High-Value Bioconversion of Ginseng Extracts in Betaine-Based Deep Eutectic Solvents for the Preparation of Deglycosylated Ginsenosides

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of DES

2.3. Enzyme Stability in DES

2.4. Enzyme Activity Analysis

2.5. Enzymatic Conversion of Ginsenosides

2.6. Preparation of Phase Diagrams

2.7. DES-Based ATPS

2.8. Quantitative Analysis of Ginsenosides

2.9. Structural Characterization of Enzymes

3. Results and Discussion

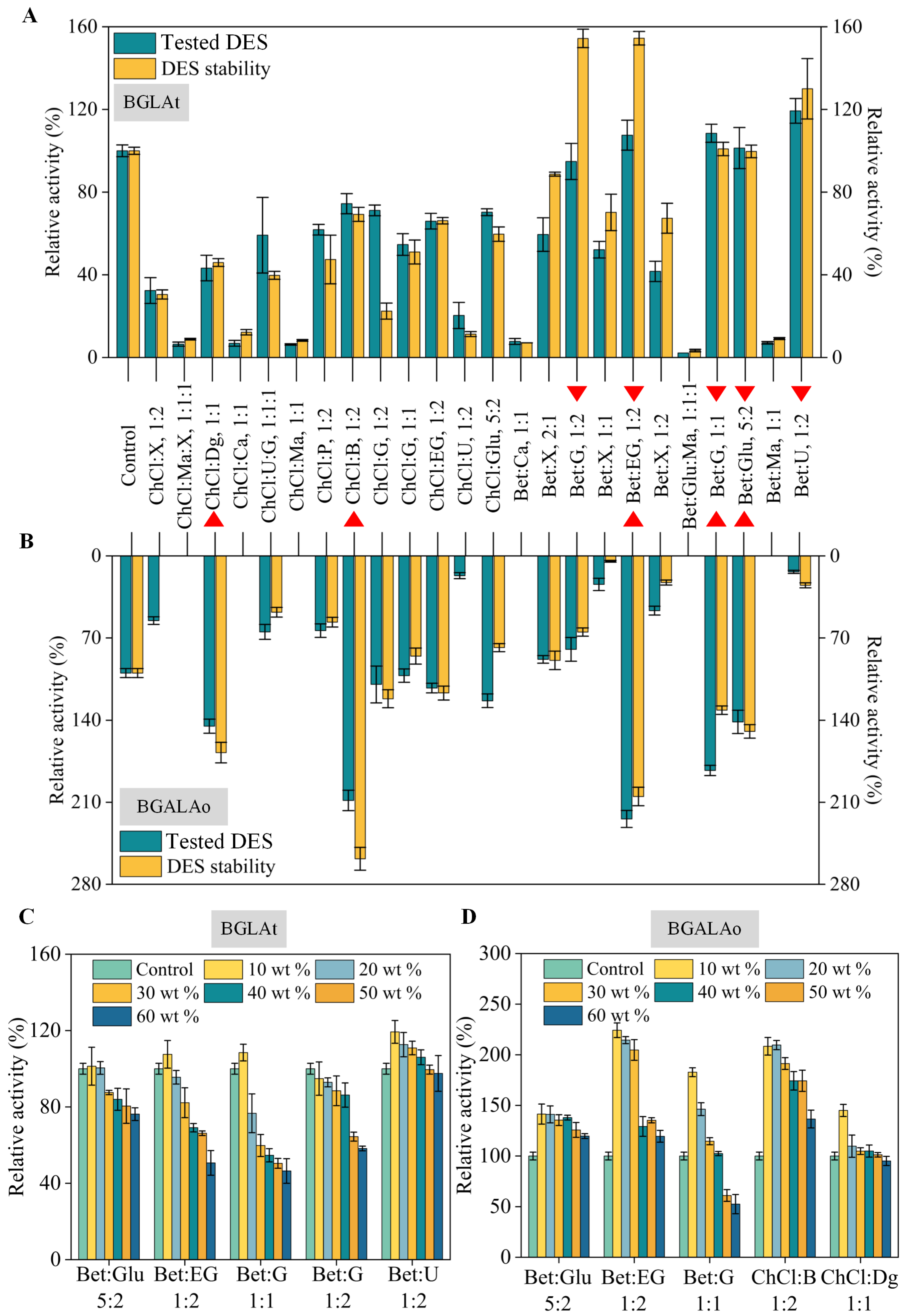

3.1. Screening of Optimal DES for Enzymatic Reactions

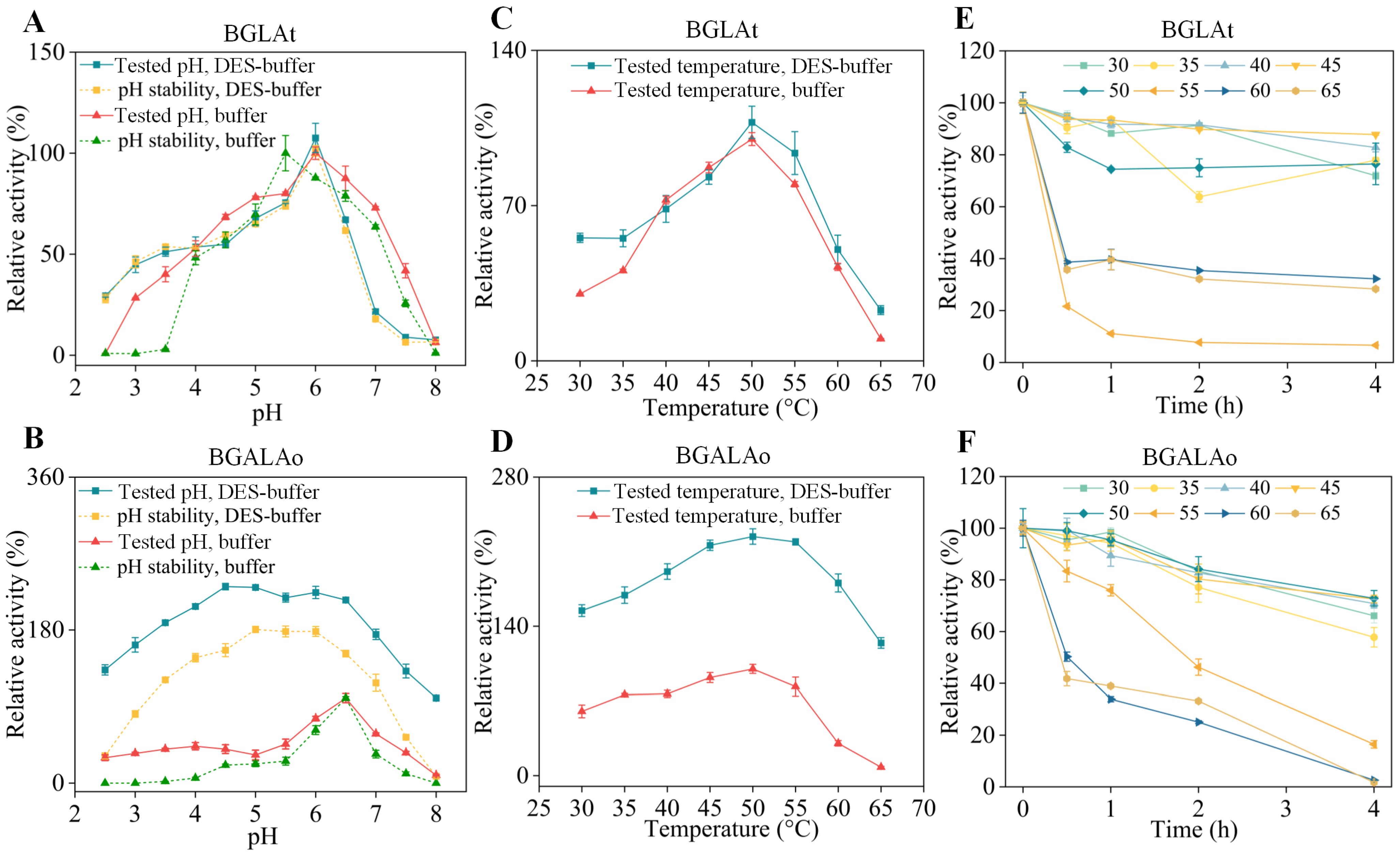

3.2. Effects of DES (Bet: EG, 2:1) on Biocatalysts

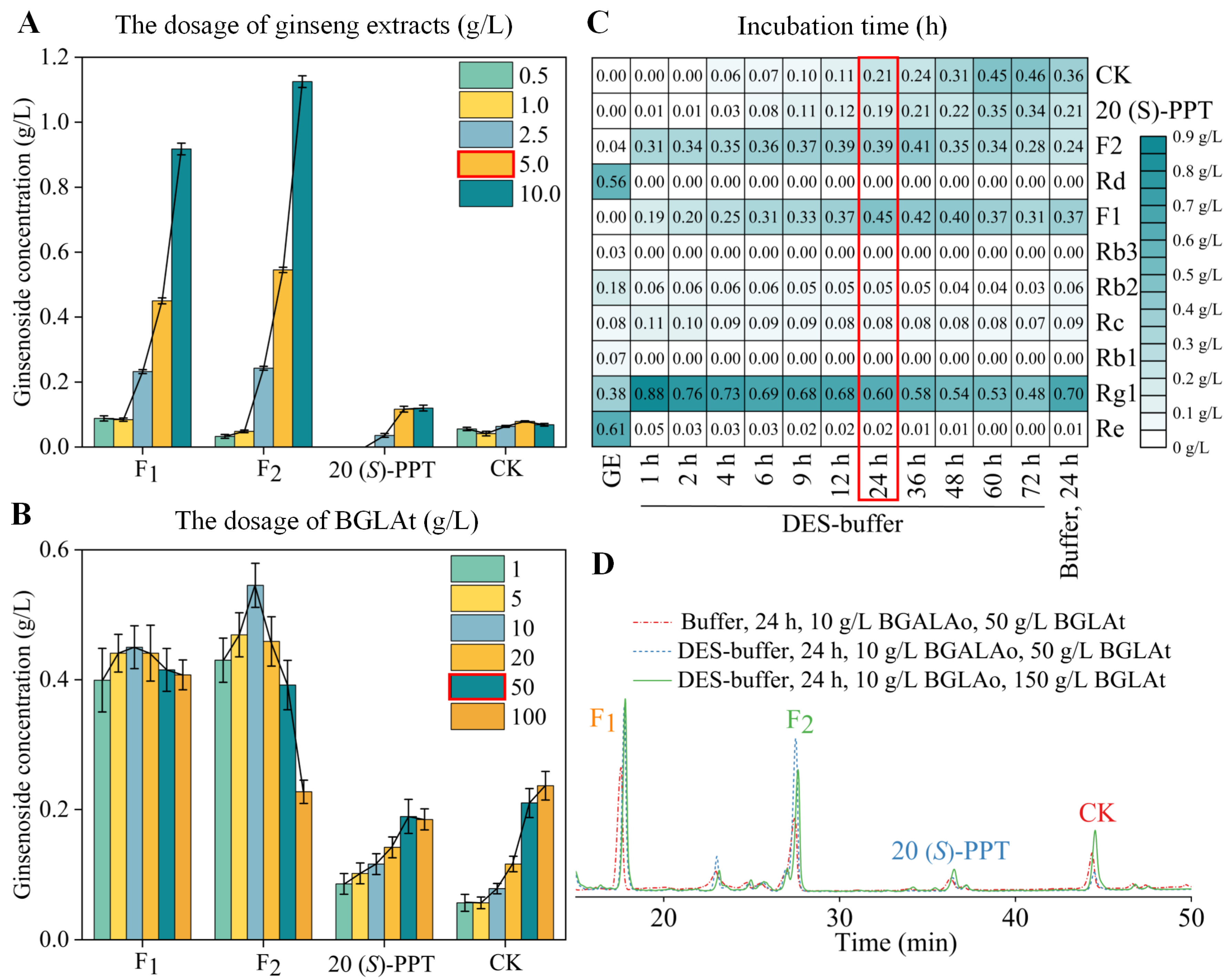

3.3. Enzymatic Conversion of GE in the DES-Buffer

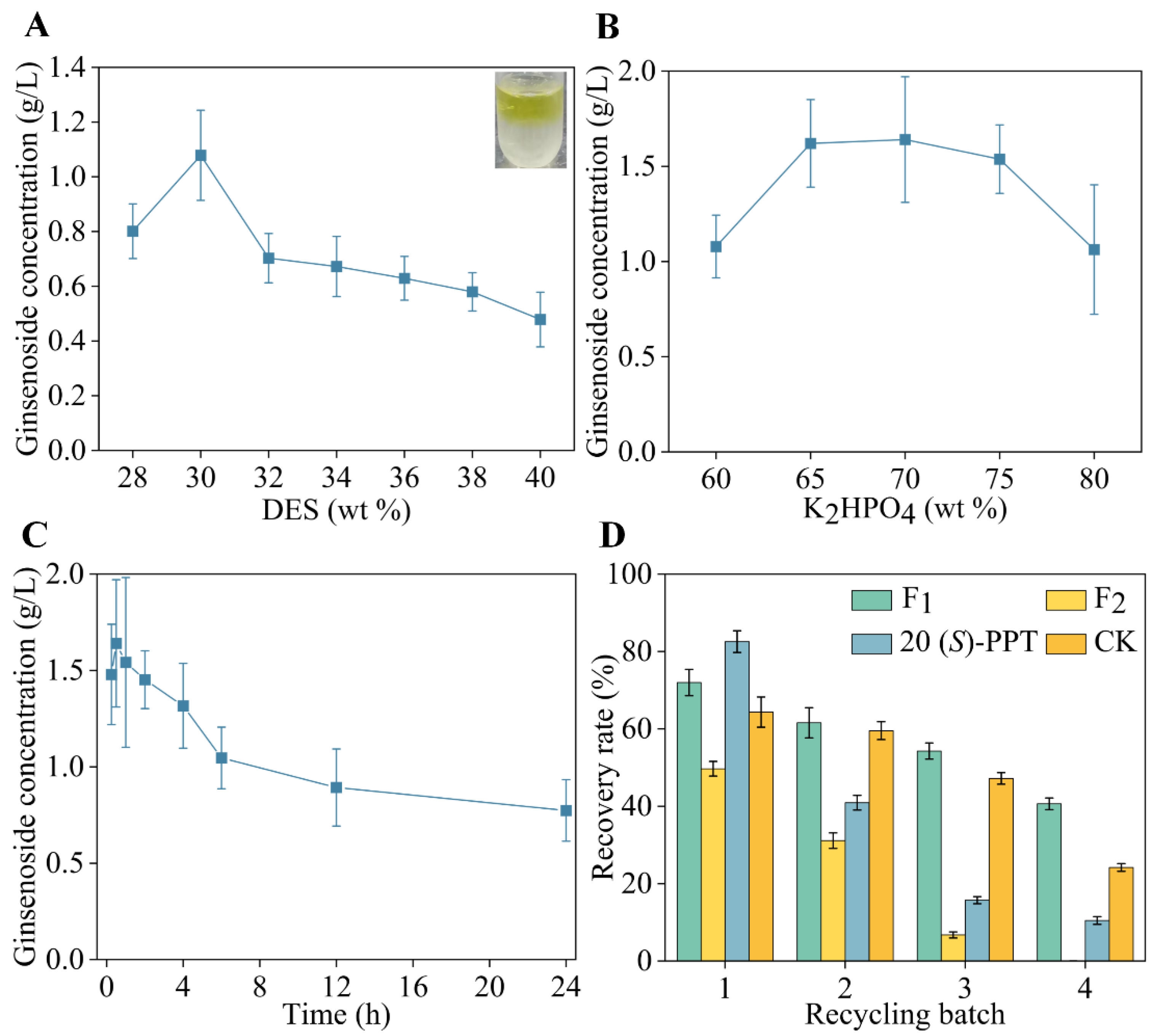

3.4. Extraction of Ginsenosides and Recycling of DES

3.5. Characterization of the Effect of DES (Bet: EG 2:1) on Enzyme Structure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Chopra, P.; Chhillar, H.; Kim, Y.-J.; Jo, I.; Kim, S.; Gupta, R. Phytochemistry of ginsenosides: Recent advancements and emerging roles. Crit. Rev. Food Sci. Nutr. 2021, 1, 61. [Google Scholar] [CrossRef]

- Cui, C.-h.; Jeon, B.-M.; Fu, Y.; Im, W.-T.; Kim, S.-C. High-density immobilization of a ginsenoside-transforming β-glucosidase for enhanced food-grade production of minor ginsenosides. Appl. Microbiol. Biotechnol. 2019, 103, 7003. [Google Scholar] [CrossRef] [PubMed]

- Cui, L.; Wu, S.-q.; Zhao, C.-a.; Yin, C.-r. Microbial conversion of major ginsenosides in ginseng total saponins by Platycodon grandiflorum endophytes. J. Ginseng Res. 2016, 40, 366. [Google Scholar] [CrossRef] [PubMed]

- Mai, T.; Moon, J.; Song, Y.; Viet, P.; Phuc, P.; Lee, J.; Yi, T.-H.; Cho, M.; Cho, S. Ginsenoside F2 induces apoptosis accompanied by protective autophagy in breast cancer stem cells. Cancer Lett. 2012, 321, 144. [Google Scholar] [CrossRef]

