Rice-Based Gluten-Free Foods and Technologies: A Review

Abstract

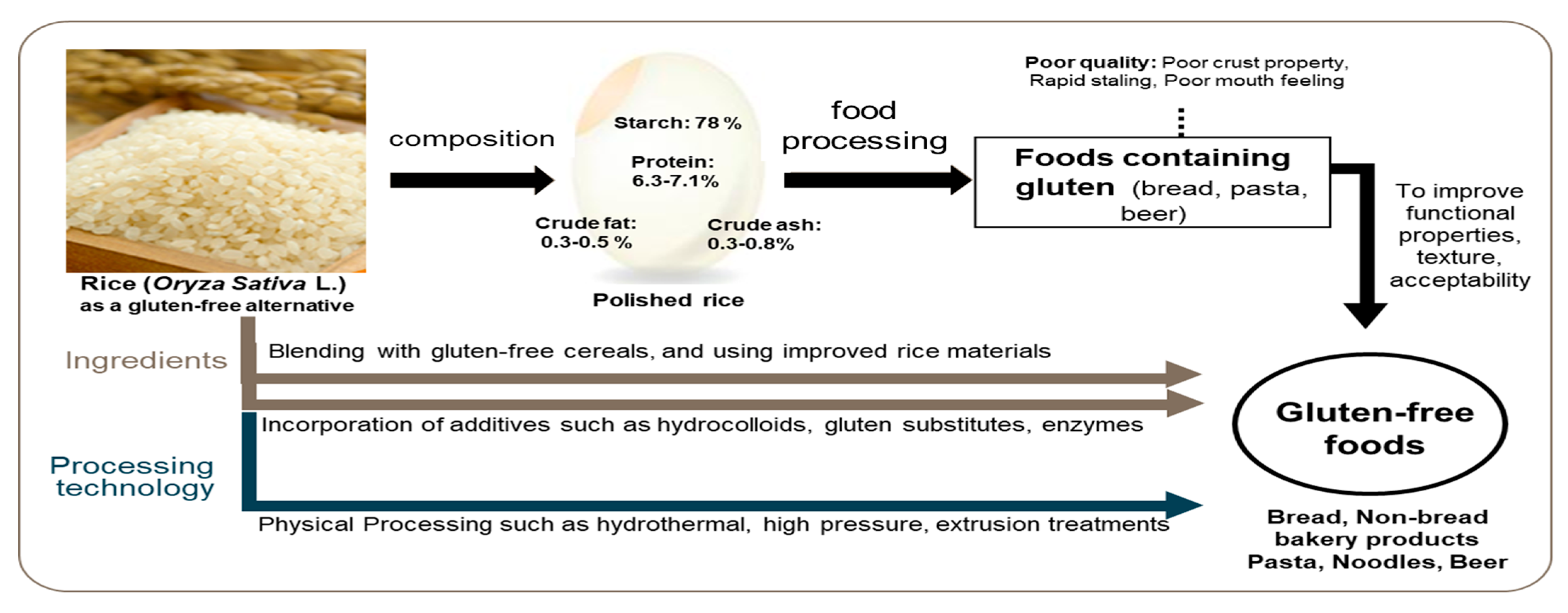

:1. Introduction

2. Rice as a GF Material

3. Rice-Based GF Food Products

3.1. Rice-Based GF Bread and Bakery Products

| Product | GF Materials | Main Conclusions | References |

|---|---|---|---|

| Bread | Eleven commercial rice flours | Rice flour with low starch damage (<5 g/100 g) resulted in a high specific volume of bread. | [58] |

| Rice flour (Fukumori Shitogi No. 2) | Bread treated with thermoase had a good crumb appearance and low staling rate and showed high specific volume. | [43] | |

| Polished japonica rice (Panjin, China) | Rice flour with a damaged starch content of 4–6%, which had a good gas retention capacity, resulted in a high specific volume, dense cell structure, and elastic bread texture. | [59] | |

| Short-grain rice flour Long-grain rice flour | The finest flours produced bread with a lower specific volume. Short-grain rice flour produced bread with higher specific volumes and lower firmness. | [60] | |

| Commercial certified brown rice cultivar (INIAP 15) | Flours obtained after 24 h of germination improved bread texture (more than 24 h of germination was not suitable). | [46] | |

| Japonica rice (Panjin, China) | Samples prepared by blending semidry-ground and dry-ground rice flour with particle sizes of 75–100 µm exhibited characteristics similar to those of wet-ground rice flour, as visualized via principal component analysis, and exhibited good bread volume and crumb texture. | [61] | |

| Wet-milled rice flour | Increased loaf volume and porosity of pre-gelatinized rice flour (50% water mixed with 1% rice flour at 80 °C for 2 min). | [44] | |

| Ten normal and glutinous rice cultivars | GF bread made using normal rice showed a higher specific volume and evener crumb cell distribution than those made using glutinous rice. | [62] | |

| Rice flour Four rice brans | The addition of rice brans, especially with high amounts of soluble dietary fiber, resulted in the higher specific volume, softer crumb firmness, and improved porosity of bread. | [47] | |

| Brown rice flour | GF bread with medium-sized brown rice flour prepared using a low-temperature impact mill showed a large specific volume, low hardness, and homogeneous gas cells. | [48] | |

| Commercial rice flour | Coarse rice particles (132–200 µm) with high dough hydration (90–110%) produced bread with a high specific volume. | [63] | |

| Commercial rice (Indica, Japonica, and waxy rice) | Adding 30% rice sourdough improved the specific volume of rice bread. Indica and Japonica rice bread with sourdough fermented for 48 h exhibited the highest cohesiveness and chewiness and the lowest hardness. | [22] | |

| Cake | High-protein Frontière brown rice | High-protein brown rice showed the highest specific volume and was softer than the other rice flour cupcakes. | [64] |

