Optimization of Processing Parameters for Continuous Microwave Drying of Crab Apple Slices via Response Surface Methodology

Abstract

1. Introduction

- (1)

- To analyze the effects of the processing parameters (slice thickness, microwave power, air velocity, and conveyor belt speed) on the evaluation indexes of CASs under CMD;

- (2)

- To evaluate the quality changes of CASs dried at different processing parameters under CMD, and obtain appropriate processing parameters via the response surface method.

2. Materials and Methods

2.1. Sample Preparation

2.2. Continuous Microwave Dryer

2.3. Experimental Design of CMD of CAS

2.3.1. Single Factor Experimental Design

2.3.2. Design of Response Surface Test

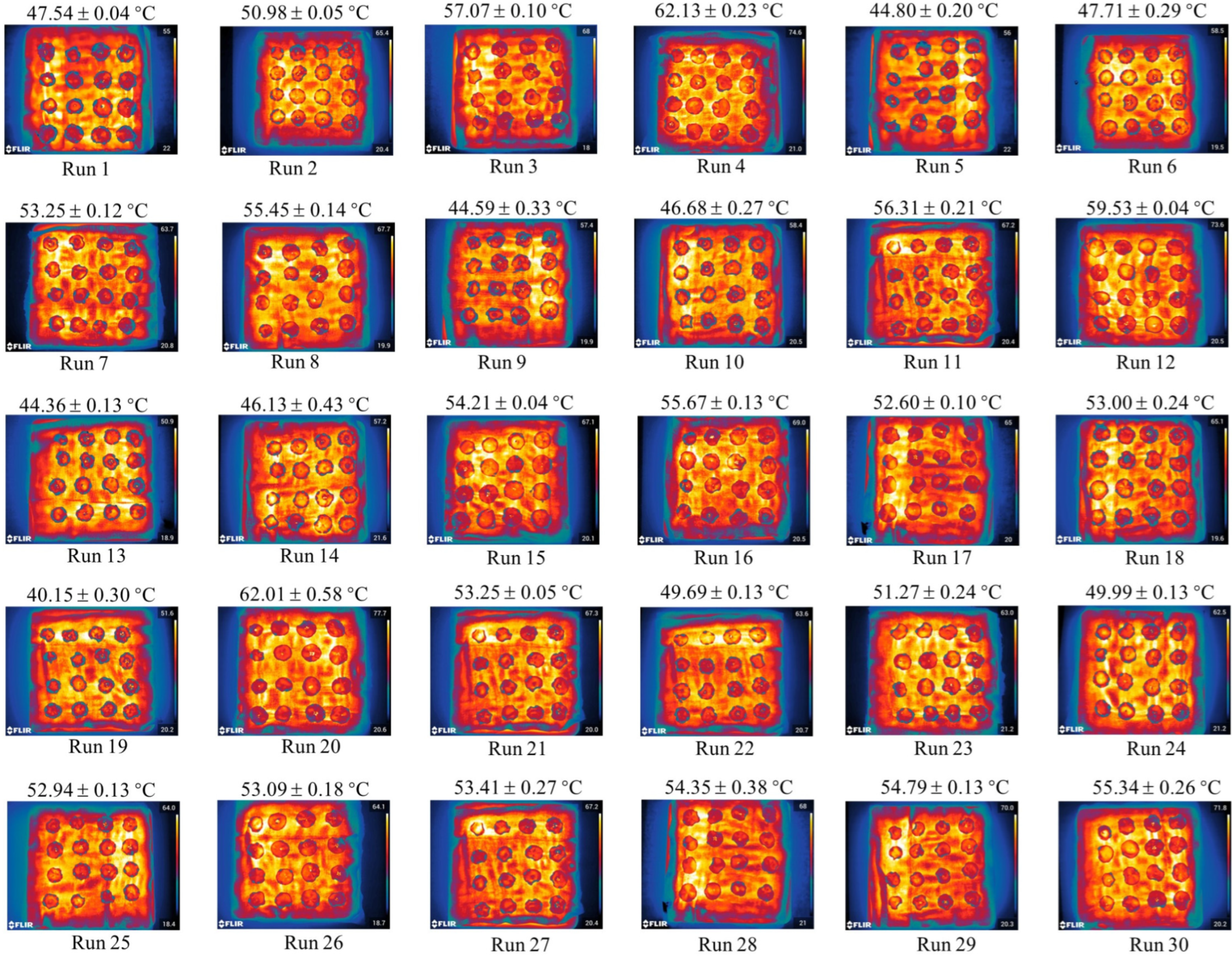

2.4. Temperature Measured by an Infrared Thermal Camera

2.5. Determination of Moisture Content

2.6. Color Measurement

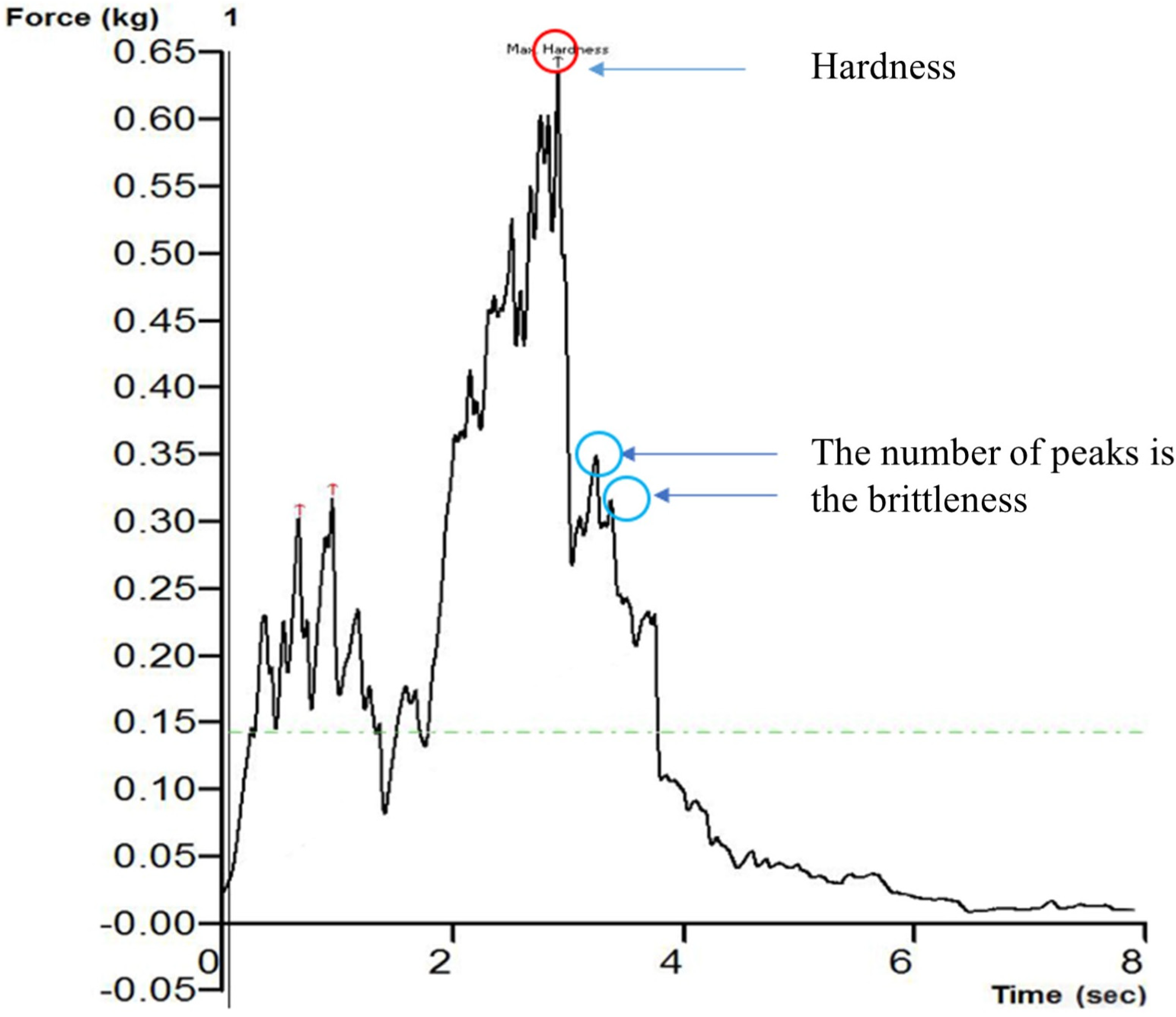

2.7. Determination of Hardness and Brittleness

2.8. Total Phenolic Content (TPC)

2.9. Data Analysis

3. Results and Discussion

3.1. The Effects of Processing Parameters on Evaluation Indexes of CASs under CMD

3.1.1. Development of a Regression Model

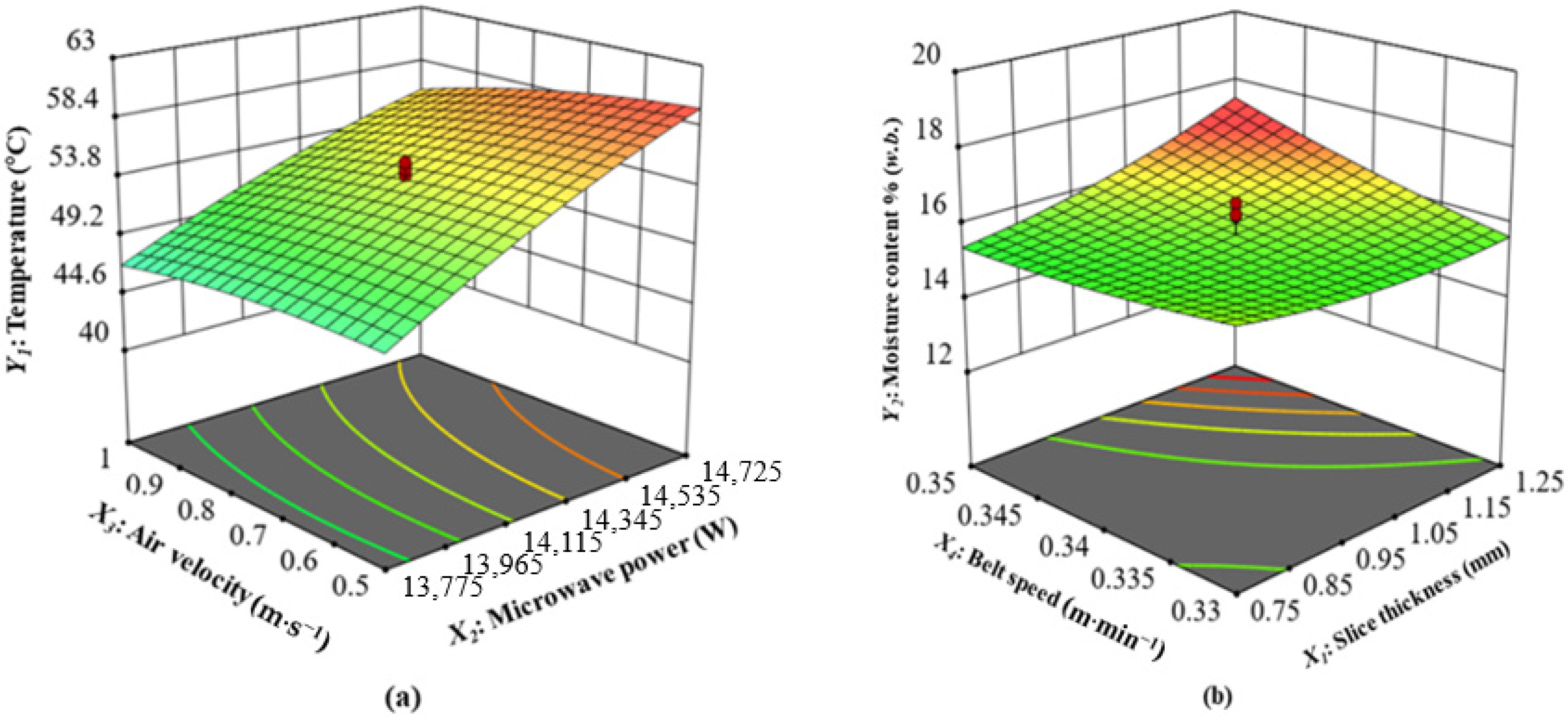

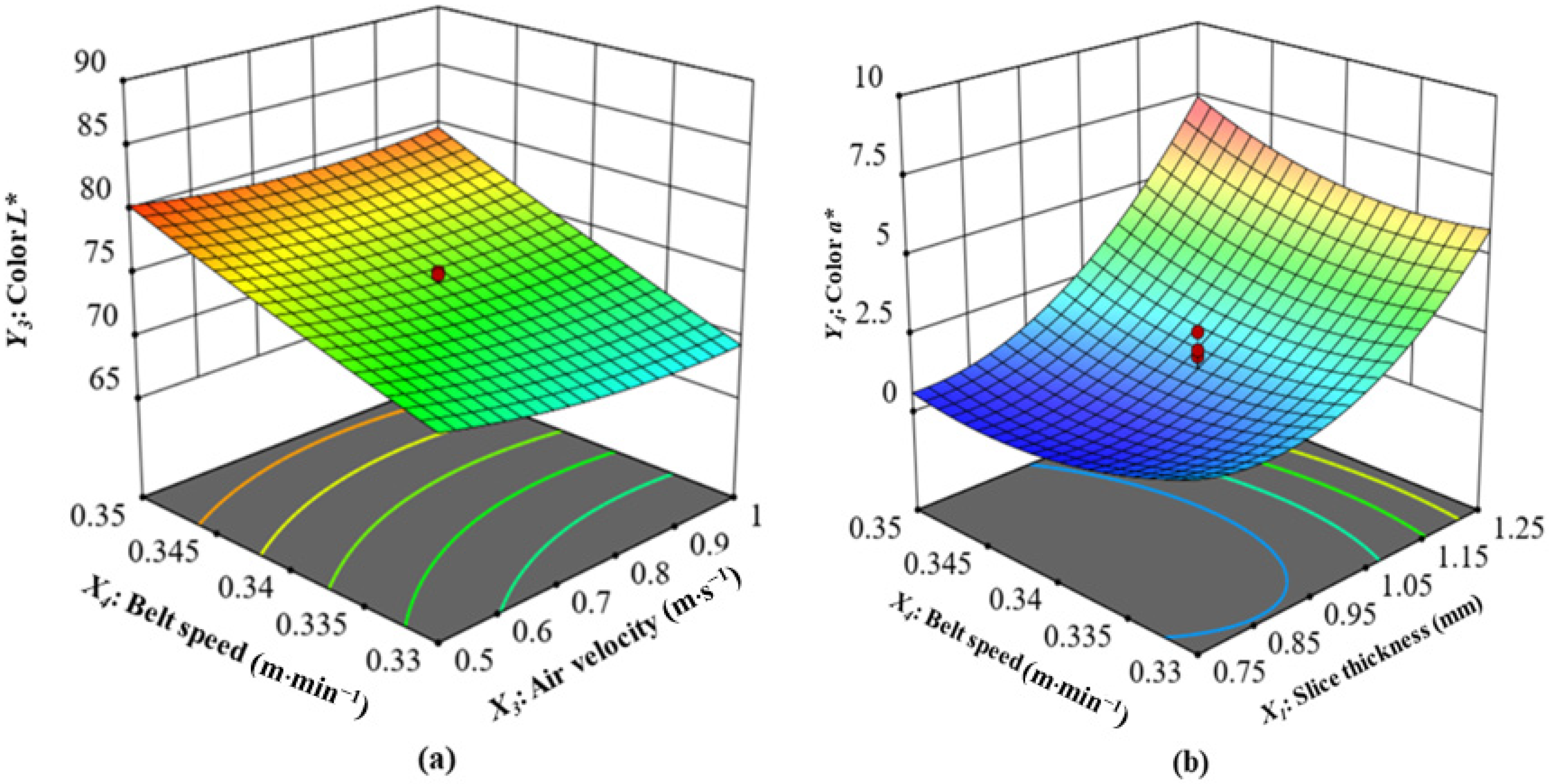

3.1.2. Interaction of CMD Parameters on Evaluation Indexes

- (1)

- Interaction of Microwave Power and Air Velocity on Temperature

- (2)

- Interaction of Slice Thickness and Belt Speed on Moisture Content

- (3)

