Yolk and Casein Sequence Self-Assembly for Low-Oil Emulsion Gel and Its Application in Low-Fat Mayonnaise

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Yolk–Casein Solution

2.2.2. Interfacial Tension

2.2.3. Preparation of Low-Fat Mayonnaise

2.2.4. Preparation of Yolk–Casein-Mixture-Based Low-Fat Mayonnaise with Stained Yolk

2.2.5. Confocal Laser Scanning Microscopy (CLSM)

2.2.6. Sodium Dodecyl Sulphate-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

2.2.7. Cryo-Scanning Electron Microscopy (Cryo-SEM)

2.2.8. Optical Microscopic

2.2.9. Sensory Evaluation

2.2.10. Low-Field NMR (LF-NMR) Measurements

2.2.11. Rheological Measurements

2.2.12. Statistical Analysis

3. Results and Discussion

3.1. Interfacial Stability of Yolk–Casein-Mixture-Based Low-Fat Mayonnaise

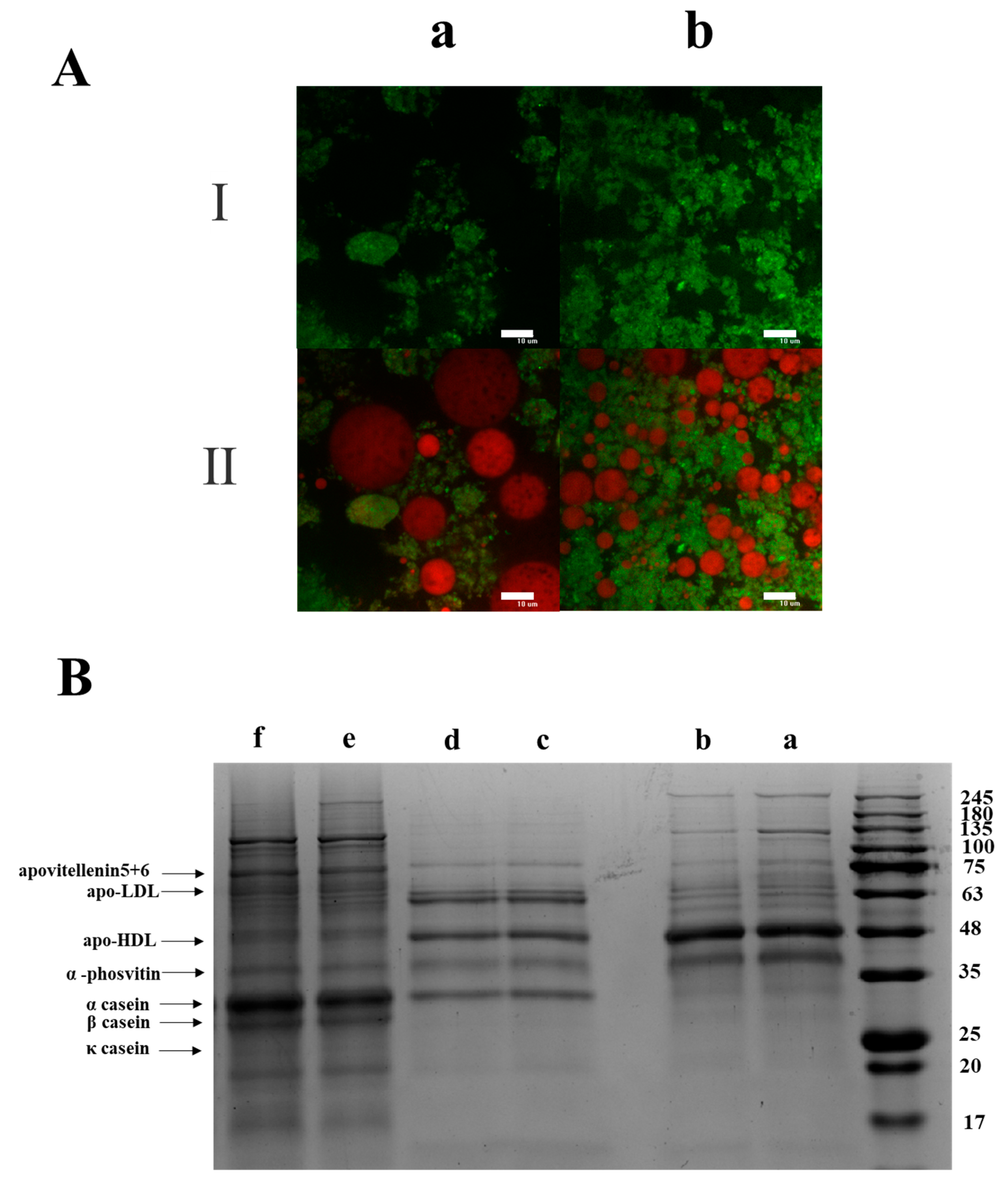

3.2. The Distribution of Yolk and Casein in Low-Fat Mayonnaise

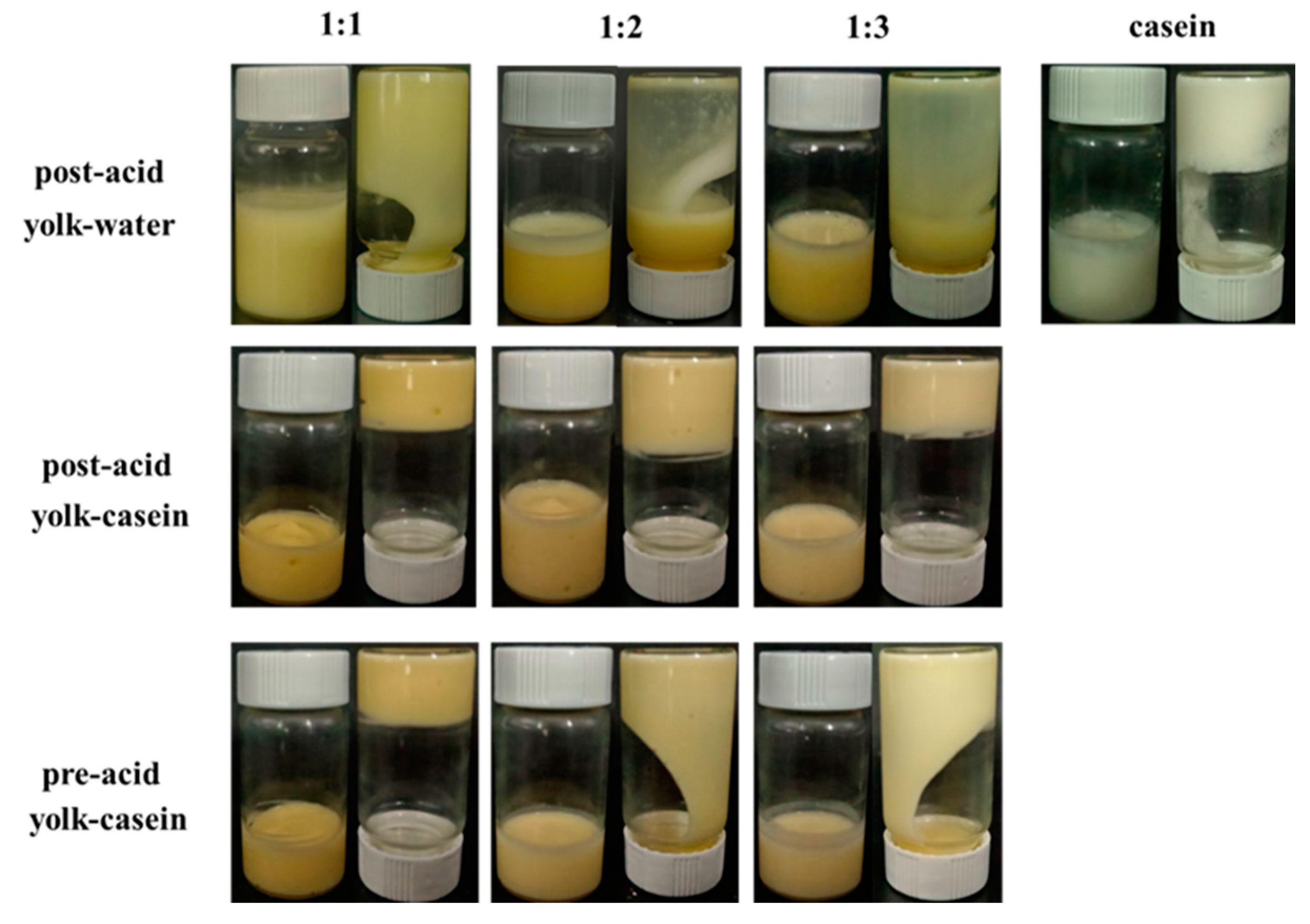

3.3. Post-Acid-Treated Yolk–Casein-Mixture-Based Emulsion to Form Low-Fat Mayonnaise

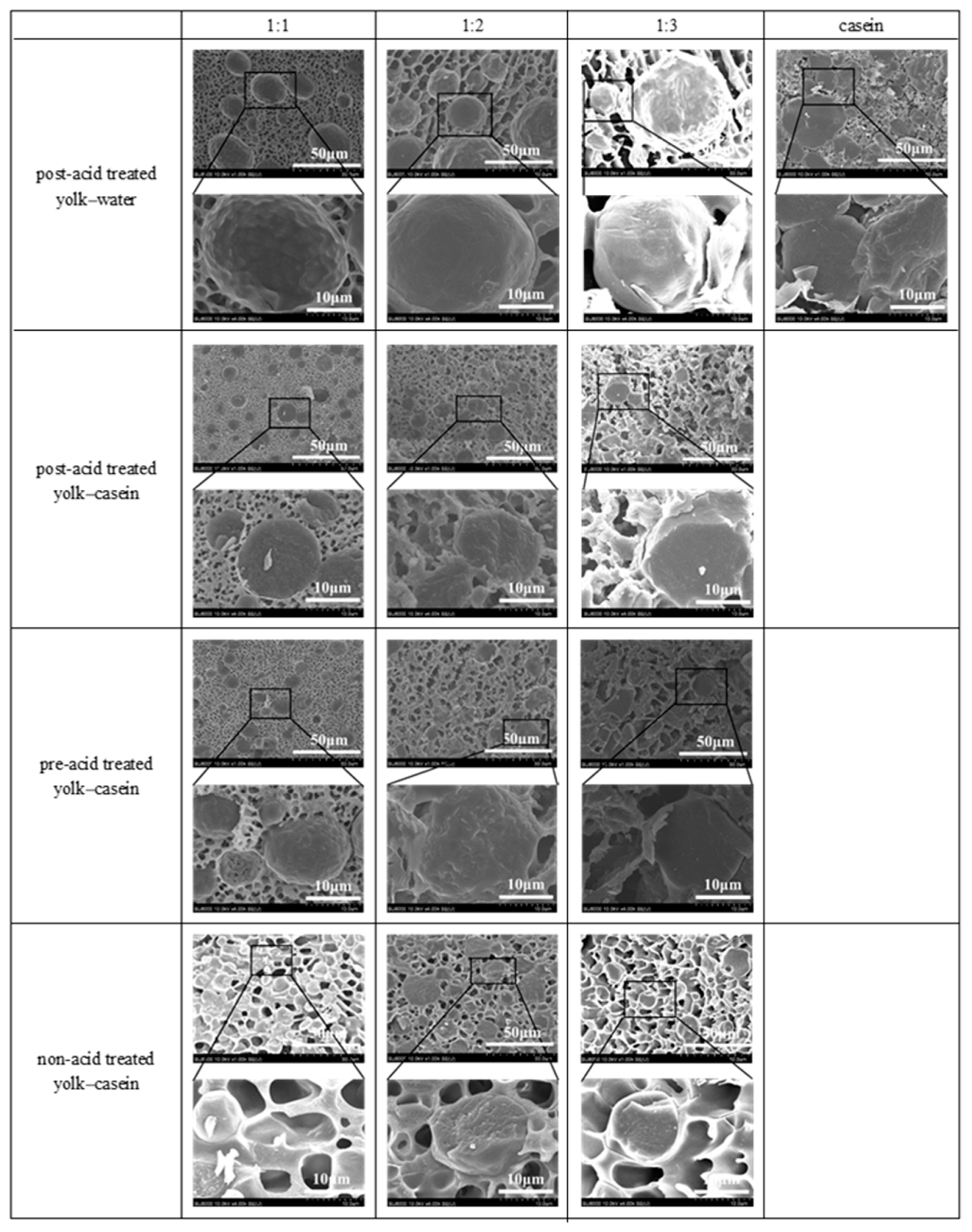

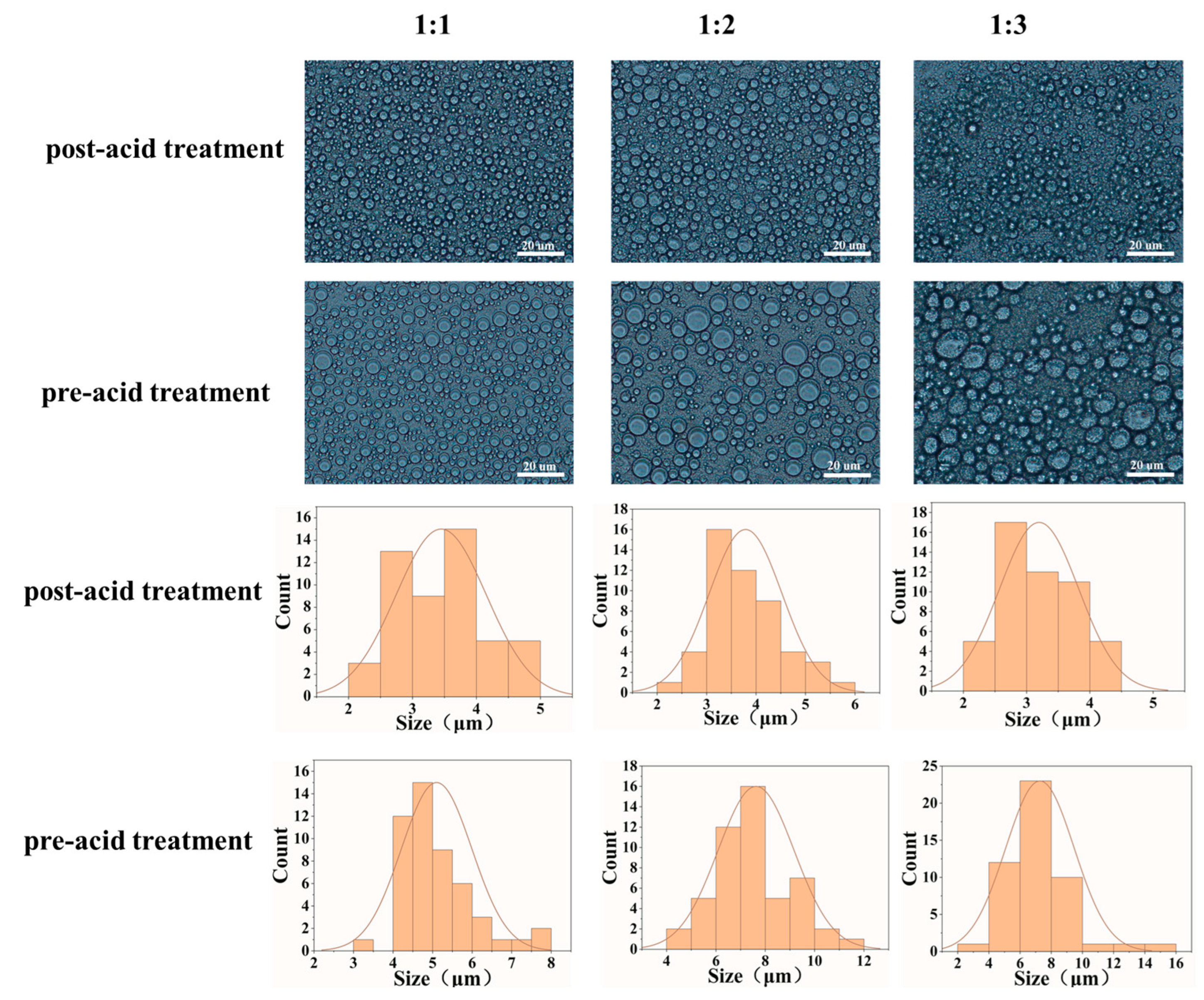

3.4. The Dense Network Structure Formed by Self-Assembly of the Yolk and Casein “Traps” the Oil Droplets

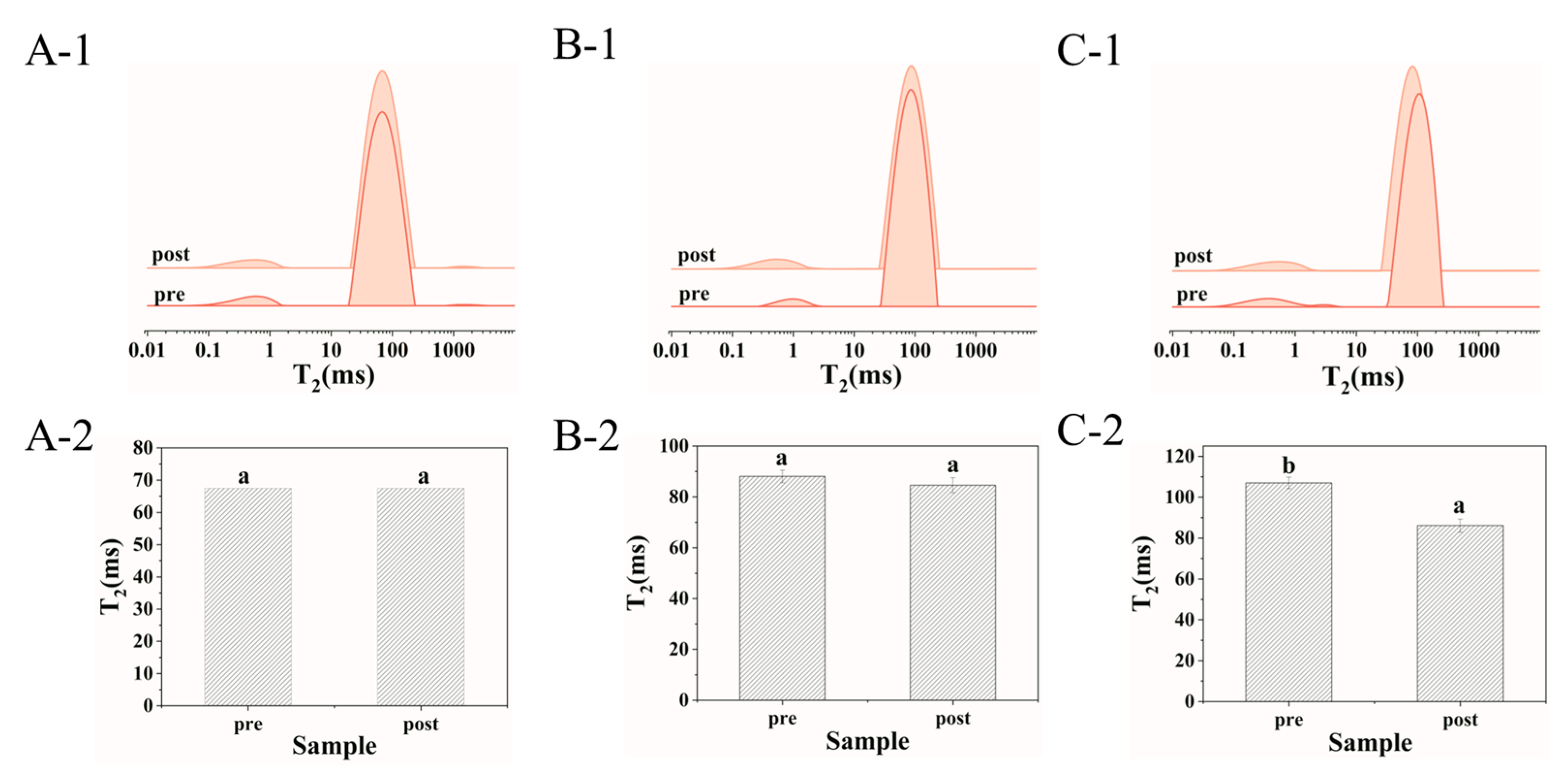

3.5. Enhancement Effect of Post-Acidification on Viscosity of Yolk–Casein-Mixture-Based Low-Fat Mayonnaise

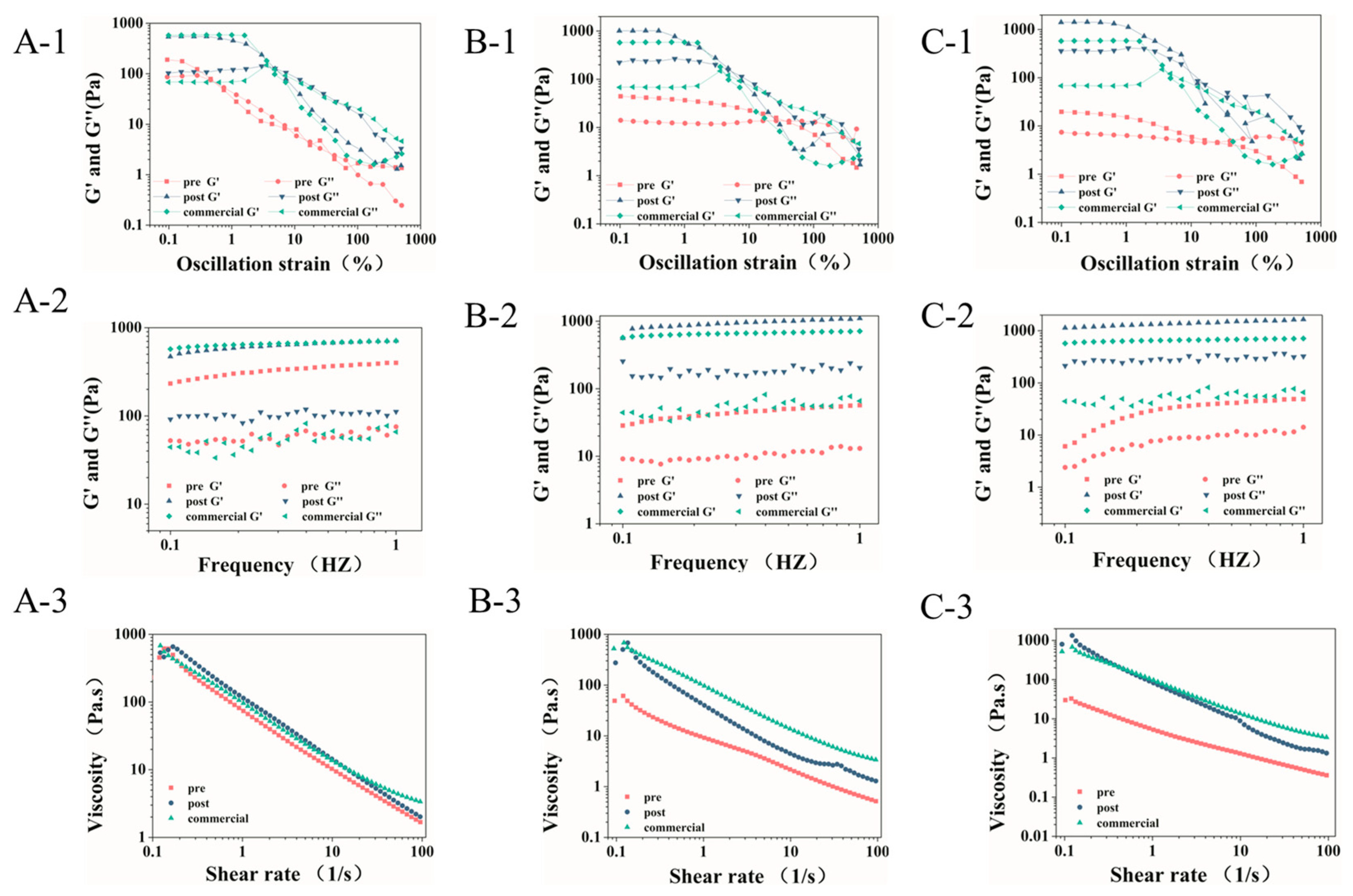

3.6. Enhancement Effect of Post-Acidification on Rheological Properties of Yolk–Casein-Mixture-Based Low-Fat Mayonnaise

3.7. Advantages of Post-Acidification Strategy for the Preparation of Low-Fat Mayonnaise