- Kim, J.-H. Pharmacological and medical applications of Panax ginseng and ginsenosides: A review for use in cardiovascular diseases. J. Ginseng Res. 2018, 42, 264. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-Y.; Liu, Q.-P.; An, P.; Jia, M.; Luan, X.; Tang, J.-Y.; Zhang, H. Ginsenoside Rd: A promising natural neuroprotective agent. Phytomedicine 2022, 95, 153883. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Kim, D.; Yoo, S.; Hong, Y.; Han, S.; Jeong, S.; Jeong, D.; Kim, J.-H.; Cho, J.; Park, J. The skin protective effects of compound K, a metabolite of ginsenoside Rb1 from Panax ginseng. J. Ginseng Res. 2018, 42, 218. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, Y.; Jiang, Y.; Liu, T.; Luo, Y.; Diao, E.; Cao, Y.; Chen, L.; Zhang, L.; Gu, Q.; et al. Enhanced cytotoxic and apoptotic potential in hepatic carcinoma cells of chitosan nanoparticles loaded with ginsenoside Compound K. Carbohydr. Polym. 2018, 198, 537. [Google Scholar] [CrossRef]

- Liu, Z.; Xia, J.; Wang, C.; Zhang, J.; Ruan, C.; Sun, G.; Yuan, C. Remarkable Impact of Acidic Ginsenosides and Organic Acids on Ginsenoside Transformation from Fresh Ginseng to Red Ginseng. J. Agric. Food Chem. 2016, 64, 5389. [Google Scholar] [CrossRef]

- Cao, J.; Liu, C.; Wang, Q.; Li, Y.; Yu, Q. A novel catalytic application of heteropolyacids: Chemical transformation of major ginsenosides into rare ginsenosides exemplified by Rg1. Sci. China Chem. 2017, 60, 748. [Google Scholar] [CrossRef]

- Zhang, S.; Xie, J.; Zhao, L.; Pei, J.; Su, E.; Xiao, W.; Wang, Z. Cloning, overexpression and characterization of a thermostable β-xylosidase from Thermotoga petrophila and cooperated transformation of ginsenoside extract to ginsenoside 20(S)-Rg3 with a β-glucosidase. Bioorg. Chem. 2019, 85, 159. [Google Scholar] [CrossRef]

- Clark, J.H.; Deswarte, F.; Farmer, T. The integration of green chemistry into future biorefineries. Biofuels Bioprod. Biorefining 2009, 3, 72. [Google Scholar] [CrossRef]

- Makkliang, F.; Siriwarin, B.; Yusakul, G.; Phaisan, S.; Sakdamas, A.; Chuphol, N.; Putalun, W.; Sakamoto, S. Biocompatible natural deep eutectic solvent-based extraction and cellulolytic enzyme-mediated transformation of Pueraria mirifica isoflavones: A sustainable approach for increasing health-bioactive constituents. Bioresour. Bioprocess. 2021, 8, 76. [Google Scholar] [CrossRef]

- Itoh, T. Ionic Liquids as Tool to Improve Enzymatic Organic Synthesis. Chem. Rev. 2017, 117, 10567. [Google Scholar] [CrossRef] [PubMed]

- Weiz, G.; Braun, L.; Lopez, R.; de María, P.; Breccia, J. Enzymatic deglycosylation of flavonoids in deep eutectic solvents-aqueous mixtures: Paving the way for sustainable flavonoid chemistry. J. Mol. Catal. B Enzym. 2016, 130, 70. [Google Scholar] [CrossRef]

- Zhou, R.-R.; Jian-Hua, H.; Dan, H.; Zi-Yang, Y.; Di, Z.; Zhao, L.; Shui-Han, Z.; Lu-Qi, H. Green and efficient extraction of polysaccharide and ginsenoside from American ginseng (Panax quinquefolius L.) by deep eutectic solvent extraction and aqueous two-phase system. Molecules 2022, 27, 3132. [Google Scholar] [CrossRef] [PubMed]

- Li, P.; Zhao, P.; Liu, W.; Jiang, Y.; Wang, W.; Bao, L.; Jin, Y.; Li, X. Determination of common ginsenosides in Kang’ai injection by aqueous two-phase extraction with deep eutectic solvents and HPLC-UV/DAD. Microchem. J. 2018, 137, 302. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Y.; Chen, J.; Wei, X.; Xu, W.; Ni, R.; Meng, J.; Zhou, Y. Development of deep eutectic solvent-based aqueous biphasic system for the extraction of lysozyme. Talanta 2019, 1, 202. [Google Scholar] [CrossRef]

