In this section, the findings obtained throughout the study are presented and discussed in the context of the literature. The reasons for some of the significant results obtained are outlined. Each topic is discussed in its respective section. The findings are initially presented in a table format, followed by a discussion of the results in relation to the existing literature.

3.1. Physicochemical, Color and Fusibility Results of Block-Type Melted Cheeses

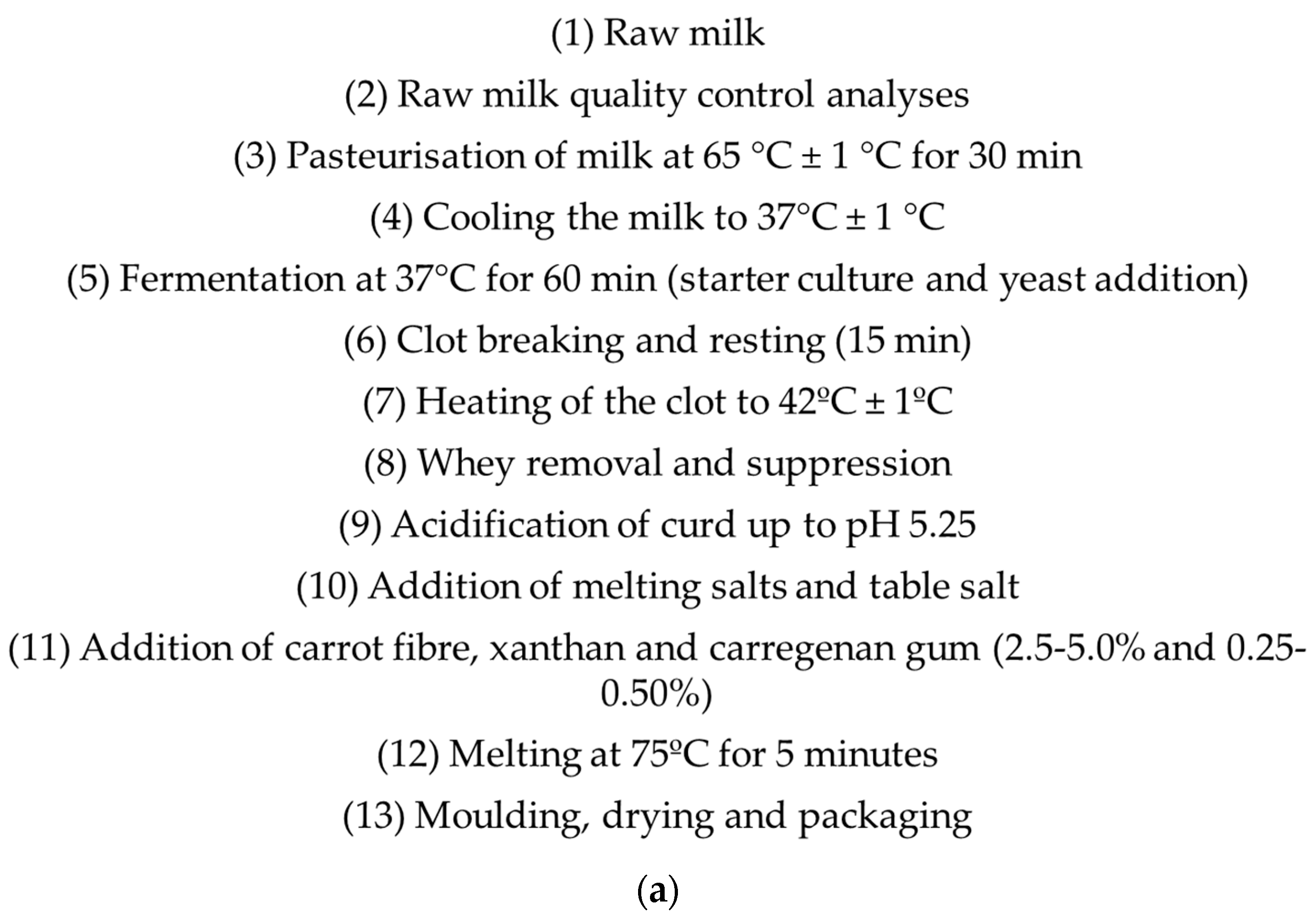

In this study, fat and dry matter fat values, dry matter, salt and dry matter salt values, pH value, total acidity value, protein values, and color values (L*, a*, b*) of block-type melting cheeses were measured.

