Effects of Sun Withering Degree on Black Tea Quality Revealed via Non-Targeted Metabolomics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Materials

2.2. Main Reagents

2.3. Black Tea Processing

2.4. Black Tea Sensory Quality Evaluation

2.5. Determination of Main Quality Components of Black Tea

2.6. UPLC-Q-TOF/MS Analysis of Non-Volatile Components of Black Tea

2.7. Analysis of Volatile Components of BLACK Tea by SAFE-GC-MS and HS-SPME-GC-MS

2.8. Data Statistics and Analysis

3. Results and Discussion

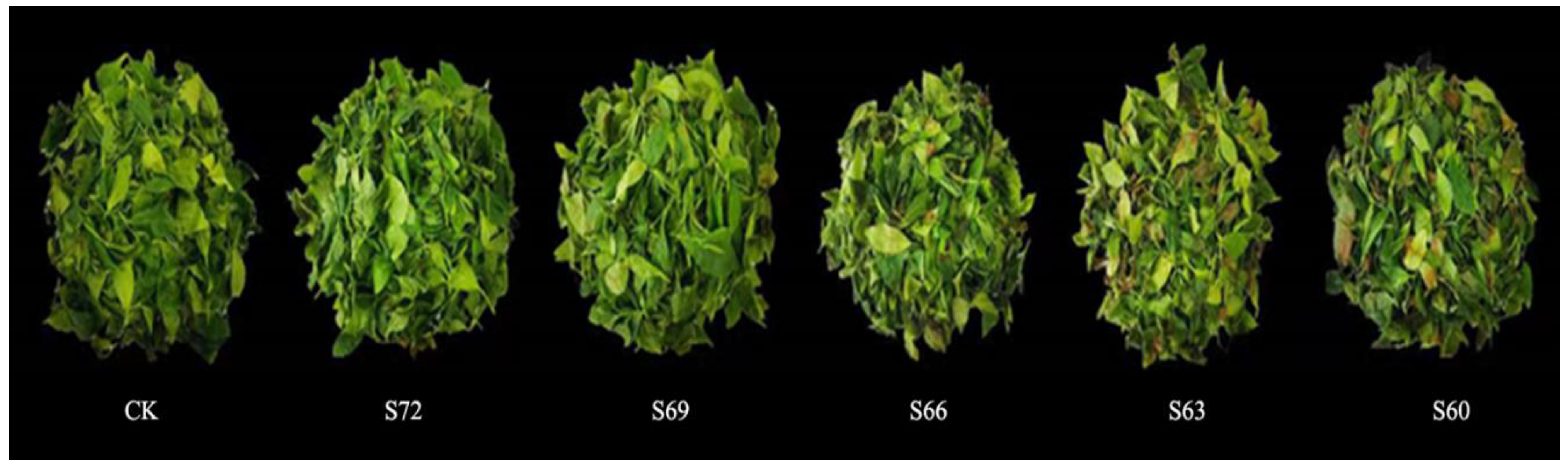

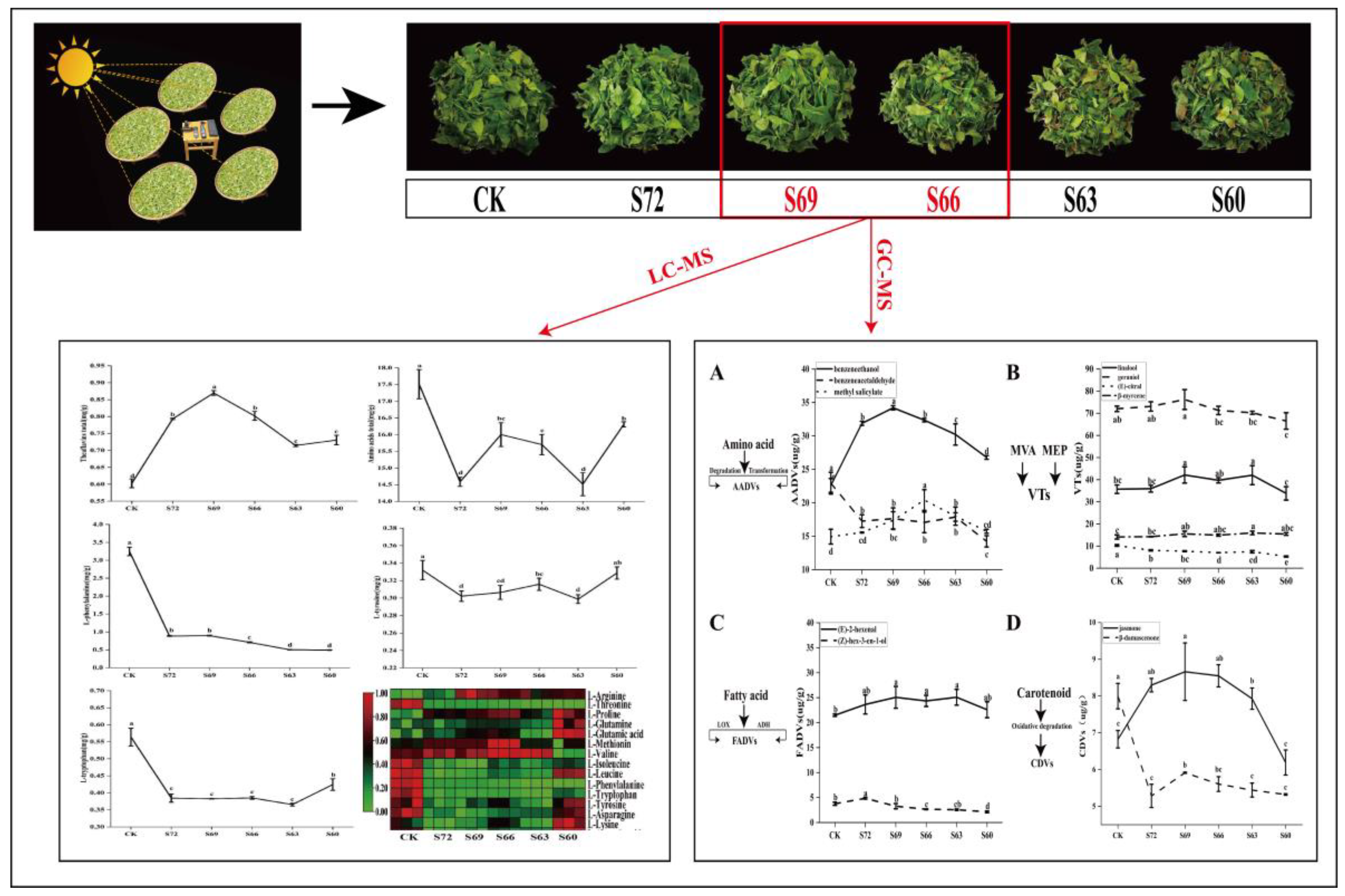

3.1. Effects of Different Sun Withering Degrees on the Appearance of Fresh Leaves

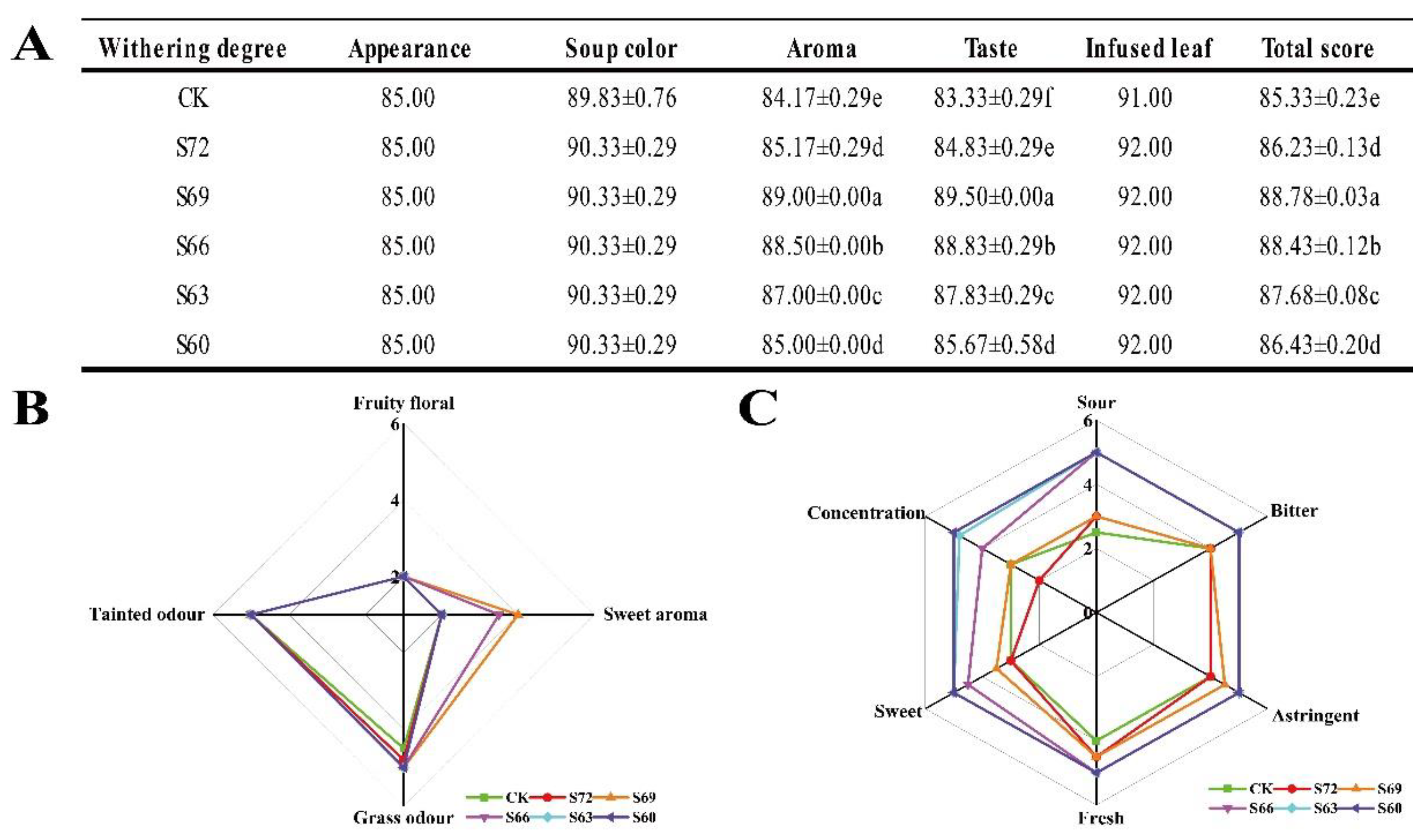

3.2. Effects of Different Sun Withering Degrees on the Sensory Quality of Black Tea

3.3. Effects of Different Sun Withering Degrees on the Main Quality Components of Tea Leaves

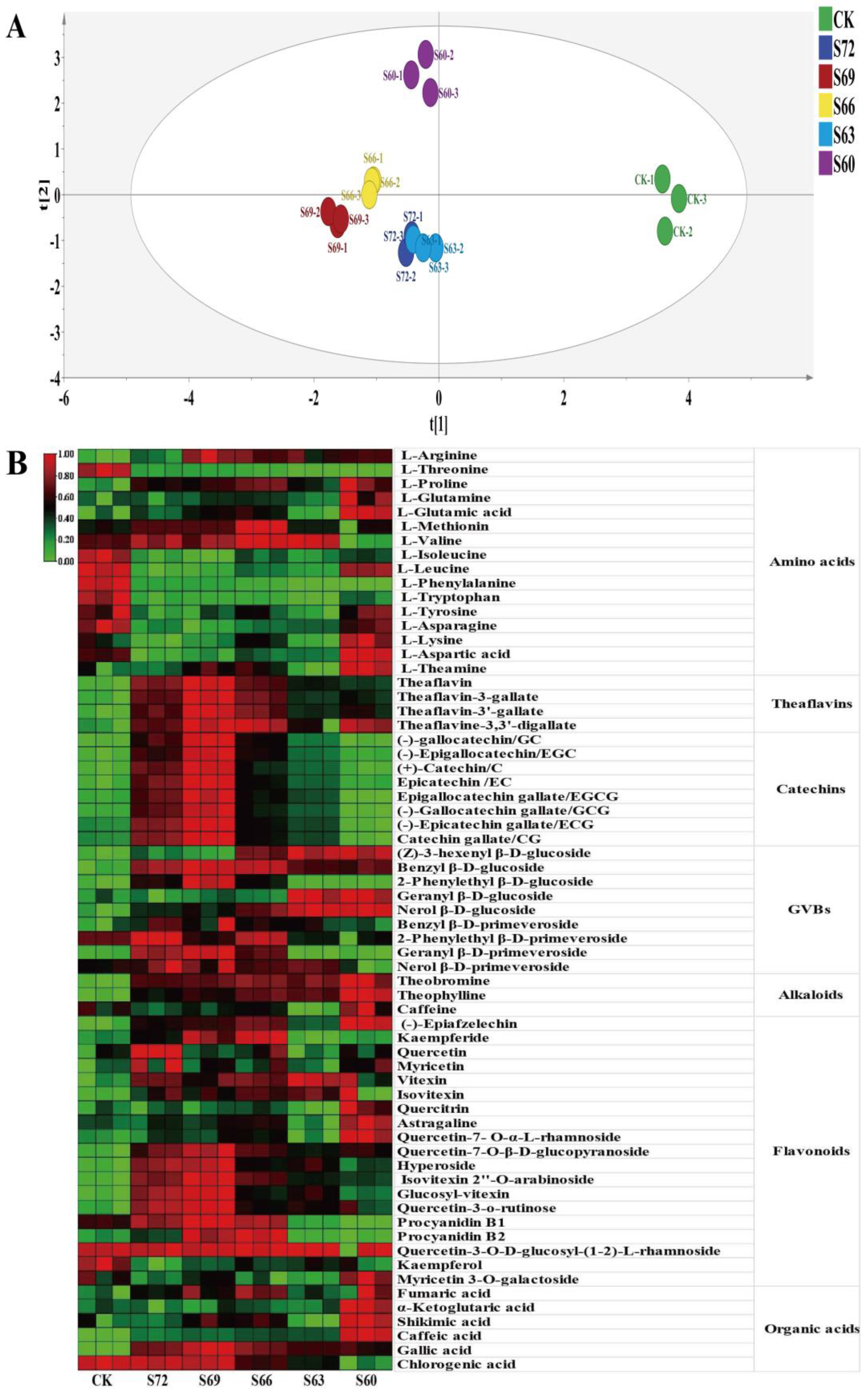