- Interaction of Air Velocity and Belt Speed on the Color L* Value

- (4)

- Interaction of Slice Thickness and Belt Speed on the Color a* Value

- (5)

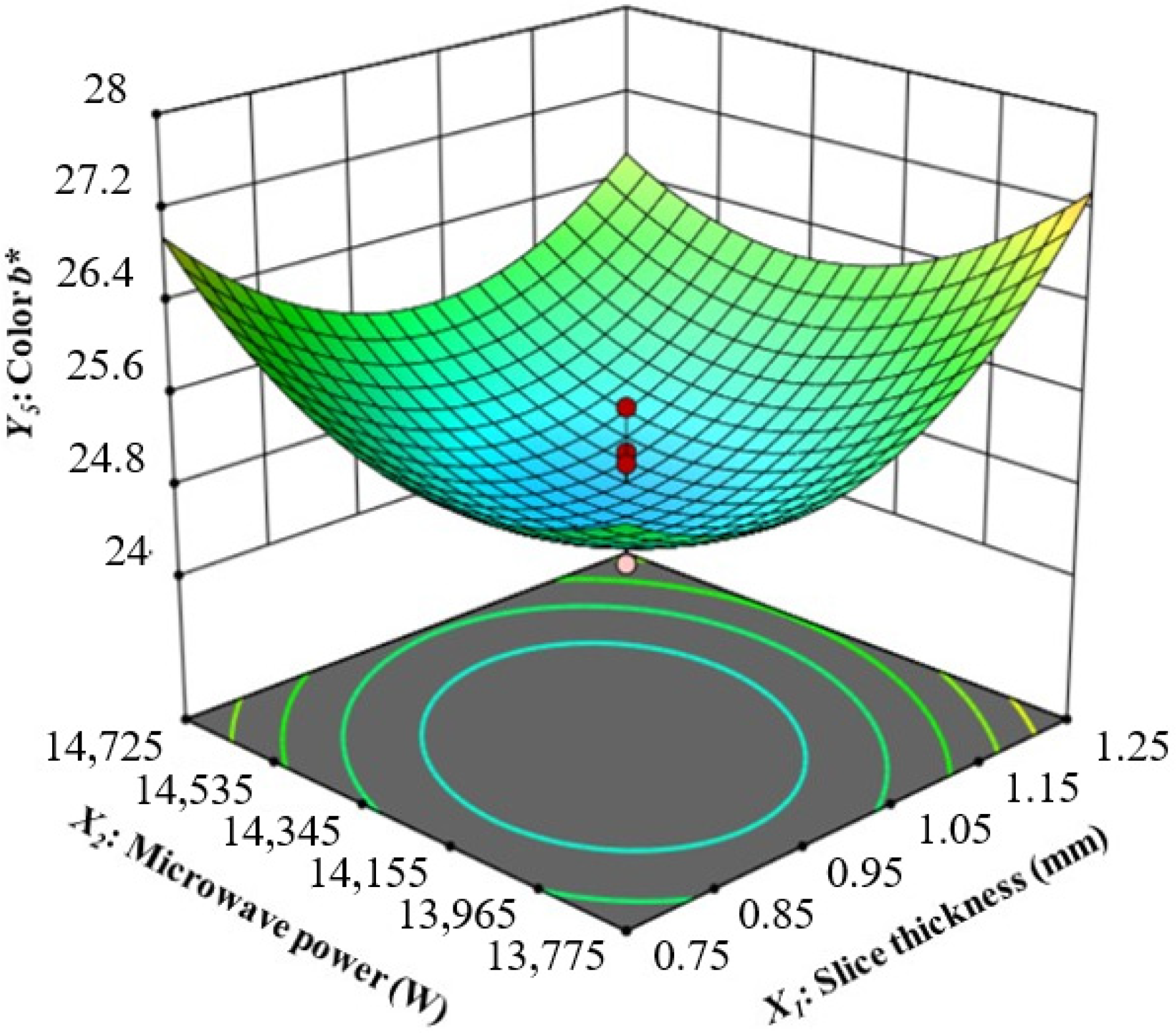

- Interaction of Slice Thickness and Microwave Power on the Color b* Value

- (6)

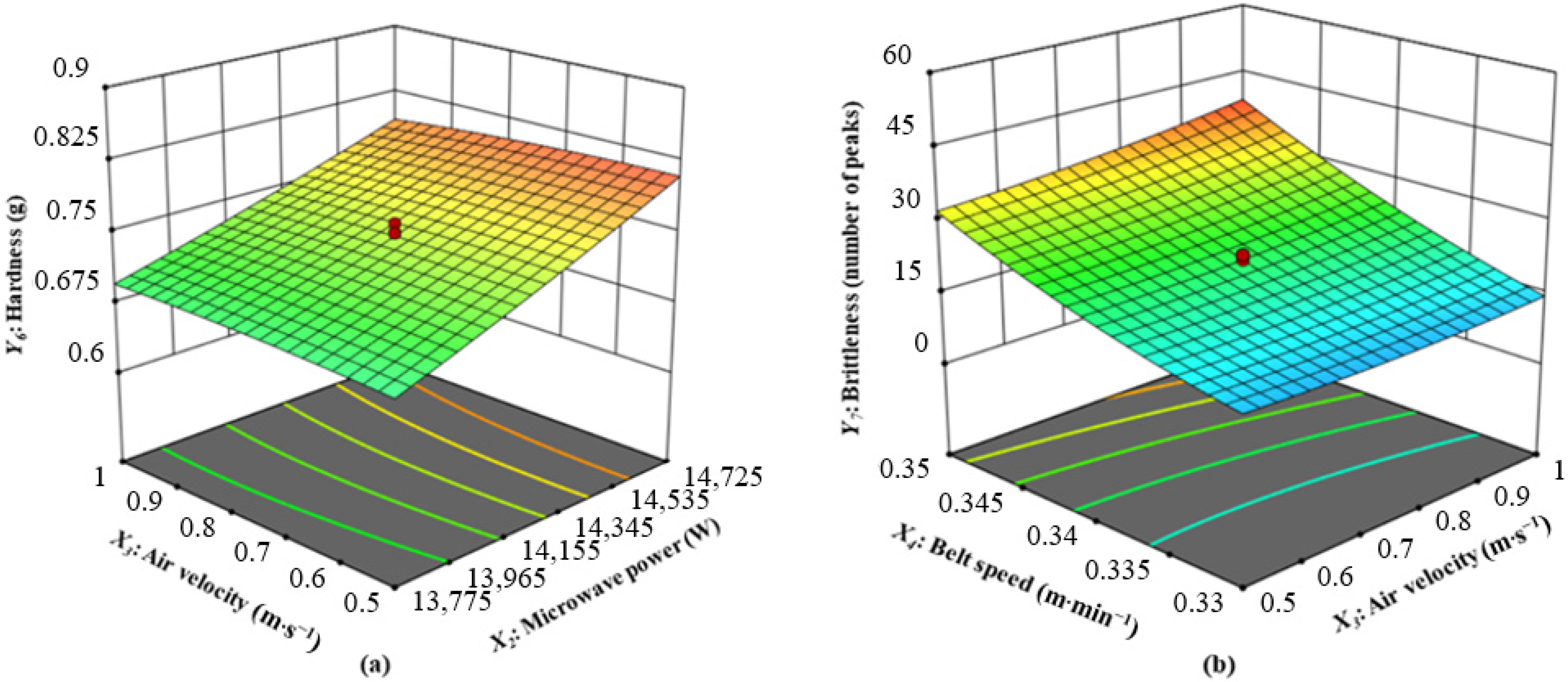

- Interaction of Microwave Power and Air Velocity on Hardness

- (7)

- Interaction of Air Velocity and Belt Speed on Brittleness

- (8)