| Commercial rice flour | No significant difference in physical properties or results of sensory evaluation were observed for high-content resistant starch (RS)-added cakes. Highest RS (up to 20 g/100 g) added to cake is acceptable. | [51] | |

| Rice flour | A higher pore area fraction was observed in cakes containing a mixture of xanthan, guar gum, and xanthan gum. Cakes baked in an infrared microwave combination oven had high porosity. | [52] | |

| Muffins | Basmati rice | Incorporation of (>8 g/100 g) cowpea protein isolates decreased flour paste viscosity and increased batter viscoelasticity, firmness, springiness, cohesiveness, and chewiness. | [53] |

| Commercial rice flour | Casein and egg white protein increased the specific volume of muffins. Soy protein did not have any effect on the muffin texture, while pea protein-containing muffins were softer and springier. | [54] | |

| Cookies | Commercial rice flour | Rice flour with alfalfa seed flour had higher protein and total dietary fiber contents. The cookies showed high slowly digestible starch properties. | [56] |

| Rice flour, commercial native waxy rice starch | Cookies made from annealing-treated waxy rice starch had the highest dietary fiber and RS contents but the lowest rapidly digestible starch content. | [57] |

3.2. Rice-Based GF Pasta and Noodles

3.3. Rice-Based GF Beer

4. Additives and Processing Technologies for Rice-Based GF Foods

4.1. Ingredients as Nutritional Enhancers or Gluten Substitutes

4.2. Processing Technologies

| Processing Methods | GF Materials/Additives | Major Conclusion | References |

|---|---|---|---|

| Baking | 60% high-protein Frontière brown rice flour, 30.71% tapioca starch, 9.29% potato starch | Addition of starch to the cupcake formula decreased the hardness and increased the specific volume of the cupcakes. | [114] |

| Baking | Rice flours, tamarind gum, modified tamarind gum (MTG; thermoresponsive xyloglucan), and xanthan gum | The bread with MTG added was soft, moist, and preferred over those with other additives. The addition of 0.5–0.75% polysaccharides inhibited the hardening and aging of the bread with MTG added. | [115] |

| Baking | Rice flour, rice protein, hydroxypropyl methylcellulose (HPMC) | Amounts of 3% rice protein (RP) and 2% HPMC improved the quality of GF bread. RP provided a moist, springy, and resilient crumb matrix of the bread. | [116] |

| Baking | Broken white rice grains, carboxymethyl cellulose | Baking temperature of 185 °C, baking time of 22 min, and 0.8% concentration of carboxymethyl cellulose are desirable conditions for the development of gluten-free, low-glycemic-index cookies from rice flour. | [117] |

| Baking, hydrolysis (enzyme) | Rice flours, hydrolyzed peanut protein | The incorporation of 5% hydrolyzed protein had a positive impact on the specific volume and relative elasticity of gluten-free bread. | [118] |

| Baking, extrusion | Extrusion-cooked red rice flour | An increase in extrusion temperature increased the attractive red color of samples. The acceptance of the sensory properties was improved with the incorporation of extrusion-cooked flour. | [119] |

| Extrusion | Rice, buckwheat (partial replacement: 0, 15, 30, 45, 60 g/100 g) | The quality of buckwheat-added rice noodles (BRNs) improved, dietary fiber increased, and the cooking loss and broken rate of 30 g/100 g BRNs were the lowest. | [120] |

| Extrusion | Red and black rice | The optimum conditions, which are feed moistures of 15.5% and 16.0% and temperatures of 159 and 150 °C for black and red rice extrudates, respectively, resulted in cereal breakfast balls with optimal water solubility, volume, and texture and good color. | [121] |

| Steaming | Rice flours, Apios americana tubers (Apios) | Addition of Apios powder (a high level of β-amylase activity) to gluten-free bread improved bread texture and delayed staling. | [122] |

| Ultrasound, microwave, hydrothermal | Semidry-milled rice flour | Ultrasound treatment improved the bread quality (the specific volume increased by 15.6%, and the hardness decreased by 17.6%). | [123] |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wrigley, C.; Békés, F.; Bushuk, W. Gliadin and Glutenin: The Unique Balance of Wheat Quality; Cereals and Grains Association: Saint Paul, MN, USA, 2006. [Google Scholar]

- Wieser, H. Chemistry of Gluten Proteins. Food Microbiol. 2007, 24, 115–119. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, I.; Swaroop, A.; Bagchi, D. Chapter 6-An Overview of Gluten-Free Foods and Related Disorders. In Nutraceutical and Functional Food Regulations in the United States and Around the World, 3rd ed.; Bagchi, D., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 75–85. [Google Scholar]

- Bernardo, D.; Peña, A.S. Developing Strategies to Improve the Quality of Life of Patients with Gluten Intolerance in Patients with and Without Coeliac Disease. Eur. J. Intern. Med. 2012, 23, 6–8. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced Properties of Gluten-Free Cookies, Cakes, and Crackers: A Review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Al-Toma, A.; Volta, U.; Auricchio, R.; Castillejo, G.; Sanders, D.S.; Cellier, C.; Mulder, C.J.; Lundin, K.E.A. European Society for the Study of Coeliac Disease (ESsCD) Guideline for Coeliac Disease and Other Gluten-Related Disorders. United Eur. Gastroenterol. J. 2019, 7, 583–613. [Google Scholar] [CrossRef] [PubMed]

- Leonard, M.M.; Sapone, A.; Catassi, C.; Fasano, A. Celiac Disease and Nonceliac Gluten Sensitivity: A Review. JAMA 2017, 318, 647–656. [Google Scholar] [CrossRef] [PubMed]

- Pasha, I.; Saeed, F.; Sultan, M.T.; Batool, R.; Aziz, M.; Ahmed, W. Wheat Allergy and Intolerence; Recent Updates and Perspectives. Crit. Rev. Food Sci. Nutr. 2016, 56, 13–24. [Google Scholar] [CrossRef]

- Wunsch, N.-G.; Food, G.-F. Market Value Worldwide 2022–2032. Available online: https://www.statista.com/statistics/248467/global-gluten-free-food-market-size/ (accessed on 1 September 2023).

