Optimization of Variable-Temperature Pressure-Difference Puffing Drying Process for Persimmon Chips Using Response Surface Methodology

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Experiment and Method

2.2.1. Processing Workflow for Persimmon Chips

2.2.2. Single Factor Experiment

2.2.3. Experimental Design of Response Surface Optimization

2.2.4. Verification Experiment

2.2.5. Moisture Content Determination

2.2.6. Crispness Measurement

2.2.7. Sensory Evaluation

2.2.8. Microstructure Analysis

2.2.9. Measurement of Pore Characteristics

2.2.10. Other Processing Methods for Persimmon Chips

2.3. Data Processing

3. Results and Discussion

3.1. Single-Factor Experimental Results

3.1.1. Effect of Expansion Pressure Difference on the Quality of Persimmon Chips

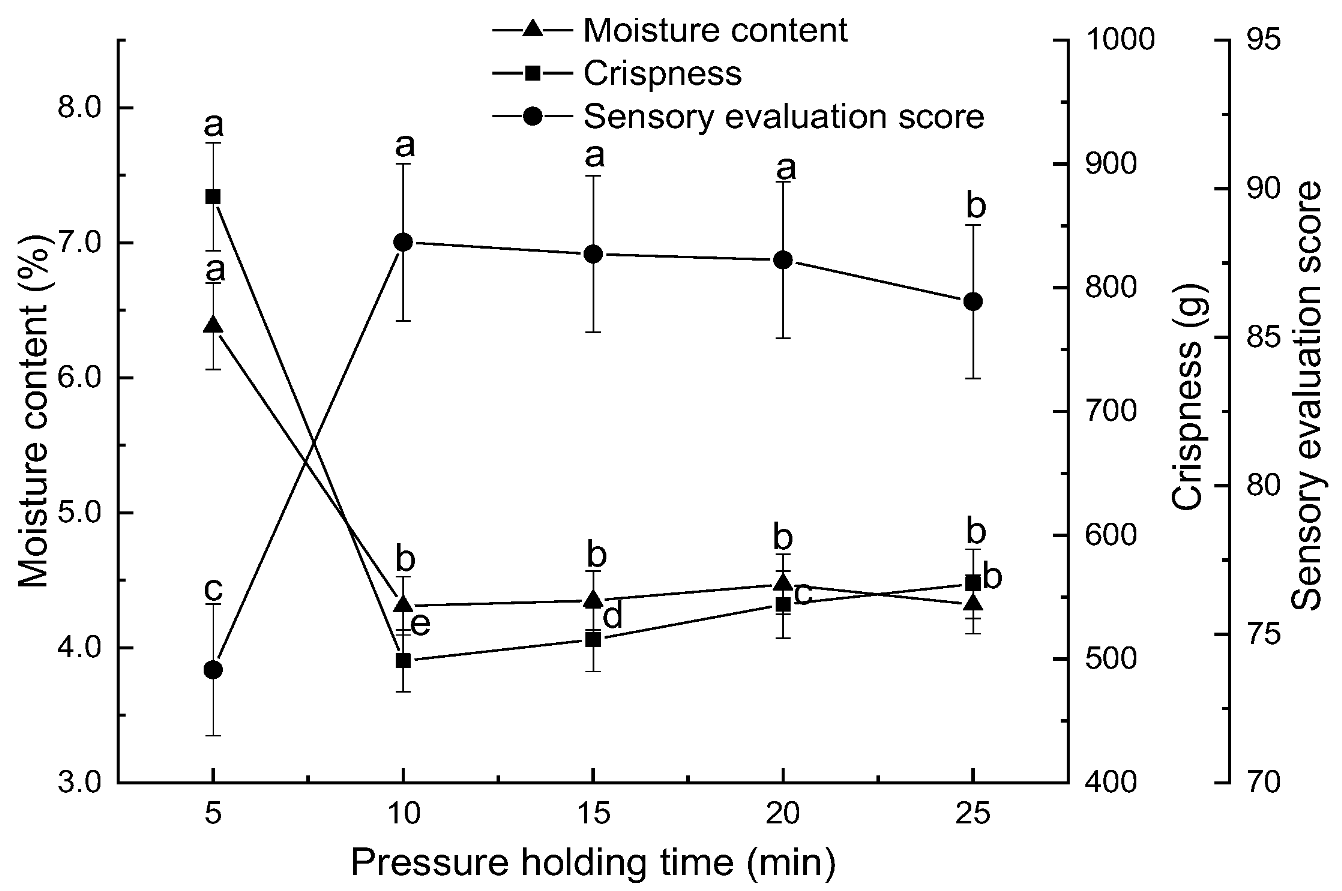

3.1.2. Effect of Holding Time on the Quality of Persimmon Chips

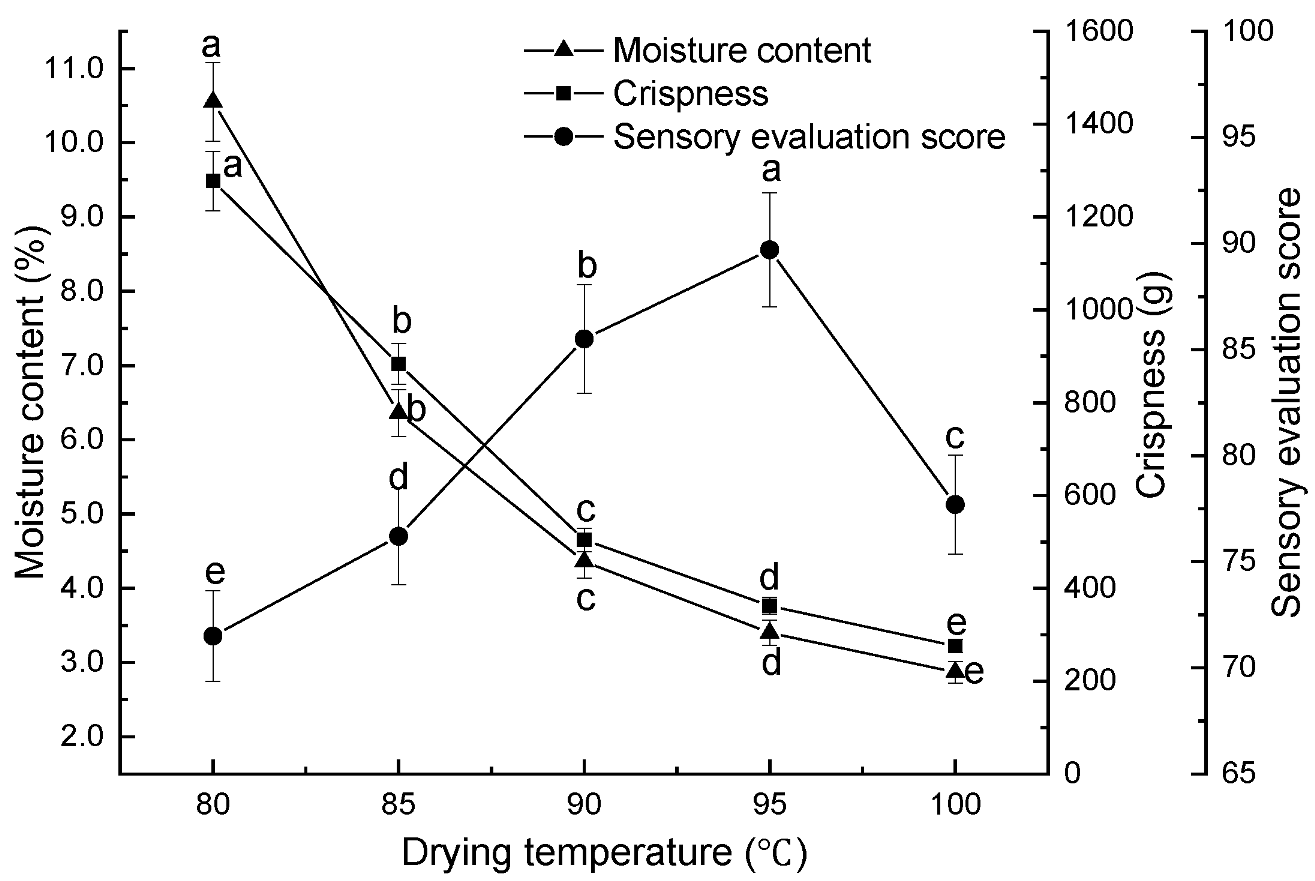

