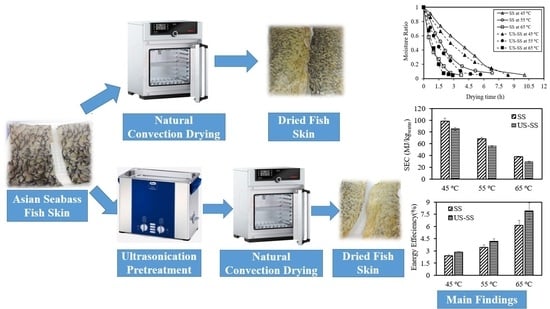

Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Sonication Treatment (US)

2.2. Drying Procedure

2.3. Determination of Moisture Content (MC) and Water Activity (aw)

2.4. Drying Kinetics Modeling

| Model | Mathematical Equation * | References |

|---|---|---|

| Lewis | MR = exp (−k . t) | [36] |

| Page | MR = exp (−k . tn) | [37] |

| Modified Page | MR = exp (−(k . t)n) | [38] |

| Henderson and Pabis | MR = a . exp (−k . t) | [39] |

| Vega-Lemus | [40] | |

| Verma et al. | [41] | |

| Two-term | [42] |

2.5. Determination of Drying Characteristics

2.5.1. Effective Moisture Diffusivity

2.5.2. Calculation of Activation Energy

2.6. Determination of Energy Consumption during Drying

2.6.1. Specific Energy Consumption (SEC)

2.6.2. Energy Efficiency

2.7. Microstructure Analysis

2.8. Data Analysis

3. Results and Discussion

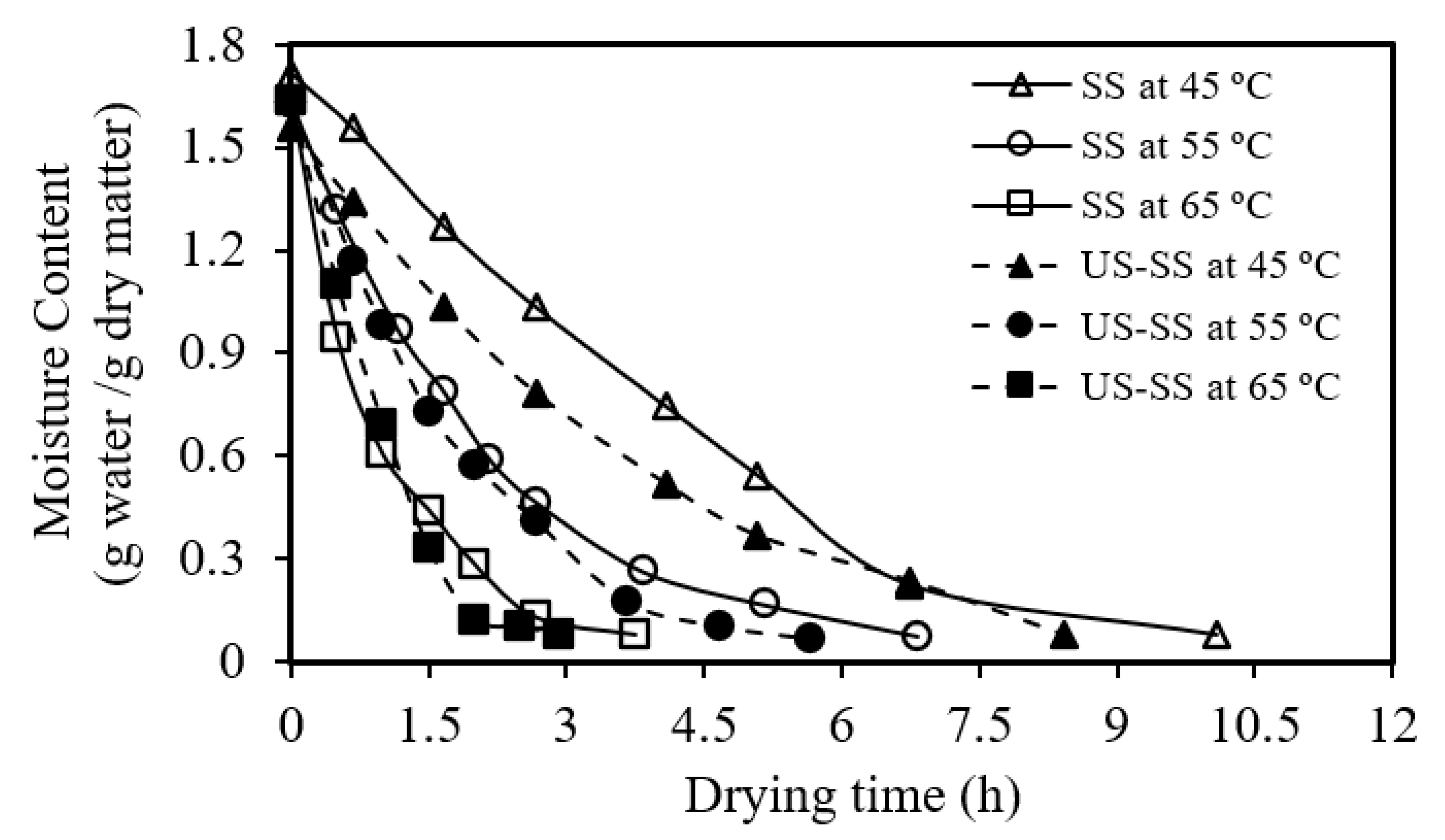

