Assessing Sensory Attributes and Properties of Infant Formula Milk Powder Driving Consumers’ Preference

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Screening of Sensory Panelists

2.3. Training of Sensory Panelists

2.4. Descriptive Sensory Analysis

2.5. Statistical Analysis

3. Results and Discussion

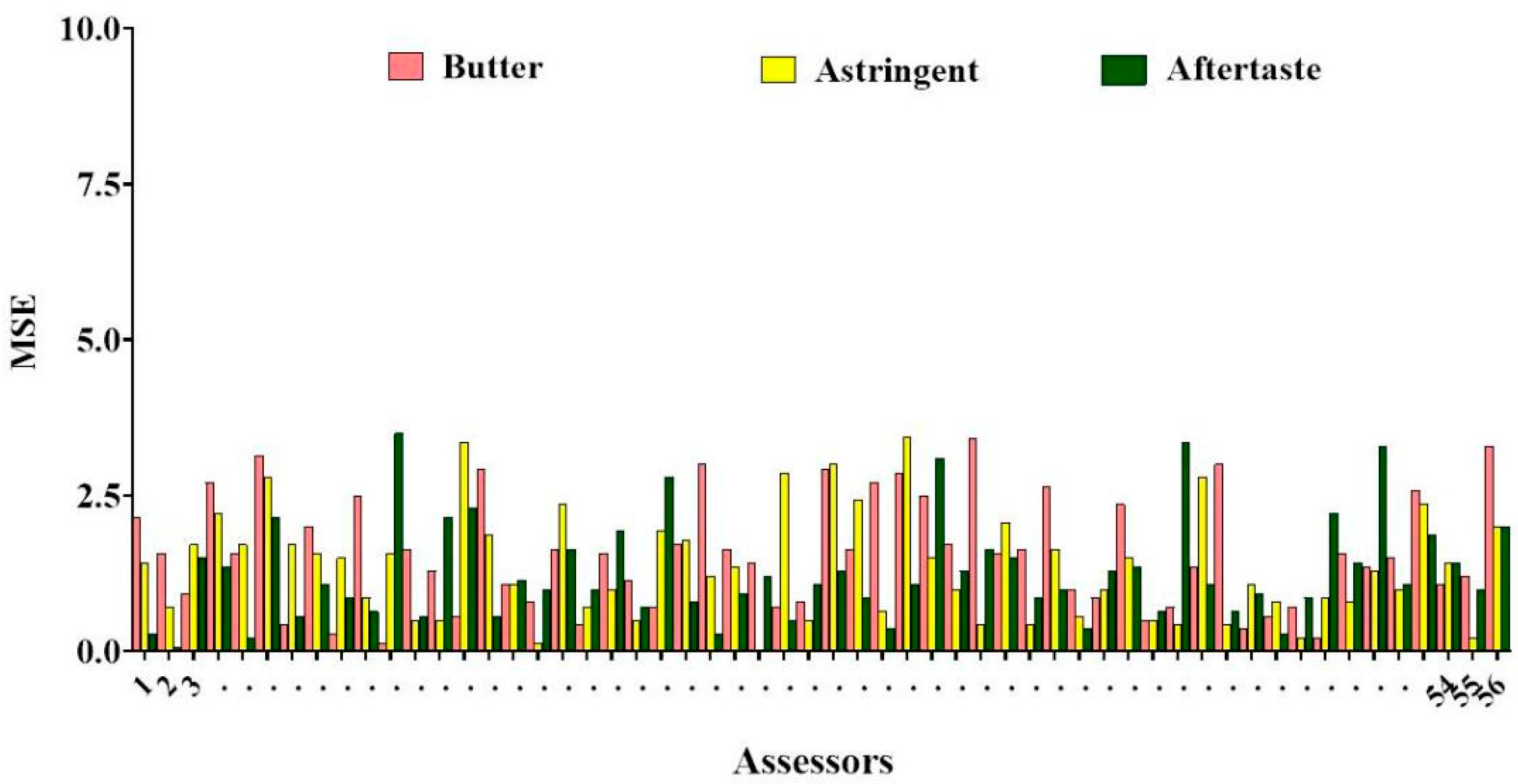

3.1. Sensory Evaluation Skills Assessment

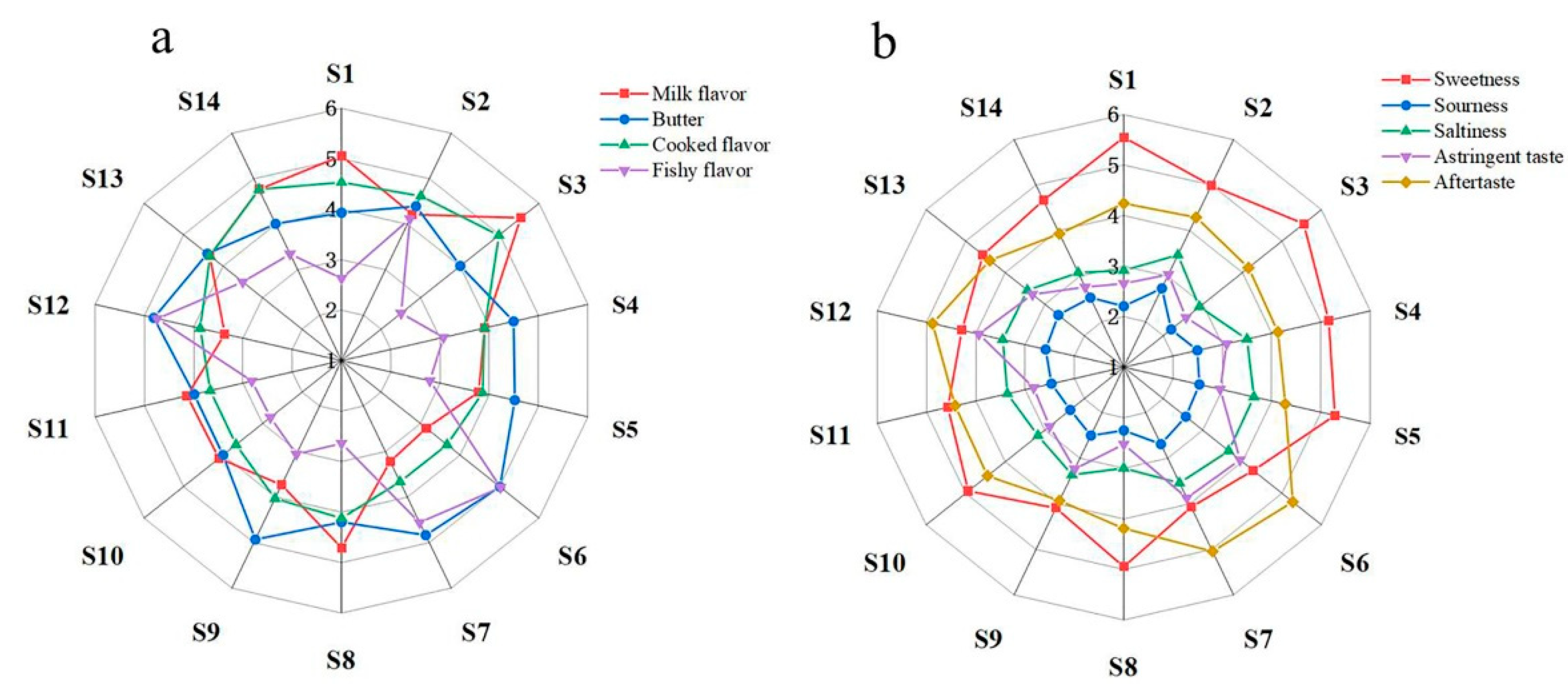

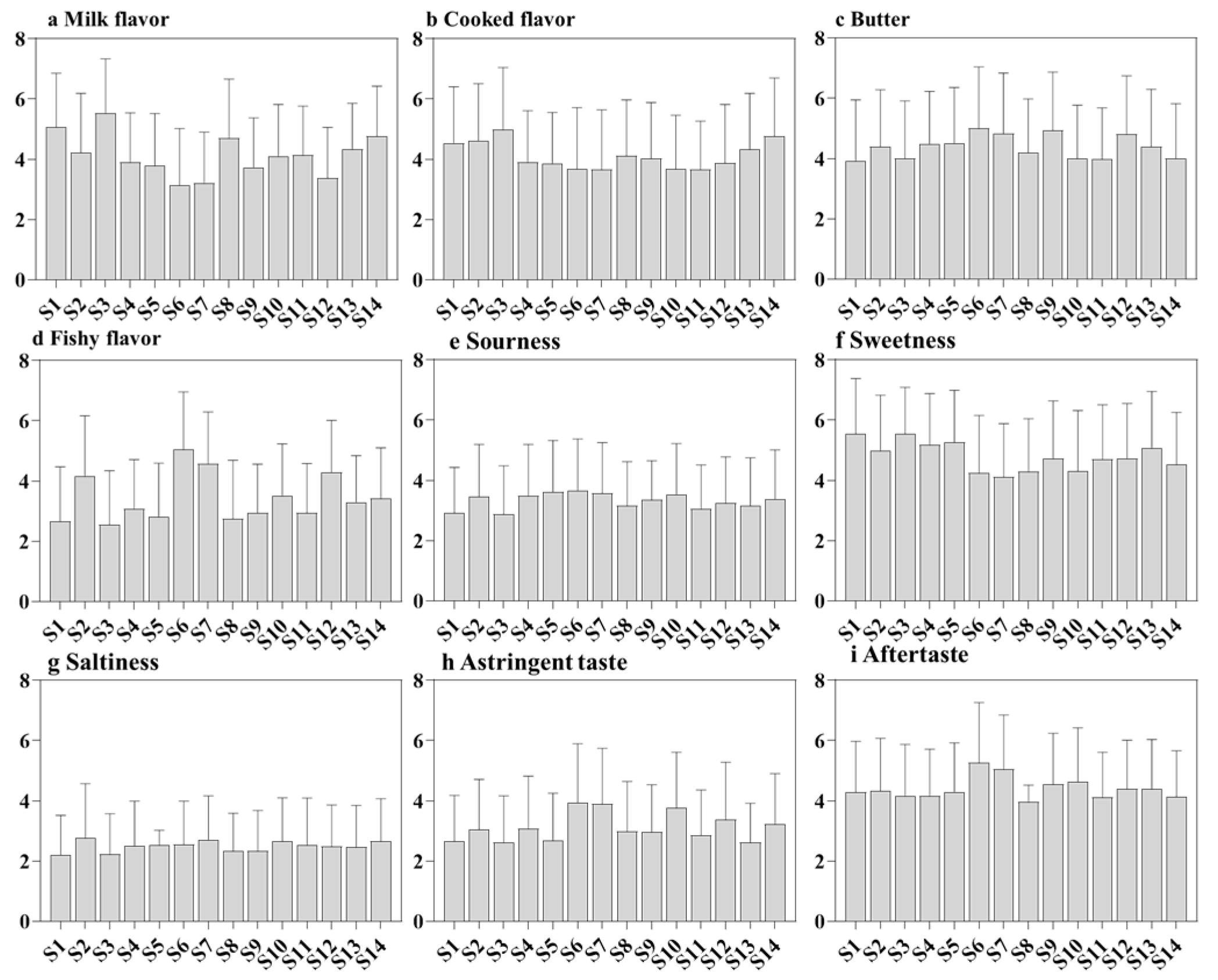

3.2. Descriptive Sensory Analysis of Milk Powder

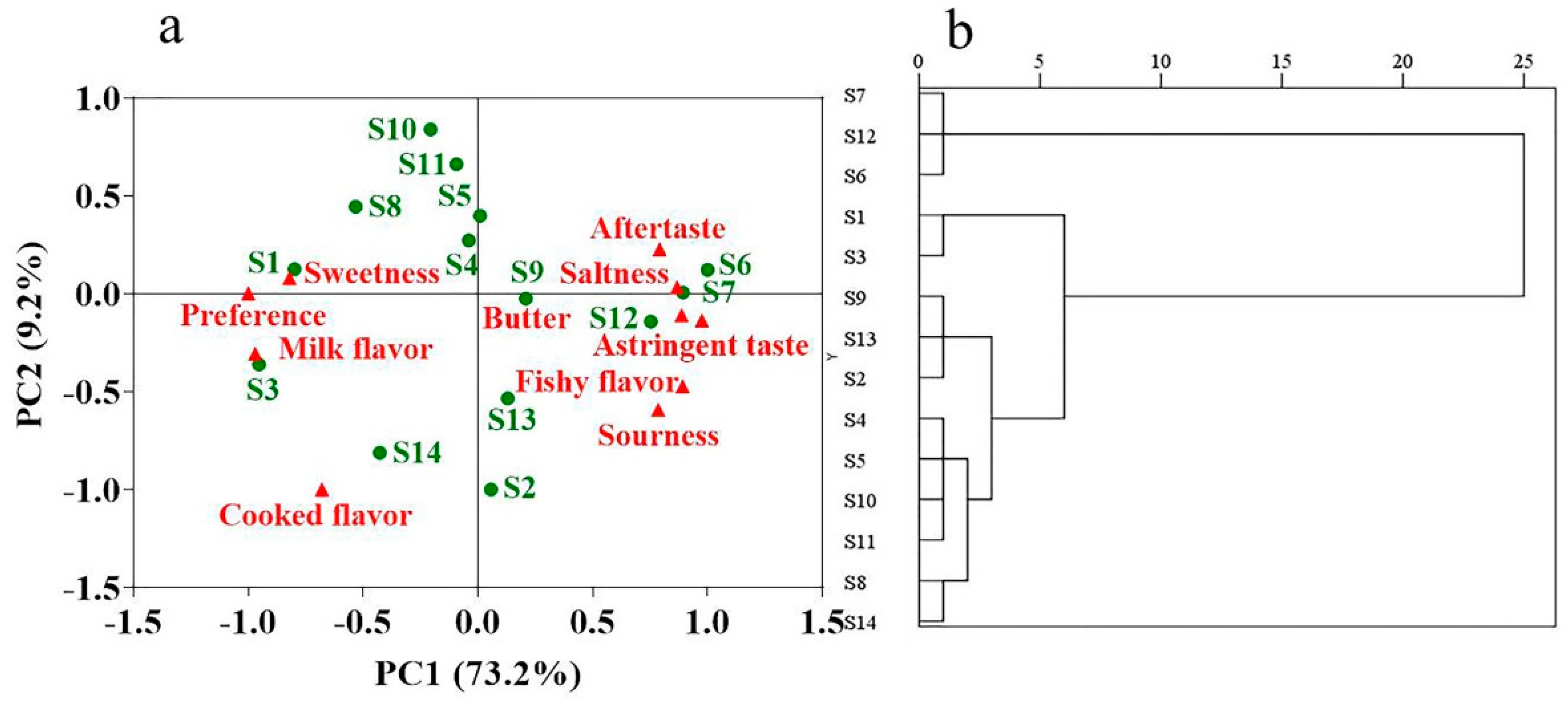

3.3. Relationship between Sensory Attributes and Quality Grades of Milk Powder

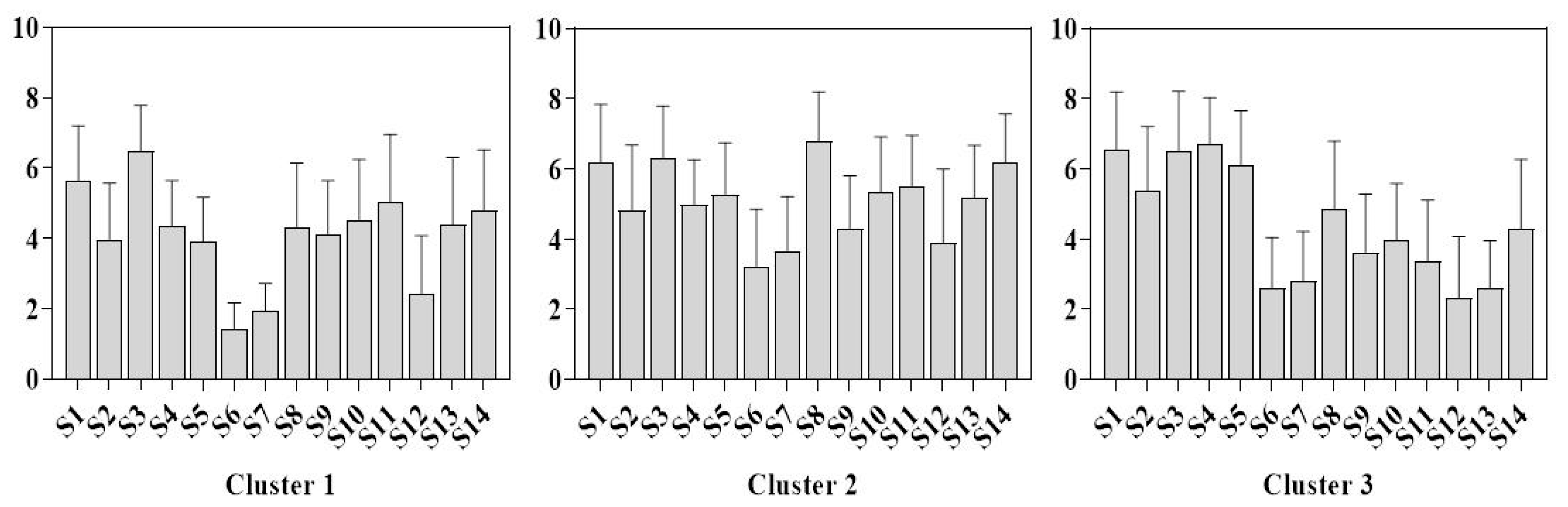

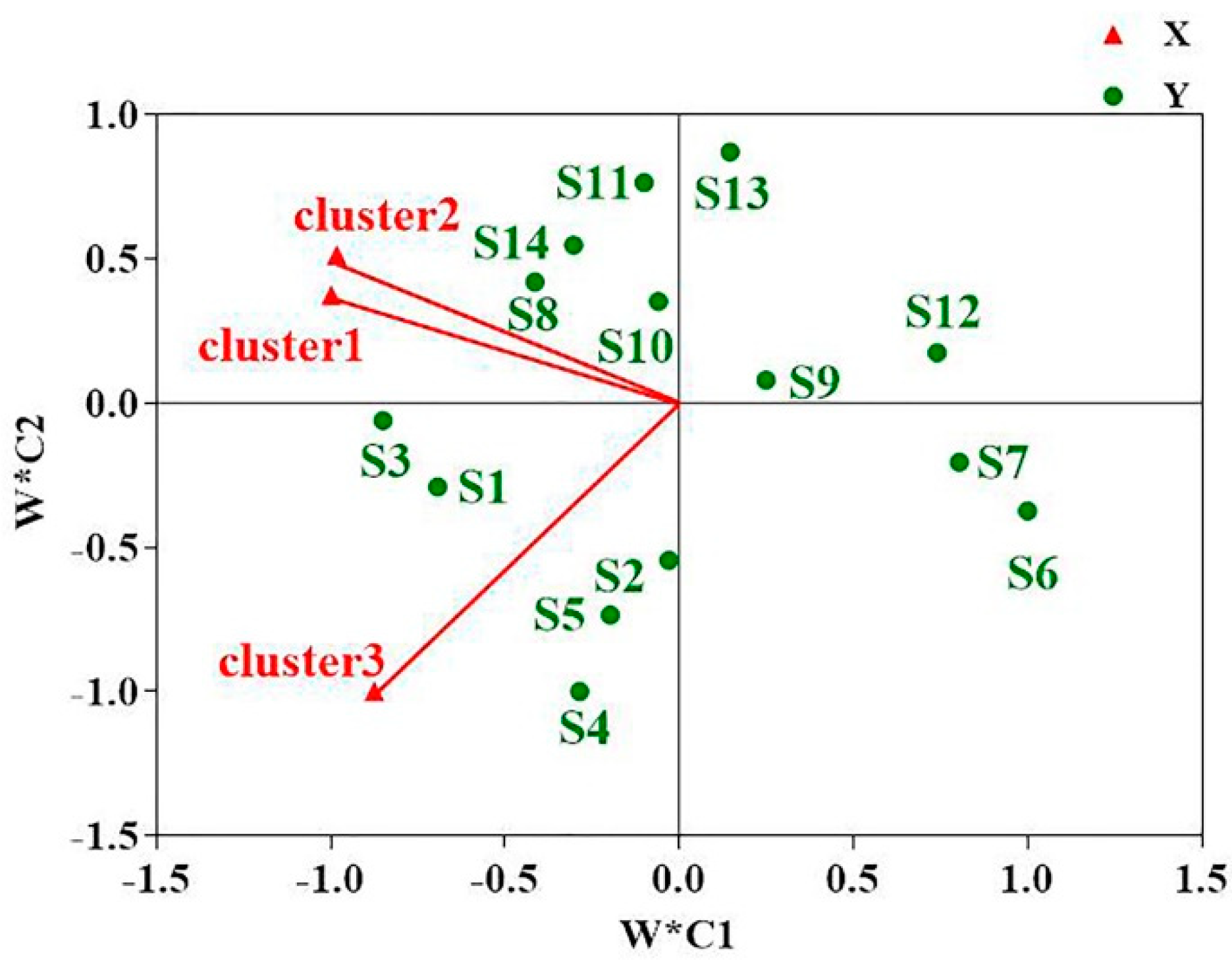

