Non-Destructive Detection of Meat Quality Based on Multiple Spectral Dimension Reduction Methods by Near-Infrared Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

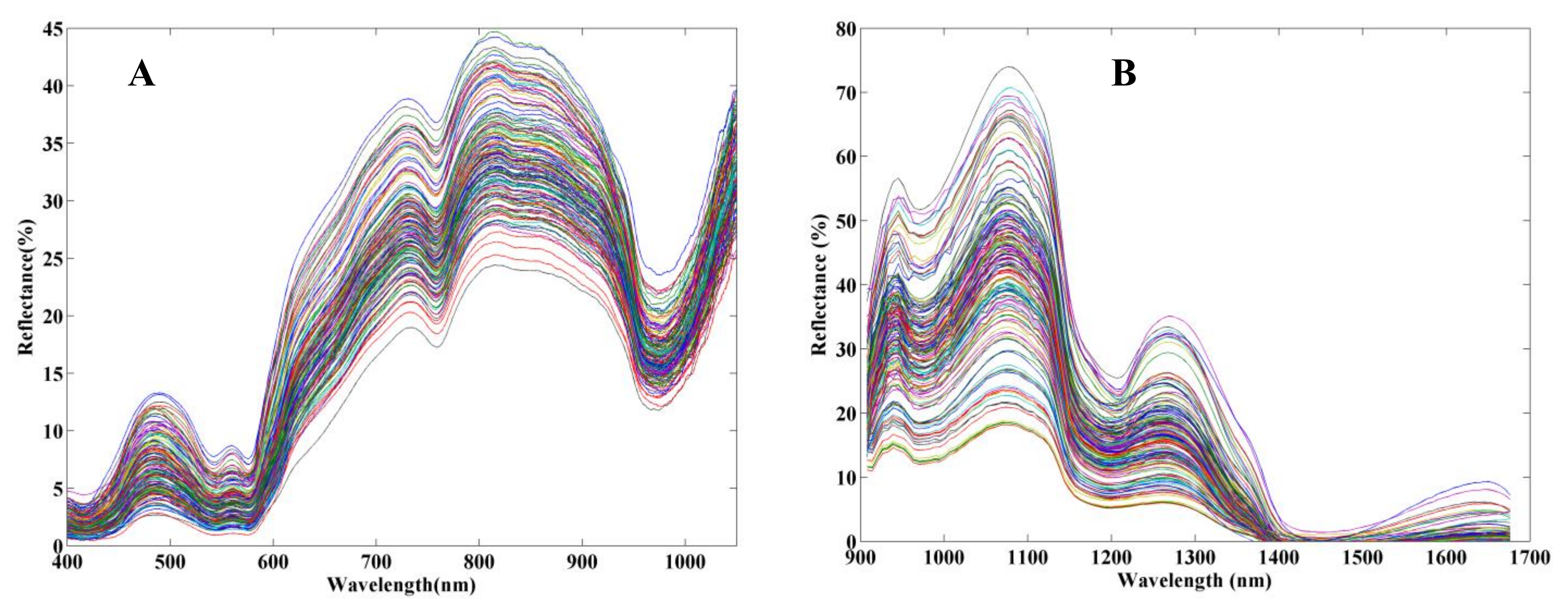

2.2. Collection of NIR Spectra

2.3. Analysis of Meat Quality

2.4. Wavelength Selection

2.5. Characteristic Extraction

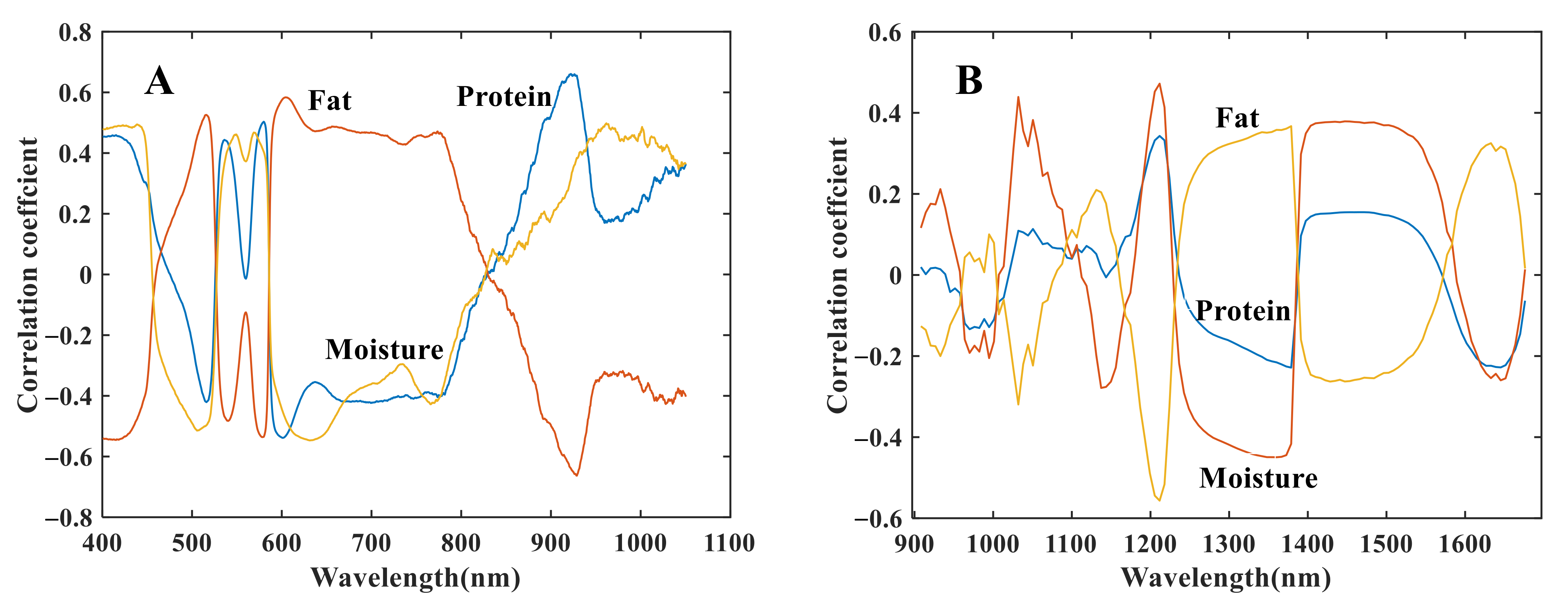

2.5.1. Extraction of Highly Correlated Spectra

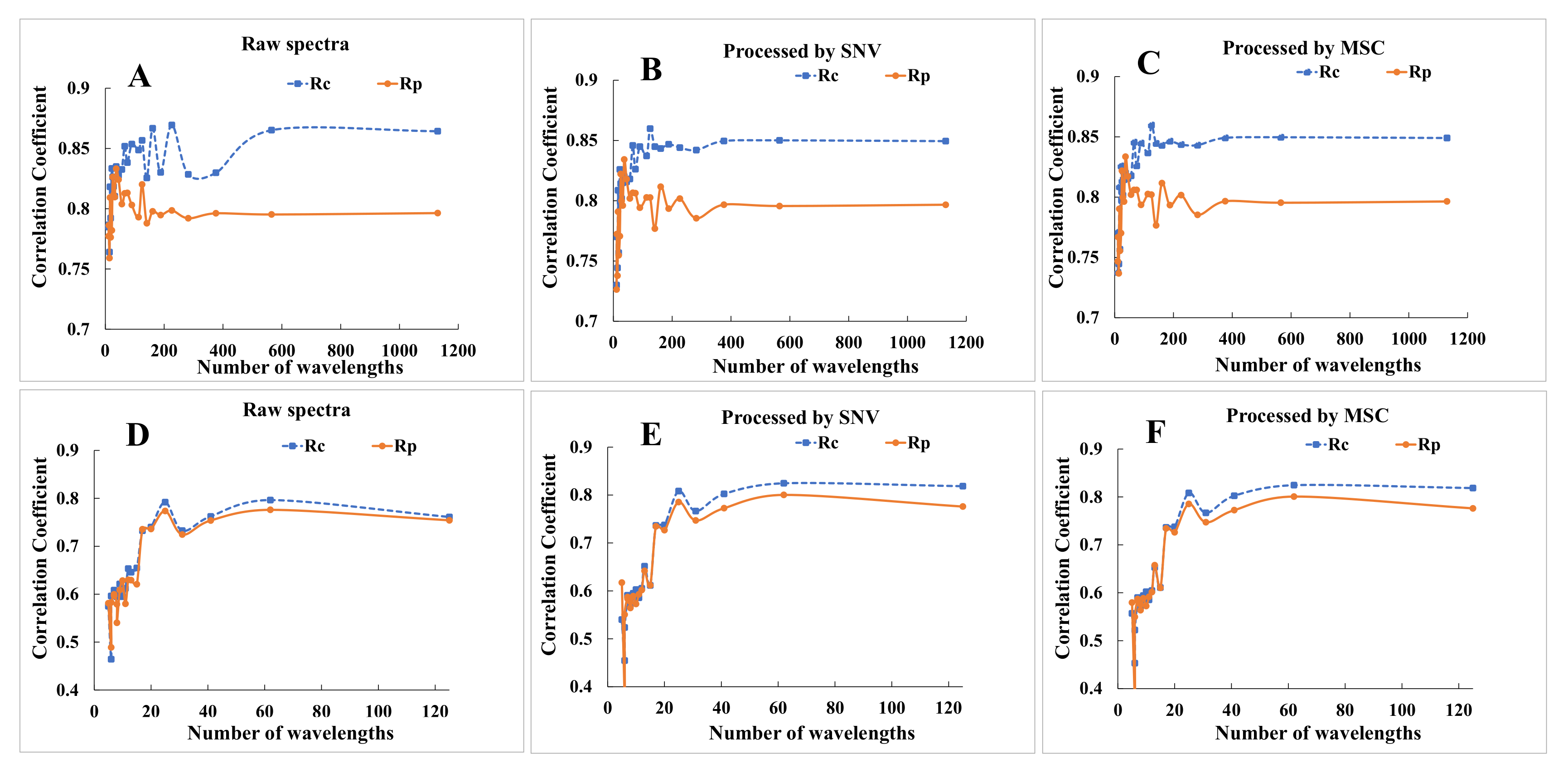

2.5.2. Reducing of Sampling Interval

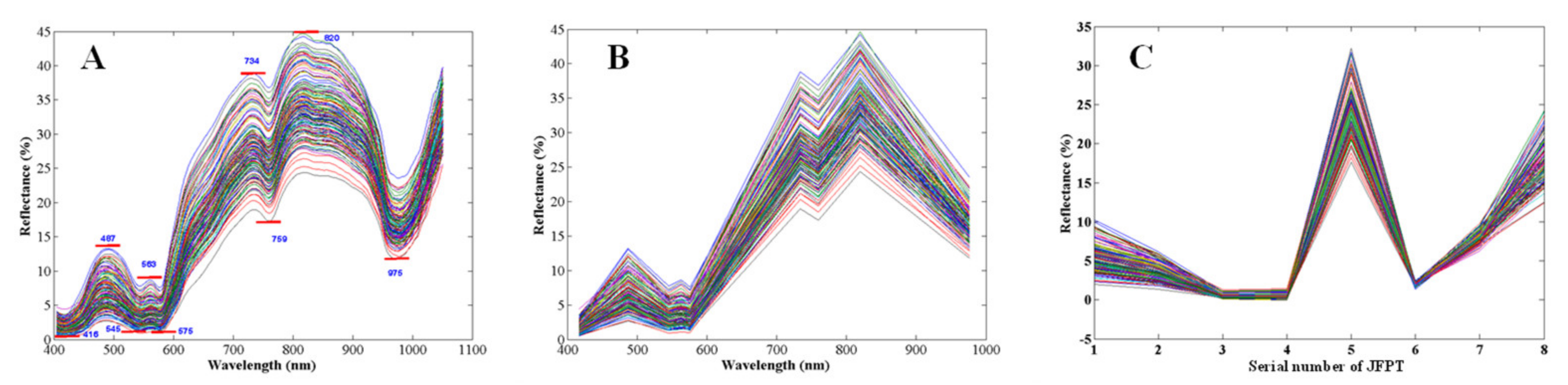

2.5.3. Extraction of Peak-to-Trough Jump Features

2.6. Data Preprocessing

2.7. Model Development

2.8. Software and Program

3. Results and Discussions

