Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake

Abstract

1. Introduction

2. Materials and Methods

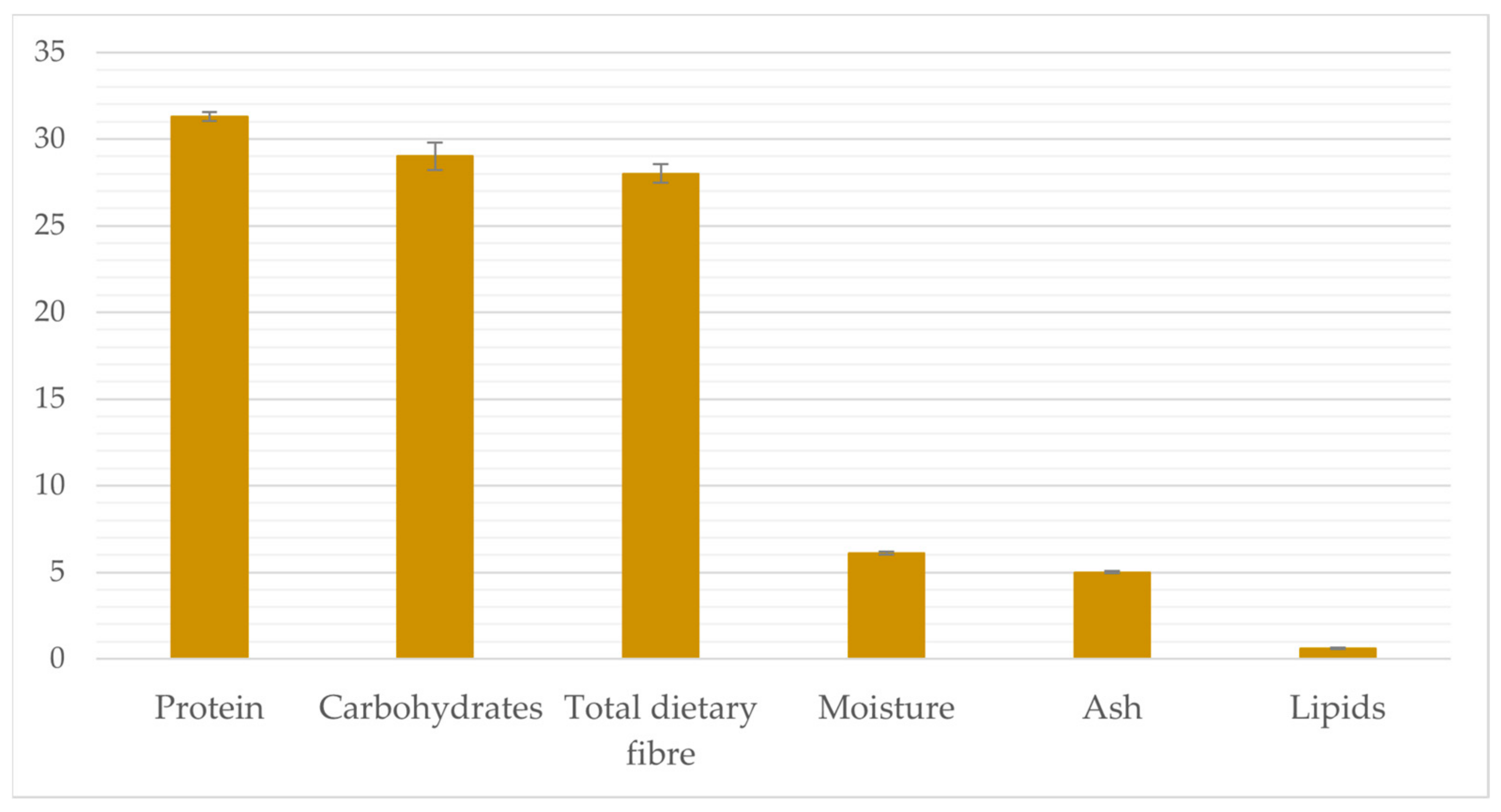

2.1. Basic Ingredients

2.2. Experimental Design and Preparation of the Snack Bars

2.3. Determination of the Chemical Composition