- Food and Drug Administration, HHS. Food Labeling; Gluten-Free Labeling of Foods. Fed. Regist. 2013, 78, 47154–47179. Available online: https://www.federalregister.gov/documents/2013/08/05/2013-18813/food-labeling-gluten-free-labeling-of-foods (accessed on 1 September 2023).

- Di Cairano, M.; Galgano, F.; Tolve, R.; Caruso, M.C.; Condelli, N. Focus on Gluten Free Biscuits: Ingredients and Issues. Trends Food Sci. Technol. 2018, 81, 203–212. [Google Scholar] [CrossRef]

- Drub, T.F.; Garcia dos Santos, F.; Ladeia Solera Centeno, A.C.; Capriles, V.D. Sorghum, Millet and Pseudocereals as Ingredients for Gluten-Free Whole-Grain Yeast Rolls. Int. J. Gastron Food Sci. 2021, 23, 100293. [Google Scholar] [CrossRef]

- Kaur, S.; Kumar, K.; Singh, L.; Sharanagat, V.S.; Nema, P.K.; Mishra, V.; Bhushan, B. Gluten-Free Grains: Importance, Processing and Its Effect on Quality of Gluten-Free Products. Crit. Rev. Food Sci. Nutr. 2022, 1–28. [Google Scholar] [CrossRef]

- El Khoury, D.; Balfour-Ducharme, S.; Joye, I.J. A Review on the Gluten-Free Diet: Technological and Nutritional Challenges. Nutrients 2018, 10, 1410. [Google Scholar] [CrossRef] [PubMed]

- Šmídová, Z.; Rysová, J. Gluten-Free Bread and Bakery Products Technology. Foods 2022, 11, 480. [Google Scholar] [CrossRef] [PubMed]

- Padalino, L.; Conte, A.; Del Nobile, M.A. Overview on the General Approaches to Improve Gluten-Free Pasta and Bread. Foods 2016, 5, 87. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Gao, X. Progress of the Use of Alternatives to Malt in the Production of Gluten-Free Beer. Crit. Rev. Food Sci. Nutr. 2022, 62, 2820–2835. [Google Scholar] [CrossRef]

- Skendi, A.; Papageorgiou, M.; Varzakas, T. High Protein Substitutes for Gluten in Gluten-Free Bread. Foods 2021, 10, 1997. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A. What Can Play the Role of Gluten in Gluten Free Pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Salehi, F. Improvement of Gluten-Free Bread and Cake Properties Using Natural Hydrocolloids: A Review. Food Sci. Nutr. 2019, 7, 3391–3402. [Google Scholar] [CrossRef]

- Bender, D.; Schönlechner, R. Innovative Approaches Towards Improved Gluten-Free Bread Properties. J. Cereal Sci. 2020, 91, 102904. [Google Scholar] [CrossRef]

- Dan, H.; Gu, Z.; Li, C.; Fang, Z.; Hu, B.; Wang, C.; Chen, S.; Tang, X.; Ren, Y.; Wu, W.; et al. Effect of Fermentation Time and Addition Amount of Rice Sourdoughs with Different Microbial Compositions on the Physicochemical Properties of Three Gluten-Free Rice Breads. Food Res. Int. 2022, 161, 111889. [Google Scholar] [CrossRef]

- Woomer, J.S.; Adedeji, A.A. Current Applications of Gluten-Free Grains—A Review. Crit. Rev. Food Sci. Nutr. 2021, 61, 14–24. [Google Scholar] [CrossRef]

- Kovach, M.J.; Sweeney, M.T.; McCouch, S.R. New Insights into the History of Rice Domestication. Trends Genet. 2007, 23, 578–587. [Google Scholar] [CrossRef]

- Zeigler, R.S.; Barclay, A. The Relevance of Rice. Rice 2008, 1, 3–10. [Google Scholar] [CrossRef]

- Turabi, E.; Sumnu, G.; Sahin, S. Rheological Properties and Quality of Rice Cakes Formulated with Different Gums and an Emulsifier Blend. Food Hydrocoll. 2008, 22, 305–312. [Google Scholar] [CrossRef]

- Amagliani, L.; O’Regan, J.; Kelly, A.L.; O’Mahony, J.A. The Composition, Extraction, Functionality and Applications of Rice Proteins: A Review. Trends Food Sci. Technol. 2017, 64, 1–12. [Google Scholar] [CrossRef]

- Honda, Y.; Inoue, N.; Kurita, M.; Okunishi, T. Alpha-Glutelin Degradation and Its Hydrolysate by Protease Enhance the Specific Volume of Gluten-Free Rice Starch Bread. J. Cereal Sci. 2021, 102, 103338. [Google Scholar] [CrossRef]

- Heo, S.; Jeon, S.; Lee, S. Utilization of Lentinus edodes Mushroom β-Glucan to Enhance the Functional Properties of Gluten-Free Rice Noodles. LWT Food Sci. Technol. 2014, 55, 627–631. [Google Scholar] [CrossRef]

- Yano, H. Recent Practical Researches in the Development of Gluten-Free Breads. NPJ Sci. Food 2019, 3, 7. [Google Scholar] [CrossRef]

- Masure, H.G.; Fierens, E.; Delcour, J.A. Current and Forward Looking Experimental Approaches in Gluten-Free Bread Making Research. J. Cereal Sci. 2016, 67, 92–111. [Google Scholar] [CrossRef]

- Renzetti, S.; Rosell, C.M. Role of Enzymes in Improving the Functionality of Proteins in Non-wheat Dough Systems. J. Cereal Sci. 2016, 67, 35–45. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Improvement of the Texture and Quality of Cooked Gluten-Free Pasta. LWT 2016, 70, 96–103. [Google Scholar] [CrossRef]

