Addition of Chickpea Flour in Durum Wheat Flour Makes Tortilla More Nutritious and Palatable, and Technologically Acceptable

Abstract

1. Introduction

2. Material and methods

2.1. Raw Material

2.2. Nutritional Attributes

2.3. Functional Properties

2.4. Technological Parameters

2.5. Baking Test

2.6. Nutritional Quality

2.7. Technological Quality

2.8. Effects of Tortilla Making and Baking on Proteins, Minerals, and Technological Parameters

2.9. Effect of Storage Time on Weight, Appearance, Odor and Shelf Stability (Flexibility)

2.10. Consumer Sensory Appreciation

2.11. Statistical Analysis

3. Results and Discussion

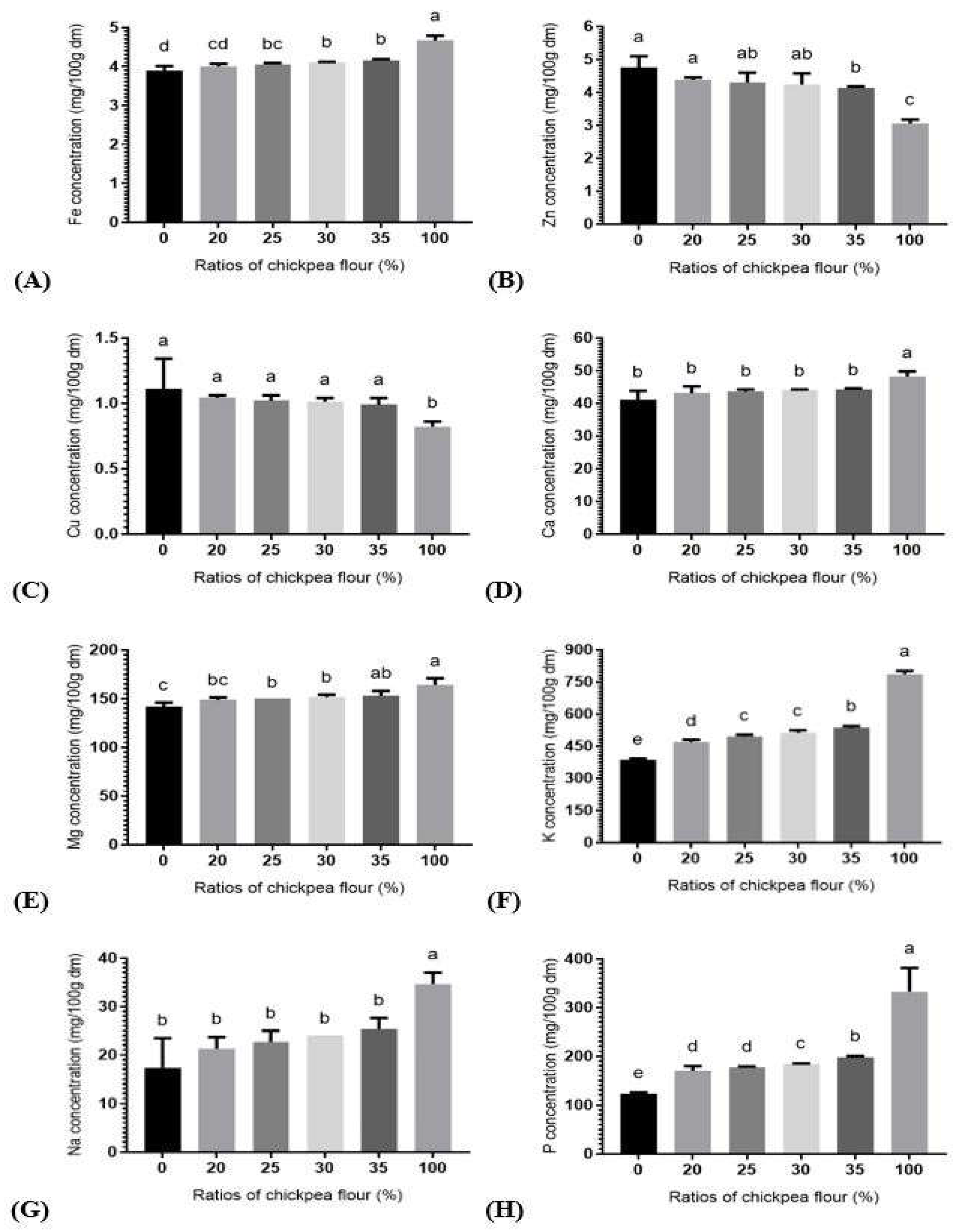

3.1. Nutritional attributes

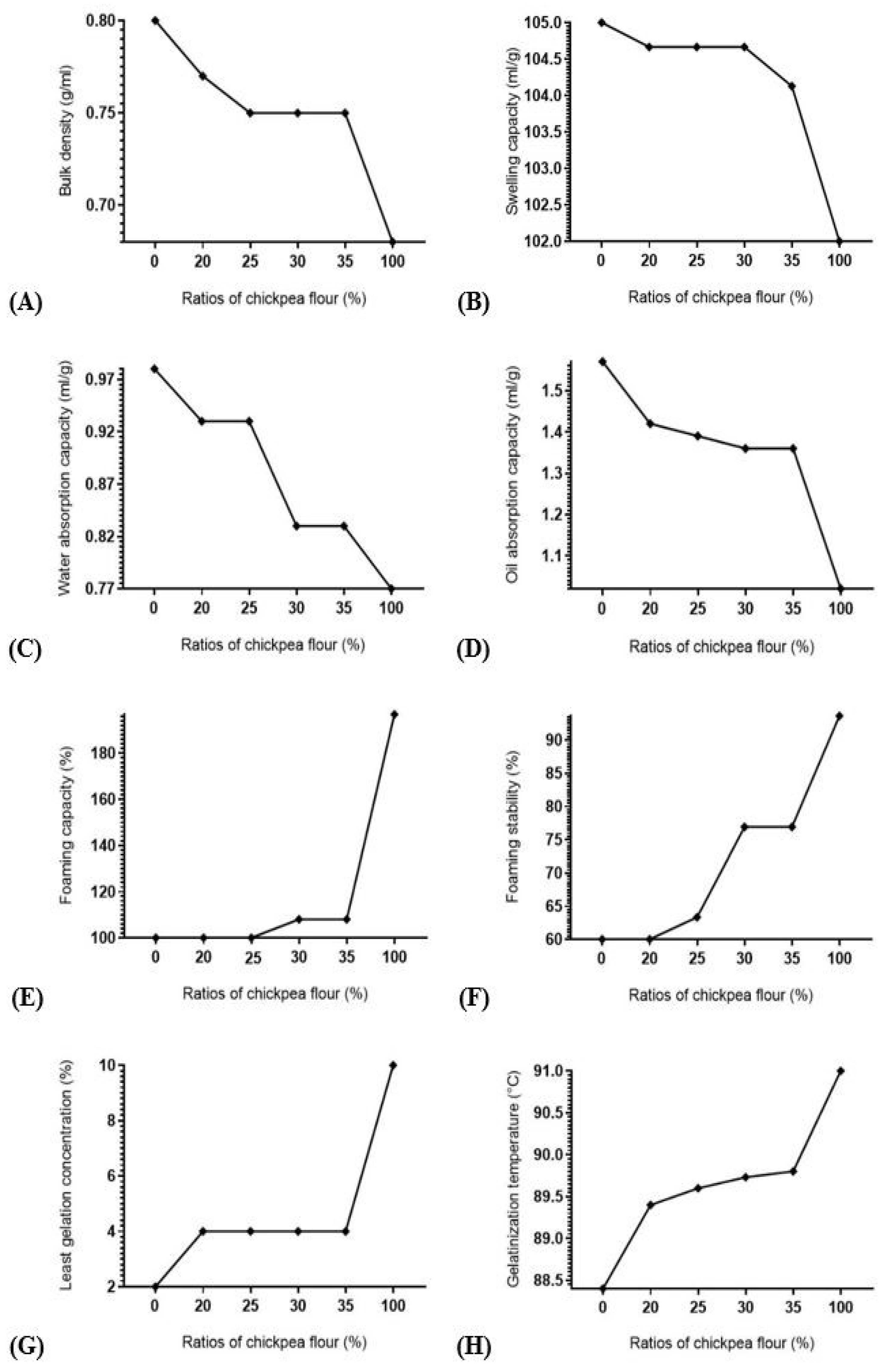

3.2. Functional Properties

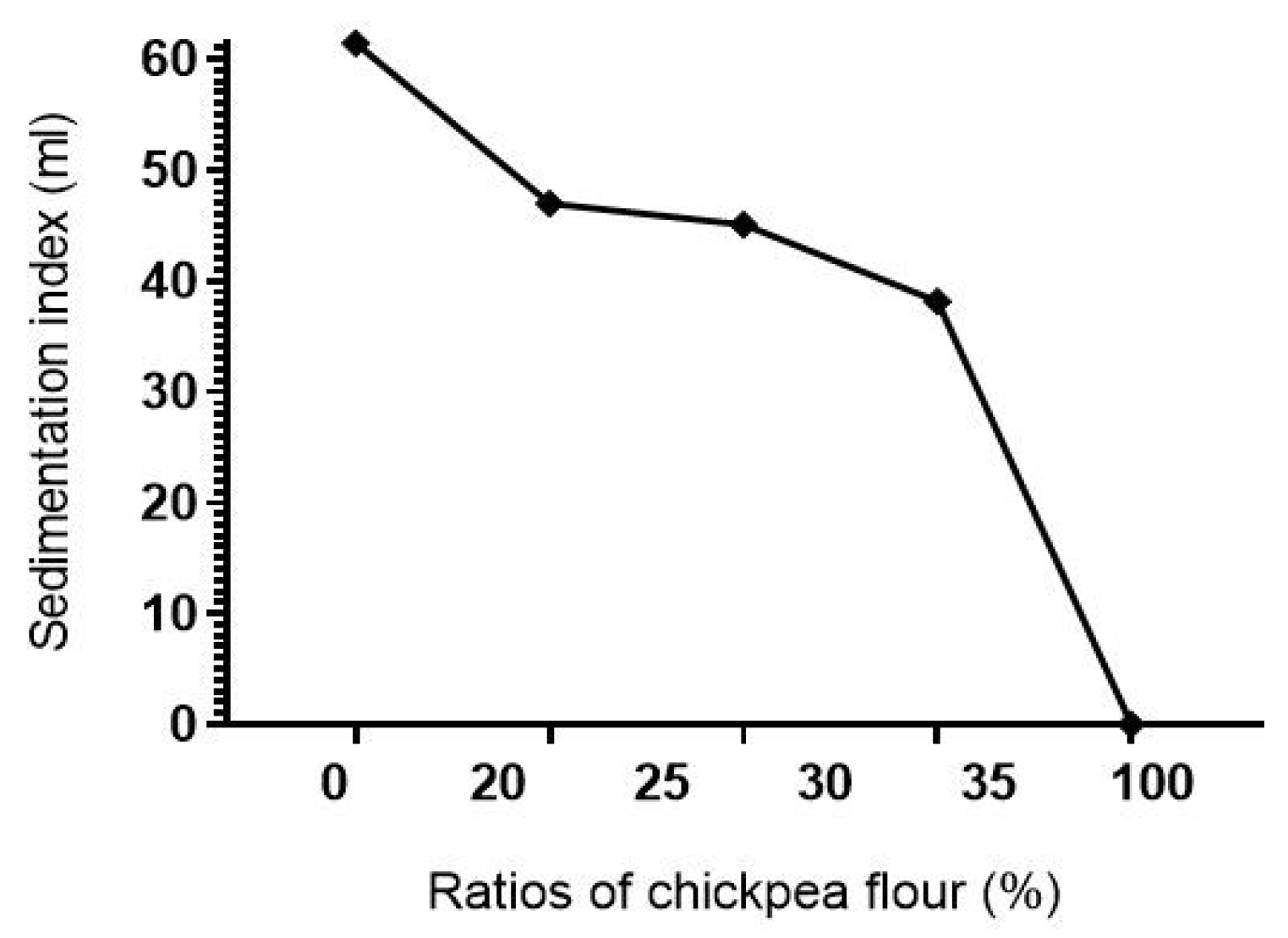

3.3. Technological Parameters

3.4. Nutritional Quality

3.5. Technological Quality

3.6. Effects of Tortillas Making and Baking on Proteins, Minerals, and Technological Parameters