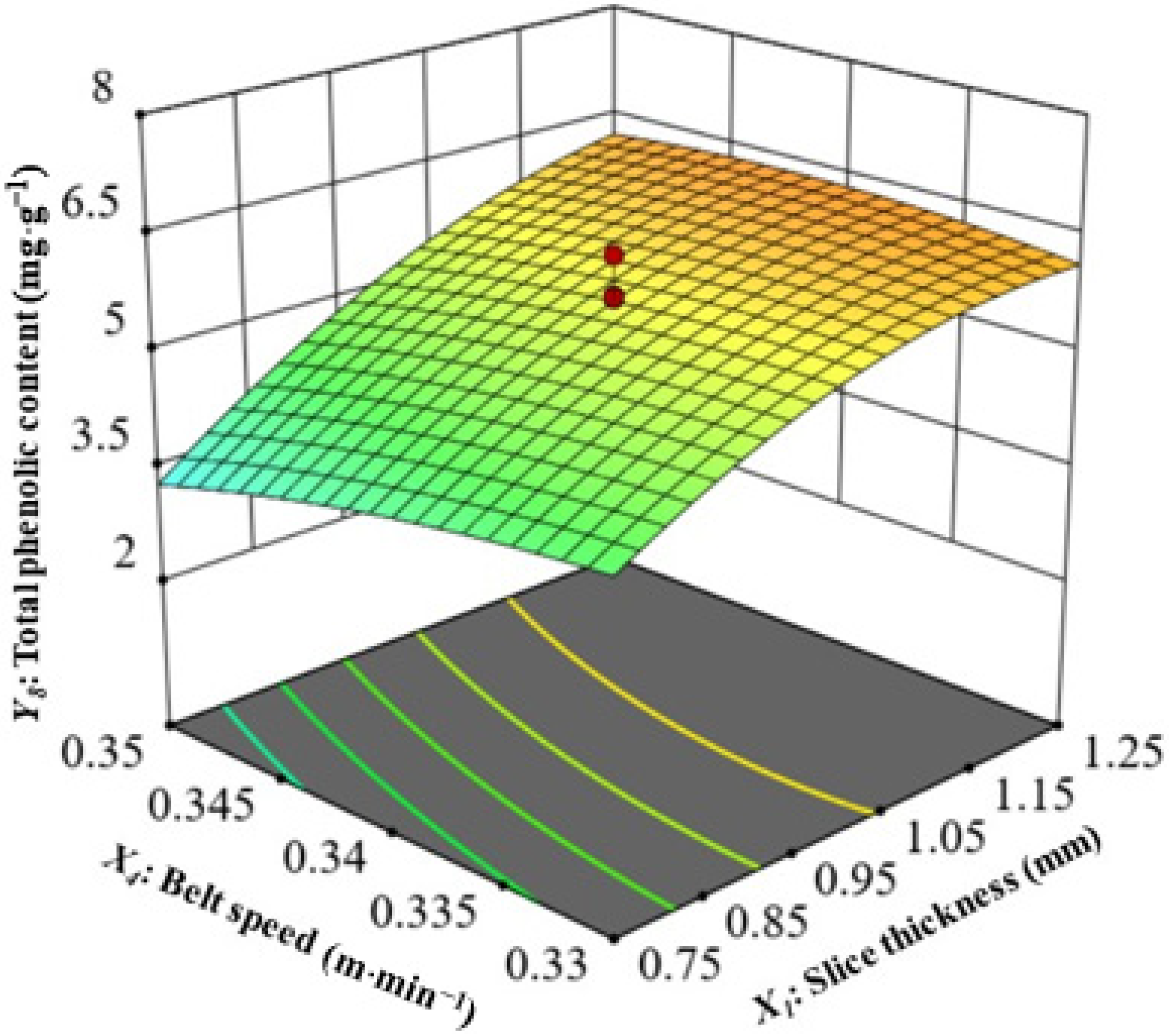

- Interaction of Slice Thickness and Belt speed on the Total Phenolic Content (TPC)

3.2. Optimization of Process Parameters for CMD of CAS

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hallmann, E.; Orpel, E.; Rembiałkowska, E. The Content of Biologically Active Compounds in Some Fruits from Natural State. J. Fruit. Ornam. Plant Res. 2011, 75, 81–90. [Google Scholar] [CrossRef]

- Zeng, X.; Li, H.; Jiang, W.; Li, Q.; Xi, Y.; Wang, X.; Li, J. Phytochemical compositions, health-promoting properties and food applications of crabapples: A review. Food Chem. 2022, 386, 132789. [Google Scholar] [CrossRef] [PubMed]

- Petkova, N.; Ognyanov, M.; Inyutin, B.; Zhelev, P.; Denev, P. Phytochemical composition and antioxidant activity of Malus baccata (L.) Borkh. fruits. Food Sci. Appl. Biotechnol. 2020, 3, 47–55. [Google Scholar] [CrossRef]

- Wu, J.; Gao, H.; Zhao, L.; Liao, X.; Chen, F.; Wang, Z.; Hu, X. Chemical compositional characterization of some apple cultivars. Food Chem. 2007, 103, 88–93. [Google Scholar] [CrossRef]

- Seeram, N.P.; Cichewicz, R.H.; Chandra, A.; Nair, M.G. Cyclooxygenase Inhibitory and Antioxidant Compounds from Crabapple Fruits. J. Agric. Food Chem. 2003, 51, 1948–1951. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Zhao, R.; Sun, Y.H.; Cong, J.P.; Meng, F.G.; Zhou, H.M. The leaf extract of Siberian Crabapple (Malus baccata (Linn.) Borkh) contains potential fatty acid synthase inhibitors. J. Enzym. Inhib. Med. Chem. 2009, 24, 234–240. [Google Scholar] [CrossRef]

- Yompakdee, C.; Thunyaharn, S.; Phaechamud, T. Bactericidal Activity of Methanol Extracts of Crabapple Mangrove Tree (Sonneratia caseolaris Linn.) Against Multi-Drug Resistant Pathogens. Indian J. Pharm. Sci. 2012, 74, 230–236. [Google Scholar]

- Kumari, A.; Dhaliwal, Y.S. A Study on Nutritional Composition and Value Addition of Crab Apple (Malus baccata). Am. J. Food Sci. Technol. 2017, 5, 19–22. [Google Scholar]

- Moscetti, R.; Raponi, F.; Ferri, S.; Colantoni, A.; Monarca, D.; Massantini, R. Real-time monitoring of organic apple (var. Gala) during hot-air drying using near-infrared spectroscopy. J. Food Eng. 2018, 222, 139–150. [Google Scholar]

- Getahun, E.; Delele, M.A.; Gabbiye, N.; Fanta, S.W.; Demissie, P.; Vanierschot, M. Importance of integrated CFD and product quality modeling of solar dryers for fruits and vegetables: A review. Sol. Energy 2021, 220, 88–110. [Google Scholar] [CrossRef]

- Marinoni, L.; Stellari, A.; Cattaneo, T. A mild and innovative solar drying process to provide high quality products. J. Food Meas. Charact. 2022, 16, 662–672. [Google Scholar] [CrossRef]

- Toğrul, H. Simple modeling of infrared drying of fresh apple slices. J. Food Eng. 2005, 71, 311–323. [Google Scholar] [CrossRef]

- Rajoriya, D.; Shewale, S.R.; Hebbar, H.U. Refractance window drying of apple slices: Mass transfer phenomena and quality parameters. Food Bioprocess. Technol. 2019, 12, 1646–1658. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; El-Seesy, A.I.; Hu, Z.; Li, Y. Recent developments in solar drying technology of food and agricultural products: A review. Renew. Sustain. Energy Rev. 2022, 157, 112070. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.-H.; Sun, D.-W. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Wojdyło, A.; Figiel, A.; Lech, K.; Nowicka, P.; Oszmiański, J. Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food Bioprocess. Technol. 2014, 7, 829–841. [Google Scholar] [CrossRef]

- Zhou, Y.-H.; Staniszewska, I.; Liu, Z.-L.; Zielinska, D.; Xiao, H.-W.; Pan, Z.; Nowak, K.W.; Zielinska, M. Microwave-vacuum-assisted drying of pretreated cranberries: Drying kinetics, bioactive compounds and antioxidant activity. LWT 2021, 146, 111464. [Google Scholar] [CrossRef]

- Akpinar, E.K. Mathematical modelling of thin layer drying process under open sun of some aromatic plants. J. Food Eng. 2006, 77, 864–870. [Google Scholar] [CrossRef]

- Babu, A.K.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Beigi, M. Hot air drying of apple slices: Dehydration characteristics and quality assessment. Heat Mass Transf. 2016, 52, 1435–1442. [Google Scholar] [CrossRef]

