Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Pasta Formulation

2.3. Dough Rheological Analysis

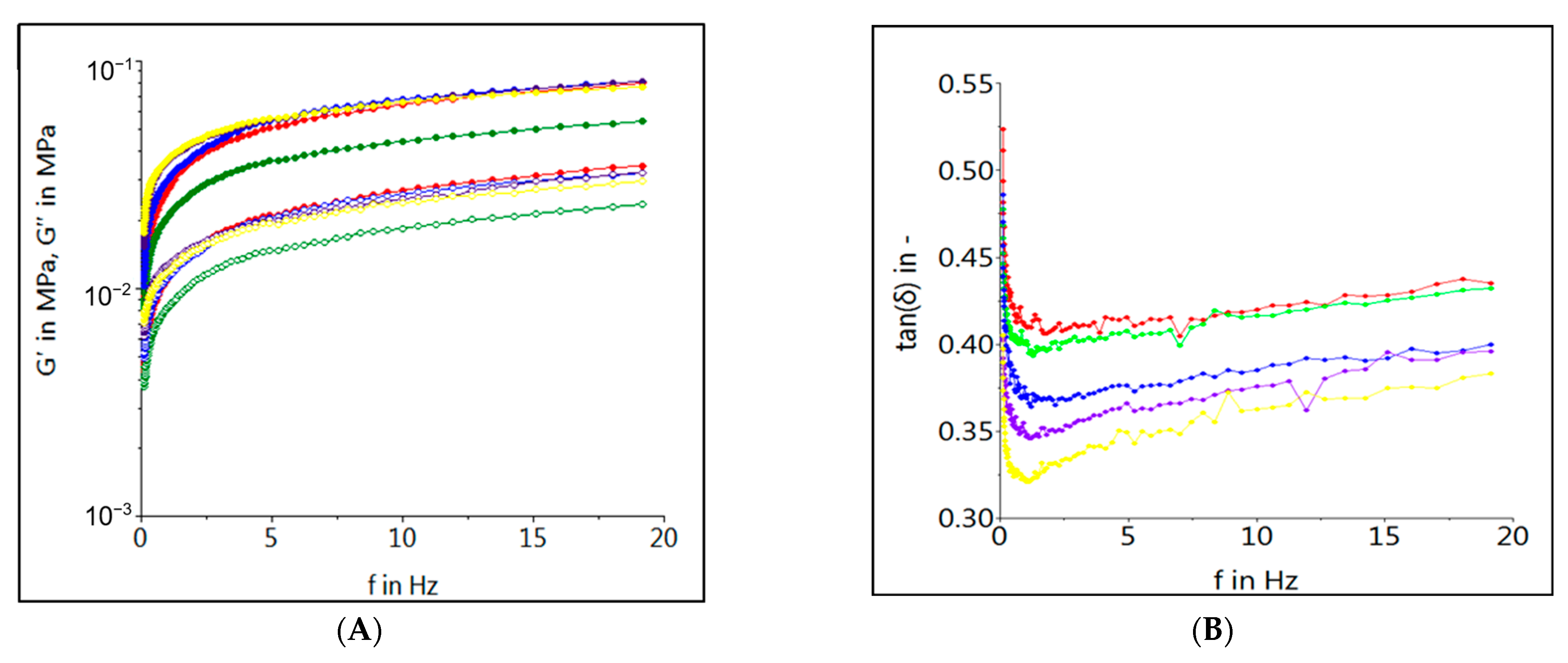

Dynamic Dough Rheological Evaluation

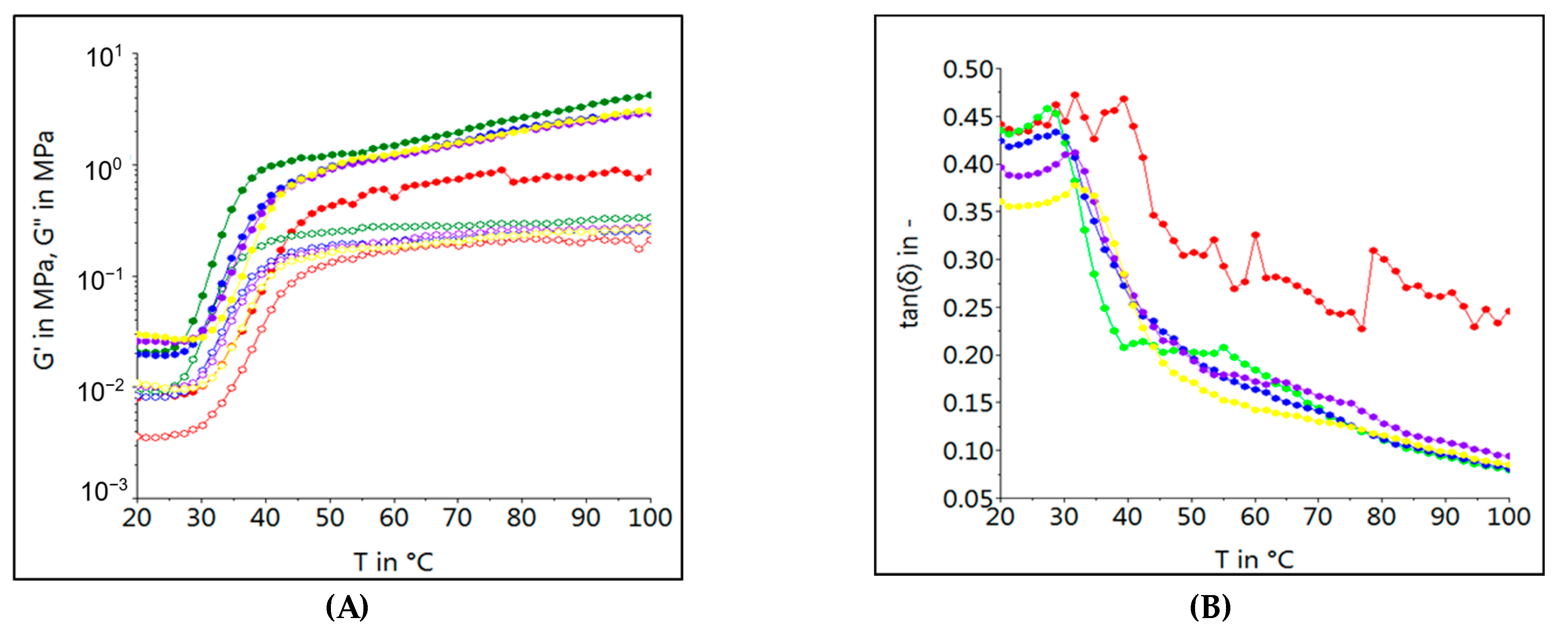

2.4. Dough Microstructure Analysis

2.5. Pasta Technological Characteristics

2.5.1. Optimal Cooking Time

2.5.2. Water Absorption (WA)

2.5.3. Cooking Loss (CL)

2.5.4. Swelling Index (SI)

2.6. Color Pasta Characteristics

2.7. Textural Pasta Characteristics

2.8. Dry Pasta Fracturability

2.9. Pasta Total Phenolic Content and Antioxidant Activity

2.10. Pasta Sensory Characteristics

2.11. Statistical Analysis

3. Results

3.1. Flour Characteristics

3.2. Dough Rheological Characteristics

3.2.1. Empirical Dough Rheological Characteristics

3.2.2. Fundamental Dough Rheological Characteristics

3.3. Dough Microstructure

3.4. Pasta Quality Evaluation

3.4.1. Pasta Technological Characteristics

3.4.2. Dry and Cooked Pasta Color Characteristics

3.4.3. Pasta Textural Characteristics

3.4.4. Dry Pasta Fracturability

3.4.5. Pasta Total Phenolic Content and Antioxidant Activity Evaluation

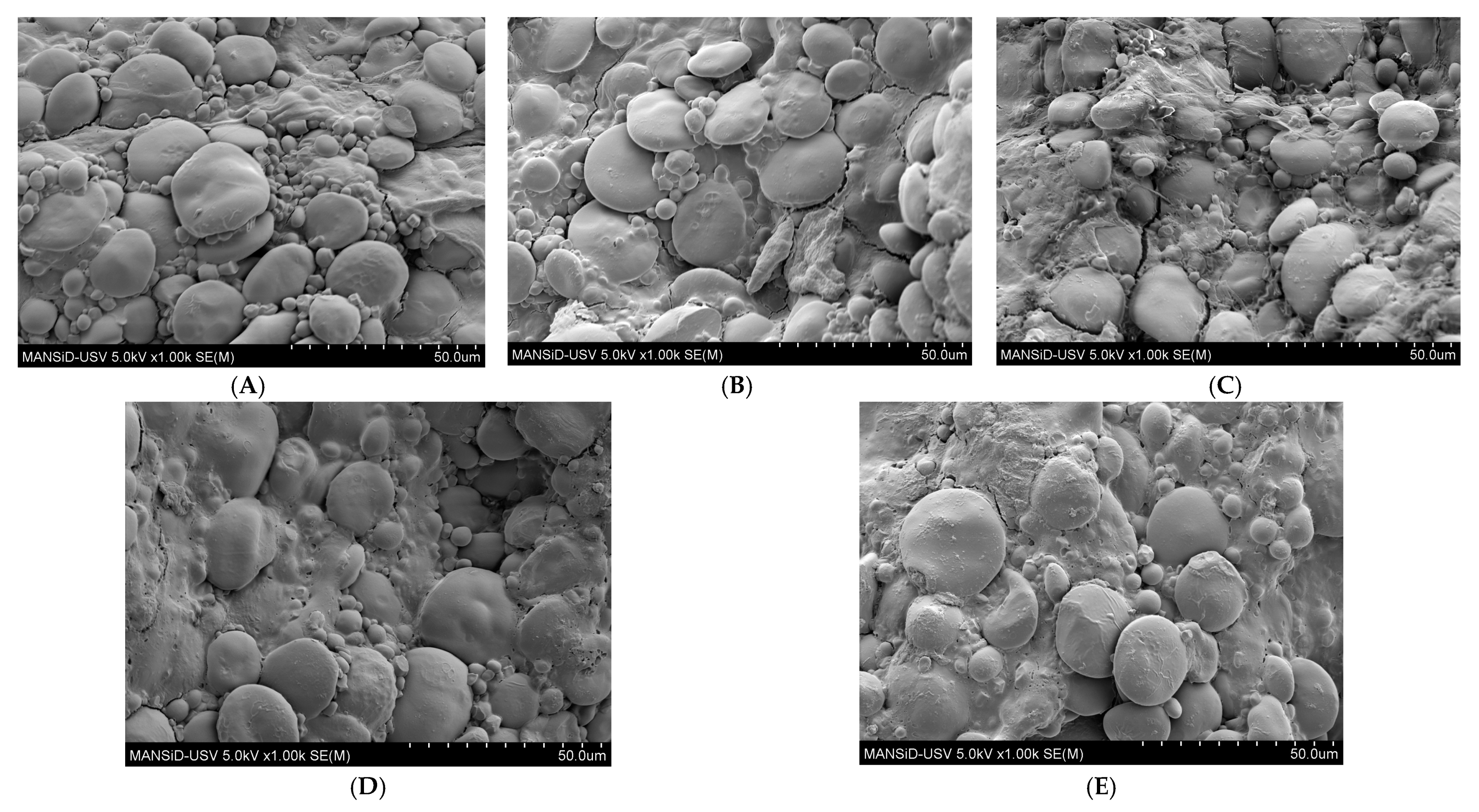

