The Effect of Sodium Chloride on the Physicochemical and Textural Properties and Flavor Characteristics of Sous Vide Cooked Duck Meat

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Sample Preparation

2.3. Experimental Design

2.4. Sensory Evaluation

2.5. Volatile Compounds Analysis

2.6. Odor Activity Value (OAV)

2.7. Determination of Weight Loss, Color, NaCl Level, TBARS Value, Shear Force, and Textural Properties

2.7.1. Weight Loss

2.7.2. Color Analysis

2.7.3. NaCl Level of Duck Meat

2.7.4. TBARS Value Analysis

2.7.5. Texture and Shear Force Analysis

2.8. Free Amino Acid Analysis

2.9. 5′-Nucleotide Analysis

2.10. Statistic Analysis

3. Results and Discussion

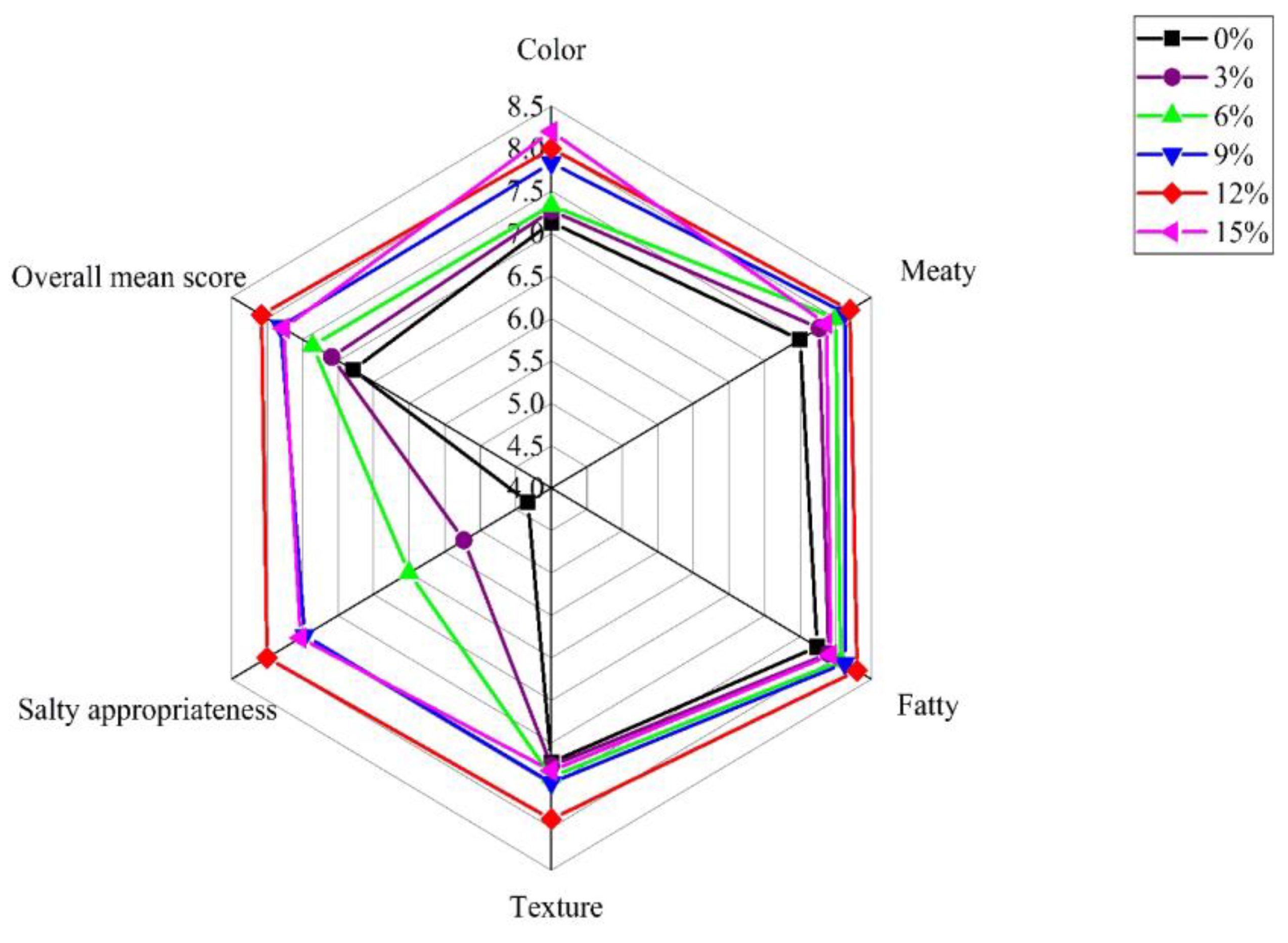

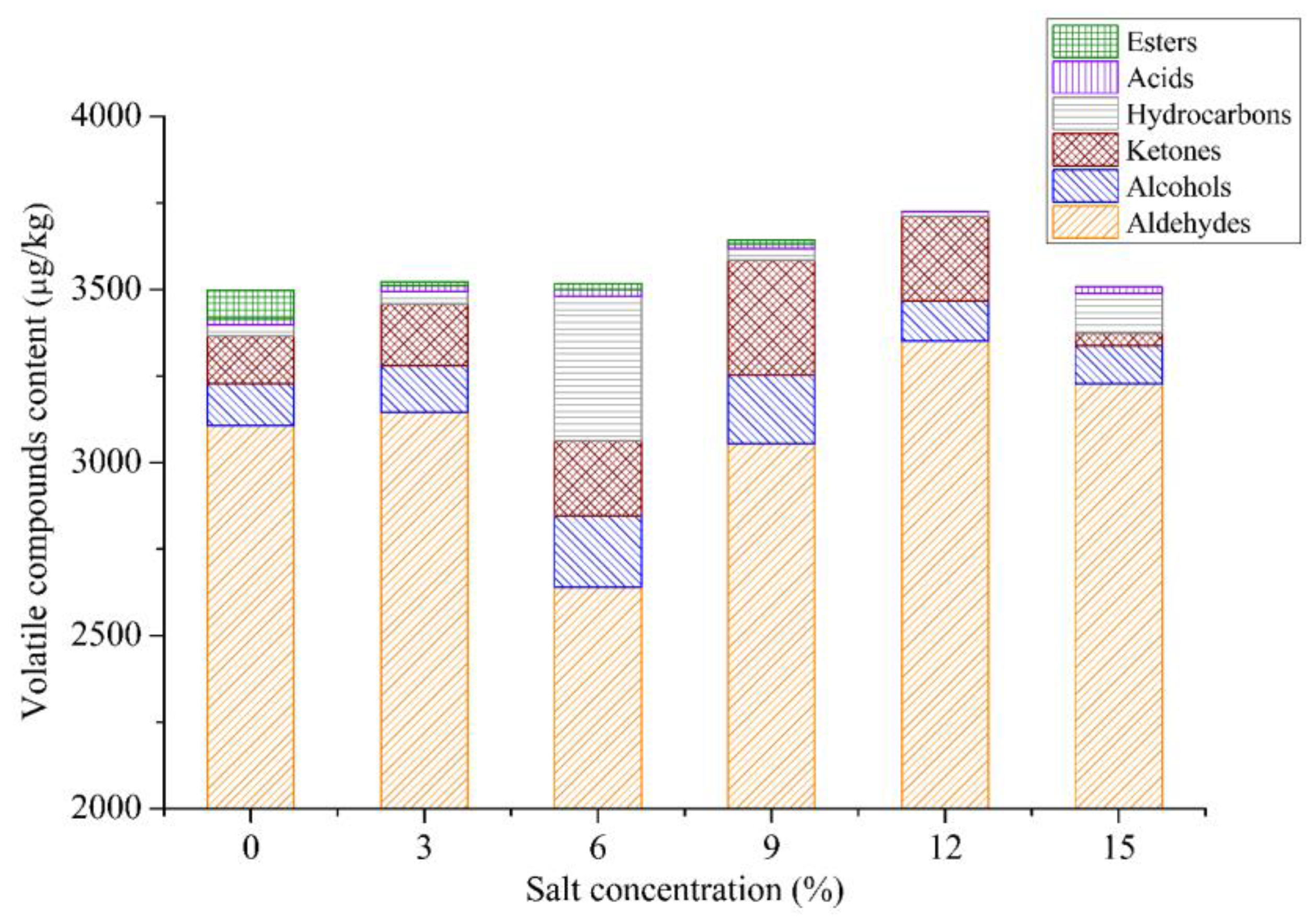

3.1. The Effects of Salt Concentration on the Sensory Quality, Flavor Components, Physicochemical Indexes, and Texture Properties of Duck Meat

