Evaluation of Drying Characteristics and Quality Attributes for Microwave Vacuum Drying of Pork Skin Crisps

Abstract

1. Introduction

2. Materials and Methods

2.1. Pre-Treatment of PSC

2.2. Microwave Vacuum Drying Experiments

2.3. Drying Characteristics

2.3.1. Water Activity

2.3.2. Moisture Content

2.3.3. Moisture Ratio

2.3.4. Drying Rate

2.3.5. Effective Moisture Diffusion Coefficient

2.3.6. Kinetics Modeling

2.4. Quality Characteristics

2.4.1. Color

2.4.2. Determination of Brittleness

2.4.3. Determination of the Expansion Ratio

2.4.4. Electronic Nose

2.4.5. Measurement of Lipid Oxidation

2.4.6. Sensory Evaluation

2.5. Statistical Analysis

3. Results

3.1. Drying Characteristics of PSC Under MVD

3.1.1. Changes in Water Activity of PSC During MVD

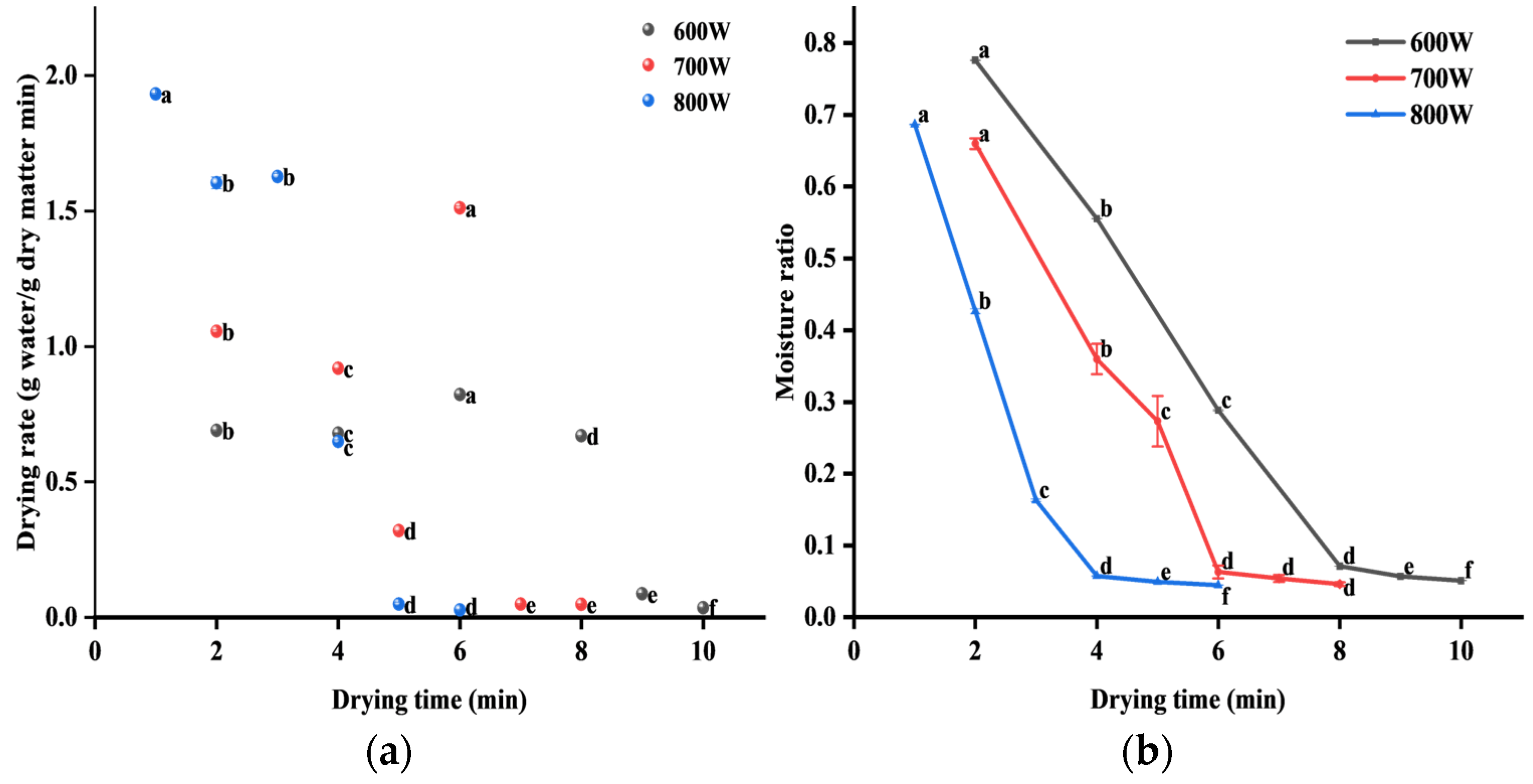

3.1.2. Changes in Drying Rate of PSC During MVD

3.1.3. Changes in Moisture Ratio of PSC During MVD

3.1.4. Changes in Effective Moisture Diffusion Coefficient of PSC During MVD