- Nadian, M.H.; Rafiee, S.; Aghbashlo, M.; Hosseinpour, S.; Mohtasebi, S.S. Continuous real-time monitoring and neural network modeling of apple slices color changes during hot air drying. Food Bioprod. Process. 2015, 94, 263–274. [Google Scholar] [CrossRef]

- Sacilik, K.; Elicin, A.K. The thin layer drying characteristics of organic apple slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Martynenko, A.; Janaszek, M.A. Texture changes during drying of apple slices. Dry. Technol. 2014, 32, 567–577. [Google Scholar] [CrossRef]

- Zhao, R.; Xiao, H.; Liu, C.; Wang, H.; Wu, Y.; Ben, A.; Wang, Y. Dynamic changes in volatile and non-volatile flavor compounds in lemon flavedo during freeze-drying and hot-air drying. LWT 2023, 175, 114510. [Google Scholar] [CrossRef]

- Chao, E.; Tian, J.; Fan, L.; Zhang, T. Drying methods influence the physicochemical and functional properties of seed-used pumpkin. Food Chem. 2022, 369, 130937. [Google Scholar] [CrossRef] [PubMed]

- Prosapio, V.; Lopez-Quiroga, E. Freeze-Drying Technology in Foods. Foods 2020, 9, 920. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Liu, Y.; Zhu, C.; Wei, M. Effects of different drying methods on the physical properties and sensory characteristics of apple chip snacks. LWT 2022, 154, 112829. [Google Scholar] [CrossRef]

- Djordjević, M.; Djordjević, M.; Maravić, N.; Teofilović, V.; Šoronja-Simović, D.; Šereš, Z. Processing of alfalfa seeds by convective hot air drying, vacuum drying and germination: Proximate composition, techno-functional, thermal and structural properties evaluation. Food Chem. 2023, 402, 134300. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Zhang, L.; Feng, Y.; ElGasim, A.; Yagoub, A.; Sun, Y.; Ma, H.; Zhou, C. Vacuum pulsation drying of okra (Abelmoschus esculentus L. Moench): Better retention of the quality characteristics by flat sweep frequency and pulsed ultrasound pretreatment. Food Chem. 2020, 326, 127026. [Google Scholar]

- Duarte-Correa, Y.; Díaz-Osorio, A.; Osorio-Arias, J.; Sobral, P.J.A.; Vega-Castro, O. Development of fortified low-fat potato chips through Vacuum Impregnation and Microwave Vacuum Drying. Innov. Food Sci. Emerg. Technol. 2020, 64, 102437. [Google Scholar] [CrossRef]

- Jeevarathinam, G.; Pandiselvam, R.; Pandiarajan, T.; Preetha, P.; Balakrishnan, M.; Thirupathi, V.; Kothakota, A. Infrared assisted hot air dryer for turmeric slices: Effect on drying rate and quality parameters. LWT 2021, 144, 111258. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A. Microwave-convective drying of food materials: A critical review. Crit. Rev. Food Sci. Nutr. 2019, 59, 379–394. [Google Scholar] [CrossRef] [PubMed]

- Nowak, D.; Lewicki, P.P. Infrared drying of apple slices. Innov. Food Sci. Emerg. Technol. 2004, 5, 353–360. [Google Scholar] [CrossRef]

- Chen, A.; Achkar, G.E.L.; Liu, B.; Bennacer, R. Experimental study on moisture kinetics and microstructure evolution in apples during high power microwave drying process. J. Food Eng. 2021, 292, 110362. [Google Scholar] [CrossRef]

- González-Cavieres, L.; Pérez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Díaz-Álvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- Yue, Y.; Zhang, Q.; Wan, F.; Ma, G.; Zang, Z.; Xu, Y.; Jiang, C.; Huang, X. Effects of Different Drying Methods on the Drying Characteristics and Quality of Codonopsis pilosulae Slices. Foods 2023, 12, 1323. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Gao, M.; Gao, R.; Xue, L.; Gao, F.; Shen, L.; Zheng, X. Effects of process parameters on texture quality of blue honeysuckle berry snack under continuous microwave puffing conditions. J. Food Process. Preserv. 2021, 45, e16047. [Google Scholar] [CrossRef]

- Vongpradubchai, S.; Rattanadecho, P. The microwave processing of wood using a continuous microwave belt drier. Chem. Eng. Process. Process Intensif. 2009, 48, 997–1003. [Google Scholar] [CrossRef]

- Shen, L.; Gao, M.; Zhu, Y.; Liu, C.; Wang, L.; Kamruzzaman, M.; Liu, C.; Zheng, X. Microwave drying of germinated brown rice: Correlation of drying characteristics with the final quality. Innov. Food Sci. Emerg. Technol. 2021, 70, 102673. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.; Ma, W.; Shen, L.; Liu, C.; Liu, C.; Zheng, X.; Li, S. Utilization efficiency of microwave energy for granular food in continuous drying: From propagation properties to technology parameters. Dry. Technol. 2022, 40, 1881–1900. [Google Scholar] [CrossRef]

- Kaveh, M.; Taghinezhad, E.; Witrowa-Rajchert, D.; Imanian, K.; Khalife, E.; Nowacka, M. Use of ultrasound pre-treatment before microwave drying of kiwifruits—An optimization approach with response surface methodology. J. Food Process. Preserv. 2022, 46, 3707–3731. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Yang, Y.; Wei, H.; Xue, L.; Zhao, M.; Cai, J. Optimization of combined microwave and hot air drying technology for purple cabbage by Response Surface Methodology (RSM). Food Sci. Nutr. 2021, 9, 4568–4577. [Google Scholar] [CrossRef] [PubMed]

- Al-Mentafji, H.N. A.O.A.C 2005. 2016. Available online: https://www.researchgate.net/publication/292783651_AOAC_2005 (accessed on 10 May 2024).

- Shen, L.; Wang, L.; Zheng, C.; Liu, C.; Zhu, Y.; Liu, H.; Liu, C.; Shi, Y.; Zheng, X.; Xu, H. Continuous microwave drying of germinated brown rice: Effects of drying conditions on fissure and color, and modeling of moisture content and stress inside kernel. Dry. Technol. 2020, 39, 669–697. [Google Scholar] [CrossRef]

- Cai, Y.; Luo, Q.; Sun, M.; Corke, H. Antioxidant activity and phenolic compounds of 112 traditional Chinese medicinal plants associated with anticancer. Life Sci. 2004, 74, 2157–2184. [Google Scholar] [CrossRef] [PubMed]

- Zannou, O.; Pashazadeh, H.; Ghellam, M.; Hassan, A.; Koca, I. Optimization of drying temperature for the assessment of functional and physical characteristics of autumn olive berries. J. Food Process. Preserv. 2021, 45, e15658. [Google Scholar] [CrossRef]

- Xue, L.; Gao, R.; Shen, L.; Zheng, X.; Gao, M. Dependence of degradation of anthocyanins on non-uniformity of microwave heating in blueberry puree. Food Bioprod. Process. 2023, 139, 129–143. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Ah-Hen, K.; Chacana, M.; Vergara, J.; Martínez-Monzó, J.; García-Segovia, P.; Lemus-Mondaca, R.; Di Scala, K. Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chem. 2012, 132, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Yuan, L.; Zheng, X.; Shen, L. Continuous microwave drying of germinated red adzuki bean: Effects of various drying conditions on drying behavior and quality attributes. J. Food Process. Preserv. 2022, 46, e17090. [Google Scholar] [CrossRef]

- Zeng, S.; Wang, B.; Lv, W.; Wu, Y. Effects of microwave power and hot air temperature on the physicochemical properties of dried ginger (Zingiber officinale) using microwave hot-air rolling drying. Food Chem. 2023, 404, 134741. [Google Scholar] [CrossRef]

- Doymaz, I.; KIPÇAK, A.; Piskin, S. Microwave drying of green bean slices: Drying kinetics and physical quality. Czech J. Food Sci. 2015, 33, 367–376. [Google Scholar] [CrossRef]

- Liu, C.; Liu, C.; Xue, H.; Sun, Y.; Lin, Z.; Liu, H.; Huo, J.; Zheng, X. Effect of microwave energy dissipation on drying process of berry puree under microwave foam drying conditions. Dry. Technol. 2017, 35, 1388–1397. [Google Scholar] [CrossRef]

