Modelling the Rheology of Olive Paste for Oil Extraction Plant Automation: Effects of the Crushing Process on the Rheology of Olive Pastes

Abstract

1. Introduction

2. Materials and Methods

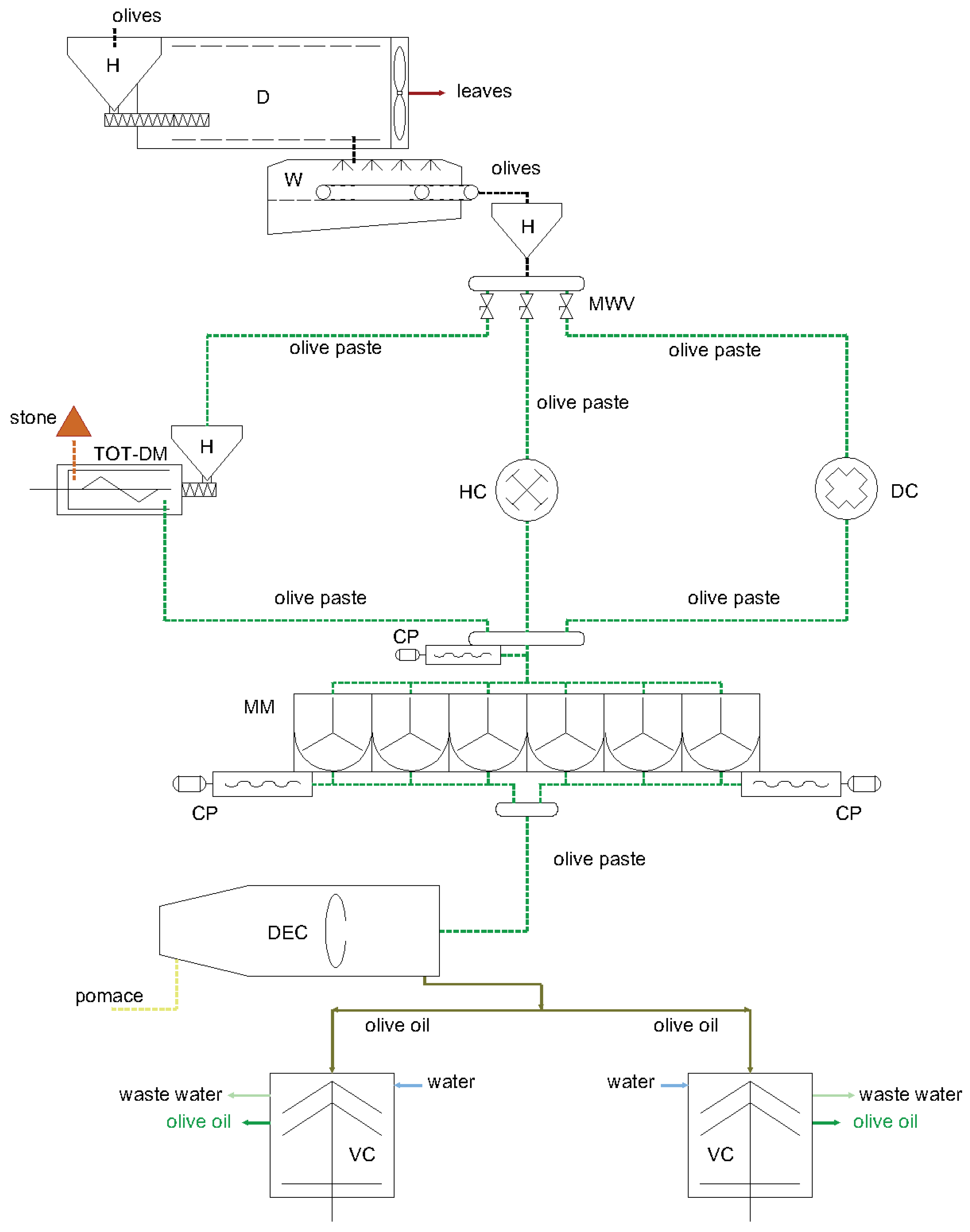

2.1. Extraction Process Line with Different Crushers

2.2. Rheological Behavior of Olive Paste

2.3. Experimental Plan

2.4. Legal Quality Parameters

2.5. Statistical Analysis