3.4.6. Pasta Sensory Characteristics

3.4.7. Effect of HSM Enrichment on Pasta Compositional Analysis

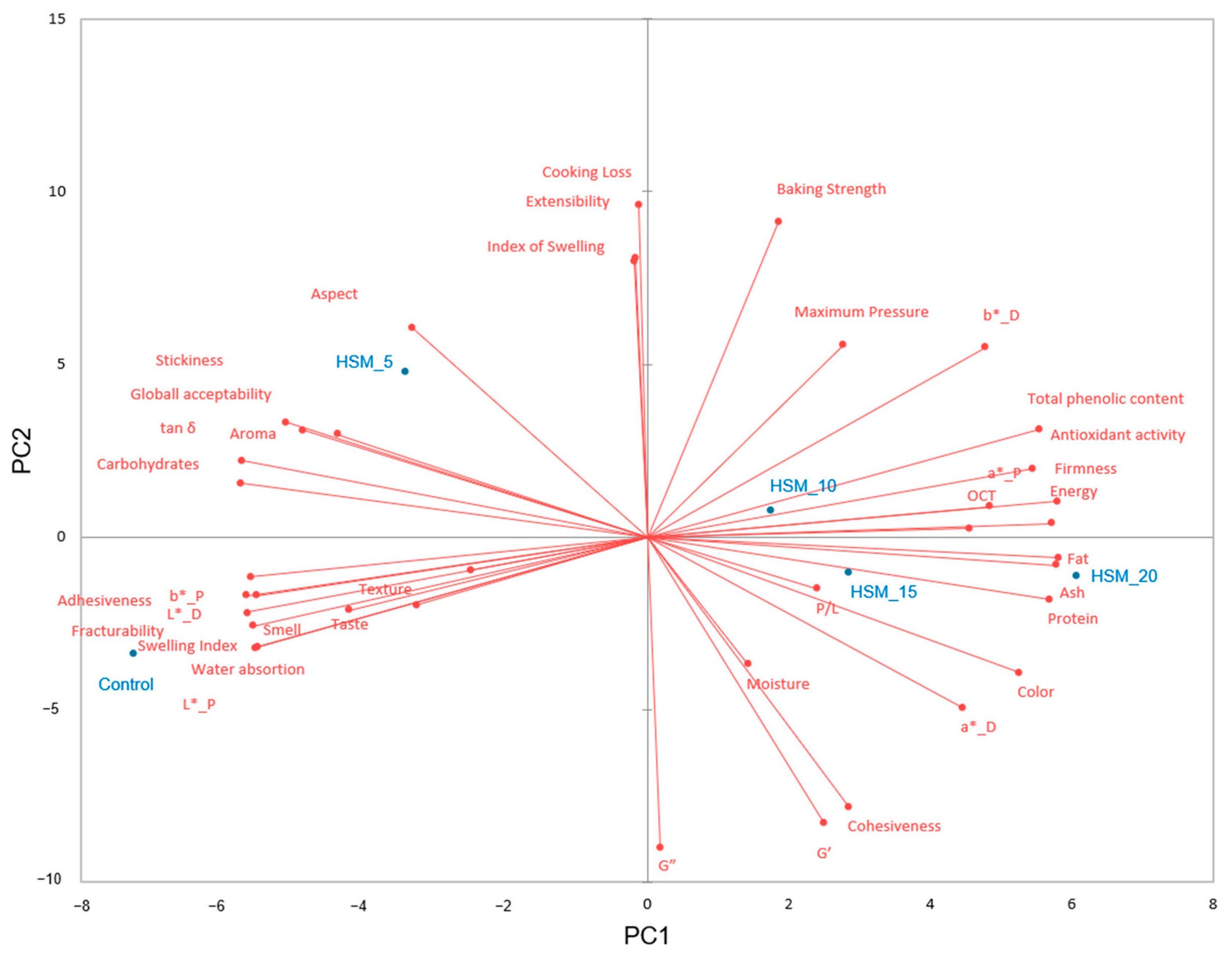

3.4.8. Principal Component Analysis between Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pasta Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023–2028. Available online: https://www.imarcgroup.com/pasta-market (accessed on 23 November 2022).

- Nasrollahzadeh, F.; Roman, L.; Swaraj, V.J.S.; Ragavan, K.V.; Vidal, N.P.; Dutcher, J.R.; Martinez, M.M. Hemp (Cannabis sativa L.) Protein Concentrates from Wet and Dry Industrial Fractionation: Molecular Properties, Nutritional Composition, and Anisotropic Structuring. Food Hydrocoll. 2022, 131, 107755. [Google Scholar] [CrossRef]

- Sissons, M. Development of Novel Pasta Products with Evidence Based Impacts on Health—A Review. Foods 2022, 11, 123. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, Nutritional and Sensory Properties of Pasta Fortified with Agro-industrial By-products: A Review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Saget, S.; Costa, M.; Barilli, E.; Wilton de Vasconcelos, M.; Santos, C.S.; Styles, D.; Williams, M. Substituting Wheat with Chickpea Flour in Pasta Production Delivers More Nutrition at a Lower Environmental Cost. Sustain. Prod. Consum. 2020, 24, 26–38. [Google Scholar] [CrossRef]

