Effect of Mixing Time on Properties of Whole Wheat Flour-Based Cookie Doughs and Cookies

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Cookies

2.3. Impedance Analysis of Dough

2.4. FTIR

2.5. Physical Dimensions

2.6. Microscopic Analysis

2.6.1. Dough Microstructure

2.6.2. Surface Topology of Cookies

2.7. Moisture Content

2.8. Texture Analysis

2.8.1. Dough Spreadability

2.8.2. Stress Relaxation of Dough

2.8.3. Puncture Strength of Cookies

2.8.4. Three-Point Bending Test of Cookies

2.9. Statistical Analysis

3. Results and Discussions

3.1. Analysis of Dough

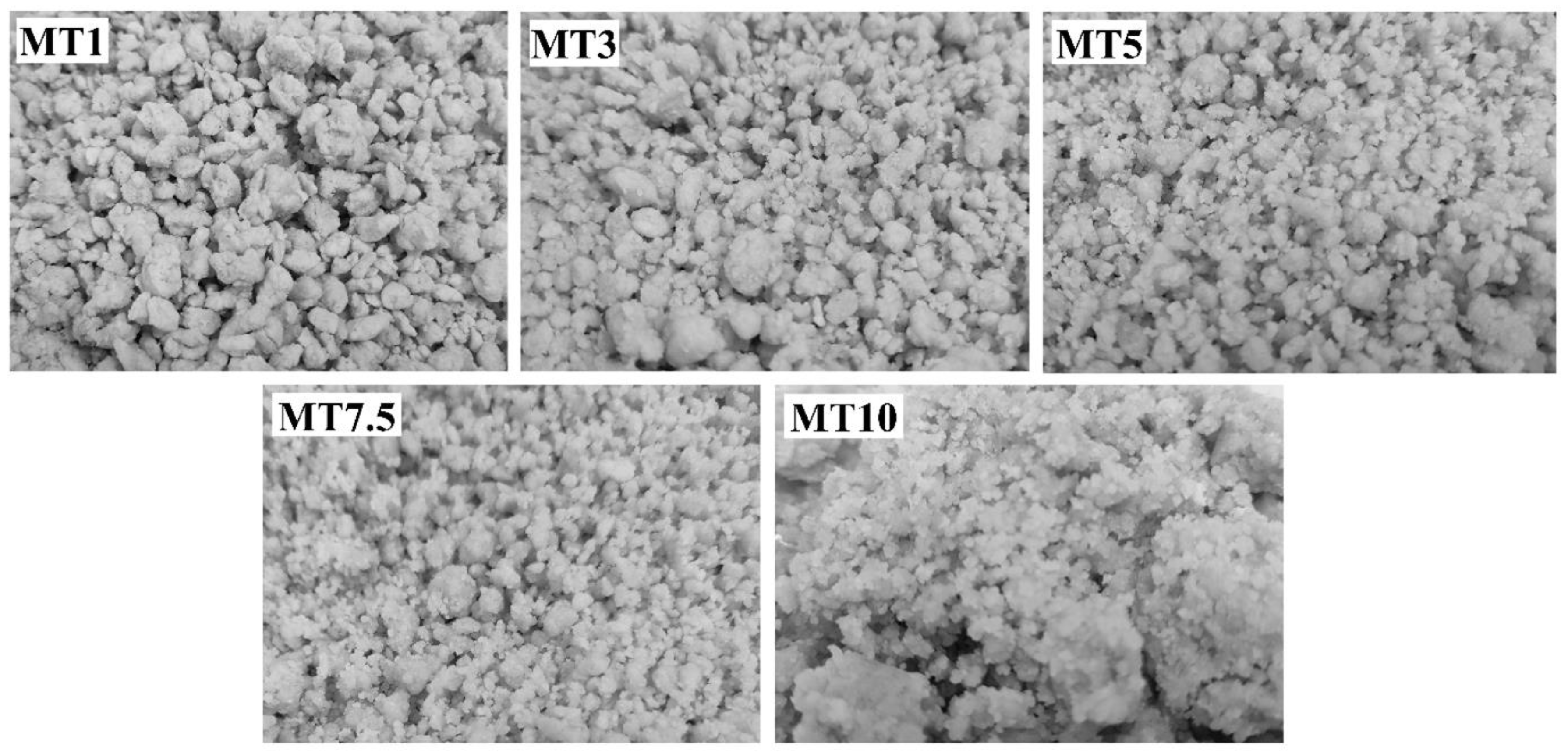

3.1.1. Visual Appearance of Dough

3.1.2. Moisture Content of Cookie Dough

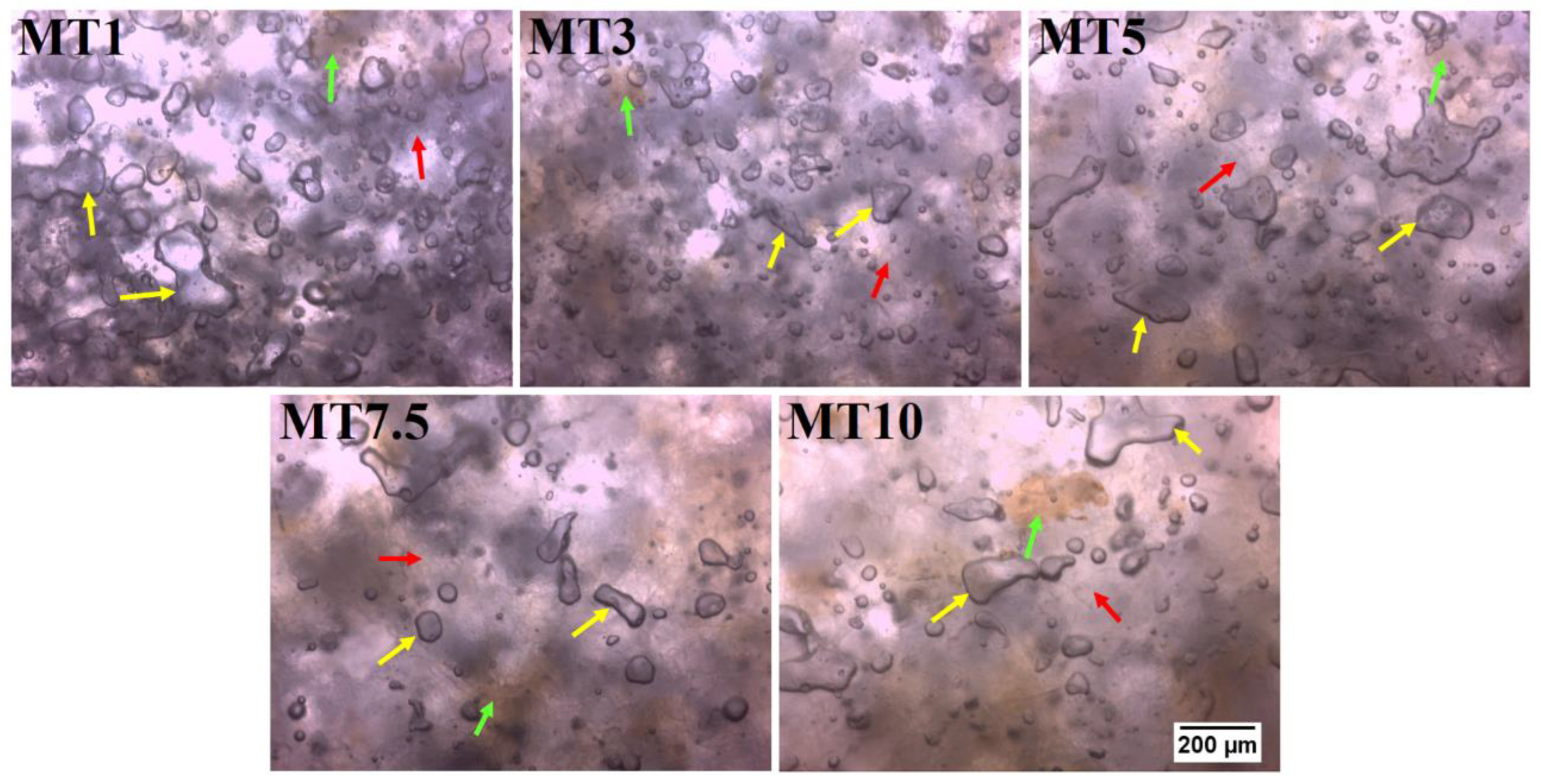

3.1.3. Dough Microstructure

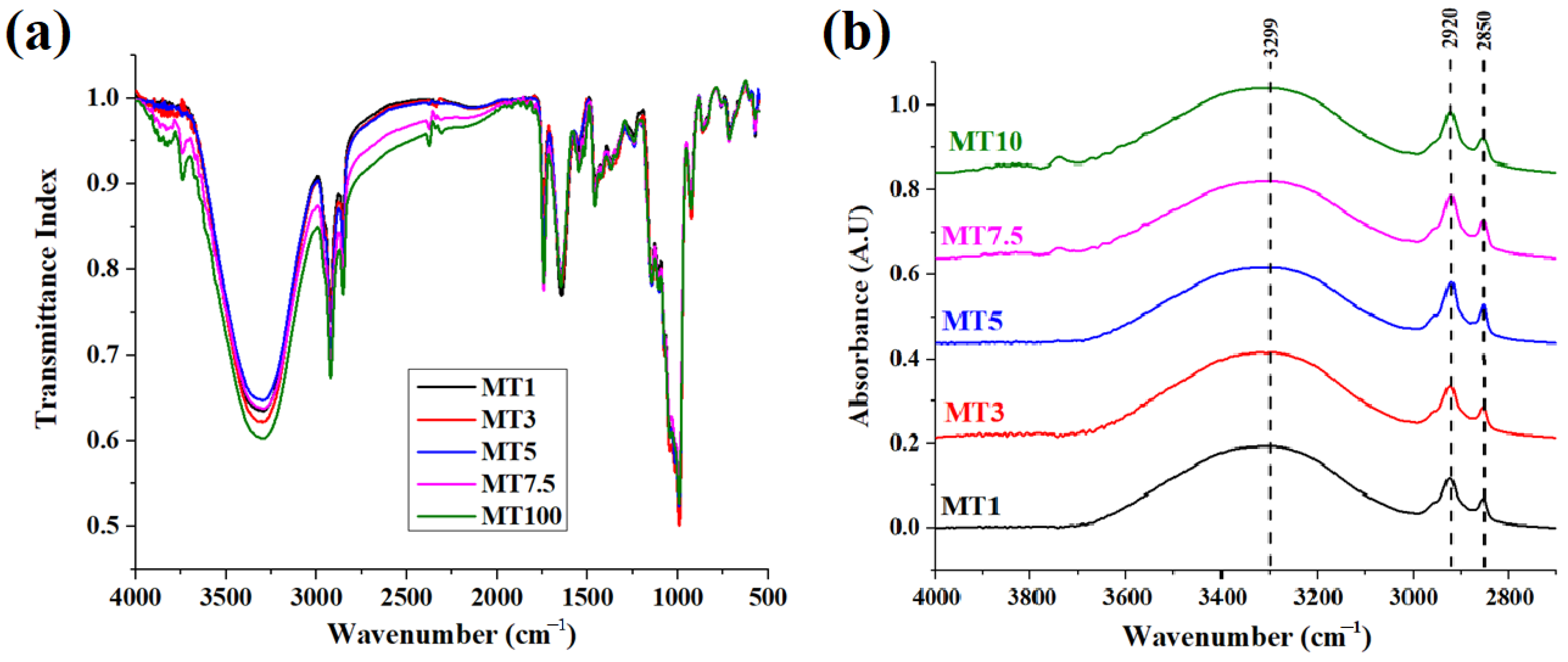

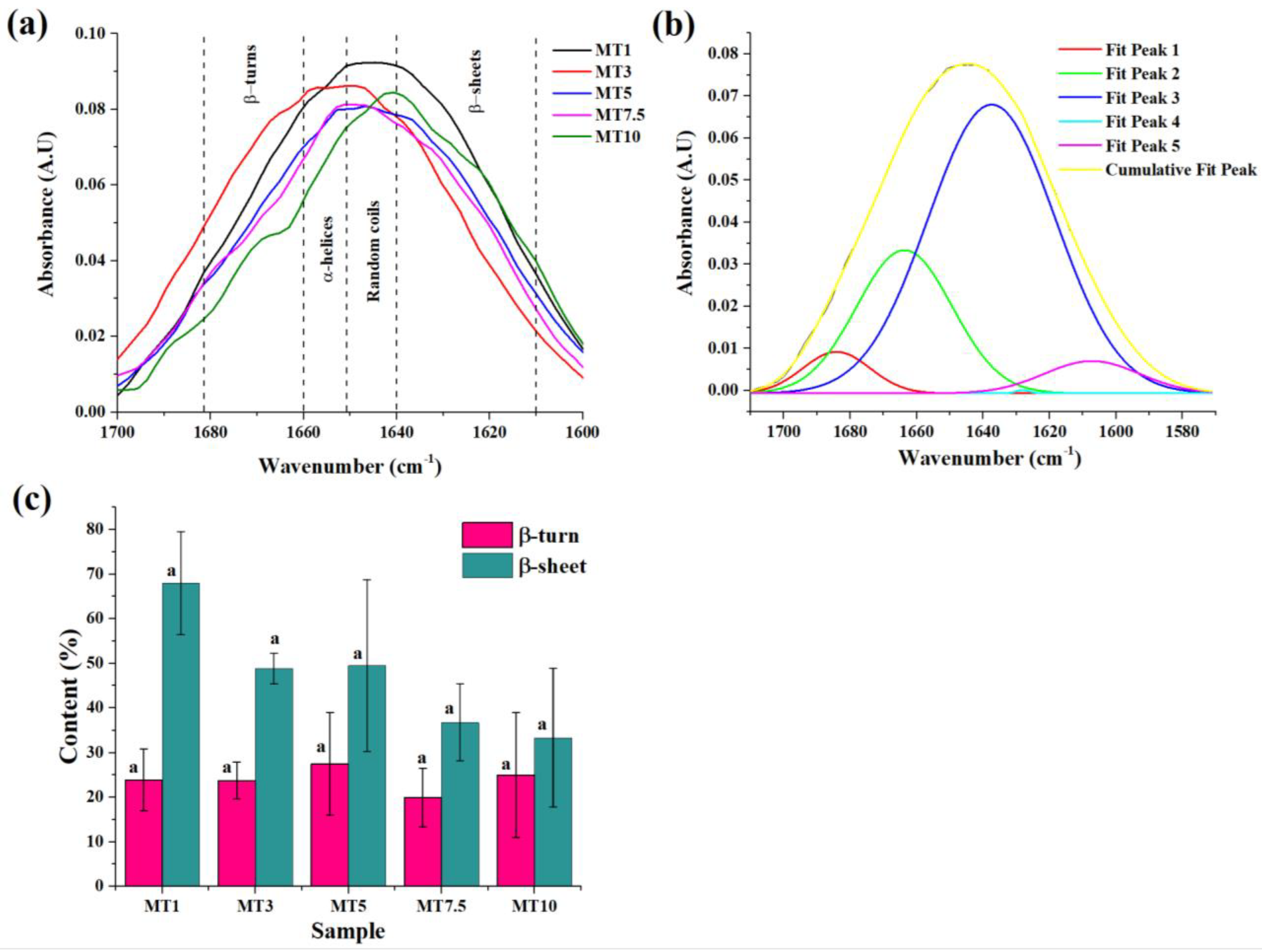

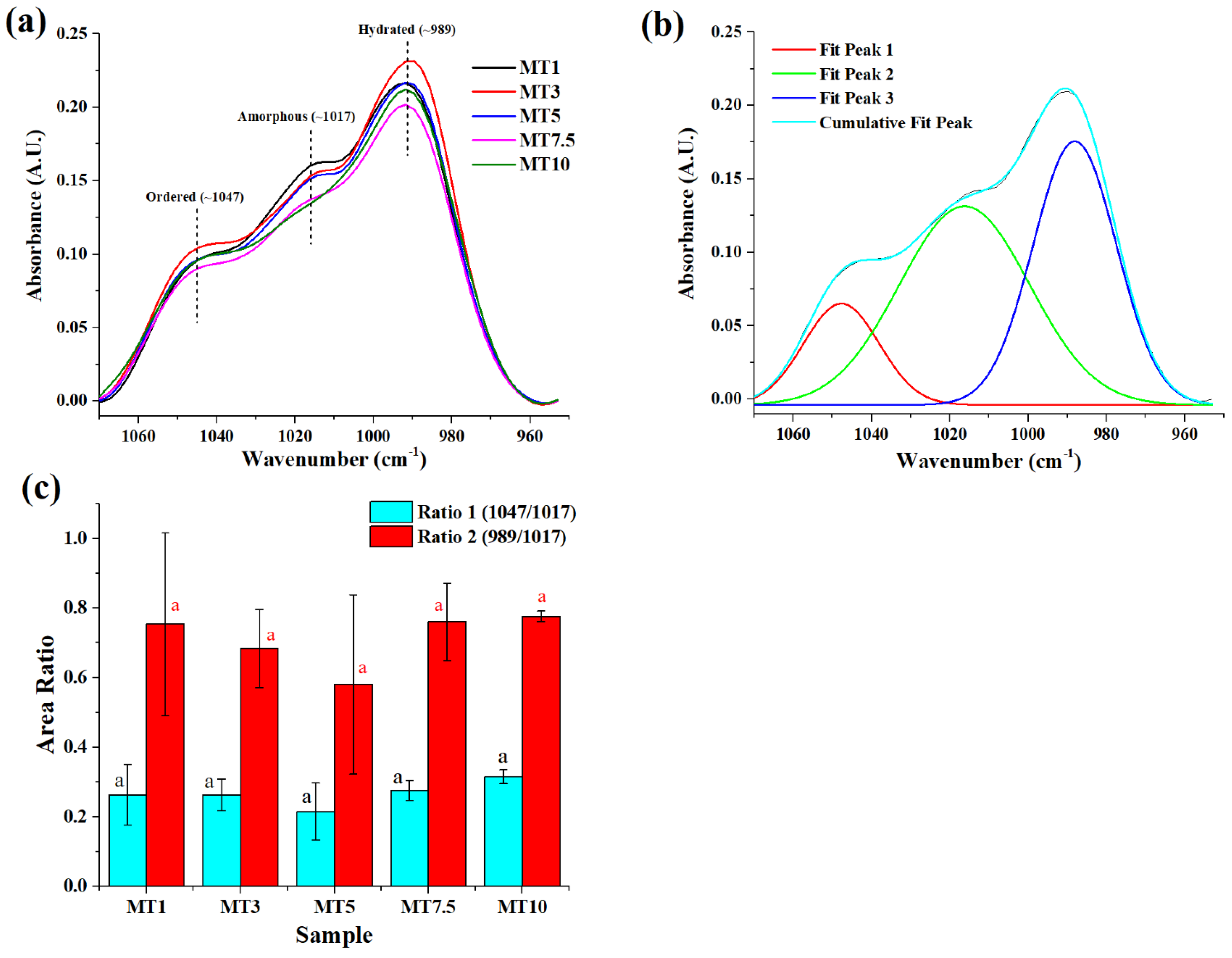

3.1.4. FTIR Analysis of Dough

3.1.5. Texture Analysis of Dough

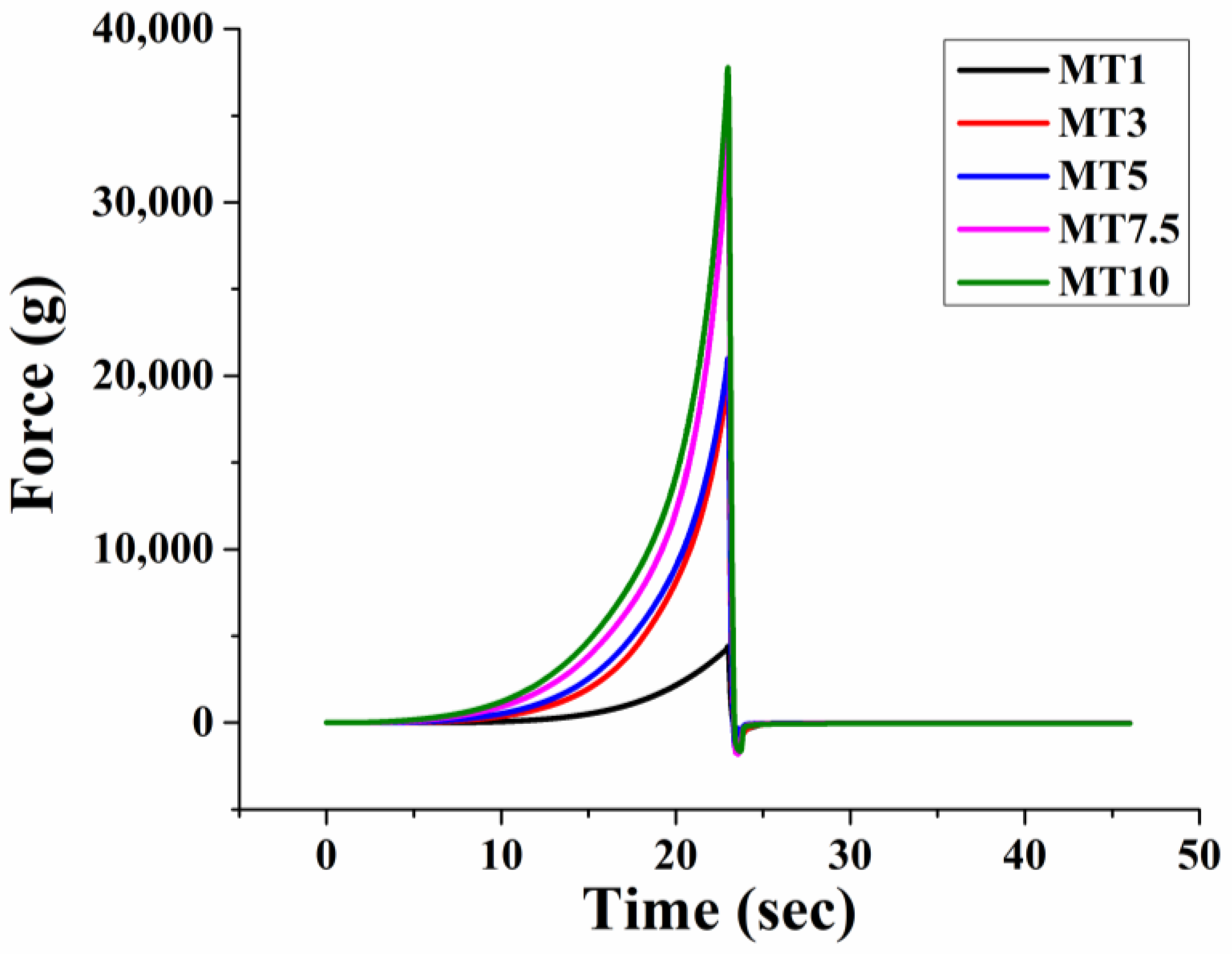

Firmness

Work of Shear

Stickiness

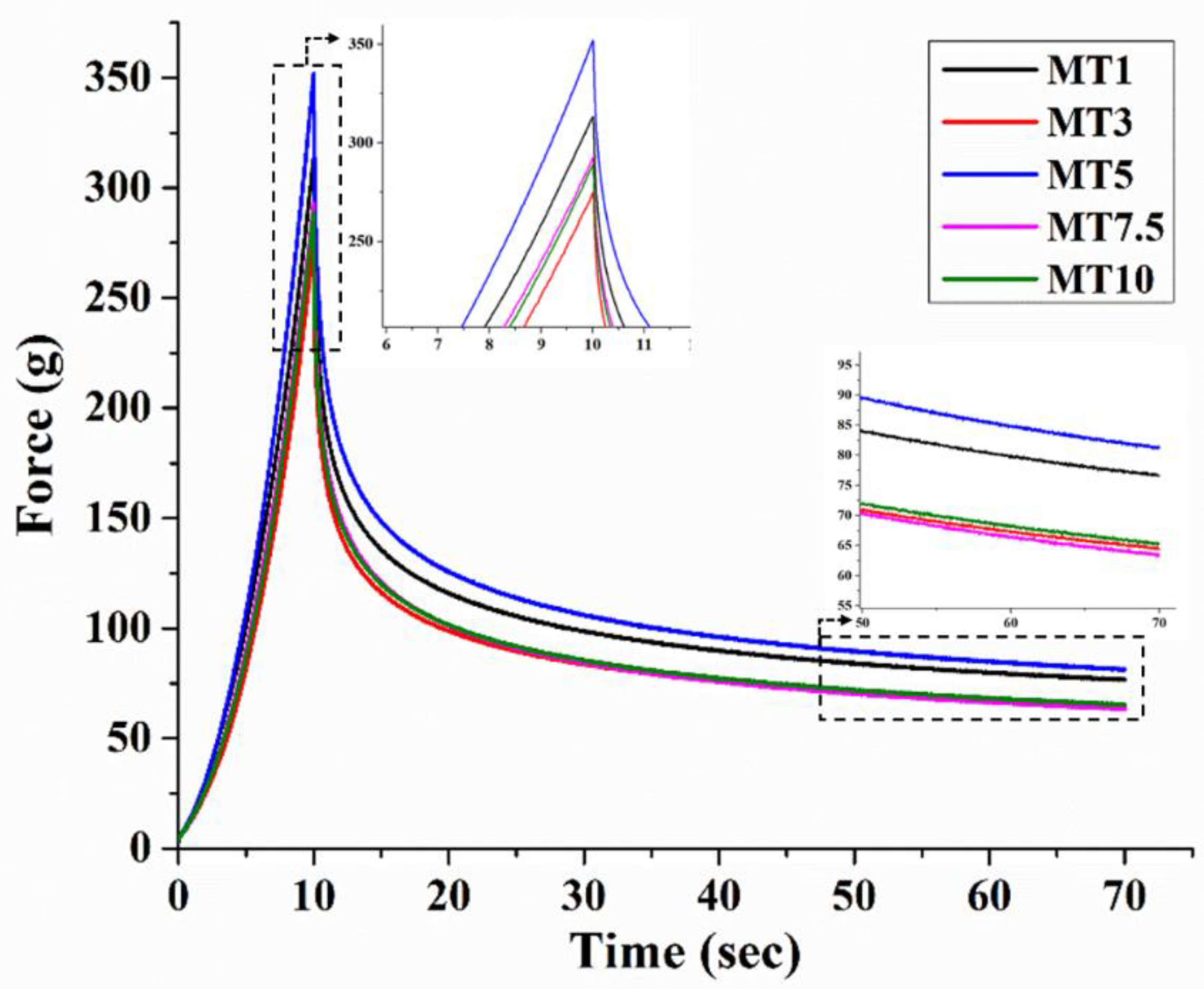

