Can Citrus Fiber Improve the Quality of Gluten-Free Breads?

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Flour Characteristics (Hydration, Gel, and Pasting Properties)

2.2.2. Bread Elaboration

2.2.3. Evaluation of Dough Rheology

2.2.4. Bread Characteristics

2.2.5. Consumer Test

2.2.6. Statistical Analysis

3. Results and Discussion

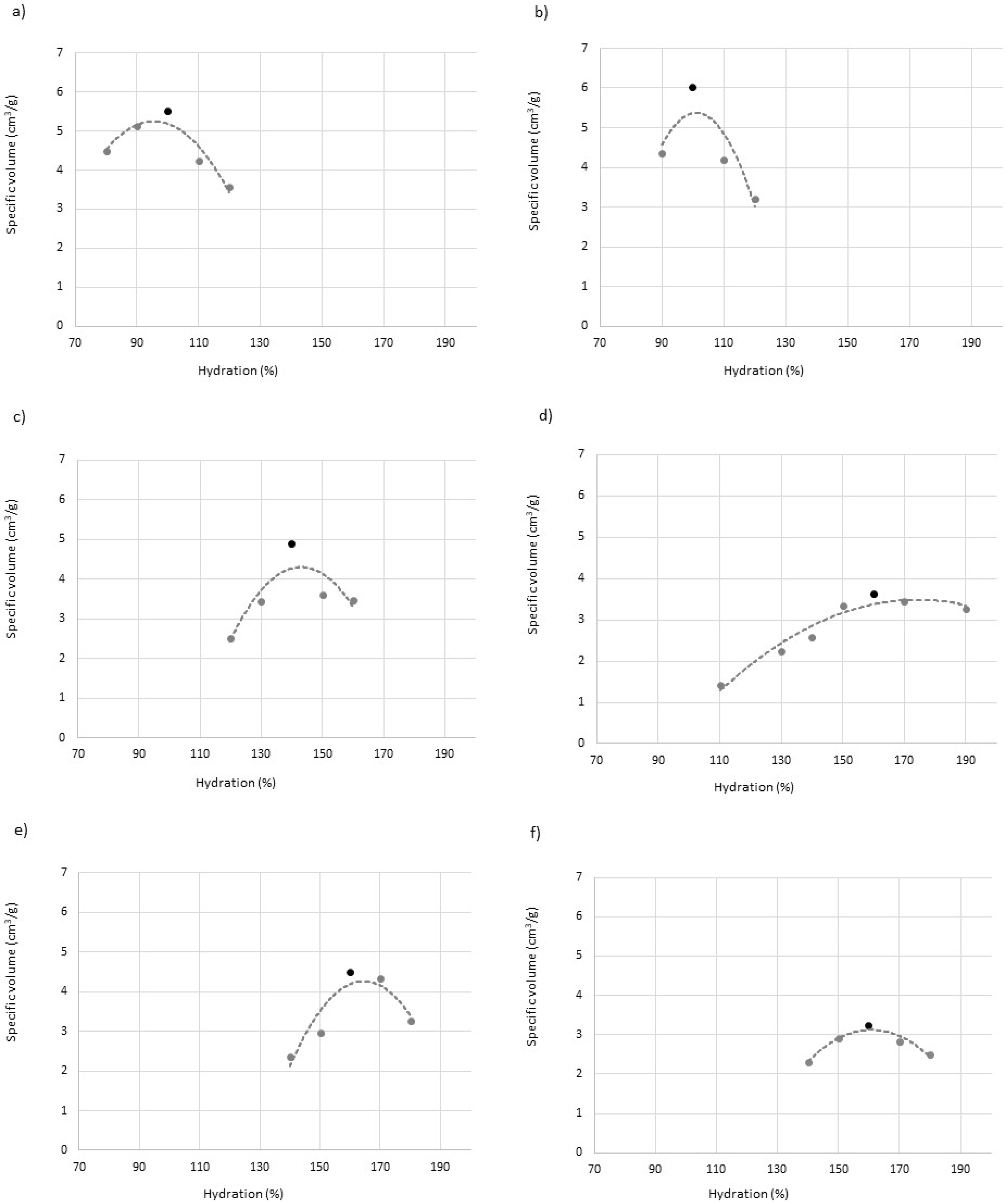

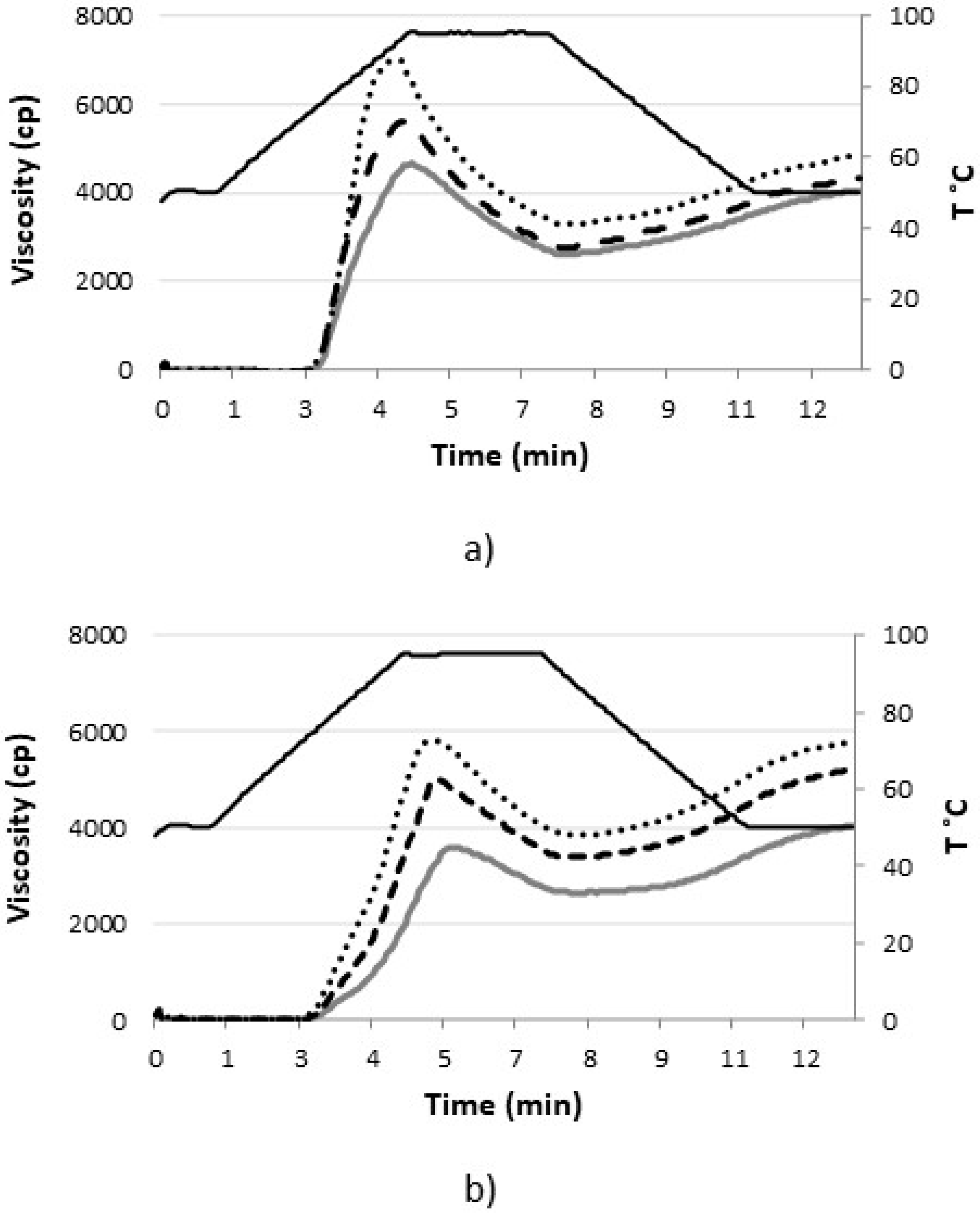

3.1. Starches and Flour Properties