3.1.5. Analysis of Drying Kinetics of PSC During MVD

3.2. Drying Quality Characteristics of PSC Under MVD

3.2.1. Analysis of Color Characteristics of PSC

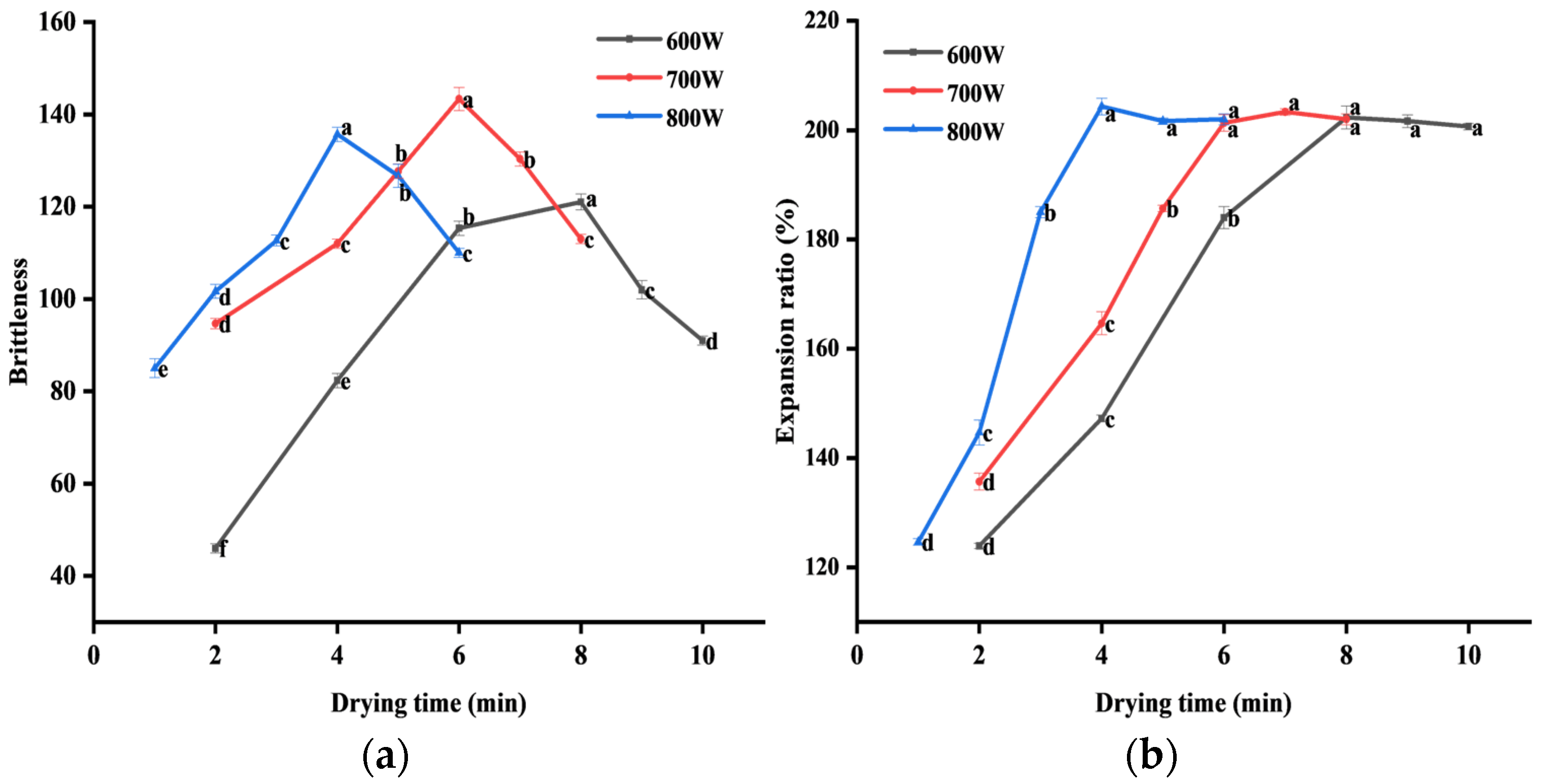

3.2.2. Changes in Brittleness of PSC

3.2.3. Changes in Expansion Ratio of PSC

3.2.4. Analysis of TBRAS

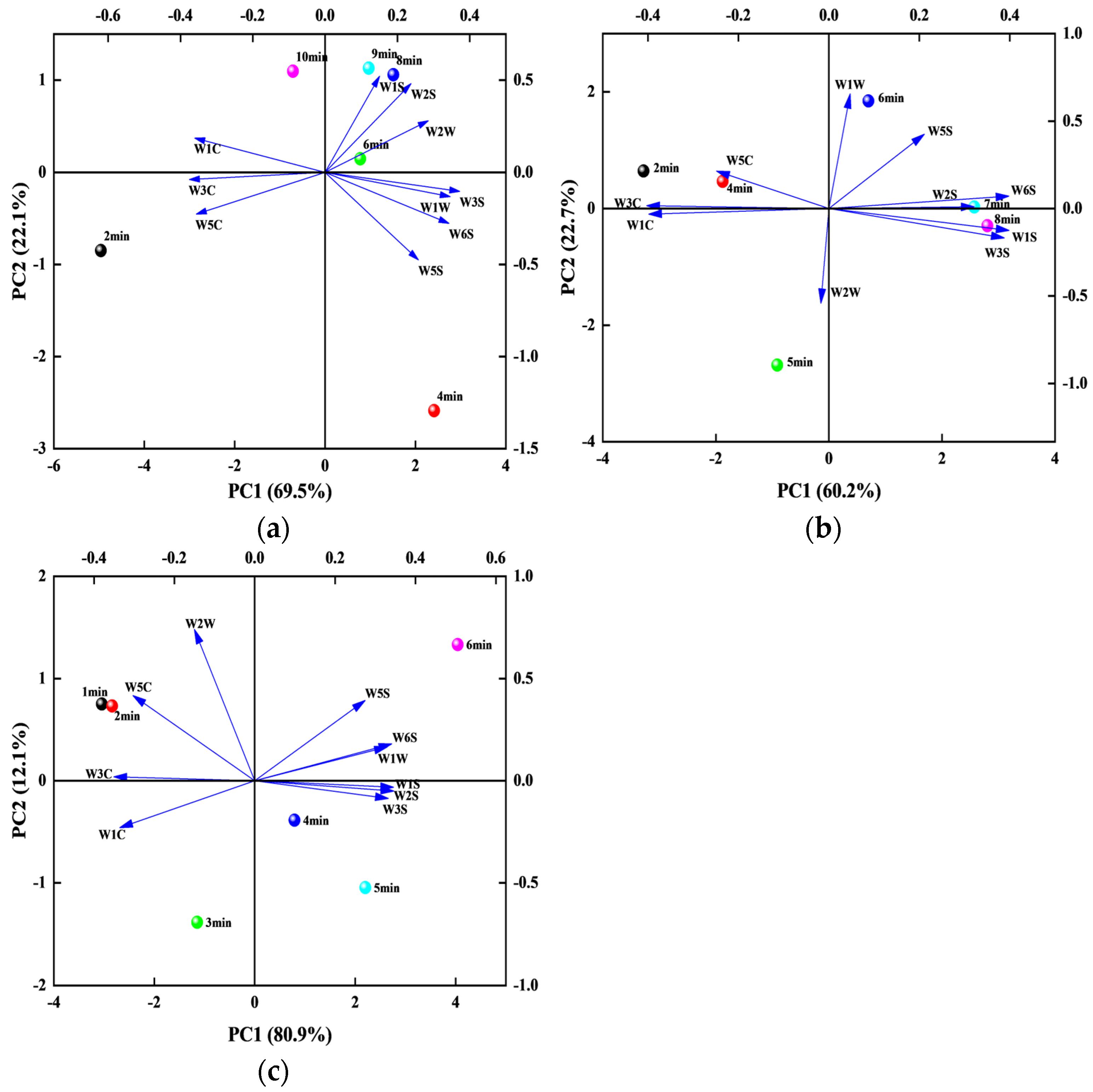

3.2.5. Detection of the Electronic Nose and PCA

3.2.6. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Al-Zohairi, S.; Knudsen, M.T.; Mogensen, L. Utilizing animal by-products in European slaughterhouses to reduce the environmental footprint of pork products. Sustain. Prod. Consum. 2023, 37, 306–319. [Google Scholar] [CrossRef]

- Toldrá, F.; Aristoy, M.C.; Mora, L.; Reig, M. Innovations in value-addition of edible meat by-products. Meat Sci. 2012, 92, 290–296. [Google Scholar] [CrossRef] [PubMed]

