Influence of Stirring Parameters on Creaminess of Spring Blossom Honey Measured by Crystal Size, Whiteness Index and Mouthfeel

Abstract

1. Introduction

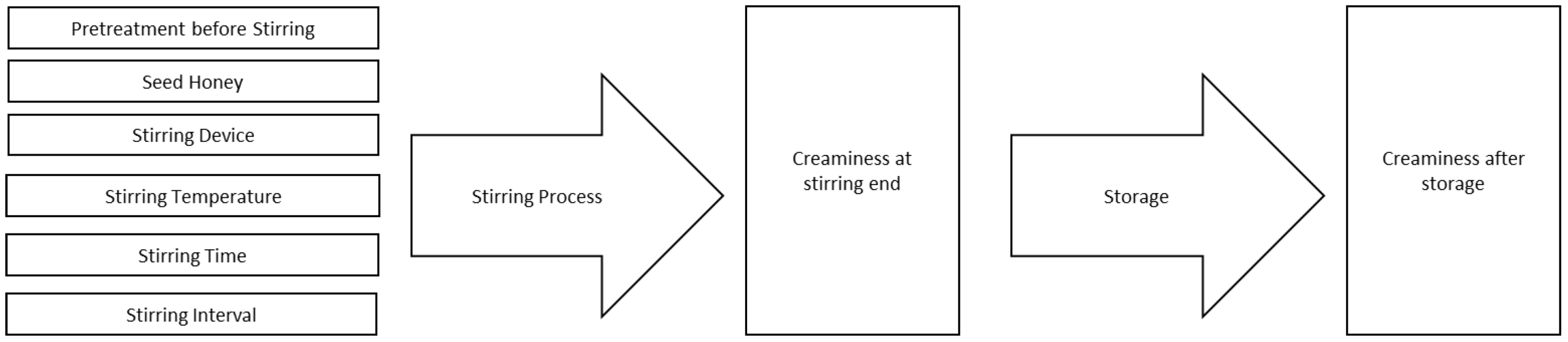

2. Materials and Methods

2.1. Material and Treatment of Honey

2.2. Determination of the Crystal Size by Microscopic Analysis and the Whiteness Index

2.3. Determination of the Mouthfeel by Sensory Analysis

3. Results

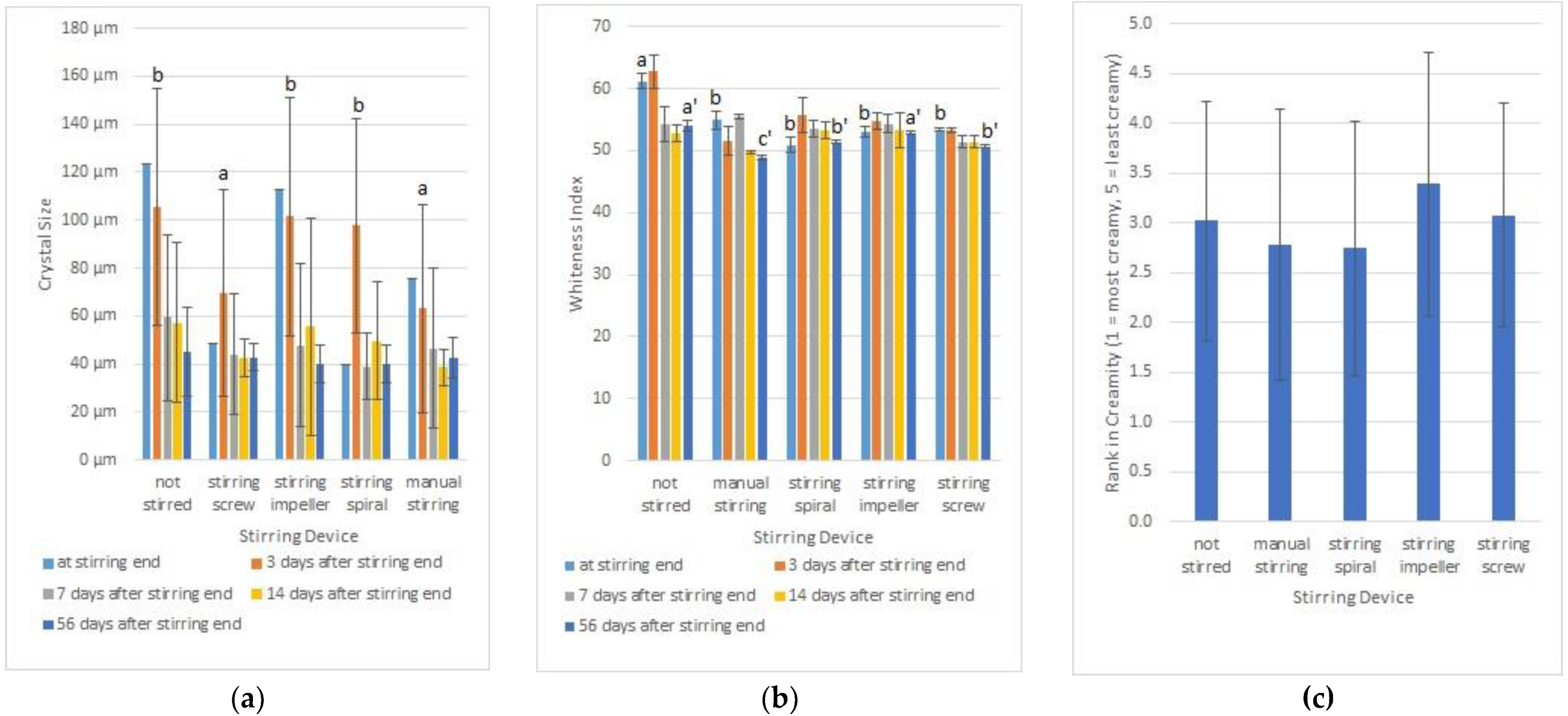

3.1. Influence of the Stirring Device on Creaminess

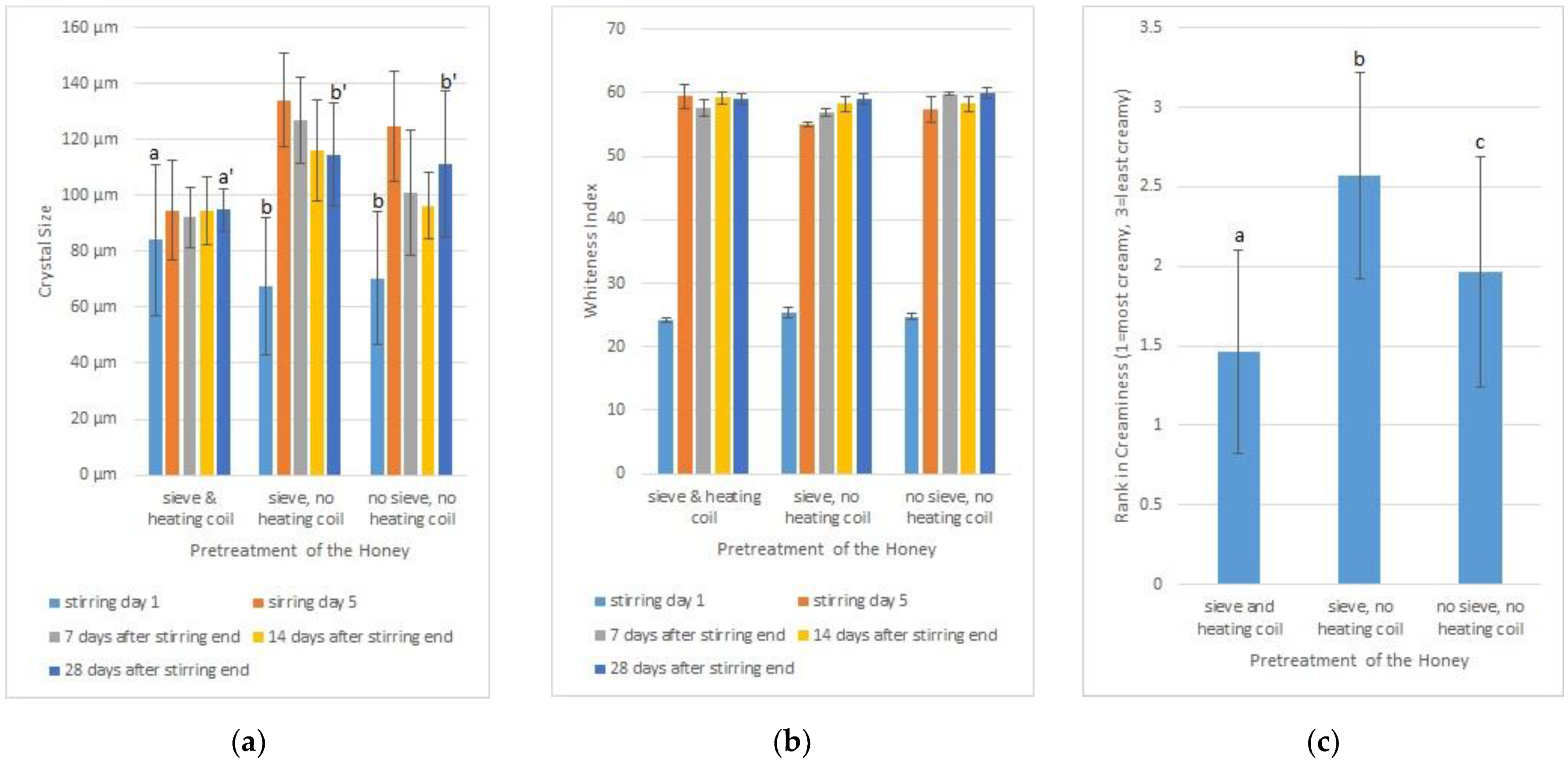