3. Results

3.1. Olive Oil Extractability (E) and Quality

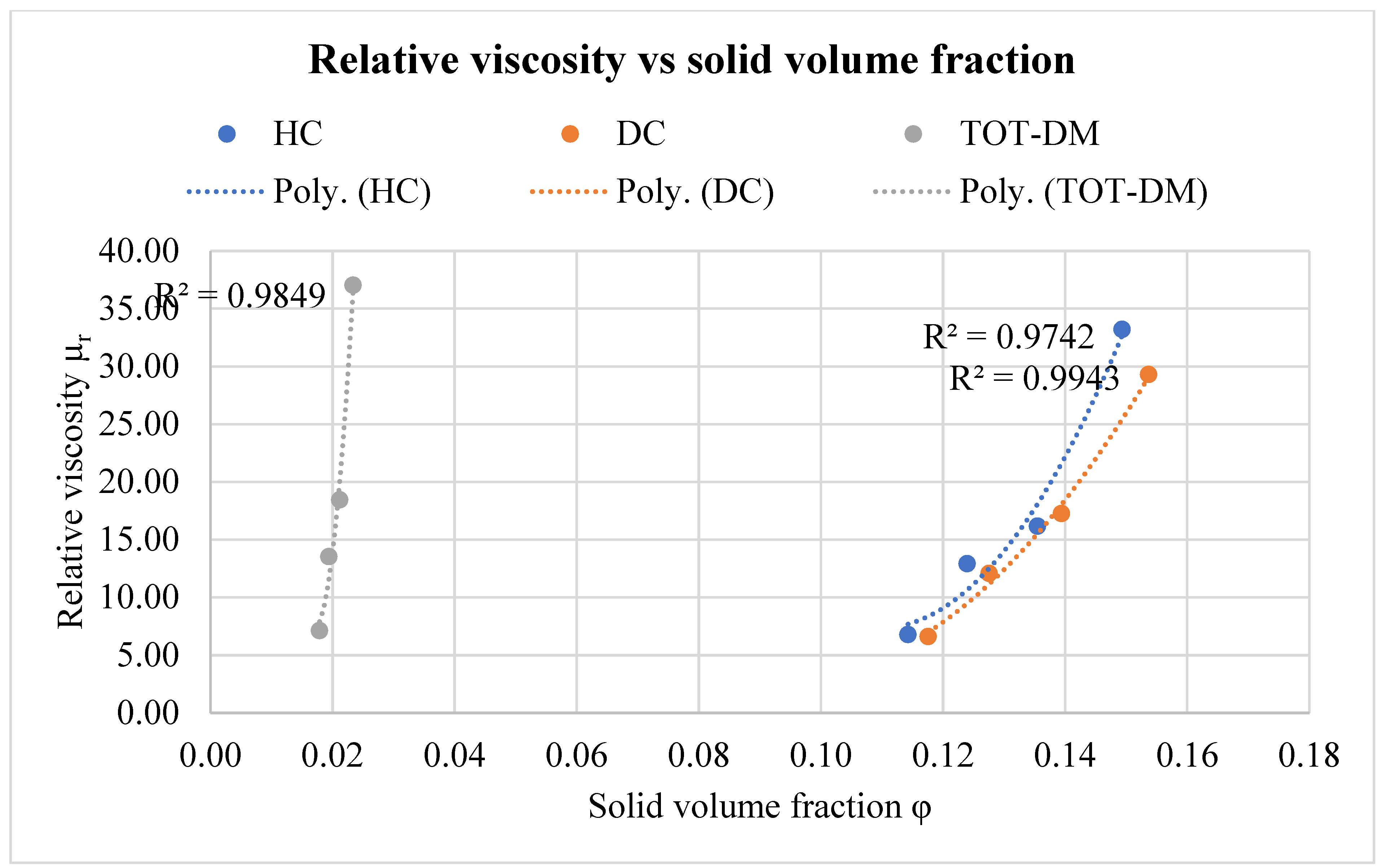

3.2. Rheological Model

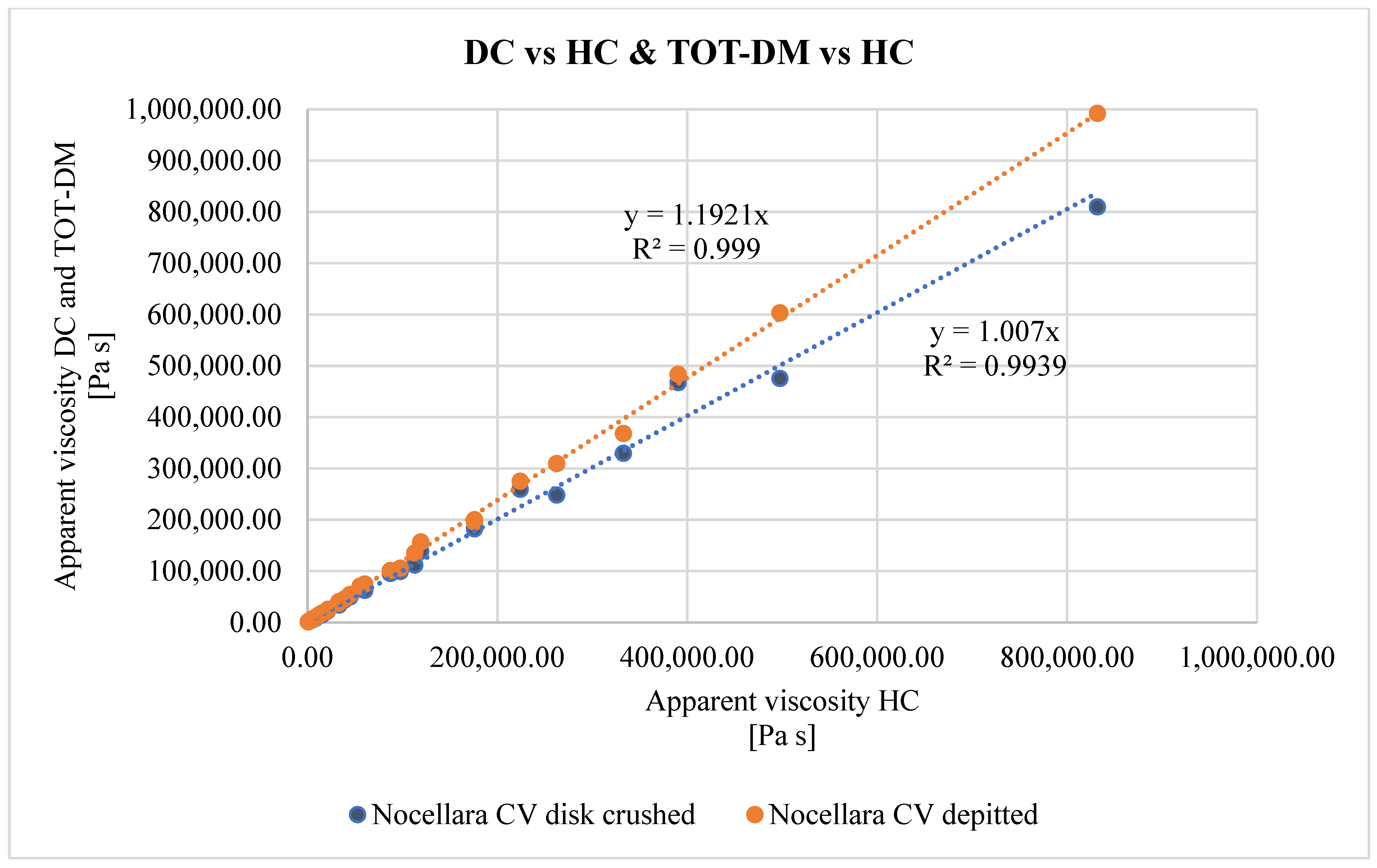

3.3. Paste Rheology According to the Crushing Method

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amirante, P.; Clodoveo, M.L.; Leone, A.; Tamborrino, A.; Patel, V.B. Influence of different centrifugal extraction systems on antioxidant content and stability of virgin olive oil. In Olives and Olive Oil in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2010; pp. 85–93. [Google Scholar] [CrossRef]

- Veillet, S.; Tomao, V.; Bornard, I.; Ruiz, K.; Chemat, F. Chemical Changes in Virgin Olive Oils as a Function of Crushing Systems: Stone Mill and Hammer Crusher. Comptes Rendus Chim. 2009, 12, 895–904. [Google Scholar] [CrossRef]

