Control of Beany Flavor from Soybean Protein Raw Material in Plant-Based Meat Analog Processing

Abstract

1. Introduction

2. Main Components and Production Mechanism of Beany Flavor in Soybean Protein

2.1. Main Beany Flavor Compounds in Soybean Protein

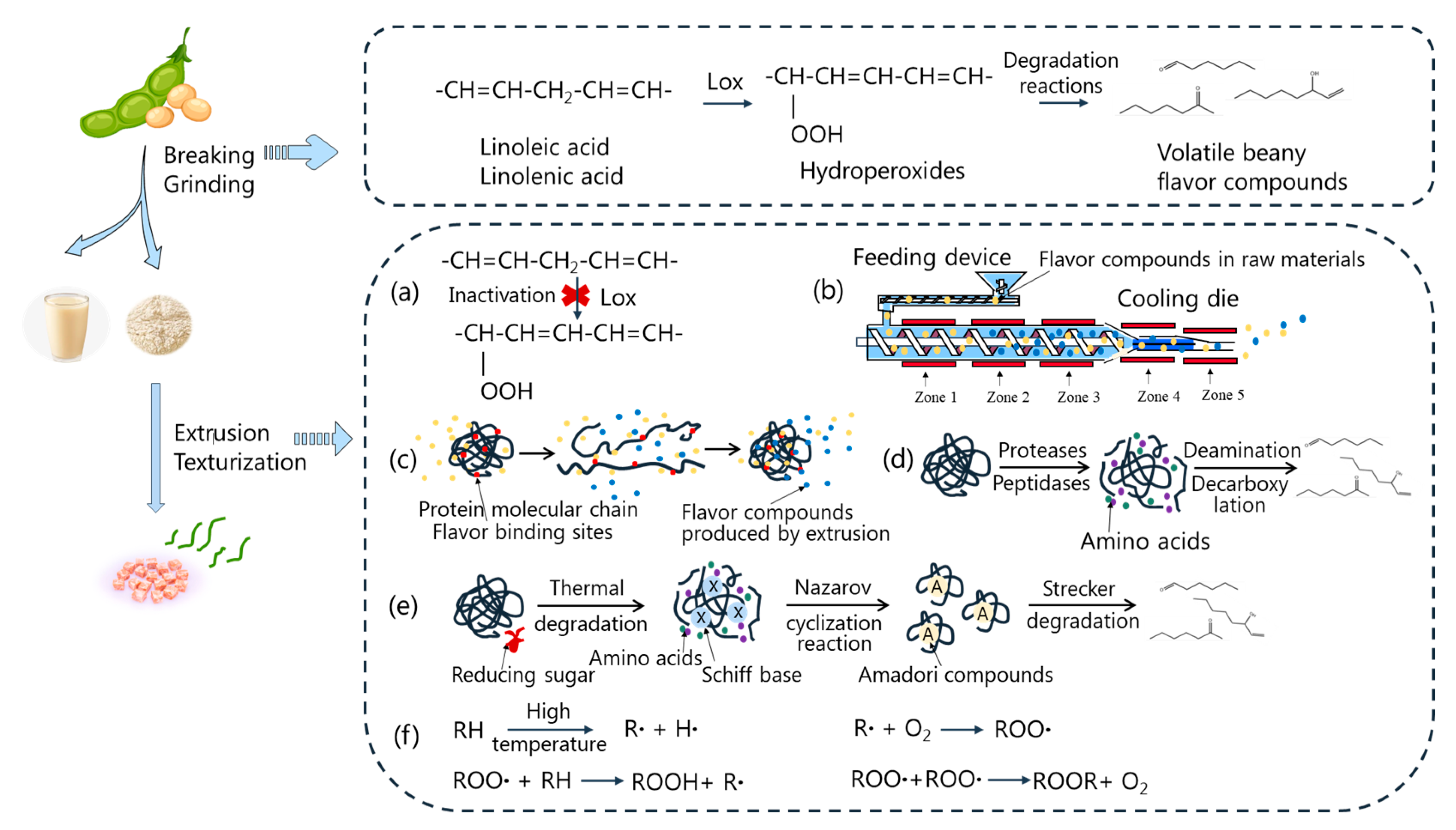

2.2. Mechanism of Beany Flavor Generation in Soybean Protein Raw Material

2.3. Mechanism of Beany Flavor Generation during Extrusion

3. Retention and Release of Beany Flavor Compounds in Soybean Protein Raw Materials and Textured Proteins

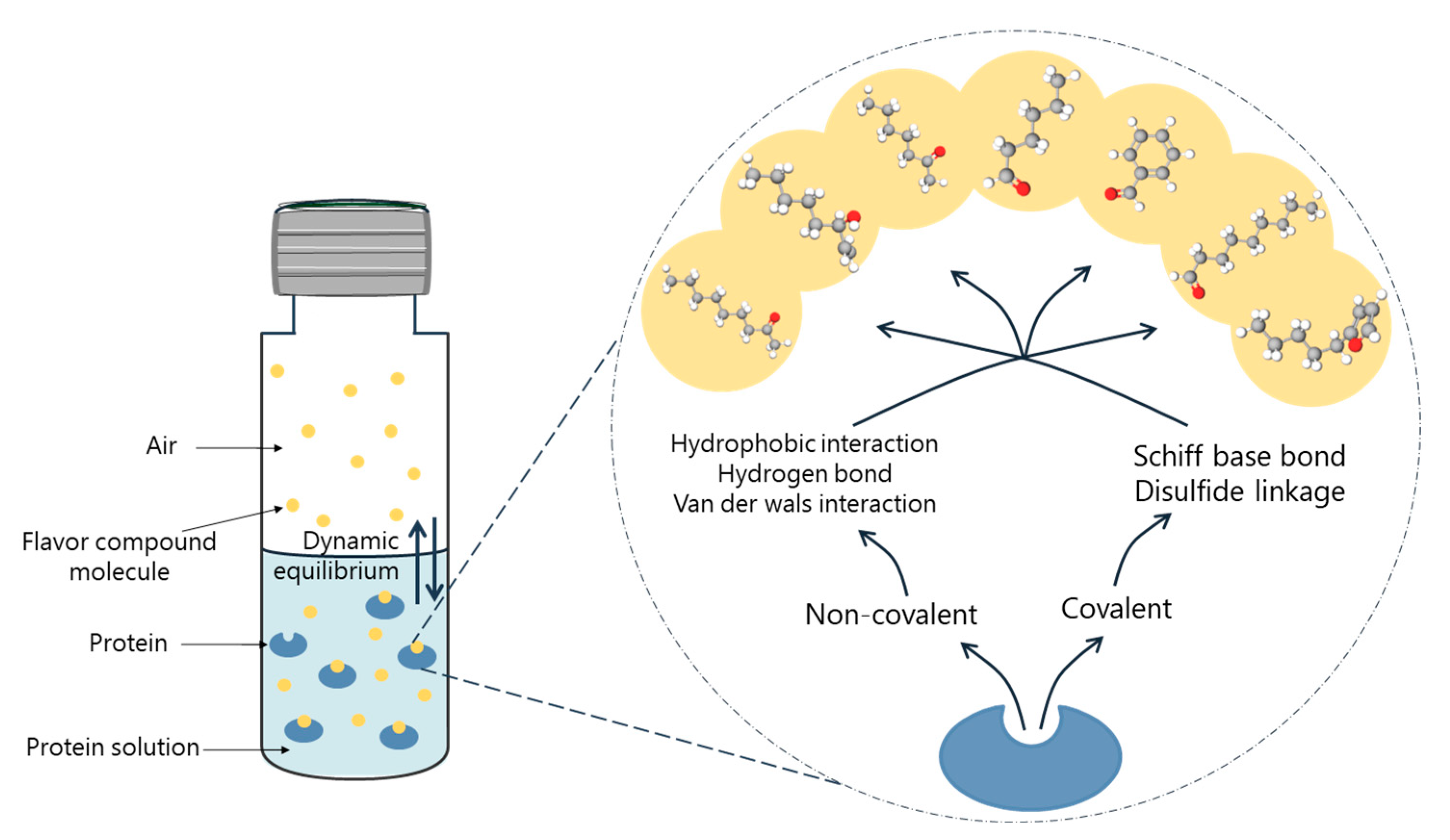

3.1. Interaction Mechanism of Beany Flavor Compounds and Soybean Protein

3.2. Interaction between Different Beany Flavor Compounds and Soybean Protein

3.2.1. Aldehydes

3.2.2. Alcohols

3.2.3. Ketones

3.3. Release and Retention of Beany Flavor during Extrusion

4. Control of Beany Flavor in Soybean Protein Raw Materials

4.1. Effect of Different Treatment Conditions on Beany Flavor

4.2. Effect of Different Drying Methods on Beany Flavor

| Drying Method | Advantages | Disadvantages | Reference |

|---|---|---|---|

| Solar drying | Low energy consumption; inexpensive | Long process; poor flavor; drying speed is difficult to control; product cannot be dried evenly; slow drying speed; exposure to environmental pollution; requires large space for drying. | [58] |

| Oven drying | Low energy consumption; inexpensive; good flavor | Small processing capacity | [64] |

| Freeze drying | Minimal degradation; generally high retention rate and efficient extraction of nutrients from raw products | Expensive; slow drying speed; low product output | [61,62] |