- Toldrá, F.; Aristoy, M.C.; Mora, L.; Reig, M. New insights into meat by-product utilization. Meat Sci. 2016, 120, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Vidal, V.A.; Biachi, J.P.; Paglarini, C.S.; Pinton, M.B.; Campagnol, P.C.; Esmerino, E.A.; Cruz, A.G.; Morgano, M.A.; Pollonio, M.A. Reducing 50% sodium chloride in healthier jerked beef: An efficient design to ensure suitable stability, technological and sensory properties. Meat Sci. 2019, 152, 49–57. [Google Scholar] [CrossRef]

- Chan, D.S.; Lin, H.T.V.; Huang, Y.H.; Syu, Y.J.; Sung, W.C. Prediction and optimization of frying conditions of air fried pork rind using a direct linking model. Int. J. Gastron. Food Sci. 2023, 34, 100837. [Google Scholar] [CrossRef]

- Wang, D.D.; Han, W.F.; Liu, S.; Guo, X.J.; Chen, S.; Chen, L.; Qiao, Y.; Wu, W.J.; Li, J.T.; Wang, L. Effects of explosion puffing on surimi-starch blends: Structural characteristics, physicochemical properties, and digestibility. LWT-Food Sci. Technol. 2023, 183, 114902. [Google Scholar] [CrossRef]

