Upcycling of Non-Standard Cakes by Manufacturing Ring-Shaped Cookies

Abstract

1. Introduction

2. Materials and Methods

2.1. Collection and Characterization of Mini Cake Waste

2.2. Wheat Flour Analysis

2.3. Manufacture of Ring-Shaped Cookies

2.4. Rapid Viscosity Analysis (RVA) of Cookie Dough Before Baking

2.5. Characterization of Ring-Shaped Cookies After Baking

2.6. Ageing of Ring-Shaped Cookies

2.7. Data Analysis

3. Results and Discussion

3.1. Characterization of Cake Waste and Wheat Flour

3.2. Characterization of Ring-Shaped Cookie Dough Using Mini Cake Waste

3.3. Physical and Physicochemical Characterization of Ring-Shaped Cookies Before and After Baking

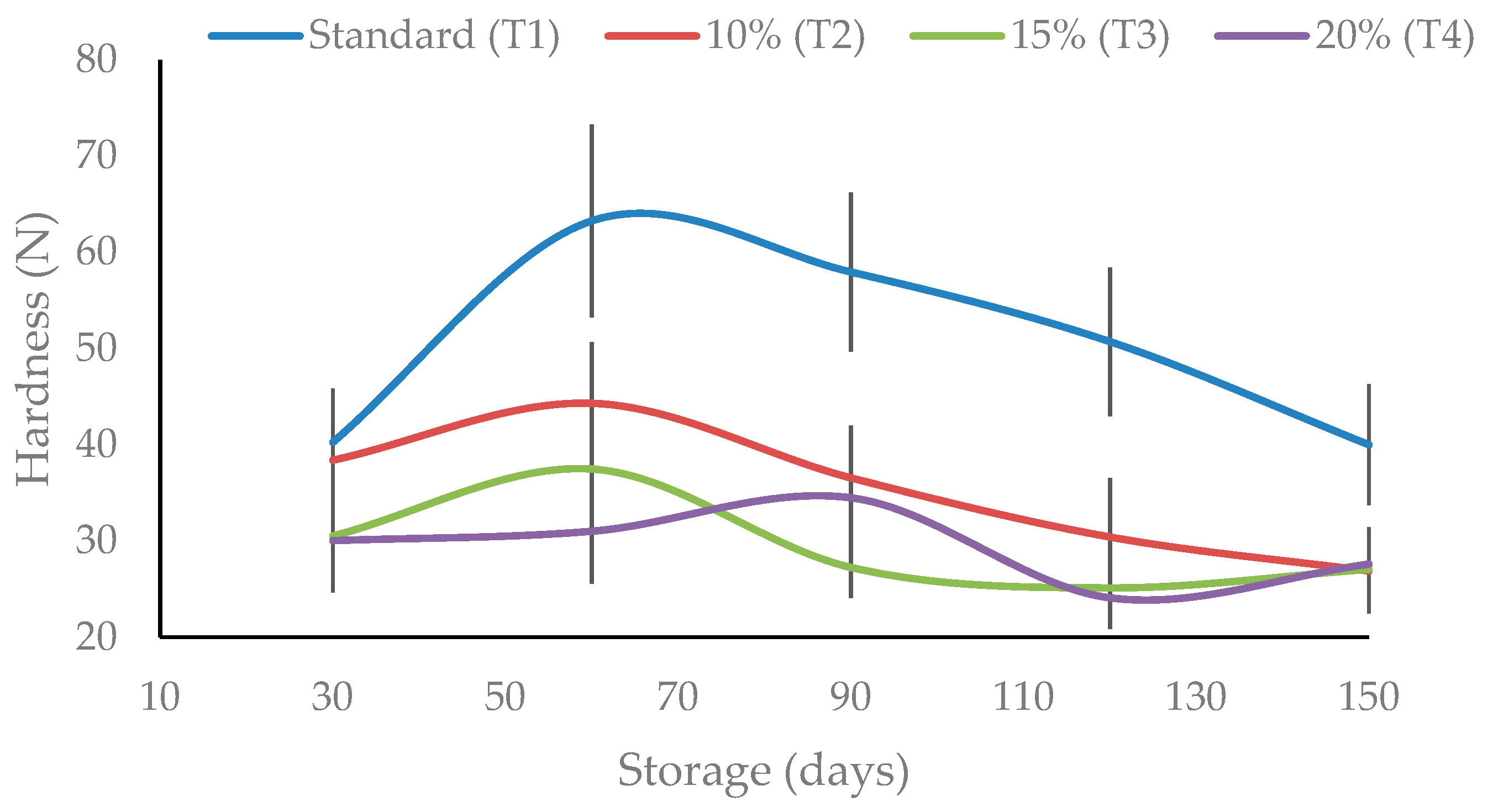

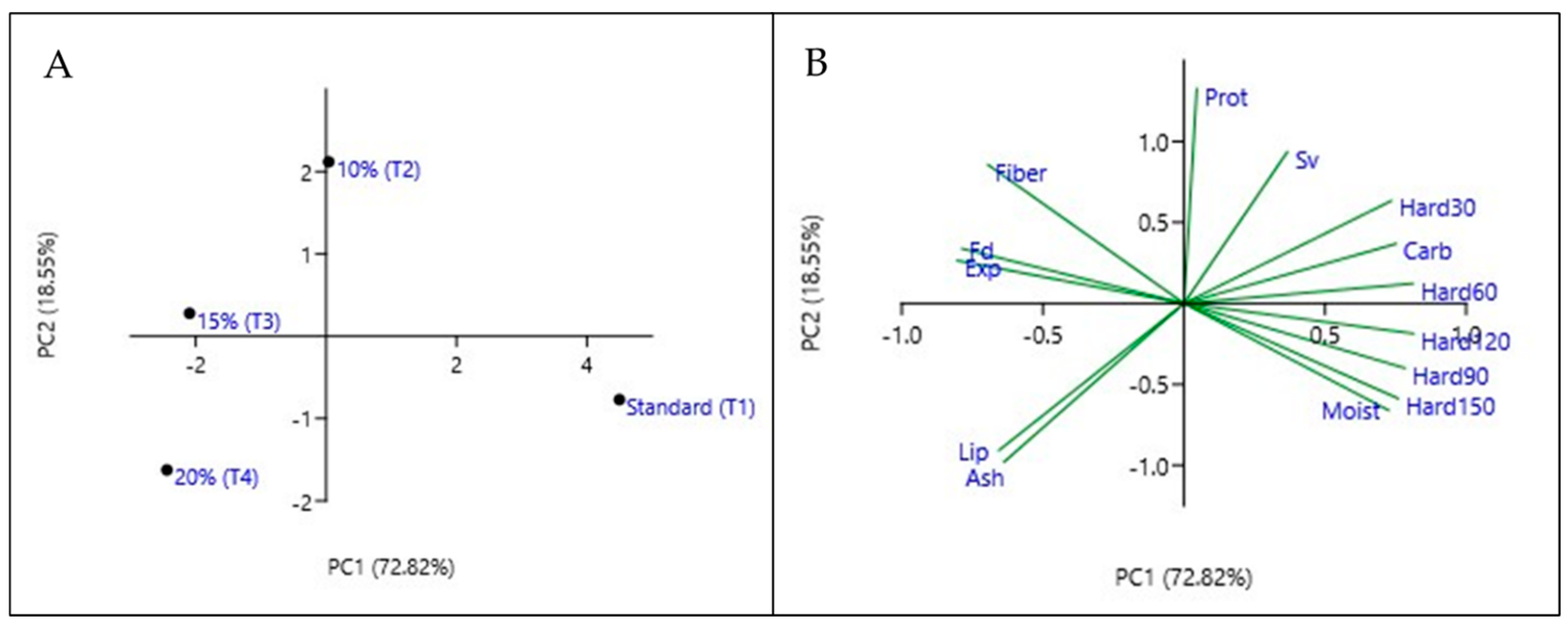

3.4. Aging Analysis of Ring-Shaped Cookies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quintelas, C.; Rodrigues, C.; Sousa, C.; Ferreira, E.C.; Amaral, A.L. Cookie Composition Analysis by Fourier Transform near Infrared Spectroscopy Coupled to Chemometric Analysis. Food Chem. 2024, 435, 137607. [Google Scholar] [CrossRef] [PubMed]