- Chourasia, V.; Pandey, A.; Pant, K.; Henry, R. Improving enzymatic digestibility of sugarcane bagasse from different varieties of sugarcane using deep eutectic solvent pretreatment. Bioresour. Technol. 2021, 337, 125480. [Google Scholar] [CrossRef]

- Verma, M.; Chaudhary, R.; Tsuzuki, T.; Barrow, C.; Puri, M. Immobilization of β-glucosidase on a magnetic nanoparticle improves thermostability: Application in cellobiose hydrolysis. Bioresour. Technol. 2013, 2, 135. [Google Scholar] [CrossRef]

- Li, N.; Wang, Y.; Xu, K.; Huang, Y.; Wen, Q.; Ding, X. Development of green betaine-based deep eutectic solvent aqueous two-phase system for the extraction of protein. Talanta 2016, 23, 152. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Li, W.; Ma, X.; Fan, D. Enzymatic hydrolysis and extraction of ginsenoside recovered from deep eutectic solvent-salt aqueous two-phase system. J. Biosci. Bioeng. 2020, 130, 390. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, J.; Gu, Q.; Zhang, J.; Harindintwali, J.; Liu, X.; Yu, X. Identification of nutritional values of the fermentative extract from the mixture of Stereum hirsutum mycelial substrates and ginseng extracts. LWT 2022, 161, 113179. [Google Scholar] [CrossRef]

- Khodaverdian, S.; Dabirmanesh, B.; Heydari, A.; Dashtban-moghadam, E.; Khajeh, K.; Ghazi, F. Activity, stability and structure of laccase in betaine based natural deep eutectic solvents. Int. J. Biol. Macromol. 2018, 107, 2574. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Gu, Q.; Shen, Y.; Harindintwali, J.; Yang, W.; Zou, S.; Han, M.; Ma, C.; Yu, X.; Liu, X. Enhancement of the performance of the GH75 family chitosanases by fusing a carbohydrate binding module and insights into their substrate binding mechanisms. LWT 2022, 163, 113390. [Google Scholar] [CrossRef]

- Park, K.; Ham, B.; Li, K.; Kang, S.; Jung, D.; Kim, H.; Liu, Y.; Hwang, I.; Lee, J. Insights into the enhanced thermal stability of lysozyme with altered structure and activity induced by choline chloride-based deep eutectic solvents containing polyols and sugars. J. Mol. Liq. 2022, 349, 118143. [Google Scholar] [CrossRef]

- Pan, L.; Li, Q.; Tao, Y.; Ma, C.; Chai, H.; Ai, Y.; He, Y.-C. An efficient chemoenzymatic strategy for valorisation of corncob to furfuryl alcohol in CA:Betaine-water. Ind. Crops Prod. 2022, 186, 115203. [Google Scholar] [CrossRef]

- Zou, Y.; Xin, X.; Xu, H.; Yuan, H.; Li, X.; Yu, Y.; Zhao, G. Highly efficient bioconversion of flavonoid glycosides from citrus-processing wastes in solvent-buffer systems. Green Chem. 2020, 22, 3196. [Google Scholar] [CrossRef]

- Kim, S.-A.; Jeong, E.-B.; Oh, D.-K. Complete bioconversion of protopanaxadiol-type ginsenosides to Compound K by extracellular enzymes from the isolated strain Aspergillus tubingensis. J. Agric. Food Chem. 2021, 69, 315. [Google Scholar] [CrossRef]

- Kim, Y.-S.; Kim, D.-Y.; Kang, D.; Park, C.-S. Hydrolysis of the outer β-(1,2)-d-glucose linkage at the C-3 position of ginsenosides by a commercial β-galactosidase and its use in the production of minor ginsenosides. Biocatal. Biotransformation 2019, 37, 53. [Google Scholar] [CrossRef]

- Toledo, M.; Pereira, M.; Freire, M.; Silva, J.; Coutinho, J.; Tavares, A. Laccase activation in deep eutectic solvents. ACS Sustain. Chem. Eng. 2019, 7, 11806. [Google Scholar] [CrossRef]

- Yanhong, B.; Zhu, C.; Wang, Z.; Luo, H.; Fu, R.; Zhao, X.; Zhao, X.; Jiang, L. Purification and characterization of a glucose-tolerant β-glucosidase from black plum seed and its structural changes in ionic liquids. Food Chem. 2019, 274, 422. [Google Scholar]