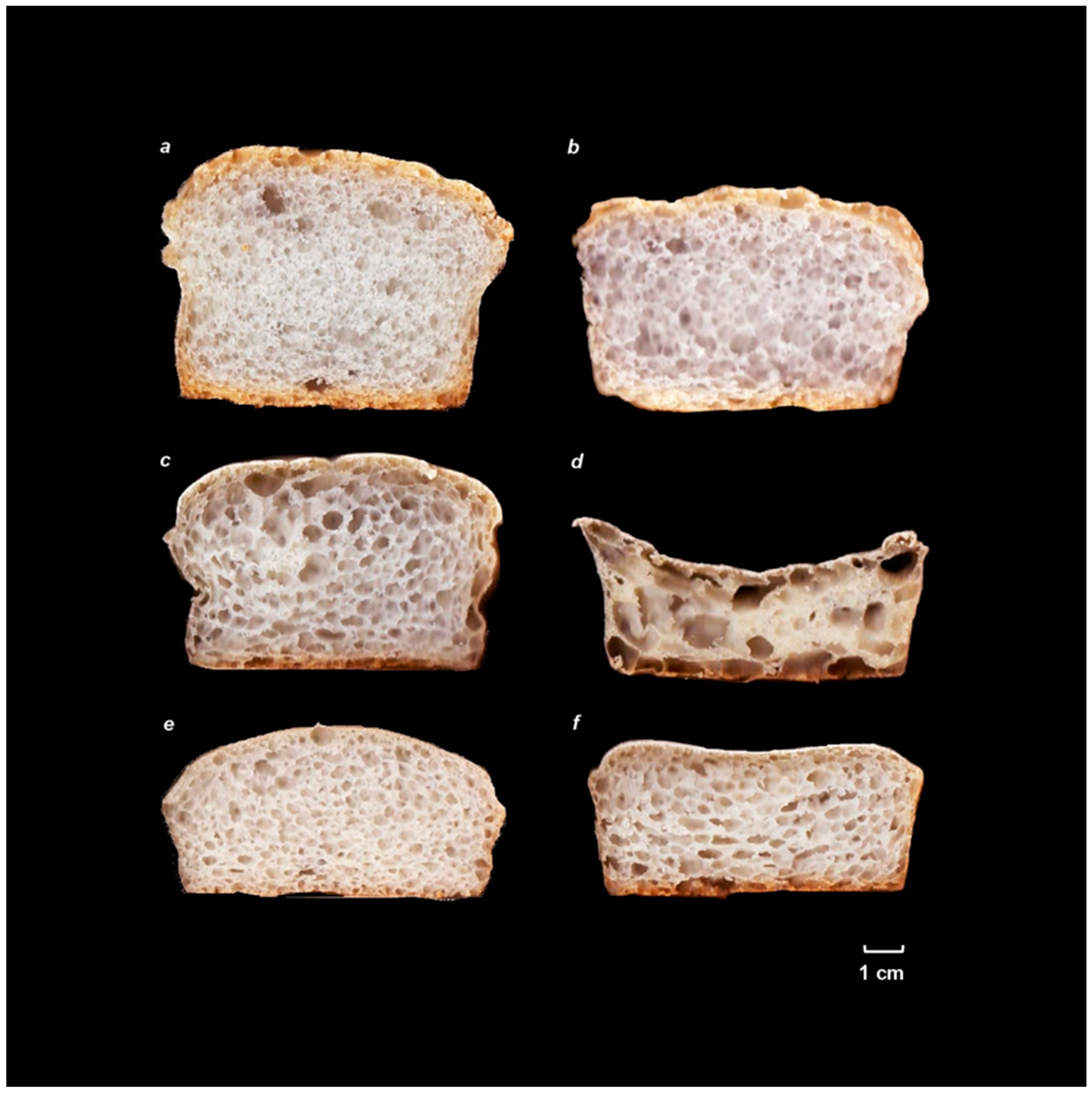

3.2. Gluten-Free Bread Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shewry, P. What Is Gluten-Why Is It Special? Front. Nutr. 2019, 6, 101. [Google Scholar] [CrossRef] [PubMed]