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kryskova, L.; Spivak, S. Developing a Strategy for Improving Mayonnaise with Different Proportions of Vegetable Oils. Technol. Audit Prod. Reserv. 2023, 4, 15–18. [Google Scholar] [CrossRef]

- Sun, C.; Liu, R.; Liang, B.; Wu, T.; Sui, W.; Zhang, M. Microparticulated Whey Protein-Pectin Complex: A Texture-Controllable Gel for Low-Fat Mayonnaise. Food Res. Int. 2018, 108, 151–160. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, S.; Alimi, M.; Shahidi, S.A.; Shokoohi, S. Investigating the Physicochemical, Rheological, and Sensory Properties of Low-Fat Mayonnaise Prepared with Amaranth Protein as an Egg Yolk Replacer. Food Sci. Nutr. 2024, 12, 5147–5161. [Google Scholar] [CrossRef]

- Yang, X.; Li, A.; Yu, W.; Li, X.; Sun, L.; Xue, J.; Guo, Y. Structuring Oil-in-Water Emulsion by Forming Egg Yolk/Alginate Complexes: Their Potential Application in Fabricating Low-Fat Mayonnaise-like Emulsion Gels and Redispersible Solid Emulsions. Int. J. Biol. Macromol. 2020, 147, 595–606. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Xu, D.; Zhu, Y.; Cao, Y.; Li, X.; Sun, B. Modulation of Stability, Rheological Properties, and Microstructure of Heteroaggregated Emulsion: Influence of Oil Content. LWT 2019, 109, 457–466. [Google Scholar] [CrossRef]

- Shi, Y.; Li, J.; Gu, L.; Su, Y.; Chen, W.; Zhang, M.; Chang, C.; Yang, Y. Synergistic Effect of Gum Arabic and Xanthan Gum on Improving Rheological Properties of Low-Fat Mayonnaise with Egg White Protein Microparticle as a Fat Mimetic. Int. J. Food Sci. Technol. 2023, 58, 1037–1048. [Google Scholar] [CrossRef]