3.7. Storage Time Effect on Weight, Appearance, Odor and Shelf Stability

3.8. Sensory Appreciation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taghouti, M.; Nsarellah, N.; Rhrib, K.; Benbrahim, N.; Amallah, L.; Rochdi, A. Evolution from durum wheat landraces to recent improved varieties in Morocco in terms of productivity increase to the detriment of grain quality. Revue Marocaine des Sciences Agronomiques et Vétérinaires 2017, 5, 351–358. [Google Scholar]

- Aboussaleh, Y.; Farsi, M.; El Hioui, M.; Ahami, A. Transition nutritionnelle au Maroc: Coexistence de l’anémie et de l’obésité chez les femmes au Nord-Ouest marocain. Antropo 2009, 19, 66–74. Available online: http://www.didac.ehu.es/antropo/19/19-8/Aboussaleh.pdfa (accessed on 20 April 2022).

- Allali, F. Evolution des pratiques alimentaires au Maroc nutrition transition in Morocco. Int. J. Med. Surg. 2017, 4, 68–71. [Google Scholar] [CrossRef]

- Aboussaleh, Y.; Sbaibi, R.; El Hioui, M.; Ahami, A. La carence en fer et le développement cognitif. Antropo 2011, 25, 91–96. Available online: http://www.didac.ehu.es/antropo/25/25-8/Aboussaleh.htm (accessed on 20 April 2022).

- Achouri, I.; Aboussaleh, Y.; Sbaibi, R.; El Hioui, M.; Ahami, A. Prevalence of iron deficiency anemia and associated factors among urban school children in Kenitra, northwest of Morocco. Pak. J. Biol. Sci. 2015, 18, 191–195. [Google Scholar] [CrossRef][Green Version]

- Chadare, F.J.; Idohou, R.; Nago, E.; Affonfere, M.; Agossadou, J.; Fassinou, T.K.; Kénou, C.; Honfo, S.; Azokpota, P.; Linnemann, A.R.; et al. Conventional and food-to-food fortification: An appraisal of past practices and lessons learned. Food Sci. Nutr. 2019, 7, 2781–2795. [Google Scholar] [CrossRef]

- Benali, A.; En-nahli, Y.; Noutfia, Y.; Elbaouchi, A.; Kabbour, M.R.; Gaboun, F.; El Maadoudi, E.H.; Benbrahim, N.; Taghouti, M.; Ouhssine, M.; et al. Nutritional and Technological Optimization of Wheat-Chickpea-Milk Powder Composite Flour and Its Impact on Rheological and Sensorial Properties of Leavened Flat Bread. Foods 2021, 10, 1843. [Google Scholar] [CrossRef]