- Teterycz, D.; Sobota, A.; Przygodzka, D.; Łysakowska, P. Hemp Seed (Cannabis sativa L.) Enriched Pasta: Physicochemical Properties and Quality Evaluation. PLoS ONE 2021, 16, e0248790. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, Y.; Zhu, H.; Li, Y.; Xiao, Q.; Yi, C. Effect of Soy Protein Isolate on Textural Properties, Cooking Properties and Flavor of Whole-Grain Flat Rice Noodles. Foods 2021, 10, 1085. [Google Scholar] [CrossRef] [PubMed]

- Di Stefano, V.; Pagliaro, A.; Del Nobile, M.A.; Conte, A.; Melilli, M.G. Lentil Fortified Spaghetti: Technological Properties and Nutritional Characterization. Foods 2020, 10, 4. [Google Scholar] [CrossRef]

- Rodríguez De Marco, E.; Steffolani, M.E.; Martínez, C.S.; León, A.E. Effects of Spirulina Biomass on the Technological and Nutritional Quality of Bread Wheat Pasta. LWT-Food Sci. Technol. 2014, 58, 102–108. [Google Scholar] [CrossRef]

- Lu, X.; Brennan, M.A.; Serventi, L.; Liu, J.; Guan, W.; Brennan, C.S. Addition of Mushroom Powder to Pasta Enhances the Antioxidant Content and Modulates the Predictive Glycaemic Response of Pasta. Food Chem. 2018, 264, 199–209. [Google Scholar] [CrossRef]

- Gupta, A.; Sharma, S.; Reddy Surasani, V.K. Quinoa Protein Isolate Supplemented Pasta: Nutritional, Physical, Textural and Morphological Characterization. LWT 2021, 135, 110045. [Google Scholar] [CrossRef]

- Aravind, N.; Sissons, M.; Egan, N.; Fellows, C. Effect of Insoluble Dietary Fibre Addition on Technological, Sensory, and Structural Properties of Durum Wheat Spaghetti. Food Chem. 2012, 130, 299–309. [Google Scholar] [CrossRef]

- Hoehnel, A.; Bez, J.; Amarowicz, R.; Arendt, E.K.; Zannini, E. Combining High-protein Ingredients from Pseudocereals and Legumes for the Development of Fresh High-protein Hybrid Pasta: Maintained Technological Quality and Adequate Sensory Attributes. J. Sci. Food Agric. 2022, 102, 4977–4987. [Google Scholar] [CrossRef] [PubMed]

- High Protein Foods and Beverages: Trends and Opportunities in This Growing Segment. Available online: https://biosolutions.novozymes.com/en/dairy/insights/article/high-protein-food-beverage-trends (accessed on 11 March 2023).