- Han, Y.M.; Zhu, L.; Qi, X.G.; Zhang, H.; Wu, G.C. Characteristics of Low-Fat Whipped Cream Containing Protein-Based Fat Replacers. Int. J. Dairy Technol. 2023, 76, 276–290. [Google Scholar] [CrossRef]

- Yang, K.; Xu, R.; Xu, X.; Guo, Q. Role of Flaxseed Gum and Whey Protein Microparticles in Formulating Low-Fat Model Mayonnaises. Foods 2022, 11, 282. [Google Scholar] [CrossRef]

- Yalmanci, D.; Dertli, E.; Tekin-Cakmak, Z.H.; Karasu, S. The Stabilisation of Low-Fat Mayonnaise by Whey Protein Isolate-Microbial Exopolysaccharides (Weissella Confusa W-16 Strain) Complex. Int. J. Food Sci. Technol. 2023, 58, 1307–1316. [Google Scholar] [CrossRef]

- Qin, J.; Yuan, Z.; An, J.; Shi, Y.; Zheng, J.; Yang, M. Highly Stable Emulsion Gels with Micellar Casein Based on the Jamming Transition, for Bioactive Molecule Delivery. Food Hydrocoll. 2023, 143, 108874. [Google Scholar] [CrossRef]

- Sun, L.; Wang, H.; Li, X.; Lan, S.; Wang, J.; Yu, D. Ultrasonic-Assisted Preparation of α-Tocopherol/Casein Nanoparticles and Application in Grape Seed Oil Emulsion. Ultrason. Sonochem. 2021, 80, 105810. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Wu, C.; Du, M.; Lin, S.; Xu, X.; Yu, P. In-Situ Dispersion of Casein to Form Nanoparticles for Pickering High Internal Phase Emulsions. LWT 2021, 139, 110538. [Google Scholar] [CrossRef]

- Lara-Castellanos, M.J.; Azuara, E.; Jimenez-Fernandez, V.M.; Luna-Solano, G.; Jimenez, M. Effect of Casein Replacement by Modified Casein on Physicochemical, Textural, Sensorial Properties and Microbiological Stability of Fresh Cheese. Int. Dairy J. 2021, 112, 104864. [Google Scholar] [CrossRef]

