Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality

Abstract

1. Introduction

2. Materials and Methods

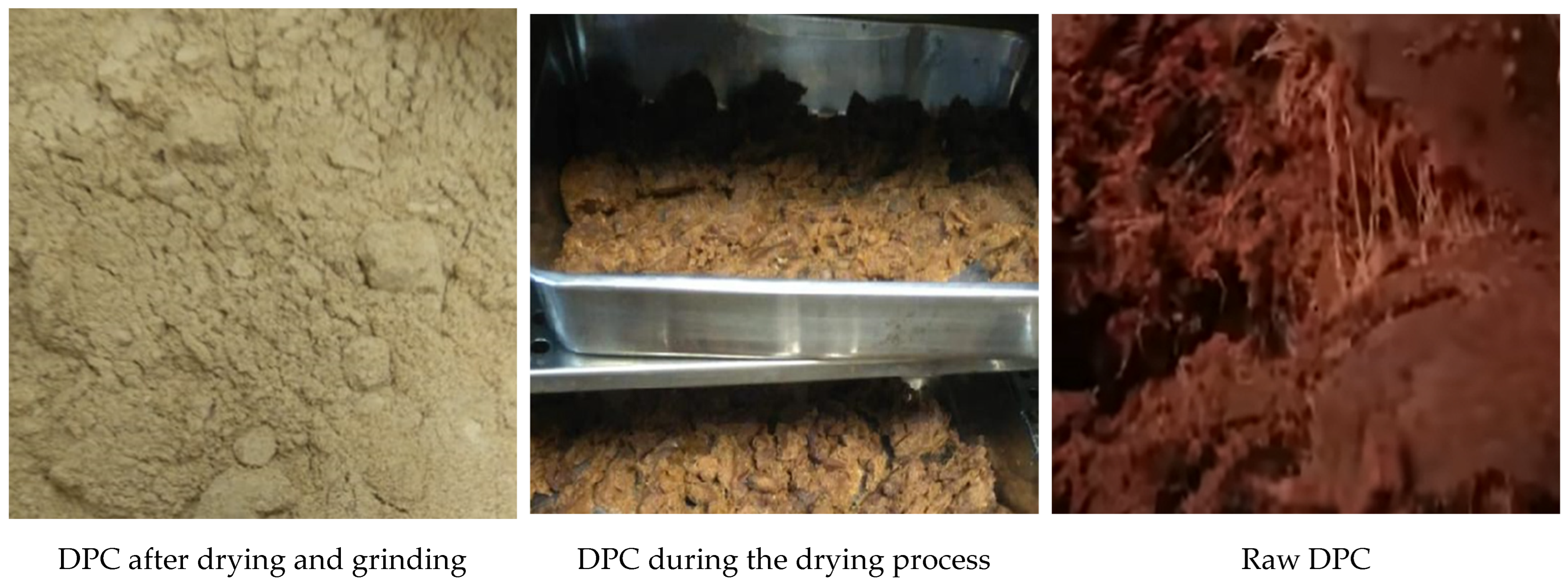

2.1. Materials

2.2. DPC, Milk, and DPC Drinkable Yogurt Analysis

2.2.1. pH and Acidity

2.2.2. Syneresis, Water Holding Capacity, and Viscosity

2.2.3. Color Parameters

2.2.4. Texture Profile Analysis (TPA)

2.3. Sensory Evaluation

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Analysis of the Milk Used and DPC