- Biesiekierski, J.R. What is gluten? J. Gastroenterol. Hepatol. 2017, 32, 78–81. [Google Scholar] [CrossRef]

- Roman, L.; Gómez, M.; Martínez, M.M. Mesoscale structuring of gluten-free bread with starch. Curr. Opin. Food Sci. 2021, 38, 189–195. [Google Scholar] [CrossRef]

- Sabanis, D.; Tzia, C. Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci. Technol. Int. 2011, 17, 279–291. [Google Scholar] [CrossRef] [PubMed]

- Belorio, M.; Gómez, M. Effect of hydration on gluten-free breads made with hydroxypropyl methylcellulose in comparison with psyllium and xanthan gum. Foods 2020, 9, 1548. [Google Scholar] [CrossRef]

- Roman, L.; Belorio, M.; Gómez, M. Gluten-free breads: The gap between research and commercial reality. Compr. Rev. Food Sci. Food Saf. 2019, 18, 690–702. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Martínez, M.M.; Merino, C.; de la Hera, E.; Gómez, M. Effect of oil and shortening in rice bread quality: Relationship between dough rheology and quality characteristics. J. Texture Stud. 2017, 48, 597–606. [Google Scholar] [CrossRef]

- Sahagún, M.; Gómez, M. Assessing influence of protein source on characteristics of gluten-free breads optimising their hydration level. Food Bioprocess Technol. 2018, 11, 1686–1694. [Google Scholar] [CrossRef]

- Marin, F.R.; Soler-Rivas, C.; Benavente-Garcia, O.; Castillo, J.; Pérez-Álvarez, J.A. By-products from different citrus processes as a source of customized functional fibers. Food Chem. 2007, 100, 736–741. [Google Scholar] [CrossRef]

- Lundberg, B.M. Using highly expanded citrus fiber to improve the quality and nutritional properties of foods. Cereal Foods World 2005, 50, 248–252. [Google Scholar]

- Lundberg, B.; Pan, X.J.; White, A.; Chau, H.; Hotchkiss, A. Rheology and composition of citrus fiber. J. Food Eng. 2014, 125, 97–104. [Google Scholar] [CrossRef]

- Qi, J.R.; Song, L.W.; Zeng, W.Q.; Liao, J.S. Citrus fiber for the stabilization of O/W emulsion through combination of Pickering effect and fiber-based network. Food Chem. 2021, 343, 128523. [Google Scholar] [CrossRef]

- Fernández-López, J.; Fernández-Gines, J.M.; Aleson-Carbonell, L.; Sendra, E.; Sayas-Barbera, E.; Pérez-Álvarez, J.A. Application of functional citrus by-products to meat products. Trends Food Sci. Technol. 2004, 15, 176–185. [Google Scholar] [CrossRef]

- Stauffer, C.E. Functional Additives for Bakery Foods; Van Nostrand Reinhold: New York, NY, USA, 1990. [Google Scholar]

- Miller, R.A. Increased yield of bread containing citrus peel fiber. Cereal Chem. 2011, 88, 174–178. [Google Scholar] [CrossRef]

- Spina, A.; Brighina, S.; Muccilli, S.; Mazzaglia, A.; Fabroni, S.; Fallico, B.; Rapisarda, P.; Arena, E. Wholegrain durum wheat bread fortified with citrus fibers: Evaluation of quality parameters during long storage. Front. Nutr. 2019, 6, 13. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, O.K.; Mert, B. The use of microfluidization for the production of xanthan and citrus fiber-based gluten-free corn breads. LWT 2018, 96, 34–41. [Google Scholar] [CrossRef]

- Korus, J.; Juszczak, L.; Witczak, M.; Ziobro, R. Effect of citrus fiber on the rheological properties of dough and quality of the gluten-free bread. Appl. Sci. 2020, 10, 6633. [Google Scholar] [CrossRef]

