Advancements in Biodegradable Active Films for Food Packaging: Effects of Nano/Microcapsule Incorporation

Abstract

1. Introduction

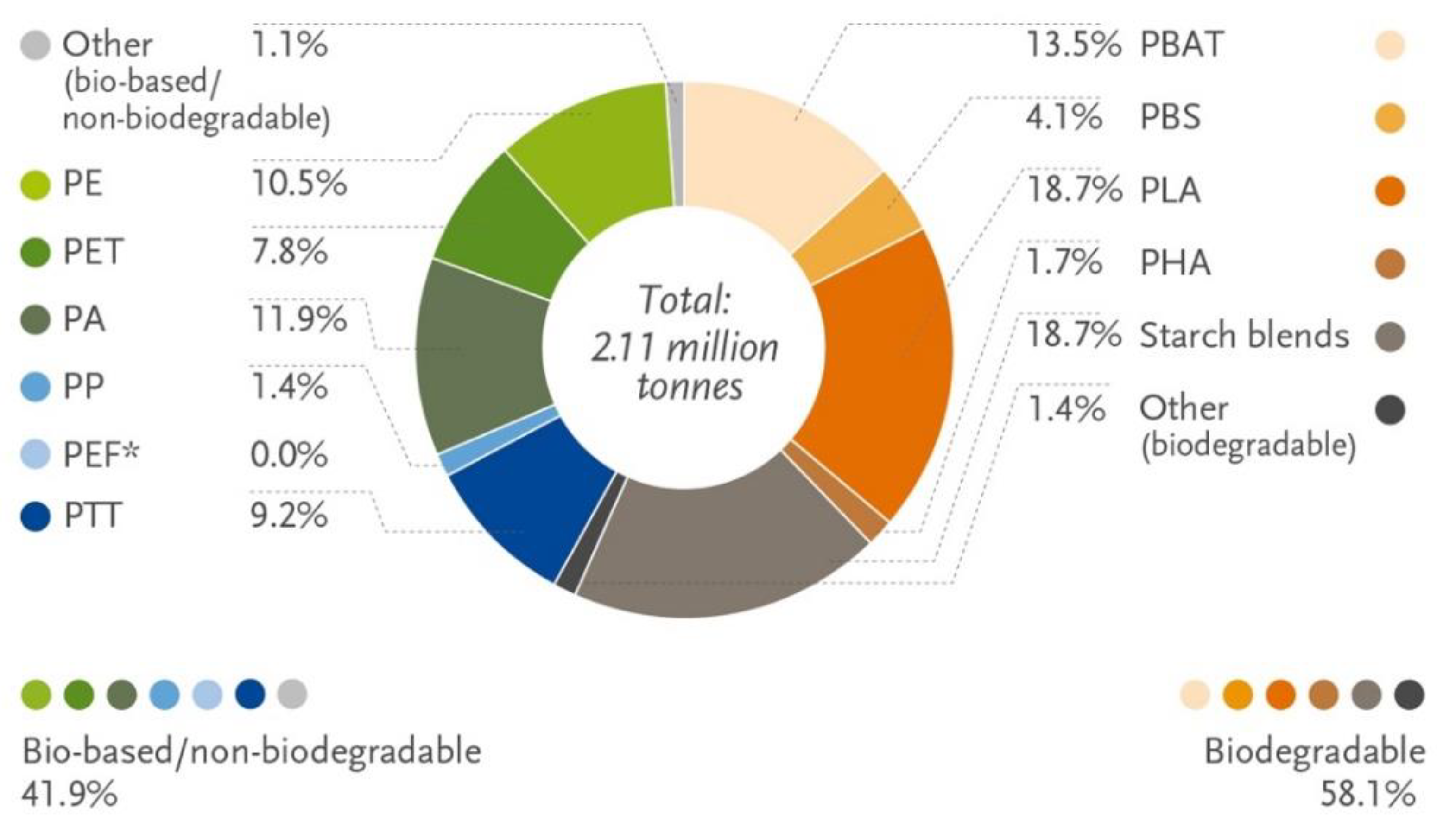

2. Biodegradable Food Packaging

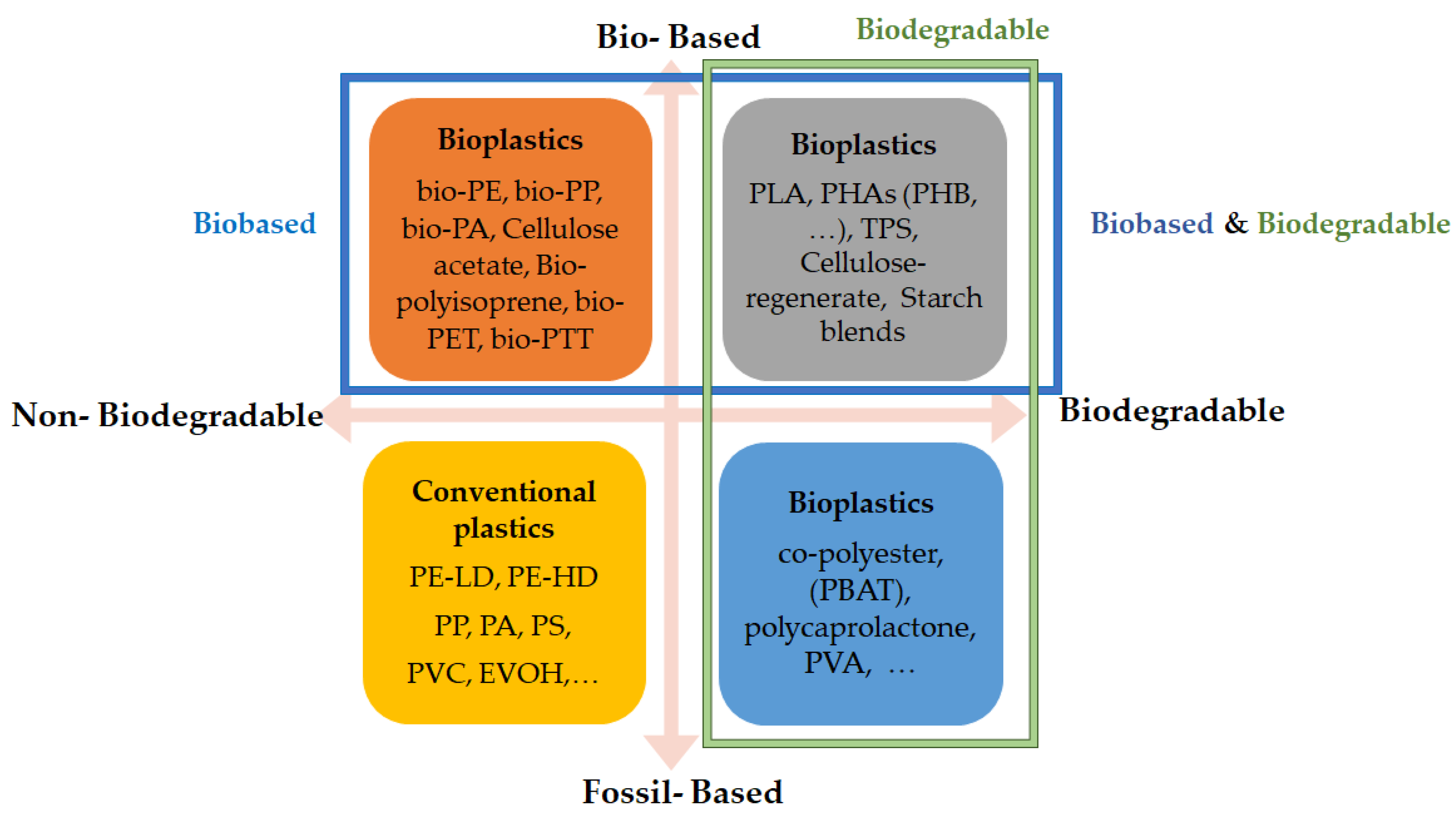

- Fossil-based and non-biodegradable: refers to classical plastics such as conventional polyethylene (PE) and polystyrene (PS);

- Fossil-based and biodegradable: includes polycaprolactone (PCL), polybutylene succinate (PBS), and poly (butylene adipate-co-terephthalate) (PBAT);

- Bio-based and non-biodegradable: bio-polyethylene (PE) is an example of this group produced from bioethanol fuel, which is produced from sugar cane;

- Bio-based and biodegradable: this group is an interesting choice with high potential to apply in food packaging without environmental impacts, which can be natural or synthetic such as cellulose, starch blends, and polyesters such as PLA and PHA [52].

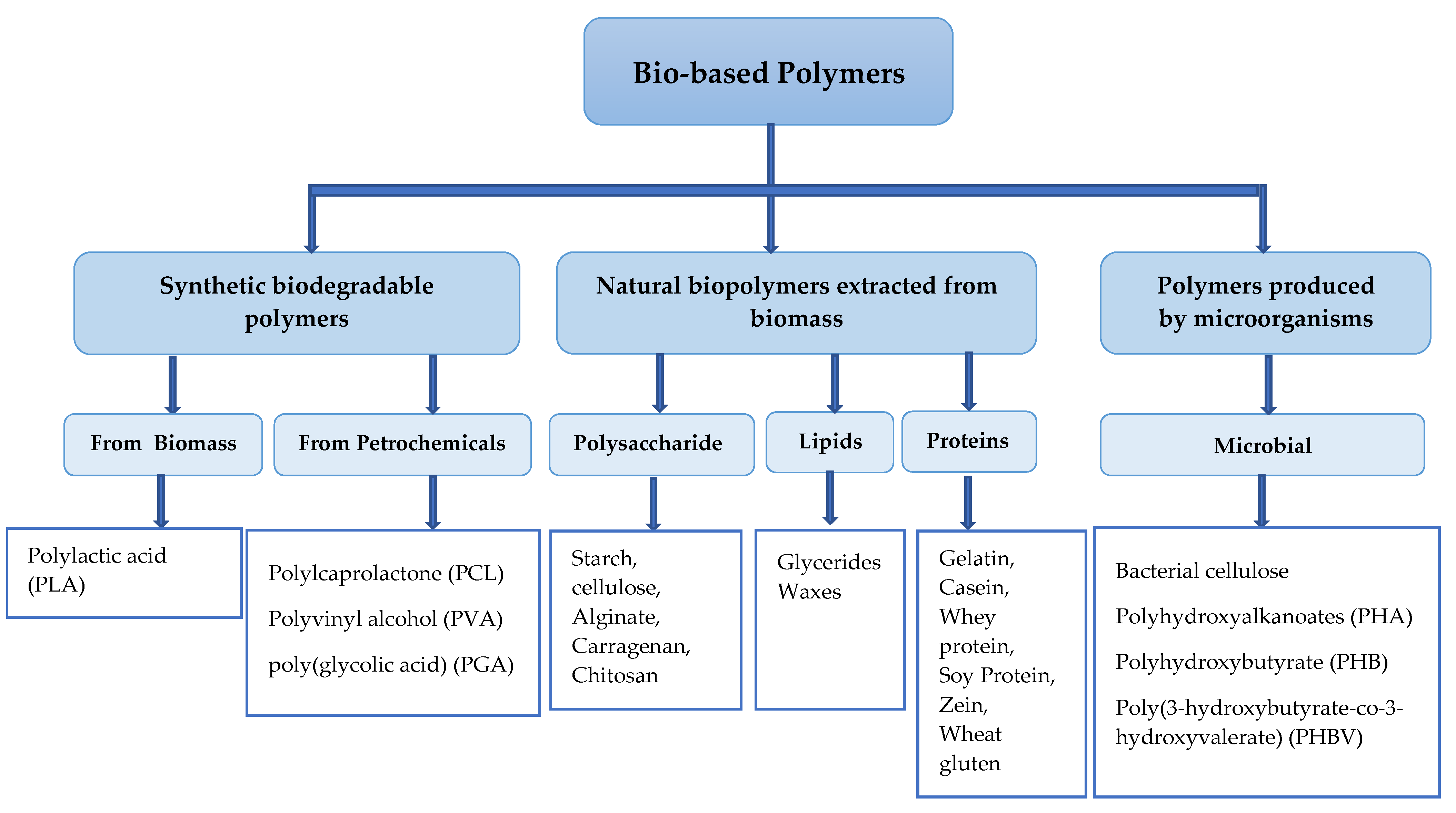

2.1. Biopolymers

2.1.1. Polysaccharide-Based Packaging

Starches

Cellulose

Alginate

Carrageenan

Chitosan

2.1.2. Protein-Based Packaging

Soy Protein

Wheat Gluten

Corn Zein

Casein and Whey Proteins

Gelatin

2.1.3. Lipids-Based Packaging

2.1.4. Microorganism-Based Packaging

3. Active Biodegradable Packaging Films

3.1. Antimicrobial Active Packaging

3.1.1. Natural Antimicrobial Agents of Plant Origin

| Food | Antimicrobial Agents | Bio-Based Polymer | Target Microorganisms | Main Findings | References |

|---|---|---|---|---|---|

| Cheese | Essential oils from the following two spices: Rosmarinus officinalis and Laurus nobilis | Zein nanofibers | Staphylococcusaureus and Listeria monocytogenes | Both showed antimicrobial activity, with higher effects from Laurus nobilis than Rosmarinus officinalis. | [183] |

| Cheese | Moringa oil | Chitosan | Listeria monocytogenes and Staphylococcus aureus | High antibacterial activity against Listeria monocytogenes and Staphylococcus aureus at 4 °C and 25 °C for 10 days, without any effect on the sensory quality of cheese. | [184] |