3.1. Results of Meat Quality and Raw Spectra

3.2. PLSR Models Based on Full Spectra

3.3. Modeling Results Based on Selected Spectra and Extracted Features

3.3.1. PLSR Models Based on High-Correlation Spectral Region

3.3.2. MLR Model Results Based on Selected Characteristic Wavelengths

3.3.3. PLSR Modeling Results Based on Sampling Interval Shortening Method

3.3.4. PLSR Modeling Results Based on Peak Jumping Feature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Qian, J.; Wang, C.; Zhuang, H.; Nasiru, M.M.; Zhang, J.; Yan, W. Evaluation of meat-quality and myofibrillar protein of chicken drumsticks treated with plasma-activated lactic acid as a novel sanitizer. LWT 2020, 138, 110642. [Google Scholar] [CrossRef]

- Du, S.; You, S.; Bao, J.; Gegentu; Jia, Y.S.; Cai, Y.M. Evaluation of the growth performance and meat quality of Mongolian lamb fed grass, hay or pellets of Inner Mongolian native grass. Small Rumin. Res. 2019, 181, 34–38. [Google Scholar] [CrossRef]

- Oh, E.K.; Grossklaus, D. Measurement of the Components in Meat Patties by near-Infrared Reflectance Spectroscopy. Meat Sci. 1995, 41, 157–162. [Google Scholar] [CrossRef] [PubMed]

- Andres, S.; Murray, I.; Navajas, E.A.; Fisher, A.V.; Lambe, N.R.; Bünger, L. Prediction of sensory characteristics of lamb meat samples by near-infrared re-flectance spectroscopy. Meat Sci. 2007, 76, 509–516. [Google Scholar] [CrossRef] [PubMed]

- Prieto, N.; López-Campos, O.; Aalhus, J.; Dugan, M.; Juárez, M.; Uttaro, B. Use of near infrared spectroscopy for estimating meat chemical composition, quality traits and fatty acid content from cattle fed sunflower or flaxseed. Meat Sci. 2014, 98, 279–288. [Google Scholar] [CrossRef]

- Candoğan, K.; Altuntas, E.G.; İğci, N. Authentication and Quality Assessment of Meat Products by Fourier-Transform Infrared (FTIR) Spectroscopy. Food Eng. Rev. 2020, 13, 66–91. [Google Scholar] [CrossRef]

- Andersen, P.V.; Wold, J.P.; Gjerlaug-Enger, E.; Veiseth-Kent, E. Predicting post-mortem meat quality in porcine longissimus lumborum using Raman, near infrared and fluorescence spectroscopy. Meat Sci. 2018, 145, 94–100. [Google Scholar] [CrossRef]

