Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Minimal Processing

2.3. Coating-Forming Formulations

2.4. Mild-Heat Treatments and Coating Application

2.5. Quality Evaluation of Minimally Processed Onions during Storage

2.5.1. Respiration Rate

2.5.2. Weight Loss

2.5.3. pH, Soluble Solids Content, and Firmness

2.5.4. Total Polyphenol Content and Antioxidant Activity

2.5.5. Microbiological Analysis

2.5.6. Decay Ratio

2.5.7. Consumer Assessment

2.6. Statistical Analysis

3. Results and Discussion

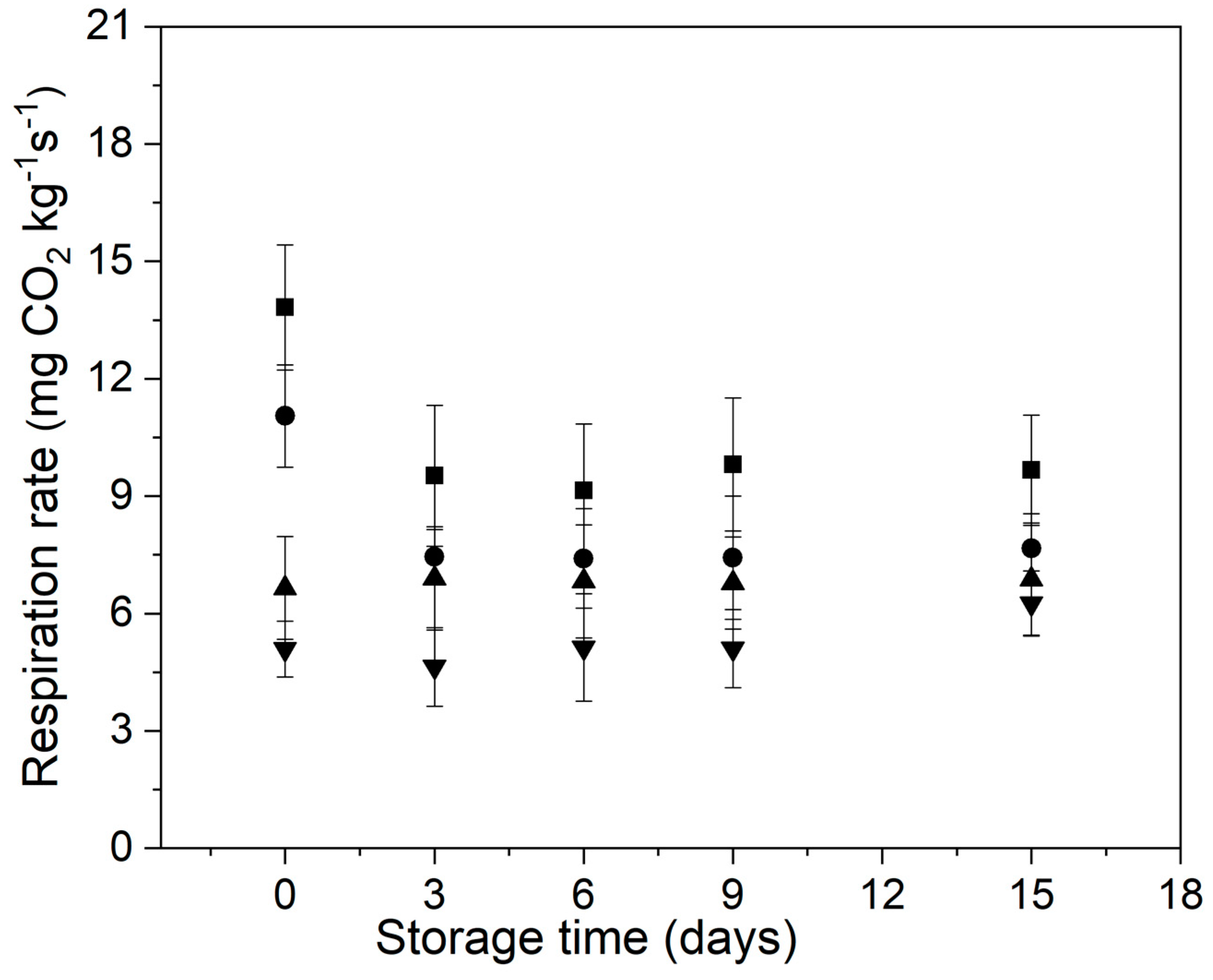

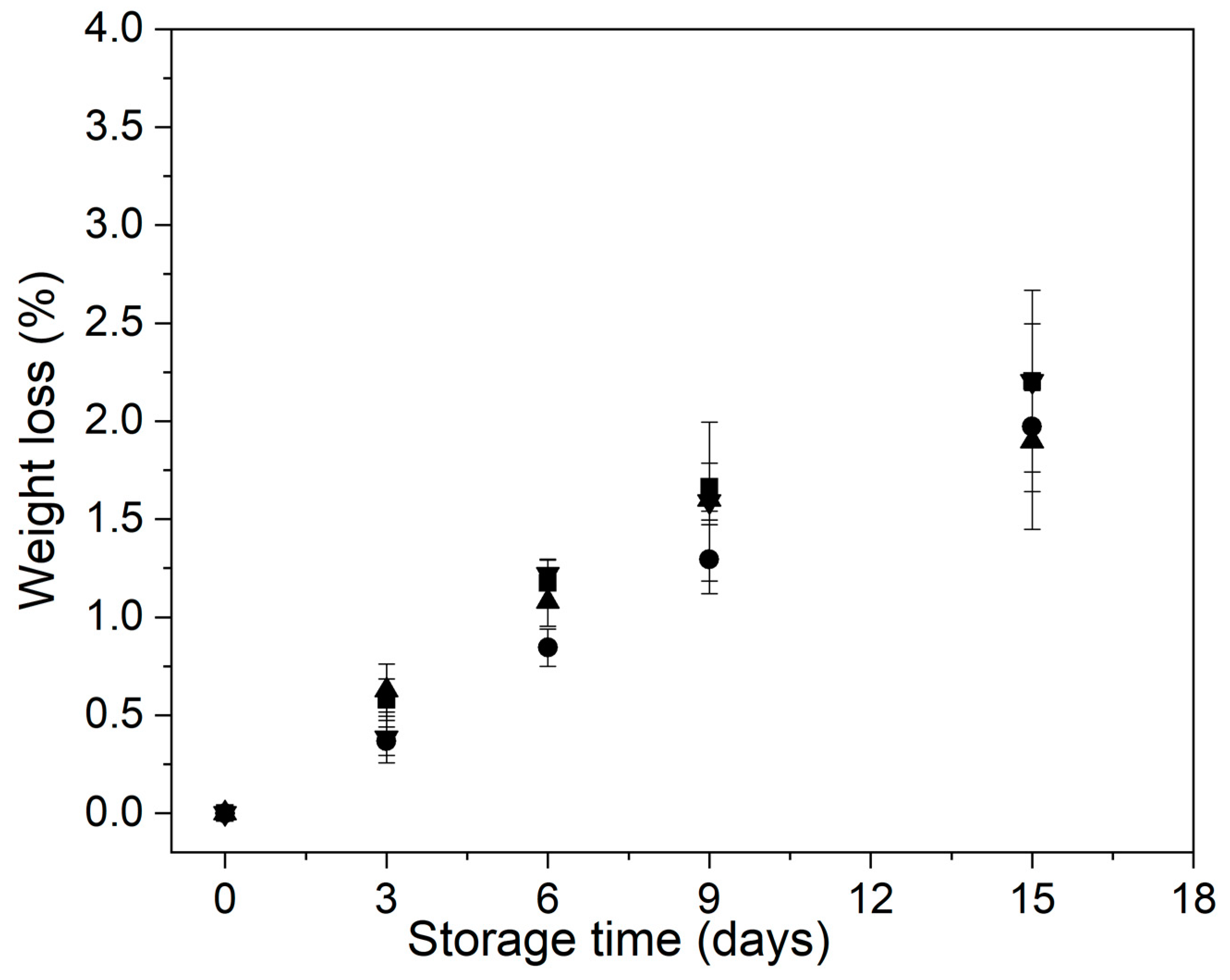

3.1. Respiration Rate and Weight Loss

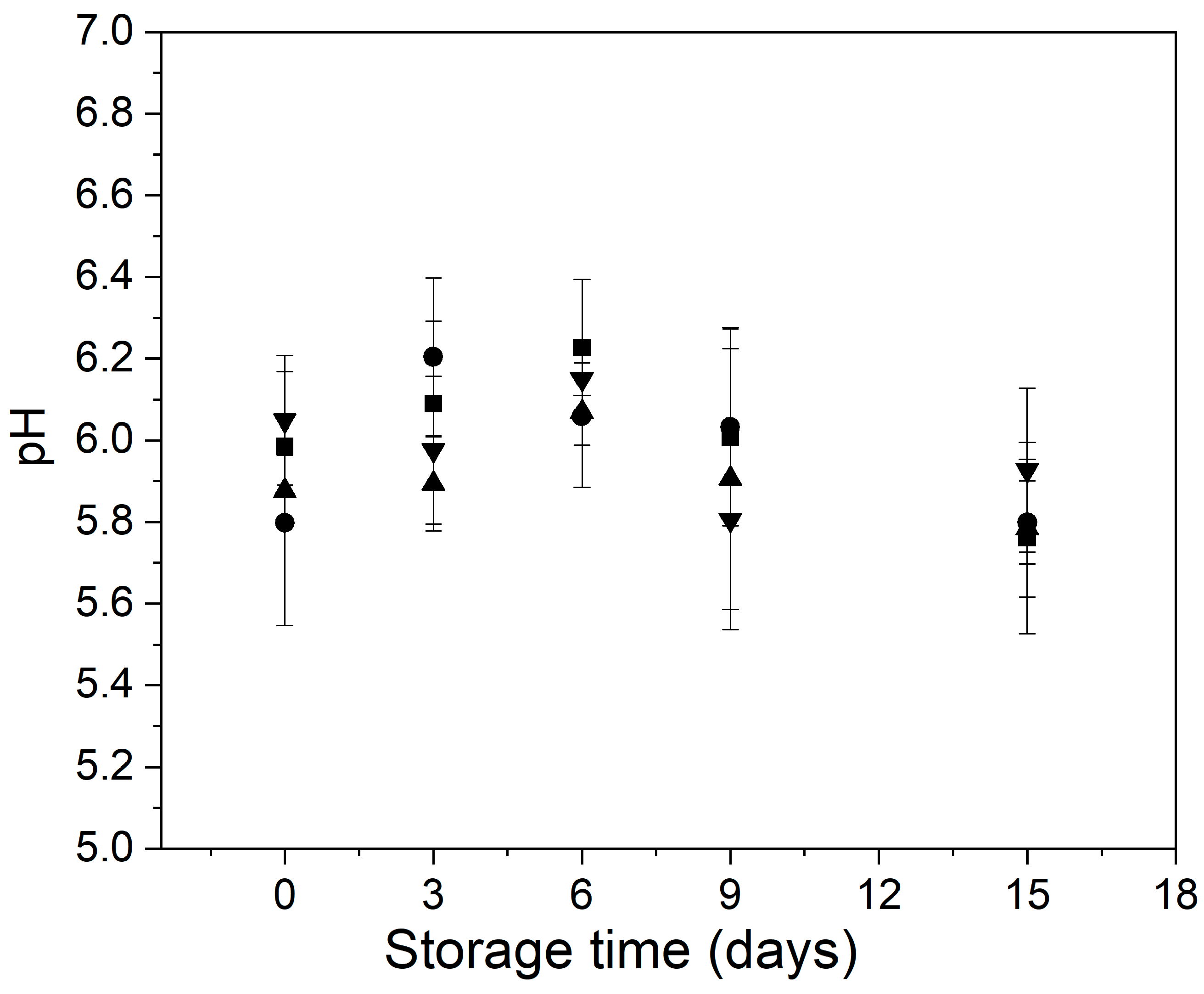

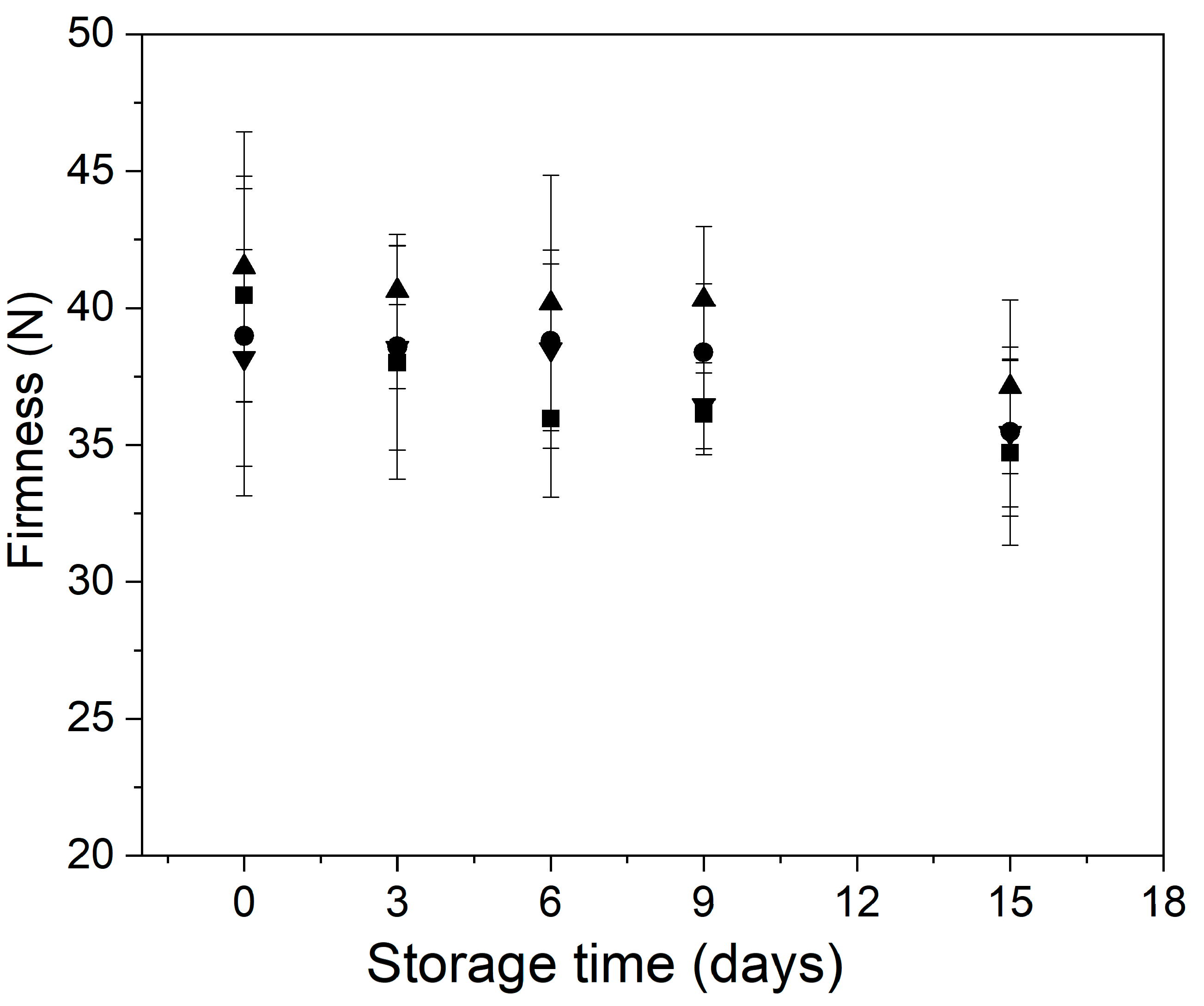

3.2. pH, Total Soluble Solids Content and Firmness

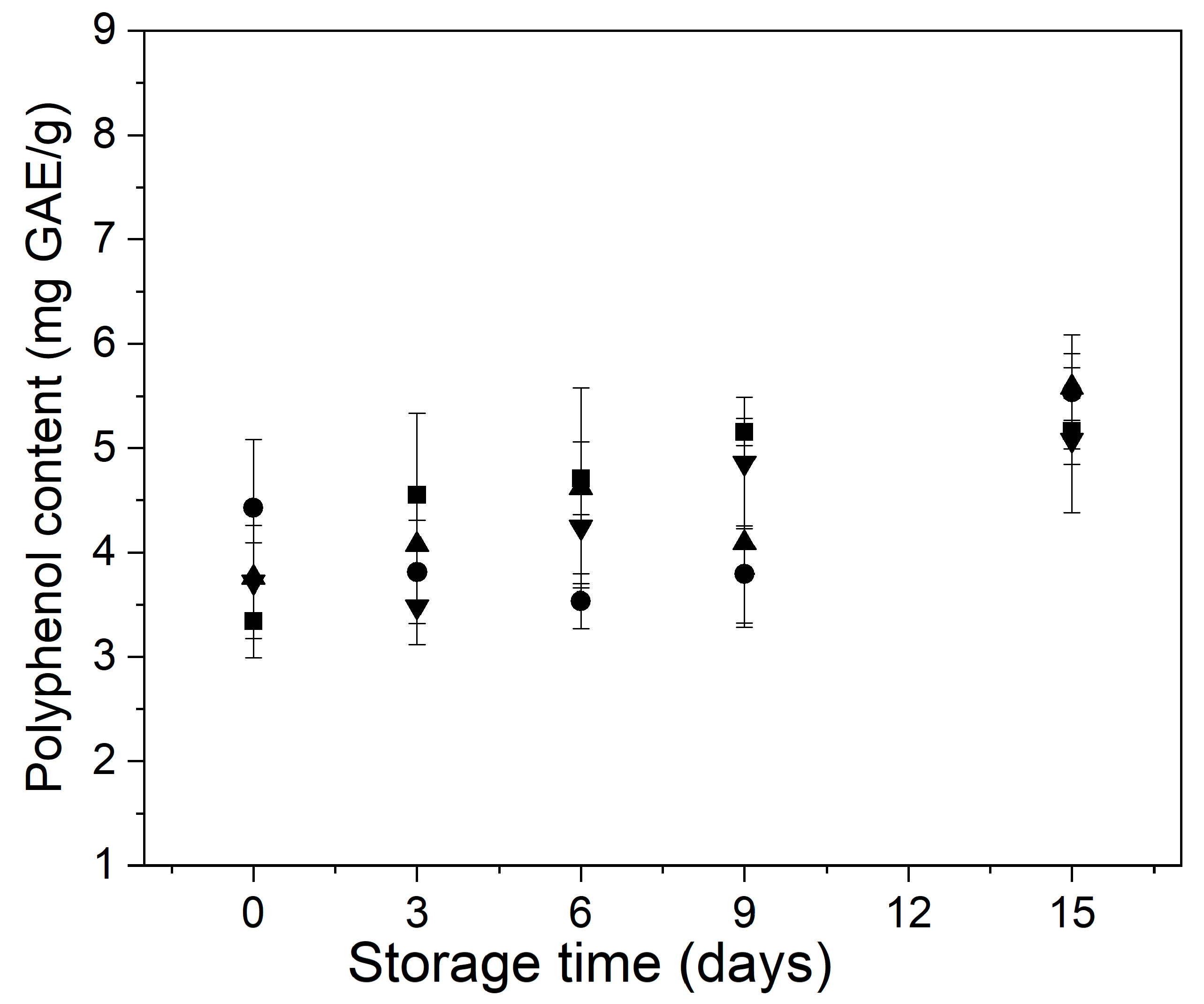

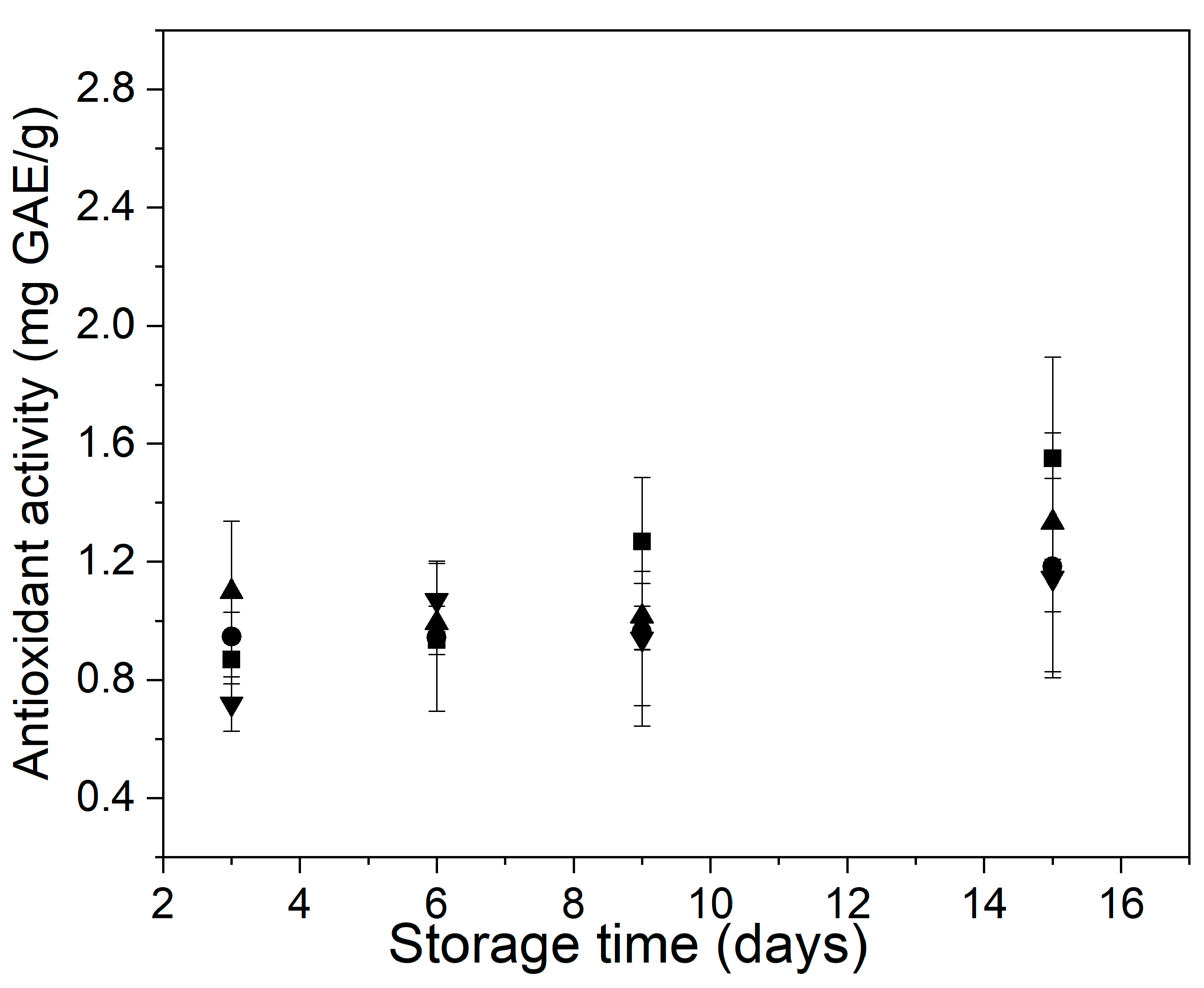

3.3. Total Polyphenol Content and Antioxidant Activity