3.2. Influence of Pretreatment of Honey on Creaminess

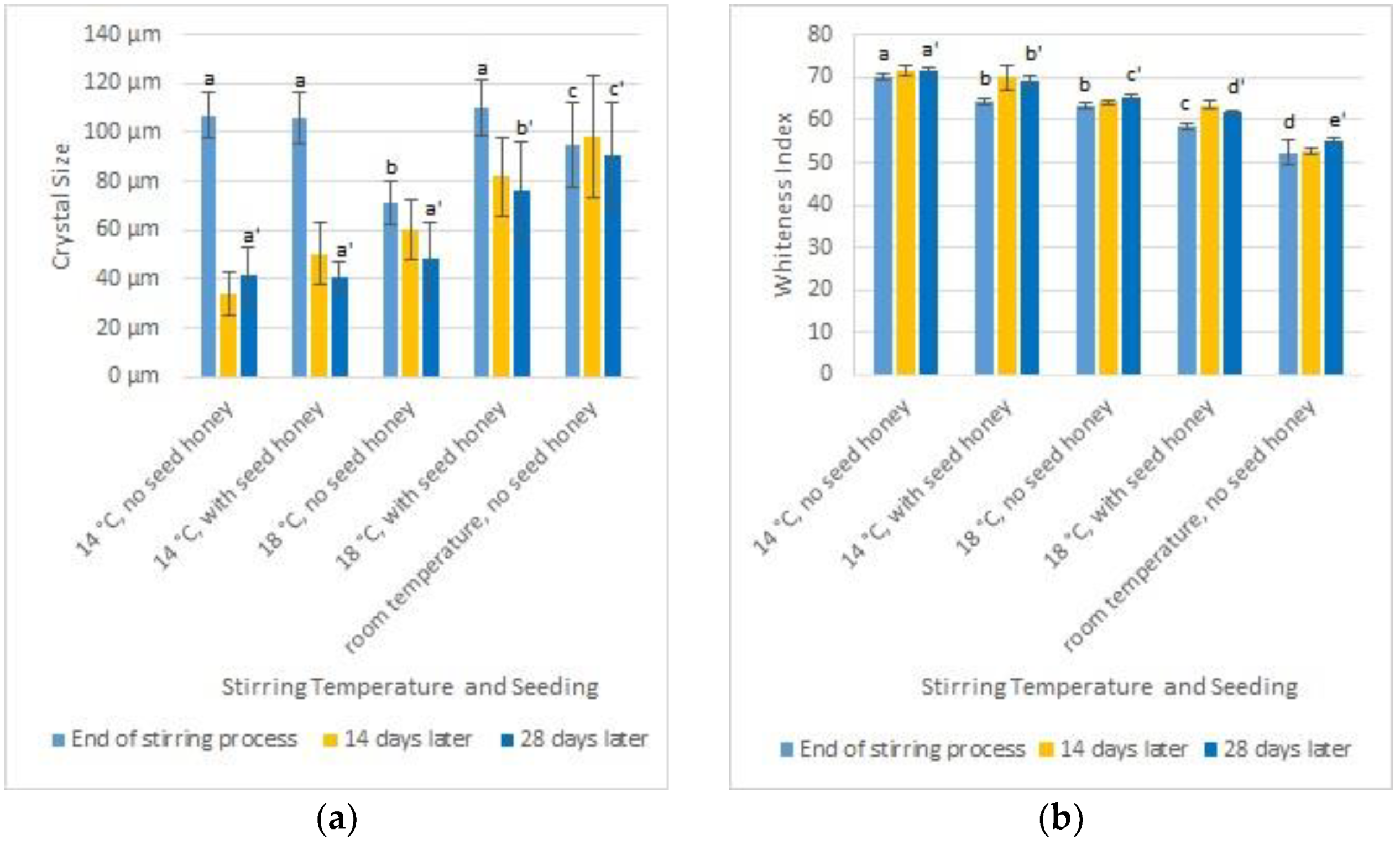

3.3. Influence of the Stirring Temperature and the Addition of Seed Honey on Creaminess

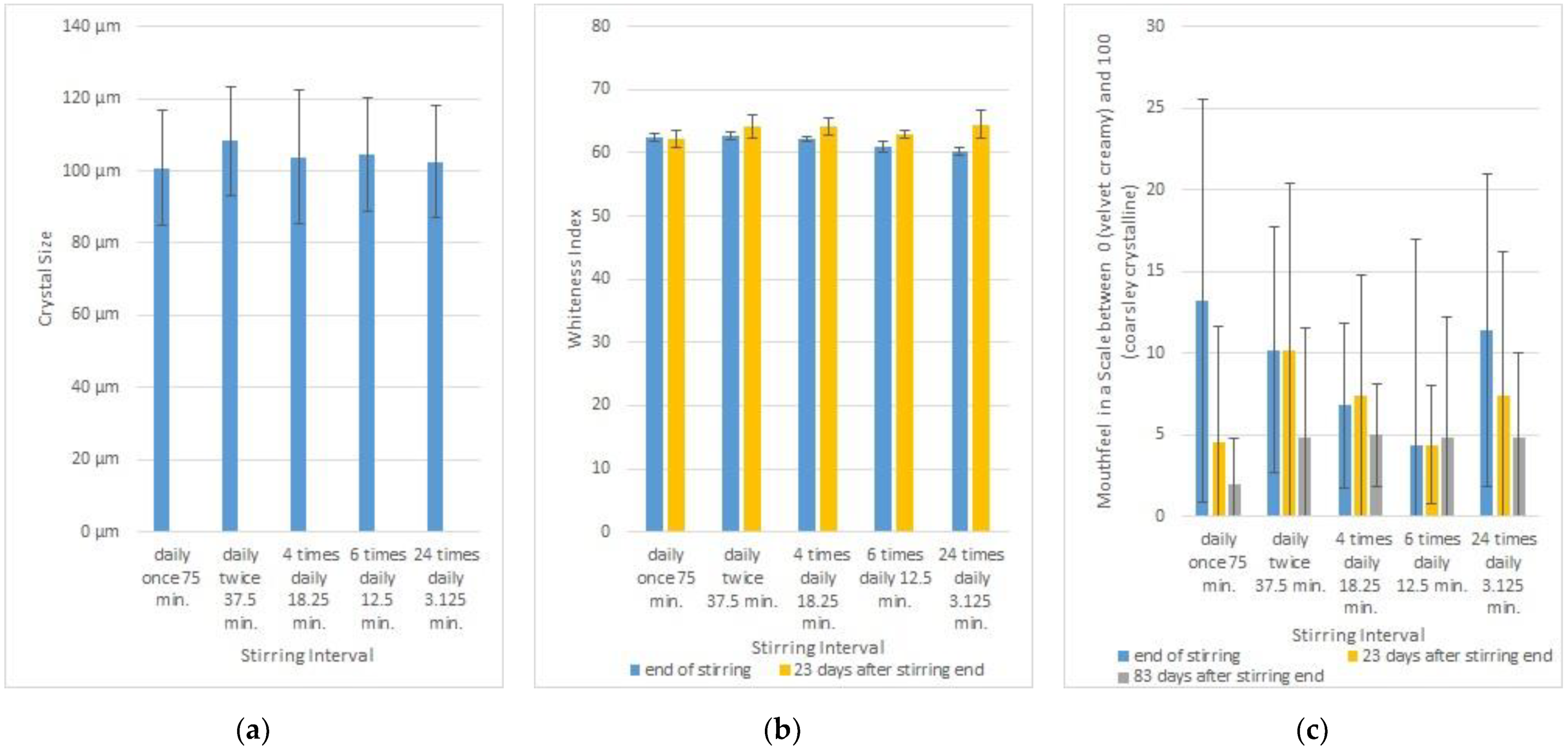

3.4. Influence of the Stirring Interval on Creaminess

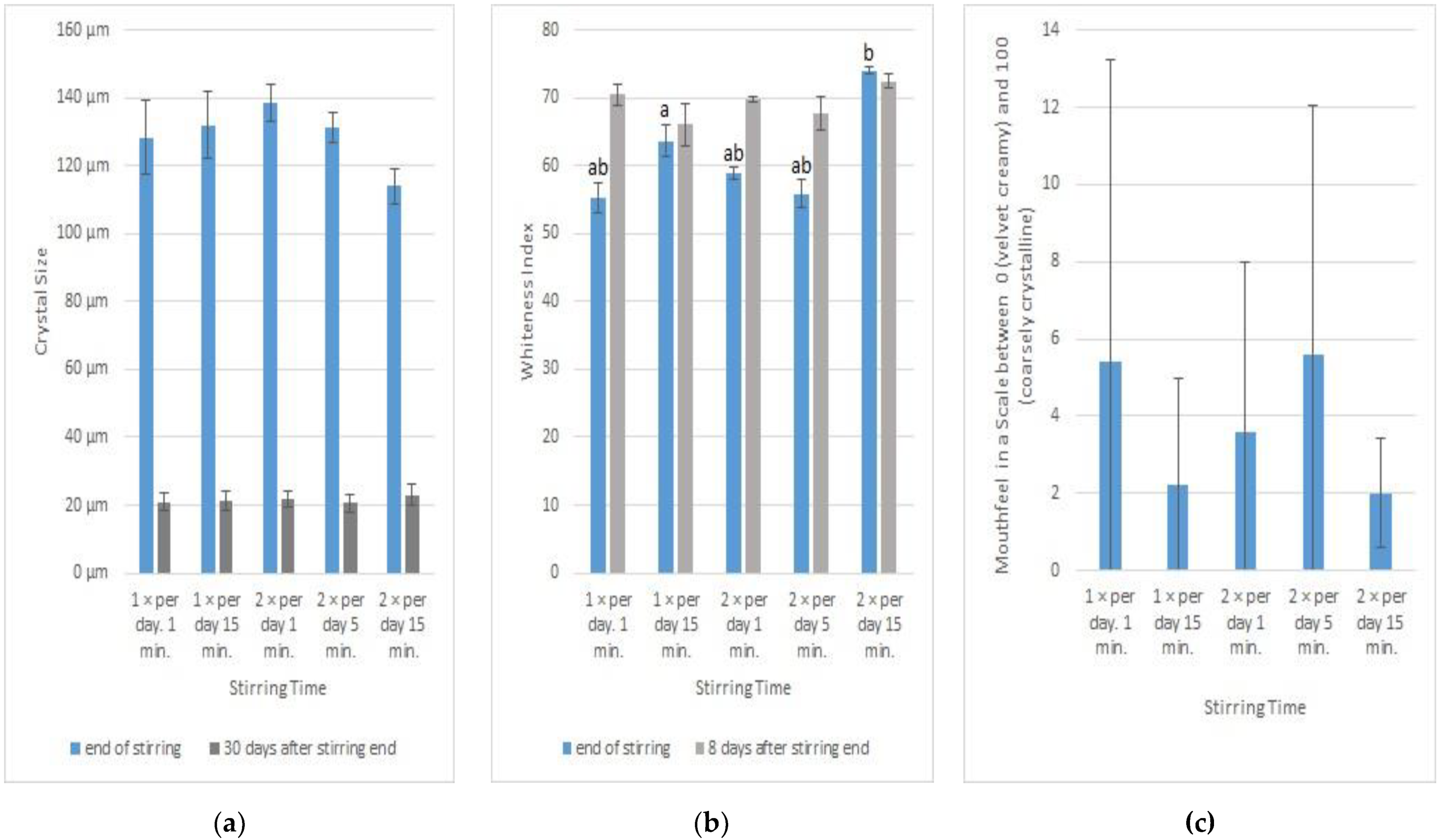

3.5. Influence of the Stirring Time on Creaminess

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- White, J.W. The composition of honey. Bee World 1959, 38, 57–66. [Google Scholar] [CrossRef]