3.1.3. Effect of Drying Temperature on the Quality of Persimmon Chips

3.1.4. Effect of Drying Time on the Quality of Persimmon Chips

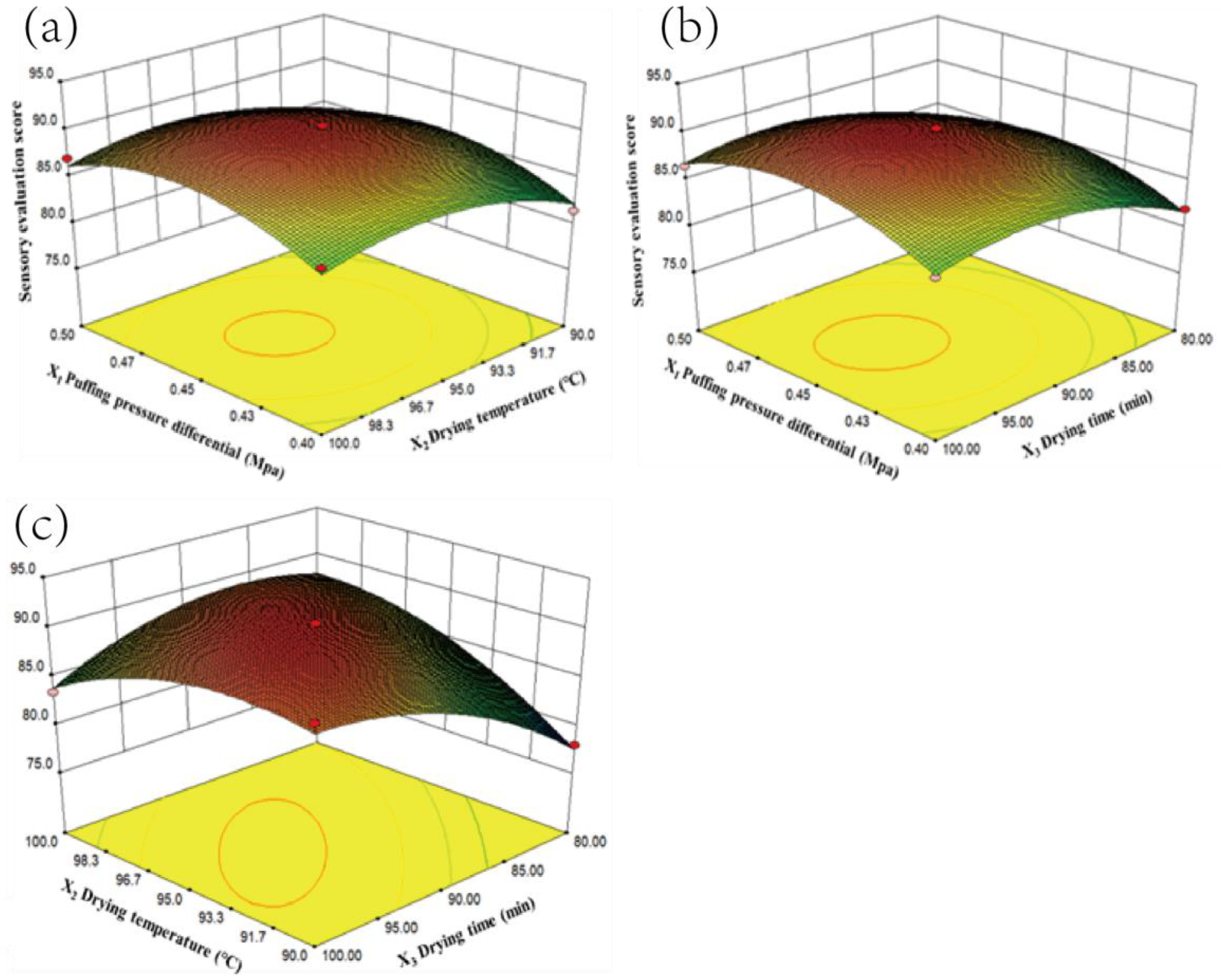

3.2. Results of Response Surface Analysis

3.2.1. Response Surface Experimental Design and Results

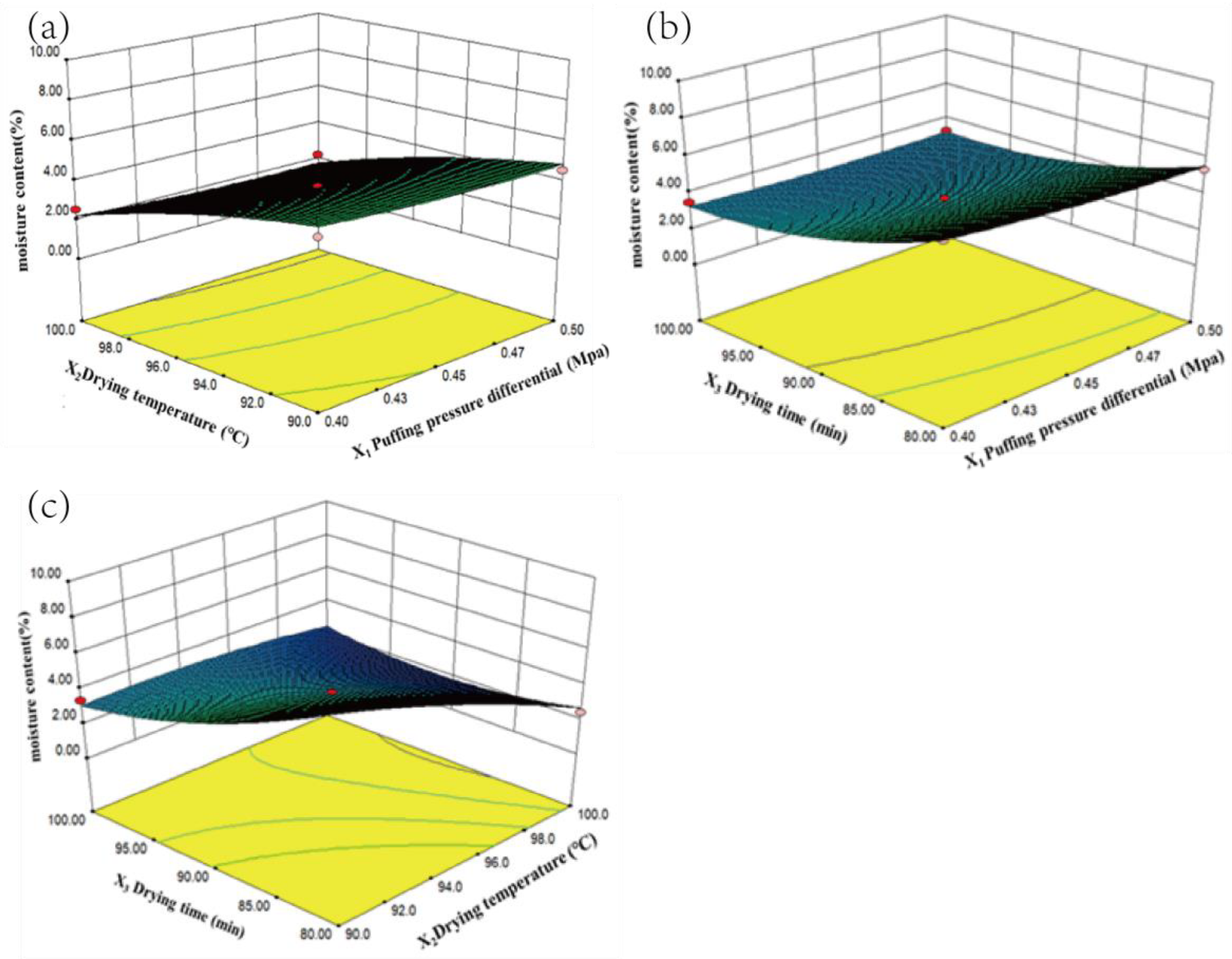

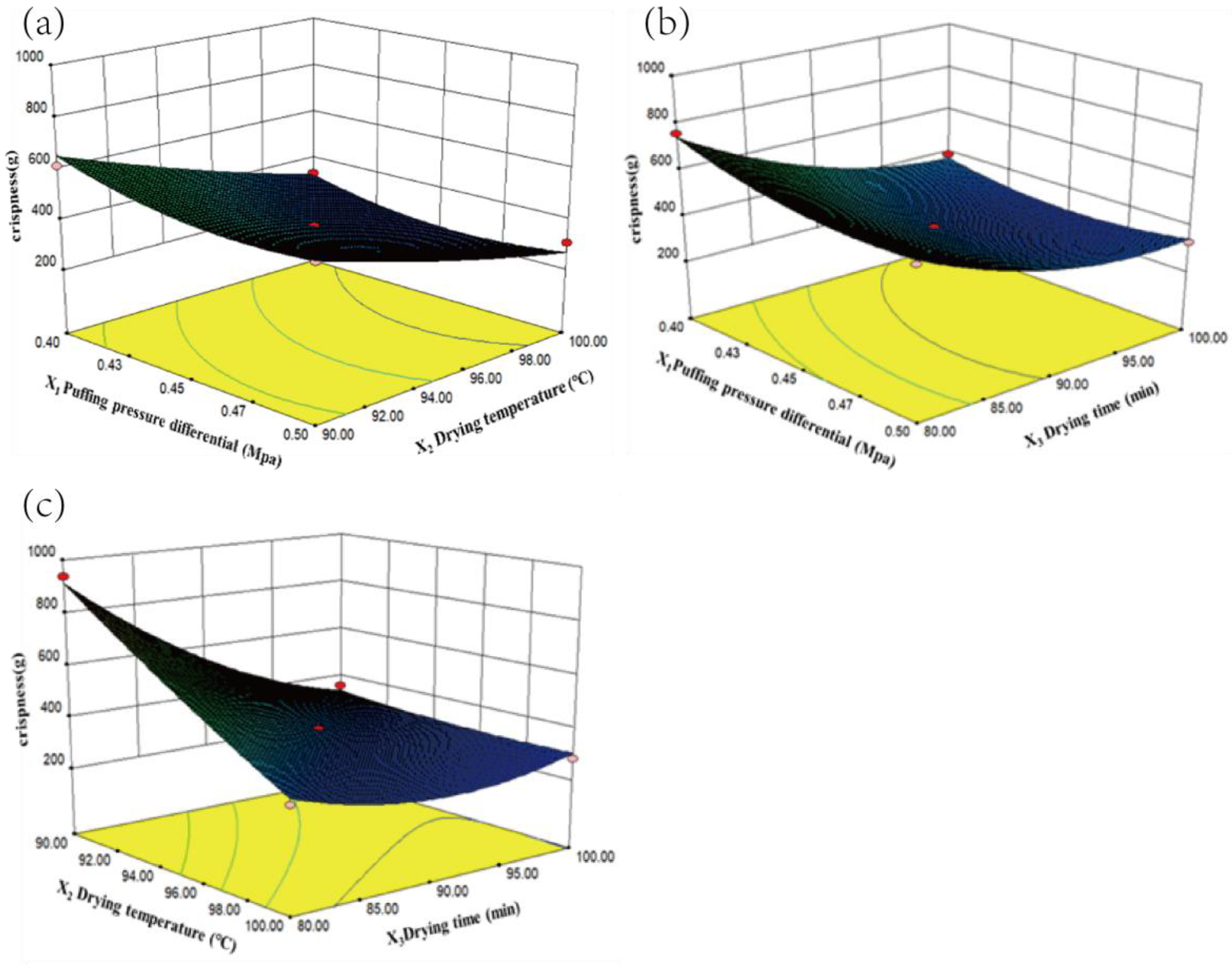

3.2.2. Response Surface Curve Analysis

3.2.3. Process Prediction and Validation