- Aoki, N.; Kataoka, T.; Nishiba, Y. Crucial Role of Amylose in the Rising of Gluten- and Additive-Free Rice Bread. J. Cereal Sci. 2020, 92, 102905. [Google Scholar] [CrossRef]

- Yano, H.; Koda, T.; Fujita, N.; Nishioka, A. Effect of Amylose Content in Rice Flour on Batter Rheology and Bread Baking Quality. J. Food Process. Preserv. 2020, 44, e14462. [Google Scholar] [CrossRef]

- Jeong, O.; Park, H.; Baek, M.; Kim, W.; Lee, G.; Lee, C.; Bombay, M.; Ancheta, M.B.; Lee, J. Review of Rice in Korea: Current Status, Future Prospects, and Comparisons with Rice in Other Countries. J. Crop Sci. Biotechnol. 2021, 24, 1–11. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.K.; Park, H.Y.; Choi, H.S.; Cho, D.H.; Lee, K.H.; Han, S.I.; Cho, J.H.; Oh, S.K. Physicochemical Properties and Digestibility of Rice Flour by Rice Variety According to Milling Method. Korean J. Crop Sci. 2017, 62, 184–192. [Google Scholar]

- Heo, S.; Lee, S.M.; Shim, J.H.; Yoo, S.H.; Lee, S. Effect of Dry- and Wet-Milled Rice Flours on the Quality Attributes of Gluten-Free Dough and Noodles. J. Food Eng. 2013, 116, 213–217. [Google Scholar] [CrossRef]

- Park, J.; Oh, S.K.; Chung, H.J.; Park, H.J. Structural and Physicochemical Properties of Native Starches and Non-digestible Starch Residues from Korean Rice Cultivars with Different Amylose Contents. Food Hydrocoll. 2020, 102, 105544. [Google Scholar] [CrossRef]

- Ha, S.K.; Kim, B.; Hwang, W.; Mo, Y.; Jeong, J.; Lee, D.; Kim, W.; Kim, J.; Jeung, J. Early Maturing Rice Variety “Baromi2” with a Floury Endosperm and Suitable for Dry-Milling of Rice Grain. Korean J. Breed. Sci. 2022, 54, 433–441. [Google Scholar] [CrossRef]

- Gallagher, E.; Gormley, T.R.; Arendt, E.K. Recent Advances in the Formulation of Gluten-Free Cereal-Based Products. Trends Food Sci. Technol. 2004, 15, 143–152. [Google Scholar] [CrossRef]

- Bascuñán, K.A.; Vespa, M.C.; Araya, M. Celiac Disease: Understanding the Gluten-Free Diet. Eur. J. Nutr. 2017, 56, 449–459. [Google Scholar] [CrossRef]

- Kawamura-Konishi, Y.; Shoda, K.; Koga, H.; Honda, Y. Improvement in Gluten-Free Rice Bread Quality by Protease Treatment. J. Cereal Sci. 2013, 58, 45–50. [Google Scholar] [CrossRef]

- Ding, X.L.; Wang, L.J.; Li, T.T.; Wang, F.; Quan, Z.Y.; Zhou, M.; Huo, Z.Y.; Qian, J.Y. Pre-gelatinisation of Rice Flour and Its Effect on the Properties of Gluten Free Rice Bread and Its Batter. Foods 2021, 10, 2648. [Google Scholar] [CrossRef] [PubMed]

- Chavan, R.S.; Chavan, S.R. Sourdough Technology—A Traditional Way for Wholesome Foods: A Review. Compr. Rev. Food Sci. Food Saf. 2011, 10, 169–182. [Google Scholar] [CrossRef]

- Cornejo, F.; Rosell, C.M. Influence of Germination Time of Brown Rice in Relation to Flour and Gluten Free Bread Quality. J. Food Sci. Technol. 2015, 52, 6591–6598. [Google Scholar] [CrossRef] [PubMed]

- Phimolsiripol, Y.; Mukprasirt, A.; Schoenlechner, R. Quality Improvement of Rice-Based Gluten-Free Bread Using Different Dietary Fibre Fractions of Rice Bran. J. Cereal Sci. 2012, 56, 389–395. [Google Scholar] [CrossRef]

- Luo, S.; Yan, X.; Fu, Y.; Pang, M.; Chen, R.; Liu, Y.; Chen, J.; Liu, C. The Quality of Gluten-Free Bread Made of Brown Rice Flour Prepared by Low Temperature Impact Mill. Food Chem. 2021, 348, 129032. [Google Scholar] [CrossRef]

- Valitutti, F.; Iorfida, D.; Anania, C.; Trovato, C.M.; Montuori, M.; Cucchiara, S.; Catassi, C. Cereal Consumption Among Subjects with Celiac Disease: A Snapshot for Nutritional Considerations. Nutrients 2017, 9, 396. [Google Scholar] [CrossRef]

- Gularte, M.A.; de la Hera, E.; Gómez, M.; Rosell, C.M. Effect of Different Fibers on Batter and Gluten-Free Layer Cake Properties. LWT Food Sci. Technol. 2012, 48, 209–214. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Papantoniou, M.; Mandala, I. Rheological, Physical, and Sensory Attributes of Gluten-Free Rice Cakes Containing Resistant Starch. J. Food Sci. 2015, 80, E341–E348. [Google Scholar] [CrossRef]

- Turabi, E.; Sumnu, G.; Sahin, S. Quantitative Analysis of Macro and Micro-structure of Gluten-Free Rice Cakes Containing Different Types of Gums Baked in Different Ovens. Food Hydrocoll. 2010, 24, 755–762. [Google Scholar] [CrossRef]

- Shevkani, K.; Kaur, A.; Kumar, S.; Singh, N. Cowpea Protein Isolates: Functional Properties and Application in Gluten-Free Rice Muffins. LWT Food Sci. Technol. 2015, 63, 927–933. [Google Scholar] [CrossRef]