3.2. Physicochemical Analysis of the Treated DPC Drinkable Yogurt

3.2.1. Total Solids, Protein, and Fat of DPC Drinkable Yogurt

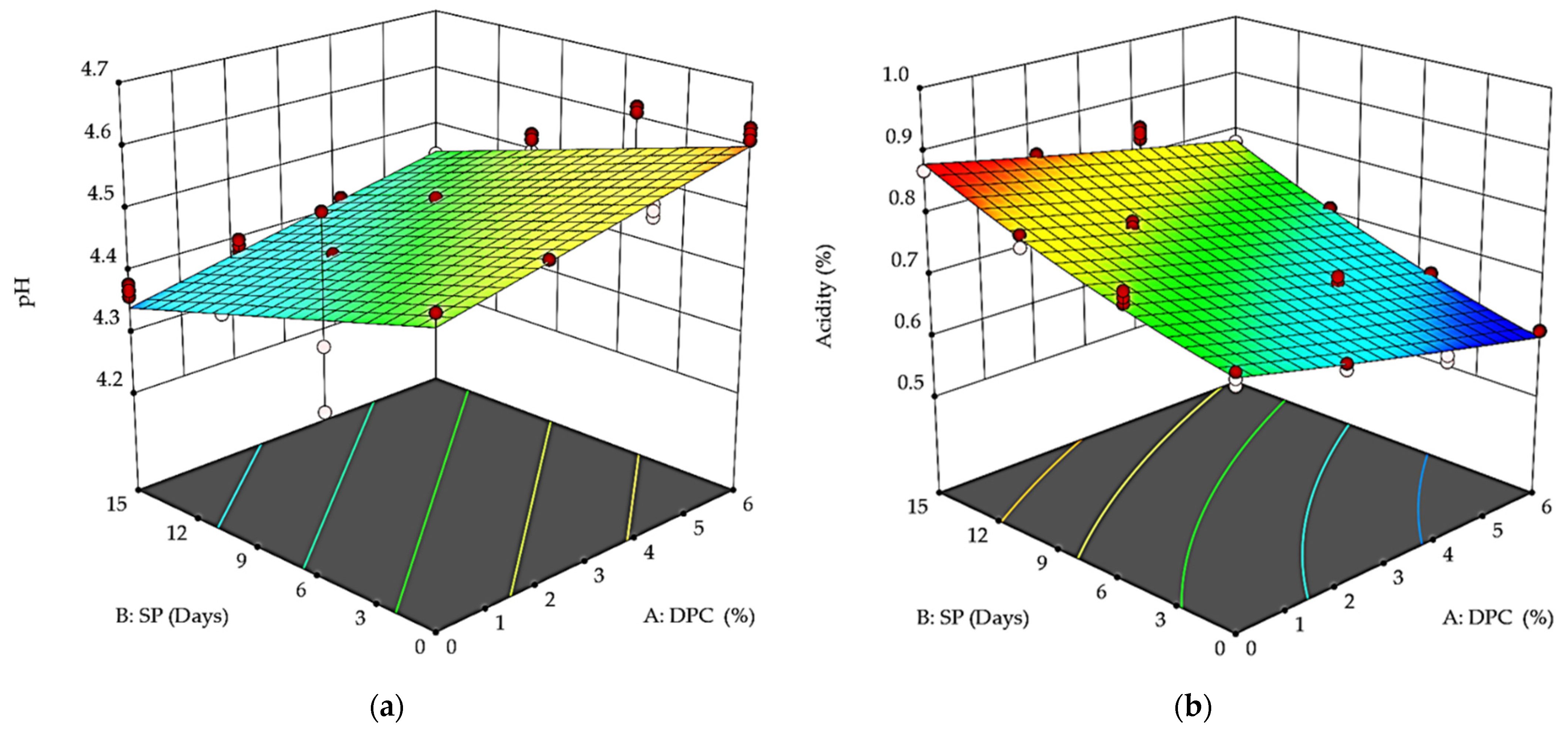

3.2.2. pH and Acidity of DPC Drinkable Yogurt

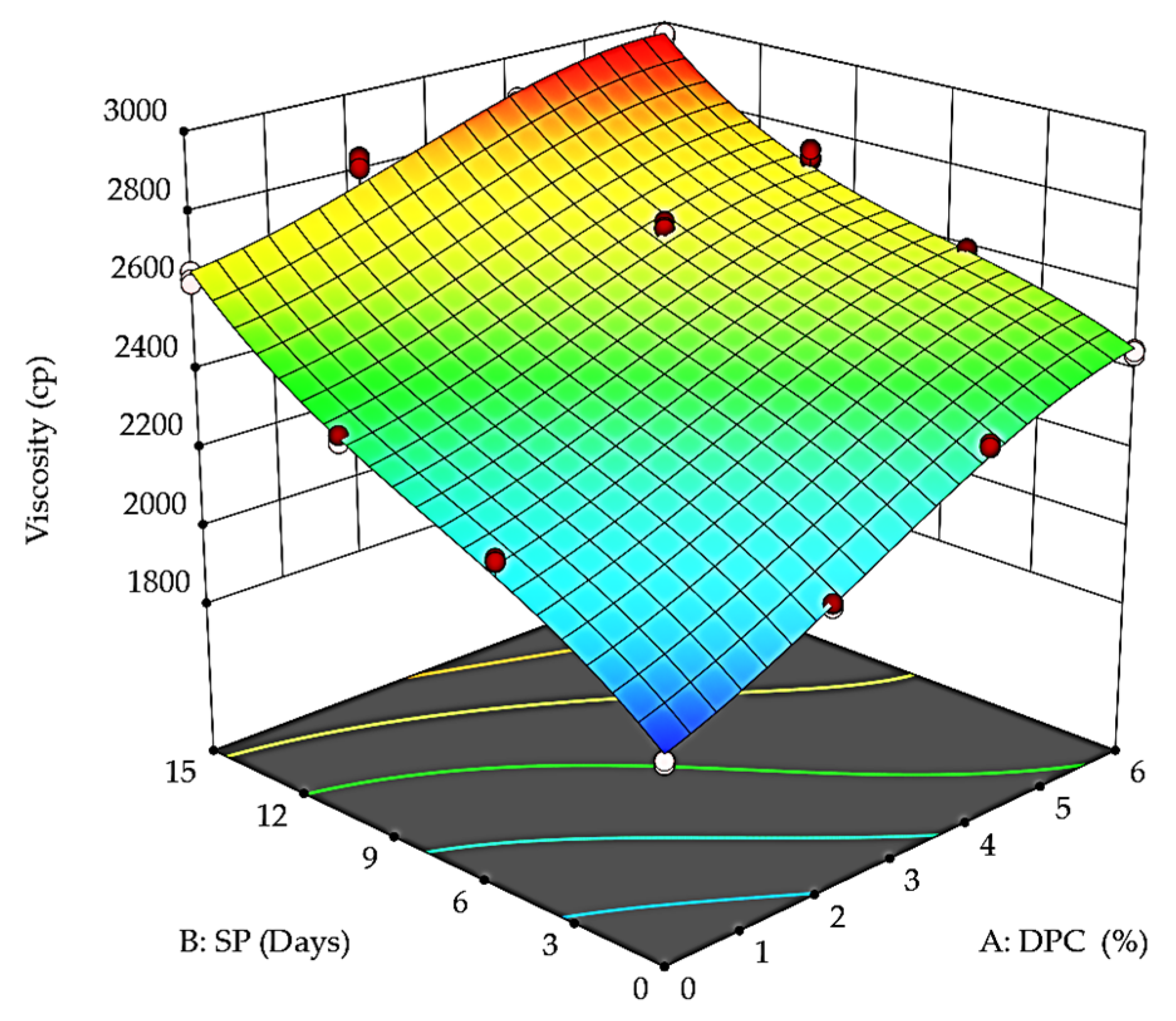

3.2.3. Syneresis, WHC, and Viscosity of DPC Drinkable Yogurt

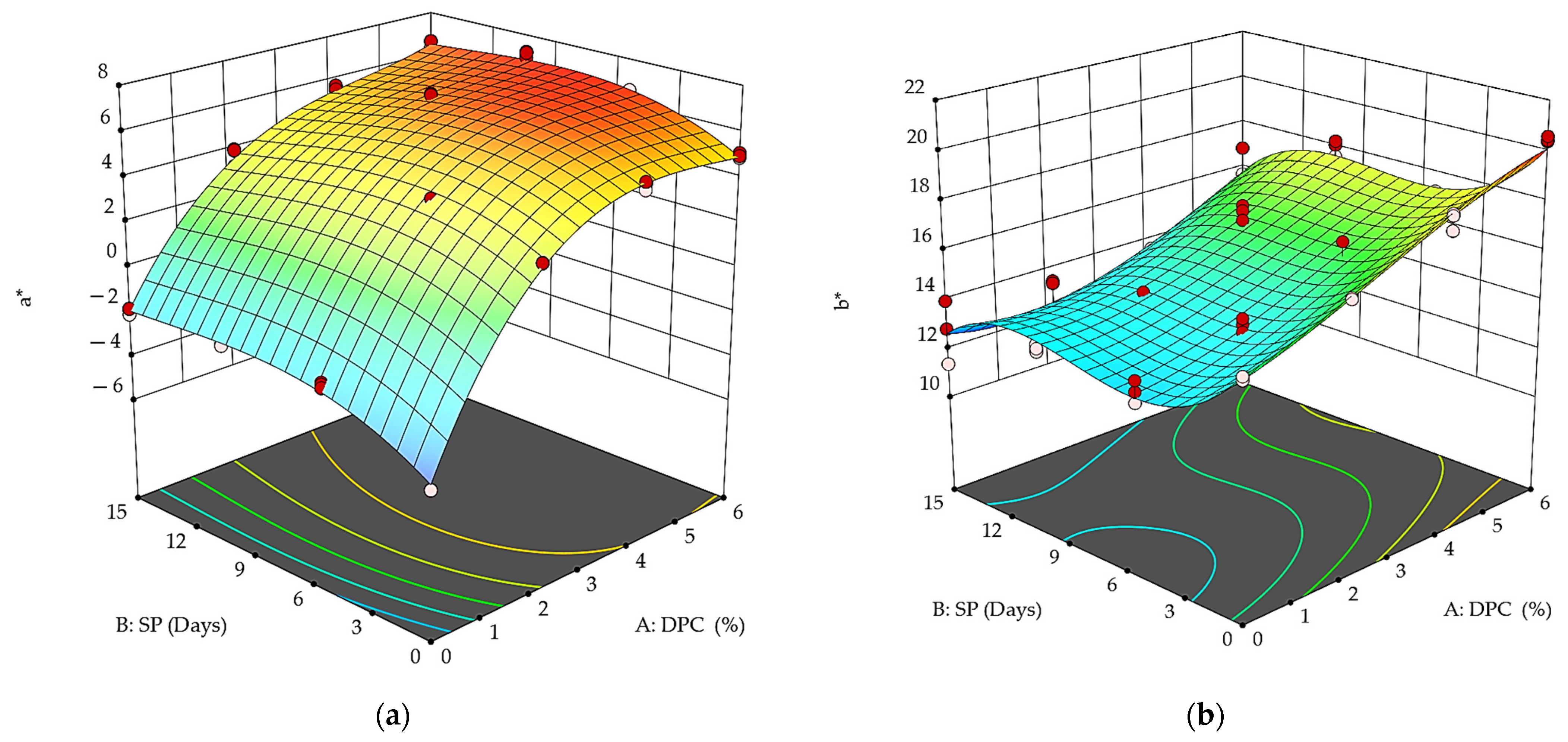

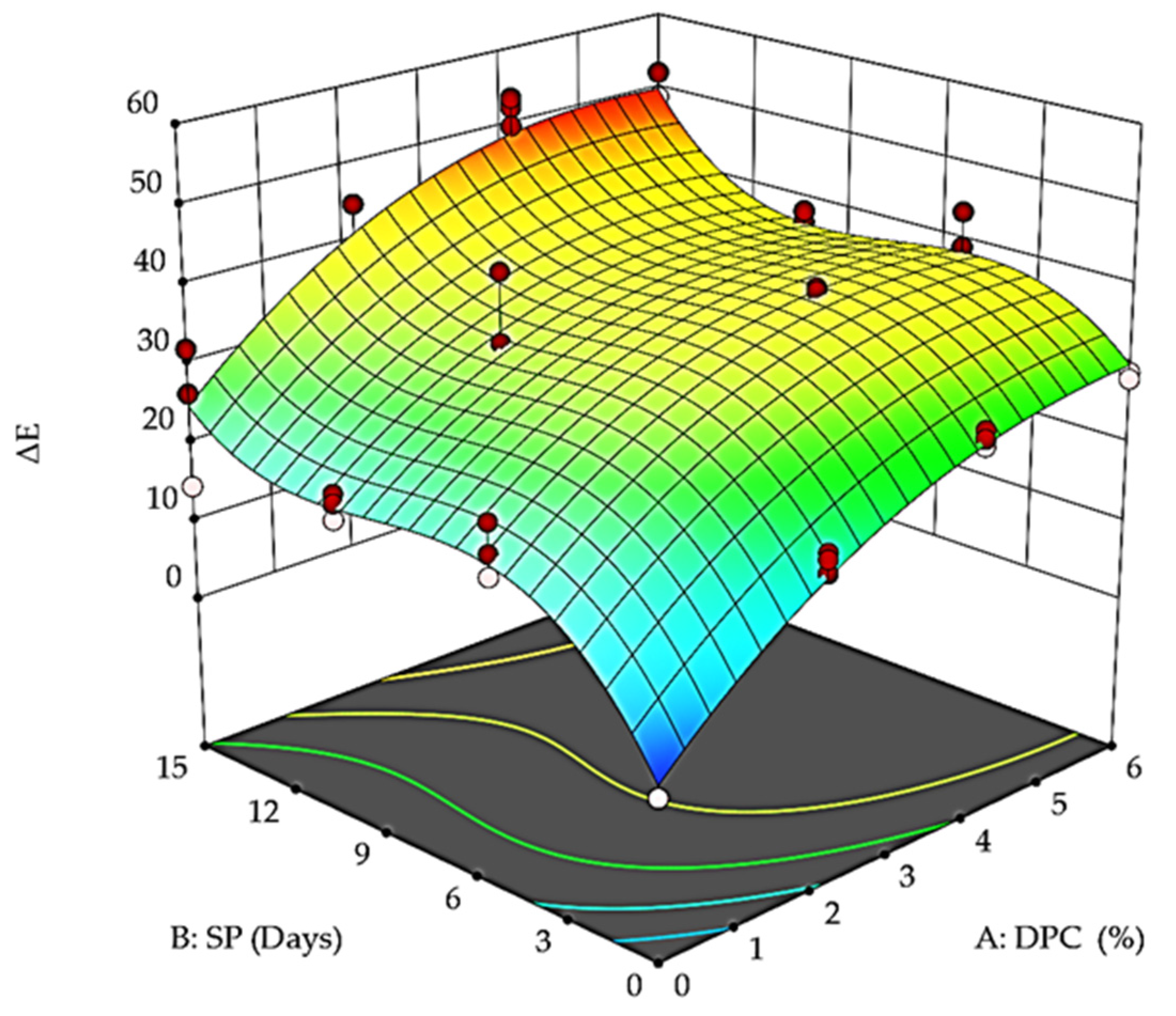

3.2.4. Color Parameters of DPC Drinkable Yogurt

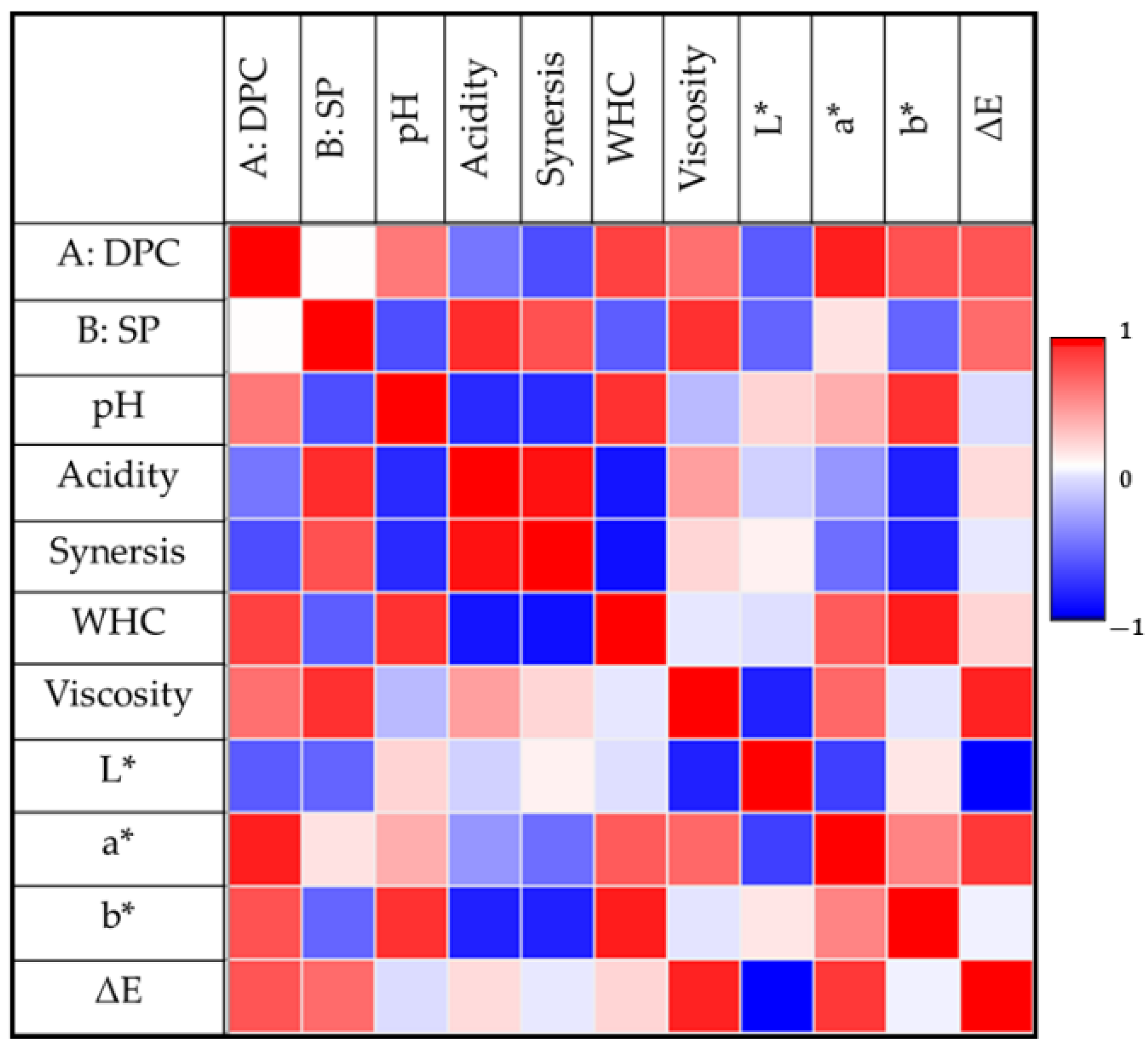

3.3. Correlation between the Factors and Physicochemical Properties of DPC Drinkable Yogurt

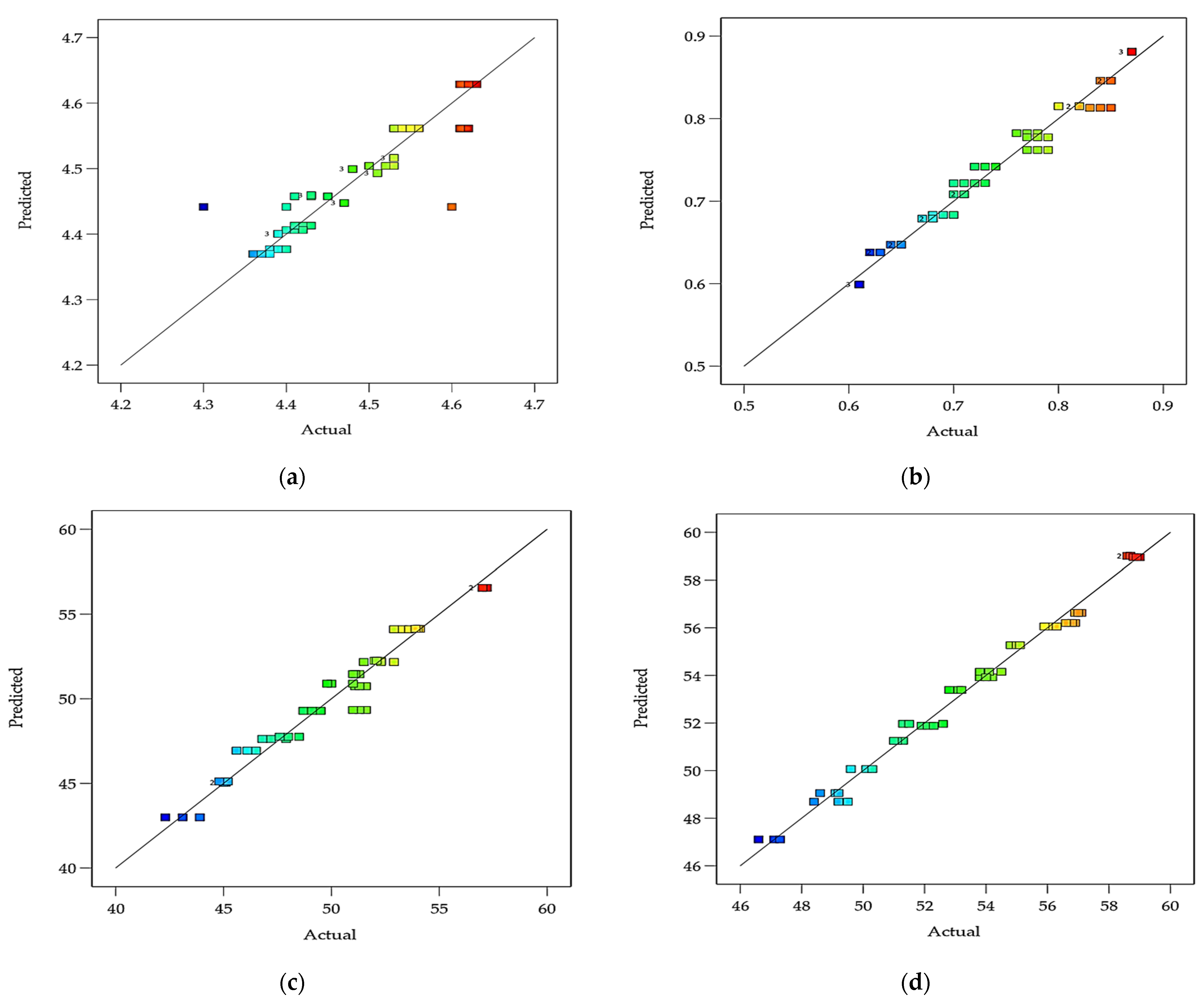

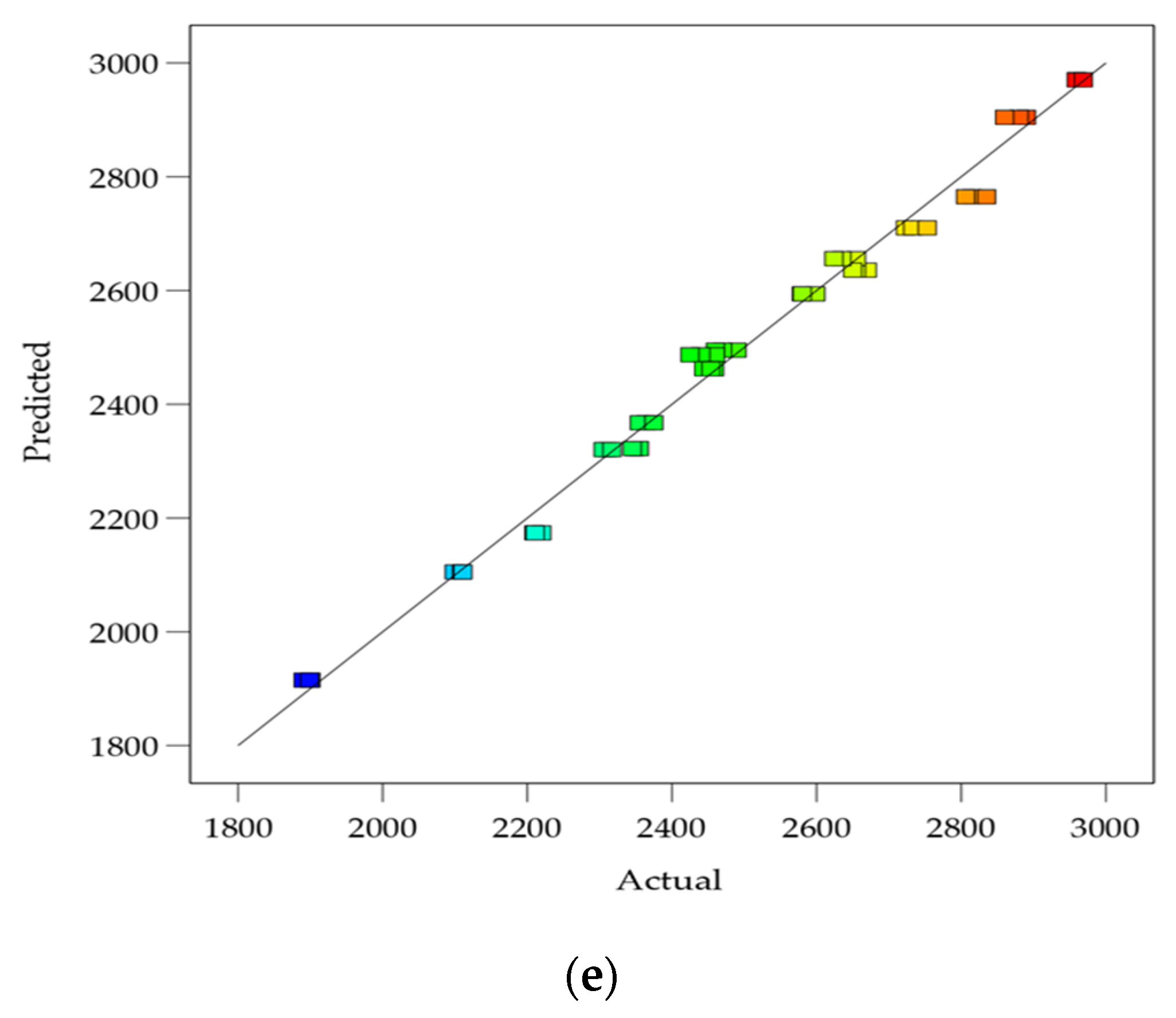

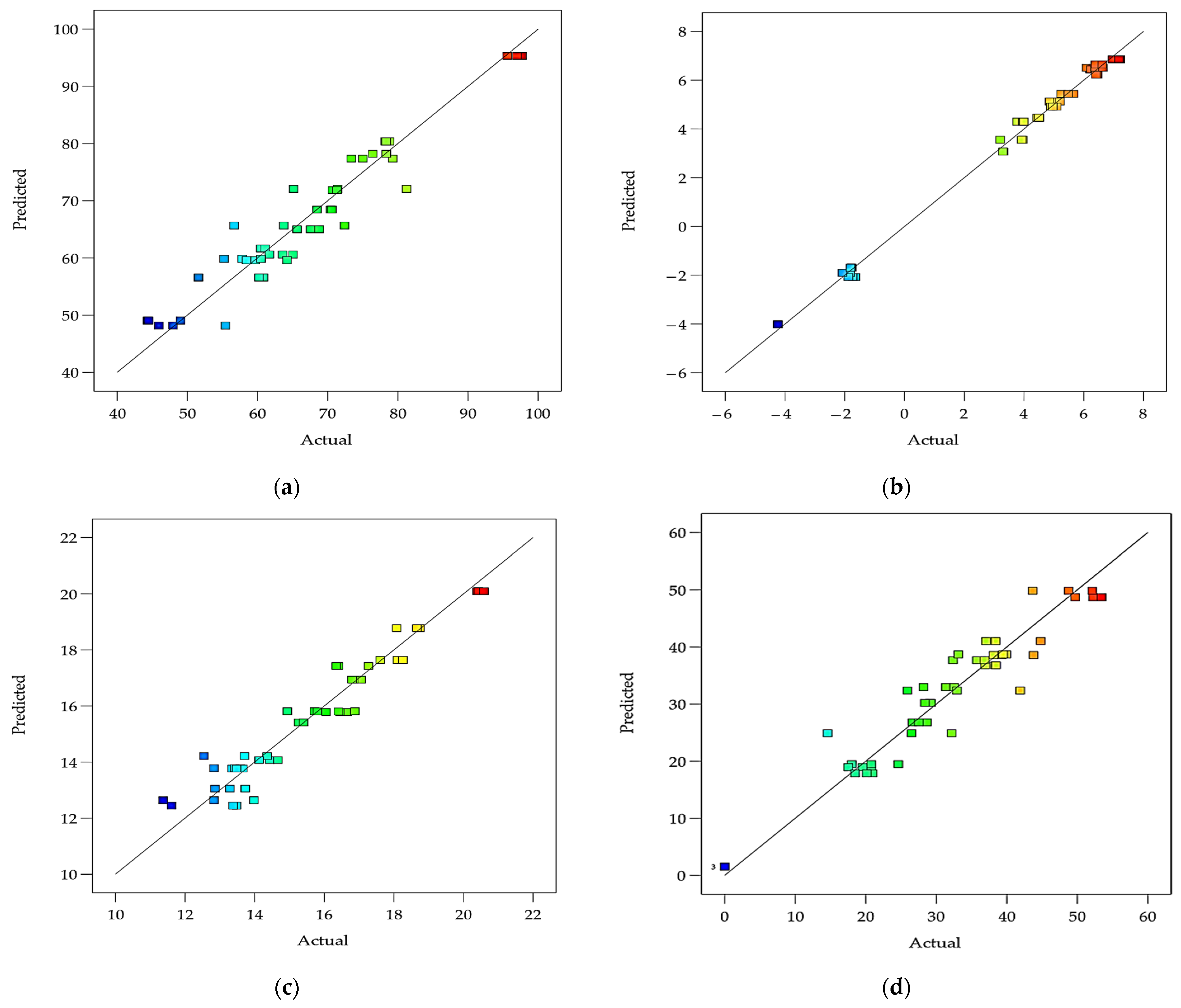

3.4. Modeling of Physicochemical Properties of DPC Drinkable Yogurt

3.5. Texture Profile Analysis of DPC Drinkable Yogurt

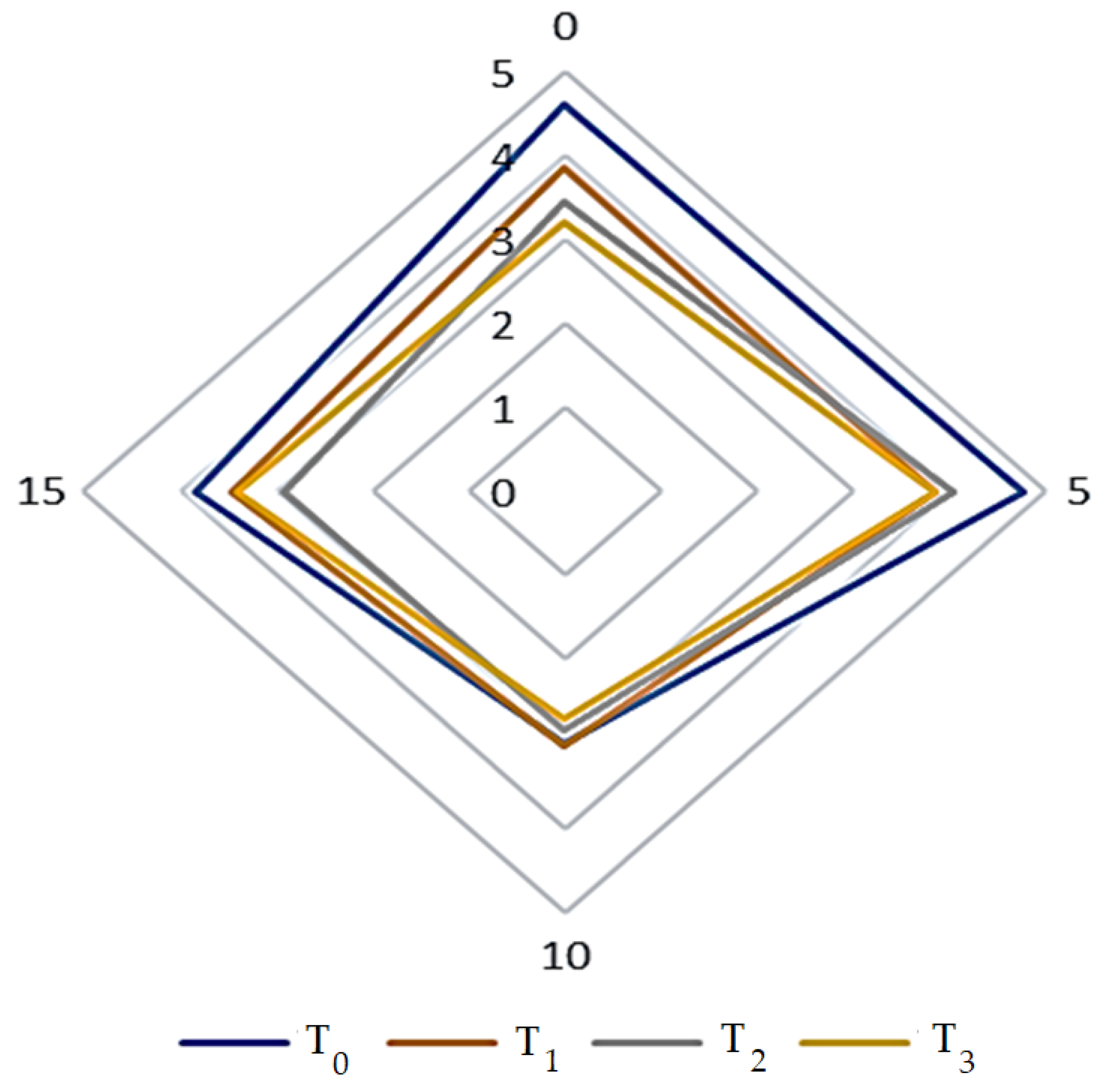

3.6. Sensory Evaluation of DPC Drinkable Yogurt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grimaldi, M.; Pitirollo, O.; Ornaghi, P.; Corradini, C.; Cavazza, A. Valorization of