| Soft (minas frescal) cheese | Nisin | Starch/halloysite/nanocomposite films | Listeria monocytogenes | After 4 days, antimicrobial nanocomposite films with 2 g/100 g nisin significantly reduced the initial counts of the bacterium and those with 6 g/100 g nisin completely inhibited L. monocytogenes. | [185] |

| Cheddar cheese | Nisin-silica liposomes | Chitosan | Listeria monocytogenes | Anti-Listeria activity without effect on the sensory properties of cheese. | [186] |

| Fresh cheese and apple juice | Nisin | pullulan nanofibers | Leuconostoc mesenteroides L. monocytogenes Salmonella Typhimurium | Bactericidal effect against L. monocytogenes, L. mesenteroides, and S. typhimurium in apple juice after 20, 48, and 48 h, respectively. | [187] |

| Chicken meat | Tea tree oil (TTO)liposome | Chitosan | Salmonella enteritidis and Salmonella typhimurium | Almost no impact on the sensory properties. In total, 5 log10 reductions of Salmonella were observed in chicken meat by TTO liposomes/chitosan nanofibers treatment for 4 days at 12 °C and 25 °C. | [188] |

| Fish | Bacteriocin 7293 (Bac7293), a novel bacteriocin from Weissella hellenica BCC 7293 | Poly (lactic acid)/sawdust particle biocomposite film | Gram-positive: Listeria monocytogenes, Staphylococcus aureus Gram-negative: Pseudomonas aeruginosa, Aeromonas hydrophila, Escherichia coli, Salmonella Typhimurium | Growth inhibition on both Gram-positive and Gram-negative bacteria. | [189] |

| Fish | Essential oil from Plectranthus amboinicus | Chitosan | Bacillus subtilis, Escherichia coli, Staphylococcus aureus, Salmonella typhimurium, Klebsiella pneumoniae, Pseudomonas aeruginosa | Improvement in tensile strength, opacity, and water vapor barrier with antimicrobial efficiency against foodborne pathogens. | [190] |

| Fish and chicken | Amaranthus leaf extract (ALE) | Polyvinyl alcohol (PVA) and gelatin | Gram-positive: Bacillus cereus and Staphylococcus aureus Gram-negative: Escherichia coli and Pseudomonas fluorescence | Better protection against UV light and reduced water solubility and water vapor permeability, and improvement of mechanical properties. Inhibition of microbial growth and minimization of oxidative rancidity in 12 days shelf life compared with 3 days shelf life for neat film. | [191] |

| Fish fillets | Curcumin and nisin | Electrospun nisin/curcumin (NCL) nanomats | Lactic acid bacteria (LAB) and Total Mesophilic Aerobic (TMAB) | On the 4th day, the count of TMAB in the samples coated with NCL mats was 3.28 log CFU g−1 compared to 6.61 log CFU g−1 in control samples. | [192] |

| Chicken breast fillets | Virgin olive oilgrape seed oiland savory essential oil | Gelatin-pectin | Staphylococcus aureus, Salmonella typhimurium Fluorescence pseudomonas | Savory essential oil presented more antimicrobial activity. The mixture of them in film showed antimicrobial activity against mentioned bacteria for 12 days storage. | [193] |

| Chicken breast fillets | Carvacrol (0.75% w/w) and citral (1.0% w/w) | Sago starch and guar gum | Bacillus cereus Escherichia coli | The tensile strength of films reduced while elongation at break increased, and the film showed good antimicrobial activity. | [194] |

| Laurus nobilis essential oil and Rosmarinus officinalis essential oil | Polyvinyl alcohol (PVOH) | Listeria monocytogenes | Inhibition of the lipid oxidation together with antimicrobial activity. | [195] | |

| Lamb meat | 2% rosemary oil | Cellulose nanofiber/whey protein matrix containing titanium dioxide particles (1% TiO2) | Escherichia coli Salmonella enteritidis Listeria. monocytogenes Staphylococcus aureus | The active packaging significantly reduced microbial growth, lipid oxidation, and lipolysis of the lamb meat during storage. | [196] |

| Strawberries | Cinnamon | Polybutylene adipate terephthalate (PBAT) films loaded ith cellulose nanofibers (CNF) | Salmonella enterica subsp. enterica serovar Choleraesuis and Listeria monocytogenes | The active film showed a high thermal stability with decreasing water vapor permeability. Strawberries had lower weight loss after 15 days of storage, better freshness preservation without fungal attack, and antimicrobial activity against bacteria. | [197] |

| Cherry tomatoes | Cinnamon | Chitosan as the outer layer and the mixture of sodium alginate and the amphiphilic starch as the intermediate layer | Escherichia coli Staphylococcus aureus, | This active film showed more freshness and lower weight loss rate within two weeks compared to polyethylene films. The inhibition growth rates for E. coli and S. aureus were 36% and 30%, respectively, and soil biodegradability rate was 70% in 28 days. | [198] |

| Cucumber | Clove oil | Chitosan | Escherichia coli | Maintained the color and flavor of cucumber for more than 4 days and until 4.97 log10, reductions of E. coli biofilm in population. | [199] |

| Strawberries | Thyme | Porous polylactic acid (PLA) nanofibers and coated with poly(vinyl alcohol)/poly(ethylene glycol) (PVA/PEG) blends | Escherichia Coli Staphylococcus aureus | Strawberries packed with this film exhibited better freshness and more than 99% antimicrobial activity against mentioned bacteria. | [200] |

| Strawberries | Citral Litsea (L.) cubeba essential oil | Polyvinyl acetate (PVA) | Escherichia coli Staphylococcus aureus Aspergillus niger | The broad-spectrum, direct, and indirect (gas phase) antimicrobial activity was observed against bacteria and fungi. | [201] |

| Vegetable products | Cinnamon and oregano | Cellulose | Listeria grayi Listeria monocytogenes | Cinnamon and oregano essential oils inhibited the growth of both bacteria in the vapor phase. The packaging with cellulose stickers impregnated with cinnamon reduced the Listeria count on frozen vegetable samples. | [202] |

| Fruit | Cinnamon | Zein | Escherichia coli | Improvement of barriers and mechanical properties of zein film with antimicrobial effect on E. coli and fruit samples. | [203] |

| - | Zataria multiflora and Cinnamon zeylanicum essential oils | Soy Protein Isolate (SPI)/Gelatin | Staphylococcus aureusBacillus cereus Listeria monocytogenes. Salmonella typhimurium Escherichia coli | This active film incorporated with 20% Z. multiflora reduced 100% of S. aureus, B. cereus, and L. monocytogenes. The reduction for E. coli and S. typhimurium were 70% and 63%, respectively. | [204] |

| - | Lavender essential oil | Starch, furcellaran, and gelatin | Escherichia coli Staphylococcus aureus | Increase film thickness and decrease water absorption and degree of swelling of the film with increasing concentration of oils. Additionally, the film showed both antioxidant and antimicrobial activity. | [205] |

| - | Rosemary mint essential oil, nisin and lactic acid | Chitosan, pectin, and starch | Bacillus subtilis, Escherichia coli, Listeria monocytogenes | Rosemary and nisin improved water barrier properties, tensile strength, and thermal stability, as well as microstructural heterogeneity and opacity. The film also showed inhibitory activity against all mentioned bacteria and antioxidant activity. | [206] |

| - | Rosemary essential oil | Chitosan | Listeria monocytogenes, Pseudomonas putida Streptococcus agalactiae, Escherichia coli, and Lactococcus lactis | Antimicrobial activity with a better effect on Gram-positive bacteria (i.e., L. monocytogenes, S. agalactiae) | [207] |

| - | Rosemary essential oil | Glycerol, gelatin, chitosan, and pectin | Bacillus subtilis, Staphylococcus aureus, Enterococcus aerogenes, Enterococcus faecalis and Escherichia coli | Optimization of the mixture with 10.0% of chitosan, 24.3% of gelatin, 0.5% of pectin, and 65.2% of glycerol. Inhibition of the growth of the mentioned microorganisms. | [208] |

| - | Glycyrrhiza glabra L. root essential oil (GGEO) | Carboxymethyl cellulose–polyvinyl alcohol (CMC-PVA) | Gram-positive: Listeria monocytogenes, Staphylococcus aureus Gram-negative: Escherichia coli Salmonella Typhimurium | Better inhibitory effects against the Gram-positive bacteria compared with Gram-negative bacteria. | [209] |

| - | Carvacrol (0.75% w/w) and citral (1.0% w/w) | Sago starch (SS) and guar gum | Bacillus cereus Escherichia coli | The tensile strength of films reduced while elongation at break increased, and the film showed good antimicrobial activity. | [194] |