In our study, only the first-day analyses were performed on these data considering the previous studies, since the fat, fat in dry matter, protein, dry matter, salt, salt in dry matter, and ash ratios of the cheese samples stored in vacuumed and packaged form would not have changed during storage. Dry matter values of block-type melted cheese samples are given in

Table 3, fat values are given in

Table 4, fat in dry matter values are given in

Table 5, salt values are given in

Table 6, salt values in dry matter are given in

Table 7, protein values are given in

Table 8, ash values are given in

Table 9, pH values are given in

Table 10, total acidity values are given in

Table 11, L* values are given in

Table 12, a* values are given in

Table 13, b* values are given in

Table 14 and fusibility values are given in

Table 15.

When the analyses from the first day were examined, it was observed that the salt content of the cheese samples ranged between 1.31% and 1.48%. These results are detailed in

Table 6. In previous studies, Çavuş [

23] determined the salt content of the control cheese samples as 1.59% in the first-day analyses. Other researchers determined the salt content of control cheese samples as 3.26% in Öztek [

24], 3.16% in Ayar [

25], 1.78% in Yüksel [

26], 1.91% in Koca and Metin [

27], 1.17% in Keçeli et al. [

28], and 4.09% in Ayar et al. [

29]. Since there may be changes in salt ratios due to the demands of consumers and the production methods of the producer, it was thought that the comparison would not be healthy. Some of the findings given by previous researchers are the salt content of kashkaval cheese. After the kashkaval cheese is salted in salted boiling water, salt is added during kneading. In this way, the shelf life is extended, because it is a cheese that is consumed by ripening. However, less salt is used in fresh block-type melting cheese. For example, Cankurt [

20] measured the effect of different hydrosols on some properties of block-type melting cheese and found salt ratios between 2.04–2.06%.

Salt content in the dry matter of the cheese samples was determined between 2.43% and 2.51%. In the study conducted by Çavuş [

23] on the production of block-type melting cheese, it was determined that the amount of salt in dry matter was between 2.87% and 2.98%. In the study conducted by Yüksel [

26] on the production of dietary block-type melting cheese, the amount of salt in dry matter was determined as 3.83% and 4.08%. Cankurt [

20] found salt ratios in total dry matter between 3.44% and 3.62% in his study on hydrosol block-type melting cheese. The salt and dry matter salt ratios in block-type melting cheese vary according to the formula of the researcher. Therefore, comparing the results gives an idea but does not make a clear judgement.

The ash ratios of the block-type melting cheeses produced were determined as 3.52% at the lowest and 3.97% at the highest. The values are shown in

Table 9. As a result of the ash analysis of kashkaval cheese performed by Tavacı [

30], ash ratio was determined between 4.31–4.53%. In different studies conducted on kashkaval cheese, Fırat [

31], Ayar [

25], Demirci and Dıraman [

32], Kurultay [

33], and Özdemir [

34] reported ash ratios between 3.05–5.78%. A large part of the ash value is due to salt. The higher the salt content in a cheese, the higher the ash value. In addition, herbal flavorings added to cheeses are also among the factors affecting the ash value. In addition, if the added salt contains other minerals in excess, it causes an increase in the ash ratio to the same degree [

20]. Since the salt content is relatively low in our cheeses, the ash content is also low. It is seen that the difference in the ash ratios of the cheese samples is mainly due to the dry matter content, because the highest ash content was measured in the control sample with the highest dry matter content.