- Matos, M.E.; Sanz, T.; Rosell, C.M. Establishing the Function of Proteins on the Rheological and Quality Properties of Rice Based Gluten Free Muffins. Food Hydrocoll. 2014, 35, 150–158. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Rodriguez, P.; Gómez, M. Assessing Rice Flour-Starch-Protein Mixtures to Produce Gluten Free Sugar-Snap Cookies. LWT Food Sci. Technol. 2016, 67, 127–132. [Google Scholar] [CrossRef]

- Giuberti, G.; Rocchetti, G.; Sigolo, S.; Fortunati, P.; Lucini, L.; Gallo, A. Exploitation of Alfalfa Seed (Medicago sativa L.) Flour into Gluten-Free Rice Cookies: Nutritional, Antioxidant and Quality Characteristics. Food Chem. 2018, 239, 679–687. [Google Scholar] [CrossRef] [PubMed]

- Giuberti, G.; Marti, A.; Fortunati, P.; Gallo, A. Gluten Free Rice Cookies with Resistant Starch Ingredients from Modified Waxy Rice Starches: Nutritional Aspects and Textural Characteristics. J. Cereal Sci. 2017, 76, 157–164. [Google Scholar] [CrossRef]

- Yano, H.; Fukui, A.; Kajiwara, K.; Kobayashi, I.; Yoza, K.; Satake, A.; Villeneuve, M. Development of Gluten-Free Rice Bread: Pickering Stabilization as a Possible Batter-Swelling Mechanism. LWT Food Sci. Technol. 2017, 79, 632–639. [Google Scholar] [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Xiao, T.; He, Y.; Chen, Z.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of Damaged Starch on the Properties of Rice Flour and Quality Attributes of Gluten-Free Rice Bread. J. Cereal Sci. 2021, 101, 103296. [Google Scholar] [CrossRef]

- de la Hera, E.; Martinez, M.; Gómez, M. Influence of Flour Particle Size on Quality of Gluten-Free Rice Bread. LWT Food Sci. Technol. 2013, 54, 199–206. [Google Scholar] [CrossRef]

- Qin, W.; Lin, Z.; Wang, A.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L.-T. Influence of Particle Size on the Properties of Rice Flour and Quality of Gluten-Free Rice Bread. LWT 2021, 151, 112236. [Google Scholar] [CrossRef]

- Gui, Y.; Chen, G.; Tian, W.; Yang, S.; Chen, J.; Wang, F.; Li, Y. Normal Rice Flours Perform Better in Gluten-Free Bread than Glutinous Rice Flours. J. Food Sci. 2022, 87, 554–566. [Google Scholar] [CrossRef]

- de La Hera, E.; Rosell, C.M.; Gomez, M. Effect of Water Content and Flour Particle Size on Gluten-Free Bread Quality and Digestibility. Food Chem. 2014, 151, 526–531. [Google Scholar] [CrossRef]

- Aleman, R.S.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. Physicochemical Properties of Frontière Rice Flour and Its Application in a Gluten-Free Cupcake. Cereal Chem. 2022, 99, 303–315. [Google Scholar] [CrossRef]

- Phongthai, S.; D’Amico, S.; Schoenlechner, R.; Homthawornchoo, W.; Rawdkuen, S. Effects of Protein Enrichment on the Properties of Rice Flour Based Gluten-Free Pasta. LWT 2017, 80, 378–385. [Google Scholar] [CrossRef]

- Sozer, N. Rheological Properties of Rice Pasta Dough Supplemented with Proteins and Gums. Food Hydrocoll. 2009, 23, 849–855. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Mukesh. Studies on Noodle Quality of Potato and Rice Starches and Their Blends in Relation to Their Physicochemical, Pasting and Gel Textural Properties. LWT Food Sci. Technol. 2010, 43, 1289–1293. [Google Scholar] [CrossRef]

- Yang, Y.; Tao, W.-Y. Effects of lactic acid fermentation on FT-IR and pasting properties of rice flour. Food Res. Int. 2008, 41, 937–940. [Google Scholar] [CrossRef]

- Hormdok, R.; Noomhorm, A. Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT Food Sci. Technol. 2007, 40, 1723–1731. [Google Scholar] [CrossRef]

- Mariotti, M.; Iametti, S.; Cappa, C.; Rasmussen, P.; Lucisano, M. Characterisation of Gluten-Free Pasta Through Conventional and Innovative Methods: Evaluation of the Uncooked Products. J. Cereal Sci. 2011, 53, 319–327. [Google Scholar] [CrossRef]

- Detchewa, P.; Thongngam, M.; Jane, J.L.; Naivikul, O. Preparation of Gluten-Free Rice Spaghetti with Soy Protein Isolate Using Twin-Screw Extrusion. J. Food Sci. Technol. 2016, 53, 3485–3494. [Google Scholar] [CrossRef]

- Detchewa, P.; Prasajak, P.; Phungamngoen, C.; Sriwichai, W.; Naivikul, O.; Moongngarm, A. Substitution of Rice Flour with Rice Protein Improved Quality of Gluten-Free Rice Spaghetti Processed Using Single Screw Extrusion. LWT 2022, 153, 112512. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A. Rice-Buckwheat Gluten-Free Pasta: Effect of Processing Parameters on Quality Characteristics and Optimization of Extrusion-Cooking Process. Foods 2019, 8, 496. [Google Scholar] [CrossRef]

- Cabrera-Chávez, F.; Calderón de la Barca, A.M.C.; Islas-Rubio, A.R.; Marti, A.; Marengo, M.; Pagani, M.A.; Bonomi, F.; Iametti, S. Molecular Rearrangements in Extrusion Processes for the Production of Amaranth-Enriched, Gluten-Free Rice Pasta. LWT 2012, 47, 421–426. [Google Scholar] [CrossRef]

