Sci. 2022, 85, 89–99. [Google Scholar]

- Li, Y.-X.; Kim, S.-K. Utilization of seaweed derived ingredients as potential antioxidants and functional ingredients in the food industry: An overview. Food Sci. Biotechnol. 2011, 20, 1461–1466. [Google Scholar] [CrossRef]

- Wang, H.; Cao, Z.; Yao, L.; Feng, T.; Song, S.; Sun, M. Insights into the Edible and Biodegradable Ulvan-Based Films and Coatings for Food Packaging. Foods 2023, 12, 1622. [Google Scholar] [CrossRef]

- Waseem, M.; Khan, M.U.; Majeed, Y.; Ntsefong, G.N.; Kirichenko, I.; Klopova, A.; Trushov, P.; Lodygin, A. Seaweed-based films for sustainable food packaging: Properties, incorporation of essential oils, applications, and future directions. Potravin. Slovak J. Food Sci. 2023, 17, 899–917. [Google Scholar] [CrossRef]

- Liu, X.; Xu, Y.; Zhan, X.; Xie, W.; Yang, X.; Cui, S.W.; Xia, W. Development and properties of new kojic acid and chitosan composite biodegradable films for active packaging materials. Int. J. Biol. Macromol. 2020, 144, 483–490. [Google Scholar] [CrossRef]

- Kaczmarek, B.; Nadolna, K.; Owczarek, A.; Michalska-Sionkowska, M.; Sionkowska, A. The characterization of thin films based on chitosan and tannic acid mixture for potential applications as wound dressings. Polym. Test. 2019, 78, 106007. [Google Scholar] [CrossRef]

- Olawuyi, I.F.; Lee, W.Y. Development and Characterization of Biocomposite Films Based on Polysaccharides Derived from Okra Plant Waste for Food Packaging Application. Polymers 2022, 14, 4884. [Google Scholar] [CrossRef]

- Akter, A.; Sobuj, M.K.A.; Islam, M.S.; Chakroborty, K.; Tasnim, N.; Ayon, M.H.; Hossain, M.F.; Rafiquzzaman, S.M. Seaweed polysaccharides: Sources, structure and biomedical applications with special emphasis on antiviral potentials. Futur. Foods 2024, 10, 100440. [Google Scholar] [CrossRef]

- Joshi, P.; Becerra-Mora, N.; Vargas-Lizarazo, A.Y.; Kohli, P.; Fisher, D.J.; Choudhary, R. Use of edible alginate and limonene-liposome coatings for shelf-life improvement of blackberries. Futur. Foods 2021, 4, 100091. [Google Scholar] [CrossRef]

- Xue, F.; Zhao, M.; Liu, X.; Chu, R.; Qiao, Z.; Li, C.; Adhikari, B. Physicochemical properties of chitosan/zein/essential oil emulsion-based active films functionalized by polyphenols. Futur. Foods 2021, 3, 100033. [Google Scholar] [CrossRef]

- Doh, H.; Dunno, K.D.; Whiteside, W.S. Preparation of novel seaweed nanocomposite film from brown seaweeds Laminaria japonica and Sargassum natans. Food Hydrocoll. 2020, 105, 105744. [Google Scholar] [CrossRef]

- Sharmin, N.; Khan, R.A.; Salmieri, S.; Dussault, D.; Lacroix, M. Fabrication and Characterization of Biodegradable Composite Films Made of Using Poly(caprolactone) Reinforced with Chitosan. J. Polym. Environ. 2012, 20, 698–705. [Google Scholar] [CrossRef]

- Jiang, A.; Patel, R.; Padhan, B.; Palimkar, S.; Galgali, P.; Adhikari, A.; Varga, I.; Patel, M. Chitosan Based Biodegradable Composite for Antibacterial Food Packaging Application. Polymers 2023, 15, 2235. [Google Scholar] [CrossRef]

- Kloster, G.A.; Marcovich, N.E.; Mosiewicki, M.A. Composite films based on chitosan and nanomagnetite. Eur. Polym. J. 2015, 66, 386–396. [Google Scholar] [CrossRef]

- Konwar, A.; Kalita, S.; Kotoky, J.; Chowdhury, D. Chitosan-Iron Oxide Coated Graphene Oxide Nanocomposite Hydrogel: A Robust and Soft Antimicrobial Biofilm. ACS Appl. Mater. Interfaces 2016, 8, 20625–20634. [Google Scholar] [CrossRef]

- Duri, S.; Harkins, A.L.; Frazier, A.J.; Tran, C.D. Composites Containing Fullerenes and Polysaccharides: Green and Facile Synthesis, Biocompatibility, and Antimicrobial Activity. ACS Sustain. Chem. Eng. 2017, 5, 5408–5417. [Google Scholar] [CrossRef]