3.4. Preference Analysis and External Preference Mapping

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bode, L.; Raman, A.S.; Murch, S.H.; Rollins, N.C.; Gordon, J.I. Understanding the mother-breastmilk-infant “triad”. Science 2020, 367, 1070–1072. [Google Scholar] [CrossRef] [PubMed]

- Almeida, C.C.; Mendonça Pereira, B.F.; Leandro, K.C.; Costa, M.P.; Spisso, B.F.; Conte-Junior, C.A. Bioactive compounds in infant formula and their effects on infant nutrition and health: A Systematic Literature Review. Int. J. Food Sci. 2021, 2021, 8850080. [Google Scholar] [CrossRef] [PubMed]

- Johnson, S.L. Children’s Food Acceptance Patterns: The Interface of Ontogeny and Nutrition Needs. Nutr. Rev. 2002, 60, S91–S94. [Google Scholar] [CrossRef] [PubMed]

- Mennella, J.A.; Jagnow, C.P.; Beauchamp, G.K. Prenatal and postnatal flavor learning by human infants. Pediatrics 2001, 107, E88. [Google Scholar] [CrossRef] [PubMed]

- Witt, M.; Reutter, K. Embryonic and early fetal development of human taste buds: A transmission electron microscopical study. Anat. Rec. 1996, 2464, 507–523. [Google Scholar] [CrossRef]

- Beauchamp, G.K.; Cowart, B.J.; Moran, M. Developmental changes in salt acceptability in human infants. Dev. Psychobiol. 1986, 19, 17–25. [Google Scholar] [CrossRef] [PubMed]

- Oster, D.R.H. Differential Facial Responses to Four Basic Tastes in Newborns. Child Dev. 1988, 6, 1555–1568. [Google Scholar] [CrossRef]

- Carlson, S.E. Arachidonic acid status of human infants: Influence of gestational sge at birth and diets with very long chainn-3 and n-6 fatty acids. J. Nutr. 1996, 126, 1092S–1098S. [Google Scholar] [CrossRef]