Agro-Industrial Byproducts: Extraction and Analytical Characterization of Valuable Compounds for Potential Edible Active Packaging Formulation. Food Packag. Shelf Life 2022, 33, 100900. [Google Scholar] [CrossRef]

- Tapia-Quirós, P.; Montenegro-Landívar, M.F.; Reig, M.; Vecino, X.; Cortina, J.L.; Saurina, J.; Granados, M. Recovery of Polyphenols from Agri-Food By-Products: The Olive Oil and Winery Industries Cases. Foods 2022, 11, 362. [Google Scholar] [CrossRef] [PubMed]

- Bhardwaj, K.; Najda, A.; Sharma, R.; Nurzyńska-Wierdak, R.; Dhanjal, D.S.; Sharma, R.; Manickam, S.; Kabra, A.; Kuča, K.; Bhardwaj, P. Fruit and Vegetable Peel-Enriched Functional Foods: Potential Avenues and Health Perspectives. Evidence-Based Complement. Altern. Med. 2022, 2022, 8543881. [Google Scholar] [CrossRef]

- Zhu, Z.; Gavahian, M.; Barba, F.J.; Roselló-Soto, E.; Bursać Kovačević, D.; Putnik, P.; Denoya, G.I. Valorization of Waste and By-Products from Food Industries through the Use of Innovative Technologies. In Agri-Food Industry Strategies for Healthy Diets and Sustainability; Barba, F.J., Putnik, P., KovaÄ, D.B., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 249–266. [Google Scholar]