- Catalano, P.; Caponio, F. Machines for Olive Paste Preparation Producing Quality Virgin Olive Oil. Lipid/Fett 1996, 98, 408–412. [Google Scholar] [CrossRef]

- Inarejos-García, A.M.; Fregapane, G.; Salvador, M.D. Effect of Crushing on Olive Paste and Virgin Olive Oil Minor Components. Eur. Food Res. Technol. 2011, 232, 441–451. [Google Scholar] [CrossRef]

- Guerrini, L.; Migliorini, M.; Giusti, M.; Parenti, A. The Influence of Crusher Speed on Extra Virgin Olive Oil Characteristics. Eur. J. Lipid Sci. Technol. 2017, 119, 1600156. [Google Scholar] [CrossRef]

- Polari, J.J.; Wang, S.C. Hammer Mill Sieve Design Impacts Olive Oil Minor Component Composition. Eur. J. Lipid Sci. Technol. 2019, 121, 1900168. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Zagaria, R.; Sabella, E.; De Bellis, L.; Tamborrino, A. Machining Effects of Different Mechanical Crushers on Pit Particle Size and Oil Drop Distribution in Olive Paste. Eur. J. Lipid Sci. Technol. 2015, 117, 1271–1279. [Google Scholar] [CrossRef]

- Preziuso, S.M.; Di Serio, M.G.; Biasone, A.; Vito, R.; Mucciarella, M.R.; Di Giovacchino, L. Influence of Olive Crushing Methods on the Yields and Oil Characteristics. Eur. J. Lipid Sci. Technol. 2010, 112, 1345–1355. [Google Scholar] [CrossRef]

- Tamborrino, A.; Perone, C.; Veneziani, G.; Berardi, A.; Romaniello, R.; Servili, M.; Leone, A. Experimental Investigation of a New Modular Crusher Machine Developed for Olive Oil Extraction Plants. Foods 2022, 11, 3035. [Google Scholar] [CrossRef]

- Amirate, P.; Baccioni, L.; Bellomo, F.; Di Renzo, G.C. Installations Pour l’Extraction D’Huile d’Olive à Partir de Pâtes d’Olives Dénoyautées. Olivae 1987, 17, 24–29. [Google Scholar]

- Amirante, P.; Catalano, P.; Amirante, R.; Montel, G.; Dugo, G.; Lo Turco, V.; Baccioni, L.; Fazio, D.; Mattei, A.; Marotta, F. Estrazione Da Paste Snocciolate. Olivo Olio 2001, 4, 48–58. [Google Scholar]

- Tamborrino, A.; Servili, M.; Leone, A.; Romaniello, R.; Perone, C.; Veneziani, G. Partial De-Stoning of Olive Paste to Increase Olive Oil Quality, Yield, and Sustainability of the Olive Oil Extraction Process. Eur. J. Lipid Sci. Technol. 2020, 122, 2000129. [Google Scholar] [CrossRef]

- Tamborrino, A. Olive Paste Malaxation. In Extra-Virgin Olive Oil Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 127–137. [Google Scholar] [CrossRef]

- Perone, C.; Romaniello, R.; Leone, A.; Catalano, P.; Tamborrino, A. CFD Analysis of a Tubular Heat Exchanger for the Conditioning of Olive Paste. Appl. Sci. 2021, 11, 1858. [Google Scholar] [CrossRef]

- Tamborrino, A.; Veneziani, G.; Romaniello, R.; Perone, C.; Urbani, S.; Leone, A.; Servili, M. Development of an Innovative Rotating Spiral Heat Exchanger with Integrated Microwave Module for the Olive Oil Industry. LWT 2021, 147, 111622. [Google Scholar] [CrossRef]

- Perone, C.; Romaniello, R.; Leone, A.; Berardi, A.; Catalano, P.; Tamborrino, A. CFD analysis of a tube-in-tube heat exchanger to pre-heat olive pastes. Chem. Eng. Trans. 2021, 87, 253–258. [Google Scholar] [CrossRef]

- Jiménez, A.; Beltrán, G.; Uceda, M. High-Power Ultrasound in Olive Paste Pretreatment. Effect on Process Yield and Virgin Olive Oil Characteristics. Ultrason. Sonochem. 2007, 14, 725–731. [Google Scholar] [CrossRef]