- Bouasla, A.; Wójtowicz, A.; Zidoune, M.N. Gluten-Free Precooked Rice Pasta Enriched with Legumes Flours: Physical Properties, Texture, Sensory Attributes and Microstructure. LWT 2017, 75, 569–577. [Google Scholar] [CrossRef]

- Benucci, I.; Caso, M.C.; Bavaro, T.; Masci, S.; Keršienė, M.; Esti, M. Prolyl Endopeptidase from Aspergillus niger Immobilized on a Food-Grade Carrier for the Production of Gluten-Reduced Beer. Food Control 2020, 110, 106987. [Google Scholar] [CrossRef]

- Fanari, M.; Forteschi, M.; Sanna, M.; Zinellu, M.; Porcu, M.C.; Pretti, L. Comparison of Enzymatic and Precipitation Treatments for Gluten-Free Craft Beers Production. Innov. Food Sci. Emerg. Technol. 2018, 49, 76–81. [Google Scholar] [CrossRef]

- Bogdan, P.; Kordialik-Bogacka, E. Alternatives to Malt in Brewing. Trends Food Sci. Technol. 2017, 65, 1–9. [Google Scholar] [CrossRef]

- Park, J.; Park, H.Y.; Chung, H.J.; Oh, S.K. Starch Structure of Raw Materials with Different Amylose Contents and the Brewing Quality Characteristics of Korean Rice Beer. Foods 2023, 12, 2544. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Lee, S.K.; Choi, I.; Choi, H.S.; Kim, N.; Shin, D.S.; Jeong, K.H.; Park, C.H.; Oh, S.K. Quality Characteristics of Rice Wort and Rice Beer by Rice Processing. Food Eng. Progr. 2019, 23, 290–296. [Google Scholar] [CrossRef]

- Ceccaroni, D.; Marconi, O.; Sileoni, V.; Wray, E.; Perretti, G. Rice Malting Optimization for the Production of Top-Fermented Gluten-Free Beer. J. Sci. Food Agric. 2019, 99, 2726–2734. [Google Scholar] [CrossRef]

- Deželak, M.; Zarnkow, M.; Becker, T.; Košir, I.J. Processing of Bottom-Fermented Gluten-Free Beer-Like Beverages Based on Buckwheat and Quinoa Malt with Chemical and Sensory Characterization. J. Inst. Brew. 2014, 120, 360–370. [Google Scholar] [CrossRef]

- Piddocke, M.P.; Kreisz, S.; Heldt-Hansen, H.P.; Nielsen, K.F.; Olsson, L. Physiological Characterization of Brewer’s Yeast in High-Gravity Beer Fermentations with Glucose or Maltose Syrups as Adjuncts. Appl. Microbiol. Biotechnol. 2009, 84, 453–464. [Google Scholar] [CrossRef]

- Usansa, U.; Burberg, F.; Geiger, E.; Back, W.; Wanapu, C.; Arendt, E.K.; Kreisz, S.; Boonkerd, N.; Teaumroong, N.; Zarnkow, M. Optimization of Malting Conditions for Two Black Rice Varieties, Black Non-waxy Rice and Black Waxy Rice (Oryza sativa L. Indica). J. Inst. Brew. 2011, 117, 39–46. [Google Scholar] [CrossRef]

- Agu, R.C.; Chiba, Y.; Goodfellow, V.; MacKinlay, J.; Brosnan, J.M.; Bringhurst, T.A.; Jack, F.R.; Harrison, B.; Pearson, S.Y.; Bryce, J.H. Effect of Germination Temperatures on Proteolysis of the Gluten-Free Grains Rice and Buckwheat During Malting and Mashing. J. Agric. Food Chem. 2012, 60, 10147–10154. [Google Scholar] [CrossRef] [PubMed]

- Mayer, H.; Ceccaroni, D.; Marconi, O.; Sileoni, V.; Perretti, G.; Fantozzi, P. Development of an All Rice Malt Beer: A Gluten Free Alternative. LWT Food Sci. Technol. 2016, 67, 67–73. [Google Scholar] [CrossRef]

- Ceccaroni, D.; Sileoni, V.; Marconi, O.; De Francesco, G.; Lee, E.G.; Perretti, G. Specialty Rice Malt Optimization and Improvement of Rice Malt Beer Aspect and Aroma. LWT 2019, 99, 299–305. [Google Scholar] [CrossRef]

- Habiyaremye, C.; Matanguihan, J.B.; D’Alpoim Guedes, J.; Ganjyal, G.M.; Whiteman, M.R.; Kidwell, K.K.; Murphy, K.M. Proso Millet (Panicum miliaceum L.) and Its Potential for Cultivation in the Pacific Northwest, US: A Review. Front. Plant Sci. 2016, 7, 1961. [Google Scholar] [CrossRef]

- Saha, D.; Bhattacharya, S. Hydrocolloids as Thickening and Gelling Agents in Food: A Critical Review. J. Food Sci. Technol. 2010, 47, 587–597. [Google Scholar] [CrossRef]

- Chillo, S.; Laverse, J.; Falcone, P.M.; Del Nobile, M.A. Effect of Carboxymethylcellulose and Pregelatinized Corn Starch on the Quality of Amaranthus Spaghetti. J. Food Eng. 2007, 83, 492–500. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Lynch, K.M.; Arendt, E.K. Starch Characteristics Linked to Gluten-Free Products. Foods 2017, 6, 29. [Google Scholar] [CrossRef]

- Deora, N.S.; Deswal, A.; Mishra, H.N. Functionality of Alternative Protein in Gluten-Free Product Development. Food Sci. Technol. Int. 2015, 21, 364–379. [Google Scholar] [CrossRef]

- Pedrosa Silva Clerici, M.T.P.S.; Airoldi, C.; El-Dash, A.A. Production of Acidic Extruded Rice Flour and Its Influence on the Qualities of Gluten-Free Bread. LWT Food Sci. Technol. 2009, 42, 618–623. [Google Scholar] [CrossRef]