The lowest dry matter values of the block-type melting cheese samples were found to be 53.62%, and the highest 59.65%. Ayar [

25] analyzed cheese samples produced in Trabzon market and found that the average dry matter content was 57.34%. In a study conducted by Coşkun and Öztürk [

35] on cheeses produced in Van and offered for consumption, it was found that the lowest was 44.02% and the highest was 63.54%. When the analyses of other studies were examined, it was found that there were differences. Keçeli et al. [

28] found an average of 46.56%, while Estürk [

36] found this value to be 56.37%. The results obtained in our study were found to be closer to the results obtained by Estürk [

36]. Block-type melting cheese can be produced at desired dry matter values. In this cheese, the texture is provided by the product content, and emulsifying salts are used as a support. Some of them provide hardness, while others provide hot meltability and creep. Therefore, the dry matter content of cheeses depends entirely on the will of the producer [

20]. In our study, the dry matter of all samples containing gum and fiber was found to be lower than the control sample, because gums have water binding properties. In our study, less additional water was added to the samples containing low levels of gum and fiber, while more water was added to the samples containing high levels of gum and fiber, so the dry matter values varied.

The fat values obtained from the block-type melting cheese samples we produced ranged between the lowest at 25.00% and the highest at 29.40%. Detailed fat values are provided in

Table 4. In the study conducted by Demirci and Dıraman [

32], the fat content of fresh kashar cheese was found to be 24.11%. In a study conducted by Ayar [

25] in which the properties of cheeses produced in Trabzon were investigated, it was reported that the fat ratio was found to be 25.10%. In another study conducted by Fırat [

31], the fat content was determined as 27.66%. Cankurt [

20] investigated the effect of some plant hydrosols and essential oils on the physicochemical, textural, microbiological, and sensory properties of block-type melting cheese and found fat ratios between 29.77% and 31.50%. The fat content in cheese is affected by the fat content of the raw milk used, the heat treatment applied to the milk, and other production stages, as well as the ratio and type of other ingredients added. The milk used in our study is the same. However, although the rate of gums added to the formulations is low, the rate of carrot fiber added is high enough to affect the overall composition. Accordingly, it was expected that the control sample, which had the highest dry matter content, would have a high ratio of gum. In the carrot fiber 5.0 sample, the oil ratio was low because the amount of water and carrot fiber used was high.

Fat ratios in dry matter were determined as 46.35% at the lowest and 49.52% at the highest. When the studies on kashkaval cheese were analyzed, it was found that the fat ratios in dry matter were 40.97% by Fırat [

31], 42.79% by Öztek [

24], 43.63% by Ayar [

29], 38.6% by Estürk [

36], and 32.77% by Keçeli et al. [

28]. Cankurt [

20] found the oil content in total dry matter to be between 52.41% and 53.24%. The results found in our study are between the results of this researcher and the results of Öztek [

24]. The fact that other researchers found lower results is due to the fact that either they used less fat milk or some of the fat passed into the water while boiling in water. The lower fat content in the total dry matter in the carrot fiber 5.0 sample is due to the fact that 5% fiber was included in the composition.

In the pH analyses of block-type melting cheeses, a decreasing trend was observed from the first day to the last day. On the first day, pH values varied between 5.63 and 5.70. In the 15th day analyses, pH values ranged between 5.65 and 5.70, and in the 30th day analyses, they varied between 5.58 and 5.66. The pH values are presented in

Table 10. In other studies, Keçeli et al. [

28], Demirci and Dıraman [

32], and Estürk [

36] reported pH values between 5.13 and 5.70. Say [

37] reported that the lowest value was 5.30 on the first day and 5.17 on the last day of storage in a study on the properties of cheese during storage. Tavacı [

30] determined the pH value of the cheeses he produced as 5.42–5.47, and Fındık [

38] determined that the pH value was between 5.27 and 5.29 in the production of fresh kashkaval cheese. In our study, it was observed that our pH values were higher than those of other researchers. Cankurt [

20] found the pH values of the samples to be between 5.73–5.91 on the 30th day of storage. Our results appear similar to those of this researcher, because when we look at the production methods, it can be said that they are exactly the same. The reason why other researchers’ cheeses have low values is that they are generally produced by boiling with water. In such a case, the internal temperature remains around 57 °C. As a result, lactic acid bacteria remain largely alive, lactic acid development continues, and the pH value decreases. However, melted cheese is boiled in a Stefan type machine and usually at 75 °C. Additionally, pH-increasing emulsifying salts are added to the structure. For this reason, the pH value of melted cheese is higher. Melting salts are not used in wet boiled kashar cheese [

20]. In our study, it was understood that the pH values were not different enough to be discussed. Accordingly, the use and amounts of gum or carrot fiber did not significantly affect the pH value.