- Wang, X.H.; Tian, X.J.; Wang, Q.L.; Shen, R.X.; Ma, C.W.; Bai, L.; Wang, W.H. The combination of microwave and hot-air drying to prepare collagen fiber powder from cowhide. J. Food Eng. 2024, 363, 111773. [Google Scholar] [CrossRef]

- Xu, M.F.; Liu, Q.W.; Ni, X.X.; Chen, C.C.; Deng, X.H.; Fang, Y.J.; Wang, X.; Shen, Q.; Yu, R.R. Lipidomics reveals the effect of hot-air drying on the quality characteristics and lipid oxidation of Tai Lake whitebait (Neosalanx taihuensis Chen). LWT-Food Sci. Technol. 2024, 197, 115942. [Google Scholar] [CrossRef]

- Cheng, J.Y.; Wang, J.Y.; Chen, F.L.; Wu, D.; Gao, C.C.; Cheng, W.W.; Wang, Z.J.; Shen, X.C.; Tang, X.Z. Effect of low temperature extrusion-modified potato starch addition on properties of whole wheat dough and texture of whole wheat youtiao. Food Chem. 2023, 412, 135595. [Google Scholar] [CrossRef]

- Zaki, N.A.M.; Alwi, H.; Abd Hashib, S.; Ibrahim, U.K.; Jai, J. Microwave drying characteristics and quality of Ananas comosus peel, core and pulp. Mater. Today Proc. 2023, 87, 8–12. [Google Scholar] [CrossRef]

- Zhang, P.L.; Li, B.; Hu, Z.G.; Zhang, Q.Y.; Zhu, Y.S.; Hao, W.R. Effects of ultrasonic and microwave treatment on color, quality and drying characteristics of rice. J. Cereal Sci. 2024, 116, 103856. [Google Scholar] [CrossRef]

- Shao, Z.H.; Song, Y.; Hong, Y.; Tao, S.; Sun, J.; Liu, C.; Wu, Z.Y.; Cao, L. The extension of vacuum microwave drying time improved the physicochemical properties, in vitro digestibility and antioxidant activity of brown rice flour. LWT-Food Sci. Technol. 2023, 184, 115023. [Google Scholar] [CrossRef]

- Sharma, P.; Venugopal, A.P.; Sutar, P.P. Development of steam-impinged microwave-vacuum assisted blanching of ready-to-cook vegan patties. Innov. Food Sci. Emerg. Technol. 2024, 92, 103595. [Google Scholar] [CrossRef]

- Liang, X.; Xu, Z.H.; Li, X.; Kong, B.H.; Xia, X.F.; Zhang, Y.H.; Liu, Q.; Shen, L.Y. Effect of microwave drying on the brittleness quality of pork chip snacks: Perspectives on drying kinetics and microstructural traits. LWT-Food Sci. Technol. 2023, 185, 115147. [Google Scholar] [CrossRef]

- Wang, X.J.; Wang, X.W.; Feng, T.T.; Shen, Y.; Xia, S.Q. Saltiness perception enhancement of fish meat treated by microwave: The significance of conformational characteristics, water and sodium mobility. Food Chem. 2021, 347, 129033. [Google Scholar] [CrossRef]

- Gutiérrez, J.D.; Catalá-Civera, J.M.; Bows, J.; Peñaranda-Foix, F.L. Dynamic measurement of dielectric properties of food snack pellets during microwave expansion. J. Food Eng. 2017, 202, 1–8. [Google Scholar] [CrossRef]

- Gaikwad, P.S.; Sunil, C.K.; Negi, A.; Pare, A. Effect of microwave assisted hot-air drying temperatures on drying kinetics of dried black gram papad (Indian snack food): Drying characteristics of black gram papad. Appl. Food Res. 2022, 2, 100144. [Google Scholar] [CrossRef]

- Ishibashi, R.; Numata, T.; Tanigawa, H.; Tsuruta, T. In-situ measurements of drying and shrinkage characteristics during microwave vacuum drying of radish and potato. J. Food Eng. 2022, 323, 110988. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.Y.; Li, X.L.; Zhu, J.B.; Wang, X.M.; Ma, L.C. Drying characteristics, quality changes, parameters optimization and flavor analysis for microwave vacuum drying of garlic (Allium sativum L.) slices. LWT-Food Sci. Technol. 2023, 173, 114372. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Szumny, A.; Figiel, A.; Jałoszyński, K.; Adamski, M.; Carbonell-Barrachina, Á.A. Effects of vacuum level and microwave power on rosemary volatile composition during vacuum–microwave drying. J. Food Eng. 2011, 103, 219–227. [Google Scholar] [CrossRef]