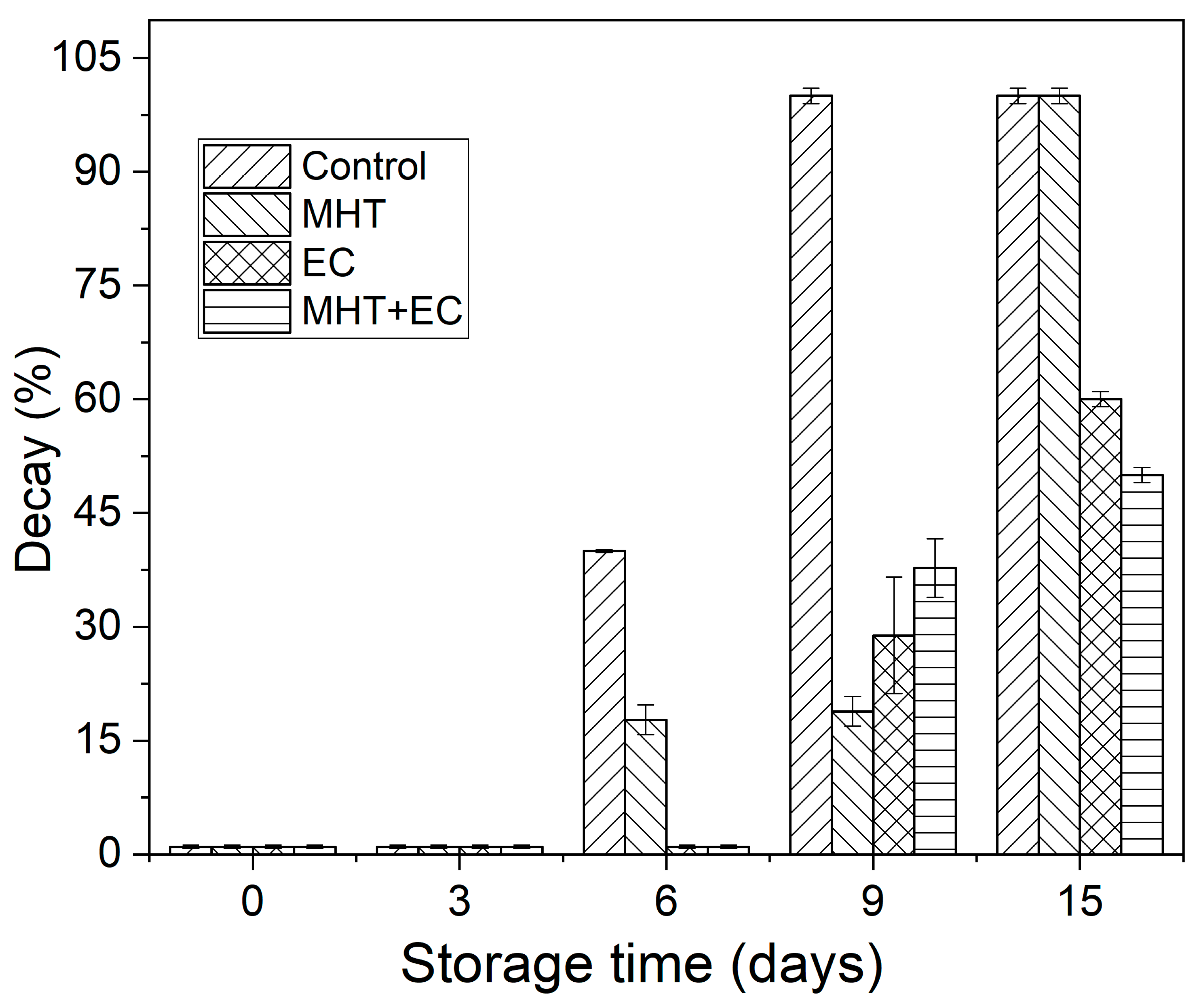

3.4. Microbial Count and Decay

3.5. Consumer Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grzegorzewska, M.; Badełek, E.; Szczech, M.; Kosson, R.; Wrzodak, A.; Kowalska, B.; Colelli, G.; Szwejda-Grzybowska, J.; Maciorowski, R. The effect of hot water treatment on the storage ability improvement of fresh-cut Chinese cabbage. Sci. Hortic. (Amst.) 2022, 291, 110551. [Google Scholar] [CrossRef]

- Botondi, R.; Barone, M.; Grasso, C. A Review into the Effectiveness of Ozone Technology for Improving the Safety and Preserving the Quality of Fresh-Cut Fruits and Vegetables. Foods 2021, 10, 748. [Google Scholar] [CrossRef]

- Testa, R.; Schifani, G.; Migliore, G. Understanding Consumers’ Convenience Orientation. An Exploratory Study of Fresh-Cut Fruit in Italy. Sustainability 2021, 13, 1027. [Google Scholar] [CrossRef]

- De Corato, U. Improving the shelf-life and quality of fresh and minimally-processed fruits and vegetables for a modern food industry: A comprehensive critical review from the traditional technologies into the most promising advancements. Crit. Rev. Food Sci. Nutr. 2020, 60, 940–975. [Google Scholar] [CrossRef]

- Lwin, W.; Srilaong, V.; Kanlayanarat, S.; Pongprasert, N.; Uthairatanakij, A. Effects of Different Exposure Times of 1-MCP on the Quality of Bunching Onions (Allium fistulosum). Agric. Sci. J. 2013, 3, 269–272. [Google Scholar]