- Chua, D.; Deeth, H.C.; Oh, H.E.; Bansal, N. Altering the Casein to Whey Protein Ratio to Enhance Structural Characteristics and Release of Major Yoghurt Volatile Aroma Compounds of Non-Fat Stirred Yoghurts. Int. Dairy J. 2017, 74, 63–73. [Google Scholar] [CrossRef]

- Xiao, F.; Hu, S.; Li, J.; Pan, J.; Dong, X.; Du, M.; Xu, X. Universal Strategy for Regulating Protein-Based High Internal Phase Emulsions as 3D Printing Materials. Adv. Funct. Mater. 2024, 34, 2308967. [Google Scholar] [CrossRef]

- Zhang, L.; Zaky, A.A.; Zhou, C.; Chen, Y.; Su, W.; Wang, H.; Abd El-Aty, A.M.; Tan, M. High Internal Phase Pickering Emulsion Stabilized by Sea Bass Protein Microgel Particles: Food 3D Printing Application. Food Hydrocoll. 2022, 131, 107744. [Google Scholar] [CrossRef]

- Yu, X.; Han, L.; Xu, Q.; Li, S.; Prakash, S.; Dong, X. Enhanced Rheological and 3D-Printing Properties of High Internal Phase Emulsions Stabilized by Egg White Microgels Synergized with Konjac Gum/Xanthan Gum. Food Hydrocoll. 2024, 153, 109981. [Google Scholar] [CrossRef]

- Cheng, C.; Wu, Z.; Wang, Y.; Chen, J.; Zhong, Y.; Liang, R.; Peng, S.; McClements, D.J.; Liu, W. Tunable High Internal Phase Emulsions (HIPEs) Formulated Using Lactoferrin-Gum Arabic Complexes. Food Hydrocoll. 2021, 113, 106445. [Google Scholar] [CrossRef]

- Liu, X.; Chen, X.W.; Guo, J.; Yin, S.W.; Yang, X.Q. Wheat Gluten Based Percolating Emulsion Gels as Simple Strategy for Structuring Liquid Oil. Food Hydrocoll. 2016, 61, 747–755. [Google Scholar] [CrossRef]

- Xu, T.; Pan, M.; Chiou, Y.; Li, Z.; Wei, S.; Yin, X.; Ding, B. Improvement of Emulsifying Properties of Potato Starch via Complexation with Nanoliposomes for Stabilizing Pickering Emulsion. Food Hydrocoll. 2023, 136, 108271. [Google Scholar] [CrossRef]

- Liu, Y.; Lee, W.J.; Tan, C.P.; Lai, O.M.; Wang, Y.; Qiu, C. W/O High Internal Phase Emulsion Featuring by Interfacial Crystallization of Diacylglycerol and Different Internal Compositions. Food Chem. 2022, 372, 131305. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhou, C.; Xing, S.; Chen, Y.; Su, W.; Wang, H.; Tan, M. Sea Bass Protein-Polyphenol Complex Stabilized High Internal Phase of Algal Oil Pickering Emulsions to Stabilize Astaxanthin for 3D Food Printing. Food Chem. 2023, 417, 135824. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Wang, N.; Dai, Y.; Yu, D.; Cheng, J. Interfacial Adsorption Properties, Rheological Properties and Oxidation Kinetics of Oleogel-in-Water Emulsion Stabilized by Hemp Seed Protein. Food Hydrocoll. 2023, 137, 108402. [Google Scholar] [CrossRef]

- Zhou, B.; Drusch, S.; Hogan, S.A. Confined Flow Behavior under High Shear Rates and Stability of Oil/Water High Internal Phase Emulsions (HIPEs) Stabilized by Whey Protein Isolate: Role of Protein Concentration and PH. Food Res. Int. 2022, 160, 111674. [Google Scholar] [CrossRef]

- Miao, J.; Xu, N.; Cheng, C.; Zou, L.; Chen, J.; Wang, Y.; Liang, R.; McClements, D.J.; Liu, W. Fabrication of Polysaccharide-Based High Internal Phase Emulsion Gels: Enhancement of Curcumin Stability and Bioaccessibility. Food Hydrocoll. 2021, 117, 106679. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, L.; Czaja, T.P.; Bakalis, S.; Zhang, W.; Lametsch, R. Structural Characteristics of High-Moisture Extrudates with Oil-in-Water Emulsions. Food Res. Int. 2022, 158, 111554. [Google Scholar] [CrossRef]

- Wang, M.; Feng, M.; Jia, K.; Sun, J.; Xu, X.; Zhou, G. Effects of Flaxseed Gum Concentrations and PH Values on the Stability of Oil-in-Water Emulsions. Food Hydrocoll. 2017, 67, 54–62. [Google Scholar] [CrossRef]

