Development of a Nutraceutical Product Derived from By-Products of the Lipid Extraction of the Brazil Nut (Bertolletia excelsa H.B.K)

Abstract

1. Introduction

2. Material and Methods

2.1. Raw Material

2.2. Methods

2.2.1. Microbiological and Mycotoxicological Analyzes on Brazil Nuts

2.2.2. Process of Obtaining of the Defatted Flour Brazil Nut

2.2.3. Determination of the Composition of Macro and Micronutrients of the Defatted Flour of Brazil Nuts

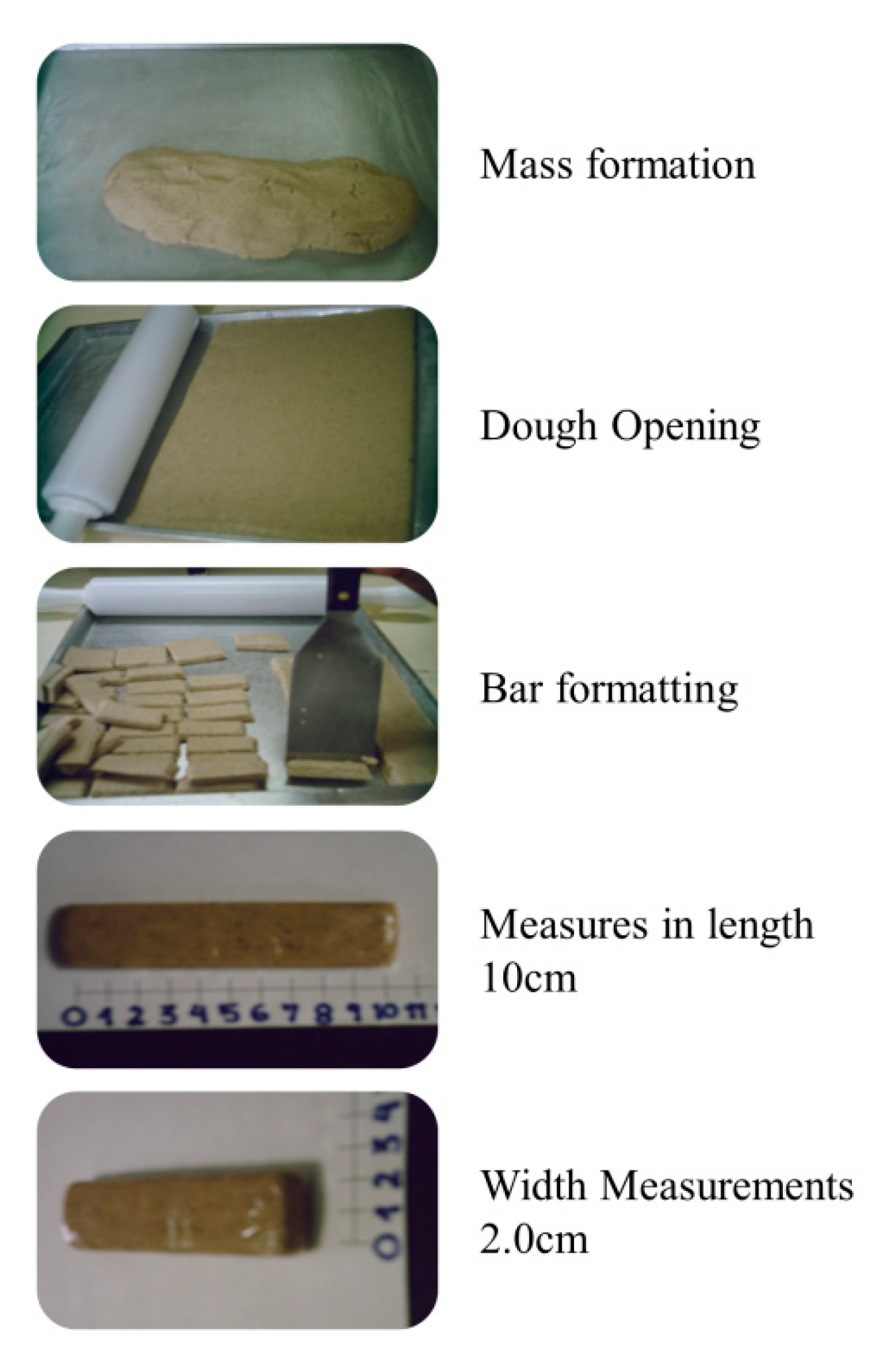

2.2.4. Formulation of the Bars

2.2.5. Microbiological and Physicochemical Analysis of the Defatted Flour of Brazil Nuts and Bar Formulations

2.2.6. Amino Acid Analysis in Bar Formulations Containing Defatted Flour of Brazil Nuts and Soy Protein Isolate

2.2.7. Sensory Analysis of the Formulated Bars