| Spray drying | Rapid drying time; continuous operation; full automated control | Large equipment; low thermal efficiency; high requirements with two-stage separation equipment | [65] |

| Low-temperature drying | Inexpensive; eliminates need for direct sunlight | Slow speed of drying; loss of nutrients in protein | [66] |

| Hot air drying | Low equipment investment cost; low operation cost; high thermal efficiency; avoids heat loss | Covers a large area | [67] |

| Hot-air-assisted radio frequency drying | Strong penetration; stable temperature control; drying uniformity | Poor economic benefits | [68] |

| Microwave drying | Short starting time; reduced drying time; improved extraction of bioactive compounds | Bumping, degradation of heat-sensitive components | [69] |

| Convective drying | High processing economy; high drying rate; energy efficient; not affected by weather | Small drying system; low heat and mass transfer efficiency; deteriorated product quality; bioactive compounds degraded | [56] |

| Microwave vacuum drying | Maintains or accelerates microwave drying; eliminates need for high temperature; increases drying speed; reduces total drying time; minimizes oxidation reaction | High cost; high moisture evaporation; low capacity of the vacuum pump | [69] |

| Swelling drying | Improved volatile and non-volatile molecules extraction; strengthened drying dynamics; reduced energy consumption | Large amount of steam; expansion and cracking of plant materials; structure of materials change | [70] |

