Quality Standards and Contractual Terms Affecting Food Losses: The Perspective of Producer Organisations in Germany and Italy

Abstract

1. Introduction

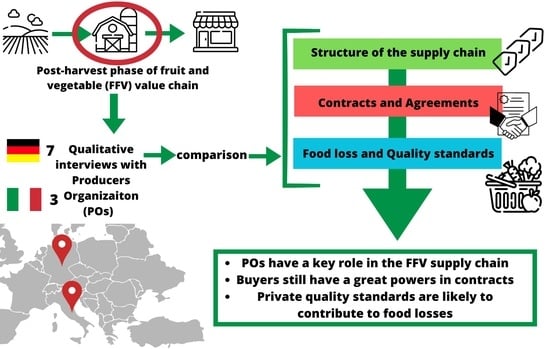

2. Materials and Methods

2.1. Data Acquisition

- Causes of FL in the supplier/retailer interface;

- Design of contracts and arrangements that POs have in place with farmers and retailers;

- Relation between the structure of contracts, orders’ management, and quantity of FL;

- Quality management process along the supply chain and criteria that influence the decisions;

- Management of products that do not meet the required quality standards.

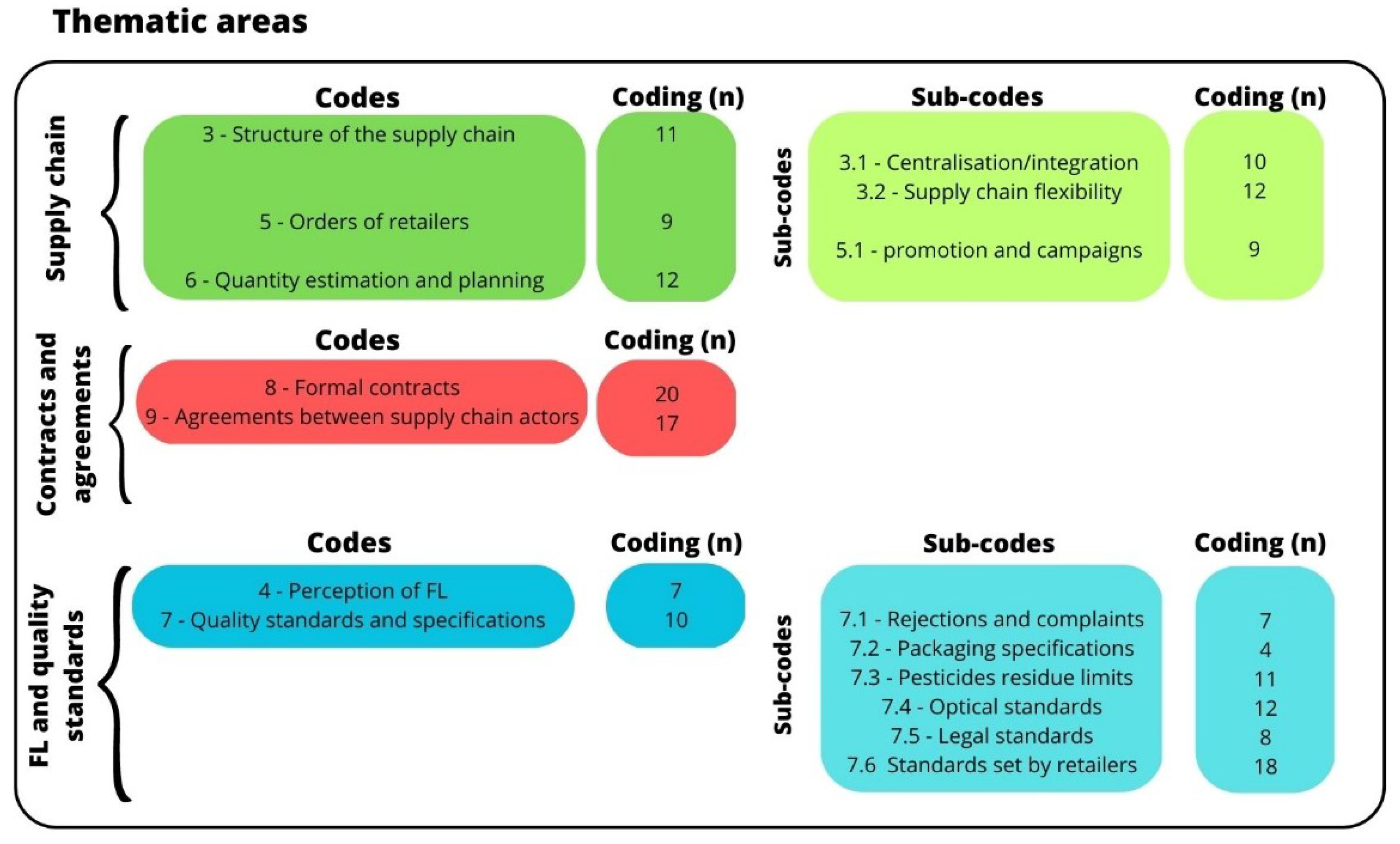

2.2. Data Analysis

3. Results and Discussion

3.1. Supply Chain Organization

3.2. Contracts and Agreements

3.3. FL and Quality Standards

3.4. Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. Women in agriculture, closing the gender gap for development. In The State of Food and Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. [Google Scholar]

- FAO. Moving forward on food loss and waste reduction. In The State of Food and Agriculture; Food and Agriculture Organization of the United Nations: Rome, Italy, 2019. [Google Scholar]

- UNEP. Annual Report; UNEP: Nairobi, Kenya, 2013. [Google Scholar]

- UNEP. Food Waste Index, Report; UNEP: Nairobi, Kenya, 2021. [Google Scholar]

- United Nations (UN). Sustainable Development Goals. 17 Goals to Transform Our World. 2015. Available online: https://sdgs.un.org/goals/goal12 (accessed on 1 December 2022).

- FAO. Methodology for monitoring SDG target 12.3 as approved by the Inter-agency and Expert Group on SDG Indicators, 6 November 2018. The Global Food Loss Index-Design, Data Collection, Methods and Challenges. In SDG 12.3.1: Global Food Loss Index; FAO: Rome, Italy, 2018; 54p, Available online: http://www.fao.org/3/CA2640EN/ca2640en.pdf (accessed on 10 May 2023).