3.1.6. Stress Relaxation of Dough

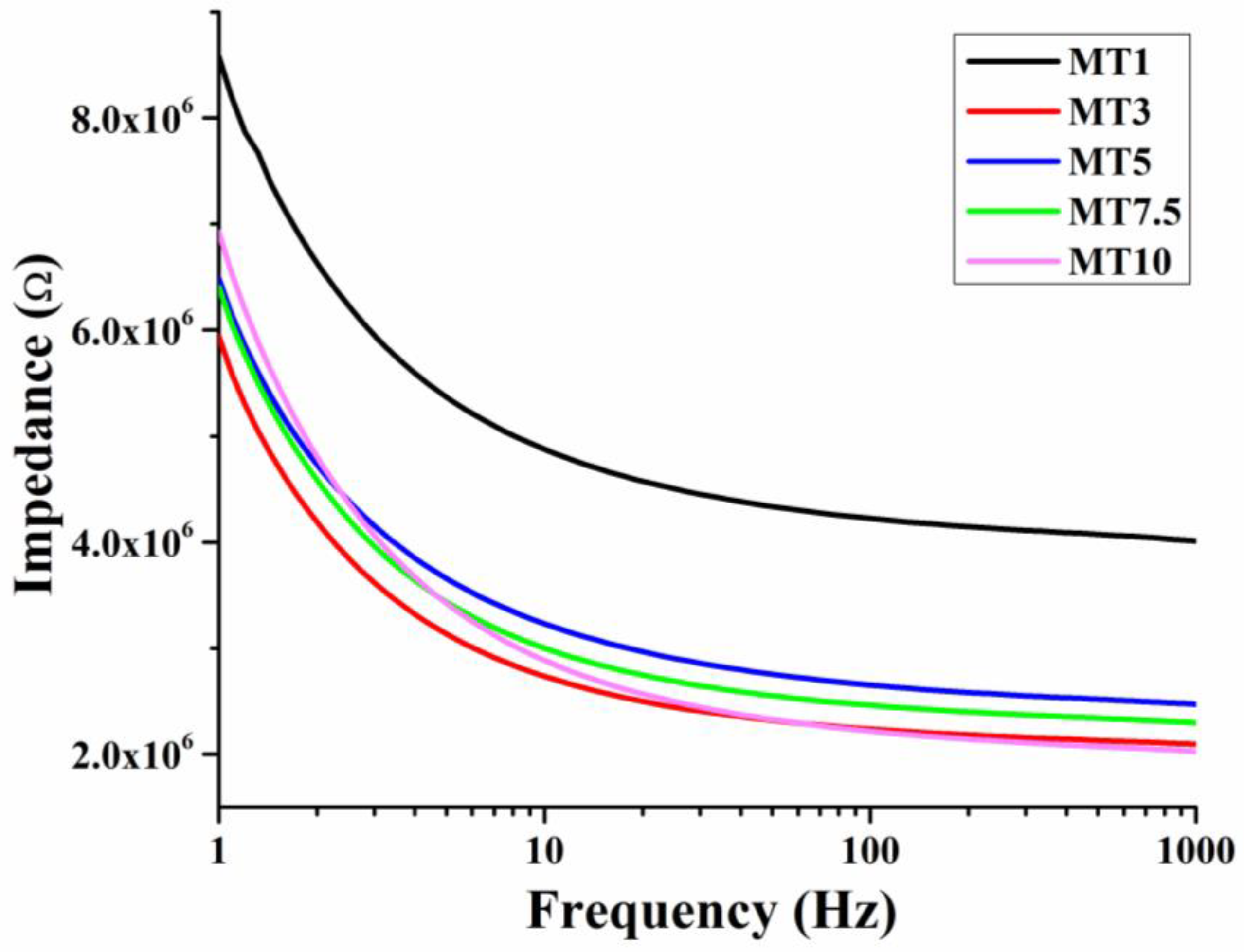

3.1.7. Impedance Analysis of Dough

3.2. Analysis of Cookies

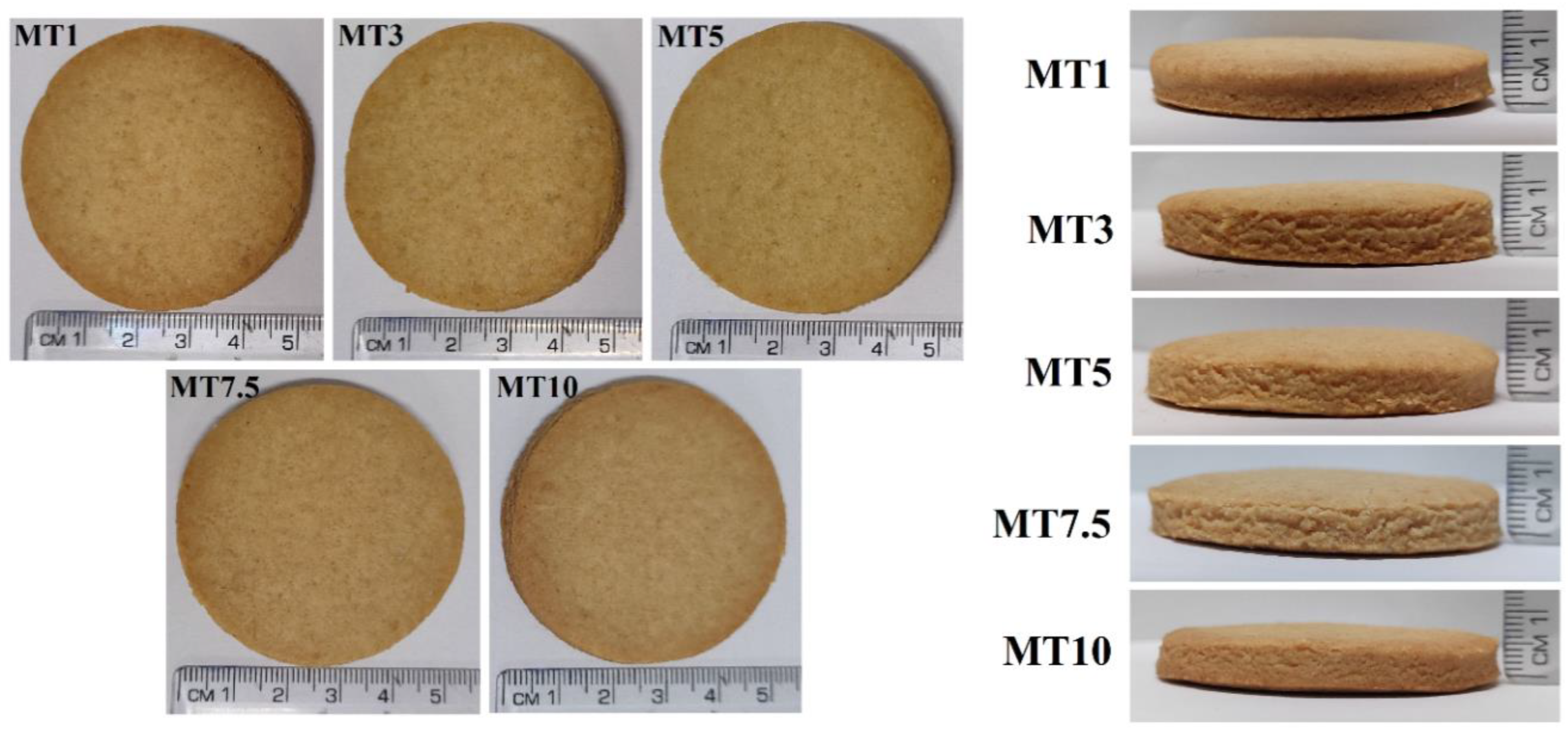

3.2.1. Visual Appearance of Cookies

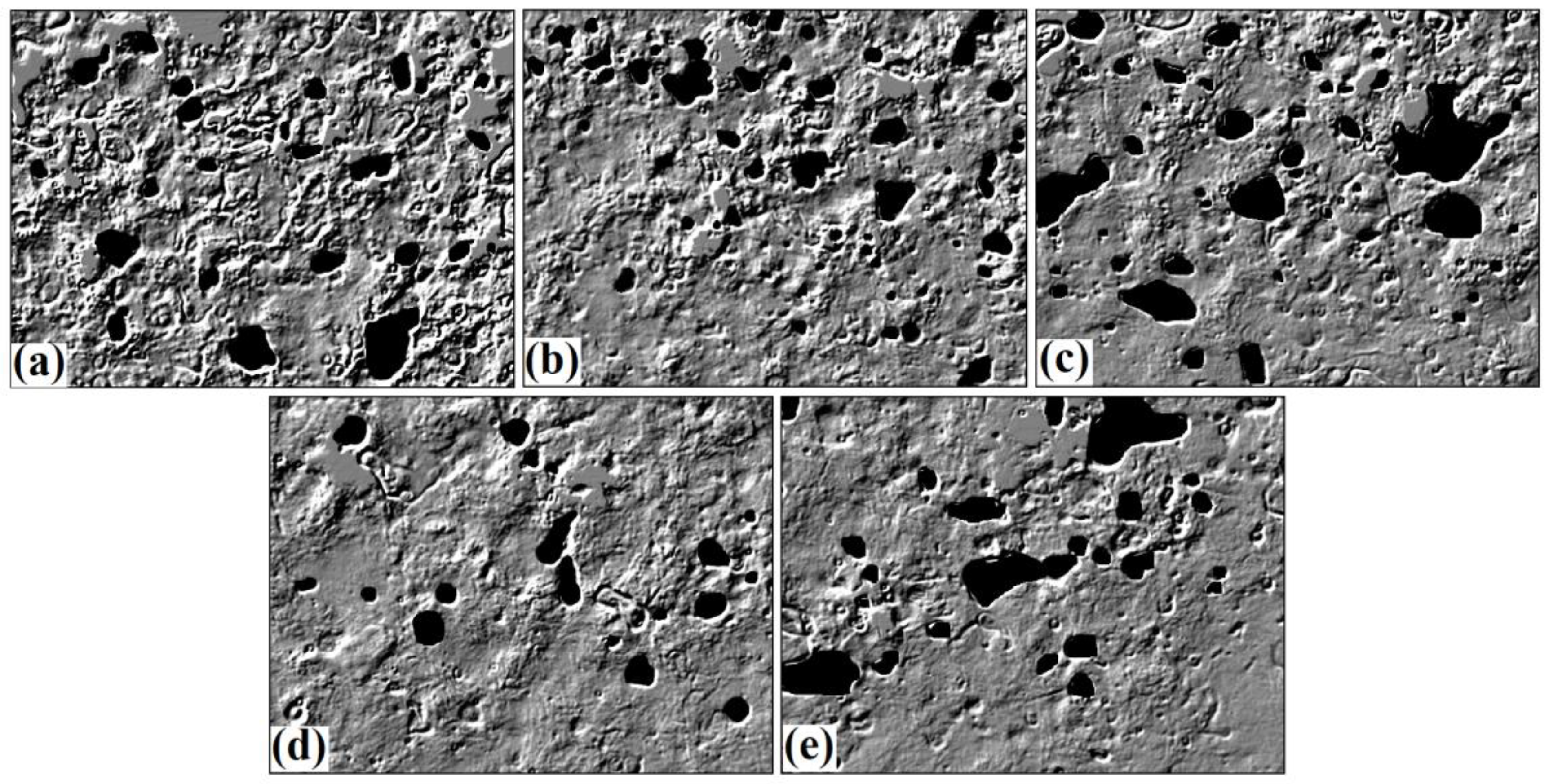

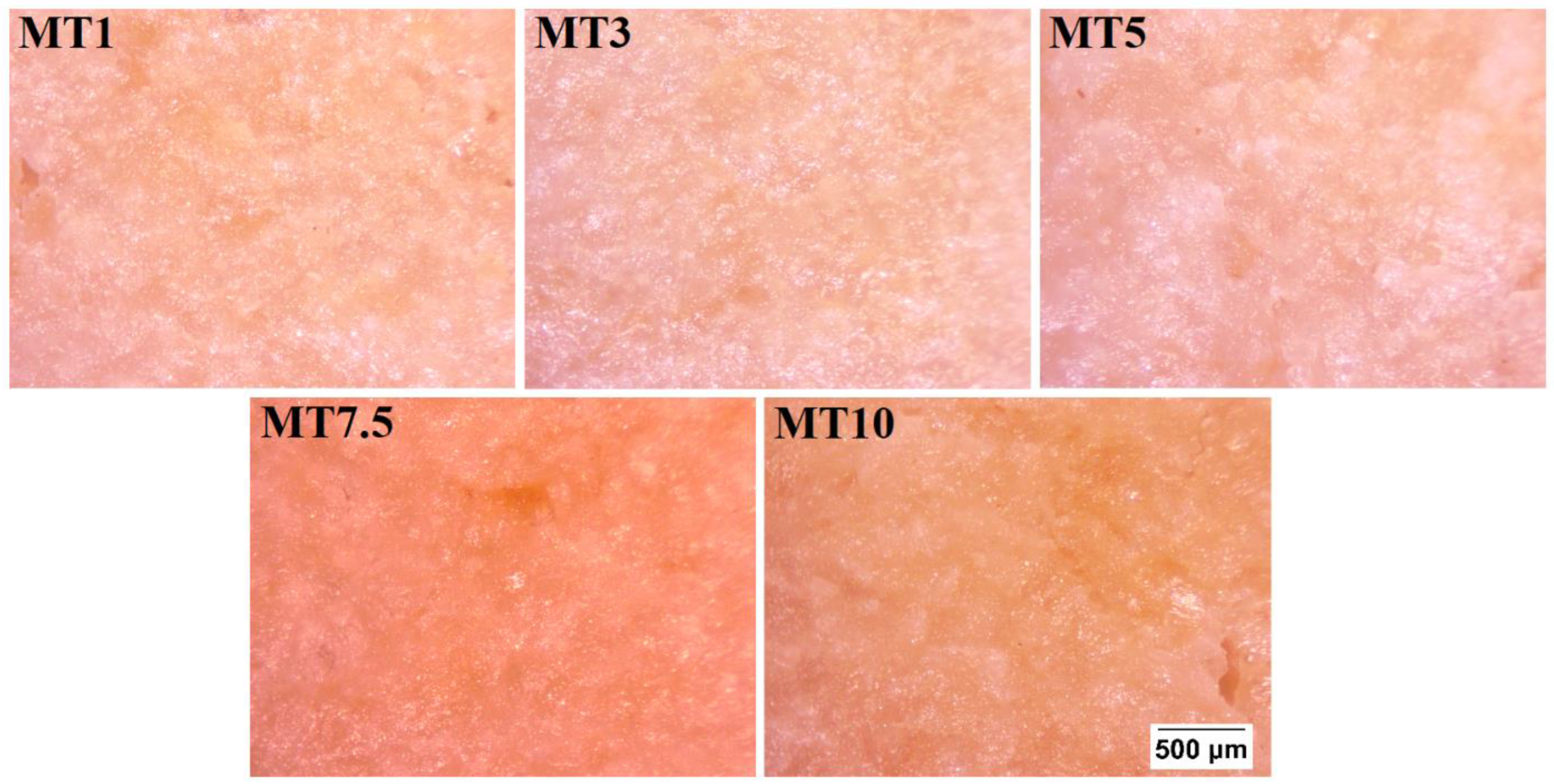

3.2.2. Surface Topology

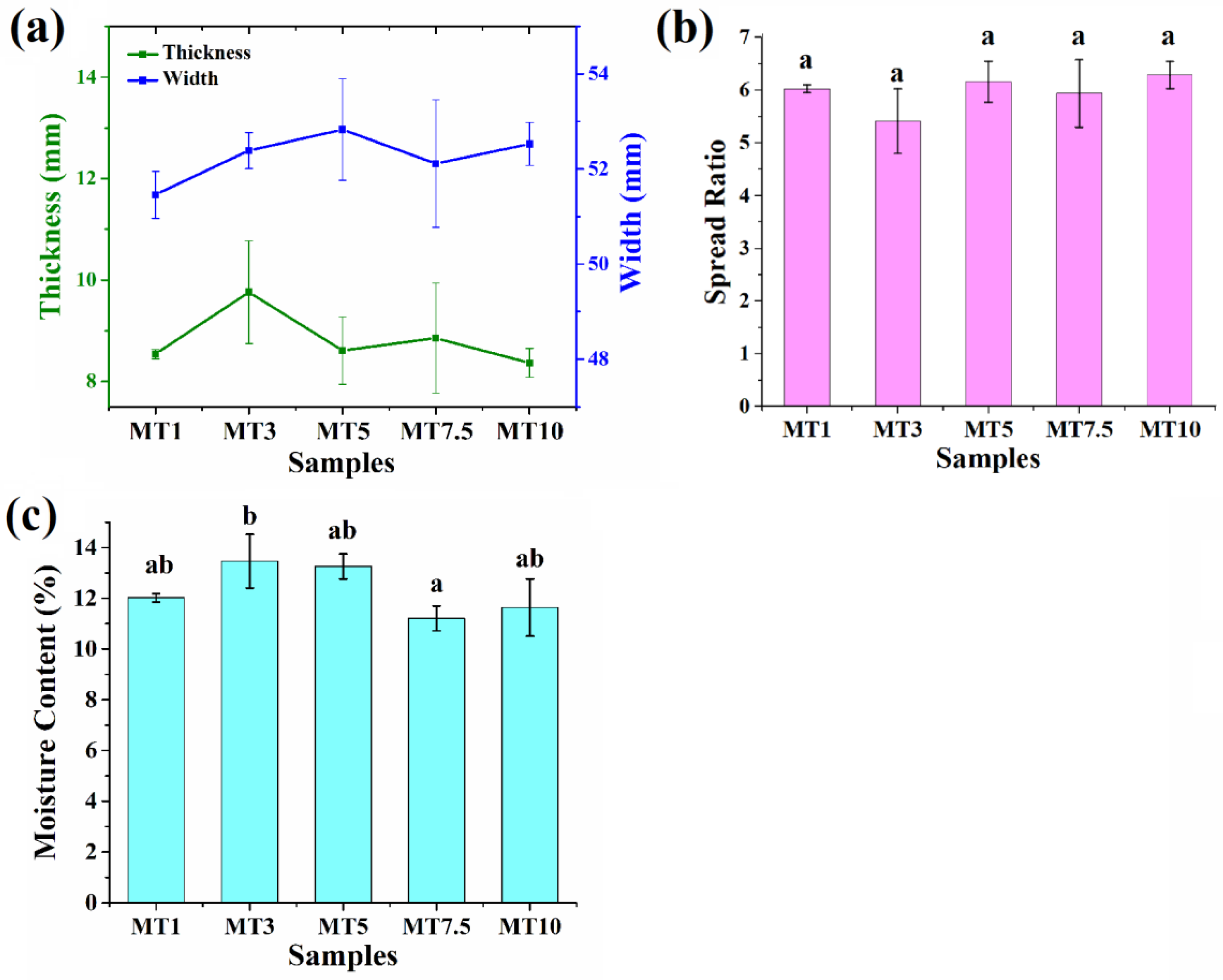

3.2.3. Physical Dimensions

3.2.4. Moisture Content

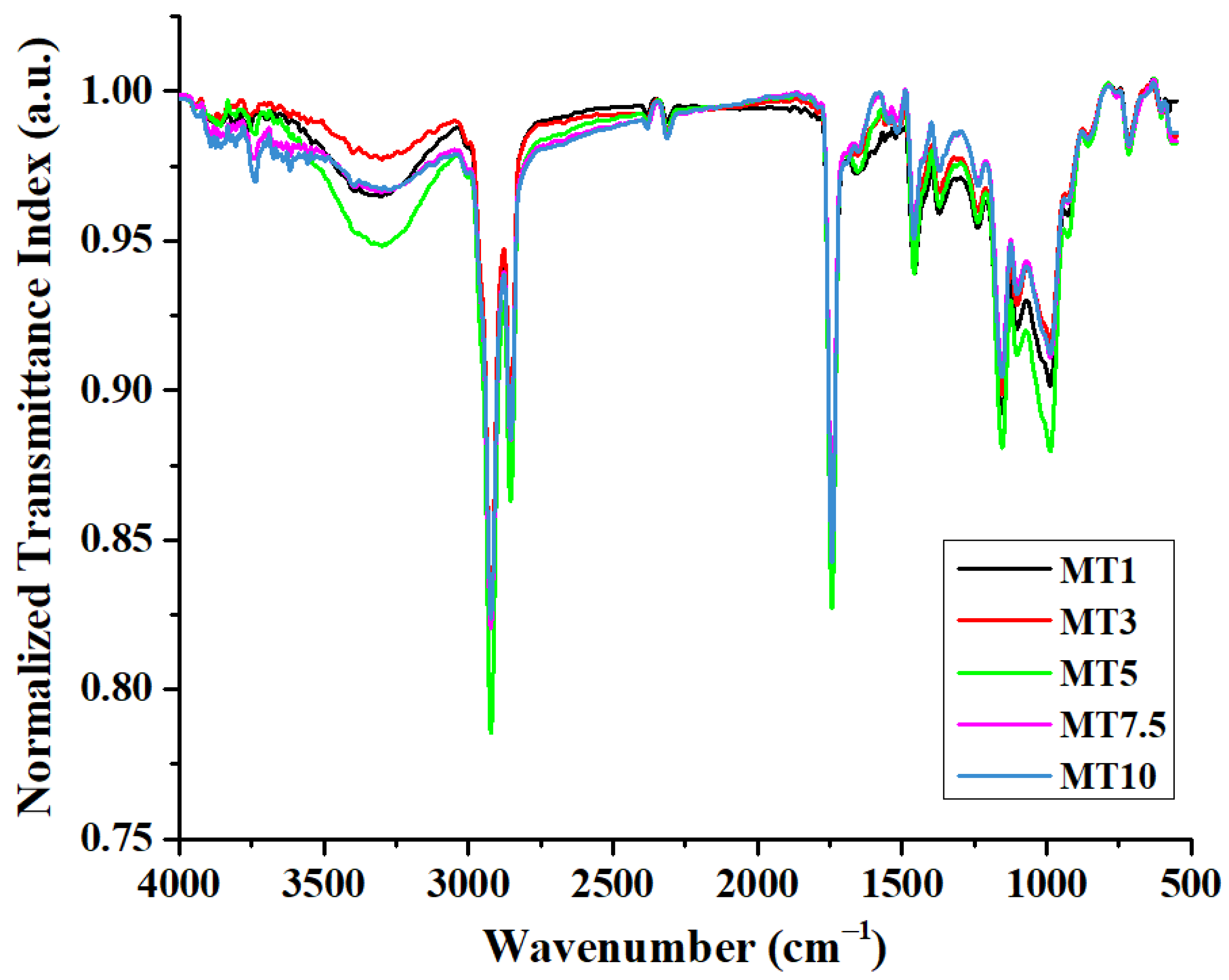

3.2.5. FTIR of Cookies

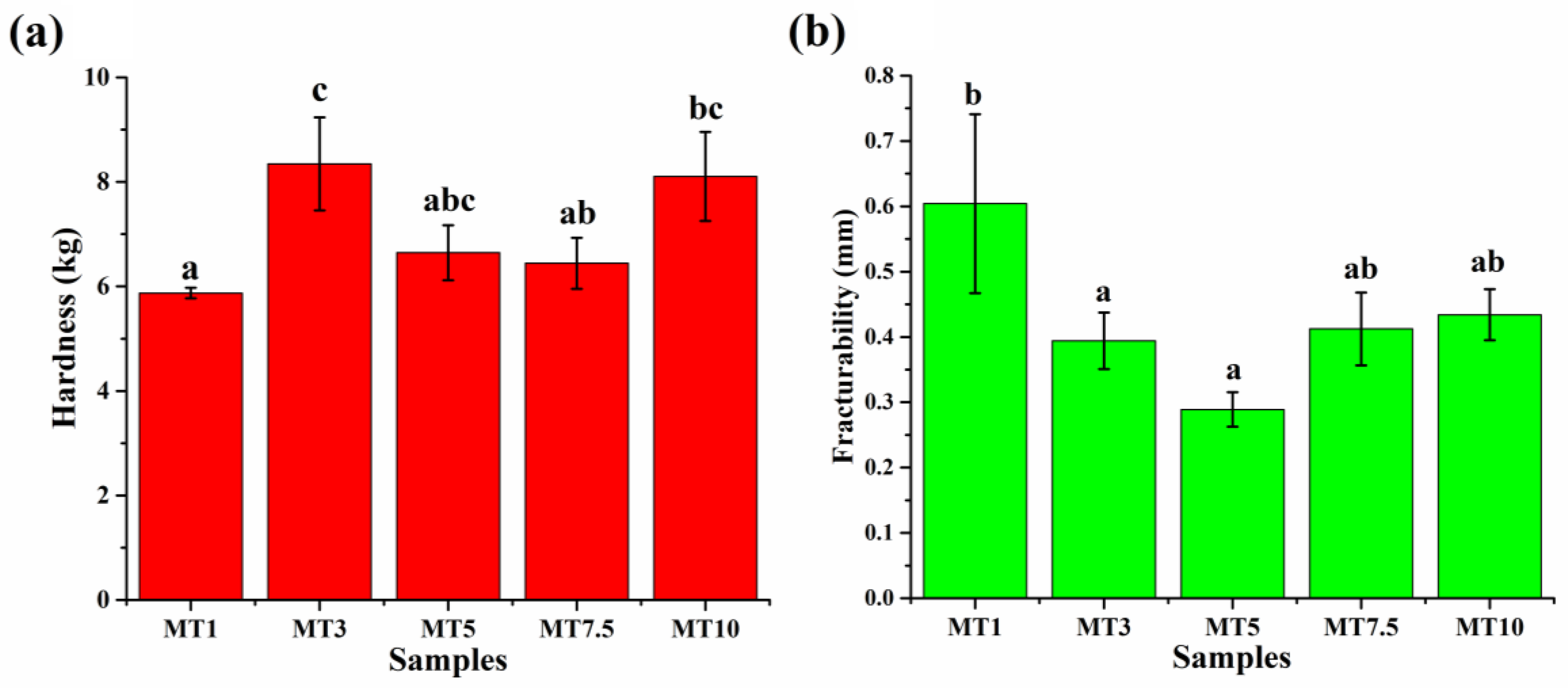

3.2.6. Texture Analysis of Cookies

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jerome, R.E.; Singh, S.K.; Dwivedi, M. Process analytical technology for bakery industry: A review. J. Food Process Eng. 2019, 42, e13143. [Google Scholar] [CrossRef]

- Ortolan, F.; Steel, C.J. Protein characteristics that affect the quality of vital wheat gluten to be used in baking: A review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 369–381. [Google Scholar] [CrossRef]

