The Sensory Quality and the Physical Properties of Functional Green Tea-Infused Yoghurt with Inulin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

Yoghurt Processing

2.2. Methods

2.2.1. Sensory Evaluation

The Method

Expert Panel

Study Conditions

Preparation and Presentation of Samples

2.2.2. Instrumental Analysis

Yield Stress

Textural Properties

Physical Stability—CSA Method

Color Parameters

2.2.3. Statistical Analysis

3. Results

3.1. Sensory Evaluation

3.1.1. Quantitative Descriptive Profile Analysis

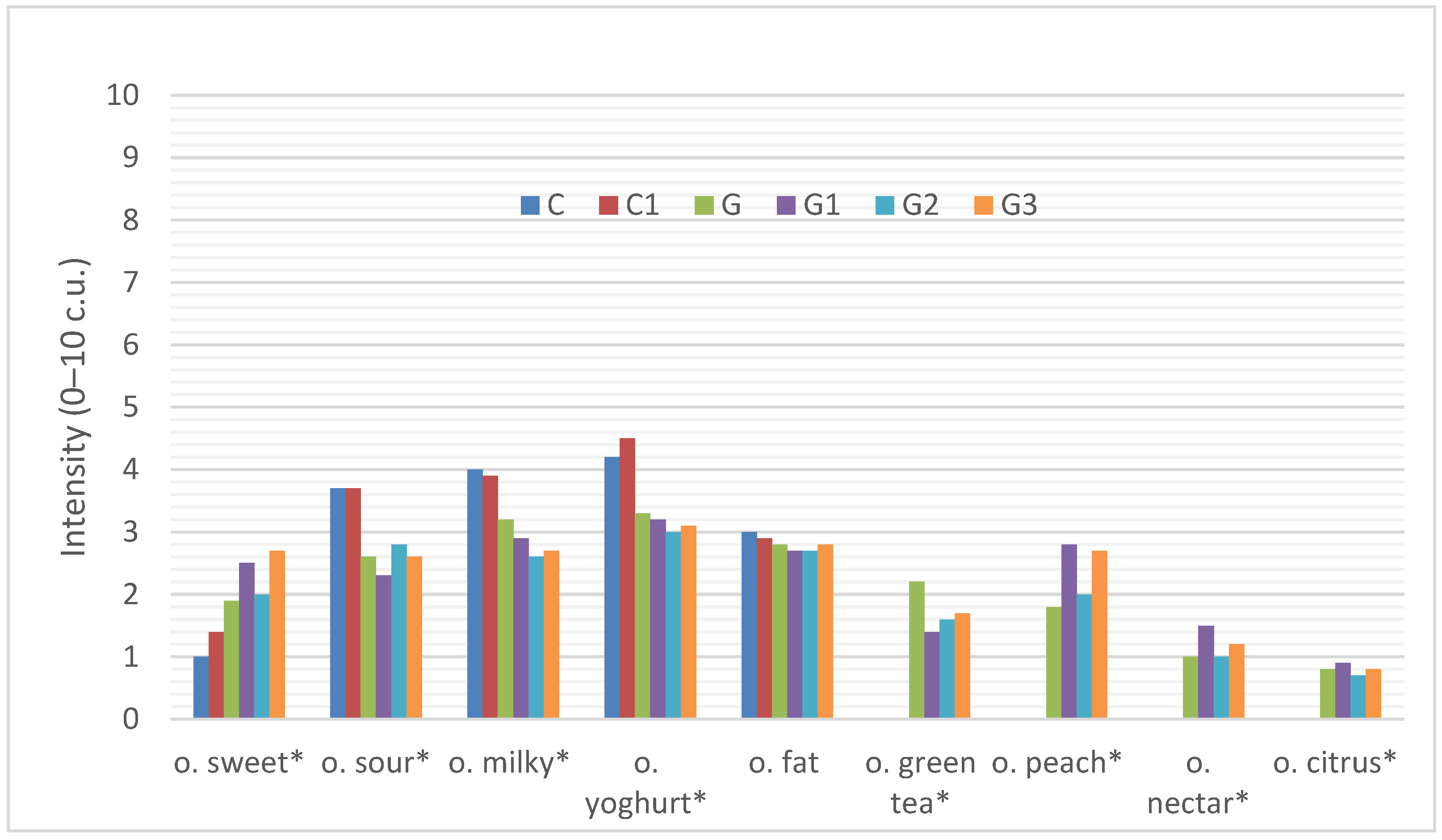

Odor

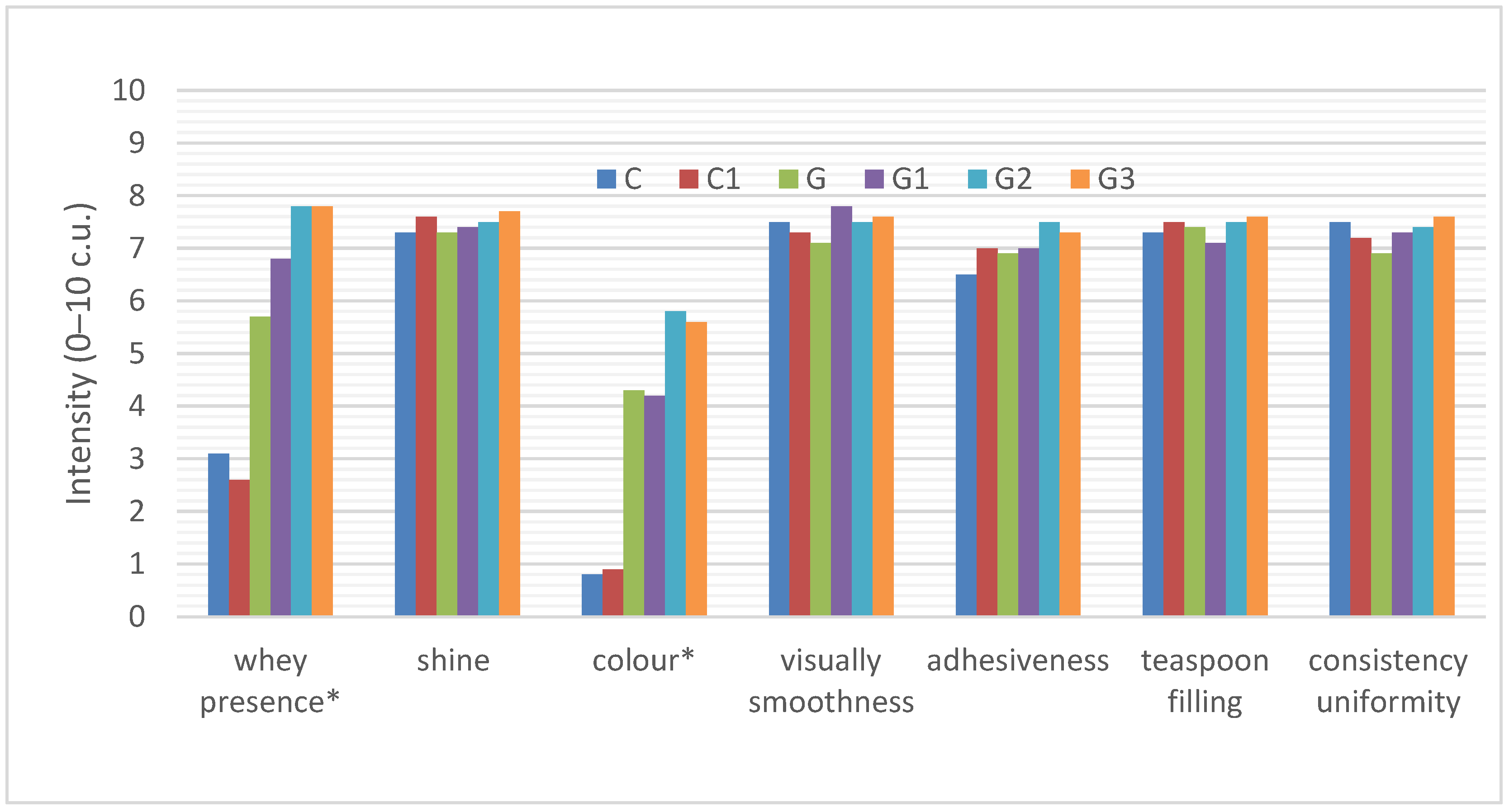

Appearance Perceived Visually

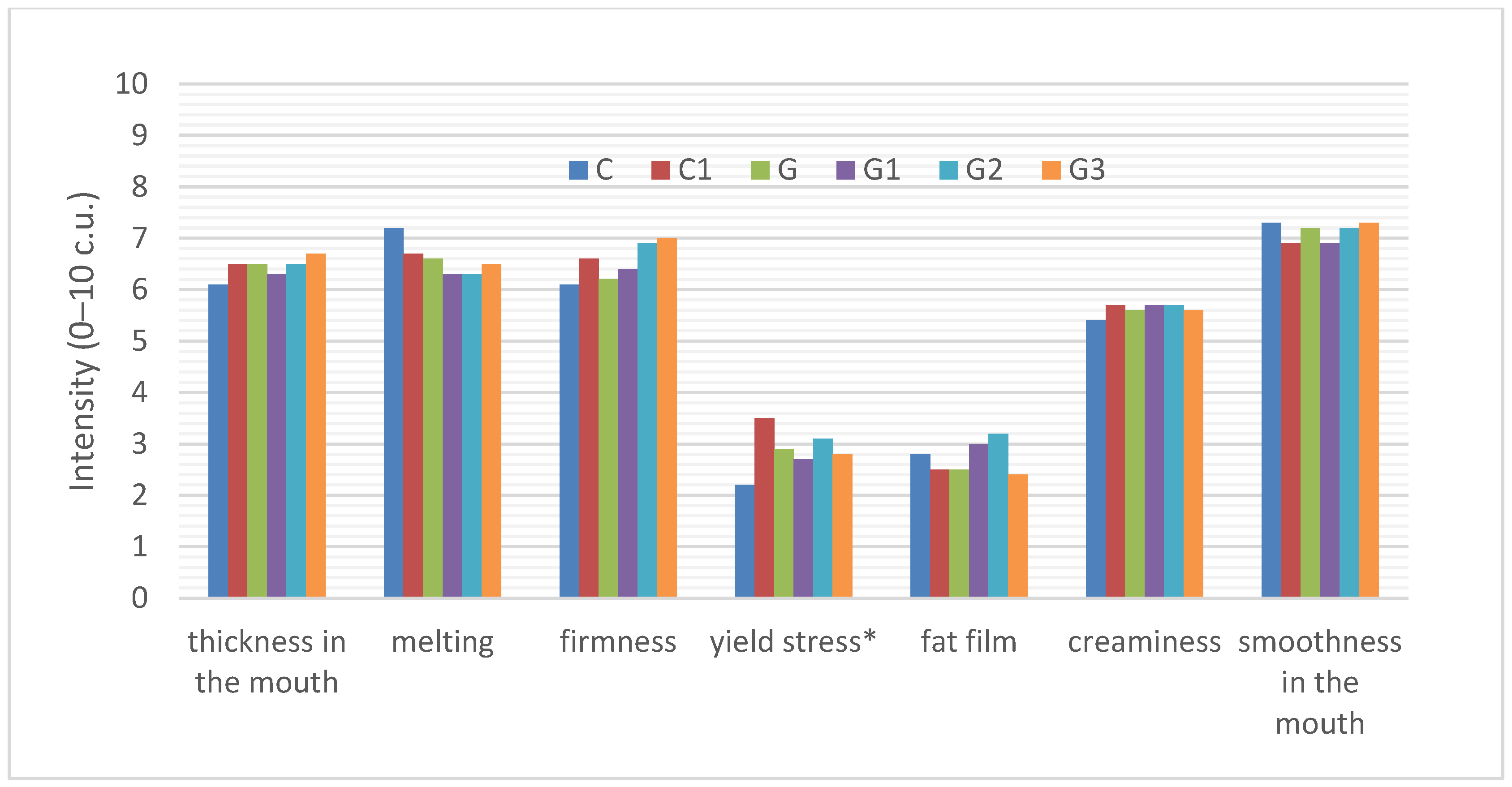

Consistency Perceived in the Mouth