- Chauhan, A. Nutrition and Health Benefits of Hemp-Seed Protein (Cannabis sativa L.). Pharma Innov. J. 2021, 10, 16–19. [Google Scholar]

- Rodriguez-Martin, N.M.; Montserrat-de la Paz, S.; Toscano, R.; Grao-Cruces, E.; Villanueva, A.; Pedroche, J.; Millan, F.; Millan-Linares, M.C. Hemp (Cannabis sativa L.) Protein Hydrolysates Promote Anti-Inflammatory Response in Primary Human Monocytes. Biomolecules 2020, 10, 803. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Griffin, J.; Li, Y.; Wang, D.; Wang, W. Antioxidant Properties of Hemp Proteins: From Functional Food to Phytotherapy and Beyond. Molecules 2022, 27, 7924. [Google Scholar] [CrossRef]

- Hemp Protein Market. Available online: https://www.transparencymarketresearch.com/hemp-protein-market.html (accessed on 14 February 2023).

- Murray, J.C.; Kiszonas, A.M.; Morris, C.F. Pasta Production: Complexity in Defining Processing Conditions for Reference Trials and Quality Assessment Methods. Cereal Chem. J. 2017, 94, 791–797. [Google Scholar] [CrossRef]

- Dziki, D.; Laskowski, J. Evaluation of the Cooking Quality of Spaghetti. Pol. J. Food Nutr. Sci. 2005, 14, 153–158. [Google Scholar]

- Iuga, M.; Mironeasa, S. Use of Grape Peels By-Product for Wheat Pasta Manufacturing. Plants 2021, 10, 926. [Google Scholar] [CrossRef]

- Ungureanu-Iuga, M.; Dimian, M.; Mironeasa, S. Development and Quality Evaluation of Gluten-Free Pasta with Grape Peels and Whey Powders. LWT 2020, 130, 109714. [Google Scholar] [CrossRef]

- UNGUREANU-IUGA, M. By-Products Ingredients in Corn Based Pasta: Effects on the Technological and Quality Characteristics. Sci. Bulletin. Ser. F. Biotechnol. 2020, 14, 97–106. [Google Scholar]

- Šeregelj, V.; Škrobot, D.; Kojić, J.; Pezo, L.; Šovljanski, O.; Tumbas Šaponjac, V.; Vulić, J.; Hidalgo, A.; Brandolini, A.; Čanadanović-Brunet, J.; et al. Quality and Sensory Profile of Durum Wheat Pasta Enriched with Carrot Waste Encapsulates. Foods 2022, 11, 1130. [Google Scholar] [CrossRef] [PubMed]

- Cecchini, C.; Bresciani, A.; Menesatti, P.; Pagani, M.A.; Marti, A. Assessing the Rheological Properties of Durum Wheat Semolina: A Review. Foods 2021, 10, 2947. [Google Scholar] [CrossRef]

- Piwińska, M.; Wyrwisz, J.; Kurek, M.; Wierzbicka, A. Effect of Oat β-Glucan Fiber Powder and Vacuum-Drying on Cooking Quality and Physical Properties of Pasta. CyTA-J. Food 2016, 14, 101–108. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Quality Characteristics of Spelt Pasta Enriched with Spent Grain. Agronomy 2021, 11, 1824. [Google Scholar] [CrossRef]

- Codină, G.G.; Dabija, A.; Oroian, M. Prediction of Pasting Properties of Dough from Mixolab Measurements Using Artificial Neuronal Networks. Foods 2019, 8, 447. [Google Scholar] [CrossRef]

- AbuHammad, W.A.; Elias, E.M.; Manthey, F.A.; Alamri, M.S.; Mergoum, M. A Comparison of Methods for Assessing Dough and Gluten Strength of Durum Wheat and Their Relationship to Pasta Cooking Quality. Int. J. Food Sci. Technol. 2012, 47, 2561–2573. [Google Scholar] [CrossRef]

- Atudorei, D.; Atudorei, O.; Codină, G.G. Dough Rheological Properties, Microstructure and Bread Quality of Wheat-Germinated Bean Composite Flour. Foods 2021, 10, 1542. [Google Scholar] [CrossRef]

- Istrate, A.M.; Dabija, A.; Codină, G.G.; Rusu, L. Influence of Hemp Flour on Dough Rheology and Bread Quality. Chem. Chem. Eng. Biotechnol. 2021, 22, 521–531. [Google Scholar]

- Renoldi, N.; Brennan, C.S.; Lagazio, C.; Peressini, D. Evaluation of Technological Properties, Microstructure and Predictive Glycaemic Response of Durum Wheat Pasta Enriched with Psyllium Seed Husk. LWT 2021, 151, 112203. [Google Scholar] [CrossRef]

- Rigatoni Pasta Product & Nutrition-Barilla. Available online: https://www.barilla.com/en-us/products/pasta/classic-blue-box/rigatoni (accessed on 14 November 2022).