4.3. Effects of Different Storage Conditions on Beany Flavor

4.3.1. Temperature Conditions

4.3.2. Humidity Conditions

4.3.3. Lighting Conditions

4.3.4. Inflatable Components

4.4. Effects of Different Extraction Methods on Beany Flavor

5. Effects of Raw Material Characteristics and Environmental Factors on Beany Flavor Retention

| Influence Factor | Protein Type | Processing Method | Result | Reference |

|---|---|---|---|---|

| Flavor compound concentration | Soybean protein isolate | 1% SPI, 0.04–0.16 mM flavors, propylene glycol dissolution, shaken for 24 h at 37 °C to reach equilibration. | Higher concentration of flavor compounds affected the hydrophobic sites of protein to a greater extent | [12] |

| Malondialdehyde | Soybean protein isolate | MDA and 40 mg/mL SPI shaking reaction for 24 h | Concentration of MDA was ≤1 mM, the combination of flavor and SPI ↑; MDA content ≥2.5 mM, the combination of hexanal and nonanal with SPI ↓ | [80] |

| Preheat treatment | Soybean protein isolate | Preheating at 80 °C, 90 °C and 100 °C | The temperature of SPI aqueous solution ↑; the binding ability of SPI to HxAc and HpAc ↓ | [82] |

| Disodium inosine | Soybean protein isolate | Addition of 25 mg/100 g inosine disodium to 220 g soy protein isolate | Isovaleraldehyde and ethyl butyrate retention rates were significantly ↑ | [83] |

| Glutaminase deamination | Soybean protein isolate | Glutaminase deamidation reaction for 2 h | Binding effect of vanillin and maltol with SPI was stronger than that with DSPI | [81] |

| β-Cyclodextrin | Soybean protein | Injected addition of 20 mM β-CD stock solution to buffer solution at 25 °C for 24 h to reach equilibrium | SP-bound 2-nonanone ↓ in a concentration-dependent manner | [84] |

| Temperature | Soybean protein | Addition of 1 mL of 30 mM Tris-HCl buffer solution to 0.5 mL of 20 mg/mL protein solution | Structural changes; at 20 °C and 30 °C, the number of binding sites of glycine was higher ↑ than that of p-homologous glycine | [85] |

| pH | Soybean protein | In 0.05N HCl, 2% soybean protein solution heated at 95 °C for 30 min | SP was preferentially deamidated, but the peptide bond did not break obviously; improved protein flavor | [86] |

| High-temperature pretreatment and enzymatic hydrolysis | Soybean protein isolate | Pretreatment at 121 °C, under optimal enzyme conditions (pH 6.0 and 45 °C), and hydrolysis with 100 mg Protemex | Some volatile compounds such as hexanol, hexanal, and pentanol in SPI ↓ | [87] |

| NaCl | Defatted soybean extract | Defatted soybean extract precipitated at pH 4.5 | The defatted soybean extract combined flavor volatiles and non-protein substances | [88] |

| Na2SO4 and CaCl2 | Defatted soybean extract | At pH 2.8, 30 mM Na2SO4, and 30 mM CaCl2, conventional centrifugation (10,000× g for 10 min) | SPI prepared from defatted soybean extract contained volatile flavor compounds ↓ | [89] |

6. Control of Beany Flavor in Soybean Protein Extrusion Processing

6.1. Effects of Different Extrusion Parameters on Beany Flavor

6.1.1. Moisture Content

6.1.2. Extrusion Temperature

6.1.3. Screw Speed

6.2. Effects of Different Additives on Beany Flavor in Textured Protein

7. Conclusions and Prospective Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pojić, M.; Mišan, A.; Tiwari, B. Eco-innovative technologies for extraction of proteins for human consumption from renewable protein sources of plant origin. Trends Food Sci. Technol. 2018, 75, 93–104. [Google Scholar] [CrossRef]

- Sanchez-Sabate, R.; Sabate, J. Consumer Attitudes Towards Environmental Concerns of Meat Consumption: A Systematic Review. Int. J. Environ. Res. Public Health 2019, 16, 1220. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 2019, 19, 100102. [Google Scholar] [CrossRef]

- Michel, F.; Hartmann, C.; Siegrist, M. Consumers’ associations, perceptions and acceptance of meat and plant-based meat alternatives. Food Qual. Prefer. 2021, 87, 104063. [Google Scholar] [CrossRef]

- Wild, F. Manufacture of Meat Analogues through High Moisture Extrusion. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Sá, A.G.A.; Moreno, Y.M.F.; Carciofi, B.A.M. Plant proteins as high-quality nutritional source for human diet. Trends Food Sci. Technol. 2020, 97, 170–184. [Google Scholar] [CrossRef]

- Ismail, I.; Hwang, Y.H.; Joo, S.T. Meat analog as future food: A review. J. Anim. Sci. Technol. 2020, 62, 111–120. [Google Scholar] [CrossRef]