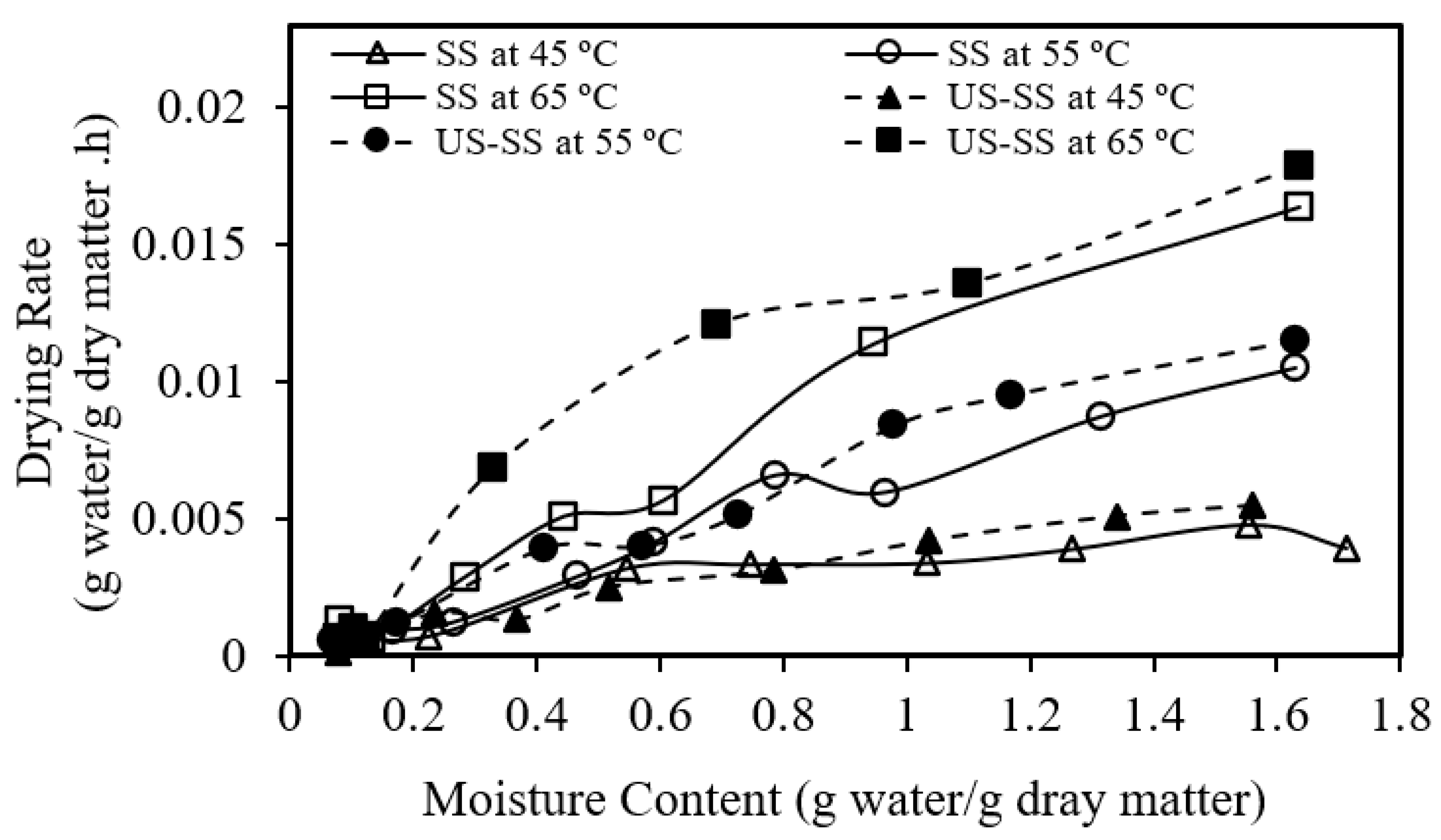

3.1. Drying Curves and Water Activity of Asian Seabass Skin

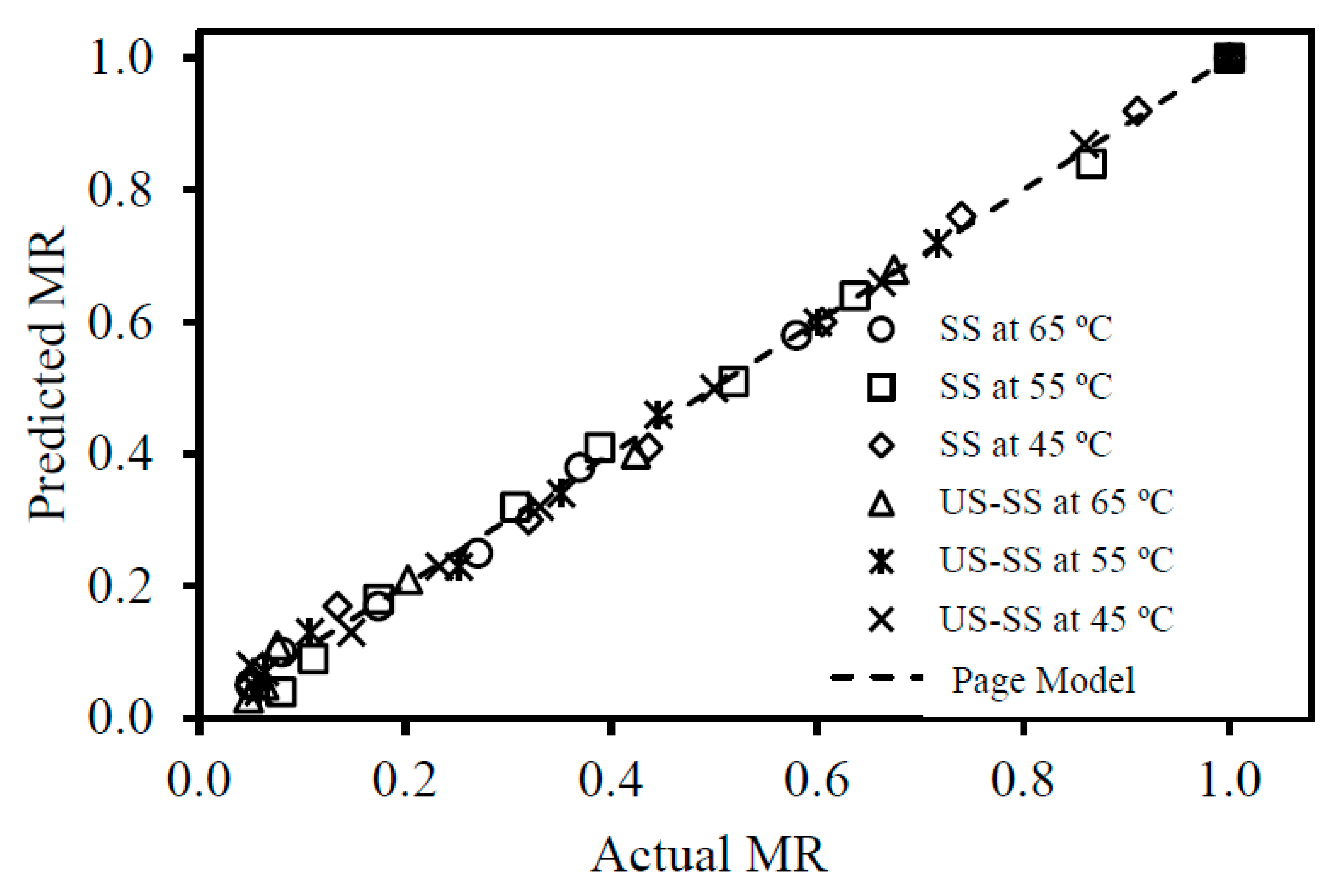

3.2. Drying Kinetic Modeling

3.3. Temperature Dependency and Activation Energy

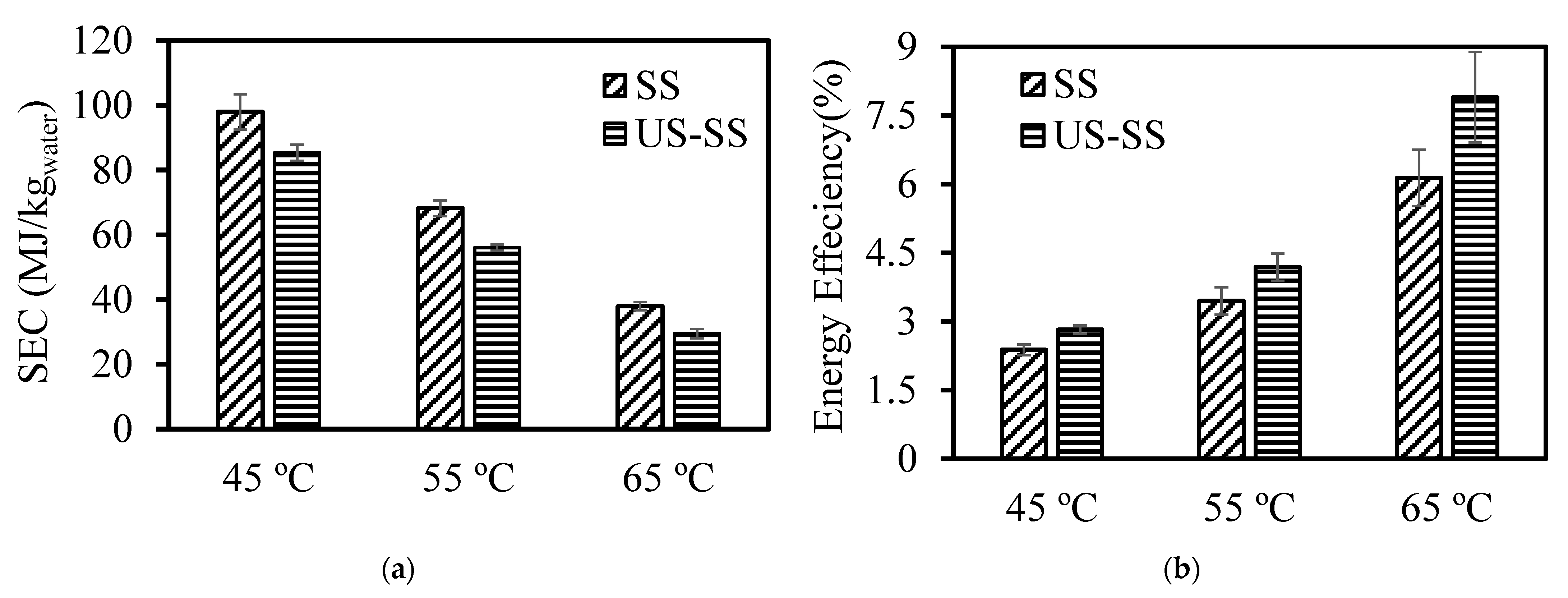

3.4. Specific Energy Consumption (SEC)

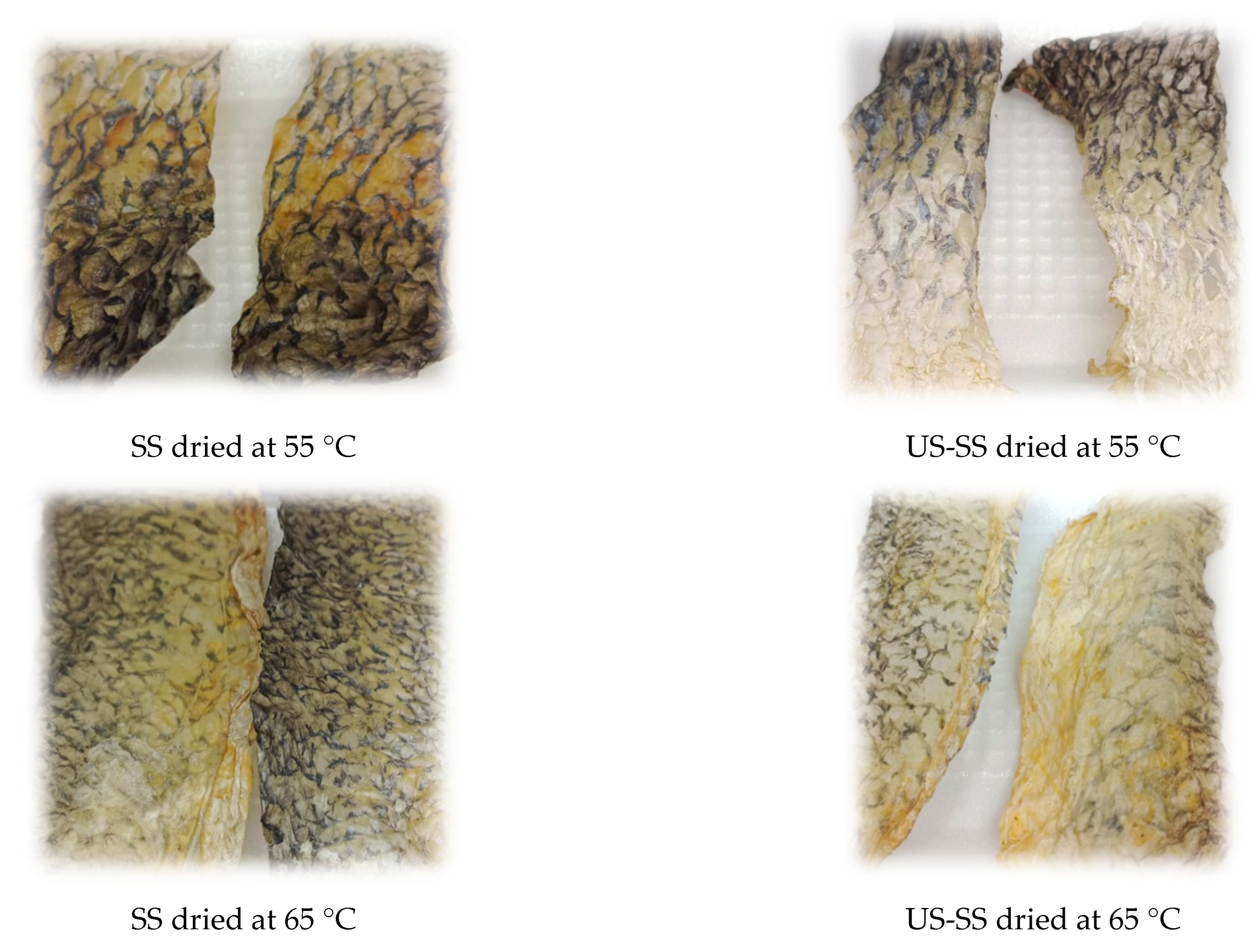

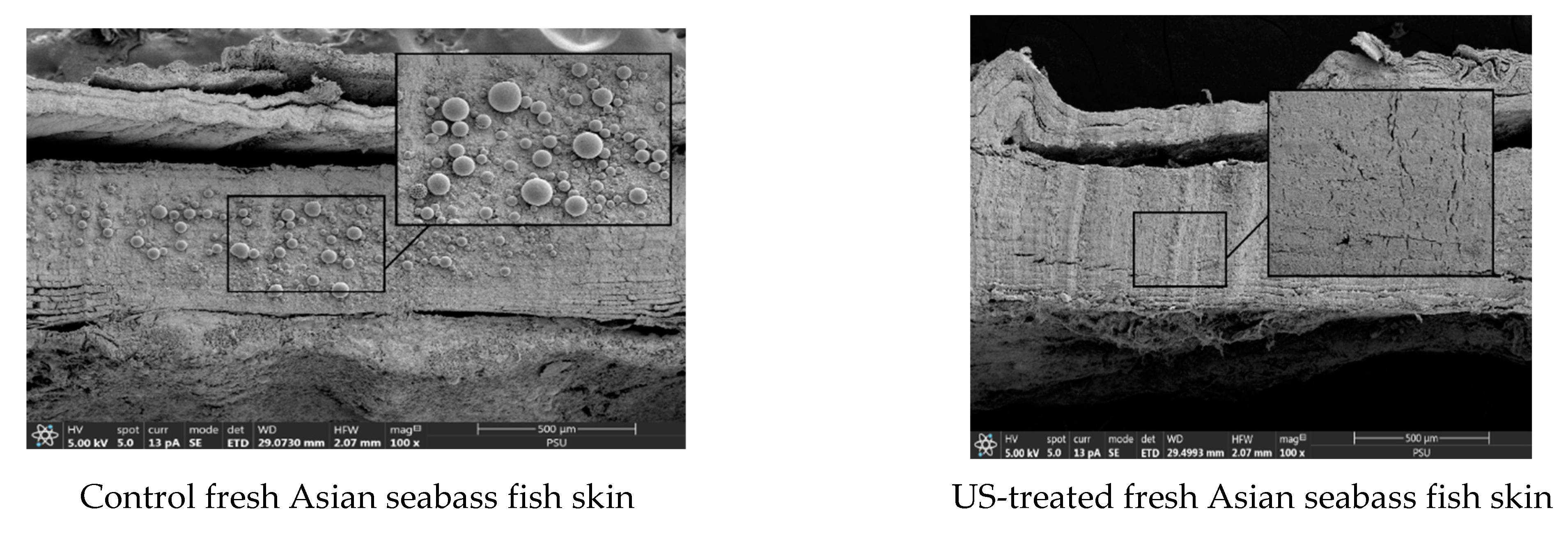

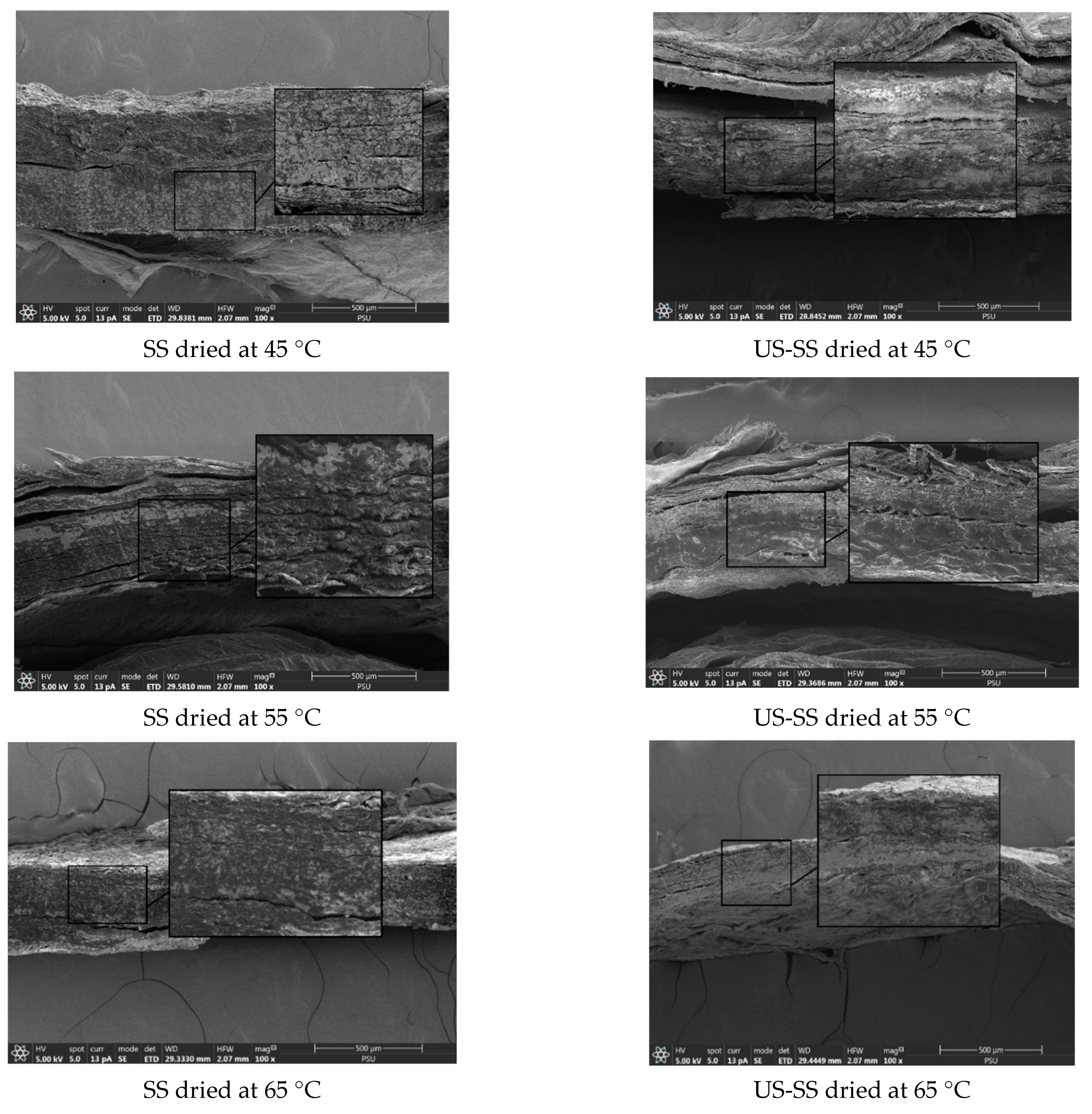