When examining the total acidity values of the block-type melted cheese samples, it was observed that the acidity increased in all samples. On the first day analyses, it ranged between 1.45% and 1.72%. In the 15th day analyses, it varied between 1.55% and 1.77%, and in the 30th day analyses, it ranged between 1.54% and 1.83%. Özdemir [

34] and Çağlar and Çakmakçı [

39] reported that the acidity ratios of kashkaval cheese samples increased continuously during storage. Öksüztepe et al. [

40] reported the average titration acidity value as 0.42% in their study on the microbiological and chemical qualities of kashkaval cheese produced in Elazığ. Aydın [

41] reported that titration acidity values in kashkaval cheese samples were between 1.17 and 1.66%. Yaşar [

42] found the titration acidity values determined during the ripening period of kashkaval cheese as 0.70% and 2.15%, respectively. Cankurt [

20] determined total acidity values as 1.47 to 1.84%. In our study, total acidity values were found to be similar to those found by Cankurt [

20]. While the results of some researchers were found to be close to our results, some were found to be significantly lower. The reason why it is low is that kashar cheese is boiled in water. Accordingly, the lactic acid formed in the curd passes into the boiling water during boiling. Thus, the total acidity is weak. However, the live lactic acid bacteria in these cheeses increase the total acidity again over time. As a result, total acidity varies depending on many factors such as the level of heat treatment applied to the milk, boiling method, starter culture addition, storage temperature, packaging type, and the amount of water in the composition. Since there was no wet boiling in our study, the acid formed in the curd remained in the resulting cheese. Therefore, the acidity on the first day was relatively high. This acidity increased with storage, albeit slowly. In this study, no significant relationship was found between increasing the water amount and increasing the gum and total acidity.

When examining the protein values of block-type melted cheeses, the lowest protein value was determined to be 22.07% in the cheese sample with 5% carrot fiber, while the highest value was determined to be 24.48% in the control group cheese sample, as shown in

Table 8. Cankurt [

20] reported that the protein values of cheeses were between 25.71 and 27.48%. Çavuş [

23] stated that the protein values of the cheeses he produced were between 26.55 and 28.75%. Aydın [

41] found protein values between 20.17% and 25.01% in the study of the effects of different herb varieties used in cheese production on ripening. Hayaloğlu [

43] stated the protein values of cheeses as 12.78% and 17.21% in his study on the properties and ripening of white cheeses. Bayram [

44] reported that the protein values of the cheeses produced were between 23.17 and 25.83%. When similar studies are analyzed, it is thought that the reasons for the occurrence of different protein values may be due to the method of cheese production, the type of animal from which the milk used comes, nutritional status, and the amount of salt added to the cheese. Cankurt [

20] reported that total protein in block-type processed cheese decreased by around 0.7% after 90 days of storage. However, we only measured the total protein ratio in the first day analysis, anticipating that there would be no decrease. The difference in the protein values of our samples is largely due to formulation differences. The fact that some researchers’ protein ratios are lower than ours is most likely due to production differences, because in the wet boiling method, not only is fat lost, but water-soluble proteins and proteins combined with fat are also removed.

When examining the L* values of the color values of the block-type melting cheese samples produced, differences were observed. On the first day analyses, L* values varied between 82.02 and 87.41. On the 15th day analyses, they ranged from 79.86 to 88.09, and on the 30th day analyses, they ranged from 81.86 to 87.81. The highest L* value was 88.09 in the cheese sample in which 0.50% carrageenan gum was used, while the lowest L* value of 79.86 was found in the cheese sample with 5% carrot fiber added. In the study by Fırat [

31] titled “Determination of some microbiological, physical and chemical properties of kashkaval cheese during ripening”, the highest L* value was 87.30 in control kashkaval cheese samples. Cankurt [