- Bora, P.; Ragaee, S.; Abdel-Aal, E.-S.M. Effect of incorporation of goji berry by-product on biochemical, physical and sensory properties of selected bakery products. LWT 2019, 112, 108225. [Google Scholar] [CrossRef]

- Vaclavik, V.A.; Christian, E.W.; Campbell, T. Baked products: Batters and dough. In Essentials of Food Science; Springer: Berlin/Heidelberg, Germany, 2021; pp. 303–324. [Google Scholar]

- Panghal, A.; Chhikara, N.; Khatkar, B. Effect of processing parameters and principal ingredients on quality of sugar snap cookies: A response surface approach. J. Food Sci. Technol. 2018, 55, 3127–3134. [Google Scholar] [CrossRef]

- Gazi, S.; Taş, N.G.; Görgülü, A.; Gökmen, V. Effectiveness of asparaginase on reducing acrylamide formation in bakery products according to their dough type and properties. Food Chem. 2023, 402, 134224. [Google Scholar] [CrossRef]

- Demirkesen, I. Linear and Non-Linear Rheological Properties of Gluten-Free Dough Systems Probed by Fundamental Methods. Food Eng. Rev. 2023, 15, 56–85. [Google Scholar] [CrossRef]

- Culetu, A.; Stoica-Guzun, A.; Duta, D.E. Impact of fat types on the rheological and textural properties of gluten-free oat dough and cookie. Int. J. Food Sci. Tech. 2021, 56, 126–137. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, H.; Fu, B.; Iftikhar, M.; Liu, G.; Wang, J. Interactions between dietary fiber and ferulic acid change the aggregation of glutenin, gliadin and glutenin macropolymer in wheat flour system. J. Sci. Food Agric. 2021, 101, 1979–1988. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Rodriguez, P.; Gómez, M. Assessing rice flour-starch-protein mixtures to produce gluten free sugar-snap cookies. LWT-Food Sci. Technol. 2016, 67, 127–132. [Google Scholar] [CrossRef]

- Wu, Y.; Ye, G.; Li, X.; Wang, L.; Liu, Y.; Tan, B.; Shen, W.; Zhou, J. Comparison of quality characteristics of six reconstituted whole wheat flour with different modified bran. LWT 2022, 153, 112543. [Google Scholar] [CrossRef]

- Bhat, N.A.; Wani, I.A.; Hamdani, A.M. Tomato powder and crude lycopene as a source of natural antioxidants in whole wheat flour cookies. Heliyon 2020, 6, e03042. [Google Scholar] [CrossRef]