- Andueza, D.; Listrat, A.; Durand, D.; Normand, J.; Mourot, B.; Gruffat, D. Prediction of beef meat fatty acid composition by visible-near-infrared spectroscopy was improved by preliminary freeze-drying. Meat Sci. 2019, 158, 107910. [Google Scholar] [CrossRef]

- Savoia, S.; Albera, A.; Brugiapaglia, A.; Di Stasio, L.; Ferragina, A.; Cecchinato, A.; Bittante, G. Prediction of meat quality traits in the abattoir using portable and hand-held near-infrared spectrometers. Meat Sci. 2019, 161, 108017. [Google Scholar] [CrossRef]

- Patel, N.; Toledo-Alvarado, H.; Bittante, G. Performance of different portable and hand-held near-infrared spectrometers for predicting beef composition and quality characteristics in the abattoir without meat sampling. Meat Sci. 2021, 178, 108518. [Google Scholar] [CrossRef] [PubMed]

- Ozcan, A. Mobile phones democratize and cultivate next-generation imaging, diagnostics and measurement tools. Lab A Chip 2014, 14, 3187–3194. [Google Scholar] [CrossRef] [PubMed]

- Kartakoullis, A.; Comaposada, J.; Cruz-Carrión, A.; Serra, X.; Gou, P. Feasibility study of smartphone-based Near Infrared Spectroscopy (NIRS) for salted minced meat composition diagnostics at different temperatures. Food Chem. 2018, 278, 314–321. [Google Scholar] [CrossRef] [PubMed]

- Mo, L.; Chen, H.; Chen, W.; Feng, Q.; Xu, L. Study on evolution methods for the optimization of machine learning models based on FT-NIR spectroscopy. Infrared Phys. Technol. 2020, 108, 103366. [Google Scholar] [CrossRef]

- Mishra, P.; Verkleij, T.; Klont, R. Improved prediction of minced pork meat chemical properties with near-infrared spec-troscopy by a fusion of scatter-correction techniques. Infrared. Phys. Technol. 2021, 113, 103643. [Google Scholar] [CrossRef]

- Chen, Y.F.; Li, Y.J.; Peng, M.M.; Yang, Y.J. Improvements of VIS-NIR Spectroscopy Model in the Prediction of TVB-N Using MIV Wavelength Selection. Spectrosc. Spect. Anal. 2020, 40, 1413–1419. [Google Scholar]

- Hu, L.; Yin, C.; Ma, S.; Liu, Z. Vis-NIR spectroscopy Combined with Wavelengths Selection by PSO Optimization Algorithm for Simultaneous Determination of Four Quality Parameters and Classification of Soy Sauce. Food Anal. Methods 2018, 12, 633–643. [Google Scholar] [CrossRef]

- Li, J.; Wang, Q.; Xu, L.; Tian, X.; Xia, Y.; Fan, S. Comparison and Optimization of Models for Determination of Sugar Content in Pear by Portable Vis-NIR Spectroscopy Coupled with Wavelength Selection Algorithm. Food Anal. Methods 2018, 12, 12–22. [Google Scholar] [CrossRef]

- Hu, L.; Yin, C.; Ma, S.; Liu, Z. Rapid detection of three quality parameters and classification of wine based on Vis-NIR spectroscopy with wavelength selection by ACO and CARS algorithms. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 205, 574–581. [Google Scholar] [CrossRef]

- Shan, J.; Wang, X.; Han, S.; Kondo, N. Application of Curve Fitting and Wavelength Selection Methods for Determination of Chlorogenic Acid Concentration in Coffee Aqueous Solution by Vis/NIR Spectroscopy. Food Anal. Methods 2016, 10, 999–1006. [Google Scholar] [CrossRef]

- Garcia-Martin, J.F. Optical path length and wavelength selection using Vis/NIR spectroscopy for olive oil’s free acidity de-termination. Int. J. Food Sci. Technol. 2015, 50, 1461–1467. [Google Scholar] [CrossRef]