- Benayad, A.; Taghouti, M.; Benali, A.; Aboussaleh, Y.; Benbrahim, N. Nutritional and technological assessment of durum wheat-faba bean enriched flours, and sensory quality of developed composite bread. Saudi J. Biol. Sci. 2020, 28, 635–642. [Google Scholar] [CrossRef]

- Bouhlal, O.; Taghouti, M.; Benbrahim, N.; Benali, A.; Visioni, A.; Benba, J. Wheat-lentil fortified flours: Health benefits, physicochemical, nutritional and technological properties. J. Mater. Environ. Sci. 2019, 10, 1098–1106. [Google Scholar]

- Maphosa, Y.; Jideani, V.A. The role of legumes in human nutrition. In Book of Functional Food-Improve Health through Adequate Food; María, C.H., Ed.; IntechOpen: London, UK; Cadix, Spain, 2017; pp. 104–121. [Google Scholar]

- Piga, A.; Conte, P.; Fois, S.; Catzeddu, P.; Del Caro, A.; Sanguinetti, A.M.; Fadda, C. Technological, nutritional and sensory properties of an innovative gluten-free double-layered flat bread enriched with amaranth flour. Foods 2021, 10, 920. [Google Scholar] [CrossRef]

- AACC (American Association of Cereal Chemists). Approved Methods of the AACC, 10th ed.; Cereals & Grains Assn: St Paul, MN, USA, 2000; 1200p. [Google Scholar]

- AOAC (Association of Official Analytical Chemists). Official Methods of Analysis of Association of Official Analytical Chemists, 18th ed.; Association of Officiating Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- Osborne, D.R.; Voogt, P. Calculation of caloric value. In The Analysis of Nutrients in Foods; Osborne, D.R., Voogt, P., Eds.; Academic Press: New York, NY, USA, 1978; pp. 239–340. [Google Scholar]

- Chapman, H.D.; Pratt, F.P. Determination of minerals by titration method. In Methods of Analysis for Soils, Plants and Water, 2nd ed.; Chapman, H.D., Pratt, F.P., Eds.; California University: Oakland, CA, USA, 1982; pp. 169–170. [Google Scholar]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Officiating Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Khalil, I.A.; Manan, F. Chemistry-One (Bio-Analytical Chemistry), 2nd ed.; Tajkutab Khana: Peshawar, Pakistan, 1990. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Meth. Enzymol. 1999, 299, 152–178. [Google Scholar]

- Julkunen-titto, R. Phenolic constituents in the leaves of northern willows: Methods for the analysis of certain phenolics. J. Agric. Food Chem. 1985, 33, 213–217. [Google Scholar] [CrossRef]

- Mansouri, A.; Embarek, G.; Kokkalou, E.; Kefalas, P. Phenolic profile and antioxidant activity of the Algerian ripe date palm fruit (Phoenix dactylifera). Food Chem. 2005, 89, 411–420. [Google Scholar] [CrossRef]

- Onwuka, G.I. Food Analysis and Instrumentation: Theory and Practice; Naphtali Prints: Lagos, Nigeria, 2005; 219p. [Google Scholar]

- Robertson, J.A.; DE Monredon, F.D.; Dysseler, P.; Guillon, F.; Amado, R.; Thibault, J.F. Hydration Properties of Dietary Fibre and Resistant Starch: A European collaborative study. LWT—Food Sci. Technol. 2000, 33, 72–79. [Google Scholar] [CrossRef]

- Beuchat, L.R. Functional and electrophoretic characteristics of succinylated peanut flour protein. J. Agric. Food Chem. 1977, 25, 258–261. [Google Scholar] [CrossRef]

- Narayana, K.; Narsinga, Rao, M.S. Functional properties of war and heat processed winged bean (Psophocarpus tetragonolobus) flour. J. Food Sci. 1982, 42, 534–538. [Google Scholar]

- Mugendi, J.B.W.; Njagi, E.N.M.; Kuria, E.N.; Mwasaru, M.A.; Mureithi, J.G.; Apostolides, Z. Nutritional quality and physicochemical properties of Mucuna bean (Mucuna pruriens L.) protein isolates. Int. Food Res. J. 2010, 17, 357–366. [Google Scholar]

- Shinde, B.G. Isolation and Characterization of Starch Horse Gram. Unpublished Master’s Thesis, Department of Food Science and Technology, MPKV, Rahuri, India, 2001; pp. 16–17. [Google Scholar]

- NF ISO 11664-4; Colorimetry, Part 4: Color Space L * a * b * CIE 1976 (Classification Index: T36-007-4PR). European Committee for Standardization: Brussels, Belgium, 2008.