- Brouns, F.; van Rooy, G.; Shewry, P.; Rustgi, S.; Jonkers, D. Adverse reactions to wheat or wheat components. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1437–1452. [Google Scholar] [CrossRef]

- Mohtarami, F.; Rashidi, Z.; Pirsa, S. Extraction of flaxseed and Plantago Psyllium mucilage: Investigation of rheological properties and efficiency as a fat substitute for the production of low-calorie cookies. J. Food Process. Preserv. 2022, 46, e16964. [Google Scholar] [CrossRef]

- Alam, S.S.; Bharti, D.; Pradhan, B.K.; Sahu, D.; Dhal, S.; Kim, N.M.; Jarzębski, M.; Pal, K. Analysis of the Physical and Structure Characteristics of Reformulated Pizza Bread. Foods 2022, 11, 1979. [Google Scholar] [CrossRef]

- Alvarez-Ramirez, J.; Carrera-Tarela, Y.; Carrillo-Navas, H.; Vernon-Carter, E.; Garcia-Diaz, S. Effect of leavening time on LAOS properties of yeasted wheat dough. Food Hydrocoll. 2019, 90, 421–432. [Google Scholar] [CrossRef]

- Li, S.; Wu, G.; Li, X.; Jin, Q.; Wang, X.; Zhang, H. Roles of gelator type and gelation technology on texture and sensory properties of cookies prepared with oleogels. Food Chem. 2021, 356, 129667. [Google Scholar] [CrossRef]

- Zhao, M.; Lan, Y.; Cui, L.; Monono, E.; Rao, J.; Chen, B. Physical properties and cookie-making performance of oleogels prepared with crude and refined soybean oil: A comparative study. Food Funct. 2020, 11, 2498–2508. [Google Scholar] [CrossRef]

- Kupiec, M.; Zbikowska, A.; Marciniak-Lukasiak, K.; Zbikowska, K.; Kowalska, M.; Kowalska, H.; Rutkowska, J. Study on the Introduction of Solid Fat with a High Content of Unsaturated Fatty Acids to Gluten-Free Muffins as a Basis for Designing Food with Higher Health Value. Int. J. Mol. Sci. 2021, 22, 9220. [Google Scholar] [CrossRef]

- Yılmaz, E.; Öğütcü, M. The texture, sensory properties and stability of cookies prepared with wax oleogels. Food Funct. 2015, 6, 1194–1204. [Google Scholar] [CrossRef]

- Ghanate, A.S.; Annapure, U. Effect of physicochemical and rheological properties of flour from different local wheat varieties on the quality of varanphal: An Indian traditional product. J. Food Sci. Technol. 2019, 56, 3033–3042. [Google Scholar] [CrossRef]