- Guo, H.; Chen, J.; Pan, T.; Wang, J.; Cao, G. Vis-NIR wavelength selection for non-destructive discriminant analysis of breed screening of transgenic sugarcane. Anal. Methods 2014, 6, 8810–8816. [Google Scholar] [CrossRef]

- Yang, Z.; Albrow-Owen, T.; Cai, W.; Hasan, T. Miniaturization of optical spectrometers. Science 2021, 371, eabe0722. [Google Scholar] [CrossRef] [PubMed]

- Raghavendra, A.; Guru, D.S.; Rao, M.K. Mango internal defect detection based on optimal wavelength selection method using NIR spectroscopy. Artif. Intell. Agric. 2021, 5, 43–51. [Google Scholar] [CrossRef]

- Lei, T.; Sun, D.-W. A novel NIR spectral calibration method: Sparse coefficients wavelength selection and regression (SCWR). Anal. Chim. Acta 2020, 1110, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Li, P.-F.; Wang, J.-H.; Cao, N.-N.; Han, D.-H. Selection of Variables for MLR in Vis/NIR Spectroscopy Based on BiPLS Combined with GA. Spectrosc. Spect. Anal. 2009, 29, 2637–2641. [Google Scholar]

- Li, H.; Liang, Y.; Xu, Q.; Cao, D. Key wavelengths screening using competitive adaptive reweighted sampling method for multivariate calibration. Anal. Chim. Acta 2009, 648, 77–84. [Google Scholar] [CrossRef]

- Han, Q.-J.; Wu, H.-L.; Cai, C.-B.; Xu, L.; Yu, R.-Q. An ensemble of Monte Carlo uninformative variable elimination for wavelength selection. Anal. Chim. Acta 2008, 612, 121–125. [Google Scholar] [CrossRef]

- Araujo, M.C.U.; Saldanha, T.C.B.; Galvao, R.K.H.; Yoneyama, T.; Chame, H.C.; Visani, V. The successive projections algorithm for variable selection in spectro-scopic multicomponent analysis. Chemometr. Intell. Lab 2001, 57, 65–73. [Google Scholar] [CrossRef]

- Westad, F.; Martens, H. Variable Selection in near Infrared Spectroscopy Based on Significance Testing in Partial Least Squares Regression. J. Near Infrared Spectrosc. 2000, 8, 117–124. [Google Scholar] [CrossRef]

- GB 5009.5-2016; National Food Safety Standard-Determination of Protein Content in Food. China Standards Press: Beijing, China, 2016.

- GB 5009.6-2016; National Food Safety Standard-Determination of Fat Content in Food. China Standards Press: Beijing, China, 2016.

- GB/T 9695.15-2008; Meat and Meat Product-Determination of Moisture Content. China Standards Press: Beijing, China, 2008.

- Brenchley, J.M.; Hörchner, U.; Kalivas, J.H. Wavelength Selection Characterization for NIR Spectra. Appl. Spectrosc. 1997, 51, 689–699. [Google Scholar] [CrossRef]

- Tang, X.; Xie, L.; Liu, S.; Chen, Z.; Rao, L.; Chen, L.; Li, L.; Xiao, S.; Zhang, Z.; Huang, L. Extensive evaluation of prediction performance for 15 pork quality traits using large scale VIS/NIRS data. Meat Sci. 2022, 192, 108902. [Google Scholar] [CrossRef] [PubMed]

- Cozzolino, D.; Murray, I. Effect of Sample Presentation and Animal Muscle Species on the Analysis of Meat by near Infrared Reflectance Spectroscopy. J. Near Infrared Spectrosc. 2002, 10, 37–44. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; ElMasry, G.; Sun, D.-W.; Allen, P. Non-destructive assessment of instrumental and sensory tenderness of lamb meat using NIR hyperspectral imaging. Food Chem. 2013, 141, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Zhao, J.; Povey, M.; Holmes, M.; Mao, H. Variables selection methods in near-infrared spectroscopy. Anal. Chim. Acta 2010, 667, 14–32. [Google Scholar]