- Kurnia, D.; Ajiati, D.; Heliawati, L.; Sumiarsa, D. Antioxidant Properties and Structure-Antioxidant Activity Relationship of Allium Species Leaves. Molecules 2021, 26, 7175. [Google Scholar] [CrossRef]

- Țigu, A.B.; Moldovan, C.S.; Toma, V.-A.; Farcaș, A.D.; Moț, A.C.; Jurj, A.; Fischer-Fodor, E.; Mircea, C.; Pârvu, M. Phytochemical Analysis and In Vitro Effects of Allium fistulosum L. and Allium sativum L. Extracts on Human Normal and Tumor Cell Lines: A Comparative Study. Molecules 2021, 26, 574. [Google Scholar] [CrossRef]

- Alvarez, M.V.; Moreira, M.D.R.; Roura, S.I.; Ayala-Zavala, J.F.; González-Aguilar, G.A. 13—Using natural antimicrobials to enhance the safety and quality of fresh and processed fruits and vegetables: Types of antimicrobials. In Woodhead Publishing Series in Food Science, Technology and Nutrition; Taylor, T.M., Ed.; Woodhead Publishing: Oxford, UK, 2015; pp. 287–313. ISBN 978-1-78242-034-7. [Google Scholar]

- Zudaire, L.; Viñas, I.; Abadias, M.; Simó, J.; Aguiló-Aguayo, I. Efficacy of chlorine, peroxyacetic acid and mild-heat treatment on the reduction of natural microflora and maintenance of quality of fresh-cut calçots (Allium cepa L.). LWT 2018, 95, 339–345. [Google Scholar] [CrossRef] [Green Version]

- Zudaire, L.; Lafarga, T.; Viñas, I.; Abadias, M.; Brunton, N.; Aguiló-Aguayo, I. Effect of Ultrasound Pre-Treatment on the Physical, Microbiological, and Antioxidant Properties of Calçots. Food Bioprocess Technol. 2019, 12, 387–394. [Google Scholar] [CrossRef] [Green Version]

- Rozo, G.; Gómez, D.; Rozo, C. Effect of an alginate edible film coating in the conservation of welsh onion (Allium fistulosum L.) | Efecto de una biopelícula de alginato en la conservación de cebolla larga (Allium fistulosum L.). Vitae 2016, 23, S419–S423. [Google Scholar]

- Cantwell, M.I.; Hong, G.; Suslow, T.V. Heat treatments control extension growth and enhance microbial disinfection of minimally processed green onions. HortScience 2001, 36, 732–737. [Google Scholar] [CrossRef]

- Hong, G.; Peiser, G.; Cantwell, M.I. Use of controlled atmospheres and heat treatment to maintain quality of intact and minimally processed green onions. Postharvest Biol. Technol. 2000, 20, 53–61. [Google Scholar] [CrossRef]

- Hong, S.I.; Kim, D. The effect of packaging treatment on the storage quality of minimally processed bunched onions. Int. J. Food Sci. Technol. 2004, 39, 1033–1041. [Google Scholar] [CrossRef]

- Fallik, E.; Ilić, Z. Hot Water Treatments. In Novel Postharvest Treatments of Fresh Produce; Pareek, S., Ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 231–247. ISBN 9781315370149. [Google Scholar]

- Zhang, L.; Li, S.; Wang, A.; Li, J.; Zong, W. Mild heat treatment inhibits the browning of fresh-cut Agaricus bisporus during cold storage. LWT—Food Sci. Technol. 2017, 82, 104–112. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Caleb, O.J.; Singh, Z.; Watkins, C.B.; Geyer, M. Postharvest treatments of fresh produce. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130309. [Google Scholar] [CrossRef] [Green Version]

- Moreira, M.D.R.; Ponce, A.; Ansorena, R.; Roura, S.I. Effectiveness of Edible Coatings Combined with Mild Heat Shocks on Microbial Spoilage and Sensory Quality of Fresh Cut Broccoli (Brassica oleracea L.). J. Food Sci. 2011, 76, 367–374. [Google Scholar] [CrossRef]

- Giannakourou, M.C.; Tsironi, T.N. Application of Processing and Packaging Hurdles for Fresh-Cut Fruits and Vegetables Preservation. Foods 2021, 10, 830. [Google Scholar] [CrossRef]

- Miteluț, A.C.; Popa, E.E.; Drăghici, M.C.; Popescu, P.A.; Popa, V.I.; Bujor, O.-C.; Ion, V.A.; Popa, M.E. Latest Developments in Edible Coatings on Minimally Processed Fruits and Vegetables: A Review. Foods 2021, 10, 2821. [Google Scholar] [CrossRef]

- Khan, M.R.; Di Giuseppe, F.A.; Torrieri, E.; Sadiq, M.B. Recent advances in biopolymeric antioxidant films and coatings for preservation of nutritional quality of minimally processed fruits and vegetables. Food Packag. Shelf Life 2021, 30, 100752. [Google Scholar] [CrossRef]

- Medina Jaramillo, C.; Estevez Areco, S.; Goyanes, S.; López Córdoba, A. Characterization of starches isolated from Colombian native potatoes and their application as novel edible coatings for wild Andean blueberries (Vaccinium meridionale Swartz). Polymers 2019, 11, 1937. [Google Scholar] [CrossRef] [Green Version]

- Nair, M.S.; Tomar, M.; Punia, S.; Kukula-Koch, W.; Kumar, M. Enhancing the functionality of chitosan- and alginate-based active edible coatings/films for the preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2020, 164, 304–320. [Google Scholar] [CrossRef] [PubMed]

- Zapata, P.J.; Castillo, S.; Valero, D.; Guillén, F.; Serrano, M.; Díaz-Mula, H.M. The use of alginate as edible coating alone or in combination with essential oils maintained postharvest quality of tomato. Acta Hortic. 2010, 877, 1529–1534. [Google Scholar] [CrossRef]