- Yang, Y.; Guan, E.; Zhang, T.; Li, M.; Bian, K. Influence of water addition methods on water mobility characterization and rheological properties of wheat flour dough. J. Cereal Sci. 2019, 89, 102791. [Google Scholar] [CrossRef]

- Korese, J.K.; Chikpah, S.K.; Hensel, O.; Pawelzik, E.; Sturm, B. Effect of orange-fleshed sweet potato flour particle size and degree of wheat flour substitution on physical, nutritional, textural and sensory properties of cookies. Eur. Food Res. Technol. 2021, 247, 889–905. [Google Scholar] [CrossRef]

- Aleman, R.S.; Marcia, J.; Pournaki, S.K.; Borrás-Linares, I.; Lozano-Sanchez, J.; Fernandez, I.M. Formulation of Protein-Rich Chocolate Chip Cookies Using Cricket (Acheta domesticus) Powder. Foods 2022, 11, 3275. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, I.J.; Park, S.M.; Lee, J.H.; Nguyen, M.-H.; Park, H.J. Effect of hydrocolloid addition on dimensional stability in post-processing of 3D printable cookie dough. LWT 2019, 101, 69–75. [Google Scholar] [CrossRef]

- Bozkurt, S.; Görgüç, A.; Gençdağ, E.; Elmas, F.; Koç, M.; Yılmaz, F.M. Principles and recent applications of vacuum technology in the processing of dough-based cereal products: A comprehensive review. Food Chem. 2022, 403, 134443. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, G.; Liu, M.; Mei, X.; Yu, Q.; Kan, J. Effects of multi-frequency ultrasound on physicochemical properties, structural characteristics of gluten protein and the quality of noodle. Ultrason. Sonochem. 2020, 67, 105135. [Google Scholar] [CrossRef]

- Gao, X.; Tong, J.; Guo, L.; Yu, L.; Li, S.; Yang, B.; Wang, L.; Liu, Y.; Li, F.; Guo, J. Influence of gluten and starch granules interactions on dough mixing properties in wheat (Triticum aestivum L.). Food Hydrocoll. 2020, 106, 105885. [Google Scholar] [CrossRef]

- Dube, N.M.; Xu, F.; Zhao, R. The efficacy of sorghum flour addition on dough rheological properties and bread quality: A short review. Grain Oil Sci. Technol. 2020, 3, 164–171. [Google Scholar] [CrossRef]

- Varghese, C.; Wolodko, J.; Chen, L.; Doschak, M.; Srivastav, P.P.; Roopesh, M. Influence of selected product and process parameters on microstructure, rheological, and textural properties of 3D printed cookies. Foods 2020, 9, 907. [Google Scholar] [CrossRef]

- Cappelli, A.; Bettaccini, L.; Cini, E. The kneading process: A systematic review of the effects on dough rheology and resulting bread characteristics, including improvement strategies. Trends Food Sci. Technol. 2020, 104, 91–101. [Google Scholar] [CrossRef]

- Sai Manohar, R.; Haridas Rao, P. Effects of water on the rheological characteristics of biscuit dough and quality of biscuits. Eur. Food Res. Technol. 1999, 209, 281–285. [Google Scholar] [CrossRef]

- Huang, Z.; Guo, B.; Gong, D.; Zhang, G. Oleogel-structured emulsions: A review of formation, physicochemical properties and applications. Food Chem. 2022, 404, 134553. [Google Scholar] [CrossRef]

- Chen, G.; Hu, R.; Li, Y. Potassium bicarbonate improves dough and cookie characteristics through influencing physicochemical and conformation properties of wheat gluten. Food Chem. X 2020, 5, 100075. [Google Scholar] [CrossRef]

- Arepally, D.; Reddy, R.S.; Goswami, T.K.; Datta, A.K. Biscuit baking: A review. LWT 2020, 131, 109726. [Google Scholar] [CrossRef]

- Walrafen, G.; Hokmabadi, M.; Yang, W.H. Raman isosbestic points from liquid water. J. Chem. Phys. 1986, 85, 6964–6969. [Google Scholar] [CrossRef]

- Laurson, P.; Raudsepp, P.; Kaldmäe, H.; Kikas, A.; Mäeorg, U. The deconvolution of FTIR-ATR spectra to five Gaussians for detection of small changes in plant–water clusters. AIP Adv. 2020, 10, 085214. [Google Scholar] [CrossRef]

- De Ninno, A.; De Francesco, M. ATR-FTIR study of the isosbestic point in water solution of electrolytes. Chem. Phys. 2018, 513, 266–272. [Google Scholar] [CrossRef]

- Garcia-Valle, D.E.; Bello-Pérez, L.A.; Agama-Acevedo, E.; Alvarez-Ramirez, J. Effects of mixing, sheeting, and cooking on the starch, protein, and water structures of durum wheat semolina and chickpea flour pasta. Food Chem. 2021, 360, 129993. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, D.; Zhou, H.; Wu, F.; Xu, X. Rheological, microstructure and mixing behaviors of frozen dough reconstituted by wheat starch and gluten. Int. J. Biol. Macromol. 2022, 212, 517–526. [Google Scholar] [CrossRef]

- Dewan, A.; Khatkar, B.S.; Bangar, S.P.; Chaudhary, V.; Lorenzo, J.M. Infrared spectroscopy and microstructural assessment of dough with varying wheat gluten fractions. Food Anal. Methods 2022, 15, 2821–2829. [Google Scholar] [CrossRef]

- Zheng, B.; Zhao, H.; Zhou, Q.; Cai, J.; Wang, X.; Cao, W.; Dai, T.; Jiang, D. Relationships of protein composition, gluten structure, and dough rheological properties with short biscuits quality of soft wheat varieties. Agron. J. 2020, 112, 1921–1930. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, H.; Wang, J.; Chen, H. Dynamic Changes in Glutenin Macropolymer during Different Dough Mixing and Resting Processes. Molecules 2021, 26, 541. [Google Scholar] [CrossRef]

- Ji, Y.; Yang, X.; Ji, Z.; Zhu, L.; Ma, N.; Chen, D.; Jia, X.; Tang, J.; Cao, Y. DFT-calculated IR spectrum amide I, II, and III band contributions of N-methylacetamide fine components. ACS Omega 2020, 5, 8572–8578. [Google Scholar] [CrossRef]

- Abdullah, A.; Chalimah, S.; Primadona, I.; Hanantyo, M. Physical and chemical properties of corn, cassava, and potato starchs. IOP Conf. Ser. Earth Environ. Sci. 2018, 160, 012003. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.-W.; Kenderes, S.M.; Lin, J.; Vardhanabhuti, B.; Lin, M. Effects of ingredients and pre-heating on the printing quality and dimensional stability in 3D printing of cookie dough. J. Food Eng. 2021, 294, 110412. [Google Scholar] [CrossRef]

- Yang, S.; Dhital, S.; Zhang, M.-N.; Wang, J.; Chen, Z.-G. Structural, gelatinization, and rheological properties of heat-moisture treated potato starch with added salt and its application in potato starch noodles. Food Hydrocoll. 2022, 131, 107802. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, M.-N.; Shan, C.-S.; Chen, Z.-G. Evaluation of cooking performance, structural properties, storage stability and shelf life prediction of high-moisture wet starch noodles. Food Chem. 2021, 357, 129744. [Google Scholar] [CrossRef]

- Fanari, F.; Carboni, G.; Desogus, F.; Grosso, M.; Wilhelm, M. A chemometric approach to assess the rheological properties of durum wheat dough by indirect FTIR measurements. Food Bioprocess Technol. 2022, 15, 1040–1054. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J.; Bevanda, C.; Wu, D. Effect of different edible fats on the spread ratio of sugar cookies. Expedition 2022, 13. [Google Scholar]

- Pulatsu, E.; Su, J.-W.; Kenderes, S.M.; Lin, J.; Vardhanabhuti, B.; Lin, M. Restructuring cookie dough with 3D printing: Relationships between the mechanical properties, baking conditions, and structural changes. J. Food Eng. 2022, 319, 110911. [Google Scholar] [CrossRef]

- Quilaqueo, M.; Iturra, N.; Contardo, I.; Millao, S.; Morales, E.; Rubilar, M. Food-Grade Bigels with Potential to Replace Saturated and Trans Fats in Cookies. Gels 2022, 8, 445. [Google Scholar] [CrossRef]

- Mota, J.; Lima, A.; Ferreira, R.B.; Raymundo, A. Technological Potential of a Lupin Protein Concentrate as a Nutraceutical Delivery System in Baked Cookies. Foods 2021, 10, 1929. [Google Scholar] [CrossRef]

- Almusallam, A.S. Nonlinear viscoelastic rheology of wheat dough. In Advances in Food Rheology and Its Applications; Elsevier: Amsterdam, The Netherlands, 2023; pp. 553–586. [Google Scholar]

- Mohd Basri, M.S.; Mohd Jais, N.; Sulaiman, A.; Mohd Nor, M.Z.; Abdul Karim Shah, N.N.; Ariffin, S.H. Optimizing the processing factor and formulation of oat-based cookie dough for enhancement in stickiness and moisture content using response surface methodology and superimposition. Processes 2020, 8, 797. [Google Scholar] [CrossRef]

- Schädle, C.N.; Bader-Mittermaier, S.; Sanahuja, S. The Effect of Corn Dextrin on the Rheological, Tribological, and Aroma Release Properties of a Reduced-Fat Model of Processed Cheese Spread. Molecules 2022, 27, 1864. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, L.; Gu, Z.; Hong, Y.; Li, Z.; Li, C.; Ban, X. Effects of different gelatinization degrees of potato flour on gluten network integrity and dough stickiness. LWT 2022, 153, 112577. [Google Scholar] [CrossRef]

- Daniela, C.A.; Victoria, S.M.; Cecilia, P.M. Production of legume-wheat dough of optimum quality for breadmaking: Essential analyzes required. Curr. Opin. Food Sci. 2022, 49, 100970. [Google Scholar] [CrossRef]