- Prieto, N.; Roehe, R.; Lavín, P.; Batten, G.; Andrés, S. Application of near infrared reflectance spectroscopy to predict meat and meat products quality: A review—ScienceDirect. Meat Sci. 2009, 83, 175–186. [Google Scholar] [CrossRef]

| Quality | Average | Max | Min | Range | Coefficient of Variation (%) |

|---|---|---|---|---|---|

| Protein (%) | 19.72 | 23.02 | 14.85 | 8.17 | 6.61 |

| Fat (%) | 3.55 | 16.13 | 0.55 | 15.57 | 88.42 |

| Moisture (%) | 75.03 | 78.70 | 64.94 | 13.77 | 3.72 |

| Spectral Region | Quality | Pre-Treatment | RC | SEC | RP | SEP |

|---|---|---|---|---|---|---|

| 400–1050 nm | Protein | Raw | 0.72 | 0.87 | 0.65 | 1.07 |

| SNV | 0.86 | 0.61 | 0.77 | 0.84 | ||

| S-G | 0.71 | 0.88 | 0.66 | 1.06 | ||

| MSC | 0.84 | 0.65 | 0.78 | 0.85 | ||

| Fat | Raw | 0.86 | 1.44 | 0.80 | 2.03 | |

| SNV | 0.85 | 1.58 | 0.80 | 1.83 | ||

| S-G | 0.86 | 1.49 | 0.80 | 2.02 | ||

| MSC | 0.85 | 1.58 | 0.80 | 1.83 | ||

| Moisture | Raw | 0.62 | 2.30 | 0.53 | 3.06 | |

| SNV | 0.88 | 1.27 | 0.84 | 1.47 | ||

| S-G | 0.61 | 2.36 | 0.53 | 3.07 | ||

| MSC | 0.88 | 1.28 | 0.83 | 1.48 | ||

| 900–1700 nm | Protein | Raw | 0.31 | 2.01 | 0.51 | 2.42 |

| SNV | 0.78 | 0.82 | 0.74 | 0.89 | ||

| S-G | 0.28 | 2.29 | 0.32 | 2.25 | ||

| MSC | 0.78 | 0.82 | 0.74 | 0.88 | ||

| Fat | Raw | 0.76 | 2.09 | 0.75 | 2.01 | |

| SNV | 0.85 | 1.72 | 0.76 | 1.93 | ||

| S-G | 0.75 | 2.13 | 0.76 | 1.97 | ||

| MSC | 0.85 | 1.72 | 0.76 | 1.93 | ||

| Moisture | Raw | 0.15 | 7.10 | 0.23 | 9.71 | |

| SNV | 0.78 | 1.80 | 0.75 | 1.80 | ||

| S-G | 0.17 | 7.77 | 0.13 | 8.80 | ||

| MSC | 0.78 | 1.79 | 0.75 | 1.81 |

| Spectral Region | Quality | Threshold of Correlation Coefficient | Number of Variables | RC | SEC | RP | SEP |

