Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems

Abstract

:1. Introduction

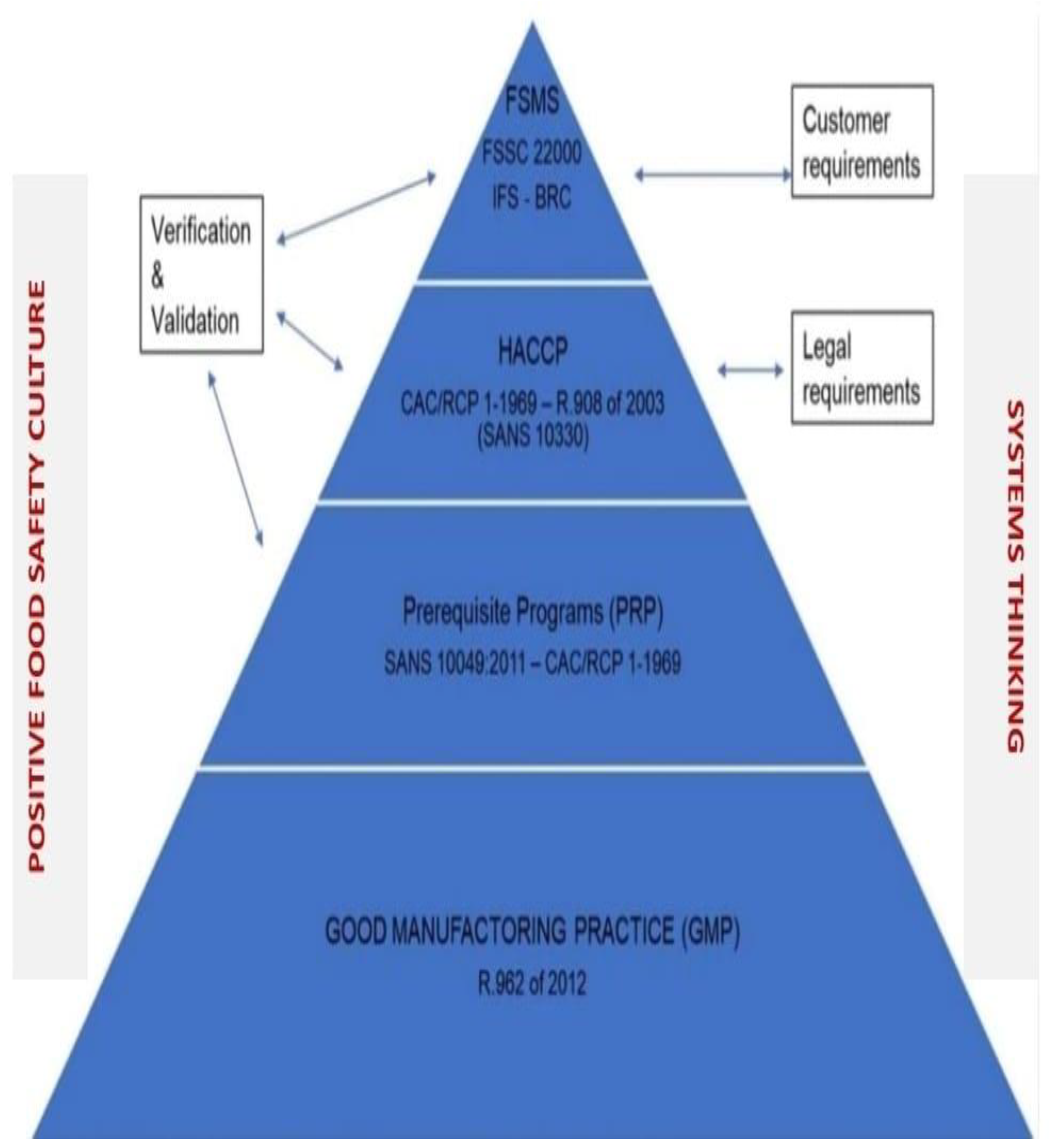

2. Food Safety Management Systems around the World

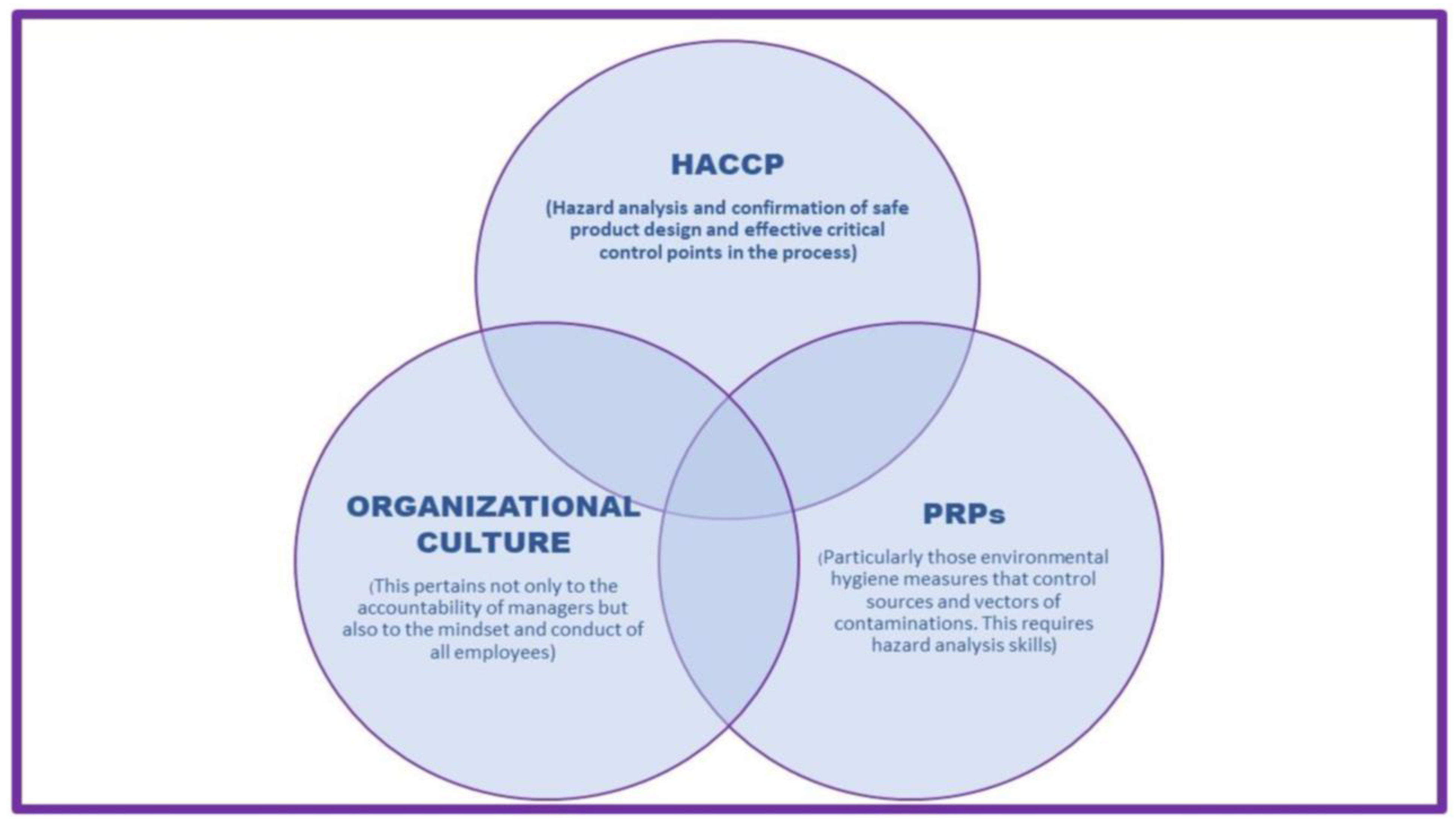

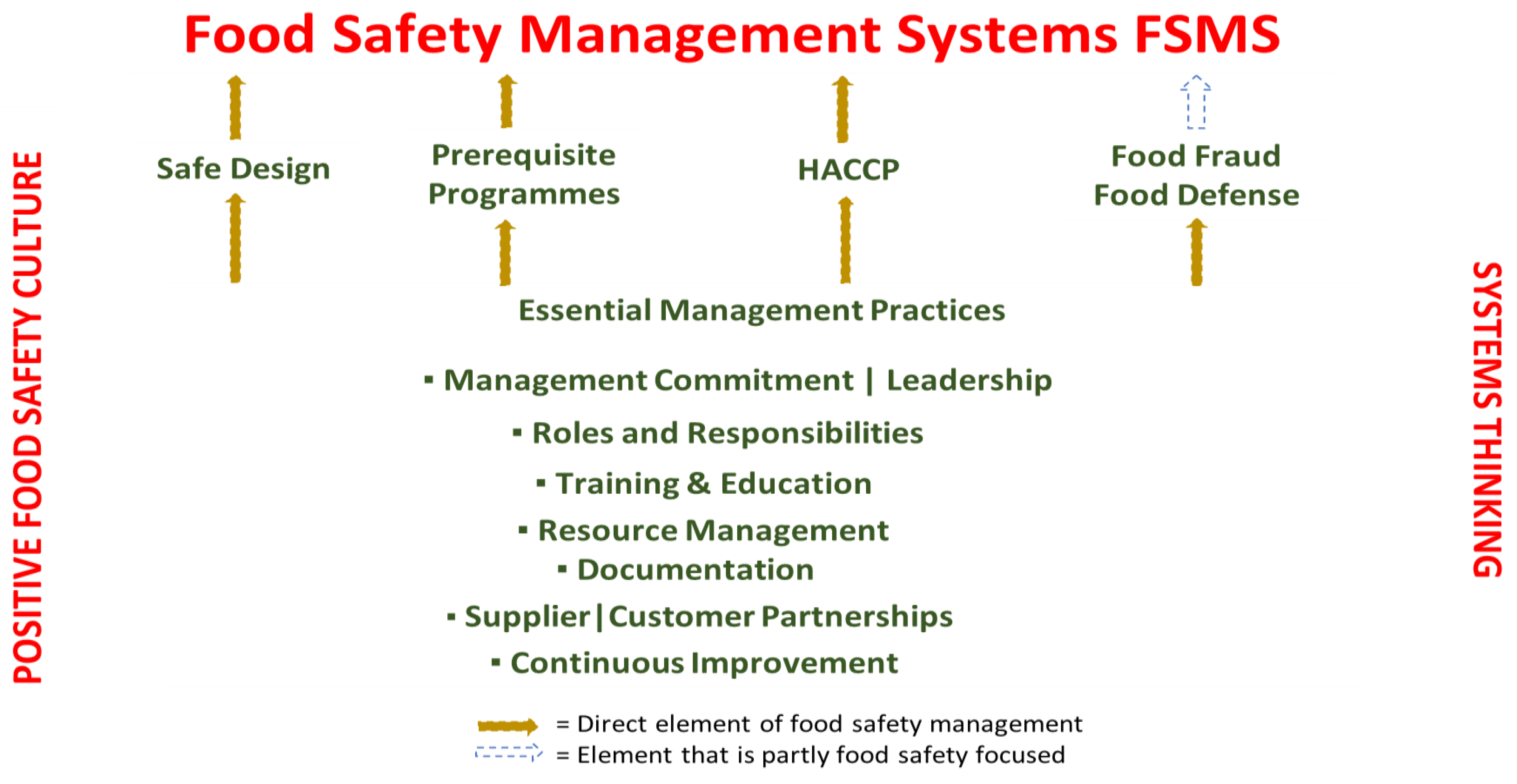

2.1. Managerial Systematic Approach to Food Safety

2.1.1. Prerequisites: FSMS Foundation in Developing and Developed Countries

2.1.2. FSMS and Systems Thinking

2.1.3. Positive Food Safety Culture

2.1.4. Food Safety, Food Security, and Food Sustainability

2.1.5. Food Fraud and Food Defense

2.1.6. Rewording the Guidelines Related to Microbiological Standards

2.1.7. Constraints and Benefits: Third-Party Food Safety Schemes

3. Materials and Methods

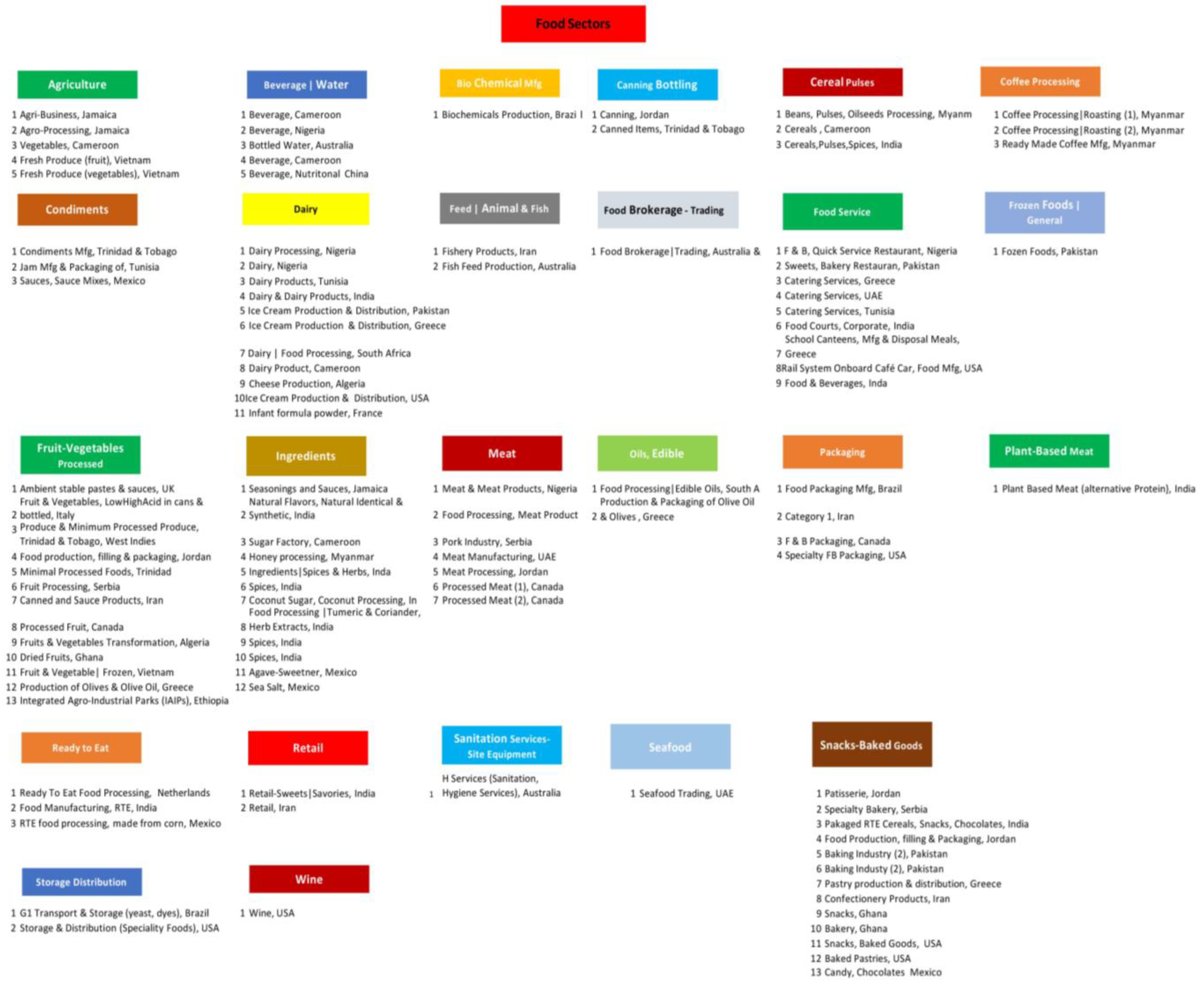

3.1. Sample Size

3.2. Content of Analyses-Case Study Survey Data Collection by Global Food Safety Professionals

3.3. Case Studies’ Confidentiality Integrity

3.4. Analytical Framework

4. Results and Discussion

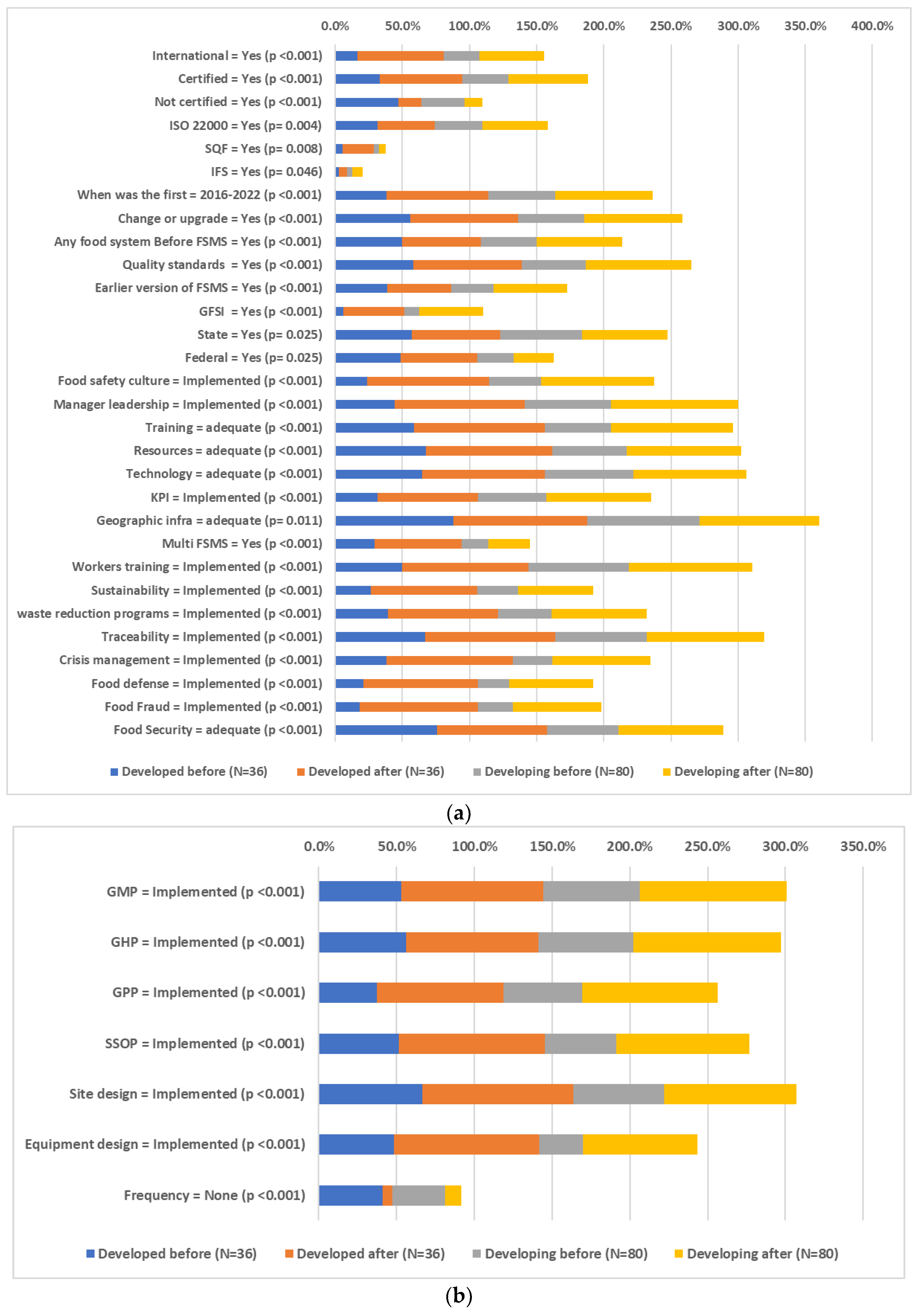

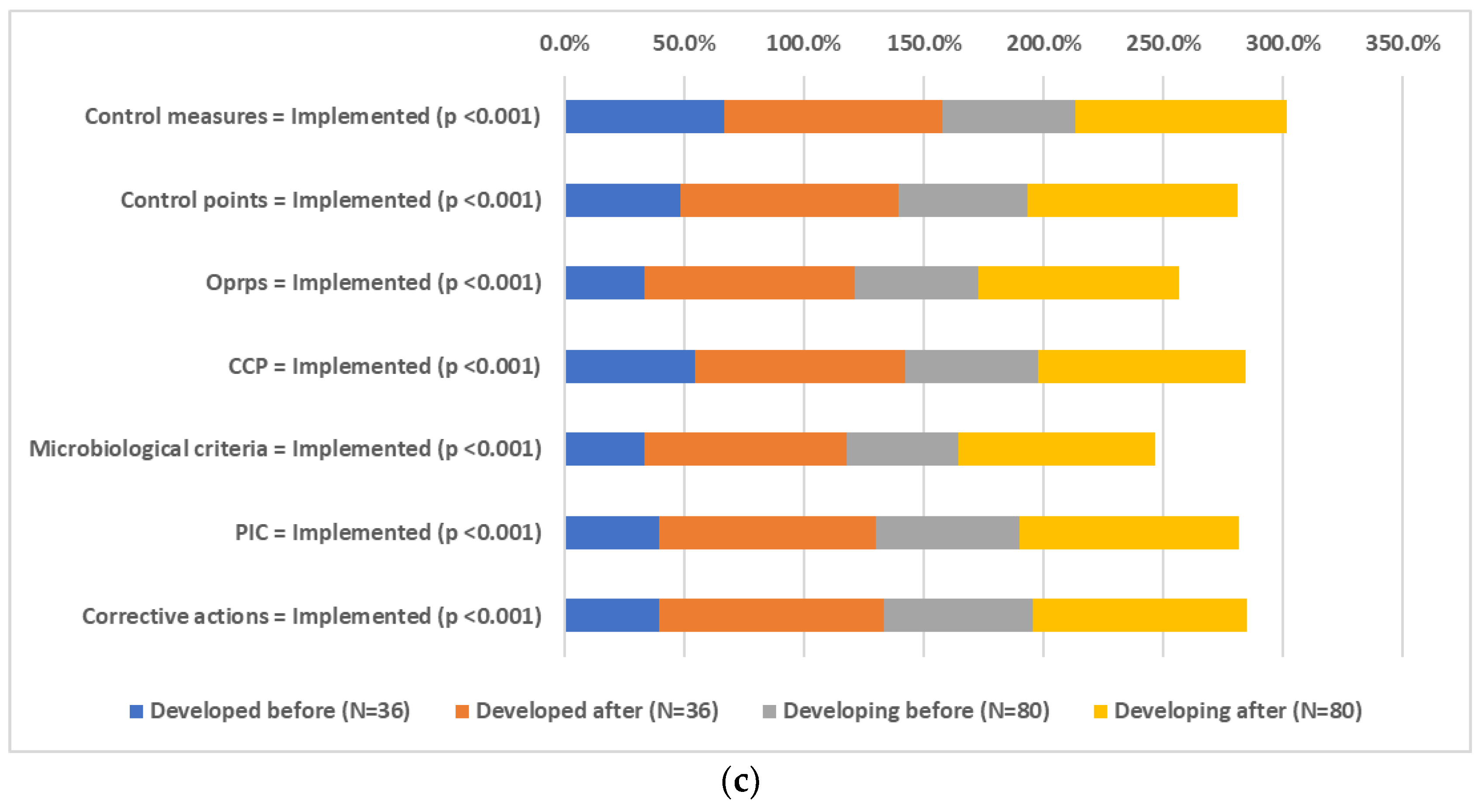

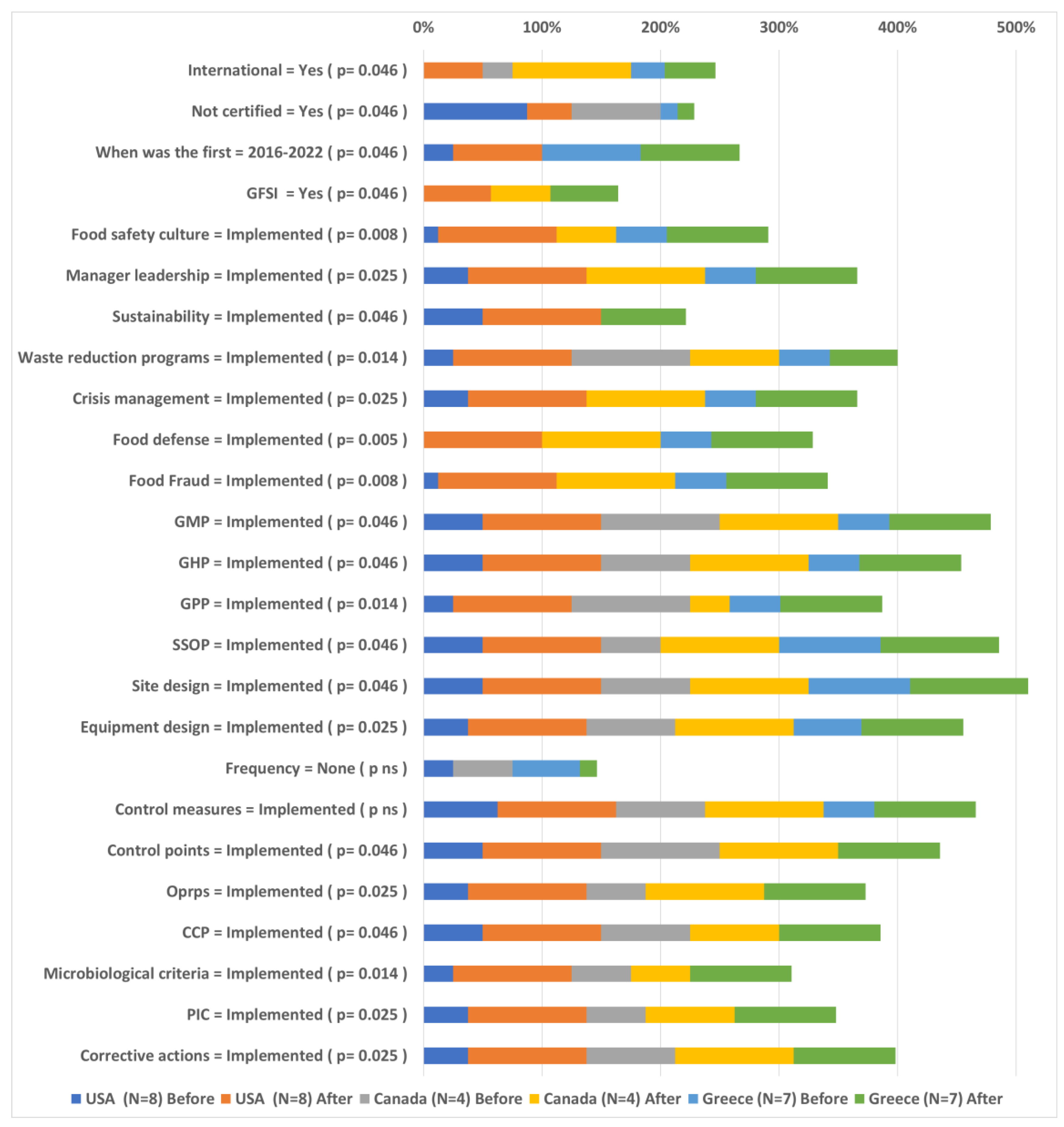