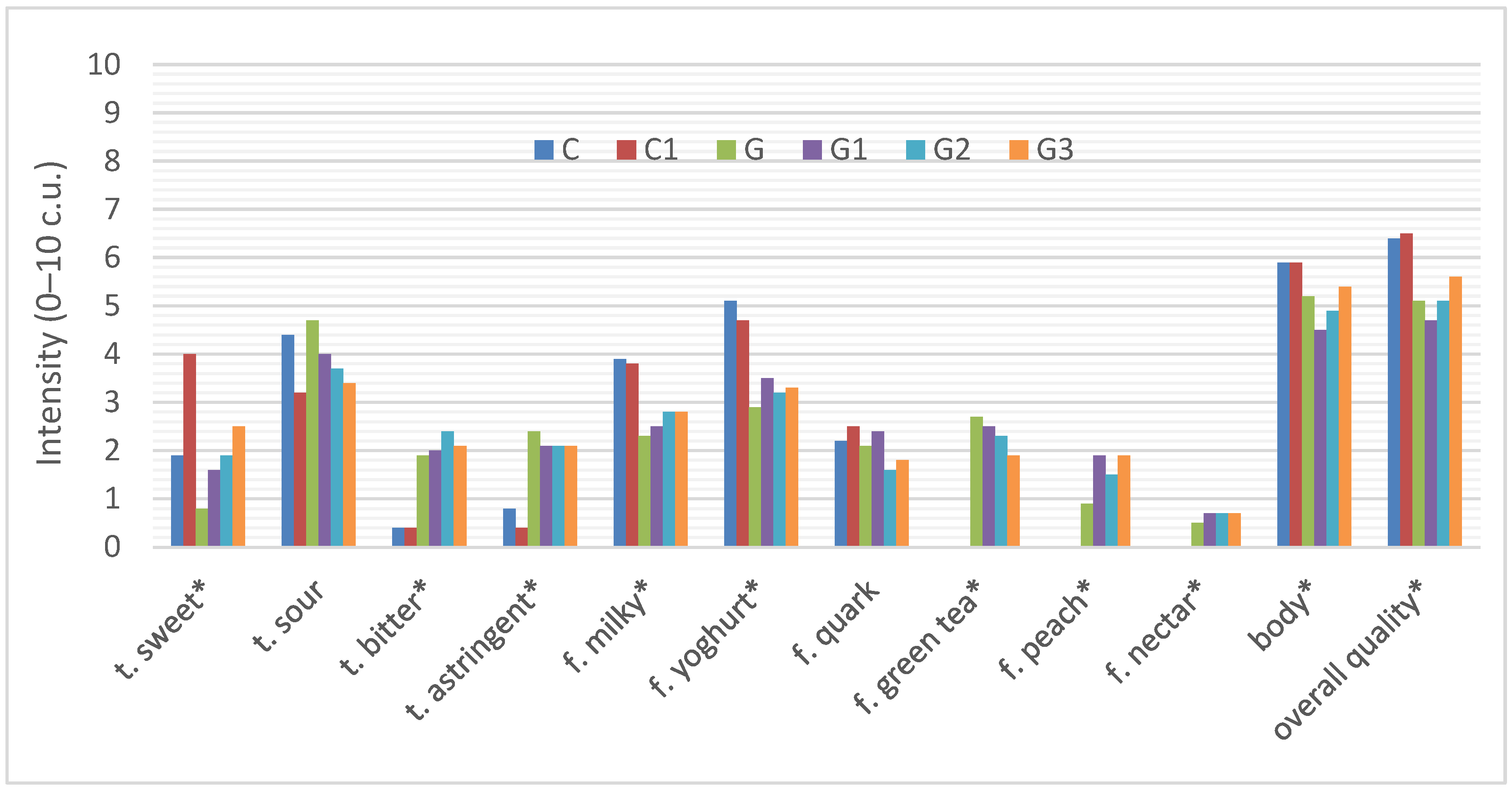

Flavor/Overall Quality

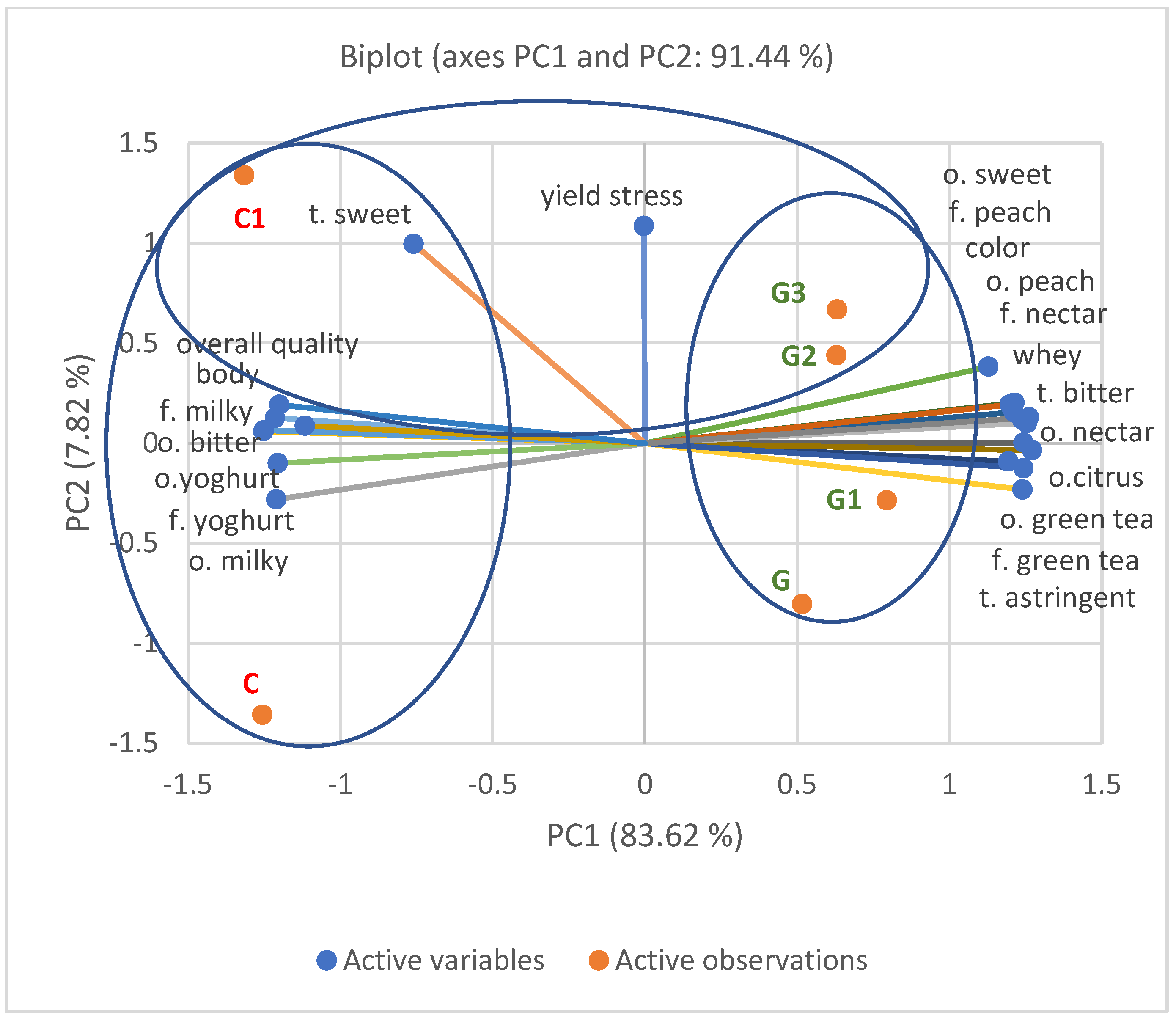

3.1.2. Principal Component Analysis

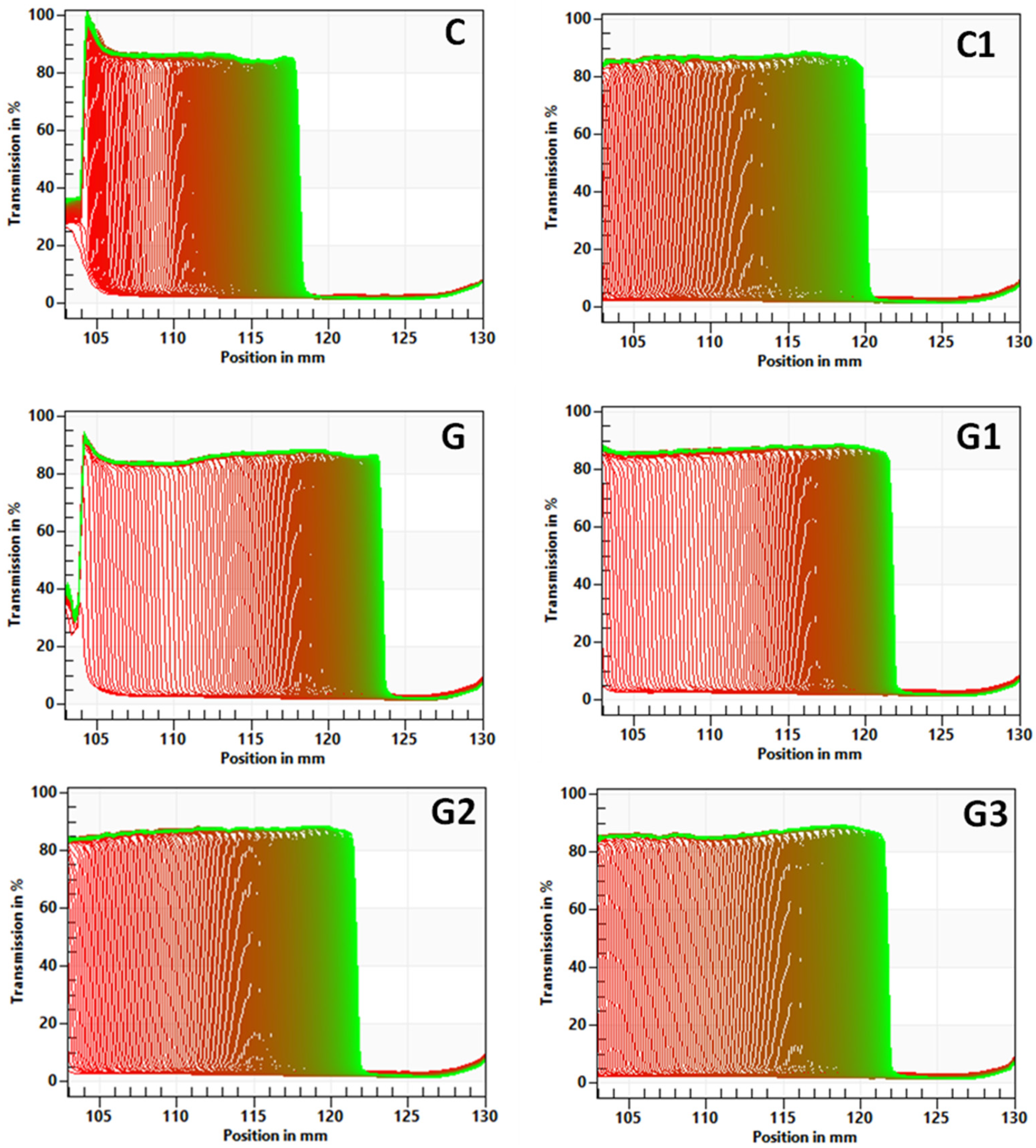

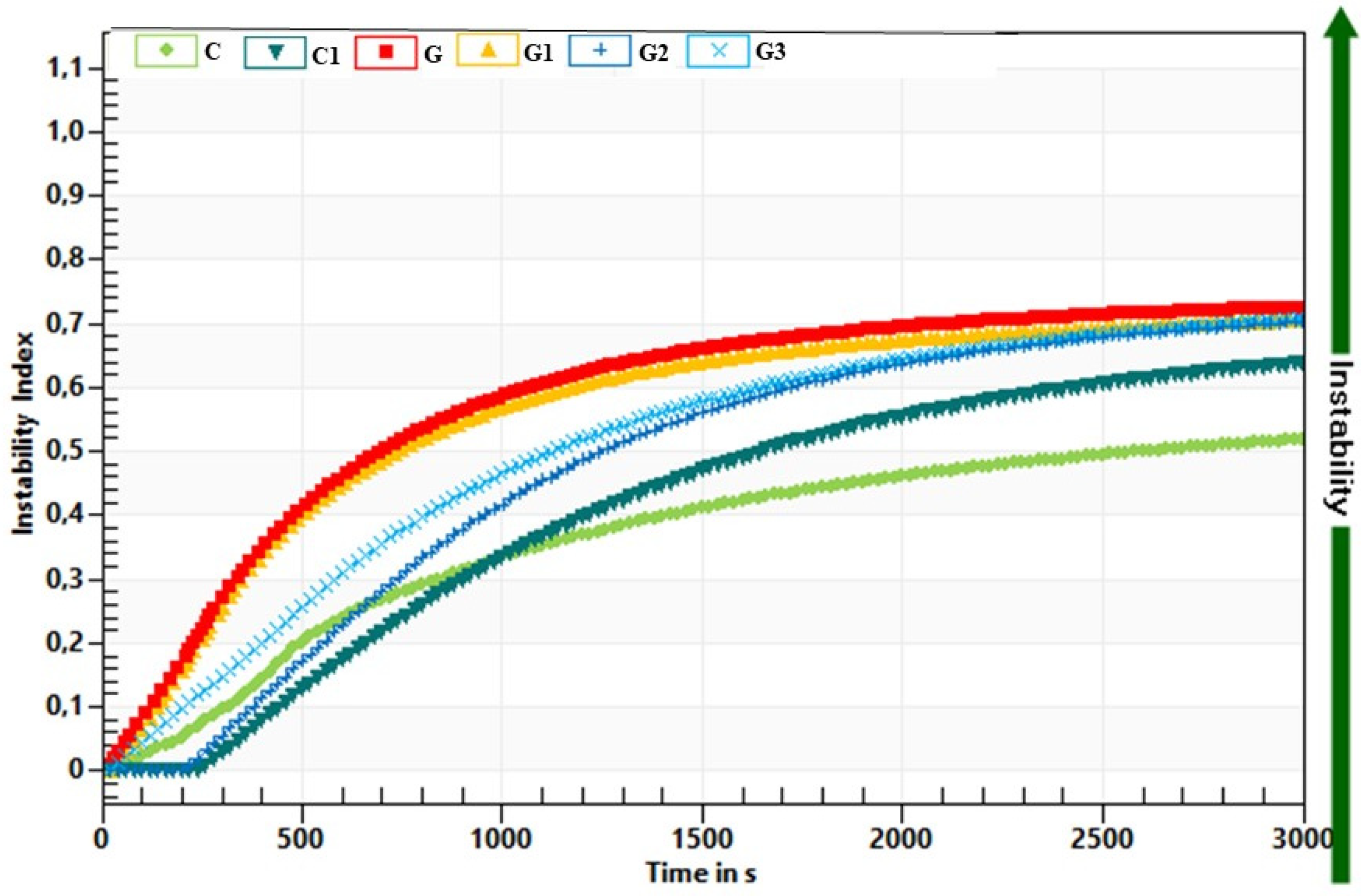

3.2. Instrumental Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Masson, E.; Debucquet, G.; Fischler, C.; Merdji, M. French consumers’ perceptions of nutrition and health claims: A psychosocial-anthropological approach. Appetite 2016, 105, 618–629. [Google Scholar] [CrossRef] [PubMed]

- Świąder, K.; Florowska, A.; Konisiewicz, Z.; Chen, Y.-P. Functional Tea-Infused Set Yoghurt Development by Evaluation of Sensory Quality and Textural Properties. Foods 2020, 9, 1848. [Google Scholar] [CrossRef]

- Sukhikh, S.A.; Astakhova, L.A.; Golubcova, Y.V.; Lukin, A.A.; Prosekova, E.A.; Milentèva, I.S.; Kostina, N.G.; Rasshchepkin, A.N. Functional dairy products enriched with plant ingredients. Foods Raw Mater. 2019, 7, 428–438. [Google Scholar] [CrossRef]