|---|---|---|---|---|---|---|---|

| 400–1050 nm | Protein | 0.3 | 828 | 0.80 | 0.73 | 0.80 | 0.80 |

| 0.4 | 558 | 0.80 | 0.72 | 0.79 | 0.79 | ||

| 0.5 | 100 | 0.52 | 1.05 | 0.52 | 1.11 | ||

| Fat | 0.3 | 880 | 0.81 | 1.75 | 0.81 | 1.75 | |

| 0.4 | 661 | 0.83 | 1.67 | 0.81 | 1.72 | ||

| 0.5 | 217 | 0.78 | 1.85 | 0.75 | 2.00 | ||

| Moisture | 0.3 | 716 | 0.87 | 1.33 | 0.84 | 1.53 | |

| 0.4 | 441 | 0.84 | 1.42 | 0.81 | 1.67 | ||

| 0.5 | 118 | 0.81 | 1.56 | 0.78 | 1.76 | ||

| 900–1700 nm | Protein | 0.1 | 78 | 0.77 | 0.84 | 0.69 | 0.93 |

| 0.2 | 22 | 0.63 | 1.02 | 0.62 | 0.98 | ||

| 0.3 | 3 | 0.36 | 1.31 | 0.37 | 1.19 | ||

| Fat | 0.1 | 98 | 0.76 | 2.10 | 0.75 | 2.00 | |

| 0.2 | 70 | 0.80 | 1.92 | 0.73 | 2.04 | ||

| 0.3 | 31 | 0.78 | 1.99 | 0.71 | 2.11 | ||

| Moisture | 0.1 | 105 | 0.78 | 1.78 | 0.72 | 1.91 | |

| 0.2 | 80 | 0.78 | 1.76 | 0.82 | 1.54 | ||

| 0.3 | 57 | 0.74 | 1.93 | 0.78 | 1.68 |

| Spectral Range | Quality | Selected Wavelengths (nm) |

|---|---|---|

| 400–1050 nm | Protein | 853, 858, 897, 942, 962, 963, 967, 986 |

| Fat | 443, 492, 804, 805, 886, 926 | |

| Moisture | 441, 444, 490, 491, 493, 559, 562, 568, 600, 601, 607, 622, 722, 886, 933, 934, 937, 940, 951, 952, 953, 961, 969, 984, 996, 997 | |

| 900–1700 nm | Protein | 914, 1212, 1435 |

| Fat | 914, 964, 1032, 1057, 1069, 1113, 1156, 1175, 1199, 1212, 1267, 1342, 1360, 1670 | |

| Moisture | 914, 964, 1199, 1212, 1342, 1360 |

| Data Source | Spectral Region | Quality | Rc | RP |

|---|---|---|---|---|

| Selected wavelengths by stepwise regression | 400–1050 nm | Protein | 0.80 | 0.79 |

| Fat | 0.82 | 0.83 | ||

| Moisture | 0.94 | 0.90 | ||

| 900–1700 nm | Protein | 0.55 | 0.55 | |

| Fat | 0.80 | 0.73 | ||

| Moisture | 0.66 | 0.70 | ||

| Jump features from peak-to-trough | 400–1050 nm | Protein | 0.72 | 0.66 |

| Fat | 0.71 | 0.74 | ||

| Moisture | 0.70 | 0.70 | ||

| 900–1700 nm | Protein | 0.52 | 0.59 | |

| Fat | 0.66 | 0.73 | ||

| Moisture | 0.63 | 0.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, X.; Chen, L.; Li, X.; Zhang, D. Non-Destructive Detection of Meat Quality Based on Multiple Spectral Dimension Reduction Methods by Near-Infrared Spectroscopy. Foods 2023, 12, 300. https://doi.org/10.3390/foods12020300

Zheng X, Chen L, Li X, Zhang D. Non-Destructive Detection of Meat Quality Based on Multiple Spectral Dimension Reduction Methods by Near-Infrared Spectroscopy. Foods. 2023; 12(2):300. https://doi.org/10.3390/foods12020300

Chicago/Turabian StyleZheng, Xiaochun, Li Chen, Xin Li, and Dequan Zhang. 2023. "Non-Destructive Detection of Meat Quality Based on Multiple Spectral Dimension Reduction Methods by Near-Infrared Spectroscopy" Foods 12, no. 2: 300. https://doi.org/10.3390/foods12020300

APA StyleZheng, X., Chen, L., Li, X., & Zhang, D. (2023). Non-Destructive Detection of Meat Quality Based on Multiple Spectral Dimension Reduction Methods by Near-Infrared Spectroscopy. Foods, 12(2), 300. https://doi.org/10.3390/foods12020300