- Viana, L.; English, M. The application of chromatography in the study of off-flavour compounds in pulses and pulse by-products. LWT-Food Sci. Technol. 2021, 150, 111981. [Google Scholar] [CrossRef]

- Ravi, R.; Taheri, A.; Khandekar, D.; Millas, R. Rapid Profiling of Soybean Aromatic Compounds Using Electronic Nose. Biosensors 2019, 9, 66. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Q.; Zhang, N.; Bak, K.H.; Soladoye, O.P.; Aluko, R.E.; Fu, Y.; Zhang, Y. Insights into formation, detection and removal of the beany flavor in soybean protein. Trends Food Sci. Technol. 2021, 112, 336–347. [Google Scholar] [CrossRef]

- Roland, W.S.U.; Pouvreau, L.; Curran, J.; van de Velde, F.; de Kok, P.M.T. Flavor Aspects of Pulse Ingredients. Cereal Chem. 2017, 94, 58–65. [Google Scholar] [CrossRef]

- Guo, J.; He, Z.; Wu, S.; Zeng, M.; Chen, J. Effects of concentration of flavor compounds on interaction between soy protein isolate and flavor compounds. Food Hydrocoll. 2020, 100, 105388. [Google Scholar] [CrossRef]

- Reineccius, G.A. Flavor interactions with proteins. Curr. Opin. Food Sci. 2022, 47, 100884. [Google Scholar] [CrossRef]

- Yang, L.; Ying, Z.; Li, H.; Li, J.; Zhang, T.; Song, Y.; Liu, X. Extrusion production of textured soybean protein: The effect of energy input on structure and volatile beany flavor substances. Food Chem. 2023, 405, 134728. [Google Scholar] [CrossRef]

- Kaneko, S.; Kumazawa, K.; Nishimura, O. Studies on the key aroma compounds in soy milk made from three different soybean cultivars. J. Agric. Food Chem. 2011, 59, 12204–12209. [Google Scholar] [CrossRef]

- Achouri, A.; Boye, J.I.; Zamani, Y. Identification of volatile compounds in soymilk using solid-phase microextraction-gas chromatography. Food Chem. 2006, 99, 759–766. [Google Scholar] [CrossRef]

- Lee, K.E.; Lee, S.M.; Choi, Y.H.; Hurh, B.S.; Kim, Y.S. Comparative volatile profiles in soy sauce according to inoculated microorganisms. Biosci. Biotechnol. Biochem. 2013, 77, 2192–2200. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, S.; Liu, Z.; Chang, S.K. Off-flavor related volatiles in soymilk as affected by soybean variety, grinding, and heat-processing methods. J. Agric. Food Chem. 2012, 60, 7457–7462. [Google Scholar] [CrossRef]

- MacLeod, G.; Ames, J. Soy flavor and its improvement. Crit. Rev. Food Sci. Nutr. 1988, 27, 219–400. [Google Scholar] [CrossRef]

- Wang, X.; Ho, C.T.; Shahidi, F. Flavor Components of Fats and Oils. In Bailey’s Industrial Oil and Fat Products; John Wiley & Sons: Hoboken, NJ, USA, 2020; pp. 1–25. [Google Scholar]

- Min, D.B.; Boff, J.M. Chemistry and Reaction of Singlet Oxygen in Foods. Compr. Rev. Food Sci. Food Saf. 2002, 1, 58–72. [Google Scholar] [CrossRef]

- Samard, S.; Gu, B.Y.; Ryu, G.H. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J. Sci. Food Agric. 2019, 99, 4922–4931. [Google Scholar] [CrossRef]

- Sohn, M.; Ho, C.T. Ammonia generation during thermal degradation of amino acids. J. Agric. Food Chem. 1995, 43, 3001–3003. [Google Scholar] [CrossRef]

- Hofmann, T.; Schieberle, P. Formation of aroma-active Strecker-aldehydes by a direct oxidative degradation of Amadori compounds. J. Agric. Food Chem. 2000, 48, 4301–4305. [Google Scholar] [CrossRef] [PubMed]

- El-Dalatony, M.M.; Saha, S.; Govindwar, S.P.; Abou-Shanab, R.A.I.; Jeon, B.H. Biological Conversion of Amino Acids to Higher Alcohols. Trends Biotechnol. 2019, 37, 855–869. [Google Scholar] [CrossRef] [PubMed]

- Sun, A.; Wu, W.; Soladoye, O.P.; Aluko, R.E.; Bak, K.H.; Fu, Y.; Zhang, Y. Maillard reaction of food-derived peptides as a potential route to generate meat flavor compounds: A review. Food Res. Int. 2022, 151, 110823. [Google Scholar] [CrossRef]

- Sun, F.; Cui, H.; Zhan, H.; Xu, M.; Hayat, K.; Tahir, M.U.; Hussain, S.; Zhang, X.; Ho, C.T. Aqueous Preparation of Maillard Reaction Intermediate from Glutathione and Xylose and its Volatile Formation during Thermal Treatment. J. Food Sci. 2019, 84, 3584–3593. [Google Scholar] [CrossRef]

- Riha, W.E.; Ho, C.T. Formation of flavors during extrusion cooking. Food Rev. Int. 1996, 12, 351–373. [Google Scholar] [CrossRef]

