Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. Physical Properties

2.3. Textural Properties

2.4. Phenolic Profile and Antioxidant Activity

2.5. E-Senses

2.5.1. E-Nose

2.5.2. E-Tongue

2.5.3. E-Eye (Colorimeter)

2.6. Statistics

3. Results

3.1. Physical Properties of Raw Couscous

3.2. Physical and Textural Properties of Cooked Couscous

3.3. Phenolic Profile Andantioxidant Activity

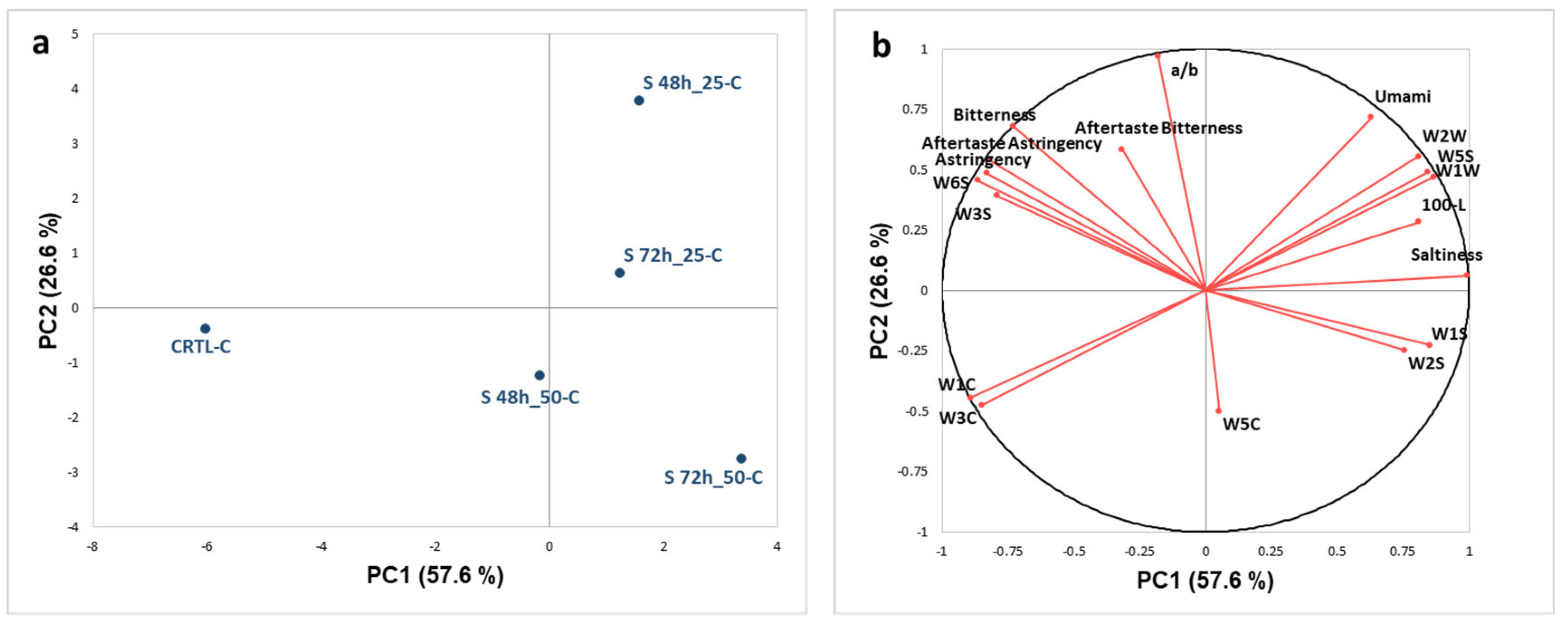

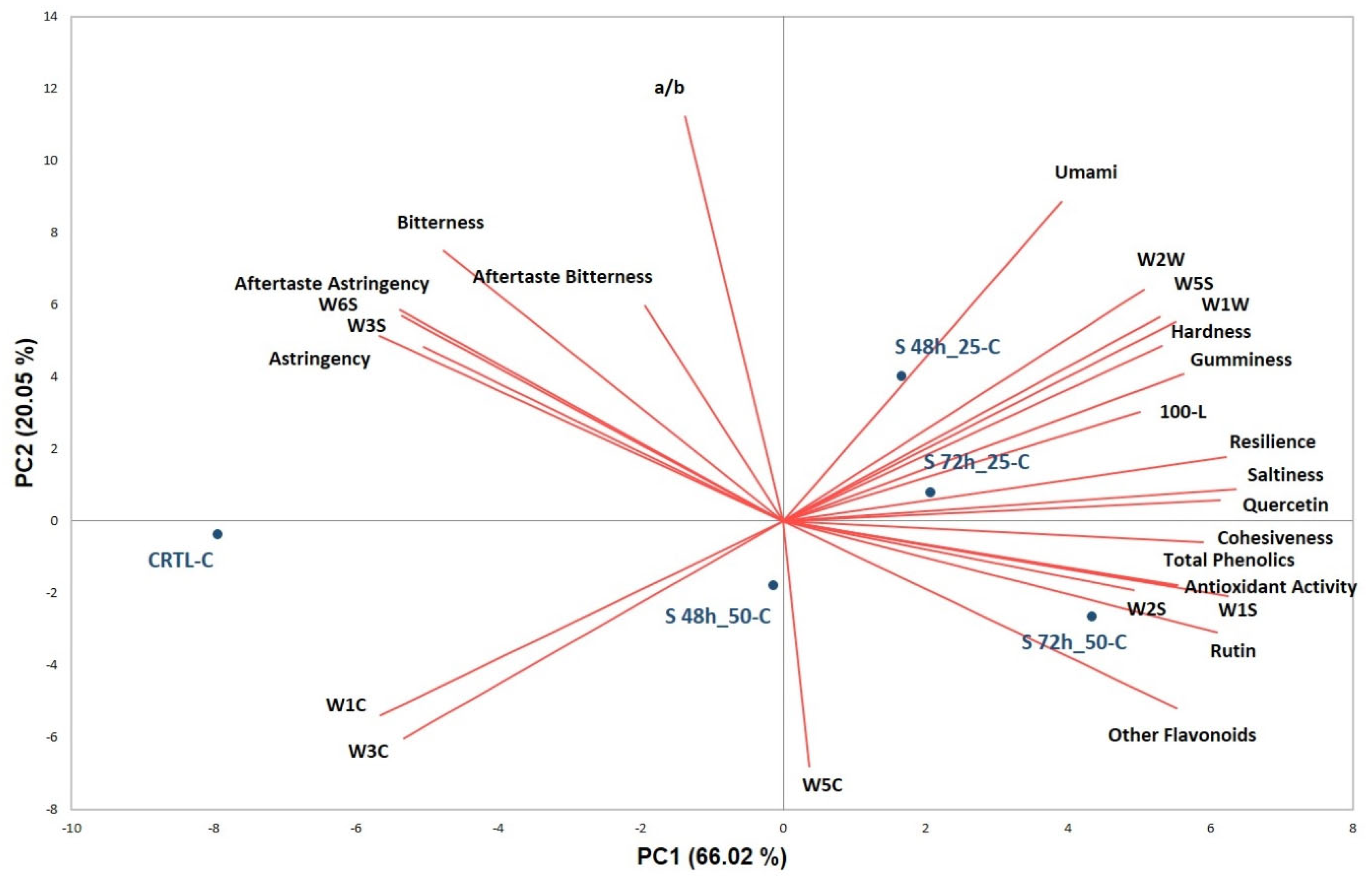

3.4. E-Senses

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Avezum, L.; Rondet, E.; Mestres, C.; Achir, N.; Madode, Y.; Gibert, O.; Lefevre, C.; Hemery, Y.; Verdeil, J.L.; Rajjou, L. Improving the nutritional quality of pulses via germination. Food Rev. Int. 2022, 1–34. [Google Scholar] [CrossRef]

- Chigwedere, C.M.; Wanasundara, J.P.; Shand, P.J. Sensory descriptors for pulses and pulse-derived ingredients: Toward a standardized lexicon and sensory wheel. Compr. Rev. Food Sci. Food Saf. 2022, 21, 999–1023. [Google Scholar] [CrossRef] [PubMed]

- Omary, M.B.; Fong, C.; Rothschild, J.; Finney, P. Effects of germination on the nutritional profile of gluten-free cereals and pseudocereals: A review. Cereal Chem. 2012, 89, 1–14. [Google Scholar] [CrossRef]

- Lemmens, E.; Moroni, A.V.; Pagand, J.; Heirbaut, P.; Ritala, A.; Karlen, Y.; Lê, K.A.; Van den Broeck, H.C.; Brouns, F.J.; De Brier, N.; et al. Impact of cereal seed sprouting on its nutritional and technological properties: A critical review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 305–328. [Google Scholar] [CrossRef] [PubMed]