- Galanakis, C.M. Food Use for Social Innovation by Optimizing Food Waste Recovery Strategies. In Food Waste Recovery; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2022; pp. 209–227. [Google Scholar]

- Varnaitė, L.; Keršienė, M.; Šipailienė, A.; Kazernavičiūtė, R.; Venskutonis, P.R.; Leskauskaitė, D. Fiber-Rich Cranberry Pomace as Food Ingredient with Functional Activity for Yogurt Production. Foods 2022, 11, 758. [Google Scholar] [CrossRef]

- Sheir, M.A. Innovative Use of Date (Phoenix dactylifera L.) Press Cake in the Food Industry. Foods Raw Mater. 2022, 10, 2–9. [Google Scholar] [CrossRef]

- Attia, A.I.; Reda, F.M.; Patra, A.K.; Elnesr, S.S.; Attia, Y.A.; Alagawany, M. Date (Phoenix dactylifera L.) by-Products: Chemical Composition, Nutritive Value and Applications in Poultry Nutrition, an Updating Review. Animals 2021, 11, 1133. [Google Scholar] [CrossRef]

- Oladzad, S.; Fallah, N.; Mahboubi, A.; Afsham, N.; Taherzadeh, M.J. Date Fruit Processing Waste and Approaches to Its Valorization: A Review. Bioresour. Technol. 2021, 340, 125625. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Hai, A.; Show, P.L.; Phong Nguyen, T.H. Ferric Oxide/Date Seed Activated Carbon Nanocomposites Mediated Dark Fermentation of Date Fruit Wastes for Enriched Biohydrogen Production. Int. J. Hydrogen Energy 2021, 46, 16631–16643. [Google Scholar] [CrossRef]

- Łopusiewicz, Ł.; Waszkowiak, K.; Polanowska, K.; Mikołajczak, B.; Śmietana, N.; Hrebień-Filisińska, A.; Sadowska, J.; Mazurkiewicz-Zapałowicz, K.; Drozłowska, E. The Effect of Yogurt and Kefir Starter Cultures on Bioactivity of Fermented Industrial By-Product from Cannabis Sativa Production—Hemp Press Cake. Fermentation 2022, 8, 490. [Google Scholar] [CrossRef]

- Zadeh, N.S.; Tedesco, M.; Basso, S.; Ghirardello, D.; Giovando, S.; Battaglia, M.; Zeppa, G. Effect of Yogurt Enrichment with Wood Tannin during Shelf Life: Focus on Physicochemical, Microbiological, and Sensory Characteristics. Foods 2023, 12, 405. [Google Scholar] [CrossRef]