- Gomaa, M.; Al-Badaani, A.A.; Hifney, A.F.; Adam, M.S. Utilization of cellulose and ulvan from the green seaweed Ulva lactuca in the development of composite edible films with natural antioxidant properties. J. Appl. Phycol. 2022, 34, 2615–2626. [Google Scholar] [CrossRef]

- Sinaga, M.Z.E.; Gea, S.; Sihombing, Y.A.; Zaidar, E.; Bulan, R.; Panindia, N.; Azhari, H. The Preparation of Agar-chitosan Film from Gracilaria. In Proceedings of the International Conference of Science, Technology, Engineering, Environmental and Ramification Researches; SCITEPRESS—Science and Technology Publications: Setúbal, Portugal, 2018; pp. 1047–1051. [Google Scholar]

- Kumar, N.; Pratibha; Trajkovska Petkoska, A.; Khojah, E.; Sami, R.; Al-Mushhin, A.A.M. Chitosan Edible Films Enhanced with Pomegranate Peel Extract: Study on Physical, Biological, Thermal, and Barrier Properties. Materials 2021, 14, 3305. [Google Scholar] [CrossRef]

- ASTM D1708-93; Standard Test Method for Tensile Properties of Plastics by Use of Microtensile Specimens. Annual Book of ASTM Standards. American Society for Testing and Materials: Philadelphia, PA, USA, 1993.

- Butnaru, E.; Stoleru, E.; Brebu, M.A.; Darie-Nita, R.N.; Bargan, A.; Vasile, C. Chitosan-Based Bionanocomposite Films Prepared by Emulsion Technique for Food Preservation. Materials 2019, 12, 373. [Google Scholar] [CrossRef]

- Alqahtani, N.; Alnemr, T.; Ali, S. Development of low-cost biodegradable films from corn starch and date palm pits (Phoenix dactylifera). Food Biosci. 2021, 42, 101199. [Google Scholar] [CrossRef]

- Jirukkakul, N. Physical and antioxidant properties of gelatine film added with sesame, rice bran, and coconut oil. Int. Food Res. J. 2022, 29, 1020–1031. [Google Scholar] [CrossRef]

- Govindaswamy, R.; Robinson, J.S.; Geevaretnam, J.; Pandurengan, P. Physico-functional and Anti-oxidative Properties of Carp Swim Bladder Gelatin and Brown Seaweed Fucoidan Based Edible Films. J. Packag. Technol. Res. 2018, 2, 77–89. [Google Scholar] [CrossRef]

- Hu, X.; Yuan, L.; Han, L.; Li, S.; Song, L. Characterization of antioxidant and antibacterial gelatin films incorporated with Ginkgo biloba extract. RSC Adv. 2019, 9, 27449–27454. [Google Scholar] [CrossRef]

- Augusto, A.; Dias, J.; Campos, M.; Alves, N.; Pedrosa, R.; Silva, S. Influence of Codium tomentosum Extract in the Properties of Alginate and Chitosan Edible Films. Foods 2018, 7, 53. [Google Scholar] [CrossRef]

- Don, T.-M.; Ma, C.-H.; Huang, Y.-C. In Situ Release of Ulvan from Crosslinked Ulvan/Chitosan Complex Films and Their Evaluation as Wound Dressings. Polymers 2022, 14, 5382. [Google Scholar] [CrossRef]

- Bharti, S.K.; Pathak, V.; Alam, T.; Arya, A.; Singh, V.K.; Verma, A.K.; Rajkumar, V. Starch bio-based composite active edible film functionalized with Carum carvi L. essential oil: Antimicrobial, rheological, physic-mechanical and optical attributes. J. Food Sci. Technol. 2022, 59, 456–466. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Benítez, J.J.; Guerrero, A.; Romero, A. Sustainable Integration of Zinc Oxide Nanoparticles: Enhancing Properties of Poly(ε-Caprolactone) Electrospun Nanofibers and Cast Films. Coatings 2023, 13, 1665. [Google Scholar] [CrossRef]

- Rattaya, S.; Benjakul, S.; Prodpran, T. Properties of fish skin gelatin film incorporated with seaweed extract. J. Food Eng. 2009, 95, 151–157. [Google Scholar] [CrossRef]

- Intawiwat, N.; Wold, J.P.; Skaret, J.; Rukke, E.O.; Pettersen, M.K. Minimizing photooxidation in pasteurized milk by optimizing light transmission properties of green polyethylene films. J. Dairy Sci. 2013, 96, 6818–6829. [Google Scholar] [CrossRef]