- Forouzanfar, A.; Hojjati, M.; Noshad, M.; Szumny, A.J. Influence of UV-B pretreatments on kinetics of convective hot air drying and physical parameters of mushrooms (Agaricus bisporus). Agriculture 2020, 10, 371. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Effect of different drying methods and storage time on the retention of bioactive compounds and antibacterial activity of wine grape pomace (Pinot noir and Merlot). J. Food Sci. 2012, 77, H192–H201. [Google Scholar] [CrossRef]

- Li, M.; Li, M.; Zhang, X.; Zhang, Q.; Yang, X. Effect of Infrared-Combined Hot Air Intermittent Drying of Jujube (Zizyphus jujuba Miller) Slices: Drying Characteristics, Quality, and Energy Consumption Dimensions. Agriculture 2024, 14, 214. [Google Scholar] [CrossRef]

- Ma, Y.; Tian, X.; Wang, Y.; Zhao, H.; Song, J. Comparative Study on Drying Characteristics and Quality of Apple Cubes Dried in Two Different Microwave Dryers. Pol. J. Food Nutr. Sci. 2023, 73, 367–374. [Google Scholar] [CrossRef]

- Maftoonazad, N.; Dehghani, M.R.; Ramaswamy, H.S. Hybrid microwave-hot air tunnel drying of onion slices: Drying kinetics, energy efficiency, product rehydration, color, and flavor characteristics. Dry. Technol. 2022, 40, 966–986. [Google Scholar] [CrossRef]

- Demiray, E.; Yazar, J.G.; Aktok, Ö.; Çulluk, B.; Çalışkan Koç, G.; Pandiselvam, R. The Effect of Drying Temperature and Thickness on the Drying Kinetic, Antioxidant Activity, Phenolic Compounds, and Color Values of Apple Slices. J. Food Qual. 2023, 2023, 7426793. [Google Scholar] [CrossRef]

- Kahraman, O.; Malvandi, A.; Vargas, L.; Feng, H. Drying characteristics and quality attributes of apple slices dried by a non-thermal ultrasonic contact drying method. Ultrason. Sonochem. 2021, 73, 105510. [Google Scholar] [CrossRef] [PubMed]

- Çelen, S.; Haksever, A.; Moralar, A. The effects of microwave energy to the drying of apple (gala) slices. Karaelmas Sci. Eng. J. 2017, 7, 228–236. [Google Scholar]

- Dehghannya, J.; Gorbani, R.; Ghanbarzadeh, B. Influence of combined pretreatments on color parameters during convective drying of Mirabelle plum (Prunus domestica subsp. syriaca). Heat Mass Transf. 2017, 53, 2425–2433. [Google Scholar] [CrossRef]

- Dehnad, D.; Jafari, S.M.; Afrasiabi, M. Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci. Technol. 2016, 57, 116–131. [Google Scholar] [CrossRef]

- He, X.; Lin, R.; Cheng, S.; Wang, S.; Yuan, L.; Wang, H.; Wang, H.; Tan, M. Effects of microwave vacuum drying on the moisture migration, microstructure, and rehydration of sea cucumber. J. Food Sci. 2021, 86, 2499–2512. [Google Scholar] [CrossRef] [PubMed]

- Dak, M.; Jain, M.; Jat, S. Optimization of microwave-vacuum drying of pomegranate arils. J. Food Meas. Charact. 2014, 8, 398–411. [Google Scholar] [CrossRef]

- Yi, J.-Y.; Zhou, L.-Y.; Bi, J.-F.; Wang, P.; Liu, X.; Wu, X.-Y. Influence of number of puffing times on physicochemical, color, texture, and microstructure of explosion puffing dried apple chips. Dry. Technol. 2016, 34, 773–782. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Gan, R.-Y.; Li, S.; Zhou, Y.; Li, A.-N.; Xu, D.-P.; Li, H.-B. Antioxidant phytochemicals for the prevention and treatment of chronic diseases. Molecules 2015, 20, 21138–21156. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Li, Y.; Zhou, X.; Wang, J.; Zhang, Q.; Yang, X.; Zhu, L.; Geng, Z. Prediction of Apple Slices Drying Kinetic during Infrared-Assisted-Hot Air Drying by Deep Neural Networks. Foods 2022, 11, 3486. [Google Scholar] [CrossRef] [PubMed]

- Akter, F.; Akther, S.; Sultana, A.; Rahman, M.M.; Deb, U.K. Optimization of drying parameters for total phenolic content of papaya using response surface methodology. Int. J. Food Sci. 2022, 2022, 7426793. [Google Scholar] [CrossRef]

- Aghilinategh, N.; Rafiee, S.; Gholikhani, A.; Hosseinpur, S.; Omid, M.; Mohtasebi, S.S.; Maleki, N. A comparative study of dried apple using hot air, intermittent and continuous microwave: Evaluation of kinetic parameters and physicochemical quality attributes. Food Sci. Nutr. 2015, 3, 519–526. [Google Scholar] [CrossRef]

| Code | Experimental Factors | |||

|---|---|---|---|---|

| Slice Thickness X1 (mm) | Microwave Power X2 (W) | Air Velocity X3 (m·s−1) | Belt Speed X4 (m·min−1) | |

| −2 | 0.50 | 13,300 | 0.25 | 0.32 |

| −1 | 0.75 | 13,775 | 0.50 | 0.33 |

| 0 | 1.00 | 14,250 | 0.75 | 0.34 |

| 1 | 1.25 | 14,725 | 1.00 | 0.35 |

| 2 | 1.50 | 15,200 | 1.25 | 0.36 |

| No. | Experimental Factors | Responses | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature | Moisture Content | Color | Hardness | Brittleness | TPC | |||||||

| X1 (mm) | X2 (W) | X3 (m·s1) | X4 (m·min−) | Y1 (°C) | Y2 (%) | Y3 L* | Y4 a* | Y5 b* | Y6 (g) | Y7 (number of peaks) | Y8 (mg·g−1) | |

| 1 | −1 | −1 | −1 | −1 | 47.54 ± 0.04 | 19.45 ± 0.12 | 76.40 ± 0.62 | 5.10 ± 0.44 | 27.80 ± 0.55 | 0.68 ± 0.03 | 16.00 ± 0.30 | 4.13 ± 0.08 |

| 2 | 1 | −1 | −1 | −1 | 50.98 ± 0.05 | 17.93 ± 0.06 | 75.90 ± 0.36 | 8.60 ± 0.30 | 28.20 ± 0.36 | 0.71 ± 0.04 | 17.00 ± 0.40 | 5.64 ± 0.06 |

| 3 | −1 | 1 | −1 | −1 | 57.07 ± 0.10 | 15.35 ± 0.07 | 75.20 ± 0.56 | 5.00 ± 0.46 | 27.40 ± 0.50 | 0.79 ± 0.02 | 18.00 ± 0.20 | 3.81 ± 0.05 |

| 4 | 1 | 1 | −1 | −1 | 62.13 ± 0.23 | 13.87 ± 0.07 | 73.90 ± 0.44 | 8.30 ± 0.75 | 27.30 ± 0.36 | 0.81 ± 0.04 | 10.00 ± 0.40 | 4.97 ± 0.07 |

| 5 | −1 | −1 | 1 | −1 | 44.80 ± 0.20 | 16.51 ± 0.12 | 72.40 ± 0.39 | 4.40 ± 0.36 | 24.20 ± 0.30 | 0.69 ± 0.04 | 13.00 ± 0.12 | 3.57 ± 0.04 |

| 6 | 1 | −1 | 1 | −1 | 47.71 ± 0.29 | 18.43 ± 0.16 | 71.80 ± 0.36 | 8.10 ± 0.26 | 27.50 ± 0.12 | 0.7 ± 0.03 | 17.00 ± 0.30 | 4.69 ± 0.09 |

| 7 | −1 | 1 | 1 | −1 | 53.25 ± 0.12 | 16.07 ± 0.14 | 71.60 ± 0.75 | 4.10 ± 0.36 | 27.50 ± 0.46 | 0.79 ± 0.02 | 21.00 ± 0.60 | 3.32 ± 0.11 |