3.1.2. Natural Antimicrobial Agents of Animal Origin

Pleurocidin

Lactoferrin

Lactoperoxidase

Lysozyme

3.1.3. Antimicrobial Agent Produced by Microorganisms

3.1.4. Natural Antimicrobial of Algal and Mushrooms Origin

3.2. Antioxidant Active Packaging

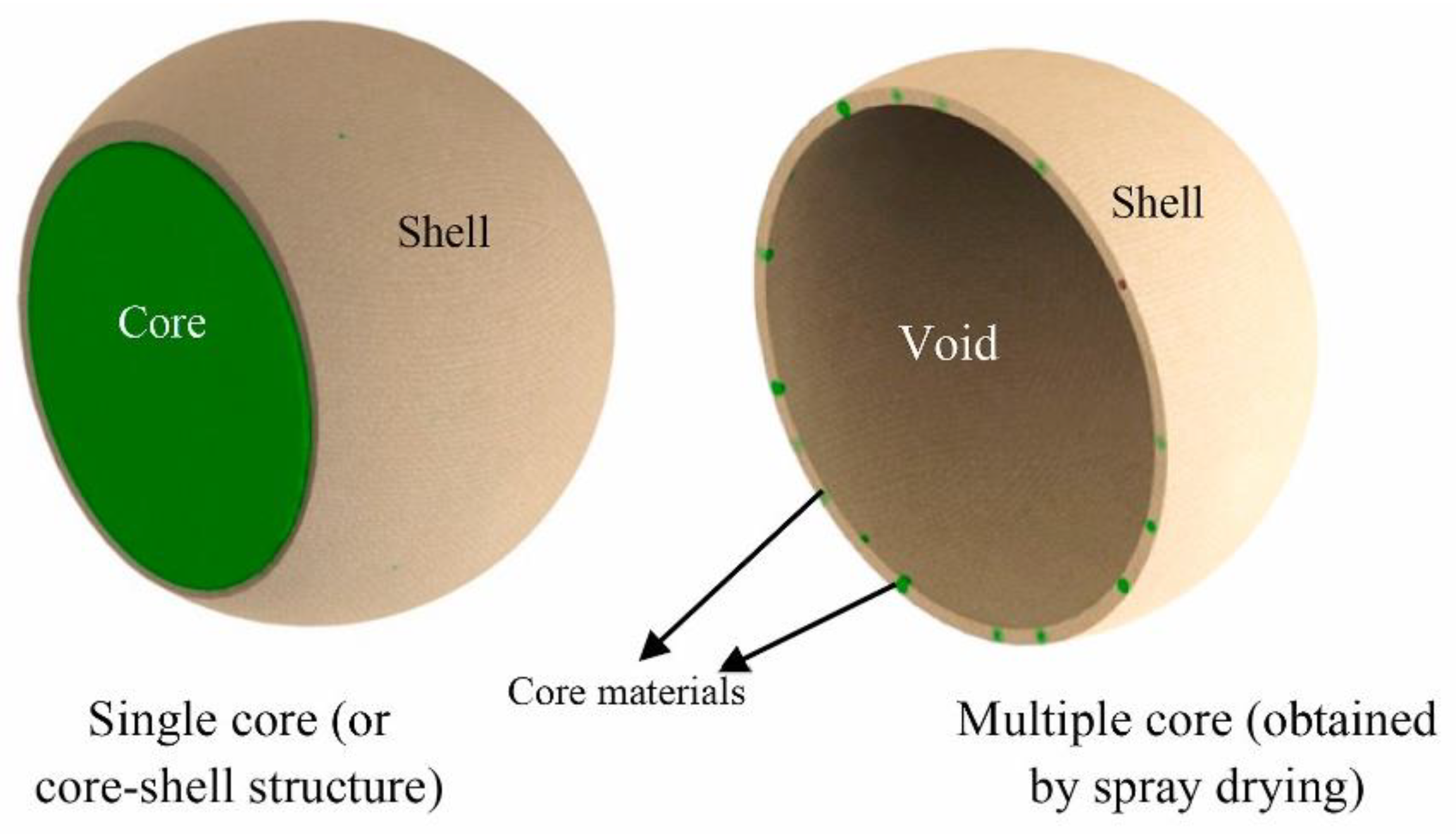

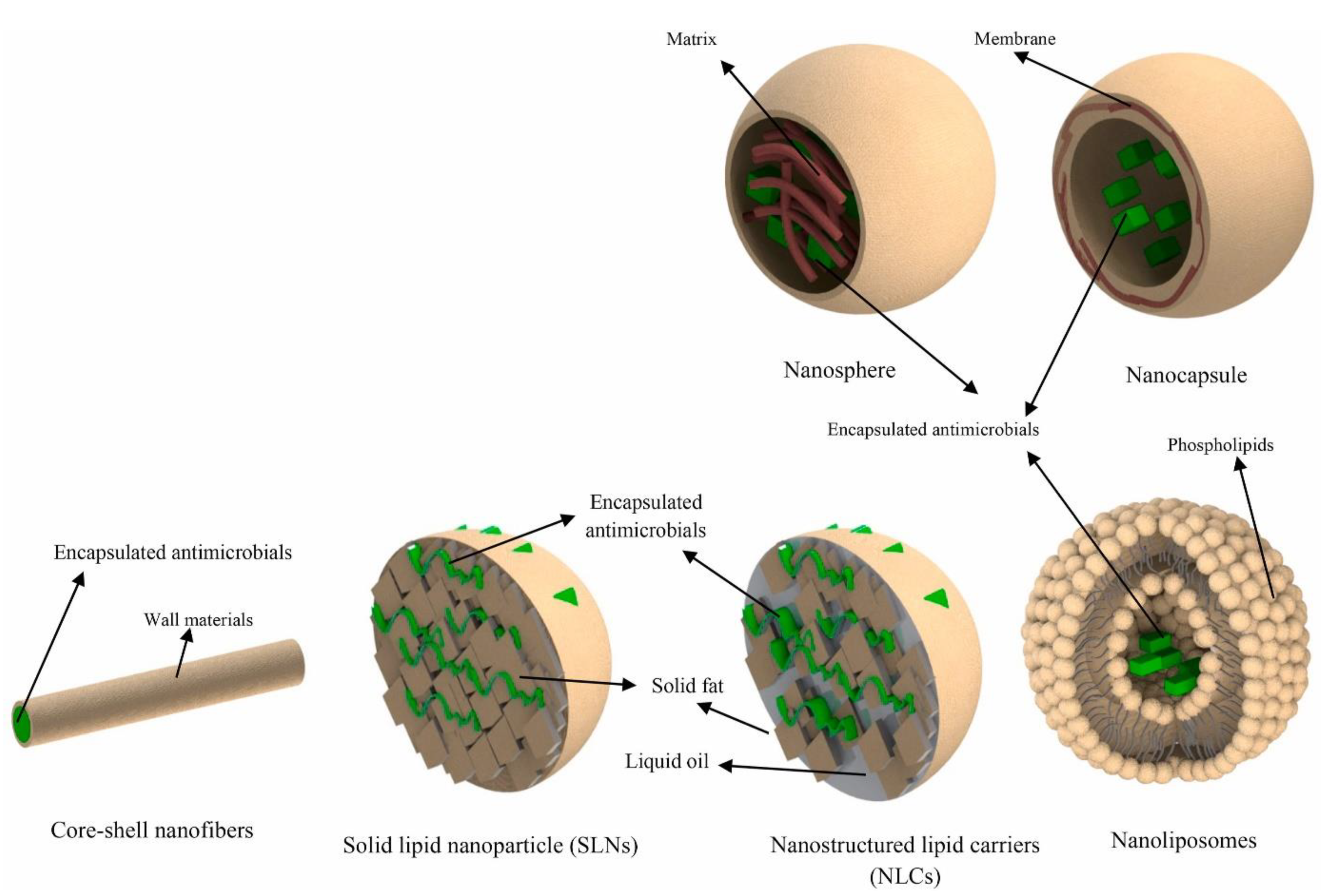

4. Active Food Packaging with Nano/Microencapsulated Ingredients

- The preservation of sensitive molecules during processing conditions such as phenolic compounds with antimicrobial and antioxidant activity;

- Encapsulation at nano and micro sizes enhances the bioavailability of active molecules;

- The prevention of the alteration of the sensory properties of food by some bioactive agents with unpleasant aroma and taste. Essential oils and oil fish are two examples of active molecules with extreme aromas that can alter the taste of food. Encapsulation prevents the change in taste by covering the molecules and reducing the necessary concentration;

- Controlled release of active compounds to improve food quality and safety;

- The final product of the encapsulation process is mostly a fine powder. It offers several benefits, such as improvement of stability and flowability. It is easier to handle and store the active molecules. In addition, agglomeration and change in density can be reduced by encapsulation.

5. Conclusions and Future Developments

Author Contributions

Funding

Conflicts of Interest

References

- Bahrami, A.; Delshadi, R.; Assadpour, E.; Jafari, S.M.; Williams, L. Antimicrobial-loaded nanocarriers for food packaging applications. Adv. Colloid Interface Sci. 2020, 278, 102140. [Google Scholar] [CrossRef]

- Chawla, R.; Sivakumar, S.; Kaur, H. Antimicrobial edible films in food packaging: Current scenario and recent nanotechnological advancements—A review. Carbohydr. Polym. Technol. Appl. 2021, 2, 100024. [Google Scholar] [CrossRef]

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential oils as additives in active food packaging. Food Chem. 2021, 343, 128403. [Google Scholar] [CrossRef] [PubMed]

- Ibarra, G.V.; Sendón, R.; Rodríguez-Bernaldo de Quirós, A. Chapter 29—Antimicrobial Food Packaging Based on Biodegradable Materials. In Antimicrobial Food Packaging; Barros-Velázquez, J., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 363–384. ISBN 978-0-12-800723-5. [Google Scholar] [CrossRef]

- López-Carballo, G.; Gómez-Estaca, J.; Catalá, R.; Hernández-Muñoz, P.; Gavara, R. 3-Active antimicrobial food and beverage packaging. In Emerging Food Packaging Technologies; Yam, K.L., Lee, D.S., Eds.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2012; pp. 27–54. [Google Scholar] [CrossRef]

- Ahamed, A.; Veksha, A.; Giannis, A.; Lisak, G. Flexible packaging plastic waste-environmental implications, management solutions, and the way forward. Curr. Opin. Chem. Eng. 2021, 32, 100684. [Google Scholar] [CrossRef]

- Kunwar, B.; Cheng, H.N.; Chandrashekaran, S.R.; Sharma, B.K. Plastics to fuel: A review. Renew. Sustain. Energy Rev. 2016, 54, 421–428. [Google Scholar] [CrossRef]

- Alojaly, H.; Benyounis, K.Y. Packaging With Plastics and Polymeric Materials. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 978-0-12-803581-8. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Y.; Cao, J.; Jiang, W. Improving the performance of edible food packaging films by using nanocellulose as an additive. Int. J. Biol. Macromol. 2021, 166, 288–296. [Google Scholar] [CrossRef]

- Ahmed, J.; Hiremath, N.; Jacob, H. Antimicrobial efficacies of essential oils/nanoparticles incorporated polylactide films against L. monocytogenes and S. typhimurium on contaminated cheese. Int. J. Food Prop. 2017, 20, 53–67. [Google Scholar] [CrossRef]

- Artham, T.; Doble, M. Biodegradation of Aliphatic and Aromatic Polycarbonates. Macromol. Biosci. 2008, 8, 14–24. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Mohamed, S.A.A.; El-Sakhawy, M.; El-Sakhawy, M.A.-M. Polysaccharides, Protein and Lipid -Based Natural Edible Films in Food Packaging: A Review. Carbohydr. Polym. 2020, 238, 116178. [Google Scholar] [CrossRef]

- Pereira, J.M.; Rodríguez, Y.; Blasco-Monleon, S.; Porter, A.; Lewis, C.; Pham, C.K. Microplastic in the stomachs of open-ocean and deep-sea fishes of the North-East Atlantic. Environ. Pollut. 2020, 265, 115060. [Google Scholar] [CrossRef]

- Roman, L.; Kastury, F.; Petit, S.; Aleman, R.; Wilcox, C.; Hardesty, B.D.; Hindell, M.A. Plastic, nutrition and pollution; relationships between ingested plastic and metal concentrations in the livers of two Pachyptila seabirds. Sci. Rep. 2020, 10, 18023. [Google Scholar] [CrossRef]

- Mattsson, K.; Johnson, E.V.; Malmendal, A.; Linse, S.; Hansson, L.-A.; Cedervall, T. Brain damage and behavioural disorders in fish induced by plastic nanoparticles delivered through the food chain. Sci. Rep. 2017, 7, 11452. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Al-Tohamy, R.; Zhu, D.; Mahmoud, Y.A.-G.; Koutra, E.; Metwally, M.A.; Kornaros, M.; Sun, J. Plastic wastes biodegradation: Mechanisms, challenges and future prospects. Sci. Total Environ. 2021, 780, 146590. [Google Scholar] [CrossRef]

- Kershaw, P. Sources, Fate and Effects of Microplastics in the Marine Environment: A Global Assessment; Technical Report; International Maritime Organization: London, UK, 2015; Available online: http://localhost:8080/xmlui/handle/123456789/735 (accessed on 18 April 2021).

- Abioye, O.P.; Abioye, A.A.; Afolalu, S.A.; Ongbali, S.O. A Review of Biodegradable Plastics in Nigeria. Int. J. Mech. Eng. Technol. IJMET 2018, 9, 10. Available online: http://eprints.covenantuniversity.edu.ng/12417/#.YH6elC0itN0 (accessed on 20 April 2021).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Rai, P.; Mehrotra, S.; Priya, S.; Gnansounou, E.; Sharma, S.K. Recent advances in the sustainable design and applications of biodegradable polymers. Bioresour. Technol. 2021, 325, 124739. [Google Scholar] [CrossRef]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Banat, F.; Sivamani, S.; Sivakumar, N.; Hosseini-Bandegharaei, A.; Show, P.L. Biopolymers and composites: Properties, characterization and their applications in food, medical and pharmaceutical industries. J. Environ. Chem. Eng. 2021, 9, 105322. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable polymers and green-based antimicrobial packaging materials: A mini-review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Jeevahan, J.; Chandrasekaran, M. Nanoedible films for food packaging: A review. J. Mater. Sci. 2019, 54, 12290–12318. [Google Scholar] [CrossRef]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-Based Packaging: Materials, Modifications, Industrial Applications and Sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef]

- Mastromatteo, M.; Mastromatteo, M.; Conte, A.; Del Nobile, M.A. Advances in controlled release devices for food packaging applications. Trends Food Sci. Technol. 2010, 21, 591–598. [Google Scholar] [CrossRef]

- Jideani, V.A.; Vogt, K. Antimicrobial Packaging for Extending the Shelf Life of Bread-A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1313–1324. [Google Scholar] [CrossRef]

- Khaneghah, M.A.; Hashemi, S.M.B.; Eş, I.; Fracassetti, D.; Limbo, S. Efficacy of Antimicrobial Agents for Food Contact Applications: Biological Activity, Incorporation into Packaging, and Assessment Methods: A Review. J. Food Prot. 2018, 81, 1142–1156. [Google Scholar] [CrossRef]

- Firouz, S.M.; Mohi-Alden, K.; Omid, M. A critical review on intelligent and active packaging in the food industry: Research and development. Food Res. Int. 2021, 141, 110113. [Google Scholar] [CrossRef]

- Khaneghah, M.A.; Hashemi, S.M.B.; Limbo, S. Antimicrobial agents and packaging systems in antimicrobial active food packaging: An overview of approaches and interactions. Food Bioprod. Process. 2018, 111, 1–19. [Google Scholar] [CrossRef]

- Ribeiro-Santos, R.; Andrade, M.; Sanches-Silva, A. Application of encapsulated essential oils as antimicrobial agents in food packaging. Curr. Opin. Food Sci. 2017, 14, 78–84. [Google Scholar] [CrossRef]

- Unalan, I.; Boccaccini, A.R. Essential oils in biomedical applications: Recent progress and future opportunities. Curr. Opin. Biomed. Eng. 2021, 17, 100261. [Google Scholar] [CrossRef]

- Dhifi, W.; Bellili, S.; Jazi, S.; Bahloul, N.; Mnif, W. Essential Oils’ Chemical Characterization and Investigation of Some Biological Activities: A Critical Review. Medicines 2016, 3, 25. [Google Scholar] [CrossRef]

- Delshadi, R.; Bahrami, A.; Tafti, A.G.; Barba, F.J.; Williams, L.L. Micro and nano-encapsulation of vegetable and essential oils to develop functional food products with improved nutritional profiles. Trends Food Sci. Technol. 2020, 104, 72–83. [Google Scholar] [CrossRef]

- Gómez, B.; Barba, F.J.; Domínguez, R.; Putnik, P.; Bursać Kovačević, D.; Pateiro, M.; Toldrá, F.; Lorenzo, J.M. Microencapsulation of antioxidant compounds through innovative technologies and its specific application in meat processing. Trends Food Sci. Technol. 2018, 82, 135–147. [Google Scholar] [CrossRef]

- Jurić, S.; Jurić, M.; Siddique, M.A.B.; Fathi, M. Vegetable Oils Rich in Polyunsaturated Fatty Acids: Nanoencapsulation Methods and Stability Enhancement. Food Rev. Int. 2020, 380, 1–38. [Google Scholar] [CrossRef]

- Alehosseini, E.; Jafari, S.M. Micro/nano-encapsulated phase change materials (PCMs) as emerging materials for the food industry. Trends Food Sci. Technol. 2019, 91, 116–128. [Google Scholar] [CrossRef]

- Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti, H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify plastic waste as hazardous. Nature 2013, 494, 169–171. [Google Scholar] [CrossRef]

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic Degradation and Its Environmental Implications with Special Reference to Poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- EN 13432 Packaging—Requirements for Packaging Recoverable through Composting and Biodegradation—Test Scheme and Evaluation Criteria for the Final Acceptance of Packaging; European Committee for Standardisation: Brussels, Belgium, 2000; Available online: https://www.en-standard.eu/bs-en-13432-2000-packaging.-requirements-for-packaging-recoverable-through-composting-and-biodegradation.-test-scheme-and-evaluation-criteria-for-the-final-acceptance-of-packaging/ (accessed on 11 February 2021).