- Rego, R.A.; Vialta, A.; Ceribelli, L.F. Biscoitos Industrializados; BB Editora Abimapi: São Paulo, Brazil, 2020; ISBN 978-65-991414-1-4. [Google Scholar]

- Soares, I.D.; Cirilo, M.E.M.; Junqueira, I.G.; Vanin, F.M.; Rodrigues, C.E.D.C. Production of Cookies Enriched with Bioactive Compounds through the Partial Replacement of Wheat Flour by Cocoa Bean Shells. Foods 2023, 12, 436. [Google Scholar] [CrossRef]

- Chaturvedi, D.P.; Shukla, D.N.; Shukla, D.R.; Dhumketi, K. Development and Assessment of Healthy Multigrain Biscuits of Wheat Flour with Pearl Millet, Maize and Buckwheat Composite Flours. Pharma Innov. J. 2022, 11, 1702–1707. [Google Scholar]

- Oyeyinka, S.A.; Bassey, I.-A.V. Composition, Functionality, and Baking Quality of Flour from Four Brands of Wheat Flour. J. Culin. Sci. Technol. 2023, 1–21. [Google Scholar] [CrossRef]

- Petrescu, D.C.; Vermeir, I.; Petrescu-Mag, R.M. Consumer Understanding of Food Quality, Healthiness, and Environmental Impact: A Cross-National Perspective. Int. J. Environ. Res. Public Health 2019, 17, 169. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis, 22nd ed.; Association Official Analytical Chemists: Washington, DC, USA, 2023. [Google Scholar]

- Vandervant, C.; Splippspoesser, D.F. Compedium of Methods for Microbiological Examination of Foods, 3rd ed.; American Public Health Association: Washington, DC, USA, 1992. [Google Scholar]

- AACC. Approved Methods of the American Association of Cereal Chemists, 10th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2000. [Google Scholar]

- Sosulski, F.W. The Centrifuge Method for Determining Flour Absorption in Hard Red Spring Wheats. Cereal Chem. 1962, 39, 344–350. [Google Scholar]

- Menezes, E.W.D.; Grande, F.; Giuntini, E.B.; Lopes, T.D.V.C.; Dan, M.C.T.; Prado, S.B.R.D.; Franco, B.D.G.D.M.; Charrondière, U.R.; Lajolo, F.M. Impact of Dietary Fiber Energy on the Calculation of Food Total Energy Value in the Brazilian Food Composition Database. Food Chem. 2016, 193, 128–133. [Google Scholar] [CrossRef]

- Brasil Ministério da Saúde, Agência Nacional de Vigilância Sanitária. RDC no 429.Rotulagem nutricional dos alimentos embalados. In Diário União; 2022; 195, p. 106. Available online: https://www.in.gov.br/en/web/dou/-/resolucao-de-diretoria-colegiada-rdc-n-429-de-8-de-outubro-de-2020-282070599 (accessed on 4 March 2024).