- Barros, M.R.; Menezes, T.M.; da Silva, L.P.; Pires, D.S.; Princival, J.L.; Seabra, G.; Neves, J.L. Furan inhibitory activity against tyrosinase and impact on B16F10 cell toxicity. Int. J. Biol. Macromol. 2019, 136, 1034–1041. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.; Yu, X.; Peng, J.; Pan, L.; Tu, K. Evaluation of the adsorption capacity and mechanism of soy protein isolate for volatile flavor compounds: Role of different oxygen-containing functional groups. Food Chem. 2022, 386, 132745. [Google Scholar]

- Guo, Z.; Teng, F.; Huang, Z.; Lv, B.; Lv, X.; Babich, O.; Yu, W.; Li, Y.; Wang, Z.; Jiang, L. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 2020, 105, 105752. [Google Scholar] [CrossRef]

- Zhang, J.; Kang, D.; Zhang, W.; Lorenzo, J.M. Recent advantage of interactions of protein-flavor in foods: Perspective of theoretical models, protein properties and extrinsic factors. Trends Food Sci. Technol. 2021, 111, 405–425. [Google Scholar] [CrossRef]

- Heng, L.; van Koningsveld, G.A.; Gruppen, H.; van Boekel, M.A.J.S.; Vincken, J.P.; Roozen, J.P.; Voragen, A.G.J. Protein–flavour interactions in relation to development of novel protein foods. Trends Food Sci. Technol. 2004, 15, 217–224. [Google Scholar] [CrossRef]

- Suppavorasatit, I.; Cadwallader, K.R. Effect of enzymatic deamidation of soy protein by protein-glutaminase on the flavor-binding properties of the protein under aqueous conditions. J. Agric. Food Chem. 2012, 60, 7817–7823. [Google Scholar] [CrossRef]

- Wang, K.; Arntfield, S.D. Effect of protein-flavour binding on flavour delivery and protein functional properties: A special emphasis on plant-based proteins. Flavour Fragr. J. 2017, 32, 92–101. [Google Scholar] [CrossRef]

- Lehtonen, M.; Kekalainen, S.; Nikkila, I.; Kilpelainen, P.; Tenkanen, M.; Mikkonen, K.S. Active food packaging through controlled in situ production and release of hexanal. Food Chem. X 2020, 5, 100074. [Google Scholar] [CrossRef]

- Feussner, I.; Wasternack, C. The lipoxygenase pathway. Annu. Rev. Plant Biol. 2002, 53, 275–297. [Google Scholar] [CrossRef] [PubMed]

- Zamora, R.; Navarro, J.L.; Aguilar, I.; Hidalgo, F.J. Lipid-derived aldehyde degradation under thermal conditions. Food Chem. 2015, 174, 89–96. [Google Scholar] [CrossRef]

- Ullrich, F.; Grosch, W. Identification of the most intense volatile flavour compounds formed during autoxidation of linoleic acid. Z. Lebensm. Unters. Forsch. 1987, 187, 277–282. [Google Scholar] [CrossRef]

- Matsui, K.; Takemoto, H.; Koeduka, T.; Ohnishi, T. 1-Octen-3-ol Is Formed from Its Glycoside during Processing of Soybean [Glycine max (L.) Merr.] Seeds. J. Agric. Food Chem. 2018, 66, 7409–7416. [Google Scholar] [CrossRef]

- Grebenteuch, S.; Kanzler, C.; Klaussnitzer, S.; Kroh, L.W.; Rohn, S. The formation of methyl ketones during lipid oxidation at elevated temperatures. Molecules 2021, 26, 1104. [Google Scholar] [CrossRef]

- Shi, X.; Li, J.; Wang, S.; Zhang, L.; Qiu, L.; Han, T.; Wang, Q.; Chang, S.K.; Guo, S. Flavor characteristic analysis of soymilk prepared by different soybean cultivars and establishment of evaluation method of soybean cultivars suitable for soymilk processing. Food Chem. 2015, 185, 422–429. [Google Scholar] [CrossRef]

- Mustakas, G.C.; Albrecht, W.J.; McGhee, J.E.; Black, L.T.; Bookwalter, G.N.; Griffin, E.L., Jr. Lipoxidase deactivation to improve stability, odor and flavor of full-fat soy flours. J. Am. Oil Chem. Soc. 1969, 46, 623–626. [Google Scholar] [CrossRef]

- de Mesa, N.J.E.; Alavi, S.; Singh, N.; Shi, Y.-C.; Dogan, H.; Sang, Y. Soy protein-fortified expanded extrudates: Baseline study using normal corn starch. J. Food Eng. 2009, 90, 262–270. [Google Scholar] [CrossRef]

- Guichard, E. Flavour retention and release from protein solutions. Biotechnol. Adv. 2006, 24, 226–229. [Google Scholar] [CrossRef] [PubMed]

- Li, S.Q.; Zhang, H.Q.; Tony Jin, Z.; Hsieh, F.H. Textural modification of soya bean/corn extrudates as affected by moisture content, screw speed and soya bean concentration. Int. J. Food Sci. Technol. 2005, 40, 731–741. [Google Scholar] [CrossRef]