- Ali, S.S.; Elsamahy, T.; Koutra, E.; Kornaros, M.; El-Sheekh, M.; Abdelkarim, E.A.; Zhu, D.; Sun, J. Degradation of conventional plastic wastes in the environment: A review on current status of knowledge and future perspectives of disposal. Sci. Total Environ. 2021, 771, 144719. [Google Scholar] [CrossRef]

- Gorrasi, G.; Sorrentino, A.; Lichtfouse, E. Back to plastic pollution in COVID times. Environ. Chem. Lett. 2021, 19, 1–4. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Plastic Waste Management: Current Status and Weaknesses. In The Handbook of Environmental Chemistry; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–18. [Google Scholar] [CrossRef]

- Helinski, O.K.; Poor, C.J.; Wolfand, J.M. Ridding our rivers of plastic: A framework for plastic pollution capture device selection. Mar. Pollut. Bull. 2021, 165, 112095. [Google Scholar] [CrossRef]

- Hamilton: Solving Plastic Pollution through Accountability. Available online: https://scholar.google.com/scholar_lookup?title=Solving%20Plastic%20Pollution%20Through%20Accountability&publication_year=2019&author=A.%20Hamilton&author=R.%20Scheer&author=T.%20Stakes&author=S.%20Allan (accessed on 21 April 2021).

- Xu, H.; Sheng, J.; Wu, X.; Zhan, K.; Tao, S.; Wen, X.; Liu, W.; Cudjoe, O.; Tao, F. Moderating effects of plastic packaged food on association of urinary phthalate metabolites with emotional symptoms in Chinese adolescents. Ecotoxicol. Environ. Saf. 2021, 216, 112171. [Google Scholar] [CrossRef]

- Larrain, M.; Van Passel, S.; Thomassen, G.; Van Gorp, B.; Nhu, T.T.; Huysveld, S.; Van Geem, K.M.; De Meester, S.; Billen, P. Techno-economic assessment of mechanical recycling of challenging post-consumer plastic packaging waste. Resour. Conserv. Recycl. 2021, 170, 105607. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Medda, F. Plastic credit: A consortium blockchain-based plastic recyclability system. Waste Manag. 2021, 121, 42–51. [Google Scholar] [CrossRef]

- Mattila, H.; Virtanen, T.; Vartiainen, T.; Ruuskanen, J. Emissions of polychlorinated dibenzo-p-dioxins and dibenzofurans in flue gas from co-combustion of mixed plastics with coal and bark. Chemosphere 1992, 25, 1599–1609. [Google Scholar] [CrossRef]

- Ahmadzadeh, S.; Khaneghah, M.A. Role of Green Polymers in Food Packaging. Encycl. Renew. Sustain. Mater. 2020, 2, 305–319. [Google Scholar] [CrossRef]

- Lindström, T.; Österberg, F. Evolution of biobased and nanotechnology packaging—A review. Nord. Pulp Pap. Res. J. 2020, 35, 491–515. [Google Scholar] [CrossRef]

- EUBIO_Admin. Market. Eur. Bioplastics E.V. Available online: https://www.european-bioplastics.org/market/ (accessed on 19 July 2021).

- Hawthorne, L.M.; Beganović, A.; Schwarz, M.; Noordanus, A.W.; Prem, M.; Zapf, L.; Scheibel, S.; Margreiter, G.; Huck, C.W.; Bach, K. Suitability of Biodegradable Materials in Comparison with Conventional Packaging Materials for the Storage of Fresh Pork Products over Extended Shelf-Life Periods. Foods 2020, 9, 1802. [Google Scholar] [CrossRef]

- Ivanković, A.; Zeljko, K.; Talić, S.; Bevanda, A.M.; Lasić, M. Biodegradable Packaging in The Food Industry. Arch. Für Leb. 2017, 68, 23–52. [Google Scholar] [CrossRef]

- Kobayashi, S. Lipase-catalyzed polyester synthesis—A green polymer chemistry. Proc. Jpn. Acad. Ser. B 2010, 86, 338–365. [Google Scholar] [CrossRef]

- Van den Oever, M.; Molenveld, K.; Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics—Facts and Figures. Focus on Food Packaging in The Netherlands; (Wageningen Food & Biobased Research; No. 1722); Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Ghuttora, N. Increase the Usage of Biopolymers and Biodegradable Polymers for Sustainable Environment. Available online: http://www.theseus.fi/handle/10024/121984 (accessed on 25 April 2021).

- Öner, E.T. Microbial Production of Extracellular Polysaccharides from Biomass. In Pretreatment Techniques for Biofuels and Biorefineries; Fang, Z., Ed.; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 35–56. ISBN 978-3-642-32735-3. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N.; Bajaj, R.; Kaur, A. Wheat starch production, structure, functionality and applications—A review. Int. J. Food Sci. Technol. 2017, 52, 38–58. [Google Scholar] [CrossRef]

- Deng, N.; Deng, Z.; Tang, C.; Liu, C.; Luo, S.; Chen, T.; Hu, X. Formation, structure and properties of the starch-polyphenol inclusion complex: A review. Trends Food Sci. Technol. 2021, 112, 667–675. [Google Scholar] [CrossRef]

- Oyeyinka, S.A.; Akintayo, O.A.; Adebo, O.A.; Kayitesi, E.; Njobeh, P.B. A review on the physicochemical properties of starches modified by microwave alone and in combination with other methods. Int. J. Biol. Macromol. 2021, 176, 87–95. [Google Scholar] [CrossRef]

- Żołek-Tryznowska, Z.; Holica, J. Starch films as an environmentally friendly packaging material: Printing performance. J. Clean. Prod. 2020, 276, 124265. [Google Scholar] [CrossRef]

- Cheng, H.; Chen, L.; McClements, D.J.; Yang, T.; Zhang, Z.; Ren, F.; Miao, M.; Tian, Y.; Jin, Z. Starch-based biodegradable packaging materials: A review of their preparation, characterization and diverse applications in the food industry. Trends Food Sci. Technol. 2021, 114, 70–82. [Google Scholar] [CrossRef]

- Mali, S.; Grossmann, M.V.E.; Garcia, M.A.; Martino, M.N.; Zaritzky, N.E. Microstructural characterization of yam starch films. Carbohydr. Polym. 2002, 50, 379–386. [Google Scholar] [CrossRef]

- Nawab, A.; Alam, F.; Haq, M.A.; Lutfi, Z.; Hasnain, A. Mango kernel starch-gum composite films: Physical, mechanical and barrier properties. Int. J. Biol. Macromol. 2017, 98, 869–876. [Google Scholar] [CrossRef]

- Nordin, N.; Othman, S.H.; Rashid, S.A.; Basha, R.K. Effects of glycerol and thymol on physical, mechanical, and thermal properties of corn starch films. Food Hydrocoll. 2020, 106, 105884. [Google Scholar] [CrossRef]

- Adamus, J.; Spychaj, T.; Zdanowicz, M.; Jędrzejewski, R. Thermoplastic starch with deep eutectic solvents and montmorillonite as a base for composite materials. Ind. Crops Prod. 2018, 123, 278–284. [Google Scholar] [CrossRef]

- Thirmizir, M.Z.A.; Ishak, Z.A.M.; Salim, M.S. Compatibilization and Crosslinking in Biodegradable Thermoplastic Polyester Blends. In Reactive and Functional Polymers Volume Two: Modification Reactions, Compatibility and Blends; Gutiérrez, T.J., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 23–89. ISBN 978-3-030-45135-6. [Google Scholar] [CrossRef]

- Nafchi, A.M.; Alias, A.K.; Mahmud, S.; Robal, M. Antimicrobial, rheological, and physicochemical properties of sago starch films filled with nanorod-rich zinc oxide. J. Food Eng. 2012, 113, 511–519. [Google Scholar] [CrossRef]

- Vaezi, K.; Asadpour, G.; Sharifi, H. Effect of ZnO nanoparticles on the mechanical, barrier and optical properties of thermoplastic cationic starch/montmorillonite biodegradable films. Int. J. Biol. Macromol. 2019, 124, 519–529. [Google Scholar] [CrossRef]

- Ali, A.; Xie, F.; Yu, L.; Liu, H.; Meng, L.; Khalid, S.; Chen, L. Preparation and characterization of starch-based composite films reinfoced by polysaccharide-based crystals. Compos. Part B Eng. 2018, 133, 122–128. [Google Scholar] [CrossRef]

- de Souza, A.C.; Dias, A.M.A.; Sousa, H.C.; Tadini, C.C. Impregnation of cinnamaldehyde into cassava starch biocomposite films using supercritical fluid technology for the development of food active packaging. Carbohydr. Polym. 2014, 102, 830–837. [Google Scholar] [CrossRef] [PubMed]

- Avila-Sosa, R.; Palou, E.; Jiménez Munguía, M.T.; Nevárez-Moorillón, G.V.; Navarro Cruz, A.R.; López-Malo, A. Antifungal activity by vapor contact of essential oils added to amaranth, chitosan, or starch edible films. Int. J. Food Microbiol. 2012, 153, 66–72. [Google Scholar] [CrossRef] [PubMed]

- Souza, A.C.; Goto, G.E.O.; Mainardi, J.A.; Coelho, A.C.V.; Tadini, C.C. Cassava starch composite films incorporated with cinnamon essential oil: Antimicrobial activity, microstructure, mechanical and barrier properties. LWT-Food Sci. Technol. 2013, 54, 346–352. [Google Scholar] [CrossRef]

- Engel, J.B.; Ambrosi, A.; Tessaro, I.C. Development of biodegradable starch-based foams incorporated with grape stalks for food packaging. Carbohydr. Polym. 2019, 225, 115234. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Rosa, G.B.; Ferreira, A.L.A.; da Rosa, C.G.; Beling, P.C.; Xavier, L.O.; Hansen, C.M.; Ferrareze, J.P.; Nunes, M.R.; Barreto, P.L.M.; et al. Bioactive food packaging based on starch, citric pectin and functionalized with Acca sellowiana waste by-product: Characterization and application in the postharvest conservation of apple. Int. J. Biol. Macromol. 2020, 147, 295–303. [Google Scholar] [CrossRef]

- Baek, S.-K.; Kim, S.; Song, K.B. Cowpea starch films containing maqui berry extract and their application in salmon packaging. Food Packag. Shelf Life 2019, 22, 100394. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, H.; Kang, S.; Xia, L.; Jiang, S.; Chen, M.; Jiang, S. An active packaging film based on yam starch with eugenol and its application for pork preservation. Food Hydrocoll. 2019, 96, 546–554. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, R.; Wang, B.; Chen, K. Development and characterization of bilayer films based on pea starch/polylactic acid and use in the cherry tomatoes packaging. Carbohydr. Polym. 2019, 222, 114912. [Google Scholar] [CrossRef]

- Hassan, M.; Dave, K.; Chandrawati, R.; Dehghani, F.; Gomes, V.G. 3D printing of biopolymer nanocomposites for tissue engineering: Nanomaterials, processing and structure-function relation. Eur. Polym. J. 2019, 121, 109340. [Google Scholar] [CrossRef]

- Panrong, T.; Karbowiak, T.; Harnkarnsujarit, N. Thermoplastic starch and green tea blends with LLDPE films for active packaging of meat and oil-based products. Food Packag. Shelf Life 2019, 21, 100331. [Google Scholar] [CrossRef]

- Moreno, O.; Atarés, L.; Chiralt, A.; Cruz-Romero, M.C.; Kerry, J. Starch-Gelatin Antimicrobial Packaging Materials to Extend the Shelf Life of Chicken Breast Fillets; Elsevier: Amsterdam, The Netherlands, 2018; Volume 97, pp. 483–490. [Google Scholar] [CrossRef]

- Fadeyibi, A.; Osunde, Z.D.; Egwim, E.C.; Idah, P.A. Performance evaluation of cassava starch-zinc nanocomposite film for tomatoes packaging. J. Agric. Eng. 2017, 48, 137–146. [Google Scholar] [CrossRef]

- Hu, L.; Du, H.; Liu, C.; Zhang, Y.; Yu, G.; Zhang, X.; Si, C.; Li, B.; Peng, H. Comparative Evaluation of the Efficient Conversion of Corn Husk Filament and Corn Husk Powder to Valuable Materials via a Sustainable and Clean Biorefinery Process. ACS Sustain. Chem. Eng. 2019, 7, 1327–1336. [Google Scholar] [CrossRef]

- Liu, W.; Du, H.; Liu, H.; Xie, H.; Xu, T.; Zhao, X.; Liu, Y.; Zhang, X.; Si, C. Highly Efficient and Sustainable Preparation of Carboxylic and Thermostable Cellulose Nanocrystals via FeCl3-Catalyzed Innocuous Citric Acid Hydrolysis. ACS Sustain. Chem. Eng. 2020, 8, 16691–16700. [Google Scholar] [CrossRef]

- Zhao, G.; Du, J.; Chen, W.; Pan, M.; Chen, D. Preparation and thermostability of cellulose nanocrystals and nanofibrils from two sources of biomass: Rice straw and poplar wood. Cellulose 2019, 26, 8625–8643. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Pooresmaeil, M.; Behzadi Nia, S.; Namazi, H. Green encapsulation of LDH(Zn/Al)-5-Fu with carboxymethyl cellulose biopolymer; new nanovehicle for oral colorectal cancer treatment. Int. J. Biol. Macromol. 2019, 139, 994–1001. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Bacterial cellulose as a biodegradable food packaging material: A review. Food Hydrocoll. 2021, 113, 106530. [Google Scholar] [CrossRef]