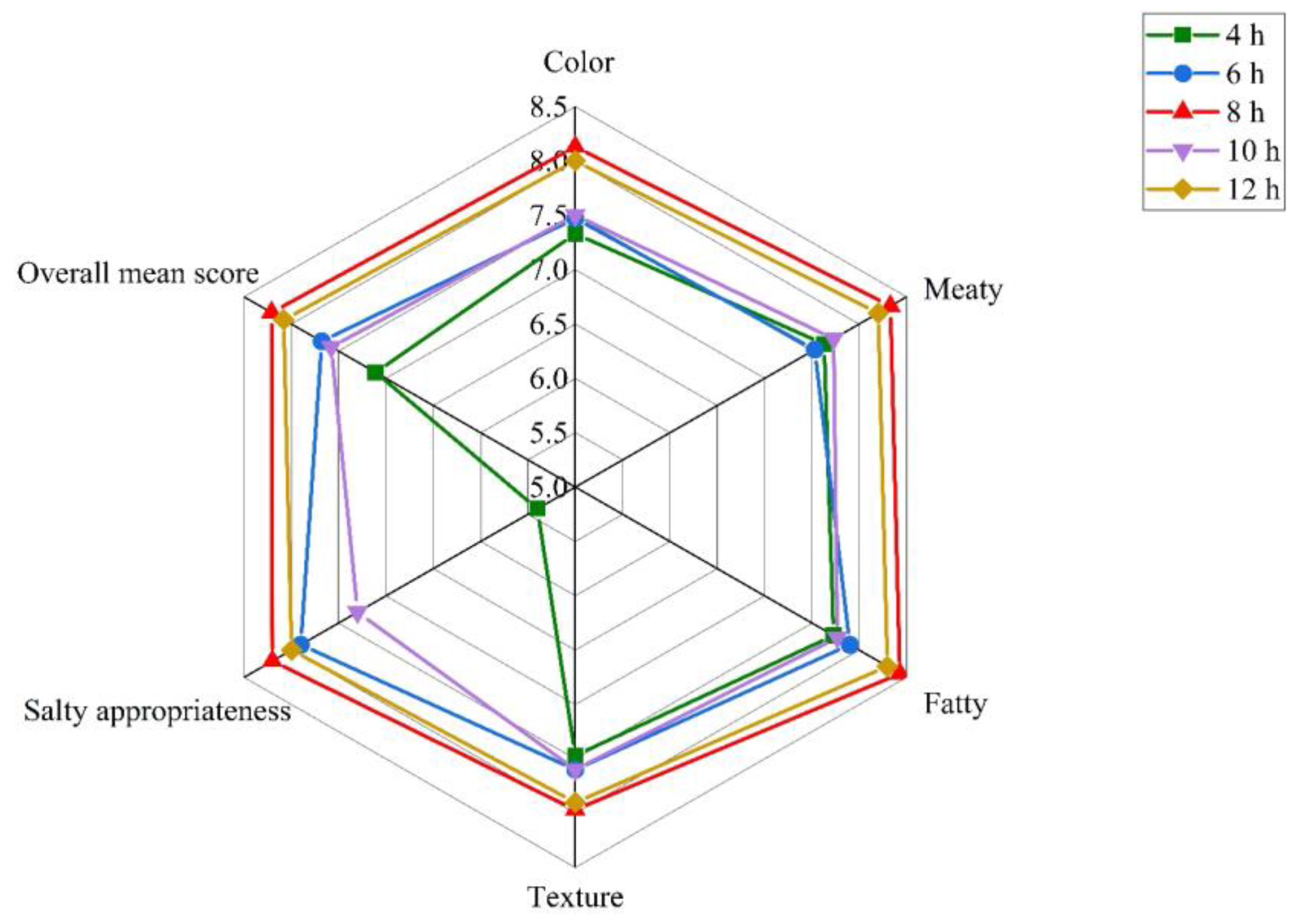

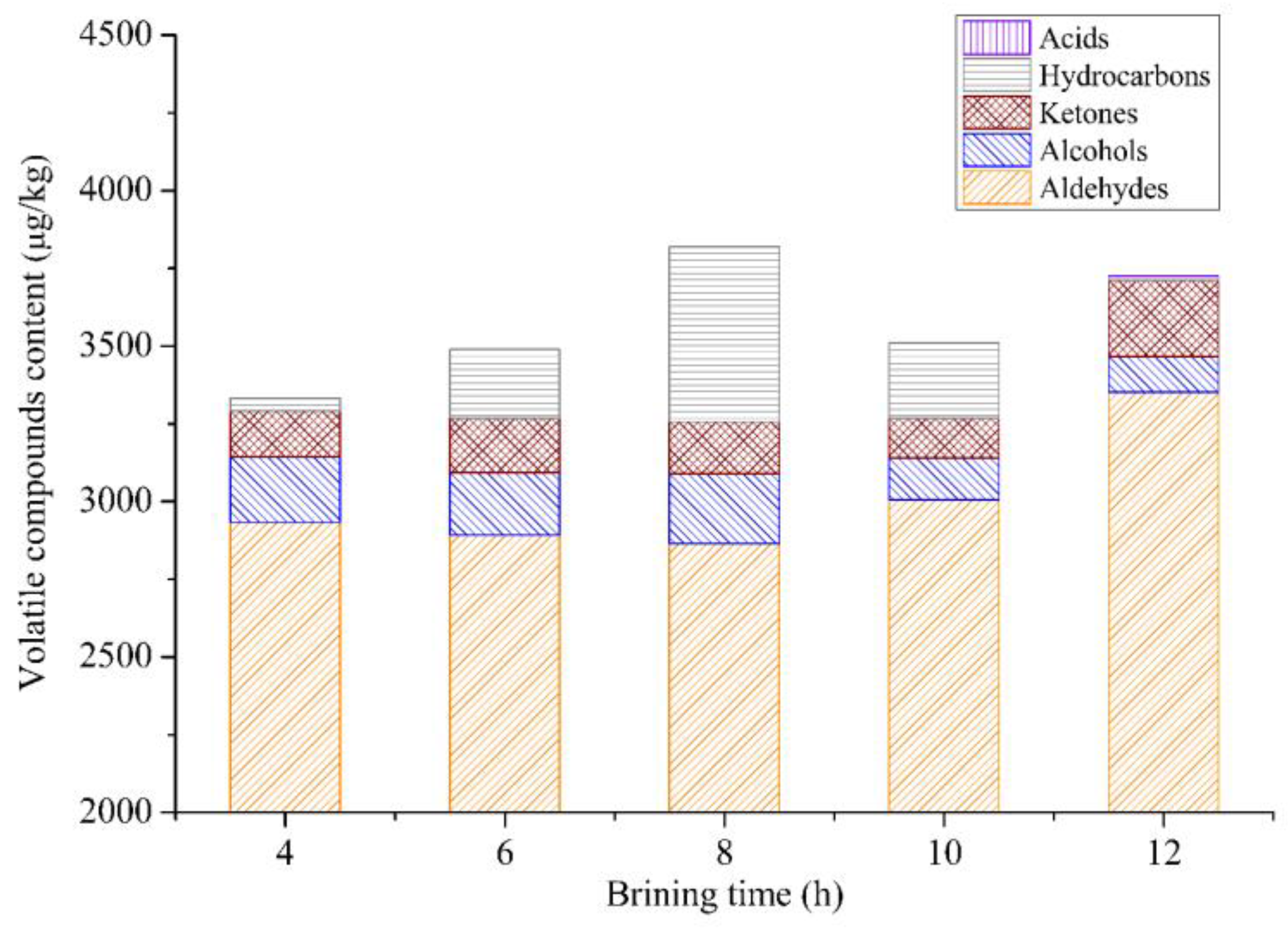

3.2. The Effects of Brining Time on the Sensory Quality, Flavor Components, Physicochemical Indexes, and Texture Properties of Duck Meat