- Zheng, X.Z.; Liu, C.H.; Shi, J.; Xue, S.; Mu, Y.Q.; Lin, Z.; Liu, H.J. Analysis of volume expansion and dehydration rate of berry slab under microwave-vacuum puffing conditions. LWT-Food Sci. Technol. 2013, 52, 39–48. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, C.J.; Lu, J.L.; Wang, H.X.; Bao, Y.T.; Han, B.Y.; Duan, S.S.; Song, Z.Q.; Chen, H. Influence of electrohydrodynamics on the drying characteristics and volatile components of iron stick yam. Food Chem. X 2023, 20, 101026. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, F.; Tanaka, F.; Tanaka, A.; Uchino, T. Mathematical modelling of thin-layer drying according to particle size distribution in crushed feed rice. Biosyst. Eng. 2015, 136, 87–91. [Google Scholar] [CrossRef]

- Ahmed, M.; Faisal, M.; Laskar, A.; Abdullah, A.; Shahadat, M.; Umar, K.; Kamyab, H.; Ubaidullah, M.; Pandit, B.; Prakash, C.; et al. Experimental studies for thin layer model validation and microwave drying characteristics of beetroot considering energy optimization. Fuel 2023, 346, 128345. [Google Scholar] [CrossRef]

- Cao, C.A.; Yuan, D.X.; Kong, B.H.; Chen, Q.; He, J.J.; Liu, Q. Effect of different κ-carrageenan incorporation forms on the gel properties and in vitro digestibility of frankfurters. Food Hydrocoll. 2022, 129, 107637. [Google Scholar] [CrossRef]

- Li, X.; Bi, J.F.; Jin, X.; Lyu, J.; Wu, X.Y.; Li, B.; Li, X. Study on the mechanism of volume expansion and texture formation of apple cube dried by instant controlled pressure drop drying (DIC). J. Food Eng. 2021, 293, 110379. [Google Scholar] [CrossRef]

- Barbosa-Pereira, L.; Rojo-Poveda, O.; Ferrocino, I.; Giordano, M.; Zeppa, G. Assessment of volatile fingerprint by HS-SPME/GC-qMS and E-nose for the classification of cocoa bean shells using chemometrics. Food Res. Int. 2019, 123, 684–696. [Google Scholar] [CrossRef]

- Yuan, D.X.; Xu, Y.N.; Kong, B.H.; Cao, C.A.; Zhang, F.X.; Xia, X.F.; Zhang, H.W.; Liu, Q.; Zhao, J.H. Application of seaweed dietary fiber as a potential alternative to phosphates in frankfurters with healthier profiles. Meat Sci. 2023, 196, 109044. [Google Scholar] [CrossRef]

- Chen, Y.C.; Jia, X.W.; Sun, F.D.; Jiang, S.; Liu, H.T.; Liu, Q.; Kong, B.H. Using a stable pre-emulsified canola oil system that includes porcine plasma protein hydrolysates and oxidized tannic acid to partially replace pork fat in frankfurters. Meat Sci. 2019, 167, 107968. [Google Scholar] [CrossRef]

- García-Moreira, D.P.; Pacheco, N.; Hernández-Guzmán, H.; Bahammou, Y.; Tagnamas, Z.; Moreno, I.; López-Vidaña, E.C. Evaluation of various drying methods for mexican yahualica chili: Drying characteristics and quality assessment. Processes 2024, 12, 9. [Google Scholar] [CrossRef]

- Chen, A.; Achkar, G.E.; Liu, B.; Bennacer, R. Experimental study on moisture kinetics and microstructure evolution in apples during high power microwave drying process. J. Food Eng. 2021, 292, 110362. [Google Scholar] [CrossRef]

- Shen, L.Y.; Zhu, Y.; Liu, C.H.; Wang, L.; Liu, H.; Kamruzzaman, M.; Liu, C.; Zhang, Y.P.; Zheng, X.Z. Modelling of moving drying process and analysis of drying characteristics for germinated brown rice under continuous microwave drying. Biosyst. Eng. 2020, 195, 64–88. [Google Scholar] [CrossRef]

- Thongcharoenpipat, C.; Yamsaengsung, R. Microwave-assisted vacuum frying of durian chips: Impact of ripening level on the drying rate, physio-chemical characteristics, and acceptability. Food Bioprod. Process. 2023, 138, 40–52. [Google Scholar] [CrossRef]

- Mbegbu, N.N.; Nwajinka, C.O.; Amaefule, D.O. Thin layer drying models and characteristics of scent leaves (Ocimum gratissimum) and lemon basil leaves (Ocimum africanum). Heliyon 2021, 7, e05945. [Google Scholar] [CrossRef]

- Li, M.G.; Wang, B.; Lv, W.Q.; Zhao, D.L. Effect of ultrasound pretreatment on the drying kinetics and characteristics of pregelatinized kidney beans based on microwave-assisted drying. Food Chem. 2022, 397, 133806. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying. J. Food Eng. 2004, 65, 609–617. [Google Scholar] [CrossRef]

- Salehi, F.; Goharpour, K.; Kamran, H.R. Effects of different pretreatment techniques on the color indexes, drying characteristics and rehydration ratio of eggplant slices. Results Eng. 2024, 21, 101690. [Google Scholar] [CrossRef]