- Sandhu, K.; Singh, N. Some Properties of Corn Starches II: Physicochemical, Gelatinization, Retrogradation, Pasting and Gel Textural Properties. Food Chem. 2007, 101, 1499–1507. [Google Scholar] [CrossRef]

- Nwachoko, N.; Akuru, U.B.; Duke, B.N.; Egbunefu, C.O. Proximate Composition and Selected Physicochemical Parameters of Cake Prepared with Preservatives. Int. J. Appl. Chem. 2023, 10, 11–17. [Google Scholar] [CrossRef]

- Akinjayeju, O.; Okoli, H.F.; Bello, B.F. Optimization of Proximate Composition, Physico-Chemical Properties and Mineral Profiles of ‘Garri’, Soy-Cake and Millet Flour Blends for Potential Functional Dough Meal. Int. J. Sci. Technol. Res. Arch. 2021, 1, 22–32. [Google Scholar] [CrossRef]

- Asamoah, E.A.; Le-Bail, A.; Oge, A.; Queveau, D.; Rouaud, O.; Le-Bail, P. Impact of Baking Powder and Leavening Acids on Batter and Pound Cake Properties. Foods 2023, 12, 946. [Google Scholar] [CrossRef] [PubMed]

- Brasil Ministério da Saúde, Agência Nacional de Vigilância Sanitária. IN no 161. Listas de padrões microbiológicos de alimentos. In Diário União; 2022; 126, p. 235. Available online: https://www.in.gov.br/en/web/dou/-/instrucao-normativa-in-n-161-de-1-de-julho-de-2022-413366880 (accessed on 4 March 2024).

- Brasil Ministério da Saúde, Agência Nacional de Vigilância Sanitária. RDC no 711. Requisitos sanitários dos amidos, biscoitos, cereais integrais, cereais processados, farelos, farinhas, farinhas integrais, massas alimentícias e pães. In Diário União; 2022. Available online: https://anvisalegis.datalegis.net/action/ActionDatalegis.php?acao=abrirTextoAto&link=S&tipo=RDC&numeroAto=00000711&seqAto=002&valorAno=2022&orgao=RDC/DC/ANVISA/MS&cod_modulo=310&cod_menu=8542 (accessed on 4 March 2024).

- Popa, C.N.; Berehoiu, R.M.T.; Lambrache, N. Assessment of Gluten Index Component Wet Gluten Remaining on the Sieveas Predictor of Wheat Bakery Potential. Rev. Chim. 2019, 70, 3994–3999. [Google Scholar] [CrossRef]

- Nandeesh, K.; Jyotsna, R.; Venkateswara Rao, G. Effect of Diferente Treates Wheat Bran on Rheology, Microstructure and Quality Characteristics of Soft Dough Biscuits. J. Food Process. Preserv. 2011, 35, 179–200. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Wang, X.; Wang, J.; Hong, J.; Liu, M.; Sun, B.; Guan, E.; Zheng, X. Regulating the Quality and Starch Digestibility of Buckwheat-Dried Noodles through Steam Treatment. LWT 2024, 195, 115826. [Google Scholar] [CrossRef]

- Jia, R.; Cui, C.; Gao, L.; Qin, Y.; Ji, N.; Dai, L.; Wang, Y.; Xiong, L.; Shi, R.; Sun, Q. A Review of Starch Swelling Behavior: Its Mechanism, Determination Methods, Influencing Factors, and Influence on Food Quality. Carbohydr. Polym. 2023, 321, 121260. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Zhang, L.; Jia, X.; Ye, Q.; Pei, J.; Song, Q.; Ge, J.; Liu, X.; Duan, X. Multi-Scale Structural Changes and Mechanistic Analysis of Wheat Starch Gels with Common Proteins in Short-Term Retrogradation at Low Temperature. Food Hydrocoll. 2024, 146, 109160. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, X.; Ma, H.; Li, C.; Li, E.; Gilbert, R.G. Characterization of the Baking-Induced Changes in Starch Molecular and Crystalline Structures in Sugar-Snap Cookies. Carbohydr. Polym. 2021, 256, 117518. [Google Scholar] [CrossRef] [PubMed]

- Feddern, V.; Vaz Oleiro Durante, V.; Zavariz De Miranda, M.; Las Mercedes Salas Mellado, M.D. Avaliação física e sensorial de biscoitos tipo cookie adicionados de farelo de trigo e arroz. Braz. J. Food Technol. 2011, 14, 267–274. [Google Scholar] [CrossRef]