- Bejaoui, M.A.; Beltran, G.; Aguilera, M.P.; Jimenez, A. Continuous Conditioning of Olive Paste by High Power Ultrasounds: Response Surface Methodology to Predict Temperature and Its Effect on Oil Yield and Virgin Olive Oil Characteristics. LWT Food Sci. Technol. 2016, 69, 175–184. [Google Scholar] [CrossRef]

- Tamborrino, A.; Taticchi, A.; Romaniello, R.; Perone, C.; Esposto, S.; Leone, A.; Servili, M. Assessment of the Olive Oil Extraction Plant Layout Implementing a High-Power Ultrasound Machine. Ultrason. Sonochem. 2021, 73, 105505. [Google Scholar] [CrossRef]

- Puértolas, E.; de Marañón, I.M. Olive Oil Pilot-Production Assisted by Pulsed Electric Field: Impact on Extraction Yield, Chemical Parameters and Sensory Properties. Food Chem. 2015, 167, 497–502. [Google Scholar] [CrossRef]

- Tamborrino, A.; Urbani, S.; Servili, M.; Romaniello, R.; Perone, C.; Leone, A. Pulsed Electric Fields for the Treatment of Olive Pastes in the Oil Extraction Process. Appl. Sci. 2019, 10, 114. [Google Scholar] [CrossRef]

- Tamborrino, A.; Mescia, L.; Taticchi, A.; Berardi, A.; Lamacchia, C.; Leone, A.; Servili, M. Continuous Pulsed Electric Field Pilot Plant for Olive Oil Extraction Process. Innov. Food Sci. Emerg. Technol. 2022, 82, 103192. [Google Scholar] [CrossRef]

- Leone, A.; Tamborrino, A.; Esposto, S.; Berardi, A.; Servili, M. Investigation on the effects of a pulsed electric field (PEF) continuous system implemented in an industrial olive oil plant. Foods 2022, 11, 2758. [Google Scholar] [CrossRef] [PubMed]

- Tamborrino, A.; Romaniello, R.; Perone, C.; Moujahed, H.; Leone, A. Development of a Pressure Control System According to Paste Rheology for Ultrasound Processing in Industrial Olive Oil Extraction. Food Bioprocess Technol. 2021, 14, 1897–1908. [Google Scholar] [CrossRef]

- Tamborrino, A.; Perone, C.; Mojaed, H.; Romaniello, R.; Berardi, A.; Catalano, P.; Leone, A. Combined Continuous Machine to Condition Olive Paste: Rheological Characterization of Olive Paste. Chem. Eng. Trans. 2021, 87, 283–288. [Google Scholar]

- Boncinelli, P.; Catalano, P.; Cini, E. Olive Paste Rheological Analysis. Trans. ASABE 2013, 56, 237–243. [Google Scholar] [CrossRef]

- Tamborrino, A.; Catalano, P.; Leone, A. Using an In-Line Rotating Torque Transducer to Study the Rheological Aspects of Malaxed Olive Paste. J. Food Eng. 2014, 126, 65–71. [Google Scholar] [CrossRef]

- Oliveto, R.; Bianchi, B.; Catalano, F.; Ricciardi, S. Dynamic Simulation Driven Design and Management of Production Facilities in Agricultural/Food Industry. Acta Hortic. 2021, 1311, 241–248. [Google Scholar] [CrossRef]

- Catalano, F.; Leone, A.; Bianchi, B.; Tamborrino, A. A New Tool for Food Industrial Plant Simulation and IoT Control. Chem. Eng. Trans. 2021, 87, 367–372. [Google Scholar]

- Perone, C.; Orsino, M.; La Fianza, G.; Giametta, F.; Catalano, P. Study of a Mechanical Ventilation System with Heat Recovery to Control Temperature in a Monitored Agricultural Environment under Summer Conditions. J. Build. Eng. 2021, 43, 102745. [Google Scholar] [CrossRef]

- Tamborrino, A.; Perone, C.; Catalano, F.; Squeo, G.; Caponio, F.; Bianchi, B. Modelling Energy Consumption and Energy-Saving in High-Quality Olive Oil Decanter Centrifuge: Numerical Study and Experimental Validation. Energies 2019, 12, 2592. [Google Scholar] [CrossRef]