2.4. Texture Analysis

2.5. Sensory Analysis

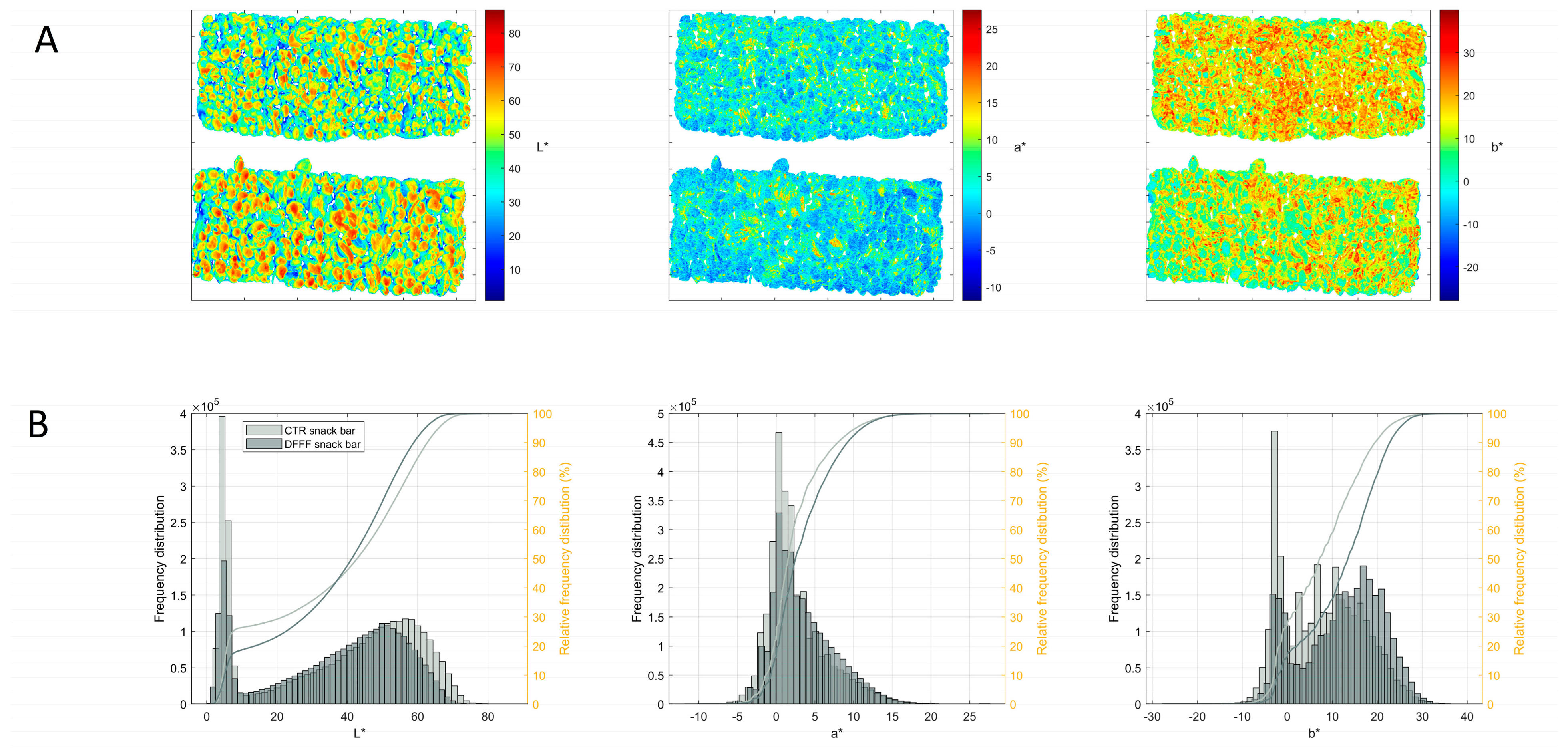

2.6. Colour Analysis

2.7. Statistical Analysis

3. Results and Discussion

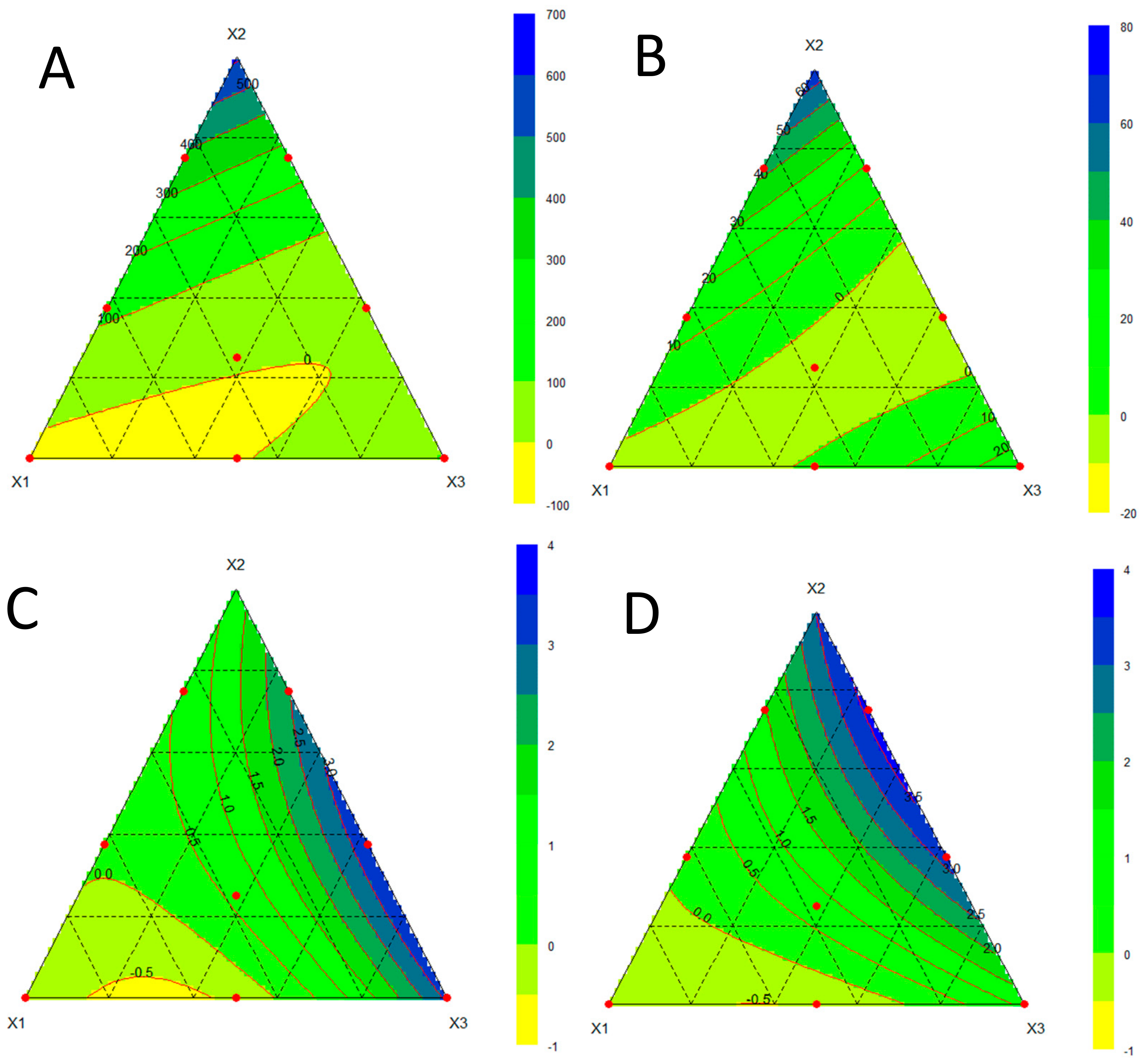

3.1. Identification of the Optimal Formulation

3.2. Nutritional, Textural, and Sensorial Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Global Food Losses and food Waste. Extent, Causes and Prevention. 2011. Available online: https://www.fao.org/3/mb060e/mb060e00.pdf (accessed on 18 March 2023).