- Doner, L.W. The sugars of honey. J. Sci. Food Agric. 1977, 28, 443–456. [Google Scholar] [CrossRef] [PubMed]

- Bogdanov, S.; Lüllmann, C.; Martin, P.; von der Ohe, W.; Russmann, H.; Vorwohl, G.; Persano Oddo, L.; Sabatini, A.G.; Marcazzan, G.L.; Piro, R.; et al. Honey Quality and International Regulatory Standards: Review of the International Honey Commission. Bee World 1999, 80, 61–69. [Google Scholar] [CrossRef]

- Horn, H.; Lüllmann, C. Der Honig: Imker, Analytik, Gesetz, Gesundheit, 1st ed.; Horn, H., Lüllmann, C., Eds.; InterQuality GmbH: Augsburg, Germany, 2017. [Google Scholar]

- Laos, K.; Kirs, E.; Pall, R.; Martverk, K. The Crystallisation Behaviour of Estonian Honeys. Agron. Res. 2011, 9, 427–432. [Google Scholar]

- Scripca, L.A.; Amariei, S. Research on Honey Crystalization. Rev. Chim. 2018, 69, 2953–2957. [Google Scholar] [CrossRef]

- Berg, B.; Cavdaroglu, C.; Grunin, L.; Ardelean, I.; Kruk, D.; Mazi, B.; Oztop, M. Use of magic sandwich echo and fast field cycling NMR relaxometry on honey adulteration with corn syrup. J. Sci. Food Agric. 2021, 102, 2667–2675. [Google Scholar] [CrossRef]