- Desobry-Banon, S.; Vetier, N.; Hardy, J. Health Benefits of Yogurt Consumption. A Review. Int. J. Food Prop. 1999, 2, 1–12. [Google Scholar] [CrossRef]

- Andrade, R.D.; Arteaga, M.R.; Simanca, M.M. Efecto Del Salvado de Trigo En El Comportamiento Reológico Del Yogurt de Leche de Búfala. Inf. Tecnol. 2010, 21, 117–124. [Google Scholar] [CrossRef]

- Mittal, M.; Thakur, A.; Kaushik, R.; Chawla, P. Physicochemical Properties of Ocimum Sanctum Enriched Herbal Fruit Yoghurt. J. Food Process. Preserv. 2020, 44, e14976. [Google Scholar] [CrossRef]

- Sigdel, A.; Ojha, P.; Karki, T.B. Phytochemicals and Syneresis of Osmo-Dried Mulberry Incorporated Yoghurt. Food Sci. Nutr. 2018, 6, 1045–1052. [Google Scholar] [CrossRef]

- Hadjimbei, E.; Botsaris, G.; Chrysostomou, S. Beneficial Effects of Yoghurts and Probiotic Fermented Milks and Their Functional Food Potential. Foods 2022, 11, 2691. [Google Scholar] [CrossRef] [PubMed]

- Khalaf, A.T.; Wei, Y.; Alneamah, S.J.A.; Al-Shawi, S.G.; Kadir, S.Y.A.; Zainol, J.; Liu, X. What Is New in the Preventive and Therapeutic Role of Dairy Products as Nutraceuticals and Functional Foods? Biomed Res. Int. 2021, 2021, 8823222. [Google Scholar] [CrossRef]

- Sanyal, M.K.; Pal, S.C.; Gangopadhyay, S.K.; Dutta, S.K.; Ganguli, D.; Das, S.; Maiti, P. Influence of Stabilizers on Quality of Sandesh from Buffalo Milk. J. Food Sci. Technol. 2011, 48, 740–744. [Google Scholar] [CrossRef]

- Bruzantin, F.P.; Daniel, J.L.P.; da Silva, P.P.M.; Spoto, M.H.F. Physicochemical and Sensory Characteristics of Fat-Free Goat Milk Yogurt with Added Stabilizers and Skim Milk Powder Fortification. J. Dairy Sci. 2016, 99, 3316–3324. [Google Scholar] [CrossRef]

- Waszkiewicz-Robak, B. Food Additives Applied in Milk Fermented Beverages. Ferment. Fruits Veg. Ind. 2012, 56, 4–6. [Google Scholar]

- Soomro, A.H. Effect of Milk Source and Stabilizers on the Compositional and Sensorial Quality of Yoghurt. Pure Appl. Biol. 2016, 5, 1316–1322. [Google Scholar] [CrossRef]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making Sense of the “Clean Label” Trends: A Review of Consumer Food Choice Behavior and Discussion of Industry Implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Karaca, O.; Güzeler, N.; Tangüler, H.; Yaşar, K.; Akın, M. Effects of Apricot Fibre on the Physicochemical Characteristics, the Sensory Properties and Bacterial Viability of Nonfat Probiotic Yoghurts. Foods 2019, 8, 33. [Google Scholar] [CrossRef]

- Tosif, M.M.; Najda, A.; Bains, A.; Kaushik, R.; Dhull, S.B.; Chawla, P.; Walasek-Janusz, M. A Comprehensive Review on Plant-Derived Mucilage: Characterization, Functional Properties, Applications, and Its Utilization for Nanocarrier Fabrication. Polymers 2021, 13, 1066. [Google Scholar] [CrossRef]

- de Pérez-Chabela, M.L.; Cebollón-Juárez, A.; Bosquez-Molina, E.; Totosaus, A. Mango Peel Flour and Potato Peel Flour as Bioactive Ingredients in the Formulation of Functional Yogurt. Food Sci. Technol. 2021, 42. [Google Scholar] [CrossRef]

- Diep, T.T.; Yoo, M.J.Y.; Rush, E. Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt. Foods 2021, 11, 79. [Google Scholar] [CrossRef]

- Mkadem, W.; Belguith, K.; Ben Zid, M.; Boudhrioua, N. Fortification of Traditional Fermented Milk “Lben” with Date Powder: Physicochemical and Sensory Attributes. In Proceedings of the 1st International Electronic Conference on Processes: Processes System Innovation, Online, 17 May 2022; MDPI: Basel, Switzerland; p. 43. [Google Scholar]

- Dello Staffolo, M.; Bertola, N.; Martino, M.; Bevilacqua, A. Influence of Dietary Fiber Addition on Sensory and Rheological Properties of Yogurt. Int. Dairy J. 2004, 14, 263–268. [Google Scholar] [CrossRef]

- Alqahtani, N.K.; Alnemr, T.M.; Ahmed, A.R.; Ali, S. Effect of Inclusion of Date Press Cake on Texture, Color, Sensory, Microstructure, and Functional Properties of Date Jam. Processes 2022, 10, 2442. [Google Scholar] [CrossRef]

- Mkadem, W.; Belguith, K.; Semmar, N.; Ben Zid, M.; ElHatmi, H.; Boudhrioua, N. Effect of Process Parameters on Quality Attributes of Lben: Correlation between Physicochemical and Sensory Properties. LWT 2022, 155, 112987. [Google Scholar] [CrossRef]

- AOAC Association of Official Analytical Chemists. Association of Official Analytical Chemists Gaithersburg (Maryland), 19th ed.; AOAC International: Washington, DC, USA, 2012. [Google Scholar]

- Cichońska, P.; Pudło, E.; Wojtczak, A.; Ziarno, M. Effect of the Addition of Whole and Milled Flaxseed on the Quality Characteristics of Yogurt. Foods 2021, 10, 2140. [Google Scholar] [CrossRef]

- Li, L.; Zhao, W.; Feng, X.; Chen, L.; Zhang, L.; Zhao, L. Changes in Fruit Firmness, Cell Wall Composition, and Transcriptional Profile in the Yellow Fruit Tomato 1 (Yft1) Mutant. J. Agric. Food Chem. 2019, 67, 463–472. [Google Scholar] [CrossRef]

- Hunter, R.S.; Harold, R.w. The Measurement of Appearance; John Wiley and Sons: Hoboken, NJ, USA, 1987; Volume 29. [Google Scholar]

- Mousavi, M.; Heshmati, A.; Daraei Garmakhany, A.; Vahidinia, A.; Taheri, M. Texture and Sensory Characterization of Functional Yogurt Supplemented with Flaxseed during Cold Storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef]

- Wang, C.; Gao, F.; Zhang, T.; Wang, Y.; Guo, M. Physiochemical, Textural, Sensory Properties and Probiotic Survivability of Chinese Laosuan Nai (Protein-Fortified Set Yoghurt) Using Polymerised Whey Protein as a Co-Thickening Agent. Int. J. Dairy Technol. 2015, 68, 261–269. [Google Scholar] [CrossRef]

- Chambers IV, E. Analysis of Sensory Properties in Foods: A Special Issue. Foods 2019, 8, 291. [Google Scholar] [CrossRef] [PubMed]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer: New York, NY, USA, 2010; Volume 2. [Google Scholar]

- Al-Farsi, M.; Alasalvar, C.; Al-Abid, M.; Al-Shoaily, K.; Al-Amry, M.; Al-Rawahy, F. Compositional and Functional Characteristics of Dates, Syrups, and Their by-Products. Food Chem. 2007, 104, 943–947. [Google Scholar] [CrossRef]

- Hashim, I.; Khalil, A. Composition and Functional Properties of the Date Fruit Residue a By-Product of Date Syrup/Debis Production. Nutr. Food Technol. 2015, 1, 2. Available online: https://www.sciforschenonline.org/journals/nutrition-food/article-data/NFTOA-1-108/NFTOA-1-108.pdf (accessed on 1 January 2023). [CrossRef]

- Majzoobi, M.; Karambakhsh, G.; Golmakani, M.T.; Mesbahi, G.R.; Farahnaky, A. Chemical Composition and Functional Properties of Date Press Cake, an Agro-Industrial Waste. J. Agric. Sci. Technol. 2019, 21, 1807–1817. [Google Scholar]