- AACC. Approved Methods of the AACC, 8th ed; AACC: St Paul, MN, USA, 1984; Method 76-30A. [Google Scholar]

- Hernández-López, I.; Benavente Valdés, J.R.; Castellari, M.; Aguiló-Aguayo, I.; Morillas-España, A.; Sánchez-Zurano, A.; Acién-Fernández, F.G.; Lafarga, T. Utilisation of the marine microalgae Nannochloropsis sp. and Tetraselmis sp. as innovative ingredients in the formulation of wheat tortillas. Algal Res. 2021, 58, 102361. [Google Scholar] [CrossRef]

- Makinde, F.M.; Akinoso, R. Physical, nutritional and sensory qualities of bread samples made with wheat and black sesame (Sesamum indicum Linn) flours. Int. Food Res. J. 2014, 21, 1635–1640. [Google Scholar]

- Araki, E.; Ikda, T.M.; Ashida, K.; Takata, K.; Yanaka, M.; Iida, S. Effects of rice flour properties on specific loaf volume of one-loaf bread made from rice flour with wheat vital gluten. Food Sci. Technol. Res. 2009, 15, 439–448. [Google Scholar] [CrossRef]

- Bello, A.B.; Senna-Saldivar, S.O.; Waniska, R.D.; Rooney, L.W. Methods to prepare and evaluate wheat tortillas. Cereal Foods World. 1991, 36, 315–322. [Google Scholar]

- Bayomy, H.; Alamri, E. Technological and nutritional properties of instant noodles enriched with chickpea or lentil flour. J. King Saud Univ. Sci. 2022, 34, 101833. [Google Scholar] [CrossRef]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Madurapperumage, A.; Tang, L.; Thavarajah, P.; Bridges, W.; Shipe, E.; Vandemark, G.; Thavarajah, D. Chickpea (Cicer arietinum L.) as a source of essential fatty acids—A biofortification approach. Front. Plant Sci. 2021, 12, 734980. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez-Grijalva, E.P.; Ambriz-Pere, D.L.; Leyva-Lopez, N.; Castillo-Lopez, R.I.; Heiedia, J.B. Review: Dietary phenolic compounds, health benefits and bioaccessibility. Arch. Latinoam. Nutr. 2016, 66, 87–100. [Google Scholar] [PubMed]

- Boucheham, N.; Galet, L.; Patry, S.; Zidoune, M.N. Physicochemical and hydration properties of different cereal and legume gluten-free powders. Food Sci. Nutr. 2019, 7, 3081–3092. [Google Scholar] [CrossRef] [PubMed]

- Yıldırım, A.; Karaboğa, Z.Y. The effects of corn and chickpea flours on the quality of mardin peksimet. In Proceedings of the International Conference on Food, Agriculture and Animal Husbandry, Gaziantep, Turkey, 19–22 September 2019. [Google Scholar]

- Diallo, S.; Doudjo, S.; Youssouf, K.K.; Emmanuel, A.N.; Benjamin, Y.K.; Dago, G. Fortification et substitution de la farine de blé par la farine de Voandzou (Vigna subterranea L. verdc) dans la production des produits de boulangerie. Int. J. Innov. Sci. Res. 2015, 18, 434–443. [Google Scholar]

- Stone, A.K.; Nosworthy, M.G.; Chiremba, C.; House, J.D.; Nickerson, M.T. A comparative study of the functionality and protein quality of a variety of legume and cereal flours. Cereal. Chem. 2019, 96, 1–11. [Google Scholar] [CrossRef]

- Orisa, C.A.; Udofia, S.U. Functional and pasting properties of composite flours from Triticum durum, Digitaria exilis, Vigna unguiculata and Moringa oleifera Powder. Asian Food Sci. J. 2020, 19, 40–49. [Google Scholar] [CrossRef]

- Falade, K.O.; Okafor, C.A. Physical, functional, and pasting properties of flours from corms of two Cocoyam (Colocasiaesculenta and Xanthosoma sagittifolium) cultivars. Food Sci. Technol. 2015, 52, 3440–3448. [Google Scholar]

- Nawaz, H.; Shad, M.A.; Mehmood, R.; Rehman, T.; Munir, H. Comparative evaluation of functional properties of some commonly used cereal and legume flours and their blends. Int. J. Food Allied Sci. 2015, 1, 67–73. [Google Scholar] [CrossRef]

- Ocheme, O.B.; Oloyede, O.O.; Mahmud, A.H. Production and evaluation of bread usingblends of wheat flour and fermented plantain flour. Niger. Food J. 2010, 28, 284–293. [Google Scholar]

- Suresh, C. Assessment of functional properties of different flours. Afr. J. Agric. Res. 2013, 8, 4849–4852. [Google Scholar]

- Culetu, A.; Susman, I.E.; Duta, D.E.; Belc, N. Nutritional and functional properties of gluten-free flours. Appl. Sci. 2021, 11, 6283. [Google Scholar] [CrossRef]

- Chaiyakul, S.; Sukkasem, D.; Natthapanpaisith, P. Effect of flour concentration and retrogradation treatment on physical properties of instant sinlek brown rice. Int. J. Food Eng. 2016, 3, 783–791. [Google Scholar]

- Buckman, E.S.; Oduro, I.; Plahar, W.A.; Tortoe, C. Determination of the chemical and functional properties of yam bean (Pachyrhizus erosus (L.) Urban) flour for food systems. Food Sci. Nutr. 2017, 6, 457–463. [Google Scholar] [CrossRef]

- Yousseff, S.A.M.; Salem, A.; Abdel-Rahman, A.H.Y. Supplementation of bread with soybean and chickpea flours. Int. J. Food Sci. Technol. 1976, 11, 599–605. [Google Scholar] [CrossRef]