- Tamborrino, A.; Catalano, F.; Berardi, A.; Bianchi, B. New Modelling Approach for the Energy and Steam Consumption Evaluation in a Fresh Pasta Industry. Chem. Eng. Trans. 2021, 87, 409–414. [Google Scholar]

- Catalano, F.; Bianchi, B.; Berardi, A.; Leone, A.; Tamborrino, A. Experimental Trials and Dynamical Simulation of the Potential Biogas Production in a Frozen Food Industry. Chem. Eng. Trans. 2021, 87, 295–300. [Google Scholar]

- Catalano, F.; Perone, C.; Iannacci, V.; Leone, A.; Tamborrino, A.; Bianchi, B. Energetic Analysis and Optimal Design of a CHP Plant in a Frozen Food Processing Factory through a Dynamical Simulation Model. Energy Convers. Manag. 2020, 225, 113444. [Google Scholar] [CrossRef]

- Amirante, R.; Catalano, P. PH—Postharvest Technology: Fluid Dynamic Analysis of the Solid–Liquid Separation Process by Centrifugation. J. Agric. Eng. Res. 2000, 77, 193–201. [Google Scholar] [CrossRef]

- Ayr, U.; Tamborrino, A.; Catalano, P.; Bianchi, B.; Leone, A. 3D Computational Fluid Dynamics Simulation and Experimental Validation for Prediction of Heat Transfer in a New Malaxer Machine. J. Food Eng. 2015, 154, 30–38. [Google Scholar] [CrossRef]

- Salas-Bringas, C.; Jeksrud, W.K.; Schüller, R.B. A New On-Line Process Rheometer for Highly Viscous Food and Animal Feed Materials. J. Food Eng. 2007, 79, 383–391. [Google Scholar] [CrossRef]

- Di Renzo, G.C.; Colelli, G. Flow Behavior of Olive Paste. Appl. Eng. Agric. 1997, 13, 751–755. [Google Scholar] [CrossRef]

- Bianchi, B.; Catalano, P. Power Consumption and Quality Features in the Hammer Crushing Process for Olive Oil Production. Grasas y Aceites 1996, 47, 136–141. [Google Scholar] [CrossRef]

- Zhang, T.; Evans, J.R.G. Predicting the Viscosity of Ceramic Injection Moulding Suspensions. J. Eur. Ceram. Soc. 1989, 5, 165–172. [Google Scholar] [CrossRef]

- Quemada, D. Rheology of Concentrated Disperse Systems and Minimum Energy Dissipation Principle: I. Viscosity-Concentration Relationship. Rheol. Acta 1977, 16, 82–94. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Juliano, P.; Tamborrino, A. Use of a Mixing-Coil Heat Exchanger Combined with Microwave and Ultrasound Technology in an Olive Oil Extraction Process. Innov. Food Sci. Emerg. Technol. 2018, 50, 66–72. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Zagaria, R.; Tamborrino, A. Mathematical Modelling of the Performance Parameters of a New Decanter Centrifuge Generation. J. Food Eng. 2015, 166, 10–20. [Google Scholar] [CrossRef]

- Leone, A.; Romaniello, R.; Peri, G.; Tamborrino, A. Development of a New Model of Olives De-Stoner Machine: Evaluation of Electric Consumption and Kernel Characterization. Biomass Bioenergy 2015, 81, 108–116. [Google Scholar] [CrossRef]

- Amirante, P.; Clodoveo, M.L.; Dugo, G.; Leone, A.; Tamborrino, A. Advance Technology in Virgin Olive Oil Production from Traditional and De-Stoned Pastes: Influence of the Introduction of a Heat Exchanger on Oil Quality. Food Chem. 2006, 98, 797–805. [Google Scholar] [CrossRef]

- Walstra, P. Physical Chemistry of Foods, 1st ed.; CRC Press: Boca Raton, FL, USA, 2002; ISBN 9780203910436. [Google Scholar] [CrossRef]