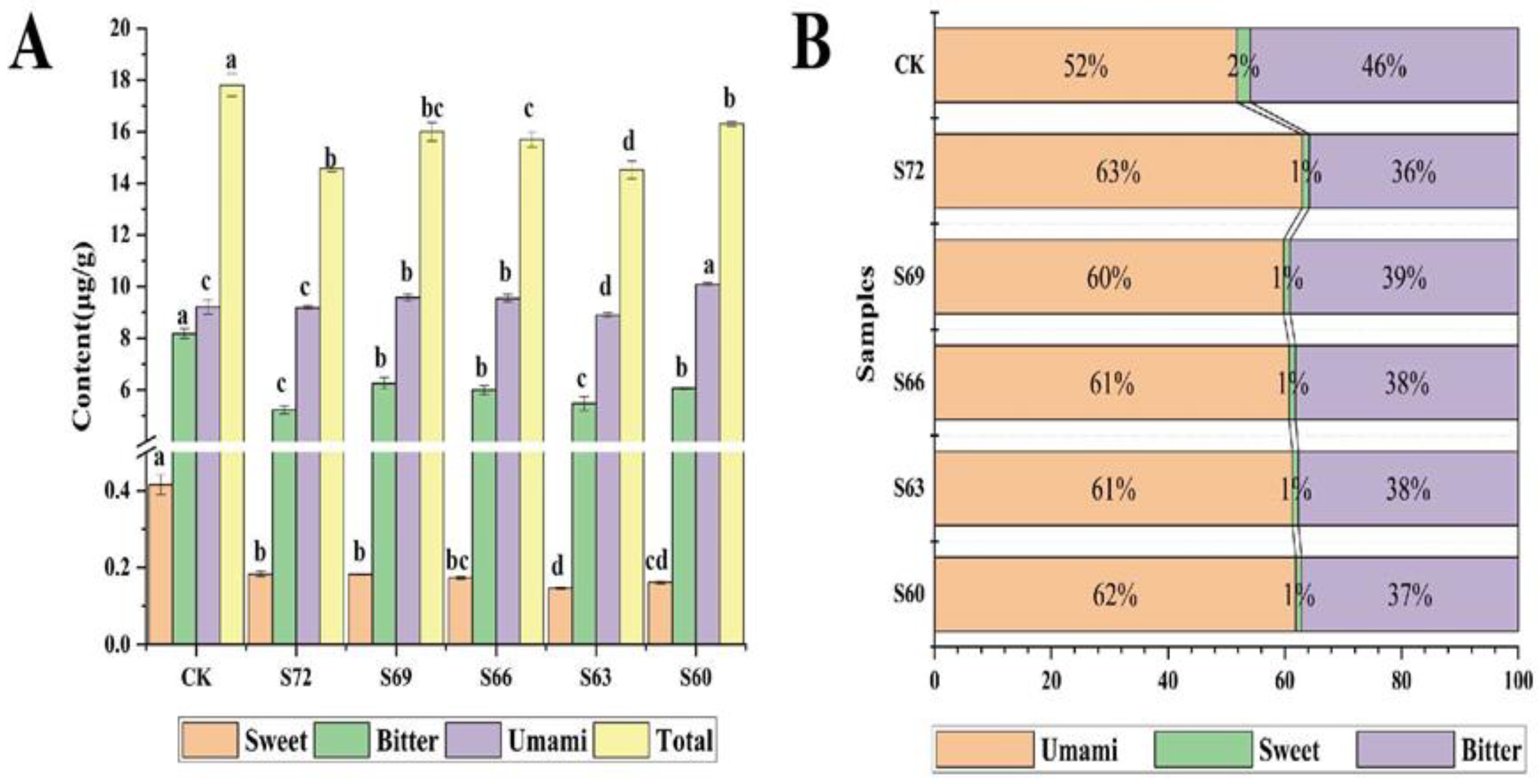

3.3.1. Effects of Different Sun Withering Degrees on Non-Volatile Components of Black Tea

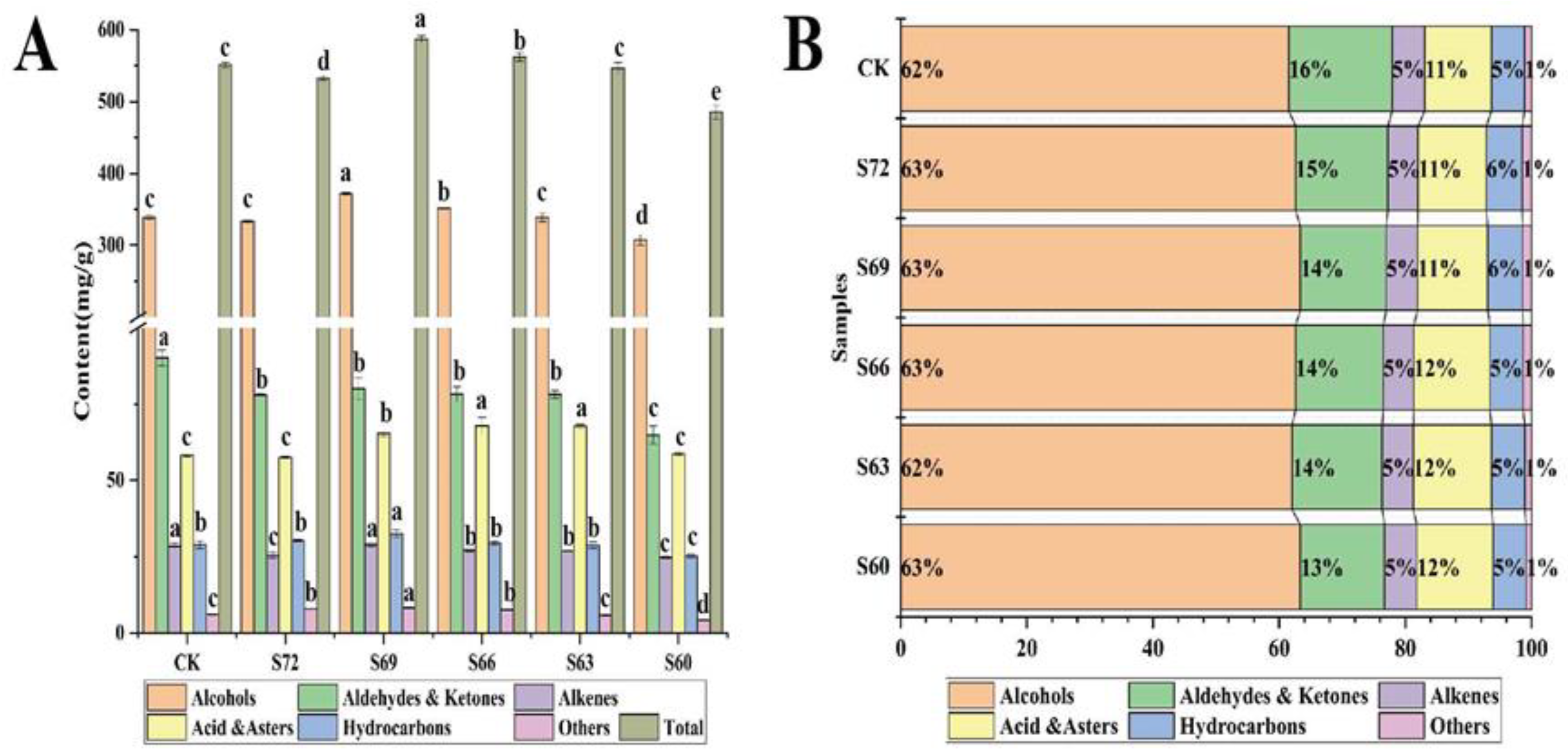

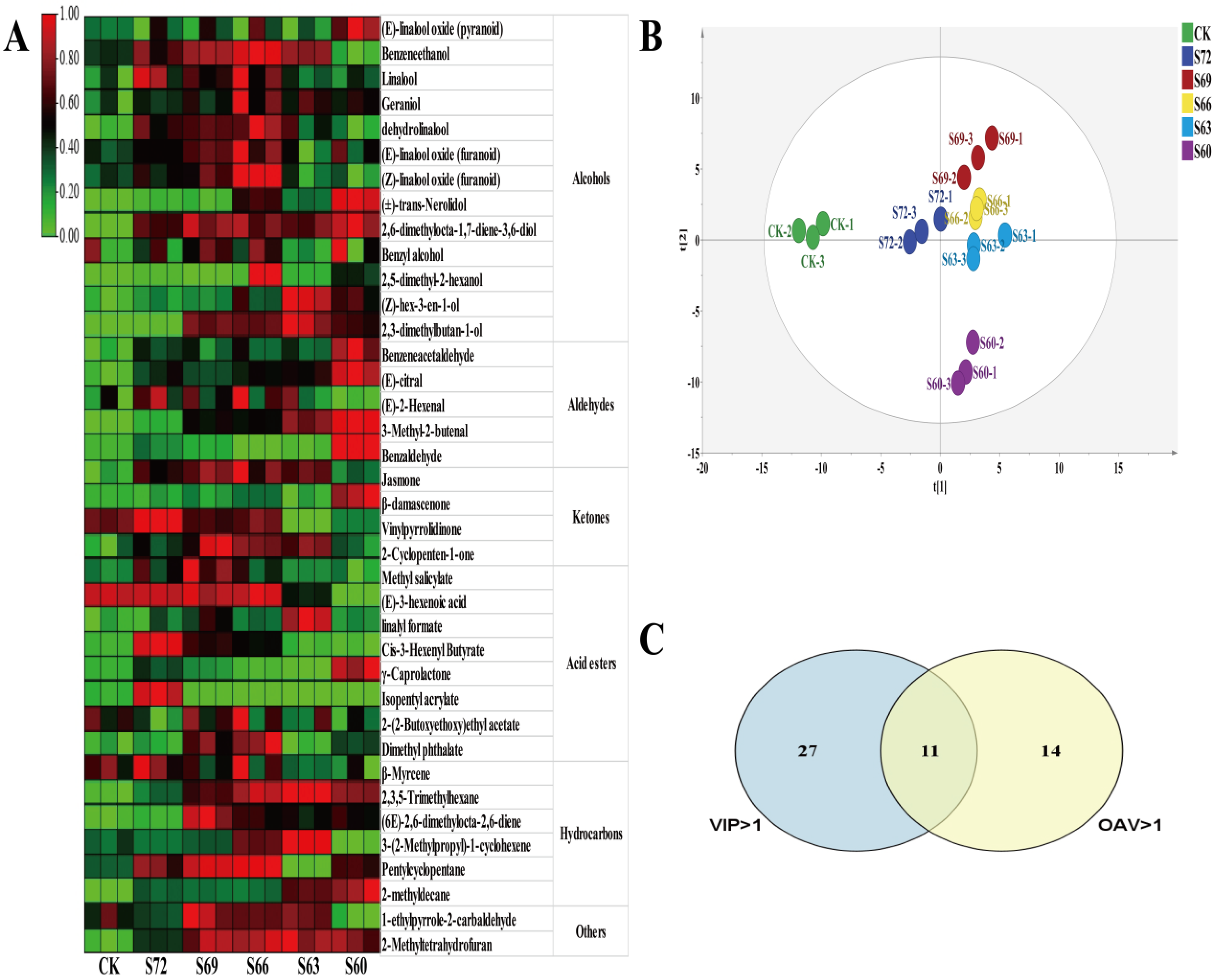

3.3.2. Effects of Different Sun Withering Degrees on Volatile Components of Black Tea

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Qi, R.; Mine, Y. The impact of oolong and black tea polyphenols on human health. Food Biosci. 2019, 29, 55–61. [Google Scholar] [CrossRef]

- Samanta, S. Potential Bioactive Components and Health Promotional Benefits of Tea (Camellia sinensis). J. Am. Nutr. Assoc. 2022, 41, 65–93. [Google Scholar] [CrossRef] [PubMed]

- Xue, J.; Liu, P.; Guo, G.; Wang, W.; Zhang, J.; Wang, W.; Le, T.; Yin, J.; Ni, D.; Jiang, H. Profiling of dynamic changes in non-volatile metabolites of shaken black tea during the manufacturing process using targeted and non-targeted metabolomics analysis. LWT Food Sci. Technol. 2022, 156, 113010. [Google Scholar] [CrossRef]