2.2.8. Statistical Analysis of the Results

3. Results and Discussion

3.1. Microbiological, Mycotoxicological and Physical-Chemical Analysis

3.2. Defatted Flour of Brazil Nuts and Bars Formulations Mineral Analysis

3.3. DFBN and Bar Formulations Amino Acids Profile

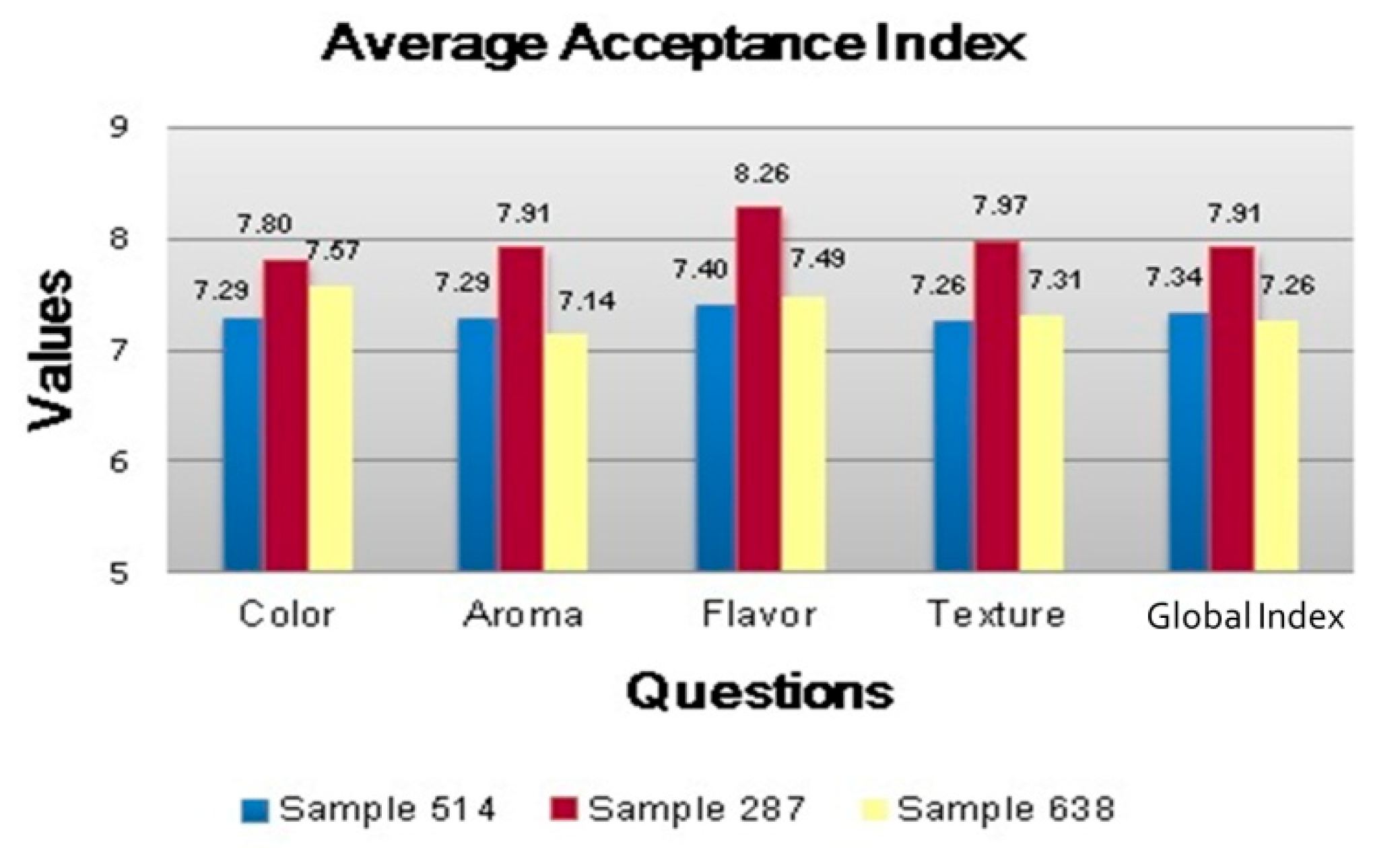

3.4. Acceptability Test

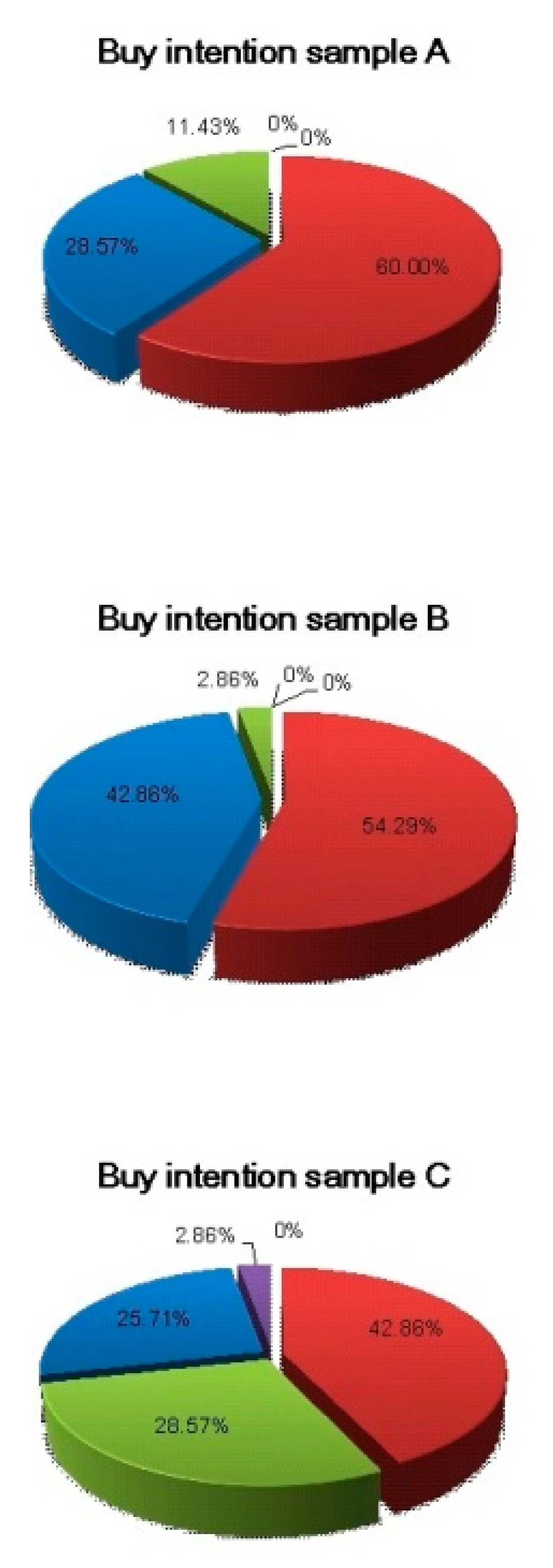

3.5. Purchase Intention

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BESO | Bi-evolutionary structural optimization |

| dof | Degree of freedom |

| ESO | Evolutionary structural optimization |

| FEM | Finite element method |

| Li | Lithium |

| Si | Silicon |

| SIMP | Solid isotropic material with penalization |

References

- Globenewswire Report, Global Nutraceuticals Market Assessment 2019: Market Overview, Share, Growth Drivers, and Key Trend; Brasília, Brazil. 2019. Available online: https://www.globenewswire.com/ (accessed on 1 March 2023).

- Ran, X.-L.; Zhang, M.; Wang, Y.; Adhikari, B. Novel technologies applied for recovery and value addition of high value compounds from plant byproducts: A review. Crit. Rev. Food Sci. Nutr. 2018, 59, 450–461. [Google Scholar] [CrossRef] [PubMed]

- Lima, D.S.; Egea, M.B.; Cabassa, I.D.C.C.; de Almeida, A.B.; de Sousa, T.L.; de Lima, T.M.; Loss, R.A.; Volp, A.C.P.; de Vasconcelos, L.G.; Dall’Oglio, E.L.; et al. Technological quality and sensory acceptability of nutritive bars produced with Brazil nut and baru almond coproducts. LWT-Food Sci. Technol. 2020, 137, 110467. [Google Scholar] [CrossRef]