- Onipe, O.O.; Ramashia, S.E.; Jideani, A.I. Wheat bran modifications for enhanced nutrition and functionality in selected food products. Molecules 2021, 26, 3918. [Google Scholar] [CrossRef] [PubMed]

- Prueckler, M.; Siebenhandl-Ehn, S.; Apprich, S.; Hoeltinger, S.; Haas, C.; Schmid, E.; Kneifel, W. Wheat bran-based biorefinery 1: Composition of wheat bran and strategies of functionalization. LWT-Food Sci. Technol. 2014, 56, 211–221. [Google Scholar] [CrossRef]

- Onipe, O.O.; Jideani, A.I.; Beswa, D. Composition and functionality of wheat bran and its application in some cereal food products. Int. J. Food Sci. Technol. 2015, 50, 2509–2518. [Google Scholar] [CrossRef]

- Squeo, G.; Silletti, R.; Napoletano, G.; Greco Miani, M.; Difonzo, G.; Pasqualone, A.; Caponio, F. Characterization and Effect of Refining on the Oil Extracted from Durum Wheat By-Products. Foods 2022, 11, 683. [Google Scholar] [CrossRef]

- Vurro, F.; Greco Miani, M.; Summo, C.; Caponio, F.; Pasqualone, A. Effect of durum wheat oil on the physico-chemical and sensory features of biscuits. Foods 2022, 11, 1282. [Google Scholar] [CrossRef]

- Vurro, F.; Summo, C.; Squeo, G.; Caponio, F.; Pasqualone, A. The Use of Durum Wheat Oil in the Preparation of Focaccia: Effects on the Oxidative Stability and Physical and Sensorial Properties. Foods 2022, 11, 2679. [Google Scholar] [CrossRef]

- Schutyser, M.A.I.; Van der Goot, A.J. The potential of dry fractionation processes for sustainable plant protein production. Trends Food Sci Technol. 2011, 22, 154–164. [Google Scholar] [CrossRef]

- Bühler, J.M.; Schlangen, M.; Möller, A.C.; Bruins, M.E.; van der Goot, A.J. Starch in plant-based meat replacers: A new approach to using endogenous starch from cereals and legumes. Starch-Stärke 2022, 74, 2100157. [Google Scholar] [CrossRef]

- Verardo, V.; Gόmez-Caravaca, A.M.; Messia, M.C.; Marconi, E.; Caboni, M.F. Development of functional spaghetti enriched in bioactive compounds using barley coarse fraction obtained by air classification. J. Agric. Food Chem. 2011, 59, 9127–9134. [Google Scholar] [CrossRef]

- Silventoinen, P.; Kortekangas, A.; Ercili-Cura, D.; Nordlund, E. Impact of ultra-fine milling and air classification on biochemical and techno-functional characteristics of wheat and rye bran. Food Res. Int. 2021, 139, 109971. [Google Scholar] [CrossRef]

- Pojić, M.; Mišan, A.; Tiwari, B. Eco-innovative technologies for extraction of proteins for human consumption from renewable protein sources of plant origin. Trends Food Sci. Technol. 2018, 75, 93–104. [Google Scholar] [CrossRef]

- Alcorta, A.; Porta, A.; Tárrega, A.; Alvarez, M.D.; Vaquero, M.P. Foods for plant-based diets: Challenges and innovations. Foods 2021, 10, 293. [Google Scholar] [CrossRef]

- GFI, The Good Food Institute. U.S. Retail Market Insights–Plant-Based Foods. 2021. Available online: https://gfi.org/wp-content/uploads/2022/03/2021-U.S.-retail-market-insights_Plant-based-foods-GFI.pdf (accessed on 20 April 2023).

- López-Martínez, M.I.; Miguel, M.; Garcés-Rimón, M. Protein and sport: Alternative sources and strategies for bioactive and sustainable sports nutrition. Front. Nutr. 2022, 9, 926043. [Google Scholar] [CrossRef]

- Westberg, K.; Stavros, C.; Parker, L.; Powell, A.; Martin, D.M.; Worsley, A.; Fouvy, D. Promoting healthy eating in the community sport setting: A scoping review. Health Promot. Int. 2022, 37, 1–17. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Extrusion effect on proximate composition, starch and dietary fibre of ready-to-eat products based on rice fortified with carob fruit and bean. LWT-Food Sci. Technol. 2019, 111, 387–393. [Google Scholar] [CrossRef]