20] found the highest L* value as 90.38 in control cheese samples. The L* values obtained in our study are similar to the L* values obtained by other researchers. Our samples were found to be different within themselves. While the use of carrageenan whitened the color, the use of carrot fiber reduced the whiteness. While some of the components in cheese have a reducing effect on whiteness, components such as calcium increase whiteness. Since the water content is high in those with high gum content, the components that suppress whiteness decreased proportionally, and thus the whiteness of the samples containing carrageenan and xanthan gum with high water content was found to be higher. However, this was not the case in samples containing carrot fiber. While carrot fiber is produced, the fibers are not washed. Therefore, they contain significant levels of colorants. Since carrot fiber has a reducing effect on whiteness, whiteness decreased as carrot fiber increased. Çavuş [

23] reported that the L* values of block-type melted cheeses produced using eggs decreased with storage, the highest values were in the control cheese, and the lowest values were in the sample with egg yolk added. Öksüz et al. [

45] found the lowest L* value in the kashar cheeses they produced to be 74.8. They found the highest to be 90.1. The L* values we obtained are consistent with the findings of previous researchers.

Significant differences were observed when examining the a* values among the color values of cheese samples. On the first day analyses, a* values ranged between 2.92 and 5.49. In the 15th day analyses, they were observed to vary between 2.53 and 5.86, and in the 30th day analyses, between 2.82 and 6.20. The highest a* value was observed in the cheese sample to which 5% carrot fiber was added, with 6.20. The lowest a* value was found in the cheese sample with 0.50% xanthan gum added, at 2.53. Except for the carrot fiber cheese samples, the other cheese samples showed a decrease in the 15th day analyses compared to the first day analyses, but it was found to increase again in the 30th day analyses. Carrot fiber-added cheese samples showed an increase in the values starting from the first day analyses. In the study on the determination of some microbiological, physical, and chemical properties of kashkaval cheeses produced by Fırat [

31] at the ripening stage, it was reported that a* values were between −4.50 and −4.54. Öksüz et al. [

45] reported that the a* value was between −0.76 and −7.8 in the color analysis of kashkaval cheese. Cankurt [

20] reported that the a* value was between 0.40 and 2.05 in his study. Aydın [

41] stated that the a* value of cheese samples was between −3.46 and −0.90. The color values in cheese are, of course, affected by the composition of the final product, the cheese, and the raw milk used in the production of this cheese. However, components that are added later and have coloring properties also have a significant effect on color. It was observed that the carrot fiber cheeses obtained in our study were redder. Since the carrot fibers were dried without washing, they gave the cheese an orange color due to the beta carotene it contains. It has been observed that other gums used also have an effect on the a* value and that this effect becomes more evident over time.

When examining the b* value of the cheese samples, it ranged between 28.08 and 33.99 in the first day analyses. In the 15th day analyses, it varied between 29.00 and 34.70, and in the 30th day analyses, between 29.42 and 37.37. The highest b* value was 37.37 in our cheese sample with 5% carrot fiber added, while the lowest b* value was 28.08 in the cheese sample with 0.50% carrageenan gum added. It was observed to increase from the first day to the last day of storage. Say [

37] reported that the b* value varied between 28.03 and 36.33 during the storage process in the study on the effects on the properties of kashkaval cheese. In different studies, the b* value was determined by Öksüz et al. [

45] at 19.24–28.87, Cankurt [

20] 19.30–24.19, Göncü [

46] 22.38–30.33, and Çavuş [

23] 18.32–39.12. Beta carotene in carrots increases both redness and yellowness. For this reason, the b* value of the carrot fiber-added samples was found to be higher. Accordingly, it was observed that cheeses with increased yellowness and redness were sensory orange, as expected. The use of other gums, mostly in carrot fiber samples, also increased the yellowness of the cheeses.