- Smriga, M.; Kameishi, M.; Tori, K. Brief exposureto NaCl during early postnatal development enhances adult intake of sweet and salty compounds. Neuroreport 2002, 13, 2565–2569. [Google Scholar] [CrossRef]

- Ge, W.P.; Yang, X.J.; Wu, X.Y.; Wang, Z.; Geng, W.; Guo, C.F. Phthalate residue in goat milk-based infant formulas manufactured in China. J. Dairy Sci. 2016, 99, 7776–7781. [Google Scholar] [CrossRef]

- He, Y.; Zeng, W.; Zhao, Y.; Zhu, X.; Wan, H.; Zhang, M.; Li, Z. Rapid detection of adulteration of goat milk and goat infant formulas using near-infrared spectroscopy fingerprints. Int. Dairy J. 2023, 137, 105536. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, W.; Zhang, J.; Li, X.; Wu, X.; Li, T.; Li, T.; Zhang, X.; Wang, X. Detection of Bacillus cereus sensu lato from environments associated with goat milk powdered infant formula production facilities. Int. Dairy J. 2018, 83, 10–16. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, M.; Li, F.; Wang, M.; Zhang, Y.; Wei, M.; Chai, Y. Development of matrix certified reference material for accurate determination of docosahexaenoic acid in milk powder. Food Chem. 2023, 406, 135012. [Google Scholar] [CrossRef]

- Zhu, R.; Cheng, H.; Li, L.; Erichsen, H.R.; Petersen, M.A.; Soerensen, J.; Skibsted, L.H. Temperature effect on formation of advanced glycation end products in infant formula milk powder. Int. Dairy J. 2018, 77, 1–9. [Google Scholar] [CrossRef]