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of food waste per product group along the food supply chain in the European Union: A mass flow analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef] [PubMed]

- Sorrentino, A.; Russo, C.; Cacchiarelli, L. Market power and bargaining power in the EU food supply chain: The role of Producer Organizations. New Medit 2018, 17, 21–31. [Google Scholar] [CrossRef]

- European Commission. EU Regulation 2013/1308 and the Commission Delegated Regulation 2016/232; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Chlebicka, A.; Pietrzak, M. Size of membership and survival patterns of producers’ organizations in agriculture—Social aspects based on evidence from Poland. Sustainability 2018, 10, 2293. [Google Scholar] [CrossRef]

- Hendrikse, G.W.J.; Bijman, J. On the emergence of new growers’ associations: Self-selection versus market power. Eur. Rev. Agric. Econ. 2002, 29, 255–269. [Google Scholar] [CrossRef]

- Menard, C. Cooperatives: Hierarchies or Hybrids? In Vertical Markets and Cooperative Hierarchies. The Role of Cooperatives in the Agri-Food Industry; Karantininis, K., Nillson, J., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 1–17. ISBN 1-4020-4072-5. [Google Scholar]

- Devin, B.; Richards, C. Food Waste, Power, and Corporate Social Responsibility in the Australian Food Supply Chain. J. Bus. Ethics 2018, 150, 199–210. [Google Scholar] [CrossRef]

- Eriksson, M.; Ghosh, R.; Mattsson, L.; Ismatov, A. Take-back agreements in the perspective of food waste generation at the supplier-retailer interface. Resour. Conserv. Recycl. 2017, 122, 83–93. [Google Scholar] [CrossRef]

- Skorbiansky, S.R.; Ellison, B. Contracting and quality standards in fresh produce markets and how they impact food loss. In The Economics of Food Loss in the Produce Industry; Routledge: London, UK, 2019; pp. 250–262. [Google Scholar] [CrossRef]

- European Union. Regulation (EU) No 1308/2013 of the European Parliament and of the Council of 17 December 2013; European Union: Luxembourg, 2013. [Google Scholar]