- Kaur, G.; Sharma, S.; Nagi, H.P.S.; Ranote, P.S. Enrichment of Pasta with Different Plant Proteins. J. Food Sci. Technol. 2013, 50, 1000–1005. [Google Scholar] [CrossRef] [PubMed]

- Espinosa-Solis, V.; Zamudio-Flores, P.B.; Tirado-Gallegos, J.M.; Ramírez-Mancinas, S.; Olivas-Orozco, G.I.; Espino-Díaz, M.; Hernández-González, M.; García-Cano, V.G.; Sánchez-Ortíz, O.; Buenrostro-Figueroa, J.J.; et al. Evaluation of Cooking Quality, Nutritional and Texture Characteristics of Pasta Added with Oat Bran and Apple Flour. Foods 2019, 8, 299. [Google Scholar] [CrossRef]

- Irakli, M.; Tsaliki, E.; Kalivas, A.; Kleisiaris, F.; Sarrou, E.; Cook, C.M. Effect οf Genotype and Growing Year on the Nutritional, Phytochemical, and Antioxidant Properties of Industrial Hemp (Cannabis sativa L.) Seeds. Antioxidants 2019, 8, 491. [Google Scholar] [CrossRef]

- Korus, A.; Gumul, D.; Krystyjan, M.; Juszczak, L.; Korus, J. Evaluation of the Quality, Nutritional Value and Antioxidant Activity of Gluten-Free Biscuits Made from Corn-Acorn Flour or Corn-Hemp Flour Composites. Eur. Food Res. Technol. 2017, 243, 1429–1438. [Google Scholar] [CrossRef]

- Radočaj, O.; Dimić, E.; Tsao, R. Effects of Hemp (Cannabis sativa L.) Seed Oil Press-Cake and Decaffeinated Green Tea Leaves (Camellia Sinensis) on Functional Characteristics of Gluten-Free Crackers. J. Food Sci. 2014, 79, C318–C325. [Google Scholar] [CrossRef] [PubMed]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) Flour and Protein Preparation as Natural Nutrients and Structure Forming Agents in Starch Based Gluten-Free Bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Pojić, M.; Dapčević Hadnađev, T.; Hadnađev, M.; Rakita, S.; Brlek, T. Bread Supplementation with Hemp Seed Cake: A By-Product of Hemp Oil Processing. J. Food Qual. 2015, 38, 431–440. [Google Scholar] [CrossRef]

- Švec, I.; Hrušková, M. Properties and Nutritional Value of Wheat Bread Enriched by Hemp Products. Potravin. Slovak J. Food Sci. 2015, 9, 304–308. [Google Scholar] [CrossRef] [PubMed]

- Švec, I.; Hrušková, M. The Mixolab Parameters of Composite Wheat/Hemp Flour and Their Relation to Quality Features. LWT-Food Sci. Technol. 2015, 60, 623–629. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- Oseyko, M.; Sova, N.; Lutsenko, M.; Kalyna, V. Chemical Aspects of the Composition of Industrial Hemp Seed Products. Ukr. Food J. 2019, 8, 544–559. [Google Scholar] [CrossRef]

- Ran, J.; Zhang, B.; Su, Y.; Deng, Y.; Li, Y.; Liang, X.; Sun, J. The Effects of the Mixed Fermentation of Honeysuckle Cereal Mixed Flour on the Dough Characteristics and Bread Quality. Fermentation 2023, 9, 271. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Jiang, P.; Zhu, Y.; Zhang, W.; Li, R.; Tan, B. The Effect of Wheat Bran Dietary Fibre and Raw Wheat Bran on the Flour and Dough Properties: A Comparative Study. LWT 2023, 173, 114304. [Google Scholar] [CrossRef]

- Wieser, H.; Koehler, P.; Scherf, K.A. Chemistry of Wheat Gluten Proteins: Quantitative Composition. Cereal Chem. 2023, 100, 36–55. [Google Scholar] [CrossRef]

- Golea, C.M.; Codină, G.G.; Oroian, M. Prediction of Wheat Flours Composition Using Fourier Transform Infrared Spectrometry (FT-IR). Food Control 2023, 143, 109318. [Google Scholar] [CrossRef]

- Hrušková, M.; Švec, I.; Jurinová, I. Chemometrics of Wheat Composites with Hemp, Teff, and Chia Flour: Comparison of Rheological Features. Int. J. Food Sci. 2013, 2013, 968020. [Google Scholar] [CrossRef] [PubMed]