- Gill, A.; Meena, G.S. Formulation of functional energy bars using dairy and non-dairy ingredients: A review. Int. J. Chem. Stud. 2020, 8, 1337–1342. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Cieśluk, P.; Barwińska, M.; Marczak, W.; Ordyniak, A.; Lenart, A.; Janowicz, M. Eating habits and sustainable food production in the development of innovative “healthy” snacks. Sustainability 2019, 11, 2800. [Google Scholar] [CrossRef]

- Anandito, R.B.K.; Nurhartadi, E.; Agustiani, R.B. Formulation of snack bars made from black rice bran (Oryza sativa L.) and sweet potato flour (Ipomoea batatas L.). Conf. Ser. Earth Environ. Sci. 2021, 828, 12028. [Google Scholar]

- Asioli, D.; Aschemann-Witzel, J.; Caputo, V.; Vecchio, R.; Annunziata, A.; Næs, T.; Varela, P. Making sense of the “clean label” trends: A review of consumer food choice behavior and discussion of industry implications. Food Res. Int. 2017, 99, 58–71. [Google Scholar] [CrossRef]

- Osborn, S. Labelling relating to natural ingredients and additives. In Advances in Food and Beverage Labelling; Woodhead Publishing: Sawston, UK, 2015; pp. 207–221. [Google Scholar]

- Boukid, F.; Klerks, M.; Pellegrini, N.; Fogliano, V.; Sanchez-Siles, L.; Roman, S.; Vittadini, E. Current and emerging trends in cereal snack bars: Implications for new product development. Int. J. Food Sci. Nutr. 2022, 73, 610–629. [Google Scholar] [CrossRef]

- Singh, A.; Kumari, A.; Chauhan, A.K. Formulation and evaluation of novel functional snack bar with amaranth, rolled oat, and unripened banana peel powder. J. Food Sci. Technol. 2022, 59, 3511–3521. [Google Scholar] [CrossRef] [PubMed]

- Baurina, A.V.; Baurin, D.V.; Shakir, I.V.; Panfilov, V.I. Use of Sunflower Protein in Snack Bars. Chem. Eng. Trans. 2021, 87, 1–6. [Google Scholar]

- De Sousa, M.F.; Guimarães, R.M.; de Oliveira Araújo, M.; Barcelos, K.R.; Carneiro, N.S.; Lima, D.S.; Egea, M.B. Characterization of corn (Zea mays L.) bran as a new food ingredient for snack bars. LWT-Food Sci. Technol. 2019, 101, 812–818. [Google Scholar] [CrossRef]

- Meethal, S.M.; Kaur, N.; Singh, J.; Gat, Y. Effect of addition of jackfruit seed flour on nutrimental, phytochemical and sensory properties of snack bar. Curr. Res. Nutr. Food Sci. 2017, 5, 154–158. [Google Scholar] [CrossRef]

- Squeo, G.; De Angelis, D.; Leardi, R.; Summo, C.; Caponio, F. Background, applications and issues of the experimental designs for mixture in the food sector. Foods 2021, 10, 1128. [Google Scholar] [CrossRef]

- Leardi, R. D-Optimal Designs. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; Wiley: Hoboken, NJ, USA, 2006; pp. 1–11. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International. In AOAC International, 18th ed.; AOAC: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Costantini, M.; Summo, C.; Faccia, M.; Caponio, F.; Pasqualone, A. Kabuli and Apulian black chickpea milling by-products as innovative ingredients to provide high levels of dietary fibre and bioactive compounds in gluten-free fresh pasta. Molecules 2021, 26, 4442. [Google Scholar] [CrossRef]

- Pasqualone, A.; Makhlouf, F.Z.; Barkat, M.; Difonzo, G.; Summo, C.; Squeo, G.; Caponio, F. Effect of acorn flour on the physico-chemical and sensory properties of biscuits. Heliyon 2019, 5, e02242. [Google Scholar] [CrossRef]

- Amigo, J.M.; Babamoradi, H.; Elcoroaristizabal, S. Hyperspectral image analysis. A tutorial. Anal. Chim. 2015, 896, 34–51. [Google Scholar] [CrossRef]

- Leardi, R.; Melzi, C.; Polotti, G. CAT (Chemometric Agile Tool). 2013. Available online: http://gruppochemiometria.it/index.php/software (accessed on 20 April 2023).