- Suppavorasatit, I.; Cadwallader, K.R. Flavor-Soy Protein Interactions. In Chemistry, Texture, and Flavor of Soy; Amer Chemical Society: Washington, DC, USA, 2010; pp. 339–359. [Google Scholar]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion process parameters, sensory characteristics, and structural properties of a high moisture soy protein meat analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Yuan, S.; Chang, S.K.C. Selected odor compounds in soymilk as affected by chemical composition and lipoxygenases in five soybean materials. J. Agric. Food Chem. 2007, 55, 426–431. [Google Scholar] [CrossRef]

- Duque-Estrada, P.; Kyriakopoulou, K.; de Groot, W.; van der Goot, A.J.; Berton-Carabin, C.C. Oxidative stability of soy proteins: From ground soybeans to structured products. Food Chem. 2020, 318, 126499. [Google Scholar] [CrossRef]

- Navicha, W.; Hua, Y.; Masamba, K.G.; Kong, X.; Zhang, C. Effect of soybean roasting on soymilk sensory properties. Br. Food J. 2018, 120, 2832–2842. [Google Scholar] [CrossRef]

- Zhang, Z.; Elfalleh, W.; He, S.; Tang, M.; Zhao, J.; Wu, Z.; Wang, J.; Sun, H. Heating and cysteine effect on physicochemical and flavor properties of soybean peptide Maillard reaction products. Int. J. Biol. Macromol. 2018, 120, 2137–2146. [Google Scholar] [CrossRef]

- Li, Y.Q.; Chen, Q.; Liu, X.H.; Chen, Z.X. Inactivation of soybean lipoxygenase in soymilk by pulsed electric fields. Food Chem. 2008, 109, 408–414. [Google Scholar] [CrossRef]

- Tewari, K.; Kumari, S.; Vinutha, T.; Singh, B.; Dahuja, A. Gamma irradiation induces reduction in the off-flavour generation in soybean through enhancement of its antioxidant potential. J. Radioanal. Nucl. Chem. 2014, 303, 2041–2051. [Google Scholar] [CrossRef]

- Iassonova, D.R.; Johnson, L.A.; Hammond, E.G.; Beattie, S.E. Evidence of an enzymatic source of off flavors in “lipoxygenase-null” soybeans. J. Am. Oil Chem. Soc. 2008, 86, 59–64. [Google Scholar] [CrossRef]

- Kumar, M.; Sansaniwal, S.K.; Khatak, P. Progress in solar dryers for drying various commodities. Renew. Sustain. Energy Rev. 2016, 55, 346–360. [Google Scholar] [CrossRef]

- Sagar, V.R.; Suresh Kumar, P. Recent advances in drying and dehydration of fruits and vegetables: A review. J. Chin. Inst. Food Sci. Technol. 2010, 47, 15–26. [Google Scholar] [CrossRef]

- Liao, X.; Wang, S.; Li, Y.; Michael Olajide, T.; Zhai, X.; Qian, J.; Miao, S.; Huang, J. Effects of “nine steaming nine sun-drying” on proximate composition, protein structure and volatile compounds of black soybeans. Food Res. Int. 2022, 155, 111070. [Google Scholar] [CrossRef]

- Navicha, W.B.; Hua, Y.; Masamba, K.; Kong, X.; Zhang, C. Optimization of soybean roasting parameters in developing nutritious and lipoxygenase free soymilk. J. Food Meas. Charact. 2017, 11, 1899–1908. [Google Scholar] [CrossRef]

- Boge, E.L.; Boylston, T.D.; Wilson, L.A. Effect of cultivar and roasting method on composition of roasted soybeans. J. Sci. Food Agric. 2009, 89, 821–826. [Google Scholar] [CrossRef]

- Erdem, B.G.; Kaya, S. Characterization and application of novel composite films based on soy protein isolate and sunflower oil produced using freeze drying method. Food Chem. 2022, 366, 130709. [Google Scholar] [CrossRef]

- Zhan, F.; Shi, M.; Wang, Y.; Li, B.; Chen, Y. Effect of freeze-drying on interaction and functional properties of pea protein isolate/soy soluble polysaccharides complexes. J. Mol. Liq. 2019, 285, 658–667. [Google Scholar] [CrossRef]

- Huang, C.; Cui, H.; Hayat, K.; Zhang, X.; Ho, C.T. Variation of moisture state and taste characteristics during vacuum drying of Maillard reaction intermediates of hydrolyzed soybean protein and characterization of browning precursors via fluorescence spectroscopy. Food Res. Int. 2022, 162, 112086. [Google Scholar] [CrossRef]

- Suryana, A.L.; Rosiana, N.M.; Olivia, Z. Effect of drying method on the chemical properties of local soy flour. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 4th International Conference on Food and Agriculture (ICOFA), Jember, Indonesia, 6–7 November 2021; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar]

- Bangs, W.E.; Reineccius, G.A. Influence of Dryer Infeed Matrices on the Retention of Volatile Flavor Compounds during Spray Drying. J. Food Sci. 1982, 47, 254–259. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I.; Azarnia, S.; Simpson, B.K. Volatile flavor profile of saskatchewan grown pulses as affected by different thermal processing treatments. Int. J. Food Prop. 2016, 19, 2251–2271. [Google Scholar] [CrossRef]