4.1. Developed Countries vs. Developing Countries

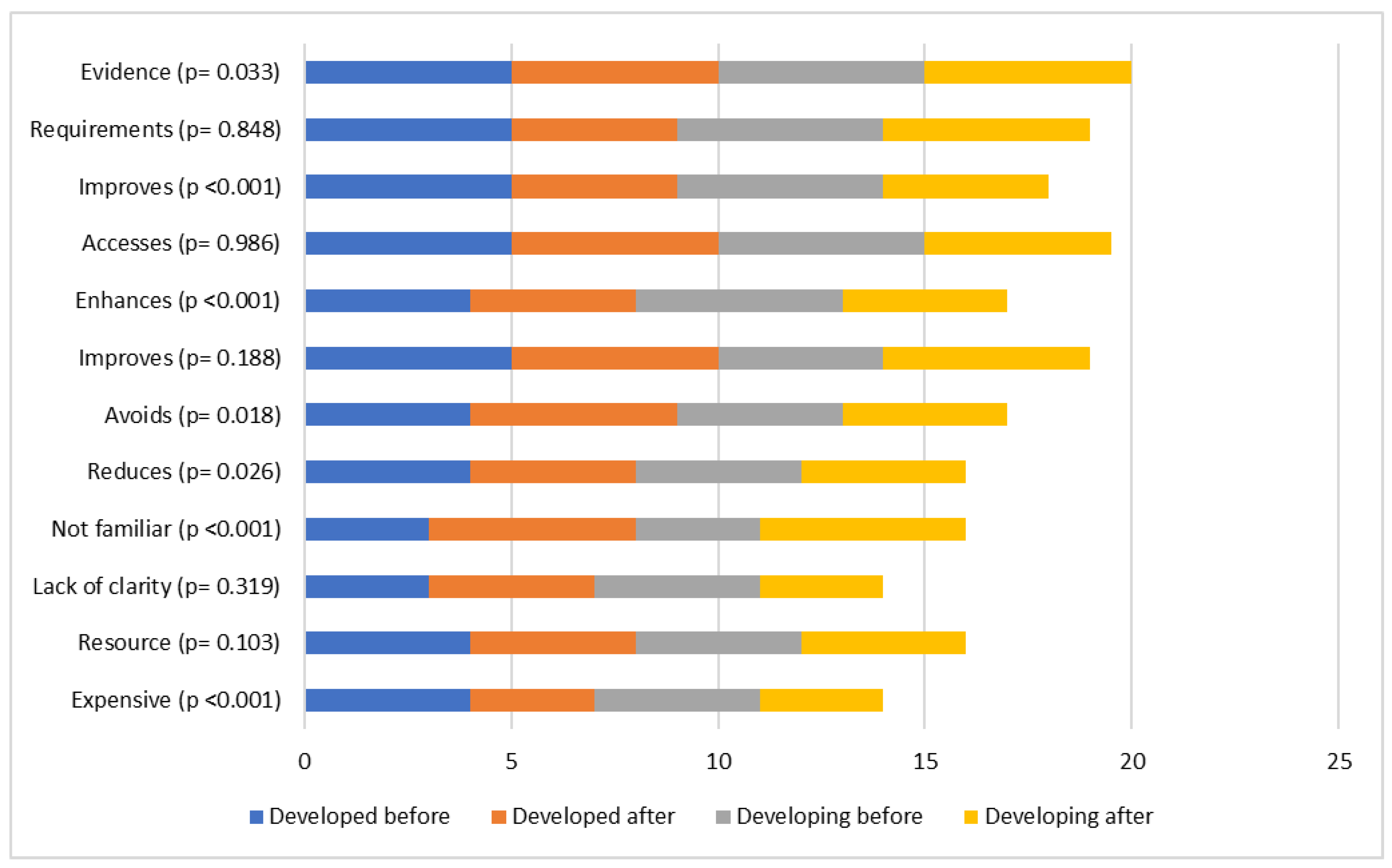

4.2. Differences per Geographical Region before and after FSMS Implementation

4.3. Differences per Sector before and after FSMS Implementation

4.4. Limitations of the Study

- Financial

- Infrastructure

- Prerequisite Programs

- Traceability Programs

- Food Safety Culture (FSC)

4.5. Areas for Further Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Acronyms Glossary | |

| BRCGS | Brand Reputation Compliance Global Standard |

| CA | Corrective Action |

| CAR | Corrective Action Report |

| CL | Control Limit |

| CM | Control Measure |

| CCP | Critical Control Point |

| EMP | Environmental Monitoring Program |

| FDP | Food Defense Plan |

| FF | Food Fraud |

| FSMS | Safety Management System |

| FSC | Food Safety Culture |

| FSC | Food Sector Category |

| FSSC 22000 | Food Safety System Certification |

| FSP | Food Safety Plan FSP |

| GAP | Good Agricultural Practices |

| GFSI | Global Food Safety Initiative |

| GMP | Good Manufacturing Practices |

| GHP | Good Hygiene Practices |