- Caponio, F.; Catalano, P. Hammer Crushers vs Disk Crushers: The Influence of Working Temperature on the Quality and Preservation of Virgin Olive Oil. Eur. Food Res. Technol. 2001, 213, 219–224. [Google Scholar] [CrossRef]

| ID | Crushing Method | Dilution Water | Composition | ||

|---|---|---|---|---|---|

| (%) | Water (%) | Oil (%) | Solids (%) | ||

| HC 1 | Hammer crusher | 0 | 60.46 | 20.69 | 18.85 |

| HC 2 | 10 | 64.05 | 18.80 | 17.13 | |

| HC 3 | 20 | 67.05 | 17.24 | 15.70 | |

| HC 4 | 30 | 69.58 | 15.91 | 14.50 | |

| DC 1 | Disc crusher | 0 | 60.2 | 20.54 | 19.26 |

| DC 2 | 10 | 63.81 | 18.67 | 17.50 | |

| DC 3 | 20 | 66.83 | 17.11 | 16.05 | |

| DC 4 | 30 | 69.38 | 15.80 | 14.81 | |

| TOT-DM 1 | Total de-stoning machine | 0 | 69.20 | 23.95 | 6.85 |

| TOT-DM 2 | 10 | 72.00 | 21.77 | 6.22 | |

| TOT-DM 3 | 20 | 74.33 | 19.95 | 5.70 | |

| TOT-DM 4 | 30 | 76.30 | 18.42 | 5.26 | |

| Crushing Method | E | Acidity | Peroxide Value | K232 | K270 | ∆K |

|---|---|---|---|---|---|---|

| (%) | (%) | (meq O2/Kg Oil) | ||||

| HC | 88.45 ± 1.23 a | 0.16 ± 0.02 a | 4.0 ± 0.9 a | 1.522 ± 0.016 a | 0.113 ± 0.014 a | −0.003 ± 0.001 a |

| DC | 86.17 ± 1.11 a | 0.15 ± 0.01 a | 3.8 ± 0.7 a | 1.582 ± 0.015 a | 0.110 ± 0.016 a | −0.003 ± 0.001 a |

| TOT-DM | 80.30 ± 1.42 b | 0.17 ± 0.02 a | 4.1 ± 0.6 a | 1.574 ± 0.016 a | 0.114 ± 0.016 a | −0.003 ± 0.001 a |

| ID | |||||||

|---|---|---|---|---|---|---|---|

| Pa sn | Mean [-] | RMSE | P [%] | Pa sn | [-] | [-] | |

| HC 1 | 154,451 | 0.844 ± 0.0283 a | 0.0245 | 2.403 | 4652 | 0.0300 | 0.179 |

| HC 2 | 75,219 | ||||||

| HC 3 | 60,127 | ||||||

| HC 4 | 31,583 | ||||||

| DC 1 | 147,905 | 0.849 ± 0.0191 a | 0.0165 | 1.636 | 5048 | 0.0493 | 0.186 |

| DC 2 | 87,131 | ||||||

| DC 3 | 60,962 | ||||||

| DC 4 | 33,405 | ||||||

| TOT-DM 1 | 186,996 | 0.835 ± 0.0174 a | 0.0151 | 1.461 | 5050 | 0.0430 | 0.0277 |

| TOT-DM 2 | 93,173 | ||||||

| TOT-DM 3 | 68,279 | ||||||

| TOT-DM 4 | 35,981 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perone, C.; Catalano, F.; Leone, A.; Berardi, A.; Tamborrino, A. Modelling the Rheology of Olive Paste for Oil Extraction Plant Automation: Effects of the Crushing Process on the Rheology of Olive Pastes. Foods 2023, 12, 2218. https://doi.org/10.3390/foods12112218

Perone C, Catalano F, Leone A, Berardi A, Tamborrino A. Modelling the Rheology of Olive Paste for Oil Extraction Plant Automation: Effects of the Crushing Process on the Rheology of Olive Pastes. Foods. 2023; 12(11):2218. https://doi.org/10.3390/foods12112218

Chicago/Turabian StylePerone, Claudio, Filippo Catalano, Alessandro Leone, Antonio Berardi, and Antonia Tamborrino. 2023. "Modelling the Rheology of Olive Paste for Oil Extraction Plant Automation: Effects of the Crushing Process on the Rheology of Olive Pastes" Foods 12, no. 11: 2218. https://doi.org/10.3390/foods12112218

APA StylePerone, C., Catalano, F., Leone, A., Berardi, A., & Tamborrino, A. (2023). Modelling the Rheology of Olive Paste for Oil Extraction Plant Automation: Effects of the Crushing Process on the Rheology of Olive Pastes. Foods, 12(11), 2218. https://doi.org/10.3390/foods12112218