- Martinez, M.L.; Marin, M.A.; Ribotta, P.D. Optimization of soybean heat-treating using a fluidized bed dryer. J. Food Sci. Technol. 2013, 50, 1144–1150. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, S.; Zhu, Y.; Shi, W.; Zhang, Y.; Liu, Y. Effect of different drying methods on the taste and volatile compounds, sensory characteristics of Takifugu obscurus. Food Sci. Hum. Wellness 2023, 12, 223–232. [Google Scholar] [CrossRef]

- Phuhongsung, P.; Zhang, M.; Bhandari, B. 4D printing of products based on soy protein isolate via microwave heating for flavor development. Food Res. Int. 2020, 137, 109605. [Google Scholar] [CrossRef]

- Charve, J.; Reineccius, G.A. Encapsulation performance of proteins and traditional materials for spray dried flavors. J. Agric. Food Chem. 2009, 57, 2486–2492. [Google Scholar] [CrossRef]

- Pinto, M.D.S.; Lajolo, F.M.; Genovese, M.I. Effect of storage temperature and water activity on the content and profile of isoflavones, antioxidant activity, and in vitro protein digestibility of soy protein isolates and defatted soy flours. J. Agric. Food Chem. 2005, 53, 6340–6346. [Google Scholar] [CrossRef]

- Lee, J.Y.; Min, S.; Choe, E.O.; Min, D.B. Formation of volatile compounds in soy flour by singlet oxygen oxidation during storage under light. J. Food Sci. 2003, 68, 1933–1937. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Z.; Qi, B.; Ran, A.; Guo, Z.; Jiang, L. Effect of oxidation on quality of chiba tofu produced by soy isolate protein when subjected to storage. Foods 2020, 9, 1877. [Google Scholar] [CrossRef]

- Hua, Y.; Huang, Y.; Qiu, A.; Liu, X. Properties of soy protein isolate prepared from aqueous alcohol washed soy flakes. Food Res. Int. 2005, 38, 273–279. [Google Scholar] [CrossRef]

- Samoto, M.; Maebuchi, M.; Miyazaki, C.; Kugitani, H.; Kohno, M.; Hirotsuka, M.; Kito, M. Abundant proteins associated with lecithin in soy protein isolate. Food Chem. 2007, 102, 317–322. [Google Scholar] [CrossRef]

- Honig, D.H.; Warner, K.A.; Selke, E.; Rackis, J.J. Effects of residual solvents and storage on flavor of hexane/ethanol azeotrope extracted soy products. J. Agric. Food Chem. 1979, 27, 1383–1386. [Google Scholar] [CrossRef]

- Zhang, J.; Ying, D.; Wei, Y.; Zhang, B.; Su, X.; Li, S. Thermal transition and decomposition properties of pH- and phosphate-induced defatted soybean meals. J. Therm. Anal. Calorim. 2016, 128, 699–706. [Google Scholar] [CrossRef]

- de Roos, K.B. Effect of texture and microstructure on flavour retention and release. Int. Dairy J. 2003, 13, 593–605. [Google Scholar] [CrossRef]

- Weerawatanakorn, M.; Wu, J.C.; Pan, M.H.; Ho, C.T. Reactivity and stability of selected flavor compounds. J. Food Drug Anal. 2015, 23, 176–190. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, M.; Qiu, C.; Sun, W. Effect of malondialdehyde modification on the binding of aroma compounds to soy protein isolates. Food Res. Int. 2018, 105, 150–158. [Google Scholar] [CrossRef]

- Suppavorasatit, I.; Lee, S.Y.; Cadwallader, K.R. Effect of enzymatic protein deamidation on protein solubility and flavor binding properties of soymilk. J. Food Sci. 2013, 78, C1–C7. [Google Scholar] [CrossRef]

- Guo, J.; He, Z.; Wu, S.; Zeng, M.; Chen, J. Binding of aroma compounds with soy protein isolate in aqueous model: Effect of preheat treatment of soy protein isolate. Food Chem. 2019, 290, 16–23. [Google Scholar] [CrossRef]

- Milani, T.M.G.; Menis, M.E.C.; Jordano, A.; Boscolo, M.; Conti-Silva, A.C. Pre-extrusion aromatization of a soy protein isolate using volatile compounds and flavor enhancers: Effects on physical characteristics, volatile retention and sensory characteristics of extrudates. Food Res. Int. 2014, 62, 375–381. [Google Scholar] [CrossRef]

- Arora, A.; Damodaran, S. Competitive binding of off-flavor compounds with soy protein and β-cyclodextrin in a ternary system: A model study. J. Am. Oil Chem. Soc. 2010, 87, 673–679. [Google Scholar] [CrossRef]

- O’Keefe, S.F.; Resurreccion, A.P.; Wilson, L.A.; Murphy, P.A. Temperature effect on binding of volatile flavor compounds to soy protein in aqueous model systems. J. Food Sci. 1991, 56, 802–806. [Google Scholar] [CrossRef]

- Matsudomi, N.; Sasaki, T.; Kato, A.; Kobayashi, K. Conformational changes and functional properties of acid-modified soy protein. Agric. Biol. Chem. 2014, 49, 1251–1256. [Google Scholar]