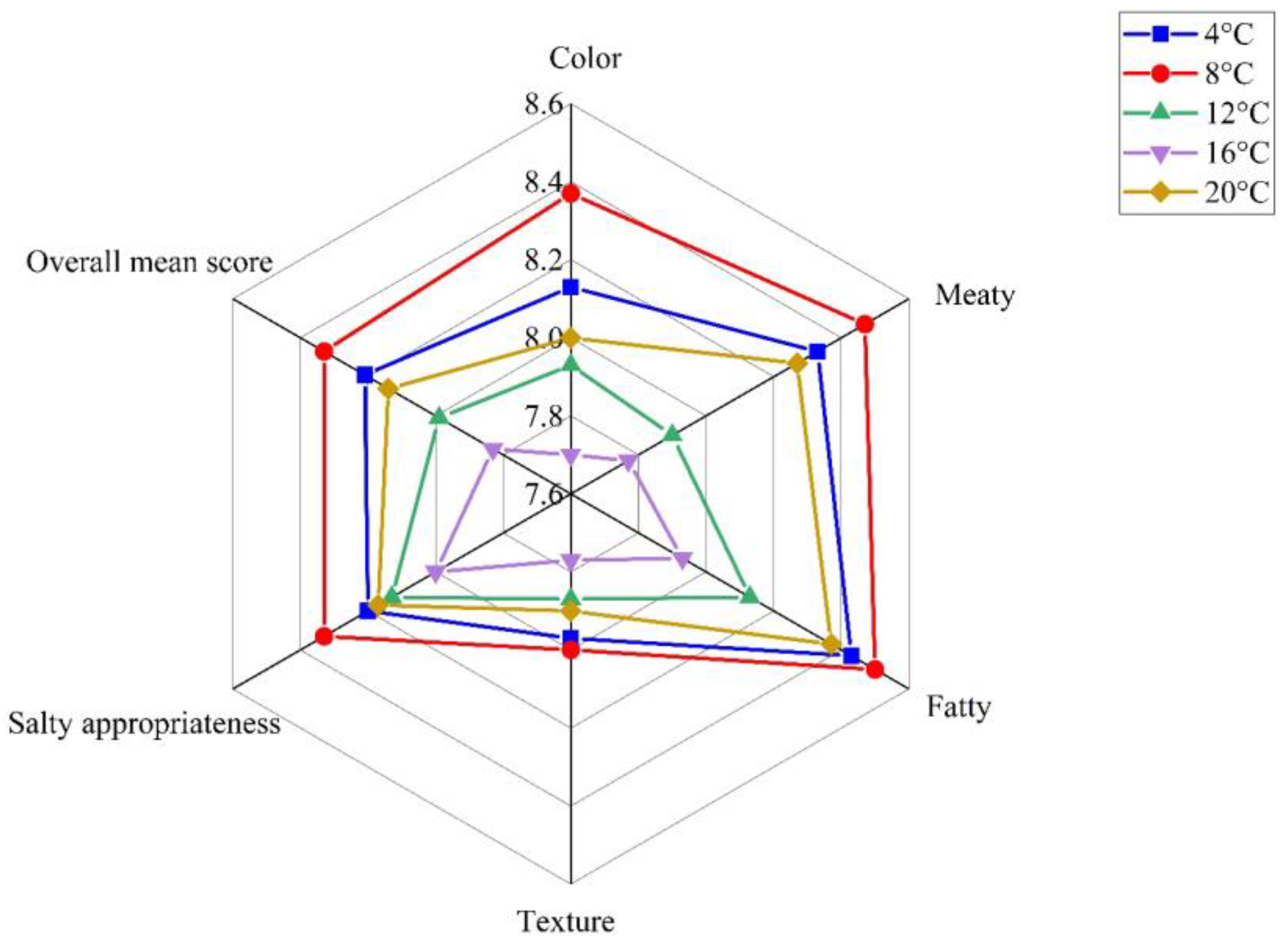

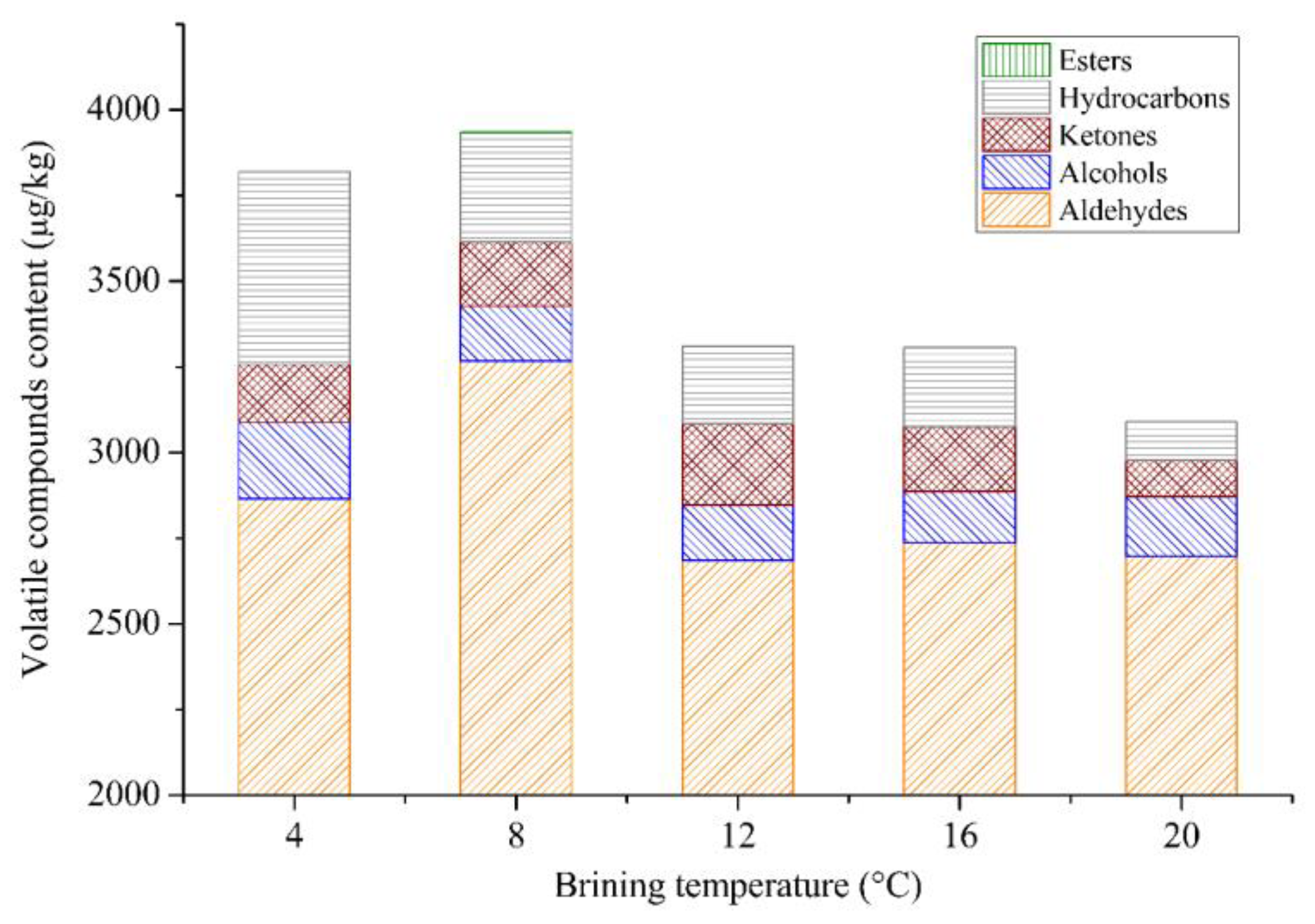

3.3. The Effects of Brining Temperature on the Sensory Quality, Flavor Components, Physicochemical Indexes, and Texture Properties of Duck Meat