- Renzetti, S.; Behr, J.; Vogel, R.F.; Barbiroli, A.; Iametti, S.; Bonomi, F.; Arendt, E.K. Transglutaminase Treatment of Brown Rice Flour: A Chromatographic, Electrophoretic and Spectroscopic Study of Protein Modifications. Food Chem. 2012, 131, 1076–1085. [Google Scholar] [CrossRef]

- Gujral, H.S.; Rosell, C.M. Functionality of Rice Flour Modified with a Microbial Transglutaminase. J. Cereal Sci. 2004, 39, 225–230. [Google Scholar] [CrossRef]

- Renzetti, S.; Arendt, E.K. Effects of Oxidase and Protease Treatments on the Breadmaking Functionality of a Range of Gluten-Free Flours. Eur. Food Res. Technol. 2009, 229, 307–317. [Google Scholar] [CrossRef]

- Miranda-Villa, P.P.; Mufari, J.R.; Bergesse, A.E.; Calandri, E.L. Effects of Whole and Malted Quinoa Flour Addition on Gluten-Free Muffins Quality. J. Food Sci. 2019, 84, 147–153. [Google Scholar] [CrossRef]

- Salehi, F.; Kashaninejad, M. Effect of Drying Methods on Textural and Rheological Properties of Basil Seed Gum. Int. Food Res. J. 2017, 24, 2090–2096. [Google Scholar]

- Phongthai, S.; D’Amico, S.; Schoenlechner, R.; Rawdkuen, S. Comparative Study of Rice Bran Protein Concentrate and Egg Albumin on Gluten-Free Bread Properties. J. Cereal Sci. 2016, 72, 38–45. [Google Scholar] [CrossRef]

- Pico, J.; Reguilón, M.P.; Bernal, J.; Gómez, M. Effect of Rice, Pea, Egg White and Whey Proteins on Crust Quality of Rice Flour-Corn Starch Based Gluten-Free Breads. J. Cereal Sci. 2019, 86, 92–101. [Google Scholar] [CrossRef]

- Wolf, B. Polysaccharide Functionality Through Extrusion Processing. Curr. Opin. Colloid Interface Sci. 2010, 15, 50–54. [Google Scholar] [CrossRef]

- Zhang, L.; Nishizu, T.; Hayakawa, S.; Nakashima, R.; Goto, K. Effects of Different Drying Conditions on Water Absorption and Gelatinization Properties of Pasta. Food Bioprocess Technol. 2013, 6, 2000–2009. [Google Scholar] [CrossRef]

- Marti, A.; Caramanico, R.; Bottega, G.; Pagani, M.A. Cooking Behavior of Rice Pasta: Effect of Thermal Treatments and Extrusion Conditions. LWT Food Sci. Technol. 2013, 54, 229–235. [Google Scholar] [CrossRef]

- Zavareze, E.; Storck, C.R.; de Castro, L.A.S.; Schirmer, M.A.; Dias, A.R.G. Effect of Heat-Moisture Treatment on Rice Starch of Varying Amylose Content. Food Chem. 2010, 121, 358–365. [Google Scholar] [CrossRef]

- Gélinas, P.; Mckinnon, C.M.; Rodrigue, N.; Montpetit, D. Heating Conditions and Bread-Making Potential of Substandard Flour. J. Food Sci. 2001, 66, 627–632. [Google Scholar] [CrossRef]

- Cappa, C.; Barbosa-Cánovas, G.V.; Lucisano, M.; Mariotti, M. Effect of High Pressure Processing on the Baking Aptitude of Corn Starch and Rice Flour. LWT 2016, 73, 20–27. [Google Scholar] [CrossRef]

- Deora, N.S.; Deswal, A.; Mishra, H.N. Alternative Approaches Towards Gluten-Free Dough Development: Recent Trends. Food Eng. Rev. 2014, 6, 89–104. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. A Systematic Review of Gluten-Free Dough and Bread: Dough Rheology, Bread Characteristics, and Improvement Strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Villanueva, M.; Harasym, J.; Muñoz, J.M.; Ronda, F. Rice Flour Physically Modified by Microwave Radiation Improves Viscoelastic Behavior of Doughs and Its Bread-Making Performance. Food Hydrocoll. 2019, 90, 472–481. [Google Scholar] [CrossRef]

- Souad, B.; Leila, B.; Colette, B.; Karim, A.; Mohammed, N.Z. Impact of Instant Controlled Pressure Drop (DIC) Treatment on the Technological Quality of Gluten-Free Bread Based on Rice-Field Bean Formula Using Design of Experiments. Afr. J. Food Sci. 2021, 15, 121–130. [Google Scholar] [CrossRef]

- Chhanwal, N.; Bhushette, P.R.; Anandharamakrishnan, C. Current Perspectives on Non-conventional Heating Ovens for Baking Process—A Review. Food Bioprocess Technol. 2019, 12, 1–15. [Google Scholar] [CrossRef]

- Ceppi, E.L.; Brenna, O.V. Experimental Studies to Obtain Rice Malt. J. Agric. Food Chem. 2010, 58, 7701–7707. [Google Scholar] [CrossRef]

- Ceppi, E.L.M.; Brenna, O.V. Brewing with Rice Malt—A Gluten-Free Alternative. J. Inst. Brew. 2010, 116, 275–279. [Google Scholar] [CrossRef]

- Aleman, R.S.; Paz, G.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. High Protein Brown Rice Flour, Tapioca Starch & Potato Starch in the Development of Gluten-Free Cupcakes. LWT 2021, 152, 112326. [Google Scholar] [CrossRef]

- Fujii, K.; Usui, M.; Ohsuga, A.; Tsuji, M. Effect of Thermoresponsive Xyloglucan on the Bread-Making Properties and Preservation of Gluten-Free Rice-Flour Bread. Foods 2023, 12, 2761. [Google Scholar] [CrossRef] [PubMed]