- Kabbani, D.; Sepulcre, F.; Wedekind, J. Ultrasound-assisted liquefaction of rosemary honey: Influence on rheology and crystal content. J. Food Eng. 2011, 107, 173–178. [Google Scholar] [CrossRef]

- Grégrová, A.; Kružík, E.; Varácovská, A.; Rajchl, A.; Čižková, H. Evaluation of factors affecting crystallization of disparate set of multi-flower honey samples. Agron. Res. 2015, 13, 1215–1226. [Google Scholar]

- Dżugan, M.; Grabek-Lejko, D.; Sidor, E.; Tomczyk, M. The impact of ultrasound decrystallization on enzymatic, antioxidant and antibacterial properties of honey. Innov. Food Sci. Emerg. Technol. 2021, 71, 102709. [Google Scholar] [CrossRef]

- Hunter, M.; Kellett, J.; Toohey, K.; Naumovski, N. Sensory and Compositional Properties Affecting the Likeability of Commercially Available Australian Honeys. Foods 2021, 10, 1842. [Google Scholar] [CrossRef]

- Scripca, L.A.; Amariei, S. The use of ultrasound for preventing honey crystallization. Foods 2021, 10, 773. [Google Scholar] [CrossRef]

- Subramanian, R.; Umesh Hebbar, H.; Rastogi, N.K. Processing of honey: A review. Int. J. Food Prop. 2007, 10, 127–143. [Google Scholar] [CrossRef]