- Alqahtani, N.K.; Barbabosa-Pliego, A.; Alnemr, T.M. Influence of Sweet Lupine Husk’s Addition on Fat-Free Stirred Yogurt Properties. Int. J. Dairy Sci. 2021, 16, 41–47. [Google Scholar] [CrossRef]

- Alqahtani, N.K.; Darwish, A.A.; El-Menawy, R.K.; Alnemr, T.M.; Aly, E. Textural and Organoleptic Attributes and Antioxidant Activity of Goat Milk Yoghurt with Added Oat Flour. Int. J. Food Prop. 2021, 24, 433–445. [Google Scholar] [CrossRef]

- Kong, X.; Xiao, Z.; Du, M.; Wang, K.; Yu, W.; Chen, Y.; Liu, Z.; Cheng, Y.; Gan, J. Physicochemical, Textural, and Sensorial Properties of Soy Yogurt as Affected by Addition of Low Acyl Gellan Gum. Gels 2022, 8, 453. [Google Scholar] [CrossRef]

- Bhat, S.V.; Deva, A.M.; Amin, T. Physicochemical and Textural Properties of Yogurt Fortified with Psyllium (Plantago ovate) Husk. J. Food Process. Preserv. 2017, 42, e13425. [Google Scholar] [CrossRef]

- Eke, M.O.; Olaitan, N.I.; Sule, H.I. Nutritional Evaluation of Yoghurt-like Product from Baobab (Adansonia digitata) Fruit Pulp Emulsion and the Micronutrient Content of Baobab Leaves. Adv. J. Food Sci. Technol. 2013, 5, 1266–1270. [Google Scholar] [CrossRef]

- Meenakshi, V.; Suganya, S.; Umamaheswari, T. Formulation of Value Enriched Probiotic Fruit Yoghurt. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1440–1450. [Google Scholar] [CrossRef]

- Manzoor, S.; Yusof, Y.A.; Chin, N.L.; Mohamed Amin Tawakkal, I.S.; Fikry, M.; Chang, L.S. Quality Characteristics and Sensory Profile of Stirred Yogurt Enriched with Papaya Peel Powder. Pertanika J. Trop. Agric. Sci. 2019, 42, 519–533. [Google Scholar]

- do Espírito Santo, A.P.; Perego, P.; Converti, A.; Oliveira, M.N. Influence of Milk Type and Addition of Passion Fruit Peel Powder on Fermentation Kinetics, Texture Profile and Bacterial Viability in Probiotic Yoghurts. LWT 2012, 47, 393–399. [Google Scholar] [CrossRef]

- Dabija, A.; Oroian, M.A.; Mironeasa, S.; Sidor, A.M. Physictochemical and Sensory Properties of Yogurt with Seabuckthorn Powder, Rosehip Powder and Grape Seed Extract during Storage. In Proceedings of the 18th International Multidisciplinary Scientific GeoConference SGEM2018, Albena, Bulgaria, 30 June–9 July 2018; Volume 18, pp. 429–436. [Google Scholar] [CrossRef]

- Matter, A.; Mahmoud, A.M.; Zidan, N.S. Fruit Flavored Yoghurt: Chemical, Functional and Rheological Properties. Int. J. Environ. Agric. Res. 2016, 2, 1–11. [Google Scholar]

- Mahdian, E.; Tehrani, M.M. Evaluation the Effect of Milk Total Solids on the Relationship Between Growth and Activity of Starter Cultures and Quality of Concentrated Yoghurt. J. Agric. Environ. Sci. 2007, 2, 587–592. [Google Scholar]

- Garcia-Amezquita, L.E.; Tejada-Ortigoza, V.; Serna-Saldivar, S.O.; Welti-Chanes, J. Dietary Fiber Concentrates from Fruit and Vegetable By-Products: Processing, Modification, and Application as Functional Ingredients. Food Bioprocess Technol. 2018, 11, 1439–1463. [Google Scholar] [CrossRef]

- Lee, H.S.; Song, M.W.; Kim, K.-T.; Hong, W.-S.; Paik, H.-D. Antioxidant Effect and Sensory Evaluation of Yogurt Supplemented with Hydroponic Ginseng Root Extract. Foods 2021, 10, 639. [Google Scholar] [CrossRef]

- Arabshahi-Delouee, S.; Ghochani, S.R.; Mohammadi, A. Effect of Flaxseed (Linum usitatissimum) Mucilage Mucilage on Physicochemical and Sensorial Properties of Semi-Fat Set Yoghurt. J. Food Biosci. Technol. 2020, 10, 91–100. [Google Scholar]

- Rojas-torres, S.A.; Quintana, S.E.; García-zapateiro, L.A. Natural Yogurt Stabilized with Hydrocolloids from Butternut Squash (Cucurbita moschata) Seeds: Effect on Physicochemical, Rheological Properties and Sensory Perception. Fluids 2021, 6, 251. [Google Scholar] [CrossRef]

- Güler-Akın, M.B.; Ferliarslan, I.; Serdar Akın, M. Apricot Probiotic Drinking Yoghurt Supplied with Inulin and Oat Fiber. Adv. Microbiol. 2016, 06, 999–1009. [Google Scholar] [CrossRef]

- Tseng, A.; Zhao, Y. Wine Grape Pomace as Antioxidant Dietary Fibre for Enhancing Nutritional Value and Improving Storability of Yogurt and Salad Dressing. Food Chem. 2013, 138, 356–365. [Google Scholar] [CrossRef] [PubMed]

- Łopusiewicz, Ł.; Drozłowska, E.; Siedlecka, P.; Mężyńska, M.; Bartkowiak, A.; Sienkiewicz, M.; Zielińska-Bliźniewska, H.; Kwiatkowski, P. Development, Characterization, and Bioactivity of Non-Dairy Kefir-Like Fermented Beverage Based on Flaxseed Oil Cake. Foods 2019, 8, 544. [Google Scholar] [CrossRef]

- Alqahtani, N.K.; Helal, A.; Alnemr, T.M.; Marquez, O. Influence of Tomato Pomace Inclusion on the Chemical, Physical and Microbiological Properties of Stirred Yoghurt. Int. J. Dairy Sci. 2020, 15, 152–160. [Google Scholar] [CrossRef]

- Otálora, M.C.; Wilches-Torres, A.; Gómez Castaño, J.A. Evaluation of Guava Pulp Microencapsulated in Mucilage of Aloe Vera and Opuntia Ficus-Indica as a Natural Dye for Yogurt: Functional Characterization and Color Stability. Foods 2022, 11, 2380. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, M.; Alqahtani, N.K. Design and Validation of Automated Sensor-Based Artificial Ripening System Combined with Ultrasound Pretreatment for Date Fruits. Agronomy 2022, 12, 2805. [Google Scholar] [CrossRef]

- Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Saleh, A.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Ababtain, I.A. Rheological, Textural, and Sensory Properties of Non-Fat Yogurt Containing Cress (Lepidium sativum) Seed Gum and Various Starches. Food Sci. Technol. 2022, 42. [Google Scholar] [CrossRef]

- Brodziak, A.; Król, J.; Matwijczuk, A.; Czernecki, T.; Glibowski, P.; Wlazło, Ł.; Litwińczuk, A. Effect of Sea Buckthorn (Hippophae rhamnoides L.) Mousse on Properties of Probiotic Yoghurt. Appl. Sci. 2021, 11, 545. [Google Scholar] [CrossRef]

- Mendoza-Taco, M.M.; Cruz-Hernández, A.; Ochoa-Flores, A.A.; Hernández-Becerra, J.A.; Gómez-Vázquez, A.; Moo-Huchin, V.M.; Piñeiro-Vázquez, Á.; Chay-Canul, A.J.; Vargas-Bello-Pérez, E. Physicochemical Characteristics of Yogurt from Sheep Fed with Moringa Oleifera Leaf Extracts. Animals 2022, 12, 110. [Google Scholar] [CrossRef]

- Aljutaily, T.; Barakat, H.; Moustafa, M.M.A.; Rehan, M. Incorporation of Sukkari Date in Probiotic-Enriched Fermented Camel Milk Improves the Nutritional, Physicochemical, and Organoleptical Characteristics. Fermentation 2022, 8, 5. [Google Scholar] [CrossRef]