| GSP | Good Standardization Practices |

| HACCP | Hazard Analysis Critical Control Point |

| IFS | International Featured Standards |

| ISO 22000 | International Standards Organization |

| Food Safety System | |

| oPRP | Operational Prerequisite Program |

| PDCA | Plan, Do, Check, Act |

| PRP | Prerequisite Program |

| RCA | Root Cause Analysis |

| SOP | Standard Operating Procedure |

| SQFI | Safe Quality Food Institute |

| SSOP | Sanitation Standard Operating Procedure |

| TACCP | Threat Analysis Critical Control Point |

| VACCP | Vulnerability Analysis Critical Control Point |

References

- Waddington, H.; Snilstveit, B.; Hombrados, J.; Vojtkova, M. Preventing Foodborne Diseases in Developing Countries: A Systematic Review. 2013. Available online: https://www.who.int/tdr/publications/documents/preventing-foodborne-diseases.pdf (accessed on 9 August 2022).

- Global Food Safety Partnership, World Bank Group. Food Safety in Low and Middle-Income Countries; The World Bank Group: Washington, DC, USA, 2018. [Google Scholar]

- Alli, I.; Okorie, N. Food safety and developing countries: The benefits of technology transfer. J. Food Saf. 2015, 35, 312–330. [Google Scholar]

- Anang, F.M.; Rusul, M.; Atiliwi, M.C. Food safety management in developing countries: An overview. Afr. J. Food Sci. 2018. [Google Scholar]

- World Health Organization (WHO). The WHO’s Website Includes Information on Food Safety, Global Foodborne Diseases, and International Food Safety Standards. Available online: https://www.who.int/foodsafety/en/ (accessed on 26 December 2022).

- Lee, J.C.; Daraba, A.; Voidarou, C.; Rozos, G.; Enshasy, H.A.E.; Varzakas, T. Implementation of Food Safety Management Systems along with Other Management Tools (HAZOP, FMEA, Ishikawa, Pareto). The Case Study of Listeria monocytogenes and Correlation with Microbiological Criteria. Foods 2021, 10, 2169. [Google Scholar] [CrossRef] [PubMed]

- Daraba, A.; Varzakas, T.; Lee, J.C. Implementation of FSMS and Correlation with Microbiological Criteria, Systems Thinking and Food Safety Culture, Food Safety Magazine (Dec 2022–Jan 2023 Issue), Process Control Column. Available online: https://digitaledition.food-safety.com/december-2022-january-2023/column-process-control/ (accessed on 8 August 2023).

- Codex Alimentarius. Food Safety and Trade: How Food Safety Standards Can Facilitate International Trade. 2020. Available online: http://www.fao.org/fao-who-codexalimentarius/sh-media/news-detail/en/c/281286/ (accessed on 9 August 2022).

- FAO. What Is Food Safety? Available online: http://www.fao.org/food-safety/about/what-is-food-safety/en/ (accessed on 30 May 2023).

- Boscheri, E.; Parisi, S.; Ferrante, M. Food safety management systems: A need for harmonization and recognition. Int. J. Food Sci. Technol. 2018. [Google Scholar]

- Aung, M.M.; Chang, Y.S.; Chang, K.W. Food safety management systems and HACCP implementation in developing countries: A review of the literature. Food Control 2013, 32, 187–194. [Google Scholar]

- Food and Drug Administration (FDA)—United States: The Official Website of the FDA, the Regulatory Agency Responsible for Ensuring the Safety, Efficacy, and Security of Food, Drugs, and Medical Devices in the United States. Available online: https://www.fda.gov/ (accessed on 30 May 2023).