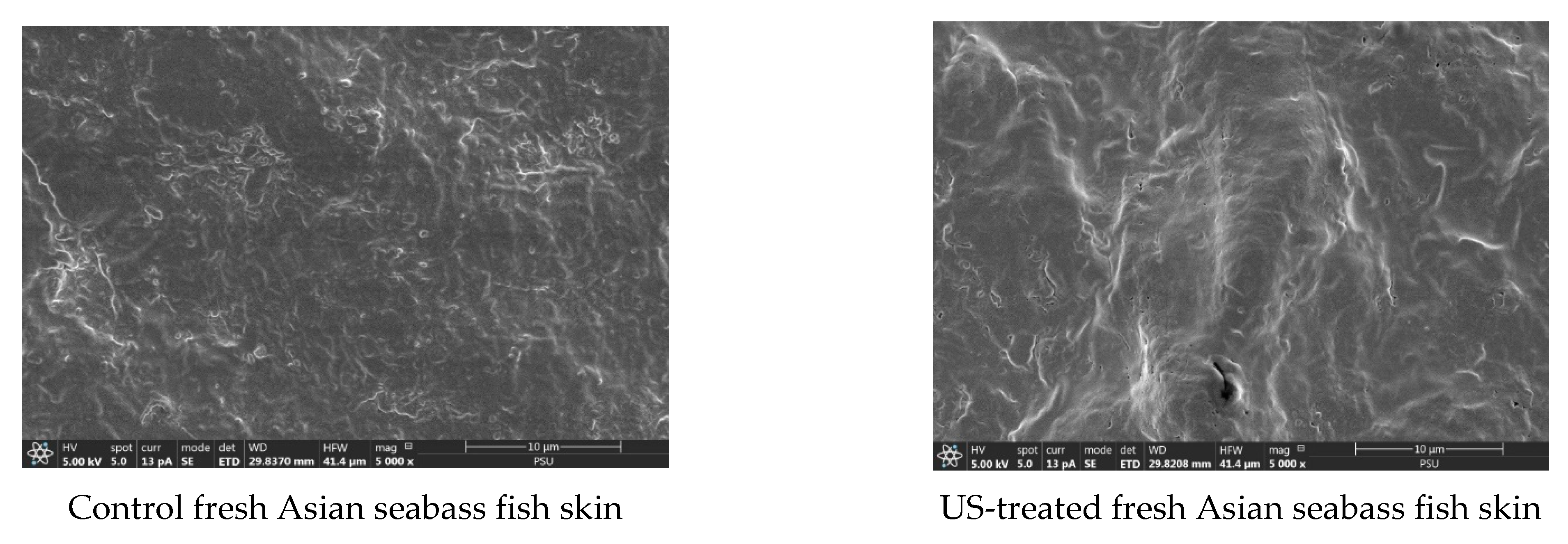

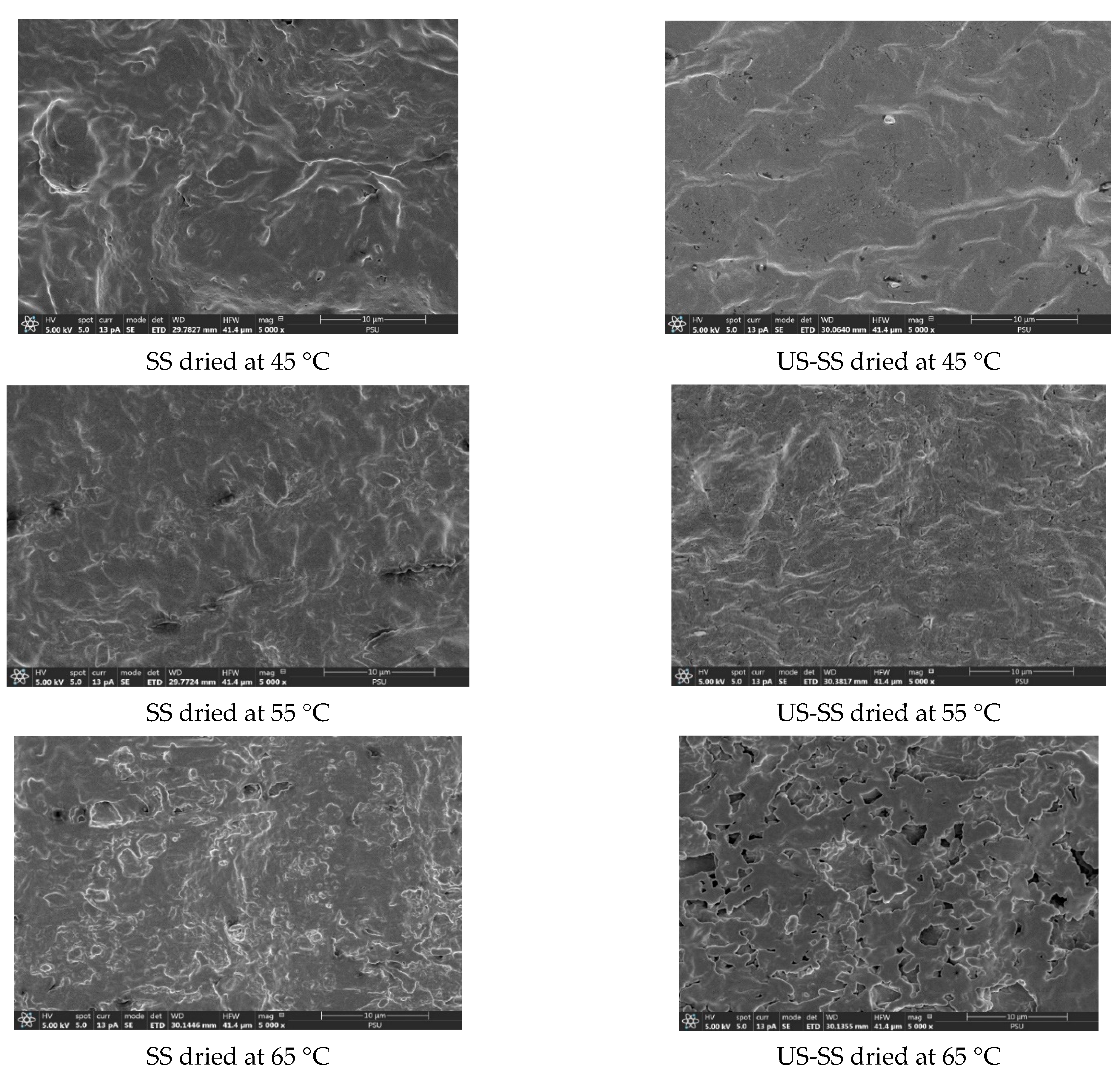

3.5. Microstructure of Dried Fish Skin

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benjakul, S.; Karnjanapratum, S.; Visessanguan, W. Hydrolysed collagen from Lates calcarifer skin: Its acute toxicity and impact on cell proliferation and collagen production of fibroblasts. Int. J. Food Sci. Technol. 2018, 53, 1871–1879. [Google Scholar] [CrossRef]

- Chotphruethipong, L.; Aluko, R.E.; Benjakul, S. Hydrolyzed collagen from porcine lipase-defatted seabass skin: Antioxidant, fibroblast cell proliferation, and collagen production activities. J. Food Biochem. 2019, 43, e12825. [Google Scholar] [CrossRef] [PubMed]

- Fang, M.C.; Chin, P.S.; Sung, W.C.; Chen, T.Y. Physicochemical and Volatile Flavor Properties of Fish Skin under Conventional Frying, Air Frying and Vacuum Frying. Molecules 2023, 28, 4376. [Google Scholar] [CrossRef]