- Chen, Y.R.; Wu, S.J. Effects of high-hydrostatic pressure and high-pressure homogenization on the biological activity of cabbage dietary fiber. J. Sci. Food Agr. 2022, 102, 6299–6308. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Yang, Y.; Liu, Q.; He, W.Q. Effect of high pressure homogenization on sugar beet pulp: Physicochemical, thermal and structural properties. LWT 2020, 134, 110177. [Google Scholar] [CrossRef]

- Jiang, Z.M.; Mu, S.N.; Ma, C.L.; Liu, Y.; Ma, Y.; Zhang, M.H.; Li, H.Y.; Liu, X.Q.; Hou, J.C.; Tian, B. Consequences of ball milling combined with high-pressure homogenization on structure, physicochemical and rheological properties of citrus fiber. Food Hydrocoll. 2022, 127, 107515. [Google Scholar] [CrossRef]

- Su, D.B.; Zhu, X.D.; Wang, Y.; Li, D.; Wang, L.J. Effect of high-pressure homogenization on rheological properties of citrus fiber. LWT 2020, 127, 109366. [Google Scholar] [CrossRef]

- AACC International Approved Methods. Method 56–30.01. Water Hydration Capacity of Protein Materials; American Association of Cereal Chemists: St Paul, MN, USA, 2012. [Google Scholar]

- AACC International Approved Methods. Method 76–21.02. General Pasting Method for Wheat or Rye Flour or Starch Using the Rapid Visco Analyzer; American Association of Cereal Chemists: St Paul, MN, USA, 2012. [Google Scholar]

- Bravo-Nuñez, A.; Sahagun, M.; Gómez, M. Assessing the importance of protein interactions and hydration level on protein-enriched gluten-free breads: A novel approach. Food Bioprocess Technol. 2019, 12, 820–828. [Google Scholar] [CrossRef]

- Sigüenza-Andrés, T.; Gallego, C.; Gómez, M. Can cassava improve the quality of gluten free breads? LWT 2021, 149, 111923. [Google Scholar] [CrossRef]

- Gómez, M.; Ronda, F.; Caballero, P.; Blanco, C.; Rosell, C.M. Functionality of different hydrocolloids on the quality y shelf-life of yellow layer cakes. Foods Hydrocoll. 2007, 21, 167–173. [Google Scholar] [CrossRef]

- Schalow, S.; Baloufaud, M.; Cottancin, T.; Fischer, J.; Drusch, S. Orange pulp and peel fibers: Pectin-rich by-products from citrus processing for water binding and gelling in foods. Eur. Food Res. Technol. 2018, 244, 235–244. [Google Scholar] [CrossRef]

- Pickardt, C.; Dongowski, G.; Kunzek, H. The influence of mechanical and enzymatic disintegration of carrots on the structure and properties of cell wall materials. Eur. Food Res. Technol. 2004, 219, 229–239. [Google Scholar] [CrossRef]

- Redgwell, R.J.; Curti, D.; Gehin-Delval, C. Physicochemical properties of cell wall materials from apple, kiwifruit and tomato. Eur. Food Res. Technol. 2008, 227, 607–618. [Google Scholar] [CrossRef]

- Ma, Y.S.; Pan, Y.; Xie, Q.T.; Li, X.M.; Zhang, B.; Chen, H.Q. Evaluation studies on effects of pectin with different concentrations on the pasting, rheological and digestibility properties of corn starch. Food Chem. 2019, 274, 319–323. [Google Scholar] [CrossRef] [PubMed]

- Díaz-Calderon, P.; MacNaughtan, B.; Hill, S.; Foster, T.; Enrione, J.; Mitchell, J. Changes in gelatinisation and pasting properties of various starches (wheat, maize and waxy maize) by the addition of bacterial cellulose fibrils. Food Hydrocoll. 2018, 80, 274–280. [Google Scholar] [CrossRef]

- Xie, F.; Ren, X.L.; Wu, H.M.; Zhang, H.; Wu, Y.; Song, Z.B.; Ai, L.Z. Pectins of different resources influences cold storage properties of corn starch gels: Structure-property relationships. Food Hydrocoll. 2022, 124, 107287. [Google Scholar] [CrossRef]