- European Food Safety Authority (EFSA)—Europe: The Website of EFSA, an Independent Scientific Agency That Provides Scientific Advice and Risk Assessment on Food Safety to the European Union. Available online: https://www.efsa.europa.eu/ (accessed on 30 May 2023).

- Canadian Food Inspection Agency (CFIA)—Canada: The Official Website of CFIA, the Federal Agency Responsible for Safeguarding Food, Animals, and Plants in Canada. Available online: https://www.inspection.gc.ca/ (accessed on 30 May 2023).

- Centers for Disease Control and Prevention (CDC)—United States: The CDC’s Website Provides Information on Food Safety, Foodborne Illnesses, Outbreaks, and Preventive Measures in the United States. Available online: https://www.cdc.gov/foodsafety/index.html (accessed on 30 May 2023).

- Food Standards Agency (FSA)—United Kingdom: The Official Website of FSA, the Government Department Responsible for Food Safety and Standards in the United Kingdom. Available online: https://www.food.gov.uk/ (accessed on 10 April 2023).

- World Health Organization. Estimates of the Global Burden of Foodborne Diseases. 2015. Available online: https://www.who.int/foodsafety/areas_work/foodborne-diseases/ferg/en/ (accessed on 10 April 2023).

- FoodSafety.gov. Recalls, Market Withdrawals, & Safety Alerts. 2021. Available online: https://www.foodsafety.gov/recalls (accessed on 9 August 2022).

- European Commission. Rapid Alert System for Food and Feed (RASFF). 2021. Available online: https://ec.europa.eu/food/safety/rasff_en (accessed on 9 August 2022).

- Business Standard. Pillsbury’s Chakki Fresh Atta Recalled on Metal Contamination Fears. 2021. Available online: https://www.business-standard.com/article/companies/pillsbury-s-chakki-fresh-atta-recalled-on-metal-contamination-fears-121031300241_1.html (accessed on 8 August 2022).

- Vanguard. NAFDAC Recalls 2 Batches of Infant Formula Milk Powder. 2021. Available online: https://www.vanguardngr.com/2021/02/nafdac-recalls-2-batches-of-infant-formula-milk-powder (accessed on 31 July 2022).

- Available online: https://www.fda.gov/food/outbreaks-foodborne-illness/fda-investigation-cronobacter-infections-powdered-infant-formula-february-2022 (accessed on 31 July 2022).

- FDA Outbreak Investigation (April 2023). Salmonella-Flour. Available online: https://www.fda.gov/food/outbreaks-foodborne-illness/outbreak-investigation-salmonella-flour-april-2023 (accessed on 30 May 2023).

- ISO 22000; Food Safety Management System. International Organization for Standardization: Geneva, Switzerland, 2018.

- Food and Agriculture Organization (FAO)—United Nations: The FAO’s Website Provides Resources on Food Safety, Food Quality, and International Food Standards. Available online: http://www.fao.org/food/food-safety-quality/home/en/ (accessed on 10 April 2023).

- What Are Food Safety Management Systems? Available online: https://chimerasystems.co.za/services/fsms/ (accessed on 10 April 2021).

- Kumar, R. Food Safety Management—Understanding and Implementing ISO 22000 and FSSC 22000; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Butts, J. Evolution of food safety systems: The past, present, and future. J. Food Nutr. Res. 2019. [Google Scholar]

- Ayodele, O.J.; Adetunji, M.O. Constraints to implementing food traceability in developing countries: A review. Cogent Food Agric. 2019, 5, 1597787. [Google Scholar]

- Pourazadi, E.; Daneshmand, A.R.; Fathi SA, A.; Elshorbagy, A. Traceability as a Key Element for Ensuring of Food Safety in Supply Chain Management: A Review. Qual. Eng. 2019, 31, 567–588. [Google Scholar]

- Schiefer, G.; Rickert, U. Traceability in food and agricultural supply chains–challenges and opportunities for developing countries. J. Chain. Netw. Sci. 2019, 19, 13–25. [Google Scholar]

- Shailja, K.; Thomas, B. An examination of international food traceability programs. J. Food Distrib. Res. 2018, 49, 92–105. [Google Scholar]

- What Is a Management System? Available online: https://images.app.goo.gl/Aqez5sSfpbvjQqmK7 (accessed on 20 June 2021).

- Huang, L.; Wang, G.; Ma, J. The effectiveness of food safety management systems and prerequisite programs in food processing plants in China. Food Control 2016, 69, 54–61. [Google Scholar]

- Wallace, C.A.; Mortimore, S.E. Chapter 3: HACCP. In Handbook of Hygiene Control in the Food Industry; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

- Wallace, C.A.; Sperber, W.H.; Mortimore, S.E. Overview of a World Class Food Safety Programme in Food Safety for the 21st Century, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2018; pp. 163–186. [Google Scholar]

- Food and Agriculture Organization. Food Safety Culture and Awareness in Developing Countries. 2017. Available online: https://sdgs.un.org/un-system-sdg-implementation/food-and-agriculture-organization-fao-44217 (accessed on 10 April 2023).

- Food and Agricultural Organization of the United Nations. Food Safety Systems and Food Security: A Review of the Critical Issues. 2017. Available online: https://www.fao.org/publications/home/fao-flagship-publications/the-state-of-food-security-and-nutrition-in-the-world (accessed on 10 April 2023).

- Grace, D. Food Safety in Low and Middle-Income Countries. Int. J. Environ. Res. Public Health 2015, 12, 10490–10507. [Google Scholar] [CrossRef]

- United Nations Development Programme. Strengthening Food Safety in Developing Countries. Available online: https://www.fao.org/publications/home/fao-flagship-publications/the-state-of-food-security-and-nutrition-in-the-world (accessed on 10 April 2023).

- Käferstein, F. Foodborne diseases in developing countries: Aetiology, epidemiology and strategies for prevention. Int. J. Environ. Health Res. 2003, 13, 161–168. [Google Scholar]

- Food Safety—World Health Organization (WHO). Available online: https://www.who.int/news-room/fact-sheets/detail/food-safety (accessed on 30 April 2023).

- Food Security|USDA. Available online: https://www.usda.gov/topics/food-and-nutrition/food-security (accessed on 30 April 2023).

- Food Safety in Food Security and Food Trade|IFPRI. Available online: https://www.ifpri.org/publication/food-safety-food-security-and-food-trade (accessed on 30 April 2023).

- Food Safety in Developing Countries: An Overview—GOV.UK. Available online: https://www.gov.uk/research-for-development-outputs/food-safety-in-developing-countries-an-overview (accessed on 30 April 2023).

- Food Safety Legislation in Some Developing Countries. Available online: https://www.intechopen.com/chapters/61873 (accessed on 30 April 2023).