- Chiang, S.-H.; Yang, K.-M.; Wang, S.-Y.; Chen, C.-W. Enzymatic treatment in black tea manufacturing processing: Impact on bioactive compounds, quality, and bioactivities of black tea. LWT Food Sci. Technol. 2022, 163, 113560. [Google Scholar] [CrossRef]

- Wu, H.; Huang, W.; Chen, Z.; Chen, Z.; Shi, J.; Kong, Q.; Sun, S.; Jiang, X.; Chen, D.; Yan, S. GC–MS-based metabolomic study reveals dynamic changes of chemical compositions during black tea processing. Food Res. Int. 2019, 120, 330–338. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, Z.; Li, M.; Yuan, W.; Zhang, Z.; Ning, J. pH indicator-based sensor array in combination with hyperspectral imaging for intelligent evaluation of withering degree during processing of black tea. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2022, 271, 120959. [Google Scholar] [CrossRef]

- Owuor, P.O.; Obanda, M. The impact of withering temperature on black tea quality. J. Sci. Food Agric. 1996, 70, 288–292. [Google Scholar] [CrossRef]

- Ntezimana, B.; Li, Y.; He, C.; Yu, X.; Zhou, J.; Chen, Y.; Yu, Z.; Ni, D. Different Withering Times Affect Sensory Qualities, Chemical Components, and Nutritional Characteristics of Black Tea. Foods 2021, 10, 2627. [Google Scholar] [CrossRef]

- Zhou, J.; Yu, X.; He, C.; Qiu, A.; Li, Y.; Shu, Q.; Chen, Y.; Ni, D. Withering degree affects flavor and biological activity of black tea: A non-targeted metabolomics approach. LWT Food Sci. Technol. 2020, 130, 109535. [Google Scholar] [CrossRef]

- Huang, W.; Fang, S.; Wang, J.; Zhuo, C.; Luo, Y.; Yu, Y.; Li, L.; Wang, Y.; Deng, W.-W.; Ning, J. Sensomics analysis of the effect of the withering method on the aroma components of Keemun black tea. Food Chem. 2022, 395, 133549. [Google Scholar] [CrossRef]

- Deng, H.; Chen, S.; Zhou, Z.; Li, X.; Chen, S.; Hu, J.; Lai, Z.; Sun, Y. Transcriptome analysis reveals the effect of short-term sunlight on aroma metabolism in postharvest leaves of oolong tea (Camellia sinensis). Food Res. Int. 2020, 137, 109347. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Zhang, S.; Fu, H.; Zhou, C.; Chen, L.; Li, X.; Lin, Y.; Lai, Z.; Guo, Y. Transcriptome and Phytochemical Analyses Provide New Insights Into Long Non-Coding RNAs Modulating Characteristic Secondary Metabolites of Oolong Tea (Camellia sinensis) in Solar-Withering. Front. Plant Sci. 2019, 10, 1638. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhu, H.; Chen, J.; Xie, J.; Shen, S.; Deng, Y.; Zhu, J.; Yuan, H.; Jiang, Y. Characterization of the key aroma compounds in black teas with different aroma types by using gas chromatography electronic nose, gas chromatography-ion mobility spectrometry, and odor activity value analysis. LWT Food Sci. Technol. 2022, 163, 113492. [Google Scholar] [CrossRef]