3.4. Optimization of Salt Brining Conditions by RSM

3.5. A Comparison of the Quality of Unsalted and Salt-Optimized Brined Duck Meat Cooked with the Sous Vide Method

3.5.1. Analysis of Physiochemical Indexes

3.5.2. Analysis of Flavor Components and the Odorants

3.5.3. Analysis of Taste Components

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Shim, J.Y.; Kim, T.K.; Kim, Y.B.; Jeon, K.H.; Choi, Y.S. The Ratios of Pre-emulsified Duck Skin for Optimized Processing of Restructured Ham. Korean J. Food Sci. An. 2018, 38, 162–171. [Google Scholar]

- Shin, D.M.; Kim, D.H.; Yune, J.H.; Kwon, H.C.; Kim, H.J.; Seo, H.G.; Han, S.G. Oxidative Stability and Quality Characteristics of Duck, Chicken, Swine and Bovine Skin Fats Extracted by Pressurized Hot Water Extraction. Food Sci. Anim. Resour. 2019, 39, 446–458. [Google Scholar] [CrossRef]

- Espinosa, M.C.; Díaz, P.; Linares, M.B.; Teruel, M.R.; Garrido, M. Quality characteristics of sous vide ready to eat seabream processed by high pressure. LWT 2015, 64, 657–662. [Google Scholar] [CrossRef]

- Jeong, K.; Hyeonbin, O.; Shin, S.Y.; Kim, Y.S. Effects of sous-vide method at different temperatures, times and vacuum degrees on the quality, structural, and microbiological properties of pork ham. Meat Sci. 2018, 143, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Biyikli, M.; Akoglu, A.; Kurhan, S.; Akoglu, I.T. Effect of different Sous Vide cooking temperature-time combinations on the physicochemical, microbiological, and sensory properties of turkey cutlet. Int. J. Gastron. Food Sci. 2020, 20, 100204. [Google Scholar] [CrossRef]

- Yang, F.; Lee, C.H.; Jeon, M.Y.; Cho, W.Y.; Han, G.S. The Physicochemical and Sensory Properties of Whey-Fed Pork Loin after Salting, Dry Aging, and Sous Vide Cooking. J. Chem. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Singh, C.B.; Kumari, N.; Senapati, S.R.; Lekshmi, M.; Nagalakshmi, K.; Balange, A.K.; Chouksey, G.; Venkateshwarlu, K.A.; Xavier, K.M. Sous vide processed ready-to-cook seerfish steaks: Process optimization by response surface methodology and its quality evaluation. LWT 2016, 74, 62–69. [Google Scholar] [CrossRef]

- Gok, V.; Uzun, T.; Tomar, O.; Caglar, M.Y.; Caglar, A. The effect of cooking methods on some quality characteristics of Gluteus medius. Food Sci. Tech. 2019, 39, 999–1004. [Google Scholar] [CrossRef]

- Rasinska, E.; Rutkowska, J.; Czarniecka-Skubina, E.; Tambor, K. Effects of cooking methods on changes in fatty acids contents, lipid oxidation and volatile compounds of rabbit meat. LWT 2019, 110, 64–70. [Google Scholar] [CrossRef]

- Weng, K.; Song, L.; Bao, Q.; Cao, Z.; Zhang, Y.; Zhang, Y.; Chen, G.; Xu, Q. Comparative Characterization of Key Volatile Compounds in Slowand Fast-Growing Duck Raw Meat Based on Widely Targeted Metabolomics. Foods 2022, 11, 3975. [Google Scholar] [CrossRef]

- Qx, A.; Bx, B.; Ying, X.A.; Zhong, Y.A.; Bz, A.; Xl, A.; Yun, S.A. Effects of different thermal treatment temperatures on volatile flavour compounds of water-boiled salted duck after packaging. LWT 2021, 154, 112625. [Google Scholar]

- Ying, W.; Jiang, Y.T.; Cao, J.X.; Chen, Y.J.; Gan, N. Study on lipolysis-oxidation and volatile flavour compounds of dry-cured goose with different curing salt content during production. Food Chem. 2016, 190, 33–40. [Google Scholar] [CrossRef]

- Fraqueza, M.J.; Laranjo, M.; Alves, S.; Fernandes, M.H.; Agulheirosantos, A.C.; Fernandes, M.J.; Potes, M.E.; Elias, M. Dry-Cured Meat Products According to the Smoking Regime: Process Optimization to Control Polycyclic Aromatic Hydrocarbons. Prog. Artif. Intell. 2020, 9, 91. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X.L.; Ouyang, G.F.; Zhou, G.H. Changes in volatile compounds of traditional Chinese Nanjing water-boiled salted duck during processing. J. Food Sci. 2006, 71, S371–S377. [Google Scholar] [CrossRef]

- Baskentli, S.; Block, L.; Morrin, M. The serving temperature effect: Food temperature, expected satiety, and complementary food purchases. Appetite 2021, 160, 105069. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.S.; Kang, S.W.; Joo, S.T.; Choi, S.G. Effects of salt concentration and drying time on the quality characteristics of pork jerky during dehydration. Korean J. Food Sci. An. 2012, 32, 285–292. [Google Scholar] [CrossRef]

- Wang, J.; Huang, X.H.; Zhang, Y.Y.; Li, S.; Dong, X.; Qin, L. Effect of sodium salt on meat products and reduction sodium strategies-A review. Meat Sci. 2023, 205, 109296. [Google Scholar] [CrossRef]

- Du, L.; Zhou, G.H.; Xu, X.L.; Li, C.B. Study on kinetics of mass transfer in water-boiled salted duck during wet-curing. J. Food Eng. 2010, 100, 578–584. [Google Scholar] [CrossRef]

- Hunter, R.W.; Dhaun, N.; Bailey, M.A. The impact of excessive salt intake on human health. Nat. Rev. Nephrol. 2022, 18, 321–335. [Google Scholar] [CrossRef]

- World Health Organization. Diet, Nutrition, and the Prevention of Chronic Diseases: Report of a Joint WHO/FAO Expert Consultation; World Health Organization: Geneva, Switzerland, 2003; Volume 916. [Google Scholar]

- Wang, Q.; Li, X.; Xue, B.; Wu, Y.; Song, H.; Luo, Z.; Huang, Q. Low-salt fermentation improves flavor and quality of sour meat: Microbiology and metabolomics. LWT 2022, 171, 114157. [Google Scholar] [CrossRef]

- Cui, B.; Mao, Y.; Liu, J.; Liang, X.; Wu, D.; Chen, X.; Li, B. Effect of salt on solution behavior of spinning medium and properties of meat analogue fibers. Food Hydrocolloid 2023, 139, 108540. [Google Scholar] [CrossRef]

- Xing, T.; Zong, J.; Yu, Z.; Zhong, Q.; Ming, X.; Shu, T.; Jie, Z.B. Evaluation by electronic tongue and headspace-GC-IMS analyses of the flavor compounds in dry-cured pork with different salt content. Food Res. Int. 2020, 137, 109456. [Google Scholar]

- Dimakopoulou-Papazoglou, D.; Katsanidis, E. Diffusion coefficients and volume changes of beef meat during osmotic dehydration in binary and ternary solutions. Food Bioprod. Process 2019, 116, 10–19. [Google Scholar] [CrossRef]

- Song, D.H.; Yang, N.E.; Seomoon, K.M.; Jang, I.S.; Chin, K.B.; Kim, H.W. Sous-vide cooking as a practical strategy to improve quality attributes and shelf stability of reduced-salt chicken breast ham. Poultry Sci. 2023, 102, 102444. [Google Scholar] [CrossRef] [PubMed]

- Guadagni, D.G.; Buttery, R.G.; Harris, J. Odour intensities of hop oil components. J. Sci. Food Agric. 2020, 17, 142–144. [Google Scholar] [CrossRef] [PubMed]

- Poehlmann, S.; Schieberle, P. Characterization of the Aroma Signature of Styrian Pumpkin Seed Oil (Cucurbita pepo subsp. pepo var. Styriaca) by Molecular Sensory Science. J. Agric. Food Chem. 2013, 61, 2933–2942. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Song, H. Variation of aroma components during frozen storage of cooked beef balls by SPME and SAFE coupled with GC-O-MS. J. Food Process Pres. 2020, 45, e15306. [Google Scholar] [CrossRef]