- Masuyer, G.; Zhang, S.; Barkho, S.; Shen, Y.; Henriksson, L.; Košenina, S.; Dong, M.; Stenmark, P. Structural characterisation of the catalytic domain of botulinum neurotoxin X—High activity and unique substrate specificity. Sci. Rep. 2018, 8, 4518. [Google Scholar] [CrossRef]

- Phosanam, A.; Chandrapala, J.; Huppertz, T.; Adhikari, B.; Zisu, B. Changes in physicochemical and surface characteristics in model infant milk formula powder (IMF) during storage. Dry Technol. 2021, 39, 2119–2129. [Google Scholar] [CrossRef]

- Gredilla, A.; de Vallejuelo, S.F.; Arana, G.; de Diego, A.; Oliveira, M.L.S.; Da Boit, K. A Rapid Routine Methodology Based on Chemometrics to Evaluate the Toxicity of Commercial Infant Milks Due to Hazardous Elements. Food Anal. Methods 2022, 15, 2312–2322. [Google Scholar] [CrossRef]

- Stone, H.; Sidel, J.; Oliver, S.; Woolsey, A.; Singleton, R.C. Sensory Evaluation by Quantitative Descriptive Analysis. Food Technol. 2004, 23–34. [Google Scholar] [CrossRef]

- Margeta, P.; Kralik, G.; Grčević, M.; Hanžek, D.; Kralik, Z. Importance of sensory evaluation in assessment of egg quality. Poljoprivreda 2019, 25, 56–63. [Google Scholar] [CrossRef]

- Drake, M.A.; Karagul-yuceer, Y.; Cadwallader, K.R.; Civille, G.V.; Tong, P.S. Determination of the sensory attributes of dried milk powders and dairy ingredients. J. Sens. Stud. 2003, 18, 199–216. [Google Scholar] [CrossRef]

- Jolliffe, I.T.; Cadima, J. Principal component analysis: A review and recent developments. Phys. Eng. Sci. 2016, 374, 20150202. [Google Scholar] [CrossRef] [PubMed]

- Torrico, D.D.; Tam, J.; Fuentes, S.; Gonzalez Viejo, C.; Dunshea, F.R. Consumer rejection threshold, acceptability rates, physicochemical properties, and shelf-life of strawberry-flavored yogurts with reductions of sugar. J. Sci. Food Agric. 2020, 100, 3024–3035. [Google Scholar] [CrossRef] [PubMed]

- Moskowitz, H.B. Product testing and sensory evaluation of foods: Marketing and R&D approaches. J. Mark. Res. 1984, 21, 473–474. [Google Scholar] [CrossRef]

- Mcewan, J.A.; Hunter, E.A.; van Gemert, L.J.; Lea, P. Proficiency testing for sensory profile panels: Measuring panel performance. Food Qual. Prefer. 2002, 13, 181–190. [Google Scholar] [CrossRef]

- Tomic, O.; Nilsen, A.; Martens, M.; Næs, T. Visualization of sensory profiling data for performance monitoring. LWT—Food Sci. Technol. 2007, 40, 262–269. [Google Scholar] [CrossRef]

- Barker, S.; Moss, R.; Mcsweeney, M.B. Identification of sensory properties driving consumers’ liking of commercially available kale and arugula. J. Sci. Food Agric. 2022, 102, 198–205. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.J. Short communication: Formation of oxidized flavor compounds in concentrated milk and distillate during milk concentration. J. Dairy Sci. 2016, 99, 9647–9651. [Google Scholar] [CrossRef]

- Li, Y.H.; Zhang, L.W.; Wang, W.J.; Han, X. Differences in particle characteristics and oxidized flavor as affected by heat-related processes of milk powder. J. Dairy Sci. 2013, 96, 4784–4793. [Google Scholar] [CrossRef]

- Clarke, H.J.; O’Sullivan, M.G.; Kerry, J.P.; Kilcawley, K.N. Correlating Volatile Lipid Oxidation Compounds with Consumer Sensory Data in Dairy Based Powders during Storage. Antioxidants 2020, 9, 338. [Google Scholar] [CrossRef]

- Solah, V.A.; Staines, V.; Honda, S.; Limley, H.A. Measurement of Milk Color and Composition: Effect of Dietary Intervention on Western Australian Holstein-Friesian Cow’s Milk Quality. J. Food Sci. 2007, 72, S560–S566. [Google Scholar] [CrossRef]

- Karagül-Yüceer, Y.; Drake, M.; Cadwallader, K.R. Aroma-Active Components of Nonfat Dry Milk. J. Agric. Food Chem. 2001, 49, 2948–2953. [Google Scholar] [CrossRef] [PubMed]

- Josephson, R.V.; Thomas, E.L.; Morr, C.V.; Coulter, S.T. Relation of Heat-Induced Changes in Protein-Salt Constituents to Astringency in Milk Systems 1. J. Dairy Sci. 1967, 50, 1376–1383. [Google Scholar] [CrossRef]

- Koch, I.S.; Muller, M.; Joubert, E.; van der Rijst, M.; Næs, T. Sensory characterization of rooibos tea and the development of a rooibos sensory wheel and lexicon. Food Res. Int. 2012, 46, 217–228. [Google Scholar] [CrossRef]