- Chen, X.; Chen, D.; Jiang, H.; Sun, H.; Zhang, C.; Zhao, H.; Li, X.; Yan, F.; Chen, C.; Xu, Z. Aroma characterization of Hanzhong black tea (Camellia sinensis) using solid phase extraction coupled with gas chromatography–mass spectrometry and olfactometry and sensory analysis. Food Chem. 2019, 274, 130–136. [Google Scholar] [CrossRef]

- Li, J.; Hao, C.; Jia, H.; Zhang, J.; Wu, H.; Ning, J.; Wang, R.; Deng, W.-W. Aroma characterization and their changes during the processing of black teas from the cultivar, Camellia sinensis (L.) O. Kuntze cv. Jinmudan. J. Food Compos. Anal. 2022, 108, 104449. [Google Scholar] [CrossRef]

- Li, Y.; He, C.; Yu, X.; Zhou, J.; Ntezimana, B.; Yu, Z.; Chen, Y.; Ni, D. Study on improving aroma quality of summer-autumn black tea by red-light irradiation during withering. LWT Food Sci. Technol. 2022, 154, 112597. [Google Scholar] [CrossRef]

- Jiao, Y.; Song, Y.; Yan, Z.; Wu, Z.; Yu, Z.; Zhang, D.; Ni, D.; Chen, Y. The New Insight into the Effects of Different Fixing Technology on Flavor and Bioactivities of Orange Dark Tea. Molecules 2023, 28, 1079. Available online: https://www.mdpi.com/1420-3049/28/3/1079 (accessed on 20 January 2023). [CrossRef]

- Li, Y.; He, C.; Yu, X.; Zhou, J.; Ran, W.; Chen, Y.; Ni, D. Effects of red-light withering on the taste of black tea as revealed by non-targeted metabolomics and transcriptomics analysis. LWT Food Sci. Technol. 2021, 147, 111620. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y.; He, C.; Zhou, J.; Chen, Y.; Yu, Z.; Wang, P.; Ni, D. Nonvolatile metabolism in postharvest tea (Camellia sinensis L.) leaves: Effects of different withering treatments on nonvolatile metabolites, gene expression levels, and enzyme activity. Food Chem. 2020, 327, 126992. [Google Scholar] [CrossRef]

- Liu, X.M.; Liu, Y.; Shan, C.H.; Yang, X.Q.; Zhang, Q.; Xu, N.; Xu, L.Y.; Song, W. Effects of five extraction methods on total content, composition, and stability of flavonoids in jujube. Food Chem. X 2022, 14, 100287. [Google Scholar] [CrossRef]

- Fangfang, Q.; Zhi, Y.; Niyi, A.; Yuqiong, C.; Guanglun, L.; Dejiang, N. Effects of withering temperature, humidity and wind speed on the quality of black tea. China Tea 2014, 36, 22–25. [Google Scholar] [CrossRef]

- Chen, Y.; Zeng, L.; Liao, Y.; Li, J.; Zhou, B.; Yang, Z.; Tang, J. Enzymatic Reaction-Related Protein Degradation and Proteinaceous Amino Acid Metabolism during the Black Tea (Camellia sinensis) Manufacturing Process. Foods 2020, 9, 66. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Luo, F.; Gong, X.; Liu, D.; Li, L.; Yao, Y.; Fang, C.; Ye, Y. Targeted metabolomics and DIA proteomics-based analyses of proteinaceous amino acids and driving proteins in black tea during withering. LWT Food Sci. Technol. 2022, 165, 113701. [Google Scholar] [CrossRef]

- Vuong, Q.V.; Bowyer, M.C.; Roach, P.D. L-Theanine: Properties, synthesis and isolation from tea. J. Sci. Food Agric. 2011, 91, 1931–1939. [Google Scholar] [CrossRef]

- Huang, F.; Li, Y.; Yang, P.; Liu, Z.; Huang, J.; Xiong, L.; Li, J. Relationship between theanine, catechins and related genes reveals accumulation mechanism during spring and summer in tea plant (Camellia sinensis L.). Sci. Hortic. 2022, 302, 111142. [Google Scholar] [CrossRef]

- Ai, Z.; Zhang, B.; Chen, Y.; Yu, Z.; Chen, H.; Ni, D. Impact of light irradiation on black tea quality during withering. J. Food Sci. Technol. 2017, 54, 1212–1227. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, P.-C.; Liu, P.-P.; Song, X.-W.; Guo, F.; Li, Y.-Y.; Ni, D.-J.; Jiang, C.-J. Novel insight into the role of withering process in characteristic flavor formation of teas using transcriptome analysis and metabolite profiling. Food Chem. 2019, 272, 313–322. [Google Scholar] [CrossRef]

- Qu, F.; Zhu, X.; Ai, Z.; Ai, Y.; Qiu, F.; Ni, D. Effect of different drying methods on the sensory quality and chemical components of black tea. LWT Food Sci. Technol. 2019, 99, 112–118. [Google Scholar] [CrossRef]

- Maoz, I.; Lewinsohn, E.; Gonda, I. Amino acids metabolism as a source for aroma volatiles biosynthesis. Curr. Opin. Plant Biol. 2022, 67, 102221. [Google Scholar] [CrossRef]

- Zeng, L.; Zhou, Y.; Gui, J.; Fu, X.; Mei, X.; Zhen, Y.; Ye, T.; Du, B.; Dong, F.; Watanabe, N.; et al. Formation of Volatile Tea Constituent Indole During the Oolong Tea Manufacturing Process. J. Agric. Food Chem. 2016, 64, 5011–5019. [Google Scholar] [CrossRef]