- Kim, E.J.; Corrigan, V.K.; Hedderley, D.I.; Motoi, L.; Wilson, A.J.; Morgenstern, M.P. Predicting the sensory texture of cereal snack bars using instrumental measurements. J. Texture Stud. 2009, 40, 457–481. [Google Scholar] [CrossRef]

- Ciudad-Mulero, M.; Fernández-Ruiz, V.; Matallana-González, M.C.; Morales, P. Dietary fiber sources and human benefits: The case study of cereal and pseudocereals. Adv. Food Nutr. Res. 2019, 90, 83–134. [Google Scholar]

- European Parliament. Regulation (EU) 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers. Off. J. Eur. Comm. 2011, L304, 18–63. [Google Scholar]

- EFSA. Sets European Dietary Reference Values for Nutrient Intakes. 2010. Available online: https://www.efsa.europa.eu/en/press/news/nda100326 (accessed on 25 June 2023).

- Garcia, M.C.; Lobato, L.P.; Benassi, M.D.T.; Soares Júnior, M.S. Application of roasted rice bran in cereal bars. Food Sci. Technol. 2012, 32, 718–724. [Google Scholar] [CrossRef]

- Zhubi-Bakija, F.; Bajraktari, G.; Bytyçi, I.; Mikhailidis, D.P.; Henein, M.Y.; Latkovskis, G.; Zirlik, A. The impact of type of dietary protein, animal versus vegetable, in modifying cardiometabolic risk factors: A position paper from the International Lipid Expert Panel (ILEP). Clin. Nutr. 2021, 40, 255–276. [Google Scholar] [CrossRef]

- Camerotto, C.; Cupisti, A.; D’Alessandro, C.; Muzio, F.; Gallieni, M. Dietary fiber and gut microbiota in renal diets. Nutrients 2019, 11, 2149. [Google Scholar] [CrossRef]

- European Parliament and the Council. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, L304, 9–25. [Google Scholar]

- Umme, H.; Ashadujjaman, R.M.; Mehedi, H.M.; Afroz, T.M.; Delara, A.; Rahman, M.M.A. Nutritional, textural, and sensory quality of bars enriched with banana flour and pumpkin seed flour. Foods Raw Mater. 2021, 9, 282–289. [Google Scholar]

- Mathu, M.; Kumari, A. Processing & utilization of fruits and vegetable in cereal, legume and pseudo cereal based composite bars. J. Pharm. Innov. 2022, 11, 42–54. [Google Scholar]

- Zulaikha, Y.; Yao, S.H.; Chang, Y.W. Physicochemical and Functional Properties of Snack Bars Enriched with Tilapia (Oreochromis niloticus) By-Product Powders. Foods 2021, 10, 1908. [Google Scholar] [CrossRef]

- Miquel-Kergoat, S.; Azais-Braesco, V.; Burton-Freeman, B.; Hetherington, M.M. Effects of chewing on appetite, food intake and gut hormones: A systematic review and meta-analysis. Physiol. Behav. 2015, 151, 88–96. [Google Scholar] [CrossRef]

- Silva, J.S.; Damiani, C.; Silva, E.P.; Ruffi, C.R.G.; Asquieri, E.R.; Vilas Boas, E.V.D.B. Effect of marolo (Annona crassiflora Mart.) pulp flour addition in food bars. J. Food Qual. 2018, 2018, 8639525. [Google Scholar] [CrossRef]