- Hoppe, J.; Byzia, E.; Szymańska, M.; Drozd, R.; Smiglak, M. Acceleration of lactose hydrolysis using beta-galactosidase and deep eutectic solvents. Food Chem. 2022, 384, 132498. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, J.; Drozd, R.; Byzia, E.; Smiglak, M. Deep eutectic solvents based on choline cation—Physicochemical properties and influence on enzymatic reaction with β-galactosidase. Int. J. Biol. Macromol. 2019, 136, 296. [Google Scholar] [CrossRef]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jérôme, F. Deep eutectic solvents: Syntheses, properties and applications. Chem. Soc. Rev. 2012, 41, 7108. [Google Scholar] [CrossRef]

- Xu, W.-J.; Huang, Y.-K.; Li, F.; Wang, D.-D.; Yin, M.-N.; Wang, M.; Xia, Z.-N. Improving β-glucosidase biocatalysis with deep eutectic solvents based on choline chloride. Biochem. Eng. J. 2018, 138, 37. [Google Scholar] [CrossRef]

- Araghi, S.H.; John, A.; Googheri, M.S. A molecular dynamics simulations study of the ionic liquid effect on the β-glucosidase active site interactions with a flavonoid glycoside. J. Mol. Liq. 2021, 340, 117115. [Google Scholar] [CrossRef]

- Mondal, S.; Biswal, D.; Pal, K.; Rakshit, S.; Halder, S.K.; Mandavgane, S.; Bera, D.; Hossain, M.; Mondal, K.C. Biodeinking of waste papers using combinatorial fungal enzymes and subsequent production of butanol from effluent. Bioresour. Technol. 2022, 353, 127078. [Google Scholar] [CrossRef]

- Laksmi, F.; Nirwantono, R.; Nuryana, I.; Agustriana, E. Expression and characterization of thermostable D-allulose 3-epimerase from Arthrobacter psychrolactophilus (Ap DAEase) with potential catalytic activity for bioconversion of D-allulose from d-fructose. Int. J. Biol. Macromol. 2022, 214, 426. [Google Scholar] [CrossRef]

- Delorme, A.; Andanson, J.-M.; Verney, V. Improving laccase thermostability with aqueous natural deep eutectic solvents. Int. J. Biol. Macromol. 2020, 163, 919. [Google Scholar] [CrossRef]

- Ma, Z.; Mi, Y.; Han, X.; Li, H.; Tian, M.; Duan, Z.; Fan, D.; Ma, P. Transformation of ginsenoside via deep eutectic solvents based on choline chloride as an enzymatic reaction medium. Bioprocess Biosyst. Eng. 2020, 43, 1195. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zheng, P.; Chen, P.; Wu, D. Highly efficient enzymatic conversion of rutin to Isoquercitrin and L-rhamnose using deep eutectic solvents. ACS Sustain. Chem. Eng. 2020, 8, 14905. [Google Scholar] [CrossRef]

- Xu, K.; Wang, Y.; Huang, Y.; Li, N.; Wen, Q. A green deep eutectic solvent-based aqueous two-phase system for protein extracting. Anal. Chim. Acta 2015, 864, 9–20. [Google Scholar] [CrossRef] [PubMed]

- Shin, K.-C.; Kim, T.-H.; Choi, J.-H.; Oh, D.-K. Complete Biotransformation of Protopanaxadiol-Type Ginsenosides to 20-O-β-Glucopyranosyl-20(S)-protopanaxadiol Using a Novel and Thermostable β-Glucosidase. J. Agric. Food Chem. 2018, 66, 2822. [Google Scholar] [CrossRef] [PubMed]

- Kazan, A.; Hu, X.; Stahl, A.; Frerichs, H.; Smirnova, I.; Yesil-Celiktas, O. An enzyme immobilized microreactor for continuous-flow biocatalysis of ginsenoside Rb1. J. Chem. Technol. Biotechnol. 2021, 96, 3349. [Google Scholar] [CrossRef]

- Wu, S.; Snajdrova, R.; Moore, J.; Baldenius, K.; Bornscheuer, U. Biocatalysis: Enzymatic Synthesis for Industrial Applications. Angew. Chem. Int. Ed. 2021, 60, 88. [Google Scholar] [CrossRef]

- Rodrigues, L.; Cardeira, M.; Leonardo, I.; Gaspar, F.; Redovniković, I.R.; Duarte, A.; Paiva, A.; Matias, A. Deep eutectic systems from betaine and polyols–Physicochemical and toxicological properties. J. Mol. Liq. 2021, 335, 116201. [Google Scholar] [CrossRef]