- Qi, N.; Liu, R.; Sun, J.; Chen, H.; Zhang, N. Characterizing key aroma-active compounds of stewed mutton using gas chromatography-olfactometry-mass spectrometry coupled with odour activity value. Flavour Frag. J. 2023, 38, 263–273. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Ye, J.; Qian, M.; Li, X.; Zhao, W.; Bai, W. HS-SPME-GC-MS and OAV analyses of characteristic volatile flavour compounds in salt-baked drumstick. LWT 2022, 170, 114041. [Google Scholar] [CrossRef]

- Li, C.; Li, X.; Huang, Q.; Zhou, Y.; Xu, B.; Wang, Z. Influence of salt content used for dry-curing on lipidomic profiles during processing of water-boiled salted duck. J. Agric. Food Chem. 2020, 68, 4017–4026. [Google Scholar] [CrossRef]

- Khan, M.A.; Ali, S.; Yang, H.; Kamboh, A.A.; Zhou, G. Improvement of color, texture and food safety of ready-to-eat high pressure-heat treated duck breast. Food Chem. 2018, 277, 646–654. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization. Sensory Analysis: General Guidance for the Design of Test Rooms; ISO: Geneva, Switzerland, 2007; p. 8589. [Google Scholar]

- Zhang, M.; Chen, M.; Fang, F.; Fu, C.; Xing, S.; Qian, C.; Liu, J.; Kan, J.; Jin, C. Effect of sous vide cooking treatment on the quality, structural properties and flavor profile of duck meat. Int. J. Gastron. Food Sci. 2022, 29, 100565. [Google Scholar] [CrossRef]

- Plácido, A.; Kupers, R.; Paíga, P.; Magalhães, J.; Nouws, H.P.A.; Delerue-Matos, C.; Oliveira, M.B.P.P. Salt content in bread and dough from northern Portugal: Method development and comparison. J. Food Compos. Anal. 2012, 27, 14–20. [Google Scholar] [CrossRef][Green Version]

- Chen, X.; Luo, J.; Lou, A.; Wang, Y.; Yang, D.; Shen, Q.W. Duck breast muscle proteins, free fatty acids and volatile compounds as affected by brined methods. Food Chem. 2021, 338, 128138. [Google Scholar] [CrossRef]

- Zhu, Z.; Bassey, A.P.; Cao, Y.; Du, X.; Huang, T.; Cheng, Y.; Huang, M. Meat quality and flavor evaluation of Nanjing water boiled salted duck (NWSD) produced by different Muscovy duck (Cairina moschata) ingredients. Food Chem. 2022, 397, 133833. [Google Scholar] [CrossRef]

- Zhan, H.; Hayat, K.; Cui, H.; Hussain, S.; Ho, C.T.; Zhang, X. Characterization of flavor active non-volatile compounds in chicken broth and correlated contributing constituent compounds in muscle through sensory evaluation and partial least square regression analysis. LWT 2020, 118, 108786. [Google Scholar] [CrossRef]

- Pei, F.; Shi, Y.; Gao, X.; Wu, F.; Mariga, A.M.; Yang, W.; Yang, F. Changes in non-volatile taste components of button mushroom (Agaricus bisporus) during different stages of freeze drying and freeze drying combined with microwave vacuum drying. Food Chem. 2014, 165, 547–554. [Google Scholar] [CrossRef]

- Xu, H.; Liu, W.; Liu, W.; Liu, C.; Wang, Y.; Zhou, L. Changes of duck breast meat texture and proteolysis during the processing of sauced duck. J. Nanchang Univ. 2014, 38, 222–227. [Google Scholar]

- Hu, Y.; Zhang, L.; Zhang, H.; Wang, Y.; Kong, B. Physicochemical properties and flavour profile of fermented dry sausages with a reduction of sodium chloride. LWT 2020, 124, 109061. [Google Scholar] [CrossRef]

- Shi, J.; Nian, Y.; Da, D.; Xu, X.; Zhou, G.; Zhao, D.; Li, C. Characterization of flavor volatile compounds in sauce spareribs by gas chromatography-mass spectrometry and electronic nose. LWT 2020, 124, 109182. [Google Scholar] [CrossRef]

- Andres, A.I.; Cava, R.; Martin, D.; Ventanas, J.; Ruiz, J. Lipolysis in dry-cured ham: Influence of salt content and processing conditions. Food Chem. 2005, 90, 523–533. [Google Scholar] [CrossRef]

- Villamonte, G.; Simonin, H.; Duranton, F.; Chéret, R.; De Lamballerie, M. Functionality of pork meat proteins: Impact of sodium chloride and phosphates under high-pressure processing. Innov. Food Sci. Emerg. 2013, 18, 15–23. [Google Scholar] [CrossRef]

- Kong, F.; Oliveira, A.; Tang, J.; Rasco, B.; Crapo, C. Salt effect on heat-induced physical and chemical changes of salmon fillet (O. gorbuscha). Food Chem. 2008, 106, 957–966. [Google Scholar] [CrossRef]

- Sárraga, C.; Garæia-Regueiro, J.A. Oxidation of microsomal fraction in the processing conditions of dry cured ham. The in-vitro effect of brine. Meat Sci. 1998, 50, 295–302. [Google Scholar] [CrossRef] [PubMed]

- Sanches, M.A.R.; Silva, P.M.O.C.; Barretto, T.L.; Darros-Barbosa, R.; da Silva-Barretto, A.C.; Telis-Romero, J. Technological and diffusion properties in the wet salting of beef assisted by ultrasound. LWT 2021, 149, 112036. [Google Scholar] [CrossRef]

- Ozuna, C.; Puig, A.; García-Pérez, J.V.; Mulet, A.; Cárcel, J.A. Influence of high intensity ultrasound application on mass transport, microstructure and textural properties of pork meat (Longissimus dorsi) brined at different NaCl concentrations. J. Food Eng. 2013, 119, 84–93. [Google Scholar] [CrossRef]

- Morales, M.L.; Callejón, R.M.; Ubeda, C.; Guerreiro, A.; Gago, C.; Miguel, M.G.; Antunes, M.D. Effect of storage time at low temperature on the volatile compound composition of Sevillana and Maravilla raspberries. Postharvest Biol. Tec. 2014, 96, 128–134. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, J.; Zheng, H.; Tian, Y.; Lin, Q. Effect of curing condition on quality of three yellow broilers. Proc. Annu. Meet. Guangdong Food Soc. 2014, 34, 120–125. [Google Scholar]

- Wen, R.; Hu, Y.; Zhang, L.; Wang, Y.; Chen, Q.; Kong, B. Effect of NaCl substitutes on lipid and protein oxidation and flavor development of Harbin dry sausage. Meat Sci. 2019, 156, 33–43. [Google Scholar] [CrossRef]

- Wang, X.; Yao, Y.; Yu, J.; Cui, H.; Hayat, K.; Zhang, X.; Ho, C.T. Evolution of lean meat tenderness stimulated by coordinated variation of water status, protein structure and tissue histology during cooking of braised pork. Food Res. Int. 2023, 171, 113081. [Google Scholar] [CrossRef]

- Jiang, Q.; Jia, R.; Nakazawa, N.; Hu, Y.; Osako, K.; Okazaki, E. Changes in protein properties and tissue histology of tuna meat as affected by salting and subsequent freezing. Food Chem. 2019, 271, 550–560. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Y.; Lan, X.; Bai, S.; Yao, K.; Jia, D. Effect of salting treatment on volatile flavor compounds of onion and the mechanism. China Condiment 2021, 46, 31–36. [Google Scholar]

- Meng, Y.; Lei, C.; Zhang, X. Effect of curing conditions on color of bacon. Meat Ind. 2012, 376, 27–30. [Google Scholar]

- Wang, Q.Y.; Dong, X.; Yang, J.; Hu, Y.H.; Cao, J. Vesicle based ultrasonic-assisted extraction of saponins in Panax notoginseng. Food Chem. 2019, 303, 125394. [Google Scholar] [CrossRef] [PubMed]

- Gemert, L.J.V. Compilations of Odour Threshold Values in Air, Water and Other Media (Second Enlarged and Revised Edition); Oliemans Punter & Partners BV: Utrecht, The Netherlands, 2011. [Google Scholar]