- Arsa, S.; Theerakulkait, C. Preparation, aroma characteristics and volatile compounds of flavorings from enzymatic hydrolyzed rice bran protein concentrate. J. Sci. Food Agric. 2018, 98, 4479–4487. [Google Scholar] [CrossRef] [PubMed]

| Experiment | Dry-Fractionated Fine Fraction of Defatted Durum Wheat Cake—X1 (g 100 g−1) | Glucose Syrup—X2 (g 100 g−1) | Puffed/Rolled Cereal Mix—X3 (g 100 g−1) |

|---|---|---|---|

| 1 | 50 | 30 | 20 |

| 2 | 20 | 60 | 20 |

| 3 | 10 | 60 | 30 |

| 4 | 10 | 30 | 60 |

| 5 | 10 | 45 | 45 |

| 6 | 35 | 45 | 20 |

| 7 | 25 | 40 | 35 |

| 8 | 30 | 30 | 40 |

| Parameter | DFFF-Enriched Snack Bar | Control Snack Bar | ||||

|---|---|---|---|---|---|---|

| Amount per 100 g | Amount per Unit (33 g) | % Daily Value per Unit (33 g) * | Amount per 100 g | Amount per Unit (33 g) | % Daily Value per Unit (33 g) * | |

| Moisture (g) | 8.3 ± 0.11 b | 2.7 | - | 9.3 ± 0.17 a | 3.2 | - |

| Protein (g) | 9.7 ± 0.24 a | 3.2 | 6.4 | 6.5 ± 0.08 b | 2.3 | 4.3 |

| Total dietary fibre (g) | 3.2 ± 0.20 a | 1.1 | 4.2 | 2.3 ± 0.31 b | 0.8 | 3.0 |

| Lipids (g) | 1.4 ± 0.09 a | 0.5 | 0.7 | 1.4 ± 0.04 a | 0.5 | 0.7 |

| Carbohydrates (g) | 76.4 ± 0.36 b | 25.2 | 9.8 | 80.1 ± 0.63 a | 26.4 | 10.2 |

| Energy value (kcal) | 363 | 120 | 6.0 | 364 | 120 | 6.0 |

| Parameter | Type of Snack Bar | |

|---|---|---|

| DFFF-Enriched | Control | |

| Cutting test | ||

| Cutting stress (N/mm2) | 1.2 ± 0.1 a | 0.52 ± 0.2 b |

| Deformation (mm) | 16.3 ± 0.29 a | 14.7 ± 0.56 b |

| Three point-bending test | ||

| Fracture stress (N/mm2) | 12.9 ± 3.9 a | 9.8 ± 4.09 b |

| Deformation (mm) | 3.6 ± 0.8 a | 2.5 ± 1.07 b |

| Sensory Parameter | Type of Snack Bar | |

|---|---|---|

| DFFF-Enriched | Control | |

| Visual | ||

| Yellowish colour | 6.1 ± 1.2 a | 4.0 ± 0.9 b |

| Brightness | 5.0 ± 1.1 b | 7.1 ± 0.8 a |

| Homogeneity of the distribution of cereals | 6.8 ± 0.4 a | 7.0 ± 0.6 a |

| Flavour | ||

| Cereal-like | 6.8 ± 0.9 a | 6.8 ± 1.3 a |

| Toasted | 4.7 ± 1.2 a | 3.8 ± 1.0 a |

| Caramel | 4.1 ± 0.7 a | 2.2 ± 1.1 b |

| Abnormal odours | 0.2 ± 0.4 a | 0.3 ± 0.8 a |

| Taste | ||

| Sweetness | 4.5 ± 0.5 a | 4.1 ± 0.5 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Squeo, G.; Latrofa, V.; Vurro, F.; De Angelis, D.; Caponio, F.; Summo, C.; Pasqualone, A. Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake. Foods 2023, 12, 2547. https://doi.org/10.3390/foods12132547

Squeo G, Latrofa V, Vurro F, De Angelis D, Caponio F, Summo C, Pasqualone A. Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake. Foods. 2023; 12(13):2547. https://doi.org/10.3390/foods12132547

Chicago/Turabian StyleSqueo, Giacomo, Vittoria Latrofa, Francesca Vurro, Davide De Angelis, Francesco Caponio, Carmine Summo, and Antonella Pasqualone. 2023. "Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake" Foods 12, no. 13: 2547. https://doi.org/10.3390/foods12132547

APA StyleSqueo, G., Latrofa, V., Vurro, F., De Angelis, D., Caponio, F., Summo, C., & Pasqualone, A. (2023). Developing a Clean Labelled Snack Bar Rich in Protein and Fibre with Dry-Fractionated Defatted Durum Wheat Cake. Foods, 12(13), 2547. https://doi.org/10.3390/foods12132547