- Pan, M.; Tong, L.; Chi, X.; Ai, N.; Cao, Y.; Sun, B. Comparison of sensory and electronic tongue analysis combined with HS-SPME-GC-MS in the evaluation of skim milk processed with different preheating treatments. Molecules 2019, 24, 1650. [Google Scholar] [CrossRef]

- Chi, X.; Shao, Y.; Pan, M.; Yang, Q.; Yang, Y.; Zhang, X.; Ai, N.; Sun, B. Distinction of volatile flavor profiles in various skim milk products via HS-SPME–GC–MS and E-nose. Eur. Food Res. Technol. 2021, 247, 1539–1551. [Google Scholar] [CrossRef]

- Cecchi, L.; Parenti, A.; Bellumori, M.; Migliorini, M.; Mulinacci, N.; and Guerrini, L. Clustering monovarietal extra virgin olive oil according to sensory profile, volatile compounds, and k-Mean algorithm. Eur. J. Lipid Sci. Technol. 2022, 124, 2–10. [Google Scholar] [CrossRef]

- Cardello, A.V. Food quallty: Relativity, contextand consume expectations. Food Qual. Prefer. 1995, 6, 163–170. [Google Scholar] [CrossRef]

| Sample | Fat (Per 100 g Milk Powder) | Protein (Per 100 g of Milk Powder) | Carbohydrates (Per 100 g of Milk Powder) |

|---|---|---|---|

| S1 | 25 | 11 | 55.2 |

| S2 | 27 | 10.9 | 54.4 |

| S3 | 28 | 10.8 | 53.2 |

| S4 | 24 | 10.6 | 51.6 |

| S5 | 28.1 | 10.2 | 50.2 |

| S6 | 27 | 12 | 56 |

| S7 | 26.1 | 11.7 | 56.4 |

| S8 | 26.04 | 11.99 | 51.9 |

| S9 | 26.8 | 11.5 | 54.6 |

| S10 | 26.6 | 11.6 | 56.1 |

| S11 | 25 | 11 | 55.2 |

| S12 | 27 | 11.5 | 56.5 |

| S13 | 27.9 | 11.1 | 52.8 |

| S14 | 25 | 11.8 | 54.4 |

| No. | Attributes | Evaluation Method |

|---|---|---|

| 1 | Milk flavor | Vanillin added to milk powder base, inherent flavor of milk powder, the aroma is gentle and scented |

| 2 | Milk fat | E, E-2,4-decadienal added to milk powder bases, intensity of greasy feeling in the mouth, harsh taste intensity of oil oxidation |

| 3 | Cooked | Milk powder substrate in water bath at 85 °C for 30 min, steaming aroma on the nose, with a slight caramel aroma |

| 4 | Fishy flavor | Freshly slice of mushrooms are added to the milk powder base, smell a metallic, mud-like fishy smell |

| 5 | Sweet taste | 5% sucrose solution, intensity of the inherent sweetness for sample |

| 6 | Sour | 1% citric acid solution, intensity of sourness was felt in the mouth |

| 7 | Saltiness | 2% NaCI solution, intensity of salty taste perceived by the mouth |

| 8 | Astringent | Soak 6 tea bags in water for 10 min, the intensity of an astringent sensation felt by the tongue |

| 9 | Aftertaste | Sensory intensity of residual milk flavor, softness and fluidity remaining in the mouth and throat |

| 10 | Fullness | Overall, degree of preference for test samples |

| Sample | Milk Flavor #,†,‡ | Milk Fat | Cooked | Fishy Flavor | Sweet Taste | Saltiness | Sour | Astringent | Aftertaste | Preference |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 5.10 ± 1.80 ab | 3.99 ± 2.03 d | 4.48 ± 1.89 abcd | 2.67 ± 1.65 e | 5.54 ± 1.84 a | 2.21 ± 1.31 c | 2.91 ± 1.52 bc | 2.65 ± 1.53 d | 4.29 ± 1.68 cde | 6.03 ± 1.66 a |

| S2 | 4.24 ± 1.99 d | 4.35 ± 1.92 cd | 4.61 ± 1.91 abc | 4.17 ± 2.21 b | 4.99 ± 1.84 bc | 2.76 ± 1.81 a | 3.46 ± 1.73 abc | 3.04 ± 1.67 cd | 4.33 ± 1.74 cde | 4.73 ± 1.86 cd |

| S3 | 5.55 ± 1.79 a | 3.99 ± 1.94 d | 5 ± 2.09 a | 2.55 ± 1.77 e | 5.54 ± 1.55 a | 2.22 ± 1.35 bc | 2.88 ± 1.60 a | 2.62 ± 1.54 d | 4.17 ± 1.70 cde | 6.4 ± 1.46 a |

| S4 | 3.92 ± 1.63 de | 4.46 ± 1.77 abcd | 3.88 ± 1.72 ef | 3.08 ± 1.85 cde | 5.18 ± 1.70 ab | 2.5 ± 1.49 abc | 3.49 ± 1.70 abc | 3.08 ± 1.74 cd | 4.17 ± 1.54 cde | 5.14 ± 1.51 bc |