- Hematian, F.; Baghaei, H.; Mohammadi Nafchi, A.; Bolandi, M. Preparation and characterization of an intelligent film based on fish gelatin and Coleus scutellarioides anthocyanin to monitor the freshness of rainbow trout fish fillet. Food Sci. Nutr. 2023, 11, 379–389. [Google Scholar] [CrossRef] [PubMed]

- Ashurov, N.S.; Abdurazakov, M.; Yugay, S.M.; Atakhanov, A.A.; Gulamjanov, K.A.; Turaev, J.I.; Akhymbetova, G.D.; Rashidova, S.S. Structure and thermal properties of chitin and chitosan from various sources. J. Phys. Conf. Ser. 2022, 2388, 012011. [Google Scholar] [CrossRef]

- Sarbon, N.M.; Sandanamsamy, S.; Kamaruzaman, S.F.S.; Ahmad, F. Chitosan extracted from mud crab (Scylla olivicea) shells: Physicochemical and antioxidant properties. J. Food Sci. Technol. 2015, 52, 4266–4275. [Google Scholar] [CrossRef] [PubMed]

- Siripatrawan, U.; Vitchayakitti, W. Improving functional properties of chitosan films as active food packaging by incorporating with propolis. Food Hydrocoll. 2016, 61, 695–702. [Google Scholar] [CrossRef]

- Jakobek, L. Interactions of polyphenols with carbohydrates, lipids and proteins. Food Chem. 2015, 175, 556–567. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Lagos, S.N.P.; Sanchez, E.J.E.; Rivera-Flores, O.; Sánchez-Barahona, M.; Guerrero, A.; Romero, A. Innovative Agrowaste Banana Peel Extract-Based Magnetic Iron Oxide Nanoparticles for Eco-Friendly Oxidative Shield and Freshness Fortification. Food Bioprocess Technol. 2024, 17, 5083–5096. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Perdomo, C.A.A.; Núñez, L.A.H.; Rivera-Flores, O.; Sánchez-Barahona, M.; Guerrero, A.; Romero, A. Lychee peel extract-based magnetic iron oxide nanoparticles: Sustainable synthesis, multifaceted antioxidant system, and prowess in eco-friendly food preservation. Food Bioprod. Process. 2024, 145, 148–157. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Perez-Puyana, V.; Guerrero, A.; Romero, A. Novel hybrid electrospun poly(ε-caprolactone) nanofibers containing green and chemical magnetic iron oxide nanoparticles. J. Appl. Polym. Sci. 2023, 140, e54345. [Google Scholar] [CrossRef]

- Albertos, I.; Martin-Diana, A.; Burón, M.; Rico, D. Development of functional bio-based seaweed (Himanthalia elongata and Palmaria palmata) edible films for extending the shelflife of fresh fish burgers. Food Packag. Shelf Life 2019, 22, 100382. [Google Scholar] [CrossRef]

- Wang, L.; Liu, F.; Jiang, Y.; Chai, Z.; Li, P.; Cheng, Y.; Jing, H.; Leng, X. Synergistic Antimicrobial Activities of Natural Essential Oils with Chitosan Films. J. Agric. Food Chem. 2011, 59, 12411–12419. [Google Scholar] [CrossRef]

- Kandhasamy, M.; Arunachalam, K.D. Evaluation of in vitro antibacterial property of seaweeds of southeast coast of India. Afr. J. Biotechnol. 2008, 7, 1958–1961. [Google Scholar] [CrossRef]

- Laksanawati, T.A.; Khirzin, M.H.; Amaniyah, M.; Meidayanti, K.; Deva, B.D. Physicochemical Properties and Biodegradability of Biofilm Based on Taro Starch and Duck Bone Gelatin. Molekul 2024, 19, 17. [Google Scholar] [CrossRef]

- Hanry, E.L.; Redzwan, N.F.M.; Badeges, N.F.A.K.; Surugau, N. Characterization of biofilms developed from alginate extracted from Padina sp. incorporated with calcium chloride (CaCl2). J. Phys. Conf. Ser. 2022, 2314, 012022. [Google Scholar] [CrossRef]