| 8 | 1 | 1 | 1 | −1 | 55.45 ± 0.14 | 15.49 ± 0.09 | 70.60 ± 0.40 | 7.90 ± 0.48 | 28.60 ± 0.31 | 0.78 ± 0.05 | 17.00 ± 0.44 | 5.69 ± 0.12 |

| 9 | −1 | −1 | −1 | 1 | 44.59 ± 0.33 | 16.93 ± 0.11 | 83.80 ± 0.40 | 3.80 ± 0.10 | 26.60 ± 0.44 | 0.66 ± 0.04 | 28.00 ± 0.26 | 3.14 ± 0.08 |

| 10 | 1 | −1 | −1 | 1 | 46.68 ± 0.27 | 22.48 ± 0.19 | 83.30 ± 0.44 | 10.40 ± 0.56 | 29.10 ± 0.56 | 0.68 ± 0.03 | 32.00 ± 0.36 | 5.93 ± 0.07 |

| 11 | −1 | 1 | −1 | 1 | 56.31 ± 0.21 | 14.84 ± 0.14 | 82.90 ± 0.36 | 3.60 ± 0.17 | 28.50 ± 0.36 | 0.79 ± 0.03 | 35.00 ± 0.44 | 2.86 ± 0.08 |

| 12 | 1 | 1 | −1 | 1 | 59.53 ± 0.04 | 14.35 ± 0.09 | 82.10 ± 0.48 | 10.00 ± 0.26 | 27.50 ± 0.26 | 0.8 ± 0.05 | 36.00 ± 0.35 | 5.68 ± 0.05 |

| 13 | −1 | −1 | 1 | 1 | 44.36 ± 0.13 | 18.76 ± 0.11 | 81.70 ± 0.38 | 3.30 ± 0.17 | 27.50 ± 0.44 | 0.69 ± 0.04 | 41.00 ± 0.30 | 2.54 ± 0.08 |

| 14 | 1 | −1 | 1 | 1 | 46.13 ± 0.43 | 20.10 ± 0.15 | 81.60 ± 0.60 | 9.80 ± 0.36 | 28.10 ± 0.36 | 0.7 ± 0.04 | 43.00 ± 0.45 | 5.00 ± 0.12 |

| 15 | −1 | 1 | 1 | 1 | 54.21 ± 0.04 | 15.71 ± 0.12 | 81.40 ± 0.44 | 3.20 ± 0.17 | 28.10 ± 0.17 | 0.78 ± 0.04 | 41.00 ± 0.26 | 2.21 ± 0.06 |

| 16 | 1 | 1 | 1 | 1 | 55.67 ± 0.13 | 17.17 ± 0.14 | 81.30 ± 0.57 | 9.70 ± 0.53 | 28.00 ± 0.26 | 0.79 ± 0.02 | 39.00 ± 0.35 | 5.14 ± 0.10 |

| 17 | −2 | 0 | 0 | 0 | 52.60 ± 0.10 | 15.92 ± 0.17 | 80.70 ± 0.46 | 1.30 ± 0.20 | 29.00 ± 0.44 | 0.73 ± 0.05 | 29.00 ± 0.56 | 1.37 ± 0.07 |

| 18 | 2 | 0 | 0 | 0 | 53.00 ± 0.24 | 18.32 ± 0.14 | 80.20 ± 0.36 | 13.60 ± 0.26 | 28.80 ± 0.40 | 0.74 ± 0.02 | 23.00 ± 0.30 | 6.87 ± 0.08 |

| 19 | 0 | −2 | 0 | 0 | 40.15 ± 0.30 | 25.05 ± 0.17 | 79.70 ± 0.31 | 3.30 ± 0.62 | 28.60 ± 0.26 | 0.63 ± 0.04 | 28.00 ± 0.62 | 4.87 ± 0.06 |

| 20 | 0 | 2 | 0 | 0 | 62.01 ± 0.58 | 14.73 ± 0.26 | 79.10 ± 0.46 | 5.80 ± 0.44 | 27.50 ± 0.20 | 0.88 ± 0.03 | 26.00 ± 0.26 | 4.18 ± 0.08 |

| 21 | 0 | 0 | −2 | 0 | 53.25 ± 0.05 | 16.79 ± 0.11 | 78.50 ± 0.70 | 4.40 ± 0.40 | 27.10 ± 0.68 | 0.74 ± 0.04 | 25.00 ± 0.20 | 5.41 ± 0.09 |

| 22 | 0 | 0 | 2 | 0 | 49.69 ± 0.13 | 16.74 ± 0.21 | 78.10 ± 0.44 | 4.30 ± 0.44 | 26.90 ± 0.26 | 0.72 ± 0.03 | 27.00 ± 0.61 | 5.63 ± 0.07 |

| 23 | 0 | 0 | 0 | −2 | 51.27 ± 0.24 | 16.46 ± 0.14 | 65.30 ± 0.44 | 3.60 ± 0.66 | 25.50 ± 0.42 | 0.71 ± 0.04 | 8.00 ± 0.46 | 6.08 ± 0.05 |

| 24 | 0 | 0 | 0 | 2 | 49.99 ± 0.13 | 16.71 ± 0.08 | 85.70 ± 0.36 | 3.30 ± 0.17 | 25.80 ± 0.40 | 0.73 ± 0.03 | 53.00 ± 0.44 | 4.72 ± 0.09 |

| 25 | 0 | 0 | 0 | 0 | 52.94 ± 0.13 | 15.20 ± 0.12 | 75.20 ± 0.26 | 2.60 ± 0.26 | 24.50 ± 0.62 | 0.74 ± 0.04 | 23.00 ± 0.26 | 5.56 ± 0.12 |

| 26 | 0 | 0 | 0 | 0 | 53.09 ± 0.18 | 16.25 ± 0.07 | 75.00 ± 0.46 | 1.80 ± 0.31 | 24.10 ± 0.44 | 0.75 ± 0.06 | 22.00 ± 0.35 | 5.70 ± 0.06 |

| 27 | 0 | 0 | 0 | 0 | 53.41 ± 0.27 | 16.57 ± 0.25 | 74.10 ± 0.35 | 2.00 ± 0.46 | 25.10 ± 0.17 | 0.76 ± 0.02 | 23.00 ± 0.17 | 5.02 ± 0.05 |

| 28 | 0 | 0 | 0 | 0 | 54.35 ± 0.38 | 15.57 ± 0.12 | 74.00 ± 0.56 | 0.90 ± 0.20 | 25.50 ± 0.46 | 0.74 ± 0.04 | 23.00 ± 0.38 | 5.73 ± 0.13 |

| 29 | 0 | 0 | 0 | 0 | 54.79 ± 0.13 | 16.27 ± 0.12 | 73.80 ± 0.53 | 0.60 ± 0.26 | 25.00 ± 0.26 | 0.75 ± 0.03 | 23.00 ± 0.30 | 5.71 ± 0.05 |

| 30 | 0 | 0 | 0 | 0 | 55.34 ± 0.26 | 14.50 ± 0.13 | 73.80 ± 0.44 | 0.50 ± 0.17 | 24.80 ± 0.30 | 0.74 ± 0.03 | 18.00 ± 0.53 | 6.25 ± 0.07 |

| Source | DF | Temperature | Moisture Content | L* | a* | b* | Hardness | Brittleness | TPC | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | P | F | P | F | P | F | P | F | P | F | P | F | P | F | P | ||

| Model | 14 | 46.67 | <0.0001 ** | 8.58 | <0.0001 ** | 45.59 | <0.0001 ** | 14.30 | <0.0001 ** | 6.55 | 0.0004 ** | 40.65 | <0.0001 ** | 24.96 | <0.0001 ** | 11.03 | <0.0001 ** |

| X1 | 1 | 20.27 | 0.0004 ** | 4.08 | 0.0616 * | 1.45 | 0.2476 | 114.51 | <0.0001 ** | 2.63 | 0.1257 | 4.48 | 0.0514 * | 0.9363 | 0.3486 | 108.96 | <0.0001 ** |

| X2 | 1 | 552.44 | <0.0001 ** | 78.89 | <0.0001 ** | 3.44 | 0.0833 * | 0.2961 | 0.5944 | 0.1915 | 0.6679 | 542.24 | <0.0001 ** | 0.1720 | 0.6842 | 0.7497 | 0.4002 |