- Fratelli, C.; Muniz, D.G.; Santos, F.G.; Capriles, V.D. Modelling the effects of psyllium and water in gluten-free bread: An approach to improve the bread quality and glycemic response. J. Funct. Foods 2018, 42, 339–345. [Google Scholar] [CrossRef]

- Mancebo, C.M.; San Miguel, M.A.; Martínez, M.M.; Gómez, M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 2015, 61, 8–15. [Google Scholar] [CrossRef]

- Puerta, P.; Laguna, L.; Villegas, B.; Rizo, A.; Fiszman, S.; Tarrega, A. Oral processing and dynamics of texture perception in commercial gluten-free breads. Food Res. Int. 2020, 134, 109233. [Google Scholar] [CrossRef] [PubMed]

- Martínez, M.M.; Gómez, M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 2017, 197, 78–86. [Google Scholar] [CrossRef]

- Carini, E.; Curti, E.; Fattori, F.; Paciulli, M.; Vittadini, E. Staling of gluten-free breads: Physico-chemical properties and H-1 NMR mobility. Eur. Food Res. Technol. 2017, 243, 867–877. [Google Scholar] [CrossRef]

- Fjljpcev, B.; Pojic, M.; Simurina, O.; Misan, A.; Mandic, A. Psyllium as an improver in gluten-free breads: Effect on volume, crumb texture, moisture binding and staling kinetics. LWT 2021, 151, 112156. [Google Scholar]

- Matos, M.E.; Rosell, C.M. Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur. Food Res. Technol. 2012, 235, 107–117. [Google Scholar] [CrossRef]

- Steffolani, E.; De la Hera, E.; Perez, G.; Gómez, M. Effect of chia (Salvia hispanica L) addition on the quality of gluten-free bread. J. Food Qual. 2014, 37, 309–317. [Google Scholar] [CrossRef]

| Ingredients | Control 1 | CF 1 | ACF 1 | Control 2 | CF 2 | ACF 2 |

|---|---|---|---|---|---|---|

| Water | x | x | x | x | x | x |

| Rice flour | - | - | - | 160 | 160 | 160 |

| Maize starch | 320 | 320 | 320 | 160 | 160 | 160 |

| Cassava starch | 80 | 80 | 80 | 80 | 80 | 80 |

| Sunflower oil | 24 | 24 | 24 | 24 | 24 | 24 |

| White sugar | 20 | 20 | 20 | 20 | 20 | 20 |

| Yeast | 12 | 12 | 12 | 12 | 12 | 12 |

| Salt | 8 | 8 | 8 | 8 | 8 | 8 |

| HPMC | 8 | 8 | 8 | 8 | 8 | 8 |

| CF | - | 24 | - | - | 24 | - |

| ACF | - | - | 24 | - | - | 24 |

| WBC (Water g/Solid g) | Gel Hardness (N) | G′ (Pa) | G″ (Pa) | tanδ | |

|---|---|---|---|---|---|

| Control 1 | 0.85 ± 0.01 a | 21.58 ± 0.53 c | 44.90 ± 5.01 a | 81.29 ± 7.12 a | 1.88 ± 0.01 c |

| CF 1 | 1.54 ± 0.03 b | 14.97 ± 2.51 b | 227.50 ±1.56 b | 253.15 ± 2.05 b | 1.16 ± 0.01 b |

| ACF 1 | 2.87 ± 0.28 d | 11.97 ± 0.45 ab | 56.39 ± 1.30 a | 103.60 ± 2.26 a | 1.97 ± 0.10 c |

| Control 2 | 1.01 ± 0.03 a | 8.60 ± 3.11 a | 181.25 ± 4.38 b | 203.68 ± 8.17 b | 1.25 ± 0.06 b |

| CF 2 | 2.15 ± 0.09 c | 9.38 ± 3.19 a | 323.40 ± 88.53 c | 350.55 ± 61.87 c | 1.15 ± 0.11 b |