- Fulponi, L. The globalization of private standards and the agri-food system. In Global Supply Chains, Standards and the Poor: How the Globalization of Food Systems and Standards Affects Rural Development and Poverty; CABI: Wallingford, UK, 2007; pp. 5–18. [Google Scholar]

- de Hooge, I.E.; Oostindjer, M.; Aschemann-Witzel, J.; Normann, A.; Loose, S.M.; Almli, V.L. This apple is too ugly for me! Consumer preferences for suboptimal food products in the supermarket and at home. Food Qual. Prefer. 2017, 56, 80–92. [Google Scholar] [CrossRef]

- Hartmann, T.; Jahnke, B.; Hamm, U. Making ugly food beautiful: Consumer barriers to purchase and marketing options for Suboptimal Food at retail level—A systematic review. Food Qual. Prefer. 2021, 90, 104179. [Google Scholar] [CrossRef]

- Huang, W.-S.; Kuo, H.-Y.; Tung, S.-Y.; Chen, H.-S. Assessing Consumer Preferences for Suboptimal Food: Application of a Choice Experiment in Citrus Fruit Retail. Foods 2020, 10, 15. [Google Scholar] [CrossRef]

- de Hooge, I.E.; van Dulm, E.; van Trijp, H.C. Cosmetic specifications in the food waste issue: Supply chain considerations and practices concerning suboptimal food products. J. Clean. Prod. 2018, 183, 698–709. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; Jensen, J.H.; Jensen, M.H.; Kulikovskaja, V. Consumer behaviour towards price-reduced suboptimal foods in the supermarket and the relation to food waste in households. Appetite 2017, 116, 246–258. [Google Scholar] [CrossRef] [PubMed]

- Porter, S.D.; Reay, D.S.; Bomberg, E.; Higgins, P. Avoidable food losses and associated production-phase green-house gas emissions arising from application of cosmetic standards to fresh fruit and vegetables in Europe and the UK. J. Clean. Prod. 2018, 201, 869–878. [Google Scholar] [CrossRef]

- Bloom, J. American Wasteland: How America Throws Away Nearly Half of Its Food (And What We Can Do about It); Da Capo Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Davis, J.; Wallman, M.; Sund, V.; Emanuelsson, A.; Cederberg, C.; Sonesson, U. Emissions of Greenhouse Gases from Production of Horticultural Products—Analysis of 17 Products Cultivated in Sweden; SIK: Gothenberg, Sweden, 2011. [Google Scholar]

- Stuart, T. Waste: Uncovering the Global Food Scandal; WW Norton & Company: New York, NY, USA, 2009. [Google Scholar]

- Fernandez-Zamudio, M.-A.; Barco, H.; Schneider, F. Direct Measurement of Mass and Economic Harvest and Post-Harvest Losses in Spanish Persimmon Primary Production. Agriculture 2020, 10, 581. [Google Scholar] [CrossRef]

- Willersinn, C.; Mack, G.; Mouron, P.; Keiser, A.; Siegrist, M. Quantity and quality of food losses along the Swiss potato supply chain: Stepwise investigation and the influence of quality standards on losses. Waste Manag. 2015, 46, 120–132. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Agriculture and Rural Development. 2018. Available online: https://agriculture.ec.europa.eu/common-agricultural-policy/agri-food-supply-chain/producer-and-interbranch-organisations_en (accessed on 7 December 2022).

- Kallio, H.; Pietilä, A.-M.; Johnson, M.; Kangasniemi, M. Systematic methodological review: Developing a framework for a qualitative semi-structured interview guide. J. Adv. Nurs. 2016, 72, 2954–2965. [Google Scholar] [CrossRef]

- Herzberg, R.; Schmidt, T.; Keck, M. Market power and food loss at the producer-retailer interface of fruit and vegetable supply chains in Germany. Sustain. Sci. 2022, 17, 2253–2267. [Google Scholar] [CrossRef]

- Kuckartz, U. Qualitative Inhaltsanalyse. Methoden, Praxis, Computerunterstützung. 4. Auflage; Beltz Juventa (Grundlagentexte Methoden): Weinheim, Germany; Basel, Switzerland, 2018. [Google Scholar]