- Culetu, A.; Stoica-Guzun, A.; Duta, D.E. Impact of Fat Types on the Rheological and Textural Properties of Gluten-free Oat Dough and Cookie. Int. J. Food Sci. Technol. 2021, 56, 126–137. [Google Scholar] [CrossRef]

- Purhagen, J.K.; Sjöö, M.E.; Eliasson, A. Fibre-rich Additives—The Effect on Staling and Their Function in Free-standing and Pan-baked Bread. J. Sci. Food Agric. 2012, 92, 1201–1213. [Google Scholar] [CrossRef] [PubMed]

- JARDIM, D.C. P Atividade de Água e a Estabilidade Dos Alimentos. In Reações de Transformação e Vida-de-Prateleira de Alimentos Processados; Ital: Campinas, Brazil, 2010; pp. 17–23. [Google Scholar]

- Molnar, D.; Novotni, D.; Kurek, M.; Galić, K.; Iveković, D.; Bionda, H.; Ščetar, M. Characteristics of Edible Films Enriched with Fruit By-Products and Their Application on Cookies. Food Hydrocoll. 2023, 135, 108191. [Google Scholar] [CrossRef]

- Arepally, D.; Reddy, R.S.; Coorey, R.; Goswami, T.K. Evaluation of Functional, Physicochemical, Textural and Sensorial Properties of Multi-millet-based Biscuit. Int. J. Food Sci. Technol. 2023, 58, 2437–2447. [Google Scholar] [CrossRef]

- Swapna, K.S. Effect of Oat Incorporation on Textural Parameters of Dough and Sensory Quality of Biscuits. J. Food Diet. Res. 2023, 3, 15–23. [Google Scholar] [CrossRef]

| Waste 1 | Moisture (%) | Ash (%) | Lipids (%) | Protein (%) | Carbohydrates (%) | pH | aw |

|---|---|---|---|---|---|---|---|

| BMC | 18.77 ± 0.49 a | 1.04 ± 0.10 b | 23.36 ± 2.83 a | 5.95 ± 0.09 a | 50.87 | 6.86 ± 0.19 a | 0.76 ± 0.01 a |

| TMC | 14.87 ± 1.41 b | 1.20 ± 0.08 ab | 17.39 ± 0.35 b | 4.98 ± 0.17 b | 61.67 | 6.84 ± 0.12 a | 0.75 ± 0.00 a |

| FMC | 14.18 ± 0.33 b | 1.25 ± 0.04 a | 20.88 ± 0.68 ab | 6.05 ± 0.05 a | 58.33 | 6.89 ± 0.24 a | 0.72 ± 0.01 b |

| Formulation 1 | Peak (cP) | Minimum (cP) | Breakdown (cP) | Final (cP) | Tendency to Retrogradation (cP) | Peak Time (min) | Paste Temperature (°C) |

|---|---|---|---|---|---|---|---|

| Standard (T1) | 248.00 ± 26.06 a | 167.33 ± 10.21 a | 80.67 ± 16.26 a | 519.33 ± 35.35 a | 352.00 ± 25.51 a | 5.56 ± 0.10 a | 94.92 ± 0.20 a |

| 10% (T2) | 169.33 ± 3.51 b | 124.67 ± 2.08 b | 44.67 ± 1.53 b | 395.67 ± 4.62 b | 271.00 ± 2.65 b | 5.44 ± 0.08 a | 94.73 ± 0.11 a |

| 15% (T3) | 141.33 ± 5.03 bc | 108.00 ± 3.61 c | 33.33 ± 2.08 b | 346.33 ± 2.31 bc | 238.33 ± 1.53 bc | 5.38 ± 0.10 a | 94.73 ± 0.03 a |