- Dettori, A.; Tappi, S.; Piana, L.; Rosa, M.D.; Rocculi, P. Kinetic of induced honey crystallization and related evolution of structural and physical properties. LWT—Food Sci. Technol. 2018, 95, 333–338. [Google Scholar] [CrossRef]

- Mayda, N.; Özkök, A. Determination and comparison of melissopalynological and some chemical characters of raw and processed honeys. Prog. Nutr. 2021, 23, e2021240. [Google Scholar] [CrossRef]

- Available online: https://www.gesetze-im-internet.de/honigv_2004/BJNR009200004.html (accessed on 5 July 2017).

- Quinteuro-Lira, A.; Angeles Santos, A.; Aguirre-Alvarez, G.; Reyes-Munguia, A.; Almarez-Buendia, I.; Campos-Montiel, R.G. Effects of liquefying crystallized honey by ultrasound on crystal size, 5-hydroxymethylfurfural, color, phenolic compounds and antioxidant activity. Eur. Food Res. Technol. 2017, 243, 619–626. [Google Scholar] [CrossRef]

- Sidor, M.; Tomczyk, M.; Dżugan, M. Application of ultrasonic or microwave radiation to delay crystallization and liquefy solid honey. J. Apic. Sci. 2021, 65, 243–253. [Google Scholar] [CrossRef]

- Kedzierska-Matysek, M.; Florek, M.; Wolanciuk, A. Effect of freezing and room temperature storage for 18 month on quality of raw rapeseed honey (Brassica napus). J. Food Sci. Technol. 2016, 53, 3349–3355. [Google Scholar] [CrossRef]

- Deora, N.S.; Misra, N.N.; Deswal, A.; Mishra, H.N.; Cullen, P.J.; Tiwari, B.K. Ultrasound for Improved Crystallisation in Food Processing. Food Eng. Rev. 2013, 5, 36–44. [Google Scholar] [CrossRef]

- Anderson, E. Controlled Crystallisation of Honey. J. Econ. Entomol. 1947, 40, 55–57. [Google Scholar] [CrossRef]

- Chen, Y.-W.; Lin, C.-H.; Wu, F.-Y.; Chen, H.-H. Rheological properties of crystallized honey prepared by new type of nuclei. J. Food Process Eng. 2009, 32, 512–527. [Google Scholar] [CrossRef]

- Sereti, V.; Lazaridou, A.; Tananaki, C.; Biliaderis, C.G. Development of an cotton honey-based spread by controlling compositional and processing parameters. Food Biophys. 2021, 16, 365–380. [Google Scholar] [CrossRef]

- Dyce, E.J. Honey Process and Product. U.S. Patent 1,987,893, 15 January 1935. Serial, No. 525,616. [Google Scholar]

- Costa, L.C.V.; Kaspchak, E.; Queiroz, M.B.; de Almeida, M.M.; Quast, E.; Quast, L.B. Influence of temperature and homogenization on honey crystallization. Braz. J. Food Technol. 2015, 18, 155–161. [Google Scholar] [CrossRef]

- Radtke, J.; Lichtenberg-Kraag, B. Long-term changes in naturally produced honey depending on processing and temperature. J. Apic. Res. 2018, 57, 615–626. [Google Scholar] [CrossRef]

- Tappi, S.; Glicerina, V.; Ragni, L.; Dettori, A.; Romani, S.; Rocculi, P. Physical and structural properties of honey crystallized by static and dynamic processes. J. Food Eng. 2021, 292, 110316. [Google Scholar] [CrossRef]

- Agius, C.; von Tucher, S.; Poppenberger, B.; Rozhon, W. Quantification of sugars and organic acids in tomato fruits. MethodsX 2018, 5, 537–550. [Google Scholar] [CrossRef]

- Weber, M. Einfluss der Rührmethode auf die Cremigkeit von Honig [Masterarbeit]; Hochschule Anhalt: Bernburg, Germany, 2020. [Google Scholar]

- Thun, F.; Lella, S. Evaluation von Einflüssen auf die Entwicklung Ausgewählter Kenngrößen von Honig [Hausarbeit]; Hochschule Anhalt: Bernburg, Germany, 2020. [Google Scholar]