- Yoo, S.H.; Chang, Y.H. Volatile compound, physicochemical, and antioxidant properties of beany flavor-removed soy protein isolate hydrolyzates obtained from combined high temperature pre-treatment and enzymatic hydrolysis. Prev. Nutr. Food Sci. 2016, 21, 338–347. [Google Scholar] [CrossRef]

- Wu, N.; Wang, L.; Yang, X.; Yin, S.; Teng, Z.; Zheng, E. Comparison of flavor volatiles and some functional properties of different soy protein products. J. Am. Oil Chem. Soc. 2011, 88, 1621–1631. [Google Scholar] [CrossRef]

- Samoto, M.; Miyazaki, C.; Kanamori, J.; Akasaka, T.; Kawamura, Y. Improvement of the off-flavor of soy protein isolate by removing oil-body associated proteins and polar lipids. Biosci. Biotechnol. Biochem. 1998, 62, 935–940. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Academic Press: Cambridge, MA, USA, 2019; pp. 103–126. [Google Scholar]

- Estrada, P.D.; Berton-Carabin, C.C.; Schlangen, M.; Haagsma, A.; Pierucci, A.; van der Goot, A.J. Protein oxidation in plant protein-based fibrous products: Effects of encapsulated iron and process conditions. J. Agric. Food Chem. 2018, 66, 11105–11112. [Google Scholar] [CrossRef]

- Prabha, K.; Ghosh, P.; Abdullah, S.; Joseph, R.M.; Krishnan, R.; Rana, S.S.; Pradhan, R.C. Recent development, challenges, and prospects of extrusion technology. Future Foods 2021, 3, 100019. [Google Scholar] [CrossRef]

- Ning, L.; Villota, R. Influence of 7s and 11s globulins on the extrusion performance of soy protein concentrates. J. Food Process. Preserv. 1994, 18, 421–436. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Texture and chemical characteristics of soy protein meat analog extruded at high moisture. J. Food Sci. 2000, 65, 264–269. [Google Scholar] [CrossRef]

- Rokey, G.J.; Plattner, B.; Souza, E.M.D. Feed extrusion process description. Rev. Bras. Zootec. 2010, 39, 510–518. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, L.; He, S.; Li, X.; Jin, R.; Liu, Q.; Chen, S.; Sun, H. High-moisture extrusion technology application in the processing of textured plant protein meat analogues: A review. Food Rev. Int. 2022, 1–36. [Google Scholar] [CrossRef]

- Zhu, S.; Riaz, M.N.; Lusas, E.W. Effect of different extrusion temperatures and moisture content on lipoxygenase inactivation and protein solubility in soybeans. J. Agric. Food Chem. 1996, 44, 3315–3318. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Liu, H.; Yoon, A.; Rizvi, S.S.H.; Wang, Q. Changes in conformation and quality of vegetable protein during texturization process by extrusion. Crit. Rev. Food Sci. Nutr. 2019, 59, 3267–3280. [Google Scholar] [CrossRef]

- Bhandari, B.R.; Howes, T. Implication of glass transition for the drying and stability of dried foods. J. Food Eng. 1999, 40, 71–79. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, Q.; Kaplan, D.L.; Wang, Q. High-moisture extruded protein fiber formation toward plant-based meat substitutes applications: Science, technology, and prospect. Trends Food Sci. Technol. 2022, 128, 202–216. [Google Scholar] [CrossRef]

- Chiba, H.; Takahashi, N.; Sasaki, R. Enzymatic improvement of food flavor II. Removal of beany flavor from soybean products by aldehyde dehydrogenase. Agric. Biol. Chem. 2014, 43, 1883–1889. [Google Scholar]

- Redrejo-Rodriguez, M.; Tejeda-Cano, A.; del Carmen Pinto, M.; Macías, P. Lipoxygenase inhibition by flavonoids: Semiempirical study of the structure–activity relation. J. Mol. Struct. THEOCHEM 2004, 674, 121–124. [Google Scholar] [CrossRef]

- Zhu, D.; Damodaran, S. Removal of off-flavour-causing precursors in soy protein by concurrent treatment with phospholipase A(2) and cyclodextrins. Food Chem. 2018, 264, 319–325. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Zhang, T.; Li, H.; Chen, T.; Liu, X. Control of Beany Flavor from Soybean Protein Raw Material in Plant-Based Meat Analog Processing. Foods 2023, 12, 923. https://doi.org/10.3390/foods12050923

Yang L, Zhang T, Li H, Chen T, Liu X. Control of Beany Flavor from Soybean Protein Raw Material in Plant-Based Meat Analog Processing. Foods. 2023; 12(5):923. https://doi.org/10.3390/foods12050923

Chicago/Turabian StyleYang, Lingyu, Tianyu Zhang, He Li, Tianpeng Chen, and Xinqi Liu. 2023. "Control of Beany Flavor from Soybean Protein Raw Material in Plant-Based Meat Analog Processing" Foods 12, no. 5: 923. https://doi.org/10.3390/foods12050923

APA StyleYang, L., Zhang, T., Li, H., Chen, T., & Liu, X. (2023). Control of Beany Flavor from Soybean Protein Raw Material in Plant-Based Meat Analog Processing. Foods, 12(5), 923. https://doi.org/10.3390/foods12050923