- Sobota, A.; Zarzycki, P.; Rzedzicki, Z.; Sykut-Domańska, E.; Wirkijowska, A. Effect on Cooking Time on the Texture and Cooking Quality of Spaghettti. Acta Agrophysica 2013, 20, 693–703. [Google Scholar]

- Grzybowski, R.A.; Donnelly, B.J. Cooking Properties of Spaghetti: Factors Affecting Cooking Quality. J. Agric. Food Chem. 1979, 27, 380–384. [Google Scholar] [CrossRef]

- Sozer, N.; Dalgıç, A.C.; Kaya, A. Thermal, Textural and Cooking Properties of Spaghetti Enriched with Resistant Starch. J. Food Eng. 2007, 81, 476–484. [Google Scholar] [CrossRef]

- Bustos, M.C.; Paesani, C.; Quiroga, F.; León, A.E. Technological and Sensorial Quality of Berry-enriched Pasta. Cereal Chem. 2019, 96, 967–976. [Google Scholar] [CrossRef]

- Gull, A.; Prasad, K.; Kumar, P. Effect of Millet Flours and Carrot Pomace on Cooking Qualities, Color and Texture of Developed Pasta. LWT-Food Sci. Technol. 2015, 63, 470–474. [Google Scholar] [CrossRef]

- Mikulec, A.; Kowalski, S.; Sabat, R.; Skoczylas, Ł.; Tabaszewska, M.; Wywrocka-Gurgul, A. Hemp Flour as a Valuable Component for Enriching Physicochemical and Antioxidant Properties of Wheat Bread. LWT 2019, 102, 164–172. [Google Scholar] [CrossRef]

- Popa, N.C.; Tamba-Berhoiu, R.; Popescu, S.; Varga, M.; Codina, G.G. Predictive Model of the Alveografic Parameters in Flours Obtained from Romanian Grains Semen Quality View Project The Quality of Wine View Project. Rom. Biotechnol. Lett. 2009, 14, 4234–4242. Available online: https://www.researchgate.net/publication/287812977 (accessed on 20 March 2023).

- Motta Romero, H.; Santra, D.; Rose, D.; Zhang, Y. Dough Rheological Properties and Texture of Gluten-Free Pasta Based on Proso Millet Flour. J. Cereal Sci. 2017, 74, 238–243. [Google Scholar] [CrossRef]

| Sample | P (mm) | L (mm) | G (mm) | W (10−4 J) | P/L (adim) |

|---|---|---|---|---|---|

| Control | 43 ± 1.52 a | 31 ± 0.57 a | 12.4 ± 0.45 a | 50 ± 0.57 a | 1.39 ± 0.07 a |

| HSM_5 | 88 ± 1.52 c | 55 ± 1.52 c | 16.5 ± 0.17 c | 157 ± 2.00 e | 1.6 ± 0.06 a |

| HSM_10 | 86 ± 2.51 c | 57 ± 2.00 c | 16.8 ± 0.35 c | 139 ± 2.08 d | 1.51 ± 0.10 a |

| HSM_15 | 105 ± 4.04 d | 28 ± 2.00 a | 11.7 ± 0.05 a | 121 ± 1.00 c | 3.75 ± 0.41 b |

| HSM_20 | 66 ± 2.51 b | 37 ± 13.00 b | 13.5 ± 0.35 b | 97 ± 1.52 b | 1.78 ± 0.16 a |

| Pasta Sample | OCT (min) | WA (%) | CL (%) | SI |

|---|---|---|---|---|

| Control | 9.00 ± 0.10 a | 113.66 ± 1.15 d | 3.28 ± 0.02 a | 1.39± 0.00 d |

| HSM_5 | 9.26 ± 0.05 b | 101.33 ± 1.52 c | 3.43 ± 0.01 c | 1.27 ± 0.01 c |

| HSM_10 | 9.23 ± 0.05 b | 98.00 ± 1.00 b | 3.39 ± 0.01 c | 1.25 ± 0.11 bc |

| HSM_15 | 9.23 ± 0.11 b | 96.00 ± 1.00 ab | 3.34 ± 0.01 b | 1.23 ± 0.01 b |

| HSM_20 | 9.96 ± 0.06 c | 93.33 ± 0.57 a | 3.30 ± 0.15 ab | 1.16 ± 0.02 a |

| Pasta Samples | Dry Pasta | Cooked Pasta | ||||

|---|---|---|---|---|---|---|

| L* | a* | b* | L* | a* | b* | |

| Control | 71.51 ± 2.28 c | 1.12 ± 0.08 ab | 16.62 ± 0.32 a | 68.32 ± 3.12 c | −0.08 ± 0.05 a | 16.66 ± 0.68 c |

| HSM_5 | 57.77 ± 2.95 b | 0.78 ± 0.10 a | 20.42 ± 0.39 b | 51.63 ± 0.92 b | 0.99 ± 0.14 b | 14.60 ± 0.17 b |