The fusibility values of the block-type melting cheese samples are provided in

Table 15. Upon an examination of the samples, differences were observed in the analyses conducted during storage. In the first day analyses, fusibility varied between 5.87 cm and 6.92 cm. In the 15th day analyses, it was observed to range between 5.79 cm and 7.04 cm, and in the 30th day analyses, between 5.92 cm and 6.79 cm. The highest fusibility value was 7.04 cm in the cheese sample with 0.25% carrageenan gum, while the lowest fusibility value was found in our cheese sample with 5% carrot fiber added, measuring 5.79 cm. When the fusibility data were examined, it was seen that all gums and carrot fiber reduced the fusibility to an acceptable level. In kashar and block-type processed cheeses, fusibility is mostly associated with protein content, calcium content, and pH value [

20]. These features of our cheeses are close to each other. However, carrot fiber samples have a lower protein content. In fact, the fusibility of carrot fiber samples was found to be lower. However, it can be said that the use of gum and carrot fiber physically prevents the fusibility of the cheese samples.

3.3. Results of Sensory Characteristics of Block-Type Melted Cheese

During the storage period, sensory analyses, including of appearance, texture, flavor, and overall impression, were conducted on the first, 15th, and 30th days. The analyses were performed by 10 panelists aged between 25 and 55 years, who were experts in their fields, and they scored on a scale of 9 points. Prior to the analyses, the panelist group was informed and instructed to evaluate accordingly.

Here, first the values are given in tables, and then the findings are discussed. Appearance values are given in

Table 20, texture values are given in

Table 21, taste values are given in

Table 22 and all impression values are given in

Table 23.

The appearance tests of the produced cheese samples were conducted by panelists. The appearance values of the cheeses ranged between 6.6 and 8.5 points. The highest score of 8.5 was awarded to the control group cheeses in the 30th day analyses, while the lowest score was given to the cheese samples with 5% carrot fiber added in the 30th day analyses. The cheese sample that consistently scored below 7 points throughout the analyses was the one with 5% carrot fiber added. It is believed that the reason it received fewer points than the other cheeses is that the addition of carrot fiber imparted a different color, which may have influenced the panelists’ perceptions. It was expected that samples with added carrot fiber would be appreciated more. However, carrot fiber gave the samples a slightly duller orange color. In addition, the visible size of the carrot fibers reduced appreciation. Since the additional water used in the samples with too much fiber and gum added to them gave these samples a wet appearance and a slight grayness, their appearance was less appreciated than the control sample.

When evaluating the texture properties of the produced cheese samples, it was found that they received scores ranging between 5.5 and 8.6. The lowest score in texture values was obtained by the cheese sample with 0.50% xanthan added in the first day analyses. The highest score of 8.6 was achieved in the 30th day analysis, specifically in the control group cheese sample. It was expected that the samples using gum would feel softer due to the water added to the samples. However, the gums used bound the water. On the other hand, the texture of those with high amounts of gum was weakened, because the amount of water added was also high. Although they were produced by adding water to carrot fiber samples, they had similar values to the control cheese on the first day. They kept their scores until the end of storage. The fact that there was no sensory hardening or softening in the samples over time shows that these cheeses are more stable in terms of texture.

The cheese samples scored between 5.6 and 8.4 points in the flavor test. The lowest score of 5.6 points was recorded in the 15th and 30th day analyses for the cheese sample with 5% carrot fiber added, while the highest score was obtained by the control group cheese sample in the 30th day analysis. All impression values are shown in

Table 23. The flavor of carrot fiber is not desired in block-type melted cheese. Perhaps cheeses would be more appreciated if the flavor of the fibers was neutralized. It was observed that the samples other than carrot fibers received quite high scores, although not as high as the control. Accordingly, it can be said that the use of gum does not significantly negatively affect taste in terms of sensory aspects.

All impression tests of the cheeses received scores between 5.8 and 8.5. The lowest score of 5.8 was attributed to the cheese sample with 0.50% xanthan gum added in the first day analysis, while the highest score of 8.5 was awarded to the control group cheese sample in the 30th day analysis. It has been understood that the samples containing xanthan and carrageenan are generally appreciated and can be used successfully in block-type melted cheese. However, it was observed that the general appreciation was low due to the decrease in both appearance and taste caused by the addition of carrot fiber. In general, the general appreciation of cheeses other than carrot fiber samples increased due to the improvement in taste and texture as the cheeses matured.