- Khan, W.U.H.; Khoja, A.H.; Gohar, H.; Naqvi, S.R.; Din, I.U.; Lumbers, B.; Salem, M.A.; Alzahrani, A.Y. In depth thermokinetic investigation on Co-pyrolysis of low-rank coal and algae consortium blends over CeO2 loaded hydrotalcite (MgNiAl) catalyst. J. Environ. Chem. Eng. 2022, 10, 108293. [Google Scholar] [CrossRef]

- Mendonça, K.S.; Corrêa, J.L.G.; Jesus Junqueira, J.R.; Carvalho, E.E.N.; Silveira, P.G.; Uemura, J.H.S. Peruvian carrot chips obtained by microwave and microwave-vacuum drying. LWT-Food Sci. Technol. 2023, 187, 115346. [Google Scholar] [CrossRef]

- Dong, X.; Wang, J.; Raghavan, V. Impact of microwave processing on the secondary structure, in-vitro protein digestibility and allergenicity of shrimp (Litopenaeus vannamei) proteins. Food Chem. 2021, 337, 127811. [Google Scholar] [CrossRef]

- Gutiérrez-Cano, J.D.; Hamilton, I.E.; Catalá-Civera, J.M.; Bows, J.; Peñaranda-Foix, F.L. Effect of water content on the dynamic measurement of dielectric properties of food snack pellets during microwave expansion. J. Food Eng. 2018, 232, 21–28. [Google Scholar] [CrossRef]

- Fang, W.J.; Zhang, Y.K.; Chen, Y.C.; Sun, J.X.; Yi, Y.W. TBARS predictive models of pork sausages stored at different temperatures. Meat Sci. 2014, 96, 1–4. [Google Scholar] [CrossRef]

- Jiang, N.; Liu, C.Q.; Li, D.J.; Zhang, Z.Y.; Liu, C.J.; Wang, D.; Niu, L.Y.; Zhang, M. Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption. LWT-Food Sci. Technol. 2017, 82, 216–226. [Google Scholar] [CrossRef]

- Wang, R.; Wang, L.H.; Wen, Q.H.; He, F.; Xu, F.Y.; Chen, B.R.; Zeng, X.A. Combination of pulsed electric field and pH shifting improves the solubility, emulsifying, foaming of commercial soy protein isolate. Food Hydrocoll. 2023, 134, 108049. [Google Scholar] [CrossRef]

| Number | Model Name | Model Expression | Model Parameters |

|---|---|---|---|

| 1 | Newton | MR = exp(−kt) | k |

| 2 | Page | MR = exp(−ktn) | k, n |

| 3 | Wang and Singh | MR = 1 + at + bt2 | a, b |

| 4 | Henderson and Pabis | MR = a × exp(−kt) | a, k |

| 5 | Midilli et al. | MR = a × exp(−ktn) + bt | a, k, n, b |

| Number | Sensor | Substances for Sensing |

|---|---|---|

| S1 | W1C | Aromatic compounds |

| S2 | W5S | Nitrogen oxide |

| S3 | W3C | Aromatic molecule |

| S4 | W6S | Hydride |

| S5 | W5C | Olefin, Aromatics |

| S6 | W1S | Alkanes |

| S7 | W1W | Sulfur compound |

| S8 | W2S | Alcohols |

| S9 | W2W | Organic compounds of sulfur |

| S10 | W3S | Aliphatic group |

| Sensory Items | Scoring Criteria | Score |

|---|---|---|

| Color | Golden yellow color, uniform color, no burnt phenomenon | 6–7 |

| It appears golden or brownish yellow, with a relatively uniform color and a slight burnt appearance | 4–5 | |

| Brownish yellow in color, uneven in color, almost dull, partially burnt | 2–3 | |

| Black brown in color, uneven in color, severely burnt | 1 | |

| Flavor | No odor | 6–7 |

| There is a slight smell of oxidation | 4–5 | |

| Has a strong oxidizing odor | 2–3 | |

| There is a noticeable smell of oxidation | 1 | |

| Appearance | Honeycomb-like uniformity, complete and evenly distributed foaming, fully expanded | 6–7 |

| Honeycomb-shaped uniform, with less complete and evenly distributed foaming and some puffing | 4–5 | |

| Honeycomb-like structure is relatively uniform, with incomplete foaming and uneven distribution around the edges and no puffing at the edges | 2–3 | |

| Honeycomb-like unevenness, incomplete foaming, significant size differences, and overall uneven distribution, without any puffing at all | 1 | |

| Brittleness | Crispy texture and good chewiness | 6–7 |

| Relatively crispy, with slightly an uneven texture of softness and hardness | 4–5 | |

| Partially crispy, with uneven texture of softness and hardness | 2–3 | |

| Soft or severely hardened texture, difficult to chew | 1 |

| Microwave Intensity (W) | Drying Time (min) | Water Activity | L* Value | a* Value | b* Value |