- Muniz, C.E.S.; Santiago, M.; Gusmão, T.A.S.; Oliveira, H.M.L.; Conrado, L.D.S.; de Gusmão, R.P. Solid-state fermentation for single-cell protein enrichment of guava and cashew by-products and inclusion on cereal bars. Biocatal. Agric. Biotechnol. 2020, 25, 101576. [Google Scholar] [CrossRef]

- ANVISA. Ministério da saúde, Agência Nacional de Vigilância Sanitária, Resolução RDC nº 12 de 2 de Janeiro de 2001; Regulamento Técnico Sobre os Padrões Microbiológicos para Alimentos: Brasília, Brazil, 2001.

- Vanderzant, C.; Splittstoesser, D.F. (Eds.) Compendium of Methods for the Microbiological Examination of Foods, 3rd ed.; APHA: Washington, DC, USA, 1992; 1087p. [Google Scholar]

- Soares, L.M.V.; Rodrigez-Amaya, D.B. Survey of aflatoxins, ochratoxin A, zearalenona and sterigmatocystin in some brazilian foods using multitoxin thin layer chromatographic method. J. Assoc. Anal. Chem. 1989, 72, 22–26. [Google Scholar]

- AOAC. Official Methods of the Analysis of AOAC International, 20th ed.; AOAC International: Gaithersburg, MD, USA, 2016. [Google Scholar]

- ANVISA. Ministério da Saúde, Agência Nacional de Vigilância Sanitária, Diário Oficial da União Resolução RDC nº 429 de 09 de Outubro de 2022; Regulamento Técnico sobre Rotulagem Nutricional de Alimentos Embalados: Brasília, Brazil, 2022.

- FAO; World Health Organization. Report of a Joint WHO/FAO/UNU Expert Consultation: Protein and Amino Acid Requirements in Human Nutrition; WHO Technical Report Series 935; World Health Organization: Geneva, Switzerland, 2007. [Google Scholar]

- Stone, H.; Sidel, J.L. Sensory Evaluation Practices, 3rd ed.; Academic Press: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Statistica for Windows: Release 7.0 A; Statsoft Inc.: Tulsa, OK, USA, 2000.

- Dutcosky, S.D. Análise Sensorial de Alimentos; Champagnat: Curitiba, Brazil, 2013. [Google Scholar]

- ANVISA. Agência Nacional de Vigilância Sanitária. Resolução n° 7, de 18 de Fevereiro de 2011; Dispõe sobre Limites Máximos Tolerados (LMT) para Micotoxinas em Alimentos. Diário Oficial [da] República Federativa do Brasil: Brasília, Brasil, 2011; Seção 1, p. 72.

- ANVISA. Agência Nacional de Vigilância Sanitária, Resolução RDC nº 274 de 22 de Setembro de 2005; Regulamento Técnico Sobre os Padrões de Tolerância em Produtos para Consumo Humanos para Alimentos: Brasília, Brazil, 2005.

- Teixeira, G.L.; Ávila, S.; Hornung, P.S.; Barbi, R.C.T.; Ribani, R.H. Sapucaia nut (Lecythis pisonis Cambess.) flour as a new industrial ingredient: Physicochemical, thermal, and functional properties. Food Res. Int. 2018, 109, 572–582. [Google Scholar] [CrossRef] [PubMed]

- Mishra, N. Potential use of germinated soy flour and flaxseed oil in formulation of functional bread. Int. J. Multidiscip. Res. 2016, 3, 22–28. [Google Scholar]

- Sibt-e-Abbas, M.; Butt, M.S.; Sultan, M.T.; Sharif, M.K.; Ahmad, A.N.; Batool, R. Nutritional and functional properties of protein isolates extracted from defatted peanut flour. Int. Food Rese. J. 2015, 22, 1533–1537. [Google Scholar]

- ANVISA. Agência Nacional De Vigilância Sanitária. Portaria nº 27, de 13 de Janeiro de 1998; Aprova o Regulamento Técnico Referente à Informação Nutricional Complementar (Declarações Relacionadas ao Conteúdo de Nutrientes): Brasília, Brazil, 1998.