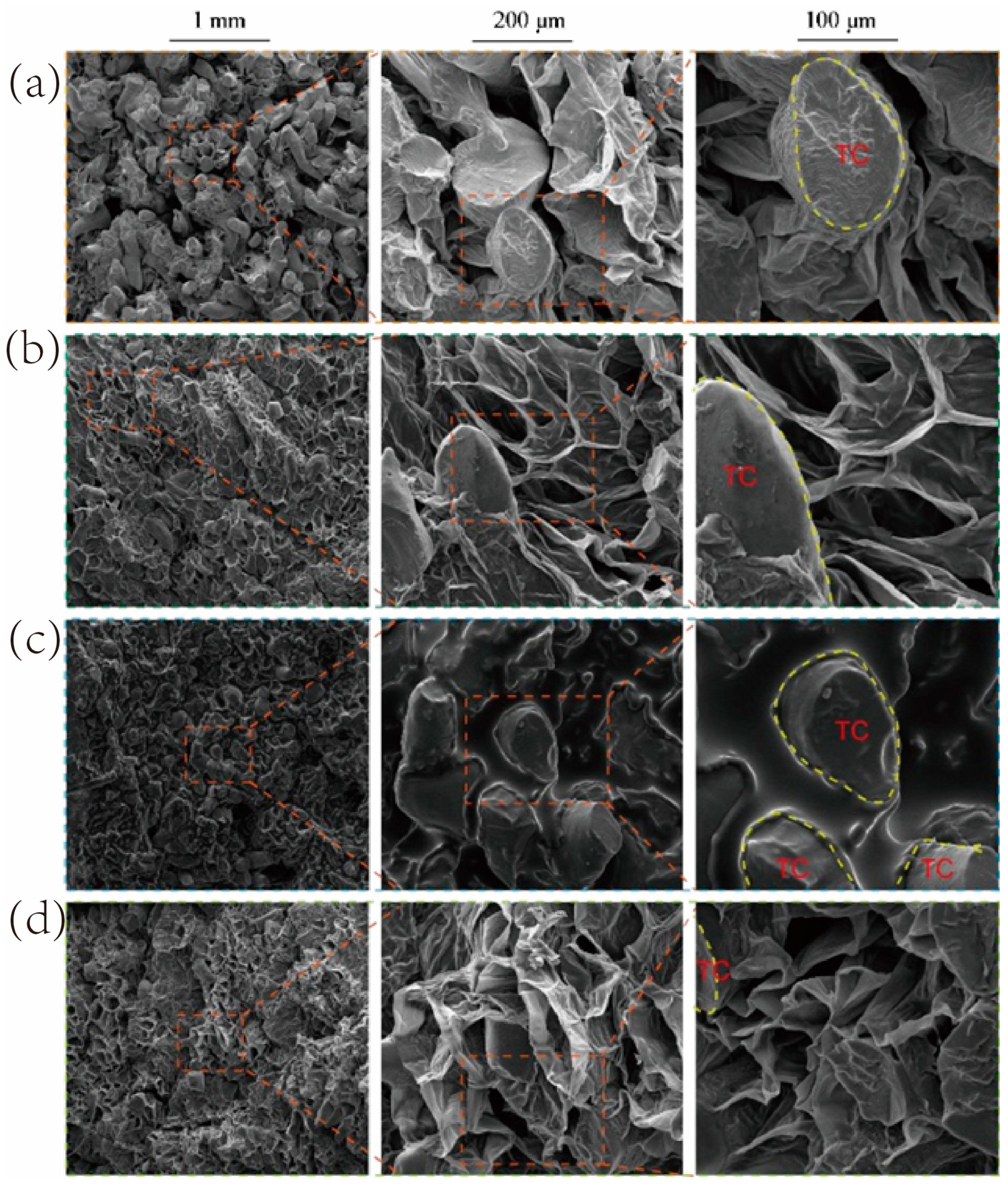

3.3. Comparison of the Microstructure of Persimmon Chips Processed by Different Methods

3.4. The Impact of Different Processing Methods on Pore Size Distribution in Persimmon Chips

3.5. The Impact of Different Processing Methods on the Porosity Characteristics of Persimmon Chips

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, S.-D.; Fang, H.; Huang, D.-D. Optimization of purification process of persimmon yellow pigment by macroporous resin. China Condiment 2021, 12, 167–171. [Google Scholar]

- Guan, C.; Chachar, S.; Zhang, P.; Hu, C.; Wang, R.; Yang, Y. Inter-and intra-specific genetic diversity in Diospyros using SCoT and IRAP markers. Hortic. Plant J. 2020, 6, 71–80. [Google Scholar] [CrossRef]

- Vivek, K.; Subbarao, K.V.; Srivastava, B. Effect of thin-layer drying on the quality parameters of persimmon slices. Int. J. Fruit Sci. 2021, 21, 587–598. [Google Scholar] [CrossRef]