- Wüstenberg, T. General Overview of Food Hydrocolloids. In Cellulose and Cellulose Derivatives in the Food industry Fundamentals and Applications; Wüstenberg, T., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 1–68. [Google Scholar]

- Medina-Jaramillo, C.; Quintero-Pimiento, C.; Gómez-Hoyos, C.; Zuluaga-Gallego, R.; López-Córdoba, A. Alginate-Edible Coatings for Application on Wild Andean Blueberries (Vaccinium meridionale Swartz): Effect of the Addition of Nanofibrils Isolated from Cocoa By-Products. Polymers 2020, 12, 824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jayakody, M.M.; Vanniarachchy, M.P.G.; Wijesekara, I. Seaweed derived alginate, agar, and carrageenan based edible coatings and films for the food industry: A review. J. Food Meas. Charact. 2022. [Google Scholar] [CrossRef]

- Medina-Jaramillo, C.; Quintero-Pimiento, C.; Díaz-Díaz, D.; Goyanes, S.; López-Córdoba, A. Improvement of Andean Blueberries Postharvest Preservation Using Carvacrol/Alginate-Edible Coatings. Polymers 2020, 12, 2352. [Google Scholar] [CrossRef]

- Prakash, A.; Baskaran, R.; Vadivel, V. Citral nanoemulsion incorporated edible coating to extend the shelf life of fresh cut pineapples. LWT 2020, 118, 108851. [Google Scholar] [CrossRef]

- Robles-Sánchez, R.M.; Rojas-Graü, M.A.; Odriozola-Serrano, I.; González-Aguilar, G.; Martin-Belloso, O. Influence of alginate-based edible coating as carrier of antibrowning agents on bioactive compounds and antioxidant activity in fresh-cut Kent mangoes. LWT—Food Sci. Technol. 2013, 50, 240–246. [Google Scholar] [CrossRef]

- Poverenov, E.; Danino, S.; Horev, B.; Granit, R.; Vinokur, Y.; Rodov, V. Layer-by-Layer Electrostatic Deposition of Edible Coating on Fresh Cut Melon Model: Anticipated and Unexpected Effects of Alginate–Chitosan Combination. Food Bioprocess Technol. 2014, 7, 1424–1432. [Google Scholar] [CrossRef]

- Sarengaowa; Hu, W.; Jiang, A.; Xiu, Z.; Feng, K. Effect of thyme oil–alginate-based coating on quality and microbial safety of fresh-cut apples. J. Sci. Food Agric. 2018, 98, 2302–2311. [Google Scholar] [CrossRef]

- Ansorena, M.R.; Marcovich, N.E.; Roura, S.I. Impact of edible coatings and mild heat shocks on quality of minimally processed broccoli (Brassica oleracea L.) during refrigerated storage. Postharvest Biol. Technol. 2011, 59, 53–63. [Google Scholar] [CrossRef]

- Koh, P.C.; Noranizan, M.A.; Karim, R.; Nur Hanani, Z.A.; Lasik-Kurdyś, M. Combination of alginate coating and repetitive pulsed light for shelf life extension of fresh-cut cantaloupe (Cucumis melo L. reticulatus cv. Glamour). J. Food Process. Preserv. 2018, 42, e13786. [Google Scholar] [CrossRef]

- Ben-Fadhel, Y.; Cingolani, M.C.; Li, L.; Chazot, G.; Salmieri, S.; Horak, C.; Lacroix, M. Effect of γ-irradiation and the use of combined treatments with edible bioactive coating on carrot preservation. Food Packag. Shelf Life 2021, 28, 100635. [Google Scholar] [CrossRef]

- Piñeros-Hernandez, D.; Medina-Jaramillo, C.; López-Córdoba, A.; Goyanes, S. Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll. 2017, 63, 488–495. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. In Methods in Enzymology (Oxidants and Antioxidants, Part A); Lester Packer, L., Ed.; Academic Press: San Diego, CA, USA, 1999; Volume 299, pp. 152–178. [Google Scholar]

- Estevez-Areco, S.; Guz, L.; Famá, L.; Candal, R.; Goyanes, S. Bioactive starch nanocomposite films with antioxidant activity and enhanced mechanical properties obtained by extrusion followed by thermo-compression. Food Hydrocoll. 2019, 96, 518–528. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- ISO 4833-1:2013; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Microorganisms—Part 1: Colony Count at 30 C by the Pour Plate Technique. International Standard Organization: Geneva, Switzerland, 2013.

- ISO 21527-2:2008; Microbiology of Food and Animal Feeding Stuffs—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 2: Colony Count Technique in Products with Water Activity Less Than or Equal to 0.95. ISO: Geneva, Switzerland, 2008.

- Moskowitz, H.R.; Beckley, J.H.; Resurreccion, A.V.A. What types of tests do sensory researchers do to measure sensory response to the product? and …why do they do them? In Sensory and Consumer Research in Food Product Design and Development; Moskowitz, H.R., Beckley, J.H., Resurreccion, A.V.A., Eds.; John Wiley & Sons: Ames, IA, USA, 2012; pp. 229–281. [Google Scholar]

- Alharaty, G.; Ramaswamy, H.S. The Effect of Sodium Alginate-Calcium Chloride Coating on the Quality Parameters and Shelf Life of Strawberry Cut Fruits. J. Compos. Sci. 2020, 4, 123. [Google Scholar] [CrossRef]

- Xylia, P.; Chrysargyris, A.; Tzortzakis, N. The Combined and Single Effect of Marjoram Essential Oil, Ascorbic Acid, and Chitosan on Fresh-Cut Lettuce Preservation. Foods 2021, 10, 575. [Google Scholar] [CrossRef] [PubMed]

- Romanazzi, G.; Feliziani, E.; Sivakumar, D. Chitosan, a Biopolymer With Triple Action on Postharvest Decay of Fruit and Vegetables: Eliciting, Antimicrobial and Film-Forming Properties. Front. Microbiol. 2018, 9, 2745. [Google Scholar] [CrossRef] [PubMed]