- Ojangba, T.; Boamah, S.; Zhang, L.; Wang, Z.; Osei, R. Effects of sodium chloride (NaCl) partial substitution by potassium chloride (KCl) in combination with high pressure on sensory and chemical properties of beef sausage during cold storage at 4 °C. CyTA J. Food 2022, 20, 412–420. [Google Scholar] [CrossRef]

- Ma, R.; Liu, X.; Tian, H.; Han, B.; Li, Y.; Tang, C.; Meng, Y. Odor-active volatile compounds profile of triploid rainbow trout with different marketable sizes. Aquac. Rep. 2020, 17, 100312. [Google Scholar] [CrossRef]

- Nyam, K.L.; Goh, K.M.; Chan, S.Q.; Tan, C.P.; Cheong, L.Z. Effect of sous vide cooking parameters on physicochemical properties and free amino acids profile of chicken breast meat. J. Food Compos. Anal. 2023, 115, 105010. [Google Scholar] [CrossRef]

- Bi, Y.; Shan, Q.; Luo, R.; Bai, S.; Ji, C.; Wang, Y.; Dong, F. Dynamic changes in water mobility and taste substances of cooked Tan lamb meat after chilled storage. J. Food Compos. Ana. 2003, 117, 105133. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, M.; Zhang, Y.; Han, M.; Sun, J. Effect of low-sodium compound salt on the taste and volatile flavor of salt-baked chicken. Int. J. Gastron. Food Sci. 2023, 32, 100740. [Google Scholar] [CrossRef]

| Indexes | 0% | 3% | 6% | 9% | 12% | 15% |

|---|---|---|---|---|---|---|

| L* | 61.96 ± 0.51 a | 54.38 ± 1.03 b | 51.25 ± 0.06 c | 52.26 ± 1.70 c | 56.44 ± 2.65 b | 42.23 ± 0.46 d |

| a* | 4.81 ± 0.35 d | 5.18 ± 0.43 cd | 5.46 ± 0.02 c | 6.31 ± 086 b | 6.12 ± 0.16 b | 7.28 ± 0.02 a |

| b* | 10.27 ± 0.04 bc | 12.48 ± 0.08 a | 12.78 ± 0.09 a | 11.03 ± 0.64 b | 9.66 ± 2.89 c | 11.91 ± 0.02 b |

| NaCl content/% | 0.00 ± 0.00 e | 1.14 ± 0.01 d | 2.32 ± 0.01 c | 2.46 ± 0.01 c | 3.79 ± 0.01 b | 4.83 ± 0.01 a |

| Weight loss/% | 39.34 ± 0.01 a | 36.58 ± 0.01 b | 35.67 ± 0.01 b | 34.54 ± 0.01 c | 32.19 ± 0.01 d | 29.76 ± 0.01 e |

| TBARS (mg/kg) | 2.64 ± 0.04 c | 1.66 ± 0.02 f | 2.21 ± 0.01 d | 3.60 ± 0.01 a | 3.25 ± 0.01 b | 1.77 ± 0.01 e |

| Groups | Hardness /N | Cohesiveness /Ratio | Elasticity /mm | Adhesiveness /N | Chewiness /mJ | Shear Force /N |

|---|---|---|---|---|---|---|

| 0% | 24.37 ± 2.81 c | 0.27 ± 0.02 b | 2.08 ± 0.14 b | 8.30 ± 3.15 b | 20.39 ± 1.73 d | 21.78 ± 0.67 e |

| 3% | 28.10 ± 3.07 b | 0.32 ± 0.02 ab | 2.39 ± 0.45 ab | 9.07 ± 1.42 b | 21.94 ± 2.26 cd | 26.11 ± 2.10 d |

| 6% | 29.63 ± 2.36 b | 0.32 ± 0.02 ab | 2.40 ± 0.12 ab | 11.90 ± 3.68 b | 25.42 ± 0.89 bc | 28.95 ± 3.28 d |

| 9% | 31.77 ± 1.12 ab | 0.33 ± 0.05 a | 2.45 ± 0.34 ab | 16.70 ± 0.40 a | 26.49 ± 2.88 b | 36.88 ± 1.41 c |

| 12% | 34.40 ± 0.53 a | 0.33 ± 0.02 a | 2.40 ± 0.12 ab | 12.47 ± 1.43 b | 29.87 ± 4.11 a | 42.61 ± 0.23 b |

| 15% | 35.17 ± 1.16 a | 0.32 ± 0.03 ab | 2.82 ± 0.70 a | 10.07 ± 1.86 b | 26.21 ± 2.79 bc | 48.28 ± 0.35 a |

| Indexes | 4 h | 6 h | 8 h | 10 h | 12 h |

|---|---|---|---|---|---|

| L* | 67.92 ± 0.07 a | 60.76 ± 1.15 b | 60.27 ± 0.43 b | 57.34 ± 0.14 c | 56.44 ±2.65 c |

| a* | 4.74 ± 0.01 c | 4.76 ± 0.09 c | 5.66 ± 0.08 b | 5.67 ± 0.03 b | 6.12 ±0.16 a |

| b* | 12.14 ± 0.02 c | 17.12 ± 1.63 a | 13.10 ± 0.08 bc | 13.06 ± 0.05 bc | 9.66 ± 2.89 c |

| NaCl content/% | 2.08 ± 0.01 c | 2.93 ± 0.01 b | 3.79 ± 0.01 a | 3.98 ± 0.01 a | 3.79 ± 0.01 a |

| Weight loss/% | 35.58 ± 0.01 a | 34.30 ± 0.01 a | 32.68 ± 0.01 b | 32.81 ± 0.01 b | 32.19 ± 0.01 b |

| TBARS (mg/kg) | 3.96 ± 0.01 d | 5.87 ± 0.01 a | 4.15 ± 0.05 c | 4.53 ± 0.02 b | 3.25 ± 0.02 e |

| Groups | Hardness /N | Cohesiveness/Ratio | Elasticity /mm | Adhesiveness /N | Chewiness /mJ | Shear Force/N |

|---|---|---|---|---|---|---|

| 4 h | 30.12 ± 2.05 b | 0.36 ± 0.04 a | 3.33 ± 0.42 a | 8.93 ± 1.62 c | 44.37 ± 11.65 a | 29.50 ± 2.13 c |

| 6 h | 30.12 ± 2.05 b | 0.36 ± 0.04 a | 3.33 ± 0.30 a | 8.93 ± 1.44 c | 44.37 ± 0.89 a | 29.05 ± 0.98 c |

| 8 h | 33.23 ± 1.78 a | 0.30 ± 0.05 c | 3.43 ± 0.28 a | 9.97 ± 0.32 b | 24.01 ± 4.70 d | 37.21 ± 2.14 b |

| 10 h | 32.16 ± 0.87 b | 0.34 ± 0.04 b | 3.36 ± 1.17 a | 9.28 ± 0.46 c | 37.58 ± 9.39 b | 34.21 ± 0.18 b |

| 12 h | 34.40 ± 0.53 a | 0.33 ± 0.02 b | 2.40 ± 0.12 b | 12.47 ± 1.43 a | 29.87 ± 4.11 c | 42.61 ± 0.23 a |

| Indexes | 4 °C | 8 °C | 12 °C | 16 °C | 20 °C |

|---|---|---|---|---|---|

| L* | 60.27 ± 0.43 a | 50.37 ± 1.07 b | 51.97 ± 0.96 b | 50.93 ± 1.90 b | 45.80 ± 1.00 c |

| a* | 5.66 ± 0.08 a | 5.20 ± 0.07 a | 5.32 ± 0.82 a | 5.70 ± 0.31 a | 4.92 ± 0.15 b |

| b* | 13.10 ± 0.08 a | 11.27 ± 0.18 b | 11.26 ± 1.66 b | 10.52 ± 0.70 c | 11.32 ± 1.03 b |

| NaCl content/% | 3.79 ± 0.01 d | 3.88 ± 0.01 c | 4.07 ± 0.01 c | 4.45 ± 0.01 b | 5.11 ± 0.01 a |