3.4. Results of Textural Properties of Block-Type Melted Cheese

Texture is an important factor in cheese production. Different parameters can be obtained in texture profile analyses [

51]. Salt, dry matter, and pH affect the texture of the cheese produced [

52]. When the texture parameters of cheese are analyzed, they are compatible with each other except internal stickiness. The fat in the dry matter is only associated with elasticity and hardness [

53].

In this study, a Texture Profile Analysis investigated the effects of the addition of carrot fiber and some gums to cheese and ripening time on different parameters such as hardness, external stickiness, elasticity, internal stickiness, gumminess, and chewiness. The results are tabulated below. Afterwards, they are discussed in light of the literature. Hardness (g) values are given in

Table 24, external stickiness values are given in

Table 25, elasticity values are given in

Table 26, internal stickiness values are given in

Table 27, gumminess values are given in

Table 28 and chewiness values are given in

Table 29.

Şanlı [

54] reported that although there are sometimes fluctuations in the hardness values of cheeses, it is generally in a decreasing trend. Another study on cheese [

21] examined the use of fat substitutes in cheese and found that hardness values fluctuated but generally decreased. Another researcher reported that Camembert cheese was hard at the beginning of storage but softened later [

55]. When we examined the hardness values of the cheese samples we produced, it was observed that the samples containing different additives were softer. Cheese samples in which no additives were added were found to be harder than the other samples. Cankurt [

20] found hardness values of block-type melting cheeses produced by using different aromatic plant juices and essential oils between 1850–3052 g in samples containing aromatic plant juice and 2141–4813 g in samples with essential oil. He attributed the lower hardness values of the samples with hydrosol to the lower dry matter of these samples. Yüksel [

26] found hardness values between 1874–2752 g in his study in which he used eggs in block-type melting cheese production. In our study, since the gum and fiber ratio was increased in the xanthan and carrot fiber samples, the water ratio was also increased, and therefore the hardness decreased significantly. However, in the carrageenan samples, the increased amount of carrageenan prevented the added water from softening the cheeses. The hardness values of our samples varied between 1189–4035 on the first day. These values are similar to the values found by Cankurt [

20] and Yüksel [

26]. In the sample to which carrot fiber was added, it was observed that carrot fiber could not retain the added water because the water retention capacity of carrot fiber was lower than that of carrageenan.

Antoniou et al. [

56] stated that the external stickiness of cheese is called the negative force field at the time of initial compression. Another researcher referred to the force applied to separate the cheese adhering to the palate with the help of the tongue as external stickiness [

57]. The external stickiness values of block-type melting cheese were analyzed. As a result of the analyses, it was determined that the external stickiness values of the cheeses produced were between −24 and −760. The cheese sample with the highest external stickiness value was found in the first day analysis of the cheese sample to which 0.50% carrageenan gum was added. The lowest value was −24 in the 30th day analysis of the cheese sample with 0.50% xanthan gum. The values are shown in detail in

Table 25. Cankurt [

20] reported that external stickiness values were found between −2.58 and −8.55 on the first day and between −19.13 and −53.02 at the end of 90 days of storage in his study on hydrosol block-type melting cheeses. He reported that increasing the water content in these cheeses decreased external stickiness. According to the same researcher from another source, proteolysis caused by storage increased external stickiness. In our study, it was observed that the increase in the water ratio in the samples generally decreased the external adhesion. Cankurt [

20], Yüksel [

26], and Çavuş [

23] are three researchers who worked on block-type melting cheese. In their studies and the studies of other researchers they cited, they reported that the external stickiness exhibited decreases and increases during storage and that this was due to the biochemical events occurring in the cheeses.

Internal stickiness is defined by Tunick [

58] as the value indicating the force applied to deform the cheese before breaking. It has been reported that the internal stickiness values of low-fat and full-fat Cheddar cheese decrease as ripening progresses during storage [

59]. It was observed that the internal stickiness values of the block-type melting cheese we produced were between 0.79 and 0.86. When the internal stickiness values of the cheese samples were analyzed, it was found that they were between 0.82–0.85 on the first day, between 0.80–0.86 on the 15th day and between 0.79–0.85 on the 30th day.