- De Jesus, M.S.; Araujo, H.C.S.; Denadai, M.; Sandes, R.D.D.; Nogueira, J.P.; Leite Neta, M.T.S.; Narain, N. Effect of different drying methods on the phenolic and volatile compounds of persimmon (Diospyros kaki L.). J. Food Meas. Charact. 2023, 17, 2576–2594. [Google Scholar] [CrossRef]

- Yildiz, E.; Yilmaz, A.; Gurbuz, O.; Alibas, I. Effect of drying methods and pre-treatments on bioactive potential of persimmon (Diospyros kaki L.). J. Food Meas. Charact. 2023, 18, 2014–2029. [Google Scholar] [CrossRef]

- Çelen, S. Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods 2019, 8, 84. [Google Scholar] [CrossRef]

- Yang, K.-W.; Wang, D.; Vidyarthi, S.K.; Li, S.-B.; Liu, Z.-L.; Wang, H.; Chen, X.-J.; Xiao, H.-W. Pulsed Vacuum Drying of Persimmon Slices: Drying Kinetics, Physicochemical Properties, Microstructure and Antioxidant Capacity. Plants 2022, 11, 2500. [Google Scholar] [CrossRef]

- Pal, U.S.; Khan, M.K. Performance evaluation of heat pump dryer. J. Food Sci. Technol. 2010, 47, 230–234. [Google Scholar] [CrossRef]

- Senadeera, W.; Adiletta, G.; Önal, B.; Di Matteo, M.; Russo, P. Influence of different hot air drying temperatures on drying kinetics, shrinkage, and colour of persimmon slices. Foods 2020, 9, 101. [Google Scholar] [CrossRef]

- Jia, Y.; Khalifa, I.; Hu, L.; Zhu, W.; Li, J.; Li, K.; Li, C. Influence of three different drying techniques on persimmon chips’ characteristics: A comparison study among hot-air, combined hot-air-microwave, and vacuum-freeze drying techniques. Food Bioprod. Process. 2019, 118, 67–76. [Google Scholar] [CrossRef]

- Sheng, J.-F.; Wang, X.F.; Lei, Y.W.; Li, C.B.; Li, J.K.; Luo, Z.S.; Zhou, Z.G.; Tang, J.; Chen, X.; Ling, D.N.; et al. Effect of temperature and thickness on the drying characteristics and quality of persimmon slices. Food Res. Dev. 2022, 43, 58–65. [Google Scholar]

- Corrêa, J.L.G.; Lopes, F.J.; de Mello Júnior, R.E.; de Jesus Junqueira, J.R.; de Mendonça, K.S.; Macedo, L.L.; Salvio, L.G.A. Drying of persimmon fruit (Diospyros kaki L.) pretreated by different osmotic processes. J. Food Process Eng. 2021, 44, e13809. [Google Scholar] [CrossRef]

- Tang, X.; Tang, W.; Ren, A.; Wei, Z.; Chen, Z.; Duan, Z. Comparative Analysis s of Physical Characteristics and Nutritional Quality of Persimmon Chips Prepared Using Different Processing Methods. Mod. Food Sci. Technol. 2022, 38, 185. [Google Scholar]

- Qin, Y.T.; Duan, Z.H.; Wei, Z.Z.; Zhou, S.Y.; Tang, X.X. Effects of microwave power on moisture migration and quality of persimmon slices during microwave intermittent drying. Food Mach. 2021, 37, 1–5. [Google Scholar]

- Ma, Y.; Yi, J.; Jin, X.; Li, X.; Feng, S.; Bi, J. Freeze-drying of fruits and vegetables in food industry: Effects on phytochemicals and bioactive properties attributes-a comprehensive review. Food Rev. Int. 2022, 39, 6611–6629. [Google Scholar] [CrossRef]

- Harguindeguy, M.; Fissore, D. On the effects of freeze-drying processes on the nutritional properties of foodstuff: A review. Dry. Technol. 2019, 38, 846–868. [Google Scholar] [CrossRef]

- Zhao, C.-C.; Ameer, K.; Eun, J.-B. Effects of various drying conditions and methods on drying kinetics and retention of bioactive compounds in sliced persimmon. LWT 2021, 143, 111149. [Google Scholar] [CrossRef]

- Lyu, J.; Bi, J.; Wang, F.; Jin, X.; Wu, X.; Xie, J. Recent developments and trends of instant controlled pressure drop drying—A review. Dry. Technol. 2021, 39, 1704–1719. [Google Scholar] [CrossRef]

- Gammoudi, N.; Mabrouk, M.; Bouhemda, T.; Nagaz, K.; Ferchichi, A. Modeling and optimization of capsaicin extraction from Capsicum annuum L. using response surface methodology (RSM), artificial neural network (ANN), and Simulink simulation. Ind. Crop. Prod. 2021, 171, 113869. [Google Scholar] [CrossRef]

- Wang, H.; Duan, X.; Zhao, L.; Duan, L.; Ren, G. Effects of different pretreatments on the pore structure of Chinese yam during microwave freeze drying. Int. J. Agric. Biol. Eng. 2020, 13, 232–237. [Google Scholar] [CrossRef]