- Wang, W.; Gu, F.; Deng, Z.; Zhu, Y.; Zhu, J.; Guo, T.; Song, J.; Xiao, H. Multilayer surface construction for enhancing barrier properties of cellulose-based packaging. Carbohydr. Polym. 2021, 255, 117431. [Google Scholar] [CrossRef]

- Assis, R.Q.; Pagno, C.H.; Stoll, L.; Rios, P.D.; Rios, A.d.O.; Olivera, F.C. Active food packaging of cellulose acetate: Storage stability, protective effect on oxidation of riboflavin and release in food simulants. Food Chem. 2021, 349, 129140. [Google Scholar] [CrossRef]

- Blanco-Cabra, N.; Paetzold, B.; Ferrar, T.; Mazzolini, R.; Torrents, E.; Serrano, L.; LLuch-Senar, M. Characterization of different alginate lyases for dissolving Pseudomonas aeruginosa biofilms. Sci. Rep. 2020, 10, 9390. [Google Scholar] [CrossRef]

- Günter, E.A.; Popeyko, O.V.; Belozerov, V.S.; Martinson, E.A.; Litvinets, S.G. Physicochemical and swelling properties of composite gel microparticles based on alginate and callus cultures pectins with low and high degrees of methylesterification. Int. J. Biol. Macromol. 2020, 164, 863–870. [Google Scholar] [CrossRef]

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126. [Google Scholar] [CrossRef]

- Xu, M.; Qin, M.; Cheng, Y.; Niu, X.; Kong, J.; Zhang, X.; Huang, D.; Wang, H. Alginate microgels as delivery vehicles for cell-based therapies in tissue engineering and regenerative medicine. Carbohydr. Polym. 2021, 266, 118128. [Google Scholar] [CrossRef]

- Parreidt, S.T.; Müller, K.; Schmid, M. Alginate-Based Edible Films and Coatings for Food Packaging Applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, F.; Yuan, R. Chapter 13—Applications of natural polymer-based hydrogels in the food industry. In Hydrogels Based on Natural Polymers; Chen, Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 357–410. ISBN 978-0-12-816421-1. [Google Scholar] [CrossRef]

- Abdel Aziz, M.S.; Salama, H.E. Effect of vinyl montmorillonite on the physical, responsive and antimicrobial properties of the optimized polyacrylic acid/chitosan superabsorbent via Box-Behnken model. Int. J. Biol. Macromol. 2018, 116, 840–848. [Google Scholar] [CrossRef]

- Aziz, M.S.A.; Salama, H.E.; Saad, G.R. Diglycidyl ether of bisphenol A/chitosan-graft-polyaniline composites with electromagnetic interference shielding properties: Synthesis, characterization, and curing kinetics. Polym. Eng. Sci. 2019, 59, 372–381. [Google Scholar] [CrossRef]

- Salama, H.E.; Aziz, A.M.S. Development of active edible coating of alginate and aloe vera enriched with frankincense oil for retarding the senescence of green capsicums. LWT 2021, 145, 111341. [Google Scholar] [CrossRef]

- Bennacef, C.; Desobry-Banon, S.; Probst, L.; Desobry, S. Advances on alginate use for spherification to encapsulate biomolecules. Food Hydrocoll. 2021, 118, 106782. [Google Scholar] [CrossRef]

- Chen, J.; Wu, A.; Yang, M.; Ge, Y.; Pristijono, P.; Li, J.; Xu, B.; Mi, H. Characterization of sodium alginate-based films incorporated with thymol for fresh-cut apple packaging. Food Control 2021, 126, 108063. [Google Scholar] [CrossRef]

- Dong, Y.; Wei, Z.; Xue, C. Recent advances in carrageenan-based delivery systems for bioactive ingredients: A review. Trends Food Sci. Technol. 2021, 112, 348–361. [Google Scholar] [CrossRef]

- Khotimchenko, M.; Tiasto, V.; Kalitnik, A.; Begun, M.; Khotimchenko, R.; Leonteva, E.; Bryukhovetskiy, I.; Khotimchenko, Y. Antitumor potential of carrageenans from marine red algae. Carbohydr. Polym. 2020, 246, 116568. [Google Scholar] [CrossRef] [PubMed]

- Zia, K.M.; Tabasum, S.; Nasif, M.; Sultan, N.; Aslam, N.; Noreen, A.; Zuber, M. A review on synthesis, properties and applications of natural polymer based carrageenan blends and composites. Int. J. Biol. Macromol. 2017, 96, 282–301. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Qin, Y.; Bai, R.; Zhang, X.; Yuan, L.; Liu, J. Preparation of pH-sensitive and antioxidant packaging films based on κ-carrageenan and mulberry polyphenolic extract. Int. J. Biol. Macromol. 2019, 134, 993–1001. [Google Scholar] [CrossRef] [PubMed]

- Pourashouri, P.; Shabanpour, B.; Heydari, S.; Raeisi, S. Encapsulation of fish oil by carrageenan and gum tragacanth as wall materials and its application to the enrichment of chicken nuggets. LWT 2021, 137, 110334. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Rhim, J.-W. Chitosan-based biodegradable functional films for food packaging applications. Innov. Food Sci. Emerg. Technol. 2020, 62, 102346. [Google Scholar] [CrossRef]

- Yu, J.; Wang, D.; Geetha, N.; Khawar, K.M.; Jogaiah, S.; Mujtaba, M. Current trends and challenges in the synthesis and applications of chitosan-based nanocomposites for plants: A review. Carbohydr. Polym. 2021, 261, 117904. [Google Scholar] [CrossRef] [PubMed]

- Mujtaba, M.; Morsi, R.E.; Kerch, G.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Khawar, K.M. Current advancements in chitosan-based film production for food technology; A review. Int. J. Biol. Macromol. 2019, 121, 889–904. [Google Scholar] [CrossRef]

- Wang, H.; Ding, F.; Ma, L.; Zhang, Y. Edible films from chitosan-gelatin: Physical properties and food packaging application. Food Biosci. 2021, 40, 100871. [Google Scholar] [CrossRef]

- Wang, H.; Qian, J.; Ding, F. Emerging Chitosan-Based Films for Food Packaging Applications. J. Agric. Food Chem. 2018, 66, 395–413. [Google Scholar] [CrossRef]

- Alirezalu, K.; Pirouzi, S.; Yaghoubi, M.; Karimi-Dehkordi, M.; Jafarzadeh, S.; Mousavi Khaneghah, A. Packaging of beef fillet with active chitosan film incorporated with ɛ-polylysine: An assessment of quality indices and shelf life. Meat Sci. 2021, 176, 108475. [Google Scholar] [CrossRef]

- Xavier, L.O.; Sganzerla, W.G.; Rosa, G.B.; da Rosa, C.G.; Agostinetto, L.; de Lima Veeck, A.P.; Bretanha, L.C.; Micke, G.A.; Dalla Costa, M.; Bertoldi, F.C.; et al. Chitosan packaging functionalized with Cinnamodendron dinisii essential oil loaded zein: A proposal for meat conservation. Int. J. Biol. Macromol. 2021, 169, 183–193. [Google Scholar] [CrossRef]

- Dubey, N.K.; Dubey, R. Chapter 27—Edible films and coatings: An update on recent advances. In Biopolymer-Based Formulations; Pal, K., Banerjee, I., Sarkar, P., Kim, D., Deng, W.-P., Dubey, N.K., Majumder, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 675–695. ISBN 978-0-12-816897-4. [Google Scholar] [CrossRef]

- Tang, X.Z.; Kumar, P.; Alavi, S.; Sandeep, K.P. Recent Advances in Biopolymers and Biopolymer-Based Nanocomposites for Food Packaging Materials. Crit. Rev. Food Sci. Nutr. 2012, 52, 426–442. [Google Scholar] [CrossRef]

- Zhang, H.; Mittal, G. Biodegradable protein-based films from plant resources: A review. Environ. Prog. Sustain. Energy 2010, 29, 203–220. [Google Scholar] [CrossRef]

- Ciannamea, E.M.; Stefani, P.M.; Ruseckaite, R.A. Properties and antioxidant activity of soy protein concentrate films incorporated with red grape extract processed by casting and compression molding. LWT 2016, 74, 353–362. [Google Scholar] [CrossRef]

- Eswaranandam, S.; Hettiarachchy, N.S.; Johnson, M.G. Antimicrobial Activity of Citric, Lactic, Malic, or Tartaric Acids and Nisin-incorporated Soy Protein Film Against Listeria monocytogenes, Escherichia coli O157:H7, and Salmonella gaminara. J. Food Sci. 2004, 69, FMS79–FMS84. [Google Scholar] [CrossRef]

- Soares, R.M.D.; Scremin, F.F.; Soldi, V. Thermal Stability of Biodegradable Films Based on Soy Protein and Corn Starch. Macromol. Symp. 2005, 229, 258–265. [Google Scholar] [CrossRef]

- Su, J.-F.; Huang, Z.; Liu, K.; Fu, L.-L.; Liu, H.-R. Mechanical Properties, Biodegradation and Water Vapor Permeability of Blend Films of Soy Protein Isolate and Poly (vinyl alcohol) Compatibilized by Glycerol. Polym. Bull. 2007, 58, 913–921. [Google Scholar] [CrossRef]

- Tian, H.; Guo, G.; Fu, X.; Yao, Y.; Yuan, L.; Xiang, A. Fabrication, properties and applications of soy-protein-based materials: A review. Int. J. Biol. Macromol. 2018, 120, 475–490. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Lee, J.H.; Ng, P.K.W. Mechanical and barrier properties of biodegradable soy protein isolate-based films coated with polylactic acid. LWT-Food Sci. Technol. 2007, 40, 232–238. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, Y.; Kang, S.; Xu, H. Insight into the formation mechanism of soy protein isolate films improved by cellulose nanocrystals. Food Chem. 2021, 129971. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Zhang, F.; Zhang, W.; Li, J. Facile design of tough, strong, and UV-shielding soy protein-based composite films. Ind. Crops Prod. 2021, 166, 113474. [Google Scholar] [CrossRef]

- Jansens, K.J.A.; Vo Hong, N.; Telen, L.; Brijs, K.; Lagrain, B.; Van Vuure, A.W.; Van Acker, K.; Verpoest, I.; Van Puyvelde, P.; Goderis, B.; et al. Effect of molding conditions and moisture content on the mechanical properties of compression molded glassy, wheat gluten bioplastics. Ind. Crops Prod. 2013, 44, 480–487. [Google Scholar] [CrossRef]

- Wang, J.; Wei, Z.; Li, L.; Bian, K.; Zhao, M. Characteristics of enzymatic hydrolysis of thermal-treated wheat gluten. J. Cereal Sci. 2009, 50, 205–209. [Google Scholar] [CrossRef]

- Tunc, S.; Angellier, H.; Cahyana, Y.; Chalier, P.; Gontard, N.; Gastaldi, E. Functional properties of wheat gluten/montmorillonite nanocomposite films processed by casting. J. Membr. Sci. 2007, 289, 159–168. [Google Scholar] [CrossRef]

- Rovera, C.; Türe, H.; Hedenqvist, M.S.; Farris, S. Water vapor barrier properties of wheat gluten/silica hybrid coatings on paperboard for food packaging applications. Food Packag. Shelf Life 2020, 26, 100561. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Mendieta, J.R.; Ortega-Toro, R. In-depth study from gluten/PCL-based food packaging films obtained under reactive extrusion conditions using chrome octanoate as a potential food grade catalyst. Food Hydrocoll. 2021, 111, 106255. [Google Scholar] [CrossRef]

- Türe, H.; Gällstedt, M.; Hedenqvist, M.S. Antimicrobial compression-moulded wheat gluten films containing potassium sorbate. Food Res. Int. 2012, 45, 109–115. [Google Scholar] [CrossRef]

- Mascheroni, E.; Guillard, V.; Gastaldi, E.; Gontard, N.; Chalier, P. Anti-microbial effectiveness of relative humidity-controlled carvacrol release from wheat gluten/montmorillonite coated papers. Food Control 2011, 22, 1582–1591. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, C.; Hu, Y.; Gao, M.; Luan, G. Zein as a structural protein in gluten-free systems: An overview. Food Sci. Hum. Wellness 2021, 10, 270–277. [Google Scholar] [CrossRef]

- Shukla, R.; Cheryan, M. Zein: The industrial protein from corn. Ind. Crops Prod. 2001, 13, 171–192. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, Y. Physical and antimicrobial properties of zein and methyl cellulose composite films with plasticizers of oleic acid and polyethylene glycol. LWT 2021, 140, 110811. [Google Scholar] [CrossRef]

- Lai, H.-M.; Padua, G.W. Properties and Microstructure of Plasticized Zein Films. Cereal Chem. 1997, 74, 771–775. [Google Scholar] [CrossRef]

- Wang, Y.; Rakotonirainy, A.M.; Padua, G.W. Thermal Behavior of Zein-based Biodegradable Films. Starch -Stärke 2003, 55, 25–29. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Oromiehi, A.R. Biodegradable biocomposite films based on whey protein and zein: Barrier, mechanical properties and AFM analysis. Int. J. Biol. Macromol. 2008, 43, 209–215. [Google Scholar] [CrossRef]