- Marti, A.; Cardone, G.; Nicolodi, A.; Quaglia, L.; Pagani, M.A. Sprouted wheat as an alternative to conventional flour improvers in bread-making. LWT 2017, 80, 230–236. [Google Scholar] [CrossRef]

- Suárez-Estrella, D.; Borgonovo, G.; Buratti, S.; Ferranti, P.; Accardo, F.; Pagani, M.A.; Marti, A. Sprouting of quinoa (Chenopodium quinoa Willd.): Effect on saponin content and relation to the taste and astringency assessed by electronic tongue. LWT 2021, 144, 111234. [Google Scholar] [CrossRef]

- Suárez-Estrella, D.; Cardone, G.; Buratti, S.; Pagani, M.A.; Marti, A. Sprouting as a pre-processing for producing quinoa-enriched bread. J. Cereal Sci. 2020, 96, 103111. [Google Scholar] [CrossRef]

- Rabitti, N.S.; Appiani, M.; Marti, A.; Buratti, S.; Benedetti, S.; Chiodaroli, G.; Proserpio, C.; Laureati, M. Valorization of common (Fagopyrum esculentum Moench.) and Tartary (Fagopyrum tataricum Gaertn.) buckwheat in gluten-free polenta samples: Chemical-physical and sensory characterization. Foods 2022, 11, 3442. [Google Scholar] [CrossRef]

- Starowicz, M.; Koutsidis, G.; Zieliński, H. Sensory analysis and aroma compounds of buckwheat containing products—A review. Crit. Rev. Food Sci. Nutr. 2018, 58, 1767–1779. [Google Scholar] [CrossRef]

- Suzuki, T.; Morishita, T.; Noda, T.; Ishiguro, K.; Otsuka, S.; Katsu, K. Breeding of buckwheat to reduce bitterness and rutin hydrolysis. Plants 2021, 10, 791. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, Y.; Liu, Q.; Bao, J.; Liu, Q. Identification and quantification of polyphenols in hull, bran and endosperm of common buckwheat (Fagopyrum esculentum) seeds. J. Funct. Foods 2017, 38, 363–369. [Google Scholar] [CrossRef]

- Koval, D.; Plocková, M.; Kyselka, J.; Skřivan, P.; Sluková, M.; Horáčková, S. Buckwheat secondary metabolites: Potential antifungal agents. J. Agric. Food. Chem. 2020, 68, 11631–11643. [Google Scholar] [CrossRef]

- Zhao, X.; Han, Y.; Li, X.; Wang, Z.; Zhang, B. Reviews on the sensory evaluation and volatile components of buckwheat products. Food Res. Dev. 2019, 40, 198–204. [Google Scholar]

- Buratti, S.; Giovanelli, G.; Benedetti, S.; Marti, A. Impact of gelatinization on common (Fagopyrum esculentum) and Tartary (Fagopyrum tataricum) buckwheat: Effect on taste and flavor assessed by e-senses in relation to phenolic compounds. Eur. Food Res. Technol. 2022, 248, 2521–2530. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, Z.; Gao, Y.; Huang, X.; Zou, Y.; Yang, T. Effects of germination on the nutritional properties, phenolic profiles, and antioxidant activities of buckwheat. J. Food Sci. 2015, 80, H1111–H1119. [Google Scholar] [CrossRef] [PubMed]

- Ling, A.; Li, X.; Hu, X.; Ma, Z.; Wu, K.; Zhang, H.; Hao, M.; Wei, S. Dynamic changes in polyphenol compounds, antioxidant activity, and PAL gene expression in different tissues of buckwheat during germination. J. Sci. Food Agric. 2018, 98, 5723–5730. [Google Scholar] [CrossRef]

- Borgonovi, S.M.; Chiarello, E.; Pasini, F.; Picone, G.; Marzocchi, S.; Capozzi, F.; Bordoni, A.; Barbiroli, A.; Marti, A.; Iametti, S.; et al. Effect of sprouting on biomolecular and antioxidant features of common buckwheat (Fagopyrum esculentum). Foods 2023, 12, 2047. [Google Scholar] [CrossRef]

- Gimenez-Bastida, J.A.; Zielinski, H. Buckwheat as a functional food and its effects on health. J. Agric. Food Chem. 2015, 63, 7896–7913. [Google Scholar] [CrossRef] [PubMed]

- Giménez-Bastida, J.A.; Piskuła, M.; Zieliński, H. Recent advances in development of gluten-free buckwheat products. Trends Food Sci. Technol. 2015, 44, 58–65. [Google Scholar] [CrossRef]