- Peng, J.; Bi, J.; Yi, J.; Wu, X.; Zhou, M.; Lyu, J.; Liu, J.N. Engineering texture properties of instant controlled pressure drop (DIC) dried carrot chips via modulating osmotic con-ditions. Food Bioprocess Technol. 2018, 11, 1674–1685. [Google Scholar] [CrossRef]

- Bao, X.J.; Liu, X.Y.; Xin, G.; Xu, H.R.; Zhang, Z.Y.; Sun, L.B.; Wei, Y.Y. Effects of variable-temperature variable-pressure puffing on umami and aroma components of Pleurotus geesteranus. Food Sci. 2019, 40, 243–248. [Google Scholar]

- Wu, Z.L.; Lin, F.; Chen, Z.L.; Mo, J.H.; Yang, Y.L.; Yang, C.M. Optimization of explosion puffing drying process for silkworm pupa at variable temperatures and pressure difference. Food Res. Dev. 2021, 42, 153–158. [Google Scholar]

- GB/T 20453-2022; Quality Grades of Products for Persimmon. The State Administration for Market Regulation and the Standardization Administration: Beijing, China, 2023.

- Dai, J.; Yang, S.L.; Wang, J.; Weng, M.; Fu, Q.; Huang, H. Effect of microwave vacuum drying conditions on drying characteristics and texture structure of banana chips. Trans. Chin. Soc. Agric. Mach. 2020, 51, 493–500. [Google Scholar]

- Tamer, C.; Isci, A.; Kutlu, N.; Sakiyan, O.; Sahin, S.; Sumnu, G. Effect of drying on porous characteristics of orange peel. Int. J. Food Eng. 2016, 12, 921–928. [Google Scholar] [CrossRef]

- Peng, J.; Yi, J.; Bi, J.; Chen, Q.; Wu, X.; Zhou, M.; Liu, J. Freezing as pretreatment in instant controlled pressure drop (DIC) texturing of dried carrot chips: Impact of freezing temperature. LWT 2018, 89, 365–373. [Google Scholar] [CrossRef]

- Lu, Y.-T.; Luo, C.-X. Effects of high hydrostatic pressure treatment on puffed carrot slices. Food Res. Dev. 2021, 42, 116–123. [Google Scholar]

- Liu, Z.; Deng, L.; Ding, W.; Wang, Y.; Zhuang, K.; Wang, G. Optimization of Varying Temperature and Pressure Puffing Drying for Lentinus edodes Chips. Sci. Technol. Food Ind. 2018, 39, 186–193, 199. [Google Scholar]

- Lyu, J.; Zhou, L.-Y.; Bi, J.-F.; Liu, X.; Wu, X.-Y. Quality evaluation of yellow peach chips prepared by explosion puffing drying. J. Food Sci. Technol. 2015, 52, 8204–8211. [Google Scholar] [CrossRef]

- Song, J.; Gonzalles, G.; Liu, J.; Dai, Z.; Li, D.; Liu, C.; Zhang, M. Optimization of explosion puffing drying for high-value yellow-fleshed peach crisps using response surface methodology. Dry. Technol. 2018, 37, 929–940. [Google Scholar] [CrossRef]

- Tessmer, M.A.; Besada, C.; Hernando, I.; Appezzato-Da-Glória, B.; Quiles, A.; Salvador, A. Microstructural changes while persimmon fruits mature and ripen. Comparison between astringent and non-astringent cultivars. Postharvest Biol. Technol. 2016, 120, 52–60. [Google Scholar] [CrossRef]

- Yu, Y.J.; Bi, J.F.; Ding, Y.Y. Effect of drying treatment methods on the quality properties of red jujube. Mod. Food Sci. Technol. 2011, 27, 610–614. [Google Scholar]

- Baldovino-Medrano, V.G.; Niño-Celis, V.; Giraldo, R.I. Systematic analysis of the nitrogen adsorption–desorption isotherms recorded for a series of materials based on microporous–mesoporous amorphous aluminosilicates using classical methods. J. Chem. Eng. Data 2023, 68, 2512–2528. [Google Scholar] [CrossRef]

- GB/T 29605-2013; Sensory Analysis—Guide for Food Sensory Quality Control. General Administration of Quality Supervision, Inspection, Quarantine and Standardization Administration of China: Beijing, China, 2013.