| Weight loss/% | 32.68 ± 0.01 a | 33.07 ± 0.01 a | 33.03 ± 0.01 a | 31.67 ± 0.01 b | 29.52 ± 0.01 c |

| TBARS (mg/kg) | 4.15 ± 0.05 c | 4.03 ± 0.01 d | 4.21 ± 0.01 b | 4.15 ± 0.01 c | 4.40 ± 0.01 a |

| Groups | Hardness /N | Cohesiveness /Ratio | Elasticity /mm | Adhesiveness /N | Chewiness /mJ | Shear Force/N |

|---|---|---|---|---|---|---|

| 4 °C | 33.23 ± 1.78 a | 0.30 ± 0.05 ab | 3.43 ± 0.28 a | 9.97 ± 0.32 b | 24.01 ± 4.70 b | 37.21 ± 2.14 a |

| 8 °C | 35.95 ± 0.15 a | 0.36 ± 0.03 a | 2.90 ± 0.24 b | 12.82 ± 0.98 a | 11.70 ± 0.26 c | 35.54 ± 0.66 a |

| 12 °C | 35.13 ± 2.59 a | 0.32 ± 0.01 ab | 2.86 ± 0.23 b | 11.17 ± 0.86 b | 31.95 ± 2.71 a | 36.92 ± 0.20 a |

| 16 °C | 35.47 ± 9.42 a | 0.29 ± 0.01 b | 2.93 ± 0.35 b | 10.27 ± 2.99 b | 30.74 ± 12.64 a | 29.30 ± 1.47 b |

| 20 °C | 29.97 ± 5.76 a | 0.26 ± 0.06 b | 2.52 ± 1.31 c | 6.88 ± 3.73 c | 11.26 ± 2.33 c | 28.51 ± 1.30 b |

| Trial | Independent Variables | Overall Mean Score | ||

|---|---|---|---|---|

| Brining Time (h) | Brining Temperature (°C) | Salt Concentration (%) | ||

| 1 | 8 | 8 | 12 | 8.59 |

| 2 | 8 | 8 | 12 | 8.62 |

| 3 | 6 | 8 | 9 | 8.07 |

| 4 | 8 | 8 | 12 | 8.54 |

| 5 | 10 | 12 | 12 | 7.96 |

| 6 | 6 | 8 | 15 | 7.85 |

| 7 | 8 | 12 | 15 | 7.98 |

| 8 | 8 | 4 | 9 | 8.11 |

| 9 | 10 | 8 | 15 | 7.96 |

| 10 | 10 | 4 | 12 | 8.25 |

| 11 | 10 | 8 | 9 | 8.12 |

| 12 | 8 | 8 | 12 | 8.51 |

| 13 | 6 | 4 | 12 | 8.23 |

| 14 | 8 | 4 | 15 | 7.96 |

| 15 | 8 | 8 | 12 | 8.60 |

| 16 | 6 | 12 | 12 | 8.12 |

| 17 | 8 | 12 | 9 | 7.98 |

| Sources of Variation | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1.10 | 9 | 0.12 | 23.65 | 0.0002 |

| X1 | 5.768 | 1 | 5.768 | 1.148 | 0.9735 |

| X2 | 0.033 | 1 | 0.033 | 6.35 | 0.0398 |

| X3 | 0.037 | 1 | 0.03 | 7.09 | 0.0323 |

| X1X2 | 7.261 | 1 | 7.261 | 1.44 | 0.2685 |

| X1X3 | 1.329 | 1 | 1.329 | 0.26 | 0.6230 |

| X2X3 | 6.057 | 1 | 6.057 | 1.20 | 0.3086 |

| X12 | 0.20 | 1 | 0.20 | 38.98 | 0.0004 |

| X22 | 0.19 | 1 | 0.19 | 36.70 | 0.0005 |

| X32 | 0.53 | 1 | 0.53 | 101.72 | <0.0001 |

| Residual | 0.036 | 7 | 5.026 | ||

| Lack of fit | 0.028 | 3 | 9.015 | 4.44 | 0.0919 |

| Pure Error | 8.126 | 4 | 2.031 | ||

| Total | 1.14 | 16 |

| Code | Compounds | RI 1 | RI 2 | Threshold [57] (μg/kg of Water) | Concentration (μg/kg) | OAV 3 | ||

|---|---|---|---|---|---|---|---|---|

| Unsalted | The Optimum Salted | Unsalted | The Optimum Salted | |||||

| Aldehydes | ||||||||

| AL1 | Pentanal | 699 | 698 | 12 | 20.17 ± 0.77 | 262.20 ± 5.96 | 1.68 | 21.85 |

| AL2 | Hexanal | 802 | 798 | 4.5 | 2485.74 ± 196.85 | 2374.83 ± 48.60 | 552.39 | 527.74 |

| AL3 | Heptanal | 904 | 905 | 2.8 | 2.57 ± 1.11 | 11.62 ± 0.35 | <1 | 4.15 |

| AL4 | Benzaldehyde | 958 | 963 | 24 [58] | 0.06 ± 0.00 | 9.76 ± 0.58 | <1 | <1 |

| AL5 | (Z)-2-Heptenal | 960 | 963 | / | 17.09 ± 0.11 | 10.77 ± 0.53 | / | / |

| AL6 | Octanal | 1005 | 1000 | 0.7 | 27.48 ± 5.88 | 95.42 ± 2.41 | 39.26 | 136.31 |

| AL7 | (E)-2-Octenal | 1061 | 1070 | 3 | 15.97 ± 0.88 | 14.84 ± 0.09 | 5.32 | 4.95 |

| AL8 | Nonanal | 1107 | 1102 | 1 | 81.94 ± 0.56 | 54.83 ± 0.26 | 81.94 | 54.83 |

| AL9 | (E)-2-Nonenal | 1162 | 1159 | 0.19 | 3.59 ± 0.50 | 23.67 ± 0.18 | 18.89 | 124.58 |

| AL10 | cis-4-Decenal | 1195 | 1193 | 0.004 | 1.23 ± 0.14 | 7.28 ± 0.20 | 307.5 | 1820 |

| AL11 | Decanal | 1208 | 1214 | 0.3 | 2.60 ± 0.30 | 233.83 ± 5.08 | 8.67 | 779.43 |

| AL12 | 2,4-Dimethyl-benzaldehyde | 1212 | 1180 | / | 0.29 ± 0.06 | / | / | / |

| AL13 | (E,E)-2,4-Nonadienal | 1218 | 1215 | 0.05 | 1.00 ± 0.26 | 0.75 ± 0.01 | 20 | 15 |

| AL14 | (Z)-2-Decanal | 1264 | 1250 | / | 3.21 ± 0.04 | 2.30 ± 0.04 | / | / |

| AL15 | 2,4-Decadienal | 1296 | 1284 | 0.3 | 192.12 ± 16.64 | 201.00 ± 2.50 | 640.4 | 670 |

| AL16 | Undecanal | 1309 | 1303 | 12.5 | / | / | / | / |

| AL17 | (E,E)-2,4-Decadienal | 1320 | 1345 | 0.027 | / | 14.37 ± 0.66 | / | 532.22 |

| AL18 | 2-Undecanal | 1365 | 1350 | / | 1.76 ± 0.13 | 2.98 ± 0.15 | / | / |

| AL19 | Dodecanal | 1413 | 1412 | 55 | 0.36 ± 0.02 | 1.00 ± 0.05 | <1 | <1 |

| AL20 | Tridecanal | 1513 | 1510 | 70 | 0.70 ± 0.01 | 0.50 ± 0.05 | <1 | <1 |

| AL21 | Tetradecaldehyde | 1613 | 1592 | / | 0.59 ± 0.01 | / | / | / |

| AL22 | Pentadecanal | 1713 | 1691 | 430 | 0.93 ± 0.04 | / | <1 | / |

| Subtotal | 2830.17 | 3322.96 | ||||||

| Alcohols | ||||||||

| A1 | 1-Hexenol | 876 | 889 | 800 | / | 7.51 ± 0.83 | / | <1 |

| A2 | 1-Heptanol | 976 | 971 | 5.4 [59] | / | 13.54 ± 0.95 | / | 2.51 |

| A3 | 1-Octen-3-ol | 984 | 979 | 1 | 432.48 ± 126.88 | 224.17 ± 2.58 | 432.48 | 224.17 |