|---|---|---|---|---|---|

| 600 | 2 | 0.462 ± 0.006 A | 80.563 ± 0.007 A | 5.087 ± 0.189 I | 17.618 ± 0.108 Q |

| 4 | 0.393 ± 0.002 C | 79.710 ± 0.021 B | 4.717 ± 0.024 J | 18.753 ± 0.072 P | |

| 6 | 0.323 ± 0.002 F | 79.203 ± 0.039 BC | 4.523 ± 0.058 K | 19.580 ± 0.087 O | |

| 8 | 0.250 ± 0.003 IJK | 78.863 ± 0.033 C | 4.403 ± 0.049 L | 20.097 ± 0.041 N | |

| 9 | 0.246 ± 0.006 JKL | 77.863 ± 0.033 D | 4.253 ± 0.026 M | 20.703 ± 0.113 M | |

| 10 | 0.239 ± 0.002 LM | 76.380 ± 0.015 E | 4.237 ± 0.034 M | 21.337 ± 0.112 AL | |

| 700 | 2 | 0.426 ± 0.007 B | 75.373 ± 0.218 E | 5.877 ± 0.058 E | 21.850 ± 0.068 K |

| 4 | 0.347 ± 0.003 E | 74.753 ± 0.041 F | 5.730 ± 0.057 F | 22.133 ± 0.062 J | |

| 5 | 0.296 ± 0.004 H | 73.887 ± 0.007 G | 5.503 ± 0.030 G | 22.657 ± 0.084 I | |

| 6 | 0.253 ± 0.009 IJ | 73.073 ± 0.050 H | 5.373 ± 0.021 H | 23.080 ± 0.064 H | |

| 7 | 0.243 ± 0.003 JKL | 72.910 ± 0.060 H | 5.270 ± 0.031 H | 23.533 ± 0.056 G | |

| 8 | 0.238 ± 0.002 LM | 71.383 ± 0.096 J | 5.137 ± 0.064 I | 24.233 ± 0.056 F | |

| 800 | 1 | 0.458 ± 0.003 A | 72.070 ± 0.070 I | 6.860 ± 0.036 A | 24.873 ± 0.067 E |

| 2 | 0.381 ± 0.001 D | 71.223 ± 0.088 J | 6.670 ± 0.064 B | 25.250 ± 0.055 D | |

| 3 | 0.309 ± 0.005 G | 69.807 ± 0.046 K | 6.490 ± 0.0292 C | 26.230 ± 0.121 C | |

| 4 | 0.258 ± 0.002 I | 69.127 ± 0.056 K | 6.423 ± 0.038 C | 26.317 ± 0.055 C | |

| 5 | 0.240 ± 0.003 KLM | 69.093 ± 0.060 K | 6.267 ± 0.074 D | 26.587 ± 0.029 B | |

| 6 | 0.231 ± 0.002 M | 69.323 ± 0.304 K | 6.193 ± 0.009 D | 26.980 ± 0.017 A | |

| P (Microwave intensity) | ** | ** | ** | ** | |

| P (Drying time) | ** | ** | ** | ** | |

| P (Microwave intensity × Drying time) | ** | ** | ns | ** |

| Microwave Intensity (W) | Fitted Equation | R2 | Deff (m2/s) |

|---|---|---|---|

| 600 | LnMR = 0.6380 − 0.3738t | 0.9562 | 2.3695 × 10−5 |

| 700 | LnMR = 0.7209 − 0.4999t | 0.9214 | 3.1689 × 10−5 |

| 800 | LnMR = −0.0451 − 0.5356t | 0.9390 | 3.3395 × 10−5 |

| Number | Model Name | Microwave Intensity (W) | Model Parameter | R2 | χ2 | RMSE |

|---|---|---|---|---|---|---|

| 1 | Newton | 600 | k = 0.2106 | 0.9734 | 0.2278 | 0.0900 |

| 700 | k = 0.2873 | 0.9794 | 0.1943 | 0.0740 | ||

| 800 | k = 0.5026 | 0.9807 | 0.0930 | 0.0543 | ||

| 2 | Page | 600 | k = 0.0589 n = 1.7345 | 0.9868 | 0.0276 | 0.0289 |

| 700 | k = 0.1311 n = 1.5152 | 0.9805 | 0.0856 | 0.0461 | ||

| 800 | k = 0.3516 n = 1.4190 | 0.9876 | 0.1208 | 0.0245 | ||

| 3 | Wang and Singh | 600 | a = −0.1378 b = 0.0038 | 0.9840 | 0.1740 | 0.0401 |

| 700 | a = −0.1972 b = 0.0092 | 0.9839 | 0.1778 | 0.0432 | ||

| 800 | a = −0.3746 b = 0.0360 | 0.9956 | 0.0361 | 0.0238 | ||

| 4 | Henderson and Pabis | 600 | a = 1.0711 k = 0.2231 | 0.9487 | 0.2016 | 0.0848 |

| 700 | a = 1.0403 k = 0.2962 | 0.9567 | 0.1851 | 0.0722 | ||

| 800 | a = 1.0387 k = 0.5192 | 0.9794 | 0.0837 | 0.0519 | ||

| 5 | Midilli et al. | 600 | a = 1.0111 b = 0.1197 n = 7.5693 k = −5.7674 | 0.9980 | 0.0192 | 0.0157 |