- Meixner, M. Einfluss der Rührintervalle und der Rührdauer auf die Kristallisation von Honig [Bachelorarbeit]; Hochschule Anhalt: Bernburg, Germany, 2021. [Google Scholar]

- Weber, M.; Meixner, M.; Dasbach, R.; Rozhon, W.; Dasbach, M. Analysis of suger cristal size in honey. MethodX 2022, 9, 101823. [Google Scholar] [CrossRef]

- Kuroshi, A.M.; Queiros, M.B.; de Almeida, M.M.; Quast, L.B. Avaliacao da cristalizacao de mel utilizando parametros de cor atividade de agua. Brazialian J. Food Technol. 2012, 15, 84–91. [Google Scholar] [CrossRef]

- Visquert, M.; Vargas, M.; Escriche, I. Effect of postharvest storage conditions on the colour and freshness parameters of raw honey. Int. J. Food Sci. Technol. 2014, 49, 181–187. [Google Scholar] [CrossRef]

- White, W.W. Honey. Adv. Food Res. 1978, 24, 287–374. [Google Scholar] [CrossRef]

- Al-Habsi, N.A.; Davis, F.J.; Niranjan, K. Development of Novel Methods to Determine Crystalline Glucose Content of Honey Based on DSC, HPLC, and Viscosity Measurements, and Their Use to Examine the Setting Propensity of Honey. J. Food Sci. 2013, 78, E845–E852. [Google Scholar] [CrossRef]

| No. | Aim and Variants | Pretreatment before Stirring | Seeding | Stirring Device | Stirring Time | Stirring Interval | Stirring Temperature | Storing Temperature after Stirring |

|---|---|---|---|---|---|---|---|---|

| 1 | Influence of the stirring device on creaminess [29]

| Sieve and heating coil | 7% seed honey | See column aim and variants | 15 min | 3× per day | 16–19 °C | 14 °C |

| 2 | Influence of honey pretreatment on creaminess [29]

| See column aim and variants | 7% seed honey | Stirring spiral | 15 min | 2× per day | 14–16 °C | 14 °C |

| 3 | Influence of seeding and stirring temperature on creaminess [30]

| Sieve and heating coil | If seeded: seed honey prepared with a kitchen food processor | Stirring screw | 15 min | 3× per day | See column aim and variants | Same temperature as the stirring temperature |

| 4 | Influence of the stirring interval on creaminess [31]

| Sieve and heating coil | None | Stirring screw | See column aim and variants | See column aim and variants | 14 °C | 14 °C |

| 5 | Influence of pretreatment and total stirring time on creaminess [31]

| Sieve and heating coil | None | Stirring screw | See column aim and variants | See column aim and variants | 14 °C | 14 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meixner, M.; Weber, M.; Lella, S.; Rozhon, W.; Dasbach, M. Influence of Stirring Parameters on Creaminess of Spring Blossom Honey Measured by Crystal Size, Whiteness Index and Mouthfeel. Foods 2023, 12, 48. https://doi.org/10.3390/foods12010048

Meixner M, Weber M, Lella S, Rozhon W, Dasbach M. Influence of Stirring Parameters on Creaminess of Spring Blossom Honey Measured by Crystal Size, Whiteness Index and Mouthfeel. Foods. 2023; 12(1):48. https://doi.org/10.3390/foods12010048

Chicago/Turabian StyleMeixner, Mario, Mareike Weber, Sebastian Lella, Wilfried Rozhon, and Margot Dasbach. 2023. "Influence of Stirring Parameters on Creaminess of Spring Blossom Honey Measured by Crystal Size, Whiteness Index and Mouthfeel" Foods 12, no. 1: 48. https://doi.org/10.3390/foods12010048

APA StyleMeixner, M., Weber, M., Lella, S., Rozhon, W., & Dasbach, M. (2023). Influence of Stirring Parameters on Creaminess of Spring Blossom Honey Measured by Crystal Size, Whiteness Index and Mouthfeel. Foods, 12(1), 48. https://doi.org/10.3390/foods12010048