- Wang, X.; Zeng, L.; Liao, Y.; Zhou, Y.; Xu, X.; Dong, F.; Yang, Z. An alternative pathway for the formation of aromatic aroma compounds derived from l-phenylalanine via phenylpyruvic acid in tea (Camellia sinensis (L.) O. Kuntze leaves. Food Chem. 2019, 270, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Kobayashi, E.; Katsuno, T.; Asanuma, T.; Fujimori, T.; Ishikawa, T.; Tomomura, M.; Mochizuki, K.; Watase, T.; Nakamura, Y.; et al. Characterisation of volatile and non-volatile metabolites in etiolated leaves of tea (Camellia sinensis) plants in the dark. Food Chem. 2012, 135, 2268–2276. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Chen, Y.; Mei, X.; Katsuno, T.; Kobayashi, E.; Dong, F.; Watanabe, N.; Yang, Z. Regulation of formation of volatile compounds of tea (Camellia sinensis) leaves by single light wavelength. Sci. Rep. 2015, 5, 16858. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Cheng, S.; Zhang, Y.; Du, B.; Feng, C.; Zhou, Y.; Mei, X.; Jiang, Y.; Duan, X.; Yang, Z. Differential responses of four biosynthetic pathways of aroma compounds in postharvest strawberry (Fragaria × ananassa Duch.) under interaction of light and temperature. Food Chem. 2017, 221, 356–364. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Y.; Wang, T.; Zhang, J. The effects of different light storage conditions on volatile flavor compounds and sensory properties of melon fruit. Food Biosci. 2022, 48, 101826. [Google Scholar] [CrossRef]

- Ravichandran, R. Carotenoid composition, distribution and degradation to flavour volatiles during black tea manufacture and the effect of carotenoid supplementation on tea quality and aroma. Food Chem. 2002, 78, 23–28. [Google Scholar] [CrossRef]

- Yu, Z.; Liao, Y.; Zeng, L.; Dong, F.; Watanabe, N.; Yang, Z. Transformation of catechins into theaflavins by upregulation of CsPPO3 in preharvest tea (Camellia sinensis) leaves exposed to shading treatment. Food Res. Int. 2020, 129, 108842. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.G.; Lee, Y.R.; Lee, M.S.; Hwang, K.H.; Park, C.Y.; Kim, E.H.; Park, J.S.; Hong, Y.S. Diverse Metabolite Variations in Tea (Camellia sinensis L.) Leaves Grown Under Various Shade Conditions Revisited: A Metabolomics Study. J. Agric. Food Chem. 2018, 66, 1889–1897. [Google Scholar] [CrossRef]

- Flaig, M.; Qi, S.C.; Wei, G.D.; Yang, X.G.; Schieberle, P. Characterisation of the key aroma compounds in aLongjinggreen tea infusion (Camellia sinensis) by the sensomics approach and their quantitative changes during processing of the tea leaves. Eur. Food Res. Technol. 2020, 246, 2411–2425. [Google Scholar] [CrossRef]

- Li, Y.; Wu, T.; Deng, X.; Tian, D.; Ma, C.; Wang, X.; Li, Y.; Zhou, H. Characteristic aroma compounds in naturally withered and combined withered γ-aminobutyric acid white tea revealed by HS-SPME-GC-MS and relative odor activity value. LWT Food Sci. Technol. 2023, 176, 114467. [Google Scholar] [CrossRef]

- Guo, X.; Ho, C.-T.; Wan, X.; Zhu, H.; Liu, Q.; Wen, Z. Changes of volatile compounds and odor profiles in Wuyi rock tea during processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef] [PubMed]

- Ho, C.-T.; Zheng, X.; Li, S. Tea aroma formation. Food Sci. Hum. Wellness 2015, 4, 9–27. [Google Scholar] [CrossRef]

- Fang, X.; Liu, Y.; Xiao, J.; Ma, C.; Huang, Y. GC–MS and LC-MS/MS metabolomics revealed dynamic changes of volatile and non-volatile compounds during withering process of black tea. Food Chem. 2023, 410, 135396. [Google Scholar] [CrossRef] [PubMed]

- Yang, P.; Yu, M.; Song, H.; Xu, Y.; Lin, Y.; Granvogl, M. Characterization of Key Aroma-Active Compounds in Rough and Moderate Fire Rougui Wuyi Rock Tea (Camellia sinensis) by Sensory-Directed Flavor Analysis and Elucidation of the Influences of Roasting on Aroma. J. Agric. Food Chem. 2022, 70, 267–278. [Google Scholar] [CrossRef]

- Cui, J.; Zhai, X.; Guo, D.; Du, W.; Gao, T.; Zhou, J.; Schwab, W.G.; Song, C. Characterization of Key Odorants in Xinyang Maojian Green Tea and Their Changes During the Manufacturing Process. J. Agric. Food Chem. 2022, 70, 279–288. [Google Scholar] [CrossRef]

- Yao, H.; Su, H.; Ma, J.; Zheng, J.; He, W.; Wu, C.; Hou, Z.; Zhao, R.; Zhou, Q. Widely targeted volatileomics analysis reveals the typical aroma formation of Xinyang black tea during fermentation. Food Res. Int. 2023, 164, 112387. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, Y.; Wang, K.; Niu, Y.; Xiao, Z. Characterization of key aroma compounds and enantiomer distribution in Longjing tea. Food Chem. 2021, 361, 130096. [Google Scholar] [CrossRef]

- Wang, H.; Hua, J.; Jiang, Y.; Yang, Y.; Wang, J.; Yuan, H. Influence of fixation methods on the chestnut-like aroma of green tea and dynamics of key aroma substances. Food Res. Int. 2020, 136, 109479. [Google Scholar] [CrossRef]

- Xu, Y.; Bi, S.; Niu, X.; Chen, Y.; Liu, Y.; Zhou, Q. Comparison of aroma active compounds in cold- and hot-pressed walnut oil by comprehensive two-dimensional gas chromatography-olfactory-mass spectrometry and headspace-gas chromatography-ion mobility spectrometry. Food Res. Int. 2023, 163, 112208. [Google Scholar] [CrossRef]

- Xu, Q.; He, Y.; Yan, X.; Zhao, S.; Zhu, J.; Wei, C. Unraveling a crosstalk regulatory network of temporal aroma accumulation in tea plant (Camellia sinensis) leaves by integration of metabolomics and transcriptomics. Environ. Exp. Bot. 2018, 149, 81–94. [Google Scholar] [CrossRef]