| ACF 2 | 4.44 ± 0.28 e | 7.92 ± 0.35 a | 793.10 ± 15.27 d | 603.70 ± 11.31 d | 0.78 ± 0.01 a |

| Optimal Hydration (%) | Specific Volume (cm3/g) | Weight Loss (%) | |

|---|---|---|---|

| Control 1 | 100 | 6.15 ± 0.44 c | 26.38 ± 1.94 bc |

| CF 1 | 140 | 4.65 ± 0.13 b | 23.48 ± 2.44 ab |

| ACF 1 | 180 | 3.72 ± 0.14 a | 20.69 ± 1.32 a |

| Control 2 | 100 | 6.01 ± 0.23 c | 28.40 ± 2.34 c |

| CF 2 | 160 | 3.51 ± 0.01 a | 26.82 ± 0.32 bc |

| ACF 2 | 160 | 3.22 ± 0.15 a | 26.76 ± 0.59 bc |

| Hardness (N) | Cohesiveness | Resilience | Elasticity (N) | Hardness Increase (%) | |

|---|---|---|---|---|---|

| Control 1 | 4.86 ± 0.06 bc | 0.31 ± 0.0052 a | 0.11 ± 0.0011 b | 0.98 ± 0.01 a | 227.23 ± 12.58 b |

| CF 1 | 4.25 ± 0.05 b | 0.49 ± 0.0071 d | 0.24 ± 0.0025 e | 2.44 ± 0.04 c | 73.62 ± 4.89 a |

| ACF 1 | 5.26 ± 0.03 c | 0.49 ± 0.0071 d | 0.23 ± 0.0026 d | 1.69 ± 0.09 b | 50.83 ± 51.14 a |

| Control 2 | 3.31 ± 0.05 a | 0.30 ± 0.0061 a | 0.10 ± 0.0046 a | 0.96 ± 0.00 a | 415.49 ± 17.20 c |

| CF 2 | 6.87 ± 0.13 d | 0.43 ± 0.0018 c | 0.12 ± 0.0006 bc | 2.69 ± 0.11 d | 82.07 ± 20.85 a |

| ACF 2 | 7.42 ± 0.62 d | 0.33 ± 0.0081 b | 0.12 ± 0.0018 c | 1.63 ± 0.01 b | 52.80 ± 21.84 a |

| Visual Appearance | Odor | Texture | Taste | Overall Acceptability | |

|---|---|---|---|---|---|

| Control 1 | 6.72 ± 1.55 b | 6.63 ± 1.57 b | 6.20 ± 1.63 b | 6.41 ± 1.66 b | 6.50 ± 1.25 b |

| Control 2 | 5.29 ± 1.78 a | 6.26 ± 1.46 ab | 4.99 ± 1.85 a | 5.58 ± 1.78 a | 5.51 ± 1.58 a |

| CF 1 | 6.77 ± 1.28 b | 5.90 ± 1.51 a | 6.73 ± 1.38 c | 6.29 ± 1.79 b | 6.56 ± 1.23 b |

| ACF 1 | 7.11 ± 1.41 b | 5.84 ± 1.72 a | 6.76 ± 1.49 c | 6.21 ± 1.79 b | 6.72 ± 1.36 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bugarín, R.; Gómez, M. Can Citrus Fiber Improve the Quality of Gluten-Free Breads? Foods 2023, 12, 1357. https://doi.org/10.3390/foods12071357

Bugarín R, Gómez M. Can Citrus Fiber Improve the Quality of Gluten-Free Breads? Foods. 2023; 12(7):1357. https://doi.org/10.3390/foods12071357

Chicago/Turabian StyleBugarín, Raquel, and Manuel Gómez. 2023. "Can Citrus Fiber Improve the Quality of Gluten-Free Breads?" Foods 12, no. 7: 1357. https://doi.org/10.3390/foods12071357

APA StyleBugarín, R., & Gómez, M. (2023). Can Citrus Fiber Improve the Quality of Gluten-Free Breads? Foods, 12(7), 1357. https://doi.org/10.3390/foods12071357