- Jones, J.M. Codex-Aligned Dietary Fiber Definitions Help to Bridge the ‘Fiber Gap’. Nutr. J. 2014, 13, 34. Available online: http://www.nutritionj.com/content/13/1/34 (accessed on 13 November 2021). [CrossRef] [PubMed]

- Sethupathy, P.; Suriyamoorthy, P.; Moses, J.A.; Chinnaswamy, A.; Anandharamakrishnan, C. Physical, sensory, in-vitro starch digestibility and glycaemic index of granola bars prepared using sucrose alternatives. Int. J. Food Sci. Technol. 2019, 55, 348–356. [Google Scholar] [CrossRef]

- Costa, J.D.P.D.; Oliveira, D.M.; Marques, D.R.; Monteiro, A.R.G.; Da Costa, J.M.C. Addition of powdered shrimp in the formulation of snacks. Rev. Ciênc. Agron. 2019, 50, 387–393. [Google Scholar] [CrossRef]

- Singh, V.; Vijay-Kumar, M. Beneficial and detrimental effects of processed dietary fibers on intestinal and liver health: Health benefits of refined dietary fibers need to be redefined. Gastroenterol. Rep. 2020, 8, 85–89. [Google Scholar] [CrossRef] [PubMed]

- Concenco, F.I.G.D.R.; Gonzales, R.N.D.L.; Vizzotto, M.; Nora, L. Manufacturing and Sensorial Acceptance of Cereal Bars Enriched with Flaxseed (Linum usitatissimum) Flour. J. Food Res. 2018, 8, 1. [Google Scholar] [CrossRef]

- FAO; World Health Organization. Expert Consultation on Human Vitamin and Mineral Requirements. Vitamin and Mineral Requirements in Human Nutrition: Report of a Joint FAO/WHO Expert Consultation, 2nd ed.; Food and Agriculture Organization of the United Nations: Bangkok, Thailand, 2004. [Google Scholar]

- FAO; World Health Organization; UNU. Expert Consulation on Protein Quality Evaluation in Human Nutrition. Findings and Recomendations Requirements: Nutrition Meetings; Report Series 92; Food and Agriculture Organization/World Health Organization: Rome, Italy, 2013. [Google Scholar]

- Li, Y.; Clark, C.; Abdulazeem, H.; Salehisahlabadi, A.; Rahmani, J.; Zhang, Y. The effect of Brazil nuts on selenium levels, Glutathione peroxidase, and thyroid hormones: A systematic review and meta-analysis of randomized controlled trials. J. King Saud Univ.-Sci. 2020, 32, 1845–1852. [Google Scholar] [CrossRef]

- Gombart, A.F.; Pierre, A.; Maggini, S. A Review of Micronutrients and the Immune System–Working in Harmony to Reduce the Risk of Infection. Nutrients 2020, 12, 236. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, S.M.F. Biodisponibilidade de Nutrientes; Editora Manole: Barueri, Brazil, 2016. [Google Scholar]

| Ingredients (g) | Formulations | ||

|---|---|---|---|

| F1 | F2 | F3 | |

| (DFBN 80: SPI20) | (DFBN 75: SPI 25) | (DFBN 70: SPI 30) | |

| DFBN | 240 g | 225 | 210 |

| SPI | 60 g | 75 | 90 |

| binder syrup (mL) | |||

| Inverted liquid sugar | 105 | 105 | 105 |

| Glucose syrup | 75 | 75 | 75 |

| Hydrogenated vegetable fat | 15 | 15 | 15 |

| Yield% | 98.60 | 98.10 | 97.70 |

| Parameters | DFBN | Formulations | ||

|---|---|---|---|---|

| F1 | F2 | F3 | ||

| Energy (kcal 100 g−1) | 402.70 | 350.94 | 354.10 | 359.90 |

| Water activity | 0.25 ± 0.03 | 0.60 ± 0.02 a | 0.55 ± 0.05 a | 0.54 ± 0.02 a |

| Carbohydrate (%) | 5.40 ± 0.50 | 32.15 ± 0.45 a | 33.0 ± 0.02 a | 33.3 ± 0.52 a |

| Protein (%) | 47.35 ± 1.33 | 28.09 ± 0.32 a | 28.5 ± 1.02 a | 29.85 ± 0.75 a |

| Lipids (%) | 21.30 ± 0.85 | 12.22 ± 0.15 a | 12.54 ± 0.75 a | 11.93 ± 0.82 a |

| Dietary fiber (%) | 18.35 ± 1.03 | 9.85 ± 0.64 a | 9.03 ± 1.15 a | 8.90 ± 1.02 a |