- Feyzi, S.; Varidi, M.; Housaindokht, M.; Es’haghi, Z. Binding of safranal to whey proteins in aqueous solution: Combination of headspace solid-phase microextraction/gas chromatography with multi spectroscopic techniques and docking studies. Food Chem. 2019, 287, 313. [Google Scholar] [CrossRef]

- Kayukawa, C.; de Oliveira, M.; Kaspchak, E.; Sanchuki, H.; Igarashi-Mafra, L.; Mafra, M. Effect of tannic acid on the structure and activity of Kluyveromyces lactis β-galactosidase. Food Chem. 2019, 275, 346. [Google Scholar] [CrossRef]

- Micsonai, A.; Wien, F.; Kernya, L.; Lee, Y.-H.; Goto, Y.; Réfrégiers, M.; Kardos, J. Accurate secondary structure prediction and fold recognition for circular dichroism spectroscopy. Proc. Natl. Acad. Sci. USA 2015, 112, E3095. [Google Scholar] [CrossRef]

- Kayukawa, C.; Oliveira, M.; Kaspchak, E.; Sanchuki, H.; Igarashi-Mafra, L.; Mafra, M. Quillaja bark saponin effects on Kluyveromyces lactis β-galactosidase activity and structure. Food Chem. 2020, 303, 125388. [Google Scholar] [CrossRef] [PubMed]

| Hydrogen Bond Acceptor (HBA) | Hydrogen Bond Donor (HBD) | Molar Ratio | Abbreviation | |

|---|---|---|---|---|

| HBD1 | HBD2 | |||

| Choline chloride | 1,2-Propanediol | 1:2 | ChCl:P | |

| Urea | 1:2 | ChCl:U | ||

| Ethylene glycol | 1:2 | ChCl:EG | ||

| 1,4-Butanediol | 1:2 | ChCl:B | ||

| Glycerol | 1:1 | ChCl:G | ||

| Glycerol | 1:2 | ChCl:G | ||

| Citric acid | 1:1 | ChCl:Ca | ||

| D-Glucitol | 1:1 | ChCl:Dg | ||

| Malic acid | 1:1 | ChCl:Ma | ||

| Xylitol | 1:2 | ChCl:X | ||

| Glucose | 5:2 | ChCl:Glu | ||

| Malic acid | Xylitol | 1:1:1 | ChCl:Ma:X | |

| Urea | Glycerol | 1:1:1 | ChCl:U:G | |

| Betaine | Xylitol | 1:2 | Bet:X | |

| Xylitol | 1:1 | Bet:X | ||

| Xylitol | 2:1 | Bet:X | ||

| Glycerol | 1:1 | Bet:G | ||

| Glycerol | 1:2 | Bet:G | ||

| Citric acid | 1:1 | Bet:Ca | ||

| Ethylene glycol | 1:2 | Bet:EG | ||

| Urea | 1:2 | Bet:U | ||

| Malic acid | 1:1 | Bet:Ma | ||

| Glucose | 5:2 | Bet:Glu | ||

| Malic acid | Glucose | 1:1:1 | Bet:Ma:Glu | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Gu, Q.; Zhou, J.; Liu, X.; Yu, X. High-Value Bioconversion of Ginseng Extracts in Betaine-Based Deep Eutectic Solvents for the Preparation of Deglycosylated Ginsenosides. Foods 2023, 12, 496. https://doi.org/10.3390/foods12030496

Yang W, Gu Q, Zhou J, Liu X, Yu X. High-Value Bioconversion of Ginseng Extracts in Betaine-Based Deep Eutectic Solvents for the Preparation of Deglycosylated Ginsenosides. Foods. 2023; 12(3):496. https://doi.org/10.3390/foods12030496

Chicago/Turabian StyleYang, Wenhua, Qiuya Gu, Jianli Zhou, Xiaobo Liu, and Xiaobin Yu. 2023. "High-Value Bioconversion of Ginseng Extracts in Betaine-Based Deep Eutectic Solvents for the Preparation of Deglycosylated Ginsenosides" Foods 12, no. 3: 496. https://doi.org/10.3390/foods12030496

APA StyleYang, W., Gu, Q., Zhou, J., Liu, X., & Yu, X. (2023). High-Value Bioconversion of Ginseng Extracts in Betaine-Based Deep Eutectic Solvents for the Preparation of Deglycosylated Ginsenosides. Foods, 12(3), 496. https://doi.org/10.3390/foods12030496