- Sari, R.; Suryaningrum, T.D.; Ayudiarti, D.; Hastarini, E.; Fransisca, D. Conversion of fisheries processing by-product into salted-egg fish skin chips. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012117. [Google Scholar]

- Kipcak, A.S. Microwave drying kinetics of mussels (Mytilus edulis). Res. Chem. Intermed. 2017, 43, 1429–1445. [Google Scholar] [CrossRef]

- Doe, P.; Olley, J. Drying and dried fish products. In Seafood; CRC Press: Boca Raton, FL, USA, 2020; pp. 125–145. [Google Scholar]

- Shabbir, I.; Mirzaeian, M. Feasibility analysis of different cogeneration systems for a paper mill to improve its energy efficiency. Int. J. Hydrogen Energy 2016, 41, 16535–16548. [Google Scholar] [CrossRef]

- Aksoy, A.; Karasu, S.; Akcicek, A.; Kayacan, S. Effects of different drying methods on drying kinetics, microstructure, color, and the rehydration ratio of minced meat. Foods 2019, 8, 216. [Google Scholar] [CrossRef]

- Kocabay, Ö.G. The experimental study and modelling the drying kinetics of mussels using ultrasound assisted vacuum drying. J. Indian Chem. Soc. 2021, 98, 100148. [Google Scholar] [CrossRef]

- Bromberger Soquetta, M.; Schmaltz, S.; Wesz Righes, F.; Salvalaggio, R.; de Marsillac Terra, L. Effects of pretreatment ultrasound bath and ultrasonic probe, in osmotic dehydration, in the kinetics of oven drying and the physicochemical properties of beet snacks. J. Food Process. Preserv. 2018, 42, e13393. [Google Scholar] [CrossRef]

- Gong, Y.; Li, J.; Li, J.; Fan, L.; Wang, L. Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus. Foods 2023, 12, 671. [Google Scholar] [CrossRef]

- Kudra, T.; Mujumdar, A.S. Advanced Drying Technologies; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wang, X.; Xu, S.; Wu, Z.; Li, Y.; Wang, Y.; Wu, Z.; Zhu, G.; Yang, M. A novel ultrasound-assisted vacuum drying technique for improving drying efficiency and physicochemical properties of Schisandra chinensis extract powder. Food Sci. Nutr. 2022, 10, 49–59. [Google Scholar] [CrossRef]

- Chavan, P.; Sharma, P.; Sharma, S.R.; Mittal, T.C.; Jaiswal, A.K. Application of high-intensity ultrasound to improve food processing efficiency: A review. Foods 2022, 11, 122. [Google Scholar] [CrossRef]

- Wiktor, A.; Sledz, M.; Nowacka, M.; Rybak, K.; Witrowa-Rajchert, D. The influence of immersion and contact ultrasound treatment on selected properties of the apple tissue. Appl. Acoust. 2016, 103, 136–142. [Google Scholar] [CrossRef]

- Tayyab Rashid, M.; Liu, K.; Ahmed Jatoi, M.; Safdar, B.; Lv, D.; Wei, D. Developing ultrasound-assisted hot-air and infrared drying technology for sweet potatoes. Ultrason. Sonochem. 2022, 86, 106047. [Google Scholar] [CrossRef] [PubMed]

- Mierzwa, D.; Szadzińska, J.; Pawłowski, A.; Pashminehazar, R.; Kharaghani, A. Nonstationary convective drying of raspberries, assisted by microwaves and ultrasound. Dry. Technol. 2019, 37, 988–1001. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Aziz, M. Combined hot air, microwave, and infrared drying of hawthorn fruit: Effects of ultrasonic pretreatment on drying time, energy, qualitative, and bioactive compounds’ properties. Foods 2021, 10, 1006. [Google Scholar] [CrossRef] [PubMed]

- Ren, F.; Perussello, C.; Zhang, Z.; Kerry, J.P.; Tiwari, B.K. Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. LWT 2018, 87, 102–111. [Google Scholar] [CrossRef]

- Salehi, F.; Kashaninejad, M. Modeling of moisture loss kinetics and color changes in the surface of lemon slice during the combined infrared-vacuum drying. Inf. Process. Agric. 2018, 5, 516–523. [Google Scholar] [CrossRef]

- Baeghbali, V.; Niakousari, M.; Ngadi, M.O.; Hadi Eskandari, M. Combined ultrasound and infrared assisted conductive hydro-drying of apple slices. Dry. Technol. 2019, 37, 1793–1805. [Google Scholar] [CrossRef]

- Menges, H.O.; Ertekin, C. Mathematical modeling of thin layer drying of Golden apples. J. Food Eng. 2006, 77, 119–125. [Google Scholar] [CrossRef]

- Baghdadi, Y.; Hii, C. Mass transfer kinetics and effective diffusivities during Cocoa roasting. J. Eng. Sci. Technol. 2017, 12, 127–137. [Google Scholar]

- Özdemir, M.; Devres, Y.O. The thin layer drying characteristics of hazelnuts during roasting. J. Food Eng. 1999, 42, 225–233. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H. Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 2003, 44, 1111–1122. [Google Scholar] [CrossRef]

- Crisp, J.; Woods, J. The drying properties of rapeseed. J. Agric. Eng. Res. 1994, 57, 89–97. [Google Scholar] [CrossRef]

- Fikry, M.; Yusof, Y.A.; Al-Awaadh, A.M.; Rahman, R.A.; Chin, N.L.; Mousa, E.; Chang, L.S. Kinetics modelling of the colour, hardness, grinding energy consumption and oil yield changes during the conventional roasting of palm date seeds. Food Sci. Technol. Res. 2019, 25, 351–362. [Google Scholar] [CrossRef]

- Manzoor, S.; Yusof, Y.A.; Ling, C.N.; Tawakkal, I.S.M.A.; Fikry, M.; Sin, C.L. Thin-layer Drying Characteristics of Papaya (Carica papaya) Peel using Convection Oven and Microwave Drying. Pertanika J. Sci. Technol. 2019, 27, 1207–1226. [Google Scholar]

- İsmail, O.; Kocabay, O. Investigation of the effect of combined drying for rainbow trout fillets and comparison with hot-air drying. Turk. J. Fish. Aquat. Sci. 2020, 20, 701–709. [Google Scholar] [CrossRef]

- Tahmasebi, M.; Tavakkoli Hashjin, T.; Khoshtaghaza, M.; Nikbakht, A. Evaluation of thin-layer drying models for simulation of drying kinetics of quercus (Quercus persica and Quercus libani). J. Agric. Sci. Technol. 2011, 13, 155–163. [Google Scholar]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar] [CrossRef]

- Van Hecke, E.; Allaf, K.; Bouvier, J. Texture and structure of crispy-puffed food products part II: Mechanical properties in puncture. J. Texture Stud. 1998, 29, 617–632. [Google Scholar] [CrossRef]