- Brannan, R.G.; Mah, E.; Schott, M.; Yuan, S.; Casher, K.L.; Myers, A.; Herrick, C. Influence of ingredients that reduce oil absorption during immersion frying of battered and breaded foods. Eur. J. Lipid Sci. Technol. 2014, 116, 240–254. [Google Scholar] [CrossRef]

- Iwe, M.O.; Onyeukwu, U.; Agiriga, A.N. Proximate, functional and pasting properties of FARO 44 rice, African yam bean and brown cowpea seeds composite flour. Cogent Food Agric. 2016, 5, 1142409. [Google Scholar] [CrossRef]

- Cubadda, R.E.; Carcea, M.; Marconi, E.; Trivisonno, M.C. Influence of protein content on durum wheat gluten strength determined by the SDS Sedimentation Test and by other methods. Cereal Food World. 2007, 52, 273–277. [Google Scholar] [CrossRef]

- Brooker, D. Tortilla Tips: Moisture Content of Tortillas. 2010. Available online: https://www.tortillanews.com/2010/04/tortilla-tips-moisture-content-of-tortilla (accessed on 19 July 2022).

- Alviola, J.N.; Waniska, R.D.; Rooney, L.W. Role of gluten in flour tortilla staling. Cereal Chem. 2008, 85, 295–300. [Google Scholar] [CrossRef]

- Jukić, M.; Komlenić, D.K.; Mastanjević, K.; Mastanjević, K.; Lučan, M.; Popovici, C.; Nakov, G.; Lukinac, J. Influence of damaged starch on the quality parameters of wheat doughand bread. Food Technol. 2019, 8, 512–521. [Google Scholar]

- Baik, B.K.; Han, I.H. Cooking, Roasting, and Fermentation of Chickpeas, Lentils, Peas, and Soybeans for Fortification of Leavened Bread. Cereal Chem. 2012, 89, 269–275. [Google Scholar] [CrossRef]

- IOM (Institute of Medicine). EBook of Dietary Reference intakes for Water, Potassium, Sodium, Chloride, and Sulfate; National Academies Press: Washington, DC, USA, 2005. Available online: https://www.ncbi.nlm.nih.gov/books/NBK545428/ (accessed on 19 July 2022).

| Combinations | Parameters | ||||||

|---|---|---|---|---|---|---|---|

| MS (%, dm) | CA (%, dm) | CP (%, dm) | CFb (%, dm) | CF (%, dm) | TC (%, dm) | EV (kcal/100 g, dm) | |

| 100%WF | 9.55 ± 0.41 abc | 1.96 ± 0.08 f | 11.37 ± 0.15 f | 3.47 ± 0.28 bc | 1.80 ± 0.20 d | 75.32 ± 0.82 a | 362.97 ± 1.01 c |

| 20%CPF:80%WF | 9.40 ± 0.02 a | 2.12 ± 0.03 e | 13.63 ± 0.06 e | 3.54 ± 0.02 c | 1.93 ± 0.12 d | 72.91 ± 0.20 b | 363.57 ± 0.45 bc |

| 25%CPF:75%WF | 9.36 ± 0.01 b | 2.24 ± 0.05 d | 14.43 ± 0.15 d | 3.56 ± 0.01 c | 2.03 ± 0.06 cd | 71.92 ± 0.25 c | 363.72 ± 0.19 bc |

| 30%CPF:70%WF | 9.32 ± 0.02 c | 2.37 ± 0.04 c | 15.27 ± 0.15 c | 3.59 ± 0.02 b | 2.13 ± 0.06 bc | 70.94 ± 0.18 d | 363.91 ± 0.36 bc |

| 35%CPF:65%WF | 9.29 ± 0.03 c | 2.48 ± 0.03 b | 16.10 ± 0.10 b | 3.62 ± 0.02 b | 2.20 ± 0.00 b | 69.94 ± 0.16 e | 363.95 ± 0.23 b |

| 100%CPF | 9.07 ± 0.11 d | 3.15 ± 0.09 a | 23.17 ± 0.15 a | 4.03 ± 0.06 a | 2.79 ± 0.20 a | 61.83 ± 0.32 f | 365.12 ± 0.97 a |

| Combinations | Parameters | |||

|---|---|---|---|---|

| TPC (mg GAE/g dm) | CT (mg CE/g dm) | TF (mg QE/g dm) | ARA (% dm) | |

| 100%WF | 0.51 ± 0.01 d | 2.50 ± 0.03 d | 0.03 ± 0.00 e | 28.29 ± 0.51 f |

| 20%CPF:80%WF | 0.54 ± 0.01 c | 2.57 ± 0.03 c | 0.05 ± 0.00 d | 35.09 ± 1.70 e |

| 25%CPF:75%WF | 0.55 ± 0.00 c | 2.58 ± 0.00 c | 0.06 ± 0.00 c | 37.16 ± 0.17 d |

| 30%CPF:70%WF | 0.55 ± 0.01 bc | 2.59 ± 0.01 bc | 0.06 ± 0.00 b | 40.02 ± 1.29 c |