| A4 | 4-Ethylcyclohexanol | 1040 | 1003 | / | / | 3.21 ± 0.50 | / | / |

| A5 | (E)-2-Octen-1-ol | 1072 | 1069 | 100 | 0.28 ± 0.05 | 10.87 ± 0.31 | <1 | <1 |

| A6 | 1-Octanol | 1076 | 1070 | 190 | / | 11.17 ± 0.76 | / | <1 |

| Subtotal | 432.76 | 270.47 | ||||||

| Ketones | ||||||||

| K1 | Cyclohexanone | 894 | 871 | 280 | 50.60 ± 1.70 | / | <1 | / |

| K2 | 2,5-Octanedione | 983 | 971 | / | 220.47 ± 9.62 | / | / | / |

| K3 | 1-Octen-3-one | 980 | 978 | 0.05 | 2.36 ± 0.27 | / | 47.2 | / |

| K4 | 2-Methyl-3-octanone | 988 | 985 | 50.2 | / | 108.00 ± 3.07 | / | 2.15 |

| Subtotal | 273.39 | 108.00 | ||||||

| Hydrocarbons | ||||||||

| H1 | Toluene | 756 | 759 | 1550 [59] | 4.34 ± 0.45 | 83.85 ± 3.13 | <1 | <1 |

| H2 | Ethylbenzene | 855 | 864 | 2205 [59] | 0.73 ± 0.06 | / | <1 | / |

| H3 | Decane | 1000 | 1000 | 10,000 | / | 2.51 ± 0.86 | / | <1 |

| H4 | p-Xylene | 866 | 875 | 490 [59] | 0.30 ± 0.07 | / | <1 | / |

| H5 | 1,3-Dimethylbenzene | 888 | 885 | 1000 | 1.71 ± 0.13 | / | <1 | / |

| H6 | Undecane | 1100 | 1100 | 10,000 | 2.87 ± 0.08 | 16.59 ± 1.48 | <1 | <1 |

| H7 | 3-Methyl-undecane | 1170 | 1169 | / | / | 0.99 ± 0.04 | / | / |

| H8 | Dodecane | 1200 | 1200 | 2040 [59] | 3.75 ± 0.23 | 20.18 ± 0.58 | <1 | <1 |

| H9 | Tridecane | 1300 | 1300 | 2140 [59] | / | 0.78 ± 0.26 | / | <1 |

| H10 | 3-Methyl-tridecane | 1369 | 1369 | / | 0.40 ± 0.02 | 2.04 ± 0.25 | / | / |

| H11 | 3-Methylenetridecane | 1386 | 1407 | / | / | / | / | / |

| H12 | Tetradecane | 1400 | 1400 | 1000 | 1.50 ± 0.02 | 2.10 ± 0.20 | <1 | <1 |

| H13 | 7-Tetradecane | 1402 | 1411 | / | 0.76 ± 0.13 | / | / | / |

| H14 | Cyclodecane | 1456 | 1406 | 290 | / | 0.40 ± 0.03 | / | <1 |

| H15 | 5-Methyltetradecane | 1454 | 1456 | / | / | 0.25 ± 0.05 | / | / |

| H16 | Pentadecane | 1500 | 1500 | / | 0.66 ± 0.12 | 0.46 ± 0.08 | / | / |

| H17 | 3-Methylpentadecane | 1574 | 1570 | / | / | 0.42 ± 0.02 | / | / |

| H18 | Hexadecane | 1600 | 1600 | / | / | 0.40 ± 0.05 | / | / |

| H19 | (1-Pentylheptyl)-benzene | 1726 | 1719 | / | / | / | / | / |

| Subtotal | 17.02 | 130.98 | ||||||

| Esters | ||||||||

| E1 | Methyl palmitate | 1927 | 1927 | 2000 | / | 0.10 ± 0.01 | / | <1 |

| E2 | Methyl oleate | 2086 | 2066 | / | 0.94 ± 0.05 | / | / | / |

| E3 | Methyl stearate | 2128 | 2093 | / | 0.37 ± 0.01 | / | / | / |

| Subtotal | 1.31 | 0.10 | ||||||

| Acids | ||||||||

| AC1 | Acetic acid | 689 | 637 | 22,000 | 3.07 ± 0.18 | / | <1 | / |

| AC2 | Hexadecanoic acid | 1961 | 1977 | 10,000 | 3.87 ± 0.02 | / | <1 | / |

| Subtotal | 6.94 | 0.00 | ||||||

| Total | 3561.59 | 3832.50 | ||||||

| Taste Component | Taste Characteristics | Unsalted | The Optimum Salted |

|---|---|---|---|

| Free amino acid | Concentration (mg/100 g) | ||

| Aspartic acid | umami | 12.97 ± 0.10 | 12.85 ± 1.00 |

| Glutamic acid | umami | 29.38 ± 1.51 | 28.58 ± 0.60 |

| Serine | sweet | 13.50 ± 0.59 | 12.20 ± 0.79 |

| Threonine | sweet | 14.80 ± 0.54 | 12.47 ± 0.52 |

| Proline | sweet | 6.98 ± 0.87 | 7.45 ± 0.40 |

| Alanine | sweet | 86.95 ± 0.54 | 74.87 ± 3.61 |

| Glycine | sweet | 14.00 ± 0.84 | 11.90 ± 0.18 |

| Histidine | bitter | 4.87 ± 0.16 | 5.36 ± 0.47 |

| Arginine | bitter | 11.17 ± 0.68 | 13.08 ± 0.73 |

| Tyrosine | bitter | 7.82 ± 0.32 | 6.50 ± 0.38 |

| Valine | bitter | 10.56 ± 0.42 | 10.89 ± 0.51 |

| Methionine | bitter | 3.80 ± 0.27 | 4.43 ± 0.40 |

| Phenylalanine | bitter | 4.45 ± 0.40 | 4.74 ± 0.18 |

| Isoleucine | bitter | 3.46 ± 0.50 | 4.39 ± 0.33 |

| Leucine | bitter | 7.35 ± 0.48 | 8.40 ± 0.34 |

| Lysine | bitter | 8.59 ± 0.27 | 8.23 ± 0.12 |

| Cysteine | tasteless | 1.15 ± 0.17 | 0.81 ± 0.04 |

| Total | 241.80 ± 4.33 | 227.16 ± 5.70 | |

| 5′-Nucleotides | Concentration (mg/kg) | ||

| 5′-CMP | 193.71 ± 12.17 | 223.66 ± 14.71 | |

| 5′-AMP | 127.56 ± 8.36 | 104.57 ± 2.43 | |

| 5′-UPM | 894.94 ± 9.83 | 981.51 ± 10.04 | |

| 5′-GMP | 42.77 ± 4.58 | 52.89 ± 5.33 | |

| 5′-IMP | 350.94 ± 5.10 | 409.06 ± 7.01 | |

| Total | 1609.91 ± 24.93 | 1771.68 ± 24.35 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Fu, C.; Chen, M.; Jin, C. The Effect of Sodium Chloride on the Physicochemical and Textural Properties and Flavor Characteristics of Sous Vide Cooked Duck Meat. Foods 2023, 12, 3452. https://doi.org/10.3390/foods12183452

Zhang M, Fu C, Chen M, Jin C. The Effect of Sodium Chloride on the Physicochemical and Textural Properties and Flavor Characteristics of Sous Vide Cooked Duck Meat. Foods. 2023; 12(18):3452. https://doi.org/10.3390/foods12183452

Chicago/Turabian StyleZhang, Man, Cuncun Fu, Mengfei Chen, and Changhai Jin. 2023. "The Effect of Sodium Chloride on the Physicochemical and Textural Properties and Flavor Characteristics of Sous Vide Cooked Duck Meat" Foods 12, no. 18: 3452. https://doi.org/10.3390/foods12183452

APA StyleZhang, M., Fu, C., Chen, M., & Jin, C. (2023). The Effect of Sodium Chloride on the Physicochemical and Textural Properties and Flavor Characteristics of Sous Vide Cooked Duck Meat. Foods, 12(18), 3452. https://doi.org/10.3390/foods12183452