- Saeleaw, M.; Schleining, G. A review: Crispness in dry foods and quality measurements based on acoustic–mechanical destructive techniques. J. Food Eng. 2011, 105, 387–399. [Google Scholar]

- Chandra, A.; Kumar, S.; Tarafdar, A.; Nema, P.K. Ultrasonic and osmotic pretreatments followed by convective and vacuum drying of papaya slices. J. Sci. Food Agric. 2021, 101, 2264–2272. [Google Scholar] [CrossRef]

- Fang, M.; Huang, G.-J.; Sung, W.-C. Mass transfer and texture characteristics of fish skin during deep-fat frying, electrostatic frying, air frying and vacuum frying. LWT 2021, 137, 110494. [Google Scholar] [CrossRef]

- Doymaz, İ. Drying behaviour of green beans. J. Food Eng. 2005, 69, 161–165. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin layers; Purdue University: West Lafayette, IN, USA, 1949. [Google Scholar]

- Babalis, S.J.; Papanicolaou, E.; Kyriakis, N.; Belessiotis, V.G. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica). J. Food Eng. 2006, 75, 205–214. [Google Scholar] [CrossRef]

- Doymaz, İ. Effect of pre-treatments using potassium metabisulphide and alkaline ethyl oleate on the drying kinetics of apricots. Biosyst. Eng. 2004, 89, 281–287. [Google Scholar] [CrossRef]

- Guiné, R. Analysis of the drying kinetics of S. Bartolomeu pears for different drying systems. EJournal Environ. Agric. Food Chem. 2010, 9, 1772–1783. [Google Scholar]

- Akpinar, E.K. Mathematical modelling and experimental investigation on sun and solar drying of white mulberry. J. Mech. Sci. Technol. 2008, 22, 1544–1553. [Google Scholar] [CrossRef]

- Rahman, M.S.; Perera, C.O.; Thebaud, C. Desorption isotherm and heat pump drying kinetics of peas. Food Res. Int. 1997, 30, 485–491. [Google Scholar] [CrossRef]

- Crank, J. The mathematics of Diffusion; Clarendon–Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Darvishi, H.; Asl, A.R.; Asghari, A.; Gazori, G. Mathematical modeling, moisture diffusion, energy consumption and efficiency of thin layer drying of potato slices. J. Food Process. Technol. 2013, 4, 215. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtagaza, M.H. Evaluation of energy consumption in different drying methods. Energy Convers. Manag. 2011, 52, 1192–1199. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Khalife, E.; Witrowa-Rajchert, D.; Nowacka, M. Effect of pretreatments on convective and infrared drying kinetics, energy consumption and quality of terebinth. Appl. Sci. 2021, 11, 7672. [Google Scholar] [CrossRef]

- Brahmi, F.; Mateos-Aparicio, I.; Mouhoubi, K.; Guemouni, S.; Sahki, T.; Dahmoune, F.; Belmehdi, F.; Bessai, C.; Madani, K.; Boulekbache-Makhlouf, L. Kinetic Modeling of Convective and Microwave Drying of Potato Peels and Their Effects on Antioxidant Content and Capacity. Antioxidants 2023, 12, 638. [Google Scholar] [CrossRef] [PubMed]

- EL-Mesery, H.S.; El-Khawaga, S. Drying process on biomass: Evaluation of the drying performance and energy analysis of different dryers. Case Stud. Therm. Eng. 2022, 33, 101953. [Google Scholar] [CrossRef]

- Ghanbarian, D.; Torki-Harchegani, M.; Sadeghi, M.; Pirbalouti, A.G. Ultrasonically improved convective drying of peppermint leaves: Influence on the process time and energetic indices. Renew. Energy 2020, 153, 67–73. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Banakar, A.; Ghobadian, B.; Khoshtaghaza, M.H. Comparison of energy parameters in various dryers. Energy Convers. Manag. 2014, 87, 711–725. [Google Scholar] [CrossRef]

- Başlar, M.; Kılıçlı, M.; Yalınkılıç, B. Dehydration kinetics of salmon and trout fillets using ultrasonic vacuum drying as a novel technique. Ultrason. Sonochem. 2015, 27, 495–502. [Google Scholar] [CrossRef]

- Fikry, M.; Al-Awaadh, A.M. Characteristics of dynamics sorption isotherms of Date flesh powder rich in fiber. Int. J. Food Eng. 2016, 12, 469–480. [Google Scholar] [CrossRef]

- Al-Awaadh, A.M.; Hassan, B.H.; Ahmed, K.M. Hot air drying characteristics of Sukkari date (Phoenix dactylifera L.) and effects of drying condition on fruit color and texture. Int. J. Food Eng. 2015, 11, 421–434. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; Wang, Y.; Lv, W.-Q.; Li, D.; Wang, L.-J. Freeze-thaw and ultrasound pretreatment before microwave combined drying affects drying kinetics, cell structure and quality parameters of Platycodon grandiflorum. Ind. Crops Prod. 2021, 164, 113391. [Google Scholar] [CrossRef]

- Darvishi, H.; Azadbakht, M.; Rezaeiasl, A.; Farhang, A. Drying characteristics of sardine fish dried with microwave heating. J. Saudi Soc. Agric. Sci. 2013, 12, 121–127. [Google Scholar] [CrossRef]

- Mohd Rozainee, T.; Ng, P. Microwave assisted hot air convective dehydration of fish slice: Drying characteristics, energy aspects and colour assessment. In Proceedings of the World Engineering Congress 2010-Conference on Advanced Processes and Materials, London, UK, 30 June–2 July 2010; pp. 41–46. [Google Scholar]

- Fernandes, F.A.; Oliveira, F.I.; Rodrigues, S. Use of ultrasound for dehydration of papayas. Food Bioprocess Technol. 2008, 1, 339–345. [Google Scholar] [CrossRef]

- Zogzas, N.; Maroulis, Z.; Marinos-Kouris, D. Moisture diffusivity data compilation in foodstuffs. Dry. Technol. 1996, 14, 2225–2253. [Google Scholar] [CrossRef]

- da Silva Lima, R.; Nunes, I.L.; Block, J.M. Ultrasound-assisted extraction for the recovery of carotenoids from guava’s pulp and waste powders. Plant Foods Hum. Nutr. 2020, 75, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Chen, G. Drying kinetic, quality, energy and exergy performance of hot air-rotary drum drying of green peas using adaptive neuro-fuzzy inference system. Food Bioprod. Process. 2020, 124, 168–183. [Google Scholar]

- Nilsuwan, K.; Fusang, K.; Pripatnanont, P.; Benjakul, S. Properties and characteristics of acid-soluble collagen from salmon skin defatted with the aid of ultrasonication. Fishes 2022, 7, 51. [Google Scholar] [CrossRef]

- Sabarez, H.; Gallego-Juarez, J.; Riera, E. Ultrasonic-assisted convective drying of apple slices. Dry. Technol. 2012, 30, 989–997. [Google Scholar] [CrossRef]