- Zhao, F.; Li, Y.; Li, C.; Ban, X.; Cheng, L.; Hong, Y.; Gu, Z.; Li, Z. Insight into the Regulations of Rice Protein on the Gluten-Free Bread Matrix Properties. Food Hydrocoll. 2022, 131, 107796. [Google Scholar] [CrossRef]

- Naseer, B.; Naik, H.R.; Hussain, S.Z.; Zargar, I.; Beenish, T.A.; Bhat, T.A.; Nazir, N. Effect of Carboxymethyl Cellulose and Baking Conditions on In-Vitro Starch Digestibility and Physico-Textural Characteristics of Low Glycemic Index Gluten-Free Rice Cookies. LWT 2021, 141, 110885. [Google Scholar] [CrossRef]

- Phongthai, S.; Singsaeng, N.; Nhoo-Ied, R.; Suwannatrai, T.; Schönlechner, R.; Unban, K.; Klunklin, W.; Laokuldilok, T.; Phimolsiripol, Y.; Rawdkuen, S. Properties of Peanut (KAC431) Protein Hydrolysates and Their Impact on the Quality of Gluten-Free Rice Bread. Foods 2020, 9, 942. [Google Scholar] [CrossRef] [PubMed]

- Das, A.B.; Bhattacharya, S. Characterization of the Batter and Gluten-Free Cake from Extruded Red Rice Flour. LWT 2019, 102, 197–204. [Google Scholar] [CrossRef]

- Fu, M.; Sun, X.; Wu, D.; Meng, L.; Feng, X.; Cheng, W.; Gao, C.; Yang, Y.; Shen, X.; Tang, X. Effect of Partial Substitution of Buckwheat on Cooking Characteristics, Nutritional Composition, and In Vitro Starch Digestibility of Extruded Gluten-Free Rice Noodles. LWT 2020, 126, 109332. [Google Scholar] [CrossRef]

- Meza, S.L.R.; Sinnecker, P.; Schmiele, M.; Massaretto, I.L.; Chang, Y.K.; Marquez, U.M.L. Production of Innovative Gluten-Free Breakfast Cereals Based on Red and Black Rice by Extrusion Processing Technology. J. Food Sci. Technol. 2019, 56, 4855–4866. [Google Scholar] [CrossRef]

- Ito, S.; Arai, E. Improvement of Gluten-Free Steamed Bread Quality by Partial Substitution of Rice Flour with Powder of Apios americana Tuber. Food Chem. 2021, 337, 127977. [Google Scholar] [CrossRef]

- Qin, W.; Xi, H.; Wang, A.; Gong, X.; Chen, Z.; He, Y.; Wang, L.; Liu, L.; Wang, F.; Tong, L. Ultrasound Treatment Enhanced Semidry-Milled Rice Flour Properties and Gluten-Free Rice Bread Quality. Molecules 2022, 27, 5403. [Google Scholar] [CrossRef]

| Product | GF Materials | Main Conclusions | References |

|---|---|---|---|

| Pasta | Rice flour | Pasta with 9% egg albumin had the lowest cooking loss, with improved firmness. | [65] |

| Rice–buckwheat flour mixture | To produce good-quality pasta (low cooking loss and stickiness and good hardness and firmness), optimal conditions (30% moisture content, 120 °C barrel temperature, and 80 rpm screw speed) were established. | [73] | |

| Parboiled milled rice (Indica cultivar) | Extruded cooking pasta with 25% amaranth flour exhibited increased firmness and decreased protein solubility. | [74] | |

| Rice flour | Precooked spaghetti with legume-containing rice flour (up to 30 g/100 g) showed low cooking loss (<6%) and acceptable sensory score and was nutritionally valuable. | [75] | |

| Two Indica cultivars | Rice spaghetti with 5% soy protein isolate showed increased firmness and decreased stickiness, cooking time, and cooking loss. | [71] | |

| High-amylose rice cultivar | Rice spaghetti containing 5–10% rice protein showed decreased cooking time and loss. Sensory evaluation was comparable to wheat spaghetti when 2.5–5% RP was added. | [72] | |

| Noodles | Commercial polished Japonica rice | Dry-milled rice flour showed high damaged starch content, increasing the water solubility of rice noodles, and resulting in increased cooking loss. | [38] |

| Commercial rice flours | Rice noodles with mushroom β-glucan-rich fragments exhibited reduced cooking loss and enhanced extensibility and firmness. | [29] |

| Product | GF Materials | Main Conclusions | References |

|---|---|---|---|

| Beer | Two Italian paddy rice varieties | The color of the rice malt beer was pale, and the foam collapsed rapidly. The sensory profile was flat compared to barley malt beer and needed to be improved. | [86] |

| Two Italian paddy rice varieties | Top-fermented beer had high alcohol content and low ester content, without off-flavors. | [81] | |

| Italian paddy rice (japonica) | The color and flavor of roasted special rice malts (caramelized and dark) were enhanced and showed high polyphenol content. | [87] | |

| Rice and buckwheat | Rice malts consistently produced more maltose than glucose. Buckwheat malts produced more glucose and free nitrogen than rice malts. | [85] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Kim, H.-S. Rice-Based Gluten-Free Foods and Technologies: A Review. Foods 2023, 12, 4110. https://doi.org/10.3390/foods12224110

Park J, Kim H-S. Rice-Based Gluten-Free Foods and Technologies: A Review. Foods. 2023; 12(22):4110. https://doi.org/10.3390/foods12224110

Chicago/Turabian StylePark, Jiyoung, and Hong-Sik Kim. 2023. "Rice-Based Gluten-Free Foods and Technologies: A Review" Foods 12, no. 22: 4110. https://doi.org/10.3390/foods12224110

APA StylePark, J., & Kim, H.-S. (2023). Rice-Based Gluten-Free Foods and Technologies: A Review. Foods, 12(22), 4110. https://doi.org/10.3390/foods12224110