| 35%CPF:65%WF | 0.56 ± 0.01 b | 2.62 ± 0.02 b | 0.07 ± 0.00 b | 42.47 ± 0.71 b |

| 100%CPF | 0.66 ± 0.05 a | 2.74 ± 0.11 a | 0.14 ± 0.00 a | 58.03 ± 0.38 a |

| Combinations | Parameters | ||

|---|---|---|---|

| a | b | L | |

| 100%WF | −1.43 ± 0.02 c | 16.50 ± 0.02 f | 68.78 ± 0.36 bcd |

| 20%CPF:80%WF | −1.41 ± 0.01 c | 17.15 ± 0.02 e | 68.86 ± 0.02 d |

| 25%CPF:75%WF | −1.39 ± 0.02 bc | 17.32 ± 0.02 d | 68.88 ± 0.01 cd |

| 30%CPF:70%WF | −1.39 ± 0.02 bc | 17.49 ± 0.01 c | 68.90 ± 0.01 c |

| 35%CPF:65%WF | −1.38 ± 0.00 b | 17.66 ± 0.01 b | 68.93 ± 0.01 b |

| 100%CPF | −1.25 ± 0.00 a | 19.97 ± 0.06 a | 69.30 ± 0.01 a |

| Parameters | Combinations | ||

|---|---|---|---|

| 100%WF | 25%CPF:75%WF | 30%CPF:70%WF | |

| MS (%, dm) | 17.74 ± 0.30 c | 22.08 ± 2.19 b | 25.73 ± 0.64 a |

| CA (%, dm) | 1.97 ± 0.01 b | 2.29 ± 0.50 a | 2.55 ± 0.43 a |

| CP (%, dm) | 11.50 ± 0.00 c | 14.50 ± 0.00 b | 15.70 ± 0.00 a |

| Fe (mg 100 g−1 dm) | 3.35 ± 0.01 c | 3.61 ± 0.01 b | 3.80 ± 0.00 a |

| Zn (mg 100 g−1 dm) | 4.04 ± 0.01 a | 3.65 ± 0.01 b | 3.62 ± 0.01 c |

| Cu (mg 100 g−1 dm) | 0.53 ± 0.00 a | 0.62 ± 0.00 b | 0.62 ± 0.00 b |

| Mn (mg 100 g−1 dm) | 1.00 ± 0.01 c | 1.32 ± 0.01 b | 1.40 ± 0.00 a |

| K (mg 100 g−1 dm) | 282.67 ± 4.62 c | 413.87 ± 0.46 b | 437.33 ± 4.62 a |

| Na (mg 100 g−1 dm) | 986.67 ± 11.54 a | 993.33 ± 11.54 a | 996.00 ± 6.92 a |

| Parameters | Combinations | ||

|---|---|---|---|

| 100%WF | 25%CPF:75%WF | 30%CPF:70%WF | |

| Added water (mL) to the dough | 50.00 | 46.00 | 44.00 |

| Cooking time (min) each tortilla side | 1.5 ± 0.00 a | 1.2 ± 0.00 b | 1.06 ± 0.00 c |

| Weight (g) | 40.00 ± 0.00 c | 44.00 ± 0.00 b | 46.00 ± 0.00 a |

| Diameter (cm) | 15.00 ± 0.00 a | 15.00 ± 0.00 a | 15.00 ± 0.00 a |

| Thickness (mm) | 2.00 ± 0.00 a | 2.00 ± 0.00 a | 2.00 ± 0.00 a |

| Volume (cm3) | 60.33 ± 0.58 a | 52.00 ± 0.00 b | 49.67 ± 0.58 c |

| Specific volume (cm3/g) | 1.51 ± 0.01 a | 1.18 ± 0.00 b | 1.08 ± 0.01 c |

| a | 2.41 ± 0.05 c | 2.63 ± 0.10 b | 3.61 ± 0.24 a |

| b | 32.28 ± 0.54 b | 34.34 ± 0.43 b | 35.01 ± 0.33 a |

| L | 65.41 ± 0.59 a | 60.10 ± 1.05 b | 58.51 ± 0.91 b |

| Parameters | Combinations | ||||||

|---|---|---|---|---|---|---|---|

| 100%WF | 25%CPF:75%WF | 30%CPF:70%WF | |||||

| Added water (mL) | 50.00 | 46.00 | 44.00 | ||||

| Cooking time (min) each side | 1.5 ± 0.00 a | 1.2 ± 0.00 b | 1.06 ± 0.00 c | ||||

| Parameters/Elements | Flour | Tortilla | Flour | Tortilla | Flour | Tortilla | |

| Proteins (%, dm) | 11.37 ± 0.15 a | 11.50 ± 0.00 a | 14.43 ± 0.15 a | 14.50 ± 0.00 a | 15.27 ± 0.15 b | 15.70 ± 0.00 a | |

| Minerals (mg 100 g−1 dm) | Fe | 3.90 ± 0.11 a | 3.35 ± 0.01 b | 4.05 ± 0.04 a | 3.61 ± 0.01 b | 4.11 ± 0.01 a | 3.80 ± 0.00 b |