- Bi, A.Q.; Xu, X.B.; Guo, Y.; Du, M.; Yu, C.P.; Wu, C. Fabrication of Flavour Oil High Internal Phase Emulsions by Casein/Pectin Hybrid Particles: 3D Printing Performance. Food Chem. 2022, 371, 131349. [Google Scholar] [CrossRef]

- Fiorotti, T.A.; Sad, C.M.S.; Castro, E.R.V.; Barbosa, L.L. Rheological Study of W/O Emulsion by Low Field NMR. J. Pet. Sci. Eng. 2019, 176, 421–427. [Google Scholar] [CrossRef]

- Barbosa, L.L.; Kock, F.V.C.; Silva, R.C.; Freitas, J.C.C.; Lacerda, V.; Castro, E.V.R. Application of Low-Field NMR for the Determination of Physical Properties of Petroleum Fractions. Energy Fuels 2013, 27, 673–679. [Google Scholar] [CrossRef]

- Li, S.; Zhu, Y.; Hao, X.; Su, H.; Chen, X.; Yao, Y. High Internal Phase Pickering Emulsions Stabilized by the Complexes of Ultrasound-Treated Pea Protein Isolate/Mung Bean Starch for Delivery of β-Carotene. Food Chem. 2024, 440, 138201. [Google Scholar] [CrossRef] [PubMed]

- Alkabaa, A.S.; Akcicek, A.; Taylan, O.; Balubaid, M.; Alamoudi, M.; Gulzar, W.A.; Alidrisi, H.; Dertli, E.; Karasu, S. Production of Novel Bigels from Cold Pressed Chia Seed Oil By-Product: Application in Low-Fat Mayonnaise. Foods 2024, 13, 574. [Google Scholar] [CrossRef]

| Sensory Parameters | 1:1 | 1:2 | 1:3 | |||

|---|---|---|---|---|---|---|

| Pre | Post | Pre | Post | Pre | Post | |

| color | 7.25 ± 1.11 a | 8.00 ± 0.82 b | 7.07 ± 1.43 a | 7.80 ± 1.01 a | 6.17 ± 0.93 a | 8.08 ± 0.10 b |

| elasticity | 7.22 ± 1.26 a | 8.65 ± 0.80 b | 5.82 ± 0.75 a | 8.15 ± 0.96 b | 6.30 ± 0.67 a | 7.67 ± 1.40 b |

| viscosity | 8.08 ± 1.03 a | 8.31 ± 1.18 a | 5.53 ± 0.97 a | 8.29 ± 0.61 b | 5.89 ± 0.78 a | 8.30 ± 0.70 b |

| acceptability | 7.77 ± 1.16 a | 8.66 ± 0.86 b | 5.22 ± 0.83 a | 7.63 ± 1.08 b | 5.18 ± 0.99 a | 8.09 ± 0.85 b |

| Emulsifier | Protein-Based Fat Replacers | Thickeners | Fat Content | References |

|---|---|---|---|---|

| egg yolk powder–whey protein–gelatin | whey protein gelatin | Cold-pressed chia seed oil by-product gum | 30% | [32] |

| egg yolk–amaranth protein isolate | amaranth protein isolate | xanthan gum guar gum | 30% | [3] |

| egg yolk–microparticulated whey protein | microparticulated whey protein | pectin | 16–48% | [2] |

| dried egg yolk–whey protein microparticles | whey protein microparticles | flaxseed gum | 15% | [8] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, A.; Zhu, B.; Cong, N.; Du, M.; Wu, C.; Zhang, L.; Guo, Y.; Cheng, T.; Yu, P.; Xu, X. Yolk and Casein Sequence Self-Assembly for Low-Oil Emulsion Gel and Its Application in Low-Fat Mayonnaise. Foods 2025, 14, 36. https://doi.org/10.3390/foods14010036

Bi A, Zhu B, Cong N, Du M, Wu C, Zhang L, Guo Y, Cheng T, Yu P, Xu X. Yolk and Casein Sequence Self-Assembly for Low-Oil Emulsion Gel and Its Application in Low-Fat Mayonnaise. Foods. 2025; 14(1):36. https://doi.org/10.3390/foods14010036

Chicago/Turabian StyleBi, Anqi, Beiwei Zhu, Ning Cong, Ming Du, Chao Wu, Ling Zhang, Yan Guo, Tingting Cheng, Pei Yu, and Xianbing Xu. 2025. "Yolk and Casein Sequence Self-Assembly for Low-Oil Emulsion Gel and Its Application in Low-Fat Mayonnaise" Foods 14, no. 1: 36. https://doi.org/10.3390/foods14010036

APA StyleBi, A., Zhu, B., Cong, N., Du, M., Wu, C., Zhang, L., Guo, Y., Cheng, T., Yu, P., & Xu, X. (2025). Yolk and Casein Sequence Self-Assembly for Low-Oil Emulsion Gel and Its Application in Low-Fat Mayonnaise. Foods, 14(1), 36. https://doi.org/10.3390/foods14010036