- Huo, W.; Wei, D.; Zhu, W.; Li, Z.; Jiang, Y. High-elongation zein films for flexible packaging by synergistic plasticization: Preparation, structure and properties. J. Cereal Sci. 2018, 79, 354–361. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, G. Synergistic Effect of Oleic Acid and Glycerol on Zein Film Plasticization. J. Agric. Food Chem. 2012, 60, 10075–10081. [Google Scholar] [CrossRef]

- Kashiri, M.; López-Carballo, G.; Hernández-Muñoz, P.; Gavara, R. Antimicrobial packaging based on a LAE containing zein coating to control foodborne pathogens in chicken soup. Int. J. Food Microbiol. 2019, 306, 108272. [Google Scholar] [CrossRef]

- Ahammed, S.; Liu, F.; Wu, J.; Khin, M.N.; Yokoyama, W.H.; Zhong, F. Effect of transglutaminase crosslinking on solubility property and mechanical strength of gelatin-zein composite films. Food Hydrocoll. 2021, 116, 106649. [Google Scholar] [CrossRef]

- Daniloski, D.; Petkoska, A.T.; Lee, N.A.; Bekhit, A.E.-D.; Carne, A.; Vaskoska, R.; Vasiljevic, T. Active edible packaging based on milk proteins: A route to carry and deliver nutraceuticals. Trends Food Sci. Technol. 2021, 111, 688–705. [Google Scholar] [CrossRef]

- Horne, D.S. Chapter 6—Casein micelle structure and stability. In Milk Proteins, 3rd ed.; Boland, M., Singh, H., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 213–250. ISBN 978-0-12-815251-5. [Google Scholar] [CrossRef]

- Fitzsimons, S.M.; Mulvihill, D.M.; Morris, E.R. Denaturation and aggregation processes in thermal gelation of whey proteins resolved by differential scanning calorimetry. Food Hydrocoll. 2007, 21, 638–644. [Google Scholar] [CrossRef]

- Boland, M. Chapter 21—Milk proteins: The future. In Milk Proteins, 3rd ed.; Boland, M., Singh, H., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 715–730. ISBN 978-0-12-815251-5. [Google Scholar] [CrossRef]

- Martins, J.T.; Bourbon, A.I.; Pinheiro, A.C.; Fasolin, L.H.; Vicente, A.A. Protein-Based Structures for Food Applications: From Macro to Nanoscale. Front. Sustain. Food Syst. 2018, 2, 77. [Google Scholar] [CrossRef]

- Moughan, P.J. Chapter 17—Milk proteins: A rich source of bioactives for developing functional foods. In Milk Proteins, 3rd ed.; Boland, M., Singh, H., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 633–649. ISBN 978-0-12-815251-5. [Google Scholar] [CrossRef]

- Bonilla, J.; Paiano, R.B.; Lourenço, R.V.; Bittante, A.M.Q.B.; Sobral, P.J.A. Biodegradation of Films Based on Natural and Synthetic Biopolymers Using an Aquatic System from Active Sludge. J. Polym. Environ. 2021, 29, 1380–1395. [Google Scholar] [CrossRef]

- Aguirre-Joya, J.A.; De Leon-Zapata, M.A.; Alvarez-Perez, O.B.; Torres-León, C.; Nieto-Oropeza, D.E.; Ventura-Sobrevilla, J.M.; Aguilar, M.A.; Ruelas-Chacón, X.; Rojas, R.; Ramos-Aguiñaga, M.E.; et al. Chapter 1—Basic and Applied Concepts of Edible Packaging for Foods. In Food Packaging and Preservation; Grumezescu, A.M., Holban, A.M., Eds.; Handbook of Food Bioengineering; Academic Press: Cambridge, MA, USA, 2018; pp. 1–61. ISBN 978-0-12-811516-9. [Google Scholar] [CrossRef]

- Makhijani, K.; Kumar, R.; Sharma, S.K. Biodegradability of Blended Polymers: A Comparison of Various Properties. Crit. Rev. Environ. Sci. Technol. 2015, 45, 1801–1825. [Google Scholar] [CrossRef]

- Tkaczewska, J. Peptides and protein hydrolysates as food preservatives and bioactive components of edible films and coatings—A review. Trends Food Sci. Technol. 2020, 106, 298–311. [Google Scholar] [CrossRef]

- Ponce, A.; Roura, S.I.; Moreira, M.R. Chapter 37—Casein and Chitosan Polymers: Use in Antimicrobial Packaging. In Antimicrobial Food Packaging; Barros-Velázquez, J., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 455–466. ISBN 978-0-12-800723-5. [Google Scholar] [CrossRef]

- Haque, E.; Chand, R.; Kapila, S. Biofunctional Properties of Bioactive Peptides of Milk Origin. Food Rev. Int. 2008, 25, 28–43. [Google Scholar] [CrossRef]

- Zhao, Q.; Shi, Y.; Wang, X.; Huang, A. Characterization of a novel antimicrobial peptide from buffalo casein hydrolysate based on live bacteria adsorption. J. Dairy Sci. 2020, 103, 11116–11128. [Google Scholar] [CrossRef]

- Bhosale, S.; Fulpagare, Y.; Desale, R. International Journal of Advanced Research in Biological Sciences Nanoliposomes: Applications in Food and Dairy Industry. Int. J. Adv. Res. Biol. Sci. 2019, 6, 79–84. [Google Scholar]

- Broumand, A.; Emam-Djomeh, Z.; Hamedi, M.; Razavi, S.H. Antimicrobial, water vapour permeability, mechanical and thermal properties of casein based Zataraia multiflora Boiss. Extract containing film. LWT-Food Sci. Technol. 2011, 44, 2316–2323. [Google Scholar] [CrossRef]

- Dinika, I.; Verma, D.K.; Balia, R.; Utama, G.L.; Patel, A.R. Potential of cheese whey bioactive proteins and peptides in the development of antimicrobial edible film composite: A review of recent trends. Trends Food Sci. Technol. 2020, 103, 57–67. [Google Scholar] [CrossRef]

- Uranga, J.; Leceta, I.; Etxabide, A.; Guerrero, P.; de la Caba, K. Cross-linking of fish gelatins to develop sustainable films with enhanced properties. Eur. Polym. J. 2016, 78, 82–90. [Google Scholar] [CrossRef]

- Weng, W.; Zheng, H. Effect of transglutaminase on properties of tilapia scale gelatin films incorporated with soy protein isolate. Food Chem. 2015, 169, 255–260. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Guillén, M.C.; Giménez, B.; López-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef]

- Gómez-Guillén, M.C.; Pérez-Mateos, M.; Gómez-Estaca, J.; López-Caballero, E.; Giménez, B.; Montero, P. Fish gelatin: A renewable material for developing active biodegradable films. Trends Food Sci. Technol. 2009, 20, 3–16. [Google Scholar] [CrossRef]

- Suderman, N.; Isa, M.I.N.; Sarbon, N.M. The effect of plasticizers on the functional properties of biodegradable gelatin-based film: A review. Food Biosci. 2018, 24, 111–119. [Google Scholar] [CrossRef]

- Limpisophon, K.; Tanaka, M.; Osako, K. Characterisation of gelatin–fatty acid emulsion films based on blue shark (Prionace glauca) skin gelatin. Food Chem. 2010, 122, 1095–1101. [Google Scholar] [CrossRef]

- Jiménez, A.; Fabra, M.J.; Talens, P.; Chiralt, A. Effect of re-crystallization on tensile, optical and water vapour barrier properties of corn starch films containing fatty acids. Food Hydrocoll. 2012, 26, 302–310. [Google Scholar] [CrossRef]

- Roy, S.; Rhim, J.-W. Preparation of antimicrobial and antioxidant gelatin/curcumin composite films for active food packaging application. Colloids Surf. B Biointerfaces 2020, 188, 110761. [Google Scholar] [CrossRef]

- Tavassoli, M.; Sani, M.A.; Khezerlou, A.; Ehsani, A.; McClements, D.J. Multifunctional nanocomposite active packaging materials: Immobilization of quercetin, lactoferrin, and chitosan nanofiber particles in gelatin films. Food Hydrocoll. 2021, 118, 106747. [Google Scholar] [CrossRef]

- Khwaldia, K.; Arab-Tehrany, E.; Desobry, S. Biopolymer Coatings on Paper Packaging Materials. Compr. Rev. Food Sci. Food Saf. 2010, 9, 82–91. [Google Scholar] [CrossRef]

- Akoh, C.C. Food Lipids: Chemistry, Nutrition, and Biotechnology, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-4987-4487-4. [Google Scholar]

- Azar, N.F.A.; Pezeshki, A.; Ghanbarzadeh, B.; Hamishehkar, H.; Mohammadi, M. Nanostructured lipid carriers: Promising delivery systems for encapsulation of food ingredients. J. Agric. Food Res. 2020, 2, 100084. [Google Scholar] [CrossRef]

- Costa-Fernandez, S.; Mattos, J.K.R.; Scheunemann, G.S.; Salata, G.C.; Chorilli, M.; Watanabe, I.-S.; de Araujo, G.L.B.; Santos, M.F.; Ishida, K.; Lopes, L.B. Nanostructured lipid carriers containing chitosan or sodium alginate for co-encapsulation of antioxidants and an antimicrobial agent for potential application in wound healing. Int. J. Biol. Macromol. 2021, 183, 668–680. [Google Scholar] [CrossRef]

- Syahida, N.S.; Ismail-Fitry, M.R.; Ainun, Z.M.A.; Nur Hanani, Z.A. Effects of palm wax on the physical, mechanical and water barrier properties of fish gelatin films for food packaging application. Food Packag. Shelf Life 2020, 23, 100437. [Google Scholar] [CrossRef]

- de Oliveira Filho, J.G.; Bezerra, C.C.D.O.N.; Albiero, B.R.; Oldoni, F.C.A.; Miranda, M.; Egea, M.B.; de Azeredo, H.M.C.; Ferreira, M.D. New approach in the development of edible films: The use of carnauba wax micro- or nanoemulsions in arrowroot starch-based films. Food Packag. Shelf Life 2020, 26, 100589. [Google Scholar] [CrossRef]

- National Academies of Sciences, Engineering, and Medicine. Genetically Engineered Crops: Experiences and Prospects; National Academies Press: Washington, DC, USA, 2016; ISBN 978-0-309-43738-7. [Google Scholar] [CrossRef]

- Baldevraj, R.S.M.; Jagadish, R.S. 14-Incorporation of chemical antimicrobial agents into polymeric films for food packaging. In Multifunctional and Nanoreinforced Polymers for Food Packaging; Lagarón, J.-M., Ed.; Woodhead Publishing: Sawston, UK, 2011; pp. 368–420. ISBN 978-1-84569-738-9. [Google Scholar] [CrossRef]

- Sung, S.-Y.; Sin, L.T.; Tee, T.-T.; Bee, S.-T.; Rahmat, A.R.; Rahman, W.A.W.A.; Tan, A.-C.; Vikhraman, M. Antimicrobial agents for food packaging applications. Trends Food Sci. Technol. 2013, 33, 110–123. [Google Scholar] [CrossRef]

- Ibrahim, S.; Elsayed, H.; Hasanin, M. Biodegradable, Antimicrobial and Antioxidant Biofilm for Active Packaging Based on Extracted Gelatin and Lignocelluloses Biowastes. J. Polym. Environ. 2021, 29, 472–482. [Google Scholar] [CrossRef]

- Kuai, L.; Liu, F.; Chiou, B.-S.; Avena-Bustillos, R.J.; McHugh, T.H.; Zhong, F. Controlled release of antioxidants from active food packaging: A Review. Food Hydrocoll. 2021, 106992. [Google Scholar] [CrossRef]

- Kruijf, N.D.; Beest, M.V.; Rijk, R.; Sipiläinen-Malm, T.; Losada, P.P.; Meulenaer, B.D. Active and intelligent packaging: Applications and regulatory aspects. Food Addit. Contam. 2002, 19, 144–162. [Google Scholar] [CrossRef]

- Dainelli, D. 8-Global legislation for active and intelligent packaging materials. In Global Legislation for Food Contact Materials; Baughan, J.S., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Sawston, UK, 2015; pp. 183–199. ISBN 978-1-78242-014-9. [Google Scholar] [CrossRef]

- Mendonca, A.; Jackson-Davis, A.; Moutiq, R.; Thomas-Popo, E. Chapter 14—Use of Natural Antimicrobials of Plant Origin to Improve the Microbiological Safety of Foods. In Food and Feed Safety Systems and Analysis; Ricke, S.C., Atungulu, G.G., Rainwater, C.E., Park, S.H., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 249–272. ISBN 978-0-12-811835-1. [Google Scholar] [CrossRef]

- Göksen, G.; Fabra, M.J.; Ekiz, H.I.; López-Rubio, A. Phytochemical-loaded electrospun nanofibers as novel active edible films: Characterization and antibacterial efficiency in cheese slices. Food Control 2020, 112, 107133. [Google Scholar] [CrossRef]

- Lin, L.; Gu, Y.; Cui, H. Moringa oil/chitosan nanoparticles embedded gelatin nanofibers for food packaging against Listeria monocytogenes and Staphylococcus aureus on cheese. Food Packag. Shelf Life 2019, 19, 86–93. [Google Scholar] [CrossRef]