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste: Extent, Causes, and Prevention; Food and Agriculture Organization of The United Nations: Rome, Italy, 2011. [Google Scholar]

- Ingram JS, I.; Muir, J.F. Aligning Food Security and Sustainable Agriculture: Policy Imperatives and Research Challenges. Front. Sustain. Food Syst. 2019, 3, 1–6. [Google Scholar]

- Lal, R. Soil Health and Sustainability: Managing the Biotic Component of Soil Quality; Elsevier: New York, NY, USA, 2018. [Google Scholar]

- Tilman, D.; Balzer, C.; Hill, J.; Befort, B.L. Global Food Demand and the Sustainable Intensification of Agriculture. Proc. Natl. Acad. Sci. USA 2011, 108, 20260–20264. [Google Scholar] [CrossRef]

- Chen, X.; Li, D. Food Fraud in China: Background, Challenges, and Prospects. Compr. Rev. Food Sci. Food Saf. 2018, 17, 806–821. [Google Scholar]

- Henson, S.; Jaffee, S. Understanding Developing Country Strategic Responses to the Enhancement of Food Safety Standards. Dev. Policy Rev. 2013, 31, 647–665. [Google Scholar] [CrossRef]

- Lelieveld, H.L.; Houben, R. Food Safety Management: A Practical Guide for the Food Industry; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Aung, M.M.; Chang, Y.S.; Ching, T.Y. Food Fraud and Vulnerability Assessment: Tools and Techniques; John Wiley & Sons: New York, NY, USA, 2016. [Google Scholar]

- Yan, Q.; Yang, Y. Cronobacter species in foods: Current state and perspectives. J. Food Prot. 2019, 82, 1732–1744. [Google Scholar]

- Osaili, T.M.; Shaker, R.R.; Al-Omary, W.; Al-Nabulsi, A.A.; Holley, R.A. Cronobacter species and their significance in foodborne illnesses. Food Control 2018, 93, 237–247. [Google Scholar]

- Kim, Y.K.; Lee, Y.; Kim, J.H.; Oh, S.W. Prevalence of Cronobacter spp. in Korean retail food: Poultry and vegetable products. Int. J. Food Microbiol. 2019, 295, 81–85. [Google Scholar]

- Li, C.; Ling, N.; Zhang, X.; Zhang, S.; Deng, X.; Fang, W. Prevalence and molecular characteristics of Cronobacter spp. isolated from spices in China. Food Control 2018, 84, 116–123. [Google Scholar] [CrossRef]

- Chon, J.W.; Choi, H.J.; Kim, J.H.; Kim, D.H.; Kwon, J.H.; Choi, I.S.; Seo, K.H. Cronobacter sakazakii in powdered infant formula marketed in Korea. Food Control 2012, 28, 225–229. [Google Scholar]

- Almajed, F.S.; Forsythe, S.J. Isolates from neonates and Cronobacter sakazakii clinical infants in England and Wales: Their molecular, phenotypic characteristics, and genotypic diversity. Front. Microbiol. 2016, 7, 1564. [Google Scholar]

- Food Safety Magazine. FSMA, Food Safety Audits and Certifications 2016. Available online: https://www.food-safety.com/articles/4995-fsma-food-safety-audits-and-certifications (accessed on 10 April 2023).

- World Bank. Food Safety Handbook 2020. Available online: https://documents1.worldbank.org/curated/en/450921587054767474/pdf/Food-Safety-Handbook-A-Practical-Guide-for-Building-a-Robust-Food-Safety-Management-System.pdf (accessed on 10 April 2023).

- Food Standards Agency. The Use of Third-Party Assurance Schemes in Relation to Food Safety. 2013. Available online: https://www.food.gov.uk/sites/default/files/media/document/835-1-1534_GSB_CR2435_3rd_Party_Assurance_Scheme_R2_V8_FCA.pdf (accessed on 10 April 2023).

- Global Food Safety Initiative. Enhancing Food Safety Through Third-Party Certification. 2011. Available online: http://mygfsi.com/wp-content/uploads/2019/09/Third-Party-Certification-GFSI-White-Paper.pdf (accessed on 10 April 2023).

- World Health Organization. Food Safety and Foodborne Illness. 2011. Available online: https://www.who.int/health-topics/foodborne-diseases#tab=tab_1 (accessed on 10 April 2023).

- Escanciano, C.; Santos-Vijande, M.L. Reasons and constraints to implementing an ISO 22000 food safety management system: Evidence from Spain. Food Control 2014, 40, 50–57. [Google Scholar]

- Abebe, G.K.; Bahn, R.A.; Chalak, A.; Yehya, A.A.K. Drivers for the implementation of market-based food safety management system: Evidence from Lebanon. Food Sci. Nutr. 2020, 8, 1082–1092. [Google Scholar] [CrossRef]

- Creswell, J.W. Qualitative Inquiry and Research Design: Choosing among Five Approaches; Sage: Thousand Oaks, CA, USA, 2013. [Google Scholar]

- Crowe, S.; Cresswell, K.; Robertson, A.; Huby, G.; Avery, A. The case study approach. BMC Med. Res. Methodol. 2011, 11, 100. [Google Scholar] [CrossRef] [PubMed]

- Field, A. Discovering Statistics Using IBM SPSS Statistics, 5th ed.; University of Sussex, UK SAGE Publications Ltd.: Brighton, UK, 2017. [Google Scholar]

- Nguyen, T.T.B.; Li, D. A systematic literature review of food safety management system implementation in global supply chains. Br. Food J. 2022, 124, 3014–3031. [Google Scholar] [CrossRef]

- Fotopoulos, C.V.; Kafetzopoulos, D.P.; Psomas, E.L. Assessing the critical factors and their impact on the effective implementation of a food safety management system. Int. J. Qual. Reliab. Manag. 2009, 26, 894–910. [Google Scholar] [CrossRef]

- Chen, H.; Liou, B.K.; Hsu, K.C.; Chen, C.S.; Chuang, P.T. Implementation of food safety management systems that meets ISO 22000:2018 and HACCP: A case study of capsule biotechnology products of chaga mushroom. J. Food Sci. 2021, 86, 40–54. [Google Scholar] [CrossRef]

- Sun, Y.-M.; Ockerman, H.W. A review of the needs and current applications of hazard analysis and critical control point (HACCP) system in foodservice areas. Food Control 2005, 16, 325–332. [Google Scholar] [CrossRef]

- Cusato, S.; Gameiro, A.H.; Corassin, C.H.; Sant, A.S.; Cruz, A.G.; Faria, J.d.A.F.; de Oliveira, C.A.F. Food Safety Systems in a Small Dairy Factory: Implementation, Major Challenges, and Assessment of Systems’ Performances. Foodborne Pathog. Dis. 2013, 10, 6–12. [Google Scholar] [CrossRef]

- Grover, A.K.; Chopra, S.; Mosher, G.A. Food safety modernization act: A quality management approach to identify and prioritize factors affecting adoption of preventive controls among small food facilities. Food Control 2016, 66, 241–249. [Google Scholar] [CrossRef]

- Rao, M.; Bast, A.; de Boer, A. European private food safety standards in global agri-food supply chains: A systematic review. Int. Food Agribus. Manag. Rev. 2021, 24, 739–754. [Google Scholar] [CrossRef]

- Wilcock, A.; Ball, B.; Fajumo, A. Effective implementation of food safety initiatives: Managers’, food safety coordinators’ and production workers’ perspectives. Food Control 2011, 22, 27–33. [Google Scholar]

- Zanin, L.M.; Stedefeldt, E.; Luning, P.A. The evolvement of food safety culture assessment: A mixed-methods systematic review. Trends Food Sci. Technol. 2021, 118, 125–142. [Google Scholar]

- Manning, L.; Luning, P.A.; Wallace, C.A. The evolution and cultural framing of food safety management systems—Where from and where next? Compr. Rev. Food Sci. Food Saf. 2019, 18, 1770–1792. [Google Scholar] [CrossRef]