- Senturk Parreidt, T.; Müller, K.; Schmid, M. Alginate-Based Edible Films and Coatings for Food Packaging Applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Siddiq, M.; Roidoung, S.; Sogi, D.S.; Dolan, K.D. Total phenolics, antioxidant properties and quality of fresh-cut onions (Allium cepa L.) treated with mild-heat. Food Chem. 2013, 136, 803–806. [Google Scholar] [CrossRef]

- Mcglynn, W. The Importance of Food pH in Commercial Canning Operations. In Food Technology Fact Sheet; Oklahoma Cooperative Extension Service, Division of Agricultural Sciences and Natural Resources, Oklahoma State University: Stillwater, OK, USA, 2003; pp. 1–8. [Google Scholar]

- Zudaire, L.; Viñas, I.; Abadias, M.; Lafarga, T.; Bobo, G.; Simó, J.; Aguiló-Aguayo, I. Effects of long-term controlled atmosphere storage, minimal processing, and packaging on quality attributes of calçots (Allium cepa L.). Food Sci. Technol. Int. 2019, 26, 403–412. [Google Scholar] [CrossRef] [PubMed]

- Toivonen, P.M.A.; Brummell, D.A. Biochemical bases of appearance and texture changes in fresh-cut fruit and vegetables. Postharvest Biol. Technol. 2008, 48, 1–14. [Google Scholar] [CrossRef]

- Andrés-Bello, A.; Barreto-Palacios, V.; García-Segovia, P.; Mir-Bel, J.; Martínez-Monzó, J. Effect of pH on Color and Texture of Food Products. Food Eng. Rev. 2013, 5, 158–170. [Google Scholar] [CrossRef]

- Kumar, N.; Pratibha; Neeraj; Ojha, A.; Upadhyay, A.; Singh, R.; Kumar, S. Effect of active chitosan-pullulan composite edible coating enrich with pomegranate peel extract on the storage quality of green bell pepper. LWT 2021, 138, 110435. [Google Scholar] [CrossRef]

- Kocira, A.; Kozłowicz, K.; Panasiewicz, K.; Staniak, M.; Szpunar-Krok, E.; Hortyńska, P. Polysaccharides as Edible Films and Coatings: Characteristics and Influence on Fruit and Vegetable Quality—A Review. Agronomy 2021, 11, 813. [Google Scholar] [CrossRef]

- Han, C.; Ji, Y.; Li, M.; Li, X.; Jin, P.; Zheng, Y. Influence of wounding intensity and storage temperature on quality and antioxidant activity of fresh-cut Welsh onions. Sci. Hortic. (Amst.) 2016, 212, 203–209. [Google Scholar] [CrossRef]

- Howard, L.R.; Yoo, K.S.; Pike, L.M.; Miller, G.H. Quality Changes in Diced Onions Stored in Film Packages. J. Food Sci. 1994, 59, 110–112. [Google Scholar] [CrossRef]

- Kubec, R.; Hrbáčová, M.; Musah, R.A.; Velíšek, J. Allium Discoloration: Precursors Involved in Onion Pinking and Garlic Greening. J. Agric. Food Chem. 2004, 52, 5089–5094. [Google Scholar] [CrossRef]

| Microorganims | Samples | Day 0 | Day 3 | Day 6 | Day 9 | Day 15 |

|---|---|---|---|---|---|---|

| Mesophilic Aerobic (Log CFU · g−1) | Control | 3.72 ± 0.01 b | 3.78 ± 0.05 b | 3.94 ± 0.01 a | 4.02 ± 0.10 a | 4.16 ± 0.08 a |

| MHT | 3.76 ± 0.01 b | 3.77 ± 0.01 b | 3.95 ± 0.05 a | 4.01 ± 0.07 a | 4.16 ± 0.04 a | |

| EC | 3.85 ± 0.02 a | 3.89 ± 0.01 a | 4.07 ± 0.01 a | 4.21 ± 0.10 a | 4.36 ± 0.01 a | |

| MHT + EC | 3.63 ± 0.02 c | 3.66 ± 0.01 c | 4.02 ± 0.11 a | 4.18 ± 0.10 a | 4.29 ± 0.08 a | |

| Molds and yeasts (Log CFU · g−1) | Control | 2.87 ± 0.04 a | 3.79 ± 0.03 b | 3.97 ± 0.02 b | 4.10 ± 0.03 bc | 4.24 ± 0.10 b |

| MHT | nd b | 3.40 ± 0.02 c | 3.50 ± 0.05 d | 4.00 ± 0.04 c | 4.14 ± 0.01 b | |

| EC | nd b | 4.65 ± 0.01 a | 4.83 ± 0.02 a | 5.20 ± 0.01 a | 5.32 ± 0.04 a | |

| MHT + EC | nd b | 3.54 ± 0.06 c | 3.69 ± 0.04 c | 4.20 ± 0.01 b | 4.28 ± 0.01 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medina-Jaramillo, C.; Usgame-Fagua, K.; Franco-González, N.; López-Córdoba, A. Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions. Foods 2022, 11, 641. https://doi.org/10.3390/foods11050641

Medina-Jaramillo C, Usgame-Fagua K, Franco-González N, López-Córdoba A. Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions. Foods. 2022; 11(5):641. https://doi.org/10.3390/foods11050641

Chicago/Turabian StyleMedina-Jaramillo, Carolina, Karen Usgame-Fagua, Nelson Franco-González, and Alex López-Córdoba. 2022. "Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions" Foods 11, no. 5: 641. https://doi.org/10.3390/foods11050641

APA StyleMedina-Jaramillo, C., Usgame-Fagua, K., Franco-González, N., & López-Córdoba, A. (2022). Single and Combined Effect of Mild-Heat Treatment and Alginate Coatings on Quality Preservation of Minimally Processed Bunching Green Onions. Foods, 11(5), 641. https://doi.org/10.3390/foods11050641