| Blend | Chitosan (%, w/v) | ULP (%, w/v) | Glycerol (%, v/v) | Ratio (v/v) |

|---|---|---|---|---|

| Control: CH | 1 | 0 | 20 | - |

| Blend 1: CH-ULP 0.5% | 1 | 1 | 20 | 1:1 |

| Blend 2: CH-ULP 1.5% | 1 | 3 | 20 | 1:1 |

| Blend 3: CH-ULP 3% | 1 | 5 | 20 | 1:1 |

| Biobased Film | Moisture Content | Solubility |

|---|---|---|

| CH | 22.3 ± 0.01 a | 27.9 ± 0.02 a |

| CH-ULP 0.5% | 19.7 ± 0.01 b | 24.4 ± 0.03 b |

| CH-ULP 1.5% | 17.7 ± 0.03 c | 20.1 ± 0.01 c |

| CH-ULP 3% | 13.6 ± 0.02 d | 15.4 ± 0.02 d |

| Parameters | Biobased Films | |||

|---|---|---|---|---|

| CH | CH-ULP 0.5% | CH-ULP 1.5% | CH-ULP 3% | |

| L* | 89.4 ± 0.04 a | 88.7 ± 0.16 a | 86.6 ± 0.02 b | 85.7 ± 0.03 c |

| a* | −0.8 ± 0.03 a | −0.8 ± 0.03 a | −0.9 ± 0.02 b | −1.1 ± 0.01 c |

| b* | 1.1 ± 0.01 a | 1.2 ± 0.02 a | 1.4 ± 0.05 b | 1.8 ± 0.06 c |

| ΔE | 5.5 ± 1.23 a | 6.2 ± 0.58 a | 8.3 ± 1.87 b | 9.4 ± 0.77 c |

| WI | 89.5 ± 1.34 a | 88.6 ± 1.45 a | 86.5 ± 0.07 b | 85.5 ± 0.45 c |

| YI | 1.7 ± 0.45 a | 1.9 ± 0.28 a | 2.2 ± 1.83 b | 3.0 ± 0.38 c |

| Opacity (%) | 16.8 ± 1.43 a | 19.3 ± 0.07 b | 19.8 ± 0.28 b | 20.3 ± 0.75 c |

| Biobased Film | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| CH | 33.4 ± 0.56 a | 3.0 ± 0.82 a |

| CH-ULP 0.5% | 41.4 ± 0.78 b | 4.9 ± 0.54 b |

| CH-ULP 1.5% | 44.2 ± 1.03 c | 5.7 ± 0.24 c |

| CH-ULP 3% | 49.8 ±0.53 d | 7.5 ± 1.37 d |

| Pathogenic Microorganism | Diameter of Inhibition Zone (mm) | |||

|---|---|---|---|---|

| CH | CH-ULP 0.5% | CH-ULP 1.5% | CH-ULP 3% | |

| Escherichia coli | 10.0 ± 0.06 a | 12.4 ± 0.02 b | 14.1 ± 0.01 c | 17.0 ± 0.06 d |

| Salmonella typhimurium | 11.1 ± 0.03 a | 12.0 ± 0.04 b | 13.1 ± 0.04 c | 15.1 ± 0.03 d |

| Staphylococcus aureus | 16.1 ± 0.08 a | 18.2 ± 0.03 b | 18.5 ± 0.01 c | 24.0 ± 0.08 d |

| Listeria monocytogenes | 15.3 ± 0.04 a | 16.9 ± 0.08 b | 17.1 ± 0.09 c | 23.2 ± 0.04 d |

| Aspergillus niger | 12.1 ± 0.13 a | 13.7 ± 0.01 b | 14.2 ± 0.02 c | 16.1 ± 0.13 d |

| Geotrichum candidum | 14.1 ± 0.02 a | 14.2 ± 0.01 a | 16.1 ± 0.01 b | 17.1 ± 0.02 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaghbib, I.; Abdullah, J.A.A.; Romero, A. Development of a Multifunctional Chitosan-Based Composite Film from Crab Shell (Portunus segnis) and Algae (Ulva lactuca) with Enhanced Antioxidant and Antimicrobial Properties for Active Food Packaging. Foods 2025, 14, 53. https://doi.org/10.3390/foods14010053

Zaghbib I, Abdullah JAA, Romero A. Development of a Multifunctional Chitosan-Based Composite Film from Crab Shell (Portunus segnis) and Algae (Ulva lactuca) with Enhanced Antioxidant and Antimicrobial Properties for Active Food Packaging. Foods. 2025; 14(1):53. https://doi.org/10.3390/foods14010053

Chicago/Turabian StyleZaghbib, Imen, Johar Amin Ahmed Abdullah, and Alberto Romero. 2025. "Development of a Multifunctional Chitosan-Based Composite Film from Crab Shell (Portunus segnis) and Algae (Ulva lactuca) with Enhanced Antioxidant and Antimicrobial Properties for Active Food Packaging" Foods 14, no. 1: 53. https://doi.org/10.3390/foods14010053

APA StyleZaghbib, I., Abdullah, J. A. A., & Romero, A. (2025). Development of a Multifunctional Chitosan-Based Composite Film from Crab Shell (Portunus segnis) and Algae (Ulva lactuca) with Enhanced Antioxidant and Antimicrobial Properties for Active Food Packaging. Foods, 14(1), 53. https://doi.org/10.3390/foods14010053