- Meira, S.M.M.; Zehetmeyer, G.; Scheibel, J.M.; Werner, J.O.; Brandelli, A. Starch-halloysite nanocomposites containing nisin: Characterization and inhibition of Listeria monocytogenes in soft cheese. LWT-Food Sci. Technol. 2016, 68, 226–234. [Google Scholar] [CrossRef]

- Cui, H.Y.; Wu, J.; Li, C.Z.; Lin, L. Anti-listeria effects of chitosan-coated nisin-silica liposome on Cheddar cheese. J. Dairy Sci. 2016, 99, 8598–8606. [Google Scholar] [CrossRef]

- Soto, K.M.; Hernández-Iturriaga, M.; Loarca-Piña, G.; Luna-Bárcenas, G.; Mendoza, S. Antimicrobial effect of nisin electrospun amaranth: Pullulan nanofibers in apple juice and fresh cheese. Int. J. Food Microbiol. 2019, 295, 25–32. [Google Scholar] [CrossRef]

- Cui, H.; Bai, M.; Li, C.; Liu, R.; Lin, L. Fabrication of chitosan nanofibers containing tea tree oil liposomes against Salmonella spp. in chicken. LWT 2018, 96, 671–678. [Google Scholar] [CrossRef]

- Woraprayote, W.; Pumpuang, L.; Tosukhowong, A.; Zendo, T.; Sonomoto, K.; Benjakul, S.; Visessanguan, W. Antimicrobial biodegradable food packaging impregnated with Bacteriocin 7293 for control of pathogenic bacteria in pangasius fish fillets. LWT 2018, 89, 427–433. [Google Scholar] [CrossRef]

- Vishnu Priya, N.; Vinitha, U.G.; Meenakshi Sundaram, M. Preparation of chitosan-based antimicrobial active food packaging film incorporated with Plectranthus amboinicus essential oil. Biocatal. Agric. Biotechnol. 2021, 34, 102021. [Google Scholar] [CrossRef]

- Kanatt, S.R. Development of active/intelligent food packaging film containing Amaranthus leaf extract for shelf life extension of chicken/fish during chilled storage. Food Packag. Shelf Life 2020, 24, 100506. [Google Scholar] [CrossRef]

- Meral, R.; Alav, A.; Karakas, C.; Dertli, E.; Yilmaz, M.T.; Ceylan, Z. Effect of electrospun nisin and curcumin loaded nanomats on the microbial quality, hardness and sensory characteristics of rainbow trout fillet. LWT 2019, 113, 108292. [Google Scholar] [CrossRef]

- Khah, M.D.; Ghanbarzadeh, B.; Roufegarinejad Nezhad, L.; Ostadrahimi, A. Effects of virgin olive oil and grape seed oil on physicochemical and antimicrobial properties of pectin-gelatin blend emulsified films. Int. J. Biol. Macromol. 2021, 171, 262–274. [Google Scholar] [CrossRef] [PubMed]

- Dhumal, C.V.; Ahmed, J.; Bandara, N.; Sarkar, P. Improvement of antimicrobial activity of sago starch/guar gum bi-phasic edible films by incorporating carvacrol and citral. Food Packag. Shelf Life 2019, 21, 100380. [Google Scholar] [CrossRef]

- Göksen, G.; Fabra, M.J.; Pérez-Cataluña, A.; Ekiz, H.I.; Sanchez, G.; López-Rubio, A. Biodegradable active food packaging structures based on hybrid cross-linked electrospun polyvinyl alcohol fibers containing essential oils and their application in the preservation of chicken breast fillets. Food Packag. Shelf Life 2021, 27, 100613. [Google Scholar] [CrossRef]

- Alizadeh-Sani, M.; Mohammadian, E.; McClements, D.J. Eco-friendly active packaging consisting of nanostructured biopolymer matrix reinforced with TiO2 and essential oil: Application for preservation of refrigerated meat. Food Chem. 2020, 322, 126782. [Google Scholar] [CrossRef]

- Montero, Y.; Souza, A.G.; Oliveira, É.R.; dos Santos Rosa, D. Nanocellulose functionalized with cinnamon essential oil: A potential application in active biodegradable packaging for strawberry. Sustain. Mater. Technol. 2021, 29, e00289. [Google Scholar] [CrossRef]

- He, X.; Li, M.; Gong, X.; Niu, B.; Li, W. Biodegradable and antimicrobial CSC films containing cinnamon essential oil for preservation applications. Food Packag. Shelf Life 2021, 29, 100697. [Google Scholar] [CrossRef]

- Cui, H.; Bai, M.; Rashed, M.M.A.; Lin, L. The antibacterial activity of clove oil/chitosan nanoparticles embedded gelatin nanofibers against Escherichia coli O157:H7 biofilms on cucumber. Int. J. Food Microbiol. 2018, 266, 69–78. [Google Scholar] [CrossRef]

- Min, T.; Sun, X.; Yuan, Z.; Zhou, L.; Jiao, X.; Zha, J.; Zhu, Z.; Wen, Y. Novel antimicrobial packaging film based on porous poly(lactic acid) nanofiber and polymeric coating for humidity-controlled release of thyme essential oil. LWT 2021, 135, 110034. [Google Scholar] [CrossRef]

- Thielmann, J.; Theobald, M.; Wutz, A.; Krolo, T.; Buergy, A.; Niederhofer, J.; Welle, F.; Muranyi, P. Litsea cubeba fruit essential oil and its major constituent citral as volatile agents in an antimicrobial packaging material. Food Microbiol. 2021, 96, 103725. [Google Scholar] [CrossRef]

- Tao, R.; Sedman, J.; Ismail, A. Antimicrobial activity of various essential oils and their application in active packaging of frozen vegetable products. Food Chem. 2021, 360, 129956. [Google Scholar] [CrossRef]

- Kaur, M.; Santhiya, D. UV-shielding antimicrobial zein films blended with essential oils for active food packaging. J. Appl. Polym. Sci. 2021, 138, 49832. [Google Scholar] [CrossRef]

- Raeisi, M.; Mohammadi, M.A.; Coban, O.E.; Ramezani, S.; Ghorbani, M.; Tabibiazar, M.; Khoshbakht, R.; Noori, S.M.A. Physicochemical and antibacterial effect of Soy Protein Isolate/Gelatin electrospun nanofibres incorporated with Zataria multiflora and Cinnamon zeylanicum essential oils. J. Food Meas. Charact. 2021, 15, 1116–1126. [Google Scholar] [CrossRef]

- Jamróz, E.; Juszczak, L.; Kucharek, M. Investigation of the physical properties, antioxidant and antimicrobial activity of ternary potato starch-furcellaran-gelatin films incorporated with lavender essential oil. Int. J. Biol. Macromol. 2018, 114, 1094–1101. [Google Scholar] [CrossRef]

- Akhter, R.; Masoodi, F.A.; Wani, T.A.; Rather, S.A. Functional characterization of biopolymer based composite film: Incorporation of natural essential oils and antimicrobial agents. Int. J. Biol. Macromol. 2019, 137, 1245–1255. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rezaei, M.; Farzi, G. Improvement of active chitosan film properties with rosemary essential oil for food packaging. Int. J. Food Sci. Technol. 2012, 47, 847–853. [Google Scholar] [CrossRef]

- Yeddes, W.; Djebali, K.; Aidi Wannes, W.; Horchani-Naifer, K.; Hammami, M.; Younes, I.; Saidani Tounsi, M. Gelatin-chitosan-pectin films incorporated with rosemary essential oil: Optimized formulation using mixture design and response surface methodology. Int. J. Biol. Macromol. 2020, 154, 92–103. [Google Scholar] [CrossRef]

- Bahrami, A.; Fattahi, R. Biodegradable carboxymethyl cellulose–polyvinyl alcohol composite incorporated with Glycyrrhiza Glabra L. essential oil: Physicochemical and antibacterial features. Food Sci. Nutr. 2021, 9, 4974–4985. [Google Scholar] [CrossRef]

- Asbahani, A.E.; Miladi, K.; Badri, W.; Sala, M.; Addi, E.H.A.; Casabianca, H.; Mousadik, A.E.; Hartmann, D.; Jilale, A.; Renaud, F.N.R.; et al. Essential oils: From extraction to encapsulation. Int. J. Pharm. 2015, 483, 220–243. [Google Scholar] [CrossRef]

- Elshafie, H.S.; Camele, I. An Overview of the Biological Effects of Some Mediterranean Essential Oils on Human Health. BioMed Res. Int. 2017, 2017, e9268468. [Google Scholar] [CrossRef]

- Tariq, S.; Wani, S.; Rasool, W.; Shafi, K.; Bhat, M.A.; Prabhakar, A.; Shalla, A.H.; Rather, M.A. A comprehensive review of the antibacterial, antifungal and antiviral potential of essential oils and their chemical constituents against drug-resistant microbial pathogens. Microb. Pathog. 2019, 134, 103580. [Google Scholar] [CrossRef]

- Guttierrez, J.; Rodriguez, G.; Barry-Ryan, C.; Bourke, P. Efficacy of Plant Essential Oils against Foodborne Pathogens and Spoilage Bacteria Associated with Ready-to-Eat Vegetables: Antimicrobial and Sensory Screening. J. Food Prot. 2008, 71, 1846–1854. [Google Scholar] [CrossRef]

- Dušan, F.; Marián, S.; Katarína, D.; Dobroslava, B. Essential oils—Their antimicrobial activity against Escherichia coli and effect on intestinal cell viability. Toxicol. Vitro 2006, 20, 1435–1445. [Google Scholar] [CrossRef]

- Fernández-López, J.; Viuda-Martos, M. Introduction to the Special Issue: Application of Essential Oils in Food Systems. Foods 2018, 7, 56. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, C.; Cui, H.; Lin, L. Encapsulation strategies to enhance the antibacterial properties of essential oils in food system. Food Control 2021, 123, 107856. [Google Scholar] [CrossRef]

- Rolim, H.M.L.; Ramalho, T.C. Chapter 7—Biopolymer essential oil nanocomposite for antimicrobial packaging. In Biopolymer-Based Nano Films; Rai, M., dos Santos, C.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 115–131. ISBN 978-0-12-823381-8. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Sauraj; Kumar, B.; Deeba, F.; Kulshreshtha, A.; Negi, Y.S. Chitosan films incorporated with Apricot (Prunus armeniaca) kernel essential oil as active food packaging material. Food Hydrocoll. 2018, 85, 158–166. [Google Scholar] [CrossRef]

- Pisoschi, A.M.; Pop, A.; Georgescu, C.; Turcuş, V.; Olah, N.K.; Mathe, E. An overview of natural antimicrobials role in food. Eur. J. Med. Chem. 2018, 143, 922–935. [Google Scholar] [CrossRef] [PubMed]

- Hoskin, D.W.; Ramamoorthy, A. Studies on anticancer activities of antimicrobial peptides. Biochim. Biophys. Acta BBA-Biomembr. 2008, 1778, 357–375. [Google Scholar] [CrossRef]

- Burrowes, O.J.; Hadjicharalambous, C.; Diamond, G.; Lee, T.-C. Evaluation of Antimicrobial Spectrum and Cytotoxic Activity of Pleurocidin for Food Applications. J. Food Sci. 2004, 69, FMS66–FMS71. [Google Scholar] [CrossRef]

- Wang, X.; Yue, T.; Lee, T. Development of Pleurocidin-poly(vinyl alcohol) electrospun antimicrobial nanofibers to retain antimicrobial activity in food system application. Food Control 2015, 54, 150–157. [Google Scholar] [CrossRef]

- Antoshin, A.A.; Shpichka, A.I.; Huang, G.; Chen, K.; Lu, P.; Svistunov, A.A.; Lychagin, A.V.; Lipina, M.M.; Sinelnikov, M.Y.; Reshetov, I.V.; et al. Lactoferrin as a regenerative agent: The old-new panacea? Pharmacol. Res. 2021, 167, 105564. [Google Scholar] [CrossRef]

- Siqueiros-Cendón, T.; Arévalo-Gallegos, S.; Iglesias-Figueroa, B.F.; García-Montoya, I.A.; Salazar-Martínez, J.; Rascón-Cruz, Q. Immunomodulatory effects of lactoferrin. Acta Pharmacol. Sin. 2014, 35, 557–566. [Google Scholar] [CrossRef]

- Niaz, B.; Saeed, F.; Ahmed, A.; Imran, M.; Maan, A.A.; Khan, M.K.I.; Tufail, T.; Anjum, F.M.; Hussain, S.; Suleria, H.A.R. Lactoferrin (LF): A natural antimicrobial protein. Int. J. Food Prop. 2019, 22, 1626–1641. [Google Scholar] [CrossRef]

- Krupińska, A.M.; Bogucki, Z. Clinical aspects of the use of lactoferrin in dentistry. J. Oral Biosci. 2021, 63, 129–133. [Google Scholar] [CrossRef]

- Biernbaum, E.N.; Gnezda, A.; Akbar, S.; Franklin, R.; Venturelli, P.A.; McKillip, J.L. Lactoferrin as an antimicrobial against Salmonella enterica and Escherichia coli O157:H7 in raw milk. JDS Commun. 2021, 2, 92–97. [Google Scholar] [CrossRef]

- Boots, J.-W.; Floris, R. Lactoperoxidase: From catalytic mechanism to practical applications. Int. Dairy J. 2006, 16, 1272–1276. [Google Scholar] [CrossRef]

- Saeed, F.; Afzaal, M.; Tufail, T.; Ahmad, A. Use of Natural Antimicrobial Agents: A Safe Preservation Approach. In Active Antimicrobial Food Packaging; IntechOpen: London, UK, 2019; ISBN 978-1-78985-003-1. [Google Scholar] [CrossRef]