- Surucu-Balci, E.; Tuna, O. Investigating logistics-related food loss drivers: A study on fresh fruit and vegetable supply chain. J. Clean. Prod. 2021, 318, 128561. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’Amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- de Oliveira, M.M.; Lago, A.; Dal’Magro, G.P. Food loss and waste in the context of the circular economy: A systematic review. J. Clean. Prod. 2021, 294, 126284. [Google Scholar] [CrossRef]

- Gandorfer, M.; Porsch, A.; Bitsch, V. Producer price volatility in the German fruit and vegetable industry. Eur. J. Hortic. Sci. 2017, 82, 149–154. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J.; de Hooge, I.E.; Almli, V.L. Suboptimal food? Food waste at the consumer–retailer interface. In Saving Food; Academic Press: Cambridge, MA, USA, 2019; pp. 347–368. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chains during the COVID-19 pandemic. Can. J. Agric. Econ./Rev. Can. D’agroecon. 2020, 68, 171–176. [Google Scholar] [CrossRef]

- Bustos, C.A.; Moors, E.H. Reducing post-harvest food losses through innovative collaboration: Insights from the Colombian and Mexican avocado supply chains. J. Clean. Prod. 2018, 199, 1020–1034. [Google Scholar] [CrossRef]

- Sexton, R.J. Market power, misconceptions, and modern agricultural markets. Am. J. Agric. Econ. 2013, 95, 209–219. [Google Scholar] [CrossRef]

- Fałkowski, J.; Chlebicka, A. What product mix do they offer and what marketing channels do they use? Exploring agricultural producer organisations’ heterogeneity. J. Rural. Stud. 2021, 85, 1–12. [Google Scholar] [CrossRef]

- Velázquez, B.; Buffaria, B.; European Commission. About farmers’ bargaining power within the new CAP. Agric. Food Econ. 2017, 5, 16. [Google Scholar] [CrossRef]

- Camanzi, L.; Malorgio, G.; Azcárate, T.G. The role of producer organizations in supply concentration and mar-keting: A comparison between European countries in the fruit and vegetable sector. J. Food Prod. Mark. 2011, 17, 327–354. [Google Scholar] [CrossRef]

- Brancoli, P.; Lundin, M.; Bolton, K.; Eriksson, M. Bread loss rates at the supplier-retailer interface—Analysis of risk factors to support waste prevention measures. Resour. Conserv. Recycl. 2019, 147, 128–136. [Google Scholar] [CrossRef]

- Kulikovskaja, V.; Aschemann-Witzel, J. Food Waste Avoidance Actions in Food Retailing: The Case of Denmark. J. Int. Food Agribus. Mark. 2017, 29, 328–345. [Google Scholar] [CrossRef]

- European Commission. EU Directive 2019/633 of the European Parliament and the Council of 17 April 2019; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Rezitis, A.N.; Pachis, D.N. Investigating the price volatility transmission mechanisms of selected fresh vegetable chains in Greece. J. Agribus. Dev. Emerg. Econ. 2020, 10, 587–611. [Google Scholar] [CrossRef]

- Van Herck, K. Assessing Efficiencies Generated by Agricultural Producer Organisations; Publications Office of the European Union: Luxemburg, 2014; ISBN 978-92-79-39284-9. [Google Scholar]

- Porter, S.D.; Reay, D.S.; Bomberg, E.; Higgins, P. Production-phase greenhouse gas emissions arising from de-liberate withdrawal and destruction of fresh fruit and vegetables under the EU’s Common Agricultural Policy. Sci. Total Environ. 2018, 631, 1544–1552. [Google Scholar] [CrossRef]

- Bilska, B.; Wrzosek, M.; Kołożyn-Krajewska, D.; Krajewski, K. Risk of food losses and potential of food recovery for social purposes. Waste Manag. 2016, 52, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Giordano, C.; Falasconi, L.; Cicatiello, C.; Pancino, B. The role of food waste hierarchy in addressing policy and research: A comparative analysis. J. Clean. Prod. 2020, 252, 119617. [Google Scholar] [CrossRef]

- European Commission. 2021. Available online: https://food.ec.europa.eu/safety/food-waste/eu-actions-against-food-waste/food-donation_en (accessed on 16 March 2023).