| Insoluble fiber (%) | 13.15 ± 0.85 | 6.15 ± 0.15 a | 6.05 ± 0.83 a | 5.85 ± 0.72 a |

| Soluble fiber (%) | 5.20 ± 0.55 | 3.70 ± 0.55 a | 2.98 ± 0.50 a | 3.05 ± 0.02 a |

| Umidity (%) | 4.45 ± 0.50 | 15.10 ± 0.54 a | 14.55 ± 0.87 a | 13.85 ± 0.78 b |

| Ash (%) | 3.15 ± 0.23 | 2.59 ± 0.76 a | 2.35 ± 0.52 a | 2.15 ± 0.52 a |

| Minerals Macrominerals (mg/100g) | |||||

|---|---|---|---|---|---|

| Formulatiions | |||||

| DFBN | F1 | F2 | F3 | FAO * (2004) mg/Day | |

| Sodium (Na) | 3.96 ± 0.01 | 4.35 ± 0.55 a | 4.38 ± 0.35 a | 4.42 ± 0.27 a | 2400 |

| Potassium (K) | 610 ± 0.03 | 755 ± 0.75 a | 767 ± 0.75 a | 770 ± 0.75 b | 1000 |

| Calcium (Ca) | 44.80 ± 4.50 | 65.8 ± 11.50 a | 66.30 ± 11.50 a | 68.70 ± 11.50 a | 1000 |

| Phosphor (P) | 670 ± 10.50 | 652 ± 5.53 a | 654.3 ± 8.50 a | 658.20 ± 7.35 a | 1000 |

| Magnesium (Mg) | 725.80 ± 28.20 | 745 ± 15.5 a | 749 ± 15.50 a | 753 ± 15.50 b | 400 |

| Microminerals (mg/100g) | |||||

| Iron (Fe) | 5.08 ± 0.65 | 4.58 ± 0.15 a | 4.43 ± 0.15 a | 4.38 ± 0.15 a | 18 |

| Copper (Cu) | 4.01 ± 0.29 | 4.05 ± 0.73 a | 3.95 ± 0.73 a | 3.88 ± 0.73 a | 2 |

| Manganese (Mn) | 3.30 ± 0.39 | 3.96 ± 0.85 a | 3.89 ± 0.85 a | 3.82 ± 0.85 a | 2 |

| Zinc (Zn) | 4.51 ± 0.43 | 4.35 ± 0.35 a | 4.38 ± 0.34 a | 4.41 ± 0.56 a | 15 |

| Selenium (Se) µg/g | 1.11 ± 0.50 | 0.97 ± 0.43 a | 0.93 ± 0.30 a | 0.95 ± 0.53 a | 70 µg-men 55 µg-women |

| Amino Acid | DFBN | EQ | F1 | EQ | F2 | EQ | F3 | EQ | Standart FAO/WHO |

|---|---|---|---|---|---|---|---|---|---|

| AA’S ESSENCIAIS | |||||||||

| Histidine | 8.00 ± 0.02 | 0.53 | 6.10 ± 0.03 a | 0.40 | 5.73 ± 0.21 a | 0.38 | 5.91 ± 0.03 a | 0.39 | 15 |

| Threonine | 9.20 ± 0.04 | 0.40 | 7.60 ± 0.02 a | 0.33 | 6.8 ± 0.02 a | 0.29 | 6.91 ± 0.02 a | 0.30 | 23 |

| Lysine | 13.20 ± 0.12 | 0.22 | 10.4 ± 0.02 a | 0.23 | 10.1 ± 0.02 a | 0.22 | 9.85 ± 0.05 a | 0.21 | 45 |

| Methionine ** | 22.50 ± 0.21 | 1.40 | 16.4 ± 0.10 a | 1.02 | 15.8 ± 0.10 a | 0.98 | 15.0 ± 0.15 b | 0.93 | 16 |

| Cysteine | 5.50 ± 0.21 | 0.91 | 3.2 ± 0.10 a | 0.53 | 2.92 ± 0.10 a | 0.48 | 2.80 ± 0.11 b | 0.46 | 6 |

| Isoleucine | 12.20 ± 0.10 | 0.40 | 9.6 ± 0.08 a | 0.32 | 9.1 ± 0.08 a | 0.30 | 9.0 ± 0.18 a | 0.30 | 30 |