- Armenteros, M.; Dalvit, P.; Leyva, V.; Ponce, P.; Alfonso, P. Risk analysis of the exacerbation of foodborne pathogens in raw milk activated with the lactoperoxidase system. Rev. Salud Anim. 2007, 29, 176–181. [Google Scholar]

- Jooyandeh, H.; Aberoumand, A.; Nasehi, B. Application of Lactoperoxidase System in Fish and Food Products: A Review. Am. Eurasian J. Agric. Environ. Sci. 2011, 10, 89–96. [Google Scholar]

- Seifu, E.; Buys, E.M.; Donkin, E.F. Significance of the lactoperoxidase system in the dairy industry and its potential applications: A review. Trends Food Sci. Technol. 2005, 16, 137–154. [Google Scholar] [CrossRef]

- Munsch-Alatossava, P.; Gursoy, O.; Lorilla, P.M.; Gauchi, J.-P.; Alatossava, T. Chapter 15—Antibacterial Effects and Modes of Action of the Activated Lactoperoxidase System (LPS), of CO2 and N2 Gas as Food-Grade Approaches to Control Bovine Raw Milk–Associated Bacteria. In Food Control and Biosecurity; Holban, A.M., Grumezescu, A.M., Eds.; Handbook of Food Bioengineering; Academic Press: Cambridge, MA, USA, 2018; pp. 519–541. ISBN 978-0-12-811445-2. [Google Scholar] [CrossRef]

- Leśnierowski, G.; Yang, T. Lysozyme and its modified forms: A critical appraisal of selected properties and potential. Trends Food Sci. Technol. 2021, 107, 333–342. [Google Scholar] [CrossRef]

- Wu, T.; Jiang, Q.; Wu, D.; Hu, Y.; Chen, S.; Ding, T.; Ye, X.; Liu, D.; Chen, J. What is new in lysozyme research and its application in food industry? A review. Food Chem. 2019, 274, 698–709. [Google Scholar] [CrossRef]

- Khan, M.I.; Dowarha, D.; Katte, R.; Chou, R.-H.; Filipek, A.; Yu, C. Lysozyme as the anti-proliferative agent to block the interaction between S100A6 and the RAGE V domain. PLoS ONE 2019, 14, e0216427. [Google Scholar] [CrossRef]

- Ragland, S.A.; Criss, A.K. From bacterial killing to immune modulation: Recent insights into the functions of lysozyme. PLoS Pathog. 2017, 13, e1006512. [Google Scholar] [CrossRef]

- Zhou, X.; Deng, J.; Fang, C.; Yu, R.; Lei, W.; He, X.; Zhang, C. Preparation and characterization of lysozyme@carbon nanotubes/waterborne polyurethane composite and the potential application in printing inks. Prog. Org. Coat. 2020, 142, 105600. [Google Scholar] [CrossRef]

- Huang, W.; Li, X.; Xue, Y.; Huang, R.; Deng, H.; Ma, Z. Antibacterial multilayer films fabricated by LBL immobilizing lysozyme and HTCC on nanofibrous mats. Int. J. Biol. Macromol. 2013, 53, 26–31. [Google Scholar] [CrossRef]

- Carrillo, W.; Spindola, H.; Ramos, M.; Recio, I.; Carvalho, J.E. Anti-Inflammatory and Anti-Nociceptive Activities of Native and Modified Hen Egg White Lysozyme. J. Med. Food 2016, 19, 978–982. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, X.; Wang, D.; Fang, C.; Zhang, W.; Wang, C.; Huang, Z. Lysozyme-based composite membranes and their potential application for active packaging. Food Biosci. 2021, 101078. [Google Scholar] [CrossRef]

- Niu, X.; Zhu, L.; Xi, L.; Guo, L.; Wang, H. An antimicrobial agent prepared by N-succinyl chitosan immobilized lysozyme and its application in strawberry preservation. Food Control 2020, 108, 106829. [Google Scholar] [CrossRef]

- Silva, N.H.C.S.; Vilela, C.; Almeida, A.; Marrucho, I.M.; Freire, C.S.R. Pullulan-based nanocomposite films for functional food packaging: Exploiting lysozyme nanofibers as antibacterial and antioxidant reinforcing additives. Food Hydrocoll. 2018, 77, 921–930. [Google Scholar] [CrossRef]

- Glicerina, V.; Siroli, L.; Canali, G.; Chinnici, F.; Capelli, F.; Lanciotti, R.; Colombo, V.; Romani, S. Efficacy of biodegradable, antimicrobial packaging on safety and quality parameters maintenance of a pear juice and rice milk-based smoothie product. Food Control 2021, 128, 108170. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, Y.; Bi, Q.; Qin, D.; Du, Q.; Jin, P. Enhanced antibacterial activity of eugenol-entrapped casein nanoparticles amended with lysozyme against gram-positive pathogens. Food Chem. 2021, 360, 130036. [Google Scholar] [CrossRef]

- Quinto, E.J.; Caro, I.; Villalobos-Delgado, L.H.; Mateo, J.; De-Mateo-Silleras, B.; Redondo-Del-Río, M.P. Food Safety through Natural Antimicrobials. Antibiotics 2019, 8, 208. [Google Scholar] [CrossRef]

- Daba, G.M.; Elkhateeb, W.A. Bacteriocins of lactic acid bacteria as biotechnological tools in food and pharmaceuticals: Current applications and future prospects. Biocatal. Agric. Biotechnol. 2020, 28, 101750. [Google Scholar] [CrossRef]

- Agriopoulou, S.; Stamatelopoulou, E.; Sachadyn-Król, M.; Varzakas, T. Lactic Acid Bacteria as Antibacterial Agents to Extend the Shelf Life of Fresh and Minimally Processed Fruits and Vegetables: Quality and Safety Aspects. Microorganisms 2020, 8, 952. [Google Scholar] [CrossRef]

- Woraprayote, W.; Malila, Y.; Sorapukdee, S.; Swetwiwathana, A.; Benjakul, S.; Visessanguan, W. Bacteriocins from lactic acid bacteria and their applications in meat and meat products. Meat Sci. 2016, 120, 118–132. [Google Scholar] [CrossRef] [PubMed]

- Settier-Ramírez, L.; López-Carballo, G.; Gavara, R.; Hernández-Muñoz, P. Broadening the antimicrobial spectrum of nisin-producing Lactococcus lactis subsp. Lactis to Gram-negative bacteria by means of active packaging. Int. J. Food Microbiol. 2021, 339, 109007. [Google Scholar] [CrossRef] [PubMed]

- Bungenstock, L.; Abdulmawjood, A.; Reich, F. Suitability of lactic acid bacteria and deriving antibacterial preparations to enhance shelf-life and consumer safety of emulsion type sausages. Food Microbiol. 2021, 94, 103673. [Google Scholar] [CrossRef] [PubMed]

- Haakensen, M.; Dobson, C.M.; Hill, J.E.; Ziola, B. 2009 Reclassification of Pediococcus dextrinicus (Coster and White 1964) Back 1978 (Approved Lists 1980) as Lactobacillus dextrinicus comb. nov., and emended description of the genus Lactobacillus. Int. J. Syst. Evol. Microbiol. 2021, 59, 615–621. [Google Scholar] [CrossRef]

- Gabrielsen, C.; Brede, D.A.; Nes, I.F.; Diep, D.B. Circular bacteriocins: Biosynthesis and mode of action. Appl. Environ. Microbiol. 2014, 80, 6854–6862. [Google Scholar] [CrossRef]

- Niamah, A.K. Structure, mode of action and application of pediocin natural antimicrobial food preservative: A review. Basrah J Agric Sci 2018, 31, 59–69. [Google Scholar] [CrossRef]

- Verma, S.K.; Sood, S.K.; Saini, R.K.; Saini, N. Pediocin PA-1 containing fermented cheese whey reduces total viable count of raw buffalo (Bubalis bubalus) milk. LWT-Food Sci. Technol. 2017, 83, 193–200. [Google Scholar] [CrossRef]

- Espitia, P.J.P.; Otoni, C.G.; Soares, N.F.F. Chapter 36—Pediocin Applications in Antimicrobial Food Packaging Systems. In Antimicrobial Food Packaging; Barros-Velázquez, J., Ed.; Academic Press: San Diego, CA, USA, 2016; pp. 445–454. ISBN 978-0-12-800723-5. [Google Scholar] [CrossRef]

- Meira, S.M.M.; Zehetmeyer, G.; Werner, J.O.; Brandelli, A. A novel active packaging material based on starch-halloysite nanocomposites incorporating antimicrobial peptides. Food Hydrocoll. 2017, 63, 561–570. [Google Scholar] [CrossRef]

- Vimont, A.; Fernandez, B.; Ahmed, G.; Fortin, H.-P.; Fliss, I. Quantitative antifungal activity of reuterin against food isolates of yeasts and moulds and its potential application in yogurt. Int. J. Food Microbiol. 2019, 289, 182–188. [Google Scholar] [CrossRef]

- Bal, C. Benefits and Uses of Mushroom. J. Bacteriol. Mycol. Open Access 2018, 6, 1. [Google Scholar] [CrossRef][Green Version]

- El-Saber Batiha, G.; Hussein, D.E.; Algammal, A.M.; George, T.T.; Jeandet, P.; Al-Snafi, A.E.; Tiwari, A.; Pagnossa, J.P.; Lima, C.M.; Thorat, N.D.; et al. Application of natural antimicrobials in food preservation: Recent views. Food Control 2021, 126, 108066. [Google Scholar] [CrossRef]

- Shameem, N.; Kamili, A.N.; Ahmad, M.; Masoodi, F.A.; Parray, J.A. Antimicrobial activity of crude fractions and morel compounds from wild edible mushrooms of North western Himalaya. Microb. Pathog. 2017, 105, 356–360. [Google Scholar] [CrossRef]

- Oli, A.N.; Edeh, P.A.; Al-Mosawi, R.M.; Mbachu, N.A.; Al-Dahmoshi, H.O.M.; Al-Khafaji, N.S.K.; Ekuma, U.O.; Okezie, U.M.; Saki, M. Evaluation of the phytoconstituents of Auricularia auricula-judae mushroom and antimicrobial activity of its protein extract. Eur. J. Integr. Med. 2020, 38, 101176. [Google Scholar] [CrossRef]

- Devi, K.P.; Suganthy, N.; Kesika, P.; Pandian, S.K. Bioprotective properties of seaweeds: In vitro evaluation of antioxidant activity and antimicrobial activity against food borne bacteria in relation to polyphenolic content. BMC Complement. Altern. Med. 2008, 8, 38. [Google Scholar] [CrossRef]

- Şen, F.; Uzunsoy, İ.; Baştürk, E.; Kahraman, M.V. Antimicrobial agent-free hybrid cationic starch/sodium alginate polyelectrolyte films for food packaging materials. Carbohydr. Polym. 2017, 170, 264–270. [Google Scholar] [CrossRef]

- Chand, K.; Rajeshwari; Hiremathad, A.; Singh, M.; Santos, M.A.; Keri, R.S. A review on antioxidant potential of bioactive heterocycle benzofuran: Natural and synthetic derivatives. Pharmacol. Rep. 2017, 69, 281–295. [Google Scholar] [CrossRef]

- Choe, E.; Min, D.B. Mechanisms of Antioxidants in the Oxidation of Foods. Compr. Rev. Food Sci. Food Saf. 2009, 8, 345–358. [Google Scholar] [CrossRef]

- Fritz, K.L.; Seppanen, C.M.; Kurzer, M.S.; Saari Csallany, A. The in vivo antioxidant activity of soybean isoflavones in human subjects. Nutr. Res. 2003, 23, 479–487. [Google Scholar] [CrossRef]

- Bera, D.; Lahiri, D.; Nag, A. Studies on a natural antioxidant for stabilization of edible oil and comparison with synthetic antioxidants. J. Food Eng. 2006, 74, 542–545. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.A.; Desobry, S. Release of synthetic phenolic antioxidants from extruded poly lactic acid (PLA) film. Food Control 2012, 28, 445–455. [Google Scholar] [CrossRef]

- Bodoira, R.M.; Penci, M.C.; Ribotta, P.D.; Martínez, M.L. Chia (Salvia hispanica L.) oil stability: Study of the effect of natural antioxidants. LWT 2017, 75, 107–113. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.L. Natural antioxidants as food and feed additives to promote health benefits and quality of meat products: A review. Meat Sci. 2016, 120, 107–117. [Google Scholar] [CrossRef]

- Pandey, A.K.; Kumar, P.; Singh, P.; Tripathi, N.N.; Bajpai, V.K. Essential Oils: Sources of Antimicrobials and Food Preservatives. Front. Microbiol. 2017, 7, 2161. [Google Scholar] [CrossRef]

- Baştürk, A.; Ceylan, M.M.; Çavuş, M.; Boran, G.; Javidipour, I. Effects of some herbal extracts on oxidative stability of corn oil under accelerated oxidation conditions in comparison with some commonly used antioxidants. LWT 2018, 89, 358–364. [Google Scholar] [CrossRef]

- Celano, R.; Piccinelli, A.L.; Pagano, I.; Roscigno, G.; Campone, L.; De Falco, E.; Russo, M.; Rastrelli, L. Oil distillation wastewaters from aromatic herbs as new natural source of antioxidant compounds. Food Res. Int. 2017, 99, 298–307. [Google Scholar] [CrossRef]