- Vandemoortele, T.; Deconinck, K. When Are Private Standards More Stringent than Public Standards? Am. J. Agric. Econ. 2013, 96, 154–171. [Google Scholar] [CrossRef]

- Athai, J.; Kuntscher, M.; Schmidt, T.G. Lebensmittelabfälle und-Verluste in der Primärproduktion und in der Verarbeitung (Food Waste and Loss in Primary Production and Processing); Thünen Working Paper 209; Johann Heinrich von Thünen-Institut: Braunschweig, Germant, 2023; 125p. [Google Scholar] [CrossRef]

- Lombart, C.; Millan, E.; Normand, J.-M.; Verhulst, A.; Labbé-Pinlon, B.; Moreau, G. Consumer perceptions and purchase behavior toward imperfect fruits and vegetables in an immersive virtual reality grocery store. J. Retail. Consum. Serv. 2019, 48, 28–40. [Google Scholar] [CrossRef]

- Bolos, L.; Lagerkvist, C.; Kulesz, M. Complementarity of implicit and explicit attitudes in predicting the purchase likelihood of visually sub-optimal or optimal apples. Food Qual. Prefer. 2019, 75, 87–96. [Google Scholar] [CrossRef]

- Beausang, C.; Hall, C.; Toma, L. Food waste and losses in primary production: Qualitative insights from horticulture. Resour. Conserv. Recycl. 2017, 126, 177–185. [Google Scholar] [CrossRef]

- Loebnitz, N.; Schuitema, G.; Grunert, K.G. Who buys oddly shaped food and why? Impacts of food shape abnormality and organic labeling on purchase intentions. Psychol. Mark. 2015, 32, 408–421. [Google Scholar] [CrossRef]

- Meyer, C.H.; Hamer, M.; Frieling, D.; Oertzen, G. Lebensmittelverluste von Obst, Gemüse, Kartoffeln zwischen Feld und Ladentheke—Ergebnisse einer Studie in Nordrhein-Westfalen. Landesamt für Natur, Umwelt und Verbraucherschutz Nordrhein-Westfalen (LANUV), Fachbericht 85. 2018. Available online: https://www.lanuv.nrw.de/fileadmin/lanuvpubl/3_fachberichte/fabe85_Lebensmittelverluste_gesichert.pdf (accessed on 23 March 2023).

- Aschemann-Witzel, J.; Giménez, A.; Ares, G. Suboptimal food, careless store? Consumer’s associations with stores selling foods with imperfections to counter food waste in the context of an emerging retail market. J. Clean. Prod. 2020, 262, 121252. [Google Scholar] [CrossRef]

- Aschemann-Witzel, J. Consumer perception and preference for suboptimal food under the emerging practice of expiration date based pricing in supermarkets. Food Qual. Prefer. 2018, 63, 119–128. [Google Scholar] [CrossRef]

- Van Giesen, R.I.; de Hooge, I.E. Too ugly, but I love its shape: Reducing food waste of suboptimal products with authenticity (and sustainability) positioning. Food Qual. Prefer. 2019, 75, 249–259. [Google Scholar] [CrossRef]

- Dein Abo zum Lebensmittel retten. Available online: https://querfeld.bio (accessed on 10 May 2023).

- DEINE BIO-KISTE. Available online: https://etepetete-bio.de (accessed on 10 May 2023).

- Gemüse & Obst in bester Bio-Qualität krumm, gerade, we don´t care Verformt statt genormt? Available online: https://www.afreshed.at (accessed on 10 May 2023).