| HSM_10 | 45.95 ± 0.05 a | 1.54 ± 0.03 bc | 21.58 ± 0.25 b | 43.84 ± 0.83 a | 0.69 ± 0.10 b | 11.95 ± 0.40 a |

| HSM_15 | 43.74 ± 0.64 a | 1.28 ± 0.36 bc | 20.47 ± 0.83 b | 43.55 ± 0.23 a | 2.28 ± 0.13 c | 11.82 ± 0.42 a |

| HSM_20 | 43.01 ± 1.01 a | 1.66 ± 0.09 c | 21.13 ± 0.70 b | 41.06 ± 1.83 a | 1.95 ± 0.20 c | 11.81 ± 0.36 a |

| Pasta Dough | Dry Pasta | |||||

|---|---|---|---|---|---|---|

| Sample | Firmness (N) | Adhesiveness (J) | Springiness (%) | Cohesiveness (adim) | Stickiness (%) | Fracturability (N) |

| Control | 13.17 ± 5.07 a | −15.97 ± 0.02 e | 0.99 ± 0.02 a | 0.36 ± 0.02 b | −41.98 ± 0.56 b | 53.08 ± 0.38 b |

| HSM_5 | 13.89 ± 0.52 b | −53.58 ± 0.01 d | 0.99 ± 0.01 a | 0.32 ± 0.01 a | −37.77 ± 0.04 c | 44.92 ± 0.33 b |

| HSM_10 | 14.69 ± 15.07 c | −63.41 ± 0.02 c | 0.99 ± 0.01 a | 0.37 ± 0.02 b | −60.49 ± 0.01 a | 38.29 ± 0.34 b |

| HSM_15 | 14.75 ± 7.71 c | −65.03 ± 0.04 b | 0.99 ± 0.02 a | 0.36 ± 0.02 b | −60.45 ± 0.02 a | 41.03 ± 0.33 a |

| HSM_20 | 15.01 ± 0.50 d | −104.59 ± 0.06 a | 1.02 ± 0.01 b | 0.37 ± 0.02 b | −59.81 ± 0.02 a | 35.26 ± 0.19 a |

| Pasta Sample | TPC (μg GAE/g) | DPPH (%) |

|---|---|---|

| Control | 13.34 ± 0.17 a | 18.48 ± 0.53 a |

| HSM_5 | 16.12 ± 0.40 b | 21.57 ± 0.39 b |

| HSM_10 | 16.68 ± 0.04 bc | 22.06 ± 0.10 b |

| HSM_15 | 17.02 ± 0.14 c | 24.16 ± 1.00 b |

| HSM_20 | 18.14 ± 0.04 d | 24.00 ± 0.16 c |

| Pasta Samples | Moisture (%) | Protein (%) | Fat (%) | Ash (%) | Carbohydrates (%) | Energy (kcal/100 g) |

|---|---|---|---|---|---|---|

| Control | 11.22 ± 0.02 b | 9.52 ± 0.01 a | 0.83 ± 0.01 a | 0.47 ± 0.01 a | 77.98 ± 0.04 e | 357 ± 0.14 a |

| HSM_5 | 11.18 ± 0.01 a | 10.24 ± 0.02 b | 1.21 ± 0.01 b | 0.59 ± 0.01 b | 76.82 ± 0.02 d | 359 ± 0.01 ab |

| HSM_10 | 11.27 ± 0.01 d | 12.13 ± 0.01 c | 1.67 ± 0.02 c | 0.76 ± 0.01 c | 74.17 ± 0.01 c | 360 ± 0.01 b |

| HSM_15 | 11.25 ± 0.01 c | 13.84 ± 0.01 d | 1.95 ± 0.03 d | 0.84 ± 0.02 d | 72.12 ± 0.01 b | 361 ± 0.01 b |

| HSM_20 | 11.20 ± 0.01 b | 14.72 ± 0.01 e | 2.38 ± 0.04 e | 1.03 ± 0.03 e | 70.67 ± 0.01 a | 363 ± 0.01 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Axentii, M.; Stroe, S.-G.; Codină, G.G. Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal. Foods 2023, 12, 1774. https://doi.org/10.3390/foods12091774

Axentii M, Stroe S-G, Codină GG. Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal. Foods. 2023; 12(9):1774. https://doi.org/10.3390/foods12091774

Chicago/Turabian StyleAxentii, Marina, Silviu-Gabriel Stroe, and Georgiana Gabriela Codină. 2023. "Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal" Foods 12, no. 9: 1774. https://doi.org/10.3390/foods12091774

APA StyleAxentii, M., Stroe, S.-G., & Codină, G. G. (2023). Development and Quality Evaluation of Rigatoni Pasta Enriched with Hemp Seed Meal. Foods, 12(9), 1774. https://doi.org/10.3390/foods12091774