- Gui, J.; Fu, X.; Zhou, Y.; Katsuno, T.; Mei, X.; Deng, R.; Xu, X.; Zhang, L.; Dong, F.; Watanabe, N.; et al. Does Enzymatic Hydrolysis of Glycosidically Bound Volatile Compounds Really Contribute to the Formation of Volatile Compounds During the Oolong Tea Manufacturing Process? J. Agric. Food Chem. 2015, 63, 6905–6914. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.-J.; Li, D.; Ma, Y.-X.; Zhang, W.; Lin, C.; Zheng, X.-Q.; Liang, Y.-R.; Lu, J.-L. Formation mechanism of the oolong tea characteristic aroma during bruising and withering treatment. Food Chem. 2018, 269, 202–211. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Niu, Y.; Xiao, Z. Characterization of the key aroma compounds in Laoshan green teas by application of odour activity value (OAV), gas chromatography-mass spectrometry-olfactometry (GC-MS-O) and comprehensive two-dimensional gas chromatography mass spectrometry (GC × GC-qMS). Food Chem. 2021, 339, 128136. [Google Scholar] [CrossRef] [PubMed]

| NO. | Compounds | Odor Threshold in Water (μg/L) | Odor Activity Values (OAVs) | |||||

|---|---|---|---|---|---|---|---|---|

| CK | S72 | S69 | S66 | S63 | S60 | |||

| 1 | Linalool | 6 b | 426.57 | 429.24 | 503.57 | 474.72 | 502.43 | 403.98 |

| 2 | Benzeneethanol | 390 a | 1.51 | 2.13 | 2.29 | 2.17 | 2.02 | 1.79 |

| 3 | Nerol | 49 a | 2.24 | 1.92 | 1.86 | 1.86 | 1.84 | 1.47 |

| 4 | Geraniol | 7.5 a | 461.05 | 467.87 | 487.78 | 456.45 | 449.66 | 426.02 |

| 5 | (Z)-hex-3-en-1-ol | 13 a | 4.30 | 5.14 | 5.30 | 6.52 | 9.68 | 7.50 |

| 6 | 1-Octene-3-ol | 1 a | 8.55 | 6.82 | 6.31 | 4.61 | 4.28 | 5.89 |

| 7 | (E)-2-Hexenal | 17 a | 264.11 | 290.65 | 308.15 | 299.34 | 308.32 | 277.75 |

| 8 | Octanal | 0.7 e | 15.37 | 30.55 | 103.42 | 103.53 | 112.51 | 37.06 |

| 9 | Benzeneacetaldehyde | 4 a | 5026.54 | 3782.8 | 3863.79 | 3741.69 | 3916.89 | 3119.73 |

| 10 | (2E,6Z)-nona-2,6-dienal | 0.03 b | 3723.37 | 1701.4 | 1578.46 | 1445.87 | 1603.33 | 1475.16 |

| 11 | (2E)-2-Nonenal | 0.19 a | 249.16 | 156.21 | 118.62 | 123.21 | 127.73 | 79.26 |

| 12 | Decanal | 3 c | 564.91 | 377.96 | 452.09 | 467.31 | 415.11 | 329.43 |

| 13 | β-Cyclocitrala | 3 a | 62.08 | 59.51 | 57.84 | 58.08 | 57.31 | 45.7 |

| 14 | (2E)-2-Decenal | 0.4 a | 95.86 | 102.09 | 79.69 | 69.5 | 56.38 | 75.83 |

| 15 | (E)-citral | 32 f | 7.35 | 5.77 | 5.52 | 5.01 | 5.34 | 3.79 |

| 16 | (2E)-2-Octenal | 4 c | 50.27 | 39.46 | 37.74 | 34.31 | 36.57 | 25.95 |

| 17 | β-damascenone | 0.002 b | 28,318.21 | 18,713.68 | 20,943.19 | 19,850.92 | 19,271.82 | 18,851.82 |

| 18 | Jasmone | 7 a | 143.29 | 174.2 | 181.89 | 179.53 | 166.49 | 130.03 |

| 19 | β-ionone | 8.4 a | 28.6 | 24.38 | 22.88 | 21.44 | 21.4 | 22.56 |

| 20 | Hexanoic acid | 35.6 d | 2.14 | 1.56 | 1.66 | 1.77 | 1.6 | 1.44 |

| 21 | Methyl salicylate | 40 a | 18.74 | 19.53 | 21.81 | 25.6 | 22.59 | 19.74 |

| 22 | Dihydroactinidiolide | 0.5 g | 414.37 | 345.2 | 377.67 | 369.67 | 349.58 | 377.31 |

| 23 | δ-Decalactone | 1.15 i | 135.31 | 151.32 | 274.94 | 308.56 | 426.99 | 152.21 |

| 24 | β-Myrcene | 15 a | 1.98 | 2 | 2.17 | 2.09 | 2.23 | 2.16 |

| 25 | 2,6,10,10-Tetramethyl-1-oxaspiro[4.5]dec-6-ene | 0.2 h | 62.58 | 57.75 | 56.66 | 51.9 | 41.25 | 28.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Jiao, Y.; Jiang, X.; Li, C.; Sun, W.; Chen, Y.; Yu, Z.; Ni, D. Effects of Sun Withering Degree on Black Tea Quality Revealed via Non-Targeted Metabolomics. Foods 2023, 12, 2430. https://doi.org/10.3390/foods12122430

Wu Z, Jiao Y, Jiang X, Li C, Sun W, Chen Y, Yu Z, Ni D. Effects of Sun Withering Degree on Black Tea Quality Revealed via Non-Targeted Metabolomics. Foods. 2023; 12(12):2430. https://doi.org/10.3390/foods12122430

Chicago/Turabian StyleWu, Zhuanrong, Yuanfang Jiao, Xinfeng Jiang, Chen Li, Weijiang Sun, Yuqiong Chen, Zhi Yu, and Dejiang Ni. 2023. "Effects of Sun Withering Degree on Black Tea Quality Revealed via Non-Targeted Metabolomics" Foods 12, no. 12: 2430. https://doi.org/10.3390/foods12122430

APA StyleWu, Z., Jiao, Y., Jiang, X., Li, C., Sun, W., Chen, Y., Yu, Z., & Ni, D. (2023). Effects of Sun Withering Degree on Black Tea Quality Revealed via Non-Targeted Metabolomics. Foods, 12(12), 2430. https://doi.org/10.3390/foods12122430