- Laureati, M.; Buratti, S.; Bassoli, A.; Borgonovo, G.; Pagliarini, E. Discrimination and characterization of three cultivars of Perilla frutescens by means of sensory descriptors and electronic nose and tongue analysis. Food Res. Int. 2010, 43, 959–964. [Google Scholar] [CrossRef]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Fusion of artificial senses as a robust approach to food quality assessment. J. Food Eng. 2016, 171, 230–239. [Google Scholar] [CrossRef]

- Debbouz, A.; Donnelly, B.J. Process effect on couscous quality. Cereal Chem. 1996, 73, 668–671. [Google Scholar]

- Anderson, R.A.; Conway, H.F.; Peplinski, A.J. Gelatinization of corn grits by roll cooking, extrusion cooking and steaming. Starch-Stärke 1970, 22, 130–135. [Google Scholar] [CrossRef]

- Aboubacar, A.; Hamaker, B.R. Physicochemical properties of flours that relate to sorghum couscous quality. Cereal Chem. 1999, 76, 308–313. [Google Scholar] [CrossRef]

- AOAC. Method 14.004. Moisture content in flour. In Official Methods of Analysis, 13th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1980. [Google Scholar]

- Kobayashi, Y.; Habara, M.; Ikezazki, H.; Chen, R.; Naito, Y.; Toko, K. Advanced taste sensors based on artificial lipids with global selectivity to basic taste qualities and high correlation to sensory scores. Sensors 2010, 10, 3411–3443. [Google Scholar] [CrossRef]

- Abecassis, J.; Cuq, B.; Boggini, G.; Namoune, H. Other traditional durum-derived products. In Durum Wheat Chemistry and Technology, 2nd ed.; Sissons, J.M., Abecassis, J., Marchylo, B., Carcea, M., Eds.; AACC International: St. Paul, MN, USA, 2012; pp. 177–199. [Google Scholar]

- Benayad, A.; Taghouti, M.; Benali, A.; Benbrahim, N.; Aboussaleh, Y. Development and nutritional, technological, microbiological, cooking and sensory characterization of durum wheat couscous partially enriched with lentil semolina. Food Biosci. 2021, 42, 101062. [Google Scholar] [CrossRef]

- Gamel, T.H.; Linssen, J.P.; Mesallam, A.S.; Damir, A.A.; Shekib, L.A. Seed treatments affect functional and antinutritional properties of amaranth flours. J. Sci. Food Agric. 2006, 86, 1095–1102. [Google Scholar] [CrossRef]

- Bhinder, S.; Singh, N.; Kaur, A. Impact of germination on nutraceutical, functional and gluten free muffin making properties of Tartary buckwheat (Fagopyrum tataricum). Food Hydrocoll. 2022, 124, 107268. [Google Scholar] [CrossRef]

- Boudouira, N.; Yüksel, A.N.; Bayram, M.; Benatallah, L.; Zidoune, M.N. Characterisation of gluten-free couscous produced with different legume flours by traditional method. Int. J. Food Sci. Technol. 2023, 58, 1186–1194. [Google Scholar] [CrossRef]

- Hammami, R.; Barbar, R.; Laurent, M.; Cuq, B. Durum wheat couscous grains: An ethnic Mediterranean food at the interface of traditional domestic preparation and industrial manufacturing. Foods 2022, 11, 902. [Google Scholar] [CrossRef]

- Yüksel, A.N.; Öner, M.D.; Bayram, M. Usage of undersize bulgur flour in production of short-cut pasta-like couscous. J. Cereal Sci. 2017, 77, 102–109. [Google Scholar] [CrossRef]

- Alvarez-Jubete, L.; Wijngaard, H.; Arendt, E.K.; Gallagher, E. Polyphenol composition and in vitro antioxidant activity of amaranth, quinoa, buckwheat and wheat as affected by sprouting and baking. Food Chem. 2010, 119, 770–778. [Google Scholar] [CrossRef]

- Ahmed, A.; Khalid, N.; Ahmad, A.; Abbasi, N.A.; Latif, M.S.Z.; Randhawa, M.A. Phytochemicals and biofunctional properties of buckwheat: A review. J. Agri. Sci. 2014, 152, 349–369. [Google Scholar] [CrossRef]