| S5 | 3.79 ± 1.77 def | 4.54 ± 1.89 abcd | 3.82 ± 1.75 ef | 2.82 ± 1.53 de | 5.26 ± 1.73 ab | 2.52 ±0.50 abc | 3.62 ± 1.77 ab | 2.68 ± 1.57 cd | 4.3 ± 1.62 cde | 4.95 ± 1.79 c |

| S6 | 3.16 ± 1.92 h | 5.02 ± 2.08 a | 3.65 ± 2.06 f | 5.04 ± 2.55 a | 4.25 ± 1.90 de | 2.56 ± 1.43 abc | 3.67 ± 1.71 a | 3.95 ± 1.94 a | 5.27 ± 1.99 a | 2.52 ± 1.74 f |

| S7 | 3.24 ± 1.71 gh | 4.85 ± 1.04 abc | 3.66 ± 1.98 f | 4.58 ± 2.46 ab | 4.11 ± 1.77 e | 2.71 ± 1.45 a | 3.57 ± 1.68 ab | 3.89 ± 1.85 a | 5.04 ± 1.81 ab | 2.88 ± 1.55 f |

| S8 | 4.74 ± 1.94 cd | 4.18 ± 1.81 d | 4.15 ± 1.86 cdef | 2.75 ± 1.79 de | 4.29 ± 1.75 de | 2.33 ± 1.26 abc | 3.16 ± 1.46 bcde | 2.99 ± 1.65 cd | 3.97 ± 0.55 e | 5.5 ± 2.03 b |

| S9 | 3.69 ± 1.61 efg | 4.96 ± 1.96 ab | 4.04 ± 1.88 def | 2.95 ± 1.85 cd | 4.73 ± 1.91 bcd | 2.33 ± 1.35 abc | 3.35 ± 1.30 abde | 2.97 ± 1.56 d | 4.55 ± 1.69 cd | 4.12 ± 1.55 e |

| S10 | 4.14 ± 1.71 de | 4.01 ± 1.82 d | 3.71 ± 1.81 f | 3.52 ± 2.11 c | 4.31 ± 2.01 de | 2.65 ± 1.43 abc | 3.54 ± 1.68 abc | 3.76 ± 1.85 ab | 4.64 ± 1.78 bc | 4.73 ± 1.70 cd |

| S11 | 4.15 ± 1.64 de | 3.98 ± 1.72 d | 3.69 ± 1.62 f | 2.94 ± 1.65 cde | 4.71 ± 1.80 bcd | 2.54 ± 1.55 abc | 3.06 ± 1.45 cde | 2.86 ± 1.50 cd | 4.11 ± 1.50 de | 4.88 ± 1.89 c |

| S12 | 3.33 ± 1.71 fgh | 4.83 ± 1.95 abc | 3.88 ± 1.97 ef | 4.3 ± 2.16 b | 4.73 ± 1.82 bcd | 2.49 ± 1.37 abc | 3.24 ± 1.54 abcde | 3.37 ± 1.91 bc | 4.39 ± 1.62 cde | 2.99 ± 1.99 f |

| S13 | 4.3 ± 1.54 d | 4.43 ± 1.93 bcd | 4.34 ± 1.91 bcde | 3.3 ± 1.74 cd | 5.08 ± 1.87 ab | 2.46 ± 1.39 abc | 3.15 ± 1.60 bcde | 2.62 ± 1.30 d | 4.39 ± 1.64 cde | 4.28 ± 1.87 de |

| S14 | 4.75 ± 1.68 bc | 4.02 ± 1.83 d | 4.78 ± 1.97 ab | 3.42 ± 1.94 c | 4.52 ± 1.74 cde | 2.66 ± 1.41 ab | 3.39 ± 1.62 abcd | 3.23 ± 1.67 c | 4.13 ± 1.53 cde | 5.21 ± 1.83 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, Y.; Zhao, T.; Liu, R.; Song, F.; Deng, J.; Ai, N. Assessing Sensory Attributes and Properties of Infant Formula Milk Powder Driving Consumers’ Preference. Foods 2023, 12, 997. https://doi.org/10.3390/foods12050997

Xi Y, Zhao T, Liu R, Song F, Deng J, Ai N. Assessing Sensory Attributes and Properties of Infant Formula Milk Powder Driving Consumers’ Preference. Foods. 2023; 12(5):997. https://doi.org/10.3390/foods12050997

Chicago/Turabian StyleXi, Yanmei, Tong Zhao, Ruirui Liu, Fuhang Song, Jianjun Deng, and Nasi Ai. 2023. "Assessing Sensory Attributes and Properties of Infant Formula Milk Powder Driving Consumers’ Preference" Foods 12, no. 5: 997. https://doi.org/10.3390/foods12050997

APA StyleXi, Y., Zhao, T., Liu, R., Song, F., Deng, J., & Ai, N. (2023). Assessing Sensory Attributes and Properties of Infant Formula Milk Powder Driving Consumers’ Preference. Foods, 12(5), 997. https://doi.org/10.3390/foods12050997