| X3 | 1 | 30.23 | <0.0001 ** | 0.29 | 0.5983 | 19.94 | 0.0005 ** | 0.5505 | 0.4696 | 0.7217 | 0.4089 | 0.4979 | 0.4912 | 9.25 | 0.0083 ** | 1.72 | 0.2091 |

| X4 | 1 | 5.93 | 0.0278 * | 2.02 | 0.1762 | 513.25 | <0.0001 ** | 0.0786 | 0.7831 | 2.00 | 0.1772 | 0.1245 | 0.7291 | 313.07 | <0.0001 ** | 5.04 | 0.0402* |

| AB | 1 | 0.03 | 0.8693 | 3.53 | 0.0799 * | 0.1403 | 0.7132 | 0.0037 | 0.9525 | 4.73 | 0.0460 * | 0.7469 | 0.4011 | 4.13 | 0.0603 * | 0.4162 | 0.5286 |

| AC | 1 | 2.20 | 0.1587 | 0.22 | 0.6488 | 0.1054 | 0.7499 | 0.0200 | 0.8895 | 0.9553 | 0.3439 | 1.68 | 0.2144 | 0.0287 | 0.8678 | 0.0734 | 0.7902 |

| AD | 1 | 1.94 | 0.1843 | 4.59 | 0.0489 * | 0.2252 | 0.6420 | 5.58 | 0.0321 * | 0.7247 | 0.4080 | 0.0000 | 1.0000 | 1.03 | 0.3258 | 4.83 | 0.0441 * |

| BC | 1 | 5.99 | 0.0272 * | 4.11 | 0.0607 * | 0.4547 | 0.5104 | 0.0037 | 0.9525 | 3.46 | 0.0826 * | 4.67 | 0.0473 * | 0.0287 | 0.8678 | 0.8794 | 0.3632 |

| BD | 1 | 1.95 | 0.1829 | 1.10 | 0.3100 | 0.3898 | 0.5418 | 0.0004 | 0.9842 | 0.5259 | 0.4795 | 0.7469 | 0.4011 | 0.1146 | 0.7396 | 0.0464 | 0.8324 |

| CD | 1 | 4.04 | 0.0627* | 0.53 | 0.4786 | 4.94 | 0.0420 * | 0.0200 | 0.8895 | 0.8360 | 0.3750 | 1.68 | 0.2144 | 4.84 | 0.0438 * | 0.4220 | 0.5258 |

| A2 | 1 | 1.76 | 0.2049 | 1.56 | 0.2308 | 56.97 | <0.0001 ** | 56.98 | <0.0001 ** | 48.38 | <0.0001 ** | 0.8892 | 0.3606 | 2.29 | 0.1506 | 21.63 | 0.0003 ** |

| B2 | 1 | 11.70 | 0.0038 ** | 20.33 | 0.0004 ** | 38.13 | <0.0001 ** | 20.08 | 0.0004 ** | 30.83 | <0.0001 ** | 1.74 | 0.2066 | 3.83 | 0.0691 * | 13.62 | 0.0022 ** |

| C2 | 1 | 8.72 | 0.0099 ** | 0.69 | 0.4201 | 22.43 | 0.0003 ** | 18.23 | 0.0007 ** | 14.58 | 0.0017 ** | 2.28 | 0.1521 | 2.29 | 0.1506 | 1.73 | 0.2084 |

| D2 | 1 | 15.69 | 0.0013 ** | 0.38 | 0.5468 | 1.15 | 0.3000 | 11.01 | 0.0047 ** | 2.53 | 0.1328 | 6.97 | 0.0185 * | 12.32 | 0.0032 ** | 2.54 | 0.1317 |

| Lack of fit | 10 | 1.34 | 0.3925 | 2.50 | 0.1614 | 3.40 | 0.0947 * | 2.64 | 0.1477 | 3.45 | 0.0920 * | 2.51 | 0.1605 | 2.77 | 0.1361 | 2.42 | 0.1712 |

| Response | Regression Model | R2 | Adj R2 |

|---|---|---|---|

| Y1 (Temperature) | Y1 = 53.99 + 1.0X1 + 5.23X2 − 1.22X3 − 0.5421X4 − 0.6669X2X3 − 0.7122X22 − 0.6147X32 − 0.8247X42 | 0.9776 | 0.9566 |

| Y2 (Moisture Content) | Y2 = 15.73 − 2.02X2 + 0.5956X1X4 + 0.9573X22 | 0.8890 | 0.7853 |

| Y3 (a*) | Y3 = 1.40 + 2.70X1 + 0.7312X1X4 + 1.78X12 + 1.06X22 + 1.01X32 + 0.7844X42 | 0.9303 | 0.8652 |

| Y4 (b*) | Y4 = 24.83 − 0.4312X1X2 + 1.05X12 + 0.8406X22 + 0.5781X32 | 0.8594 | 0.7282 |

| Y5 (Hardness) | Y5 = 0.7467 + 0.0550X2 − 0.0062X2X3 − 0.0058X42 | 0.9743 | 0.9503 |

| Y6 (Brittleness) | Y6 = 22 + 1.83X3 + 10.67X4 + 1.63X3X4 + 1.98X42 | 0.9588 | 0.9204 |

| Y7 (TPC) | Y7 = 5.66 + 1.17X1 − 0.2523X4 + 0.3023X1X4 − 0.4887X12 − 0.3879X22 | 0.9115 | 0.8289 |

| Parameters | Goal | Lower Limits | Upper Limits | Importance Level | Predicated Value | Validation Value | Relative Error (%) | |

|---|---|---|---|---|---|---|---|---|

| Factors | Slice thickness (mm) | In range | 0.75 | 1.25 | +++ | 1.25 | 1.25 | - |

| Microwave power (W) | Min. | 13,775 | 14,725 | +++ | 14,713.22 | 14,630 | 0.57 | |

| Air velocity (m·s−1) | In range | 0.50 | 1.00 | +++ | 0.50 | 0.50 | - | |

| Belt speed (m·min−1) | In range | 0.33 | 0.35 | +++ | 0.33 | 0.33 | - | |

| Evaluation indexes | Temperature | In range | 40.15 | 62.13 | +++ | 61.12 | 60.76 | 0.59 |

| Moisture content | Target | 12.00 | 14.00 | +++++ | 13.96 | 13.53 | 3.17 | |

| L* | In range | 65.30 | 85.70 | +++ | 73.61 | 72.56 | 1.45 | |

| a* | In range | 0.50 | 13.60 | +++ | 8.17 | 8.35 | 2.15 | |

| b* | In range | 24.10 | 29.10 | +++ | 27.26 | 28.21 | 3.36 | |

| Hardness | In range | 0.63 | 0.88 | +++ | 0.81 | 0.79 | 2.53 | |

| Brittleness | In range | 8.00 | 53.00 | +++ | 13.06 | 12.97 | 0.69 | |

| TPC | Max. | 1.37 | 6.87 | +++ | 5.53 | 5.48 | 0.91 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamruzzaman, M.; Shen, L.; Zhang, Y.; Xue, L.; Fu, K.; Zhu, H.; Zheng, X. Optimization of Processing Parameters for Continuous Microwave Drying of Crab Apple Slices via Response Surface Methodology. Foods 2024, 13, 2071. https://doi.org/10.3390/foods13132071

Kamruzzaman M, Shen L, Zhang Y, Xue L, Fu K, Zhu H, Zheng X. Optimization of Processing Parameters for Continuous Microwave Drying of Crab Apple Slices via Response Surface Methodology. Foods. 2024; 13(13):2071. https://doi.org/10.3390/foods13132071

Chicago/Turabian StyleKamruzzaman, Md, Liuyang Shen, Yuhan Zhang, Liangliang Xue, Kesen Fu, Haihui Zhu, and Xianzhe Zheng. 2024. "Optimization of Processing Parameters for Continuous Microwave Drying of Crab Apple Slices via Response Surface Methodology" Foods 13, no. 13: 2071. https://doi.org/10.3390/foods13132071

APA StyleKamruzzaman, M., Shen, L., Zhang, Y., Xue, L., Fu, K., Zhu, H., & Zheng, X. (2024). Optimization of Processing Parameters for Continuous Microwave Drying of Crab Apple Slices via Response Surface Methodology. Foods, 13(13), 2071. https://doi.org/10.3390/foods13132071