- Nam, T.G.; Lee, S.M.; Park, J.H.; Kim, D.O.; Baek, N.; Eom, S.H. Flavonoid analysis of buckwheat sprouts. Food Chem. 2015, 170, 97–101. [Google Scholar] [CrossRef]

- Joshi, D.C.; Chaudhari, G.V.; Sood, S.; Kant, L.; Pattanayak, A.; Zhang, K.; Fan, Y.; Janovská, D.; Meglič, V.; Zhou, M. Revisiting the versatile buckwheat: Reinvigorating genetic gains through integrated breeding and genomics approach. Planta 2019, 250, 783–801. [Google Scholar] [CrossRef]

- Sofi, S.A.; Ahmed, N.; Farooq, A.; Rafiq, S.; Zargar, S.M.; Kamran, F.; Dar, T.A.; Mir, S.A.; Dar, B.N.; Mousavi Khaneghah, A. Nutritional and bioactive characteristics of buckwheat, and its potential for developing gluten-free products: An updated overview. Food Sci.Nutr. 2023, 11, 2256–2276. [Google Scholar] [CrossRef]

- Molinari, R.; Costantini, L.; Timperio, A.M.; Lelli, V.; Bonafaccia, F.; Bonafaccia, G.; Merendino, N. Tartary buckwheat malt as ingredient of gluten-free cookies. J. Cereal Sci. 2018, 80, 37–43. [Google Scholar] [CrossRef]

- Merendino, N.; Molinari, R.; Costantini, L.; Mazzucato, A.; Pucci, A.; Bonafaccia, F.; Esti, M.; Ceccantoni, B.; Papeschi, C.; Bonafaccia, G. A new “functional” pasta containing tartary buckwheat sprouts as an ingredient improves the oxidative status and normalizes some blood pressure parameters in spontaneously hypertensive rats. Food Funct. 2014, 5, 1017–1026. [Google Scholar] [CrossRef]

- Suárez-Estrella, D.; Bresciani, A.; Iametti, S.; Marengo, M.; Pagani, M.A.; Marti, A. Effect of sprouting on proteins and starch in quinoa (Chenopodium quinoa Willd.). Plant Foods Hum. Nutr. 2020, 75, 635–641. [Google Scholar] [CrossRef]

- Marti, A.; Pagani, M.A. What can play the role of gluten in gluten free pasta? Trends Food Sci. Technol. 2013, 31, 63–71. [Google Scholar] [CrossRef]

- Carcea, M.; Narducci, V.; Turfani, V.; Giannini, V. Polyphenols in raw and cooked cereals/pseudocereals/legume pasta and couscous. Foods 2017, 6, 80. [Google Scholar] [CrossRef] [PubMed]

| Couscous | Pregelatinized Unsprouted Buckwheat (%) | Sprouted Buckwheat for 48 h (S48h) (%) | Sprouted Buckwheat for 72 h (S72h) (%) |

|---|---|---|---|

| CTRL. | 100 | 0 | 0 |

| S48h_25 | 75 | 25 | 0 |

| S48h_50 | 50 | 50 | 0 |

| S72h_25 | 75 | 0 | 25 |

| S72h_50 | 50 | 0 | 50 |

| Samples | Bulk Density (g/mL) | WAI (g/g) | WSI (g/g) |

|---|---|---|---|

| CRTL-R | 0.647 ± 0.015 b | 4.07 ± 0.20 c | 4.45 ± 2.14 a |

| S48h_25-R | 0.695 ± 0.002 c | 3.60 ± 0.09 ab | 7.80 ± 0.58 b |

| S48h_50-R | 0.623 ± 0.005 a | 3.77 ± 0.12 b | 11.39 ± 0.55 c |

| S72h_25-R | 0.706 ± 0.002 c | 3.28 ± 0.03 a | 7.22 ± 0.13 ab |

| S72h_50-R | 0.659 ± 0.001 b | 3.77 ± 0.08 b | 9.86 ± 0.93 bc |

| Samples | WI | VI | WAI | WSI |

|---|---|---|---|---|

| (%) | (%) | (g/g) | (%) | |

| CRTL-C | 88.67 ± 0.92 n.s. | 27.42 ± 2.50 a | 2.15 ± 0.01 c | 1.98 ± 0.06 a |

| S48h_25-C | 90.43 ± 0.64 n.s. | 51.84 ± 5.24 b | 1.90 ± 0.04 ab | 4.16 ± 0.31 ab |

| S48h_50-C | 90.24 ± 0.43 n.s. | 42.03 ± 4.58 b | 1.95 ± 0.04 b | 6.93 ± 0.89 c |