- De Boeck, E.; Jacxsens, L.; Bollaerts, M.; Uyttendaele, M.; Vlerick, P. Interplay between food safety climate, food safety management system and microbiological hygiene in farm butcheries and affiliated butcher shops. Food Control 2016, 65, 78–91. [Google Scholar] [CrossRef]

- Kramer, A.; Hoover, E.R.; Hedeen, N.; DiPrete, L.; Tuttle, J.; Irving, D.J.; Viveiros, B.; Nicholas, D.; Monroy, J.A.; Moritz, E.; et al. Development of an Empirically Derived Measure of Food Safety Culture in Restaurants. J. Food Prot. 2023, 86, 100043. [Google Scholar] [CrossRef]

- Marconi, F.; Sartoni, M.; Nuvoloni, R.; Torracca, B.; Gagliardi, M.; Zappalà, G.; Guidi, A.; Pedonese, F. Food safety culture in food companies: Evaluation of the perception of food safety culture in three Tuscan food companies. Ital. J. Food Saf. 2023, 12, 11012. [Google Scholar] [PubMed]

| Category | Examples of Micro-Organisms, Parasites, Toxins and Metabolites |

|---|---|

| Raw meat: Carcasses of cattle, sheep, goats, pigs, and horses | Salmonella spp., Escherichia coli, E.coli O157:H7, Yersinia enterocolitica, Campylobacter jejuni, Listeria monocytogenes, Clostridium botulinum and C. perfringens, Staphylococcus aureus Parasites: Toxoplasma, Trichinella, Taenia and Sarcocystis Mycotoxins: Obtained from the animal through animal feed |

| Carcasses of broilers and turkeys | Salmonella spp., Escherichia coli, Campylobacter spp., Listeria monocytogenes, Clostridium botulinum and C. perfringens, Staphylococcus aureus, Bacillus cereus |

| Milk and dairy products | Salmonella spp., Escherichia coli, E.coli O157:H7, Campylobacter spp., Listeria monocytogenes, Bacillus cereus, Staphylococcus aureus, Brucella spp. Mycotoxins (aflatoxins Μ1 and Μ2), toxins from S. aureus and C. botulinum (mainly from yogurt containing fruits or nuts) shelfish |

| Egg products | Enterobacteriaceae (mainly Salmonela spp.), L. monocytogenes |

| Fishery products | Staphylococcus spp., Clostridium botulinum, Vibrio spp., Vibrio parahaemolyticus, histamine-producing bacteria (Proteus morganii), Enterobacter spp., Citrobacter spp., Salmonella spp., Erysipelothrix rhusiopathiae Parasites: Diphyllobothrium latum, Clonorchis sinensis, Pseudoterranova spp. Toxins: Scombrotoxin, Ciguatera and Histamine |

| shellfish | Escherichia coli, Toxins: Amnesic shelfish toxin (ASP), Diarrhoetic shelfish toxin (DSP), Neurotoxic shellfish toxin (NSP), Paralytic shelfish toxin (PSP), Ciguatera |

| Vegetables, fruits, and products thereof | Escherichia coli, Salmonella spp., Shigella spp., Listeria spp., Staphylococcus spp. (mainly in mushrooms) Toxins: Mycotoxins (Patulin mainly in apples and apple juice, pears and peaches), aflatoxins (mainly in figs), toxins from Clostridium botulinum |

| Cereals and nuts | Salmonella spp., B. cereus, S. aureus Mycotoxins (aflatoxins) |

| Milk powder & powdered infant formula, fruit, vegetables, cereals, starches, dry food & meat products | Cronobacter spp. |

| Total Sample (N = 116) | Developed (N = 36) | Developing (N = 80) | ||||

|---|---|---|---|---|---|---|

| N | % | N | % | N | % | |

| Sectors | ||||||

| Agri | 6 | 5.2 | 2 | 5.6 | 4 | 5.0 |

| Beverage.Water | 5 | 4.3 | 2 | 5.6 | 3 | 3.8 |

| Canning/Bottling/Packaging | 6 | 5.2 | 2 | 5.6 | 4 | 5.0 |

| Coffee/Condiments/Sugar | 8 | 6.9 | 0 | 0.0 | 8 | 10.0 |

| Dairy | 11 | 9.5 | 3 | 8.3 | 8 | 10.0 |

| Services (Education, sanitary, transport, storage etc.) | 7 | 6 | 2 | 5.6 | 5 | 6.3 |

| Food service | 11 | 9.5 | 6 | 16.7 | 5 | 6.3 |

| Fruit.Veg-Processed | 16 | 13.8 | 5 | 13.9 | 11 | 13.8 |

| Ingredients | 11 | 9.5 | 0 | 0.0 | 11 | 13.8 |

| Meat | 8 | 6.9 | 3 | 8.30 | 5 | 6.3 |

| Snacks.BakedGoods | 14 | 12.1 | 4 | 11.1 | 10 | 12.5 |

| Other | 13 | 11.2 | 7 | 19.4 | 6 | 7.5 |

| Countries | ||||||

| Africa (Algeria, Cameroon, Ethiopia, Ghana, Nigeria, Pakistan, South Africa) | 24 | 20.7 | 0 | 0.0 | 24 | 30.0 |

| UK and Australia | 7 | 6.0 | 7 | 19.4 | 0 | 0.0 |

| Latin America and the Caribbean (Brazil, Jamaica, Mexico, Trinidad) | 16 | 13.8 | 0 | 0.0 | 16 | 20.0 |

| North America (USA, Canada) | 12 | 10.3 | 12 | 33.3 | 0 | 0.0 |

| South Asia (India) | 16 | 13.8 | 0 | 0.0 | 16 | 20.0 |

| Other South Asia (Iran, Pakistan) | 10 | 8.6 | 0 | 0.0 | 10 | 12.5 |

| East and West Asia (Myanmar, Vietnam, China, Jordan, UAE) | 17 | 14.7 | 7 | 19.4 | 10 | 12.5 |

| Europe | 14 | 12.1 | 10 | 27.8 | 4 | 5.0 |

| Cronbach’s Alpha | ||

|---|---|---|

| Before | After | |

| FSMS Element Details | 0.740 | 0.718 |

| Prerequisites | 0.712 | 0.827 |

| HACCP | 0.927 | 0.938 |

| Constraints | 0.559 | 0.503 |

| Incentives | 0.828 | 0.828 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.C.; Neonaki, M.; Alexopoulos, A.; Varzakas, T. Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems. Foods 2023, 12, 3218. https://doi.org/10.3390/foods12173218

Lee JC, Neonaki M, Alexopoulos A, Varzakas T. Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems. Foods. 2023; 12(17):3218. https://doi.org/10.3390/foods12173218

Chicago/Turabian StyleLee, Jocelyn C., Marina Neonaki, Athanasios Alexopoulos, and Theodoros Varzakas. 2023. "Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems" Foods 12, no. 17: 3218. https://doi.org/10.3390/foods12173218

APA StyleLee, J. C., Neonaki, M., Alexopoulos, A., & Varzakas, T. (2023). Case Studies of Small-Medium Food Enterprises around the World: Major Constraints and Benefits from the Implementation of Food Safety Management Systems. Foods, 12(17), 3218. https://doi.org/10.3390/foods12173218