| 700 | a = 0.9870 b = −0.1531 n = 5.8489 k = −1.3273 | 0.9888 | 0.0552 | 0.0362 | ||

| 800 | a = 0.9930 b = 0.0046 n = 1.5124 k = 0.3391 | 0.9960 | 0.0181 | 0.0218 |

| Microwave Intensity (W) | Drying Time (min) | Color | Flavor | Appearance | Brittleness |

|---|---|---|---|---|---|

| 600 | 2 | 6.23 ± 0.252 B | 6.40± 0.100 A | 5.33 ± 0.058 CD | 3.70 ± 0.200 EFG |

| 4 | 6.21 ± 0.100 A | 6.20 ± 0.100 A | 5.13 ± 0.153 D | 4.27 ± 0.252 CDEF | |

| 6 | 6.17 ± 0.153 B | 6.23 ± 0.208 A | 5.77 ± 0.321 B | 5.87 ± 0.252 AB | |

| 8 | 5.67 ± 0.115 C | 5.70 ± 0.265 CD | 6.23 ± 0.115 A | 6.20 ± 0.100 A | |

| 9 | 4.20 ± 0.100 E | 4.97 ± 0.208 E | 5.53 ± 0.208 BC | 4.90 ± 1.646 CD | |

| 10 | 2.47 ± 0.208 F | 3.43 ± 0.252 GH | 5.30 ± 0.100 CD | 4.20 ± 0.100 CDEF | |

| 700 | 2 | 6.70 ± 0.100 A | 6.33 ± 0.208 A | 5.60 ± 0.300 BC | 3.33 ± 0.208 FG |

| 4 | 6.40 ± 0.200 AB | 6.30 ± 0.100 A | 5.17 ± 0.058 D | 4.10 ± 0.100 DEFG | |

| 5 | 6.20 ± 0.200 B | 6.33 ± 0.153 A | 6.27 ± 0.058 A | 5.93 ± 0.351 AB | |

| 6 | 5.27 ± 0.153 D | 6.13 ± 0.153 AB | 6.50 ± 0.200 A | 6.67 ± 0.153 A | |

| 7 | 4.10 ± 0.200 E | 5.73 ± 0.153 CD | 4.73 ± 0.153 E | 5.20 ± 0.100 BC | |

| 8 | 2.13 ± 0.306 G | 4.63 ± 0.058 F | 3.50 ± 0.100 H | 4.17 ± 0.115 CDEF | |

| 800 | 1 | 6.70 ± 0.100 A | 6.30 ± 0.100 A | 5.30 ± 0.100 CD | 3.33 ± 0.321 FG |

| 2 | 6.40 ± 0.200 AB | 5.87 ± 0.153 BC | 5.20 ± 0.173 D | 4.23 ± 0.058 CDEF | |

| 3 | 6.20 ± 0.200 B | 5.43 ± 0.153 D | 5.73 ± 0.153 B | 4.67 ± 1.429 CDE | |

| 4 | 5.27 ± 0.153 D | 4.53 ± 0.289 F | 6.30 ± 0.100 A | 6.33 ± 0.153 A | |

| 5 | 4.10 ± 0.200 E | 3.73 ± 0.252 G | 5.30 ± 0.100 CD | 4.80 ± 0.100 CD | |

| 6 | 2.13 ± 0.306 G | 3.23 ± 0.153 H | 4.30 ± 0.265 G | 3.10 ± 0.300 G | |

| P (Microwave intensity) | ** | ** | ** | ** | |

| P (Drying time) | ** | ** | ** | ** | |

| P (Microwave intensity × Drying time) | ** | ** | ** | ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Zhang, J.; Wang, J.; Ren, J.; Cao, C.; Liu, Q.; Huang, X. Evaluation of Drying Characteristics and Quality Attributes for Microwave Vacuum Drying of Pork Skin Crisps. Foods 2024, 13, 4020. https://doi.org/10.3390/foods13244020

Li Y, Zhang J, Wang J, Ren J, Cao C, Liu Q, Huang X. Evaluation of Drying Characteristics and Quality Attributes for Microwave Vacuum Drying of Pork Skin Crisps. Foods. 2024; 13(24):4020. https://doi.org/10.3390/foods13244020

Chicago/Turabian StyleLi, Yuangang, Jingming Zhang, Junsheng Wang, Junpeng Ren, Chuanai Cao, Qian Liu, and Xinning Huang. 2024. "Evaluation of Drying Characteristics and Quality Attributes for Microwave Vacuum Drying of Pork Skin Crisps" Foods 13, no. 24: 4020. https://doi.org/10.3390/foods13244020

APA StyleLi, Y., Zhang, J., Wang, J., Ren, J., Cao, C., Liu, Q., & Huang, X. (2024). Evaluation of Drying Characteristics and Quality Attributes for Microwave Vacuum Drying of Pork Skin Crisps. Foods, 13(24), 4020. https://doi.org/10.3390/foods13244020