- Fathy, H.M.; Abd El-Maksoud, A.A.; Cheng, W.; Elshaghabee, F.M.F. Value-Added Utilization of Citrus Peels in Improving Functional Properties and Probiotic Viability of Acidophilus-Bifidus-Thermophilus (ABT)-Type Synbiotic Yoghurt during Cold Storage. Foods 2022, 11, 2677. [Google Scholar] [CrossRef] [PubMed]

| Materials | Properties | Values |

|---|---|---|

| Milk | TS (g/100 g) | 11.19 ± 0.11 |

| Protein (g/100 g) | 2.97 ± 0.02 | |

| Fat (g/100 g) | 2.26 ± 0.05 | |

| Ash (g/100 g) | 0.68 ± 0.01 | |

| pH | 6.76 ± 0.04 | |

| DPC | Moisture (g/100 g) | 7.40 ± 0.12 |

| Protein (g/100 g) | 4.52 ± 0.21 | |

| Fat (g/100 g) | 2.69 ± 0.03 | |

| Ash (g/100 g) | 2.26 ± 0.15 | |

| Crude fiber (g/100 g) | 8.36 ± 0.11 | |

| * Total saccharides (g/100 g) | 79.13 ± 2.35 | |

| WHC (g/100 g) | 3.49 ± 0.11 | |

| Solubility (g/100 g) | 15.46 ± 0.42 | |

| pH | 5.32 ± 0.05 | |

| L* | 64.52 ± 8.79 | |

| a* | 11.19 ± 1.20 | |

| b* | 27.28 ± 3.14 |

| Treatments | Total Solids (g/100 g) | Protein (g/100 g) | Fat (g/100 g) |

|---|---|---|---|

| T0 | 11.19 ± 0.11 d | 2.97 ± 0.02 d | 2.26 ± 0.05 b |

| T1 | 11.83 ± 0.03 c | 3.10 ± 0.10 c | 2.34 ± 0.01 a |

| T2 | 12.92 ± 0.05 b | 3.30 ± 0.04 b | 2.34 ± 0.02 a |

| T3 | 13.45 ± 0.13 a | 3.42 ± 0.01 a | 2.35 ± 0.02 a |

| Criteria | Physicochemical Properties of DPC Drinkable Yogurt | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| pH | Acidity | Syneresis | WHC | Viscosity | L* | a* | b* | ΔE | |

| Std. Dev. | 0.040 | 0.014 | 0.783 | 0.405 | 30.85 | 3.916 | 0.264 | 0.706 | 3.99 |

| Mean | 4.47 | 0.738 | 49.77 | 53.35 | 2492.85 | 66.86 | 3.364 | 15.48 | 31.02 |

| C.V.% | 0.894 | 1.86 | 1.57 | 0.759 | 1.24 | 5.858 | 7.875 | 4.565 | 12.85 |

| R² | 0.779 | 0.973 | 0.961 | 0.989 | 0.990 | 0.919 | 0.995 | 0.922 | 0.921 |

| Adjusted R² | 0.752 | 0.969 | 0.956 | 0.987 | 0.988 | 0.868 | 0.994 | 0.905 | 0.902 |

| Predicted R² | 0.717 | 0.964 | 0.949 | 0.983 | 0.985 | 23.78 | 0.993 | 0.874 | 0.870 |

| Adeq Precision | 18.316 | 58.098 | 48.999 | 64.421 | 74.943 | 3.916 | 89.907 | 23.717 | 26.563 |

| Texture Parameters | Storage Days | T0 | T1 | T2 | T3 |

|---|---|---|---|---|---|

| Hardness, g | 0 | 316.23 ± 8.28 Ad | 432.73 ± 2.51 Bc | 451.83 ± 1.60 Bb | 491.83 ± 3.68 Ba |

| 15 | 506.60 ± 7.93 Bd | 524.50 ± 9.35 Ac | 547.76 ± 4.28 Ab | 581.33 ± 2.06 Aa | |

| Adhesiveness, g s | 0 | −286.00 ± 4.35 Aa | −349.00 ± 8.54 Ab | −371.33 ± 1.52 Ac | −368.00 ± 5.29 Ac |

| 15 | −411.33 ± 1.52 Ba | −445.00 ± 6.08 Bb | −453.33 ± 2.51 Bc | −455.33 ± 5.03 Bc | |

| Springiness | 0 | 0.83 ± 0.00 Ac | 0.86 ± 0.02 Ab | 0.92 ± 0.01 Aa | 0.93 ± 0.005 Aa |

| 15 | 0.71 ± 0.005 Bb | 0.73 ± 0.01 Bb | 0.75 ± 0.04 Bab | 0.79 ± 0.01 Ba | |

| Cohesiveness | 0 | 0.80 ± 0.005 Ad | 0.84 ± 0.005 Ac | 0.86 ± 0.005 Ab | 0.97 ± 0.01 Aa |

| 15 | 0.54 ± 0.04 Bb | 0.57 ± 0.01 Bb | 0.70 ± 0.005 Ba | 0.73 ± 0.02 Ba | |

| Gumminess | 0 | 399.10 ± 0.85 Ab | 142.23 ± 0.32 Bd | 367.66 ± 0.49 Ac | 578.56 ± 0.51 Aa |

| 15 | 282.43–0.30 Bc | 244.80 ± 0.26 Ad | 366.5 ± 0.50 Ba | 291.16 ± 1.04 Bb | |

| Resilience | 0 | 0.64 ± 0.02 Aa | 0.52 ± 0.02 Ab | 0.55 ± 0.04 Ab | 0.31 ± 0.01 Ac |

| 15 | 0.53 ± 0.02 Ba | 0.34 ± 0.04 Bb | 0.15 ± 0.04 Bc | 0.10 ± 0.01 Bc |

| Sensory Parameters | Storage Days | T0 | T1 | T2 | T3 |

|---|---|---|---|---|---|

| Color | 0 | 4.30 ± 1.34 Aa | 4.00 ± 1.08 ABa | 3.20 ± 0.88 Bb | 2.90 ± 1.26 Bb |

| 5 | 4.70 ± 0.74 Aa | 4.26 ± 0.94 Aab | 4.40 ± 0.85 Aab | 4.16 ± 1.01 Ab | |

| 10 | 3.80 ± 0.84 Ba | 3.53 ± 0.77 Cab | 3.43 ± 0.72 Bab | 3.16 ± 0.98 Bb | |

| 15 | 4.30–0.59 Aa | 3.66 ± 0.66 BCbc | 3.26 ± 1.04 Bc | 3.80 ± 0.80 Ab | |

| Texture | 0 | 4.00 ± 1.28 Ba | 3.76 ± 1.16 Aab | 3.46 ± 1.10 ABab | 3.26 ± 1.11 Bb |

| 5 | 4.63 ± 0.55 Aa | 3.86 ± 1.04 Ab | 3.70 ± 1.11 Ab | 3.70 ± 1.41 ABb | |

| 10 | 3.50 ± 0.86 Ca | 3.50 ± 0.97 Aa | 3.03 ± 0.88 Ba | 3.23 ± 1.00 Ba | |

| 15 | 3.90 ± 0.66 BCa | 3.73 ± 0.90 Aa | 3.10 ± 0.92 Bb | 3.86 ± 1.10 Aa | |

| Flavor | 0 | 4.10 ± 1.29 Ba | 3.73 ± 1.31 Aab | 3.10 ± 1.29 Bbc | 3.00 ± 1.48 Bc |

| 5 | 4.56 ± 0.62 Aa | 3.80 ± 1.39 Ab | 4.10 ± 0.88 Aab | 3.90 ± 1.34 Ab | |

| 10 | 2.96 ± 0.92 Ca | 3.10 ± 0.88 Ba | 2.90 ± 0.99 Ba | 2.76 ± 1.04 Ba | |

| 15 | 3.80 ± 0.61 Ba | 3.53 ± 0.93 ABab | 3.03 ± 1.12 Bb | 3.40 ± 1.19 ABab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqahtani, N.K.; Alnemr, T.M.; Alsalem, A.K.; Alotaibi, M.M.; Mohammed, M. Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality. Foods 2023, 12, 1219. https://doi.org/10.3390/foods12061219

Alqahtani NK, Alnemr TM, Alsalem AK, Alotaibi MM, Mohammed M. Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality. Foods. 2023; 12(6):1219. https://doi.org/10.3390/foods12061219

Chicago/Turabian StyleAlqahtani, Nashi K., Tareq M. Alnemr, Abdullah K. Alsalem, Mutlaq M. Alotaibi, and Maged Mohammed. 2023. "Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality" Foods 12, no. 6: 1219. https://doi.org/10.3390/foods12061219

APA StyleAlqahtani, N. K., Alnemr, T. M., Alsalem, A. K., Alotaibi, M. M., & Mohammed, M. (2023). Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality. Foods, 12(6), 1219. https://doi.org/10.3390/foods12061219