- Fight Food Waste with a Delivery of Deliciously Odd Fruit & Veg. Available online: https://www.oddbox.co.uk (accessed on 10 May 2023).

| PO | Country | Number of Members | Total Acreage (ha) | Products |

|---|---|---|---|---|

| PO 1 | Germany | 19 | 600 | Onions |

| PO 2 | Germany | 1200 | 900 | Pomaceous Fruit, Berries, and Asparagus |

| PO 3 | Germany | 60 | 152 | Vegetables |

| PO 4 | Germany | 330 | 2500 | Pomaceous Fruit |

| PO 5 | Germany | 350 | 5500 | Pomaceous Fruit |

| PO 6 | Germany | 50 | 270 | Vegetables and Herbs |

| PO 7 | Germany | 50 | 10,000 | Vegetables and Herbs |

| PO 8 | Italy | 183 | 1200 | Salad, Potatoes, Carrots, and Fennel |

| PO 9 | Italy | 85 | 565 | Potatoes, Cabbage, Chickpeas, Beans, and Lentils |

| PO 10 | Italy | 4957 | 32,091 | Fruits, Potatoes, and Onions |

| Thematic Areas | Similarities | Differences |

|---|---|---|

| Supply chain organisation | Structure of the FFV supply chain is vertically integrated. Central role of the PO, and as intermediary between farmers and retailers. POs store and prepare the products to be sold. Orders are made with short notice. Flexibility of POs to supply orders. | Selection takes place at different stages of the products (field for Germany; POs’ warehouse in Italy). POs mostly plan the quantity and products to be cultivated by farmers in the next season to better supply orders in Italy; some members have more leeway in product and quantity planning in Germany. Timing and quantities to be delivered are negotiated at the beginning of the season in Italy, informally agreed upon within annual consultations in Germany |

| Contracts and agreements | POs represent farmers in the commercial relations and negotiations. Buyers take advantage due to their bargaining position. POs usually have contracts with different buyers. Contracts with the food industry are generally considered more reliable (hardly changing quantity and timing that is demanded). Price paid by retailers is higher than the one of the food industries; therefore, retailers are the first choice. Timing and quantity of everyday orders can vary significantly during the season. Final quantities and prices are defined on a short-term basis by retailers and last-minute changes are frequent. Some of the contracts between POs and retailers are on the edge of unfair trading practices (EU legislation). Prices between POs and retailers are negotiated upon weekly or biweekly; influenced by the European and world market prices. Promotions are scheduled by retailers at the beginning of the year, while quantities are announced few weeks before; this is considered a potentially strategic tool to avoid FL. | Economic risks are with different actors of the supply chain. Ownership of the products belongs to POs in Italy, to different stakeholders (POs or farmers) in Germany. Timing, negotiation, and structure of contracts differs between POs and buyers. Differences in the mechanism of the price setting between POs and retailers, and between farmers and POs. |

| FL and quality standards | Private quality standards are a crucial issue in generating FL. Each retailer asks for different specific quality standards that are generally stricter than the quasi-public and public standards imposed by the EU and UNECE. If private standards are not respected, products are not accepted during the retailer’s quality control and are sent back to the PO, which potentially generates FL. Visual standards, calibres, and pesticide limits are the most difficult private quality standards to be reached. Many alternative marketing channels are available to reallocate suboptimal products. The combination of restrictions to pesticide use and cosmetic standards leads to a higher likelihood of FL generation in organic supply chains compared to conventional ones. | Quality standards are mostly specified in the contracts in Italy; retailers impose these standards in an informal manner (or written form but not contract) in Germany. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pietrangeli, R.; Herzberg, R.; Cicatiello, C.; Schneider, F. Quality Standards and Contractual Terms Affecting Food Losses: The Perspective of Producer Organisations in Germany and Italy. Foods 2023, 12, 1984. https://doi.org/10.3390/foods12101984

Pietrangeli R, Herzberg R, Cicatiello C, Schneider F. Quality Standards and Contractual Terms Affecting Food Losses: The Perspective of Producer Organisations in Germany and Italy. Foods. 2023; 12(10):1984. https://doi.org/10.3390/foods12101984

Chicago/Turabian StylePietrangeli, Roberta, Ronja Herzberg, Clara Cicatiello, and Felicitas Schneider. 2023. "Quality Standards and Contractual Terms Affecting Food Losses: The Perspective of Producer Organisations in Germany and Italy" Foods 12, no. 10: 1984. https://doi.org/10.3390/foods12101984

APA StylePietrangeli, R., Herzberg, R., Cicatiello, C., & Schneider, F. (2023). Quality Standards and Contractual Terms Affecting Food Losses: The Perspective of Producer Organisations in Germany and Italy. Foods, 12(10), 1984. https://doi.org/10.3390/foods12101984