| 20% (T4) | 124.67 ± 3.51 c | 98.33 ± 2.89 c | 26.33 ± 1.53 b | 302.67 ± 7.37 c | 204.33 ± 5.86 c | 5.36 ± 0.10 a | 94.88 ± 0.19 a |

| Formulation 1 | Physical Characteristics Before Baking | Physical Characteristics After Baking | ||||

|---|---|---|---|---|---|---|

| Initial Weight (g) | Initial Diameter (cm) | Final Weight (g) | Final Diameter (cm) | Expansion Factor | Specific Volume (cm3 g−1) | |

| Standard (T1) | 6.61 ± 0.12 a | 3.43 ± 0.11 b | 5.17 ± 0.11 b | 3.73 ± 0.11 b | 3.45 ± 0.35 c | 2.31 ± 0.27 a |

| 10% (T2) | 6.67 ± 0.22 a | 3.60 ± 0.09 a | 5.20 ± 0.19 b | 4.07 ± 0.12 a | 4.28 ± 0.31 b | 2.38 ± 0.19 a |

| 15% (T3) | 6.60 ± 0.16 a | 3.55 ± 0.08 a | 5.14 ± 0.13 b | 4.07 ± 0.18 a | 4.66 ± 0.34 a | 2.22 ± 0.21 a |

| 20% (T4) | 6.61 ± 0.19 a | 3.54 ± 0.8 a | 5.40 ± 0.16 a | 4.12 ± 0.12 a | 4.48 ± 0.36 ab | 2.27 ± 0.14 a |

| Formulation 1 | Physicochemical Characteristics | |||||

| Moisture (%) | Ash (%) | Lipids (%) | Protein (%) | Dietary Fiber (%) | Carbohydrates (%) | |

| Standard (T1) | 7.26 ± 0.22 a | 1.29 ± 0.01 a | 11.27 ± 0.73 b | 7.36 ± 0.25 a | 2.72 ± 0.01 d | 70.10 ± 0.80 a |

| 10% (T2) | 3.97 ± 0.16 c | 1.30 ± 0.04 a | 11.60 ± 0.77 b | 7.71 ± 0.66 a | 5.74 ± 0.01 a | 69.68 ± 1.41 a |

| 15% (T3) | 4.49 ± 0.17 b | 1.35 ± 0.03 a | 12.33 ± 0.59 ab | 7.80 ± 0.88 a | 5.49 ± 0.01 b | 68.54 ± 1.60 a |

| 20% (T4) | 4.33 ± 0.13 bc | 1.42 ± 0.08 a | 13.59 ± 0.07 a | 6.90 ± 0.68 a | 4.97 ± 0.01 c | 68.79 ± 0.43 a |

| Nutrition Facts | Standard (T1) | 10% (T2) | 15% (T3) | 20% (T4) | ||||

|---|---|---|---|---|---|---|---|---|

| * Per Serving (30 g) | %DV | * Per Serving (30 g) | %DV | * Per Serving (30 g) | %DV | * Per Serving (30 g) | %DV | |

| Energy value | 123 kcal = 520 kJ | 6 | 125 kcal = 526 kJ | 6 | 126 kcal = 526 kJ | 6 | 128 kcal = 538 kJ | 6 |

| Carbohydrates (g) | 21 | 7 | 21 | 7 | 20.6 | 7 | 20.6 | 7 |

| Proteins (g) | 2.2 | 3 | 2.3 | 3 | 2.3 | 3 | 2.1 | 3 |

| Total fat (g) | 3.4 | 6 | 3.5 | 6 | 3.7 | 7 | 4.1 | 7 |

| Saturated fat (g) | 0.7 | 3 | 0.8 | 4 | 0.8 | 4 | 0.9 | 4 |

| Trans fat (g) | 0.9 | 0.4 | 0.9 | 0.4 | 0.9 | 0.4 | 0.9 | 0.4 |

| Dietary fiber (g) | 0.8 | 3 | 1.7 | 6 | 1.6 | 6 | 1.5 | 5 |

| Sodium (mg) | 65 | 3 | 67 | 3 | 68 | 3 | 69 | 3 |

| Storage 1 (Days) | Standard (T1) | 10% (T2) | 15% (T3) | 20% (T4) | ||||

|---|---|---|---|---|---|---|---|---|

| Moisture (%) | Aw | Moisture (%) | Aw | Moisture (%) | Aw | Moisture (%) | Aw | |