| S72h_25-C | 89.05 ± 2.59 n.s. | 42.86 ± 0.01 b | 1.76 ± 0.06 a | 4.95 ± 0.70 bc |

| S72h_50-C | 90.16 ± 0.61 n.s. | 51.11 ± 3.85 b | 1.93 ± 0.10 b | 5.19 ± 1.73 bc |

| Samples | Hardness (N) | Cohesiveness | Gumminess (N) | Resilience |

|---|---|---|---|---|

| CTRL-C | 6.24 ± 1.82 a | 0.46 ± 0.06 a | 3.06 ± 1.24 a | 0.27 ± 0.05 a |

| S48h_25-C | 14.97 ± 4.61 b | 0.57 ± 0.04 b | 8.53 ± 3.27 c | 0.38 ± 0.04 c |

| S48h_50-C | 7.86 ± 0.98 a | 0.56 ± 0.02 bc | 4.44 ± 0.65 b | 0.35 ± 0.01 b |

| S72h_25-C | 15.15 ± 2.76 b | 0.53 ± 0.03 b | 8.15 ± 1.83 c | 0.40 ± 0.03 c |

| S72h_50-C | 14.07 ± 2.81 b | 0.59 ± 0.03 c | 8.41 ± 2.06 c | 0.39 ± 0.02 c |

| Samples | Total Phenolics (mg GAE/100 g dw) | Antioxidant Activity (µmol TE/100 g dw) | Rutin (mg/100 g dw) | Quercetin (mg/100 g dw) | Other Flavonoids (mg RE/100 g dw) |

|---|---|---|---|---|---|

| CRTL-R | 62 ± 9 a | 148 ± 25 a | 2.02 ± 0.39 a | n.d. | n.d. |

| S48h_25-R | 75 ± 10 a | 220 ± 8 b | 3.63 ± 0.51 b | 0.39 ± 0.06 b | 1.33 ± 0.06 a |

| S48h_50-R | 141 ± 3 b | 373 ± 6 d | 6.04 ± 0.46 c | 0.60 ± 0.03 d | 4.05 ± 0.39 b |

| S72h_25-R | 132 ± 17 b | 444 ± 51 e | 7.15 ± 0.25 d | 0.54 ± 0.05 c | 7.02 ± 0.12 c |

| S72h_50-R | 256 ± 14 c | 730 ± 50 f | 12.88 ± 0.26 e | 1.20 ± 0.02 e | 9.45 ± 0.05 e |

| CRTL-C | 138 ± 6 b | 317 ± 24 c | 5.28 ± 0.28 c | 0.19 ± 0.01 a | n.d. |

| S48h_25-C | 331 ± 11 d | 871 ± 23 g | 15.51 ± 0.52 f | 1.23 ± 0.02 e | 8.03 ± 0.21 d |

| S48h_50-C | 414 ± 13 f | 951 ± 24 h | 17.09 ± 0.04 g | 1.19 ± 0.01 e | 13.63 ± 0.25 f |

| S72h_25-C | 354 ± 12 e | 976 ± 32 h | 21.65 ± 0.58 h | 1.54 ± 0.01 g | 19.64 ± 0.11 g |

| S72h_50-C | 373 ± 17 e | 1148 ± 30 i | 25.78 ± 1.20 i | 1.39 ± 0.02 f | 27.37 ± 0.12 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giovanelli, G.; Bresciani, A.; Benedetti, S.; Chiodaroli, G.; Ratti, S.; Buratti, S.; Marti, A. Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses. Foods 2023, 12, 3578. https://doi.org/10.3390/foods12193578

Giovanelli G, Bresciani A, Benedetti S, Chiodaroli G, Ratti S, Buratti S, Marti A. Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses. Foods. 2023; 12(19):3578. https://doi.org/10.3390/foods12193578

Chicago/Turabian StyleGiovanelli, Gabriella, Andrea Bresciani, Simona Benedetti, Giulia Chiodaroli, Simona Ratti, Susanna Buratti, and Alessandra Marti. 2023. "Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses" Foods 12, no. 19: 3578. https://doi.org/10.3390/foods12193578

APA StyleGiovanelli, G., Bresciani, A., Benedetti, S., Chiodaroli, G., Ratti, S., Buratti, S., & Marti, A. (2023). Reformulating Couscous with Sprouted Buckwheat: Physico-Chemical Properties and Sensory Characteristics Assessed by E-Senses. Foods, 12(19), 3578. https://doi.org/10.3390/foods12193578