Internal stickiness (cohesiveness) is defined as the strength of the internal bonds between proteins and fats that provide the formation of the three-dimensional structure in cheese. It is reported that the change in the texture of cheeses during storage is due to the continuous breaking and re-establishment of protein bonds [

20]. According to a researcher, the first day internal stickiness was found to be between 0.44–0.68 in caper cheese, 0.21–0.56 in transglutaminase cheese, and 0.79–0.83 in hydrosol and volatile oil cheese [

20].

The crushing force required to make semi-solid cheese into a shape suitable for swallowing is called chewiness [

60]. Chewability is not a direct characteristic of cheeses but is calculated by using the relationships between the values obtained from several parameters. The parameters used in the calculation of chewability are hardness, internal stickiness, and elasticity. The chewability value tells us the power required to chew the sample. The higher the chewability value of a sample, the more effort needed to chew that sample. Thus, in a way, the chewability value can actually be considered as non-chewability [

20]. According to Cankurt [

20], the chewability value decreases with increasing moisture content in the sample. He also reported that this value decreases with ripening. In other words, it is easier to chew cheeses with a high moisture content or matured cheeses. The chewiness values of the cheese samples to which we added carrot fiber and some gums in production followed a fluctuating course; these values are shown in

Table 29. In the analyses, values of 329–2344 were determined. While the first day chewiness value was found to be 329–2344, it was found to be between 336 and 1706 in the 15th day analyses. In the 30th day analysis, it was found at between 403 and 1738. As can be seen, chewability values decreased over time in our samples. The important thing here is free water, because on the first day, it was observed that the chewability decreased as the water content increased in all samples but increased in the samples containing carrageenan due to the strong retention of water by carrageenan.

Gumminess values are calculated by taking the internal stickiness and hardness values of any food [

61]. Gumminess is necessary to make a semi-solid food ready for swallowing. It is expressed as fragmentation force or number. It is defined numerically as the value obtained by multiplying hardness and internal stickiness [

20]. As a result of the gumminess analysis of the block-type melting cheese we produced, it was determined that there were fluctuations in the values of the samples during storage. In the analyses, it was found that the gumminess values were between 776–6089; the lowest gumminess value was 776 on the 15th day analysis in the cheese sample to which 0.50% carrageenan gum was added, while the highest value was 6089 on the 30th day analysis in the control group cheese sample. Gumminess increased in all samples, but the increase was lower in the samples with high gum and fiber content as more water was added. Cankurt [

20] reported that the gumminess of hydrosol and volatile oil samples and Yuksel [

26] reported that the gumminess of egg block-type melted cheeses decreased fluctuatingly throughout storage. It is understood from this that the gums and carrot fiber we used prevented the gumminess values from decreasing.

The rate at which the cheese returns to its original state after the initial compression is called the elasticity of the cheese [

62]. In other words, it is expressed as the return of the cheese to its original state after the removal of the force applied on the cheese [

63]. In the study in which it was used as a fat substitute in the production of kashkaval cheese, it was reported that the elasticity of the cheese samples produced fluctuated during the ripening period [

21]. It was observed that the elasticity values of the cheese samples were between 0.41–0.46 on the first day. In the 15th day analyses, it was found to be between 0.38–0.49, and in the 30th day analyses, it was found to be between 0.38 and 0.50. As a result of the analysis of the elasticity values of the block-type melting cheese, it was observed that the first day elasticity value was between 0.27 and 0.62. In the 15th day analyses, it was between 0.30 and 0.57, and in the 30th day analyses, values between 0.27 and 0.60 were determined. According to Cankurt [

62], the elasticity values of block-type melted cheese samples increased and then decreased. He found it to be between 0.39–0.45 on the first day and 0.42–0.48 at the end of 90 days. According to Yüksel [

26], the elasticity values of egg block-type melted cheese samples decreased continuously. On the first day, the values were found to be between 0.46–0.54, and at the end of 60 days, between 0.38–0.50.