- Yang, Y.L.; Guan, E.Q.; Zhang, L.L.; Pang, J.Y.; Li, M.M.; Bian, K. Effects of vacuum degree, mixing speed, and water amount on the moisture distribution and rheological properties of wheat flour dough. J. Food Sci. 2021, 86, 2421–2433. [Google Scholar] [CrossRef]

- Avramenko, N.; Tyler, R.; Scanlon, M.; Hucl, P.; Nickerson, M. The chemistry of bread making: The role of salt to ensure optimal functionality of its constituents. Food Rev. Int. 2018, 34, 204–225. [Google Scholar] [CrossRef]

- Dewan, A.; Chaudhary, N.; Khatkar, B.S. Effects of wheat gliadin and glutenin fractions on dough properties, oil uptake, and microstructure of instant noodles. J. Food Process. Preserv. 2022, e17100. [Google Scholar] [CrossRef]

- Menon, V.; Kaur, M.; Gupta, S.; Nadda, A.K.; Singh, G.B.; Sharma, S. Fabrication, properties and applications of gluten protein. In Protein-Based Biopolymers; Elsevier: Amsterdam, The Netherlands, 2023; pp. 41–57. [Google Scholar]

- Gasparre, N.; van den Berg, M.; Oosterlinck, F.; Sein, A. High-Moisture Shear Processes: Molecular Changes of Wheat Gluten and Potential Plant-Based Proteins for Its Replacement. Molecules 2022, 27, 5855. [Google Scholar] [CrossRef]

- Brandner, S. Particle-Polymer Interfaces in Foods–Using Artificial Systems to Analyze the Impact of Starch Surface Functionality. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2022. [Google Scholar]

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18. [Google Scholar] [CrossRef]

- Jumadi, M.; Jamaludin, D. Non-destructive measurement of rock melon fruit properties using Electrical Impedance Spectroscopy (EIS) technique. ASM Sci. J. 2020, 13, 20–26. [Google Scholar]

- Létang, C.; Piau, M.; Verdier, C.; Lefebvre, L. Characterization of wheat-flour-water doughs: A new method using ultrasound. Ultrasonics 2001, 39, 133–142. [Google Scholar] [CrossRef]

- Alshehry, G.A. Preparation and nutritional properties of cookies from the partial replacement of wheat flour using pumpkin seeds powder. World J. Environ. Biosci. 2020, 9, 48–56. [Google Scholar]

- Mehdizadeh, S.A. Machine vision based intelligent oven for baking inspection of cupcake: Design and implementation. Mechatronics 2022, 82, 102746. [Google Scholar] [CrossRef]

- Mas, A.L.; Brigante, F.I.; Salvucci, E.; Ribotta, P.; Martinez, M.L.; Wunderlin, D.A.; Baroni, M.V. Novel cookie formulation with defatted sesame flour: Evaluation of its technological and sensory properties. Changes in phenolic profile, antioxidant activity, and gut microbiota after simulated gastrointestinal digestion. Food Chem. 2022, 389, 133122. [Google Scholar] [CrossRef]

- Ashwath Kumar, K.; Sudha, M. Effect of fat and sugar replacement on rheological, textural and nutritional characteristics of multigrain cookies. J. Food Sci. Technol. 2021, 58, 2630–2640. [Google Scholar] [CrossRef]

- Goswami, M.; Sharma, B.; Mendiratta, S.; Pathak, V. Quality evaluation of functional carabeef cookies incorporated with guar gum (Cyamopsis tetragonoloba) as fat replacer. Nutr. Food Sci. 2019, 49, 432–440. [Google Scholar] [CrossRef]

- Pasqualone, A.; Makhlouf, F.Z.; Barkat, M.; Difonzo, G.; Summo, C.; Squeo, G.; Caponio, F. Effect of acorn flour on the physico-chemical and sensory properties of biscuits. Heliyon 2019, 5, e02242. [Google Scholar] [CrossRef]

- Chauhan, A.; Saxena, D.; Singh, S. Physical, textural, and sensory characteristics of wheat and amaranth flour blend cookies. Cogent Food Agric. 2016, 2, 1125773. [Google Scholar] [CrossRef]

- Sadat, A.; Joye, I.J. Peak fitting applied to fourier transform infrared and raman spectroscopic analysis of proteins. Appl. Sci. 2020, 10, 5918. [Google Scholar] [CrossRef]

- Lin, J.; Tan, Y.X.G.; Leong, L.P.; Zhou, W. Steamed bread enriched with quercetin as an antiglycative food product: Its quality attributes and antioxidant properties. Food Funct. 2018, 9, 3398–3407. [Google Scholar] [CrossRef]

- Agrawal, J.; Kumar, K.A.; Indrani, D.; Radha, C. Effect of Moringa oleifera seed flour on the rheological, physico-sensory, protein digestibility and fatty acid profile of cookies. J. Food Sci. Technol. 2022, 59, 4731–4739. [Google Scholar] [CrossRef]

- Roman, L.; Sahagun, M.; Gomez, M.; Martinez, M.M. Nutritional and physical characterization of sugar-snap cookies: Effect of banana starch in native and molten states. Food Funct. 2019, 10, 616–624. [Google Scholar] [CrossRef]

- Li, M.; Liu, C.; Zheng, X.; Hong, J.; Bian, K.; Li, L. Interaction between A-type/B-type starch granules and gluten in dough during mixing. Food Chem. 2021, 358, 129870. [Google Scholar] [CrossRef]

- Srichuwong, S.; Curti, D.; Austin, S.; King, R.; Lamothe, L.; Gloria-Hernandez, H. Physicochemical properties and starch digestibility of whole grain sorghums, millet, quinoa and amaranth flours, as affected by starch and non-starch constituents. Food Chem. 2017, 233, 1–10. [Google Scholar] [CrossRef]

- San José, F.J.; Collado-Fernández, M.; López, R. Texturometric determination of digestive biscuits. J. Food Meas. Charact. 2018, 12, 412–425. [Google Scholar] [CrossRef]

- Lu, H.; Guo, L.; Zhang, L.; Xie, C.; Li, W.; Gu, B.; Li, K. Study on quality characteristics of cassava flour and cassava flour short biscuits. Food Sci. Nutr. 2020, 8, 521–533. [Google Scholar] [CrossRef]

| Ingredients | Quantity (g) | Formulations | Creaming Time (min) | Mixing Time (min) | Baking Time (min); Temperature (°C) |

|---|---|---|---|---|---|

| Whole wheat flour | 100 | MT1 | 5 | 1 | 25; 180 |

| Butter | 40 | MT3 | 5 | 3 | 25; 180 |

| Sugar | 40 | MT5 | 5 | 5 | 25; 180 |

| Salt | 1 | MT7.5 | 5 | 7.5 | 25; 180 |

| Baking powder | 3 | MT10 | 5 | 10 | 25; 180 |

| Water | 25 |

| Sample | F1 (g) Firmness | Positive Area (g s) Work of Shear | F2 (g) Stickiness | Negative Area (g s) Work of Adhesion |

|---|---|---|---|---|

| MT1 | 4382.02 ± 467.77 a | 16,457.18 ± 1305.08 a | −648.30 ± 59.20 b | −807.46 ± 213.34 a |

| MT3 | 21,030.84 ± 1899.85 b | 65,836.97 ± 4269.83 b | −1140.15 ± 59.05 ab | −1537.45 ± 990.58 a |

| MT5 | 22,188.50 ± 445.71 b | 74,909.47 ± 2922.05 b | −1781.81 ± 279.29 ab | −617.85 ± 41.05 a |

| MT7.5 | 35,313.60 ± 5545.35 c | 109,079.59 ± 15,739.49 c | −2239.42 ± 532.64 a | −860.64 ± 277.00 a |

| MT10 | 39,988.39 ± 1160.97 c | 128,045.37 ± 3019.22 c | −1779.37 ± 999.53 ab | −1318.85 ± 911.76 a |

| Sample | Stress Relaxation Parameters (Average ± Standard Deviation) | ||

|---|---|---|---|

| F0 (g) | F60 (g) | %SR | |

| MT1 | 313.38 ± 18.56 b | 76.52 ± 3.87 b | 75.57 ± 0.59 a |

| MT3 | 275.07 ± 9.47 a | 64.36 ± 1.69 a | 76.60 ± 0.21 ab |

| MT5 | 352.12 ± 15.34 c | 81.25 ± 2.39 b | 76.92 ± 0.33 b |

| MT7.5 | 293.21 ± 14.36 ab | 63.21 ± 3.96 a | 78.45 ± 0.51 c |

| MT10 | 289.05 ± 8.63 ab | 65.37 ± 2.43 a | 77.39 ± 0.30 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhal, S.; Anis, A.; Shaikh, H.M.; Alhamidi, A.; Pal, K. Effect of Mixing Time on Properties of Whole Wheat Flour-Based Cookie Doughs and Cookies. Foods 2023, 12, 941. https://doi.org/10.3390/foods12050941

Dhal S, Anis A, Shaikh HM, Alhamidi A, Pal K. Effect of Mixing Time on Properties of Whole Wheat Flour-Based Cookie Doughs and Cookies. Foods. 2023; 12(5):941. https://doi.org/10.3390/foods12050941

Chicago/Turabian StyleDhal, Somali, Arfat Anis, Hamid M Shaikh, Abdullah Alhamidi, and Kunal Pal. 2023. "Effect of Mixing Time on Properties of Whole Wheat Flour-Based Cookie Doughs and Cookies" Foods 12, no. 5: 941. https://doi.org/10.3390/foods12050941

APA StyleDhal, S., Anis, A., Shaikh, H. M., Alhamidi, A., & Pal, K. (2023). Effect of Mixing Time on Properties of Whole Wheat Flour-Based Cookie Doughs and Cookies. Foods, 12(5), 941. https://doi.org/10.3390/foods12050941