- Rajewska, K.; Mierzwa, D. Influence of ultrasound on the microstructure of plant tissue. Innov. Food Sci. Emerg. Technol. 2017, 43, 117–129. [Google Scholar] [CrossRef]

| Responses * | Temperature (°C) | SS (Mean ± Standard Deviation) | US-SS (Mean ± Standard Deviation) |

|---|---|---|---|

| Moisture Content (g/g, d.b.) | 45 | 0.082 Aa ± 0.02 | 0.062 Aa ± 0.01 |

| 55 | 0.071 Aa ± 0.01 | 0.068 Aa ± 0.02 | |

| 65 | 0.075 Aa ± 0.01 | 0.078 Aa ± 0.01 | |

| Water activity (aw) | 45 | 0.576 Aa ± 0.002 | 0.530 Bb ± 0.004 |

| 55 | 0.585 Aa ± 0.014 | 0.539 Bab ± 0.014 | |

| 65 | 0.586 Aa ± 0.01 | 0.559 Ba ± 0.007 | |

| Drying time (h) | 45 | 10.08 Aa ± 0.195 | 8.42 Ba ± 0.07 |

| 55 | 6.83 Ab ± 0.215 | 5.60 Bb ± 0.07 | |

| 65 | 3.75 Ac ± 0.065 | 2.92 Bc ± 0.11 | |

| SEC (MJ/kg water) | 45 | 98.02 Aa ± 4.82 | 85.39 Ba ± 2.2 |

| 55 | 68.2 Ab ± 2.15 | 56.05 Bb ± 0.80 | |

| 65 | 37.97 Ac ± 1.11 | 29.50 Bc ± 1.24 |

| Model | Parameters * | SS | US-SS | ||||

|---|---|---|---|---|---|---|---|

| 45 | 55 | 65 | 45 | 55 | 65 | ||

| Lewis | k | 0.222 | 0.414 | 0.951 | 0.274 | 0.531 | 0.98 |

| R2 | 0.992 | 0.992 | 0.994 | 0.994 | 0.997 | 0.995 | |

| X2 | 0.001 | 0.001 | 0.001 | 0.001 | 0.000 | 0.002 | |

| RMSE | 0.029 | 0.029 | 0.024 | 0.027 | 0.017 | 0.041 | |

| Page | k | 0.139 | 0.374 | 0.979 | 0.228 | 0.508 | 0.928 |

| n | 1.327 | 1.129 | 0.865 | 1.139 | 1.07 | 1.274 | |

| R2 | 0.995 | 0.996 | 0.999 | 0.999 | 0.998 | 0.999 | |

| X2 | 0.0006 | 0.0007 | 0.0002 | 0.000 | 0.000 | 0.000 | |

| RMSE | 0.0203 | 0.0219 | 0.0116 | 0.014 | 0.015 | 0.018 | |

| Modified Page | k | 0.226 | 0.419 | 0.976 | 0.532 | 0.938 | 0.532 |

| n | 1.326 | 1.115 | 0.865 | 1.064 | 1.290 | 1.064 | |

| R2 | 0.998 | 0.998 | 0.999 | 0.999 | 0.999 | 0.999 | |

| X2 | 0.001 | 0.001 | 0.000 | 0.000 | 0.000 | 0.000 | |

| RMSE | 0.022 | 0.022 | 0.012 | 0.014 | 0.019 | 0.014 | |

| Henderson and Pabis | a | 1.048 | 1.032 | 0.981 | 1.024 | 1.013 | 1.029 |

| k | 0.235 | 0.431 | 0.932 | 0.282 | 0.539 | 1.005 | |

| R2 | 0.981 | 0.994 | 0.995 | 0.995 | 0.998 | 0.994 | |

| X2 | 0.003 | 0.001 | 0.001 | 0.001 | 0.000 | 0.002 | |

| RMSE | 0.046 | 0.028 | 0.025 | 0.024 | 0.017 | 0.040 | |

| Verma | a | −20.933 | −24.194 | 0.849 | −29.12 | −40.29 | −71.30 |

| b | −0.093 | −0.316 | −5.112 | −0.15 | −0.39 | −0.55 | |

| k | 0.088 | 0.312 | 0.807 | 0.15 | 0.39 | 0.55 | |

| R2 | 0.992 | 0.993 | 0.999 | 0.999 | 0.998 | 0.997 | |

| X2 | 0.001 | 0.001 | 0.000 | 0.000 | 0.000 | 0.0014 | |

| RMSE | 0.029 | 0.027 | 0.012 | 0.009 | 0.016 | 0.0278 | |

| Two-term Exponential | a | 0.849 | 0.000 | 0.005 | 0.58 | 0.506 | 0.013 |

| b | 0.151 | 1.035 | 1.043 | 0.44 | 0.507 | 1.016 | |

| k | 0.807 | −3.611 | 0.235 | 0.28 | 0.539 | 1.005 | |

| k1 | 5.113 | 0.434 | 0.235 | 0.28 | 0.539 | 1.005 | |

| R2 | 0.999 | 0.995 | 0.996 | 0.995 | 0.998 | 0.994 | |

| X2 | 0.0005 | 0.0019 | 0.0076 | 0.002 | 0.001 | 0.005 | |

| RMSE | 0.0122 | 0.0232 | 0.0465 | 0.024 | 0.017 | 0.040 | |

| Vega-Lemus | a | 1.007 | 1.001 | 0.966 | 0.989 | 0.985 | 0.999 |

| k | −0.088 | −0.164 | 0.312 | −0.098 | −0.194 | −0.357 | |

| R2 | 0.996 | 0.983 | 0.969 | 0.994 | 0.988 | 0.998 | |

| X2 | 0.0005 | 0.0032 | 0.0044 | 0.001 | 0.002 | 0.001 | |

| RMSE | 0.0194 | 0.0481 | 0.0561 | 0.023 | 0.039 | 0.028 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fikry, M.; Benjakul, S.; Al-Ghamdi, S.; Tagrida, M.; Prodpran, T. Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment. Foods 2023, 12, 3024. https://doi.org/10.3390/foods12163024

Fikry M, Benjakul S, Al-Ghamdi S, Tagrida M, Prodpran T. Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment. Foods. 2023; 12(16):3024. https://doi.org/10.3390/foods12163024

Chicago/Turabian StyleFikry, Mohammad, Soottawat Benjakul, Saleh Al-Ghamdi, Mohamed Tagrida, and Thummanoon Prodpran. 2023. "Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment" Foods 12, no. 16: 3024. https://doi.org/10.3390/foods12163024

APA StyleFikry, M., Benjakul, S., Al-Ghamdi, S., Tagrida, M., & Prodpran, T. (2023). Evaluating Kinetics of Convection Drying and Microstructure Characteristics of Asian Seabass Fish Skin without and with Ultrasound Pretreatment. Foods, 12(16), 3024. https://doi.org/10.3390/foods12163024