| 0 | 7.26 ± 0.22 a | - | 3.97 ± 0.16 c | - | 4.49 ± 0.17 bc | - | 4.33 ± 0.13 d | - |

| 30 | 5.09 ± 0.02 d | 0.35 ± 0.01 b | 6.36 ± 0.04 a | 0.42 ± 0.01 a | 4.30 ± 0.06 c | 0.31 ± 0.02 a | 5.27 ± 0.03 c | 0.36 ± 0.01 a |

| 60 | 6.43 ± 0.48 c | 0.37 ± 0.06 b | 6.77 ± 0.23 a | 0.35 ± 0.01 b | 6.48 ± 0.30 a | 0.33 ± 0.00 a | 7.05 ± 0.41 a | 0.33 ± 0.00 b |

| 90 | 8.14 ± 0.26 a | 0.48 ± 0.00 a | 6.49 ± 0.04 a | 0.39 ± 0.00 a | 5.80 ± 0.39 ab | 0.34 ± 0.01 a | 5.93 ± 0.14 b | 0.34 ± 0.01 b |

| 120 | 7.40 ± 0.04 b | 0.48 ± 0.01 a | 5.54 ± 0.07 b | 0.39 ± 0.01 a | 4.45 ± 0.51 bc | 0.33 ± 0.01 a | 5.21 ± 0.06 c | 0.36 ± 0.01 a |

| 150 | 7.79 ± 0.15 ab | 0.47 ± 0.00 a | 6.38 ± 0.78 a | 0.41 ± 0.04 a | 4.51 ± 1.24 bc | 0.33 ± 0.07 a | 4.82 ± 0.11 d | 0.32 ± 0.01 c |

| * Mean value | 7.02 ±1.11 | 0.43 ± 0.06 | 5.92 ±1.04 | 0.39 ± 0.03 | 5.00 ±0.91 | 0.33 ± 0.01 | 5.43 ±0.95 | 0.34 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campanini, N.C.S.V.; Weis, C.M.S.C.; Nabeshima, E.H.; Temoczko, L.C.; Bertan, L.C.; Pinto, V.Z.; Quast, L.B. Upcycling of Non-Standard Cakes by Manufacturing Ring-Shaped Cookies. Foods 2024, 13, 4041. https://doi.org/10.3390/foods13244041

Campanini NCSV, Weis CMSC, Nabeshima EH, Temoczko LC, Bertan LC, Pinto VZ, Quast LB. Upcycling of Non-Standard Cakes by Manufacturing Ring-Shaped Cookies. Foods. 2024; 13(24):4041. https://doi.org/10.3390/foods13244041

Chicago/Turabian StyleCampanini, Nicolle Christina Silvester Vieira, Cláudia Moreira Santa Catharina Weis, Elizabeth Harumi Nabeshima, Luciana Camargo Temoczko, Larissa Canhadas Bertan, Vania Zanella Pinto, and Leda Battestin Quast. 2024. "Upcycling of Non-Standard Cakes by Manufacturing Ring-Shaped Cookies" Foods 13, no. 24: 4041. https://doi.org/10.3390/foods13244041

APA StyleCampanini, N. C. S. V., Weis, C. M. S. C., Nabeshima, E. H., Temoczko, L. C., Bertan, L. C., Pinto, V. Z., & Quast, L. B. (2024). Upcycling of Non-Standard Cakes by Manufacturing Ring-Shaped Cookies. Foods, 13(24), 4041. https://doi.org/10.3390/foods13244041