| Zn | 4.75 ± 0.34 a | 4.04 ± 0.01 b | 4.30 ± 0.29 a | 3.65 ± 0.01 b | 4.23 ± 0.34 a | 3.62 ± 0.01 b | |

| Cu | 1.11 ± 0.23 a | 0.53 ± 0.00 b | 1.02 ± 0.04 a | 0.62 ± 0.00 b | 1.01 ± 0.03 a | 0.62 ± 0.00 b | |

| K | 385.33 ± 6.11 a | 282.67 ± 4.62 b | 494.67 ± 8.33 a | 413.87 ± 0.46 b | 512.00 ± 12.00 a | 437.33 ± 4.62 b | |

| Na | 17.33 ± 6.11 b | 986.67 ± 11.54 a | 22.67 ± 2.31 b | 993.33 ± 11.54 a | 24.00 ± 0.00 b | 996.00 ± 6.92 a | |

| Parameters/Elements | Dough | Tortilla | Dough | Tortilla | Dough | Tortilla | |

| Weight (g) | 50.00 ± 0.00 a | 40.00 ± 0.00 b | 50.00 ± 0.00 a | 44.00 ± 0.00 b | 50.00 ± 0.00 a | 46.00 ± 0.00 b | |

| Diameter (cm) | 16.00 ± 0.00 a | 15.00 ± 0.00 b | 16.00 ± 0.00 a | 15.00 ± 0.00 b | 16.00 ± 0.00 a | 15.00 ± 0.00 b | |

| Thickness (mm) | 2.00 ± 0.00 a | 2.00 ± 0.00 a | 2.00 ± 0.00 a | 2.00 ± 0.00 a | 2.00 ± 0.00 a | 2.00 ± 0.00 a | |

| Storage Days/ Parameters/ Combinations | Appearance | Odor | Flexibility | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 100%WF | 25%CPF | 30%CPF | 100%WF | 25%CPF | 30%CPF | 100%WF | 25%CPF | 30%CPF | |

| 1st | NL | NL | NL | NL | NL | NL | FLD | FLD | FLD |

| 2nd–5th | NL | NL | NL | NL | NL | NL | N.FLD | N.FLD | N.FLD |

| 6th–14th | NL | NL | NL | NL | NL | O.ch | N.FLD | N.FLD | N.FLD |

| 15th–25th | NL | NL | C.Ch | NL | NL | O.Ch | N.FLD | N.FLD | N.FLD |

| 26th–30th | NL | NL | C.Ch | O.Ch | O.Ch | O.Ch | N.FLD | N.FLD | N.FLD |

| Parameters | Combinations | ||

|---|---|---|---|

| 100%WF | 25%CPF:75%WF | 30%CPF:70%WF | |

| Dark spots | 2.86 ± 1.42 | 1.66 ± 0.82 | 2.08 ± 1.08 |

| Flexibility | 2.64 ± 1.28 | 2.30 ± 0.93 | 3.20 ± 1.38 |

| Puffiness | 2.62 ± 1.14 | 3.38 ± 1.44 | 3.86 ± 1.17 |

| Layering | 3.98 ± 0.14 | 3.94 ± 0.23 | 4.00 ± 0.00 |

| Weight | 1.16 ± 0.61 | 1.38 ± 0.72 | 1.36 ± 0.72 |

| Mouth feel | 2.50 ± 1.11 | 2.14 ± 1.19 | 2.46 ± 1.28 |

| Aroma | 2.26 ± 1.04 | 2.06 ± 1.07 | 2.56 ± 1.45 |

| Flavor | 2.24 ± 1.11 | 2.50 ± 1.31 | 1.40 ± 0.49 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benayad, A.; Taghouti, M.; Benali, A.; Zouahri, A.; Bikri, S.; Aboussaleh, Y.; Benbrahim, N.; Kumar, S. Addition of Chickpea Flour in Durum Wheat Flour Makes Tortilla More Nutritious and Palatable, and Technologically Acceptable. Foods 2023, 12, 72. https://doi.org/10.3390/foods12010072

Benayad A, Taghouti M, Benali A, Zouahri A, Bikri S, Aboussaleh Y, Benbrahim N, Kumar S. Addition of Chickpea Flour in Durum Wheat Flour Makes Tortilla More Nutritious and Palatable, and Technologically Acceptable. Foods. 2023; 12(1):72. https://doi.org/10.3390/foods12010072

Chicago/Turabian StyleBenayad, Asmaa, Mona Taghouti, Aouatif Benali, Abdelmajid Zouahri, Samir Bikri, Youssef Aboussaleh, Nadia Benbrahim, and Shiv Kumar. 2023. "Addition of Chickpea Flour in Durum Wheat Flour Makes Tortilla More Nutritious and Palatable, and Technologically Acceptable" Foods 12, no. 1: 72. https://doi.org/10.3390/foods12010072

APA StyleBenayad, A., Taghouti, M., Benali, A., Zouahri, A., Bikri, S., Aboussaleh, Y., Benbrahim, N., & Kumar, S. (2023). Addition of Chickpea Flour in Durum Wheat Flour Makes Tortilla More Nutritious and Palatable, and Technologically Acceptable. Foods, 12(1), 72. https://doi.org/10.3390/foods12010072