| Leucine | 24.70 ± 0.13 | 0.41 | 19.1 ± 0.09 a | 0.32 | 18.5 ± 0.09 a | 0.31 | 18.61 ± 0.10 a | 0.32 | 59 |

| Valine | 15.00 ± 0.12 | 0.38 | 11.5 ± 0.08 a | 0.29 | 10.7 ± 0.08 a | 0.27 | 10.65 ± 0.11 a | 0.27 | 39 |

| Phenylalanine *** | 14.55 ± 0.10 | 0.48 | 15.6 ± 0.10 a | 0.66 | 16.2 ± 0.10 a | 0.68 | 17.8 ± 0.12 b | 0.75 | 38 |

| Tyrosine | 8.95 ± 0.10 | 9.7 ± 0.07 a | 9.98 ± 0.07 a | 10.97 ± 0.05 b | |||||

| Tryptophan | 3.85 ± 0.08 | 0.64 | ND | ND | ND | ND | 6 | ||

| Total | 137.65 | 109.20 | 105.83 | 107.50 | 277 | ||||

| Non-Essential Amino Acids | |||||||||

| Asparagine | 27.5 ± 0.15 | - | 24.1 ± 0.18 a | - | 24.34 ± 0.03 a | - | 24.61 ± 0.52 a | - | - |

| Glutamine | 72.5 ± 0.21 | - | 47.2 ± 0.12 a | - | 46.72 ± 0.52 a | - | 46.67 ± 0.12 a | - | - |

| Serine | 15.7 ± 0.30 | - | 12.0 ± 0.21 a | - | 12.12 ± 0.21 a | - | 12.15 ± 0.21 a | - | - |

| Glycine | 16.7 ± 0.87 | - | 11.1 ± 0.10 a | - | 10.71 ± 0.70 a | - | 10.67 ± 0.53 | - | - |

| Arginine | 25.3 ± 1.02 | - | 23.0 ± 0.14 a | - | 22.7 ± 0.47 a | - | 22.93 ± 0.38 a | - | - |

| Alanine | 13.5 ± 0.91 | - | 9.8 ± 0.05 a | - | 8.92 ± 0.13 a | - | 8.97 ± 0.35 a | - | - |

| Proline | 16.3 ± 0.21 | - | 11.9 ± 0.07 a | - | 11.76 ± 0.07 a | - | 11.07 ± 0.07 a | - | - |

| Total (mg/g) | 325.15 | 248.3 | 243.10 | 244.57 | 277 | ||||

| Formulações | AI (Color) | AC (Aroma) | AC (Flavor) | AC (Texture) | AC (Impressão Global) |

|---|---|---|---|---|---|

| F1 | 81.00 a | 80.0 a | 82.22 a | 80.67 a | 81.56 a |

| F2 | 86.67 a | 87.89 b | 91.78 b | 88.56 b | 87.89 b |

| F3 | 84.11 a | 79.33 a | 83.21 a | 81.22 a | 80.67 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

dos Santos, O.V.; Azevedo, G.O.; Santos, Â.C.; Lopes, A.S. Development of a Nutraceutical Product Derived from By-Products of the Lipid Extraction of the Brazil Nut (Bertolletia excelsa H.B.K). Foods 2023, 12, 1446. https://doi.org/10.3390/foods12071446

dos Santos OV, Azevedo GO, Santos ÂC, Lopes AS. Development of a Nutraceutical Product Derived from By-Products of the Lipid Extraction of the Brazil Nut (Bertolletia excelsa H.B.K). Foods. 2023; 12(7):1446. https://doi.org/10.3390/foods12071446

Chicago/Turabian Styledos Santos, Orquidea Vasconcelos, Glaucinéia Oliveira Azevedo, Ângela Chagas Santos, and Alessandra Santos Lopes. 2023. "Development of a Nutraceutical Product Derived from By-Products of the Lipid Extraction of the Brazil Nut (Bertolletia excelsa H.B.K)" Foods 12, no. 7: 1446. https://doi.org/10.3390/foods12071446

APA Styledos Santos, O. V., Azevedo, G. O., Santos, Â. C., & Lopes, A. S. (2023). Development of a Nutraceutical Product Derived from By-Products of the Lipid Extraction of the Brazil Nut (Bertolletia excelsa H.B.K). Foods, 12(7), 1446. https://doi.org/10.3390/foods12071446