| Levels | Pressure Difference X1 | Drying Temperature X2 | Drying Time X3 |

|---|---|---|---|

| (MPa) | (°C) | (min) | |

| −1 | 0.40 | 90 | 80 |

| 0 | 0.45 | 95 | 90 |

| 1 | 0.50 | 100 | 100 |

| Evaluation Criteria | Descriptive Characteristics | Assigned Score |

|---|---|---|

| Color: 15 points | Uniform, bright golden yellow | 11~15 |

| Fairly uniform, with a deeper yellow hue | 6~10 | |

| Uneven color distribution, with some areas showing darker hue | 0~5 | |

| Appearance: 15 points | Intact shape, loose structure, uniformly distributed pores | 11~15 |

| Mostly intact shape, loose structure, fairly even pore distribution | 6~10 | |

| Incomplete shape, with cracks, curled edges, severe wrinkling, and uneven pores | 0~5 | |

| Texture: 40 points | Exceptionally crisp, moderate hardness, excellent palatability | 31~40 |

| Fairly crisp, moderate hardness, good palatability | 21~30 | |

| Moderate crispness, relatively hard, average palatability | 11~20 | |

| Soft, no crispness, poor palatability | 0~10 | |

| Aroma: 30 points | Strong persimmon aroma, no astringency Noticeable persimmon aroma, no astringency | 20~30 13~19 |

| Faint persimmon aroma, slight astringency | 7~12 | |

| Weak persimmon aroma, with strong astringency, bitterness, or off-flavors | 0~6 |

| Test | Difference in Pressure X1 (MPa) | Drying Temperature X2 (°C) | Drying Time X3 (min) | Moisture Content Y1 (%) | Crispness Y2 (g) | Sensory Evaluation Score Y3 |

|---|---|---|---|---|---|---|

| 1 | 0.4 | 90 | 90 | 4.88 | 613.41 | 81.5 |

| 2 | 0.5 | 90 | 90 | 4.55 | 531.42 | 83.0 |

| 3 | 0.4 | 100 | 90 | 2.56 | 330.55 | 85.5 |

| 4 | 0.5 | 100 | 90 | 2.21 | 306.44 | 87.0 |

| 5 | 0.4 | 95 | 80 | 6.42 | 759.27 | 82.0 |

| 6 | 0.5 | 95 | 80 | 5.36 | 580.01 | 83.0 |

| 7 | 0.4 | 95 | 100 | 3.50 | 391.79 | 85.0 |

| 8 | 0.5 | 95 | 100 | 3.28 | 330.22 | 86.5 |

| 9 | 0.45 | 90 | 80 | 8.82 | 938.09 | 78.0 |

| 10 | 0.45 | 100 | 80 | 2.43 | 326.85 | 87.0 |

| 11 | 0.45 | 90 | 100 | 3.41 | 356.98 | 90.0 |

| 12 | 0.45 | 100 | 100 | 1.97 | 279.91 | 83.5 |

| 13 | 0.45 | 95 | 90 | 3.75 | 377.65 | 89.5 |

| 14 | 0.45 | 95 | 90 | 3.73 | 374.39 | 90.0 |

| 15 | 0.45 | 95 | 90 | 3.69 | 370.37 | 90.5 |

| 16 | 0.45 | 95 | 90 | 3.71 | 371.54 | 90.0 |

| 17 | 0.45 | 95 | 90 | 3.69 | 370.28 | 90.5 |

| Processing Method | Pore Volume | Porosity | Average Diameter | Total Pore Area | Apparent Density |

|---|---|---|---|---|---|

| (cm3/g) | (%) | (nm) | (m2/g) | (g/cm3) | |

| MD | 0.1870 ± 0.007 b | 19.19 ± 0.02 b | 106.49 ± 1.00 b | 6.12 ± 0.09 c | 1.471 ± 0.063 a |

| VMD | 0.1628 ± 0.001 c | 15.67 ± 0.10 c | 67.21 ± 0.45 c | 11.12 ± 0.20 b | 1.007 ± 0.002 b |

| VF | 0.0873 ± 0.002 d | 11.33 ± 0.02 d | 25.51 ± 0.35 d | 13.68 ± 0.11 a | 1.463 ± 0.001 a |

| PDP | 0.2949 ± 0.001 a | 30.16 ± 0.03 a | 194.02 ± 0.65 a | 6.08 ± 0.05 c | 1.465 ± 0.001 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, X.; Xian, Z.; Liu, Y.; Ren, A.; Tan, H.; Pan, Y.; Duan, Z. Optimization of Variable-Temperature Pressure-Difference Puffing Drying Process for Persimmon Chips Using Response Surface Methodology. Foods 2024, 13, 3830. https://doi.org/10.3390/foods13233830

Tang X, Xian Z, Liu Y, Ren A, Tan H, Pan Y, Duan Z. Optimization of Variable-Temperature Pressure-Difference Puffing Drying Process for Persimmon Chips Using Response Surface Methodology. Foods. 2024; 13(23):3830. https://doi.org/10.3390/foods13233830

Chicago/Turabian StyleTang, Xiaoxian, Zhaokun Xian, Yan Liu, Aiqing Ren, Hanying Tan, Yuyan Pan, and Zhenhua Duan. 2024. "Optimization of Variable-Temperature Pressure-Difference Puffing Drying Process for Persimmon Chips Using Response Surface Methodology" Foods 13, no. 23: 3830. https://doi.org/10.3390/foods13233830

APA StyleTang, X., Xian, Z., Liu, Y., Ren, A., Tan, H., Pan, Y., & Duan, Z. (2024). Optimization of Variable-Temperature Pressure-Difference Puffing Drying Process for Persimmon Chips Using Response Surface Methodology. Foods, 13(23), 3830. https://doi.org/10.3390/foods13233830