- Azari-Anpar, M.; Payeinmahali, H.; Daraei Garmakhany, A.; Sadeghi Mahounak, A. Physicochemical, microbial, antioxidant, and sensory properties of probiotic stirred yoghurt enriched with Aloe vera foliar gel. J. Food Proc. Preser. 2017, 41, e13209. [Google Scholar] [CrossRef]

- Karnopp, A.R.; Oliveira, K.G.; de Andrade, E.F.; Postingher, B.M.; Granato, D. Optimization of an organic yogurt based on sensorial, nutritional, and functional perspectives. Food Chem. 2017, 233, 401–411. [Google Scholar] [CrossRef] [PubMed]

- Mousavi, M.; Heshmati, A.; Daraei Garmakhany, A.; Vahidinia, A.; Taheri, M. Texture and sensory characterization of functional yogurt supplemented with flaxseed during cold storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ndife, J. Production and Quality Assessment of Functional Yoghurt Enriched with Coconut. Int. J. Nutr. Food Sci. 2014, 3, 545. [Google Scholar] [CrossRef] [Green Version]

- Pan, L.H.; Liu, F.; Luo, S.Z.; Luo, J.P. Pomegranate juice powder as sugar replacer enhanced quality and function of set yogurts: Structure, rheological property, antioxidant activity and in vitro bioaccessibility. LWT 2019, 115, 108479. [Google Scholar] [CrossRef]

- Bchir, B.; Bouaziz, M.A.; Blecker, C.; Attia, H. Physico-Chemical, antioxidant activities, textural, and sensory properties of yoghurt fortified with different states and rates of pomegranate seeds (Punica granatum L.). J. Text. Stud. 2020, 51, 475–487. [Google Scholar] [CrossRef]

- Wang, X.; Kristo, E.; LaPointe, G. Adding apple pomace as a functional ingredient in stirred-type yogurt and yogurt drinks. Food Hydrocoll. 2020, 100, 105453. [Google Scholar] [CrossRef]

- Barkallah, M.; Dammak, M.; Louati, I.; Hentati, F.; Hadrich, B.; Mechichi, T.; Ayadi, M.A.; Fendri, I.; Attia, H.; Abdelkafi, S. Effect of Spirulina platensis fortification on physicochemical, textural, antioxidant and sensory properties of yogurt during fermentation and storage. LWT 2017, 84, 323–330. [Google Scholar] [CrossRef]

- Gaglio, R.; Gentile, C.; Bonanno, A.; Vintaloro, L.; Perrone, A.; Mazza, F.; Barbaccia, P.; Settanni, L.; Di Grigoli, A. Effect of saffron addition on the microbiological, physicochemical, antioxidant and sensory characteristics of yoghurt. Int. J. Dairy Technol. 2019, 72, 208–217. [Google Scholar] [CrossRef]

- Jaziri, I.; Ben Slama, M.; Mhadhbi, H.; Urdaci, M.C.; Hamdi, M. Effect of green and black teas (Camellia sinensis L.) on the characteristic microflora of yogurt during fermentation and refrigerated storage. Food Chem. 2009, 112, 614–620. [Google Scholar] [CrossRef]

- Najgebauer-Lejko, D.; Sady, M.; Grega, T.; Walczycka, M. The impact of tea supplementation on microflora, pH and antioxidant capacity of yoghurt. Int. Dairy J. 2011, 21, 568–574. [Google Scholar] [CrossRef]

- Muniandy, P.; Shori, A.B.; Baba, A.S. Influence of green, white and black tea addition on the antioxidant activity of probiotic yogurt during refrigerated storage. Food Pack. Shelf Life 2016, 8, 1–8. [Google Scholar] [CrossRef]

- Shokery, E.S.; Ziney, E.l.; Yossef, M.G.A.H.; Mashaly, R.I. Effect of green tea and moringa leave extracts fortification on the physicochemical, rheological, sensory and antioxidant properties of set-type yoghurt. Adv. Dairy Res. 2017, 5, 179–189. [Google Scholar] [CrossRef]

- Unal, G.; Karagozlu, C.; Kinik, O.; Akan, E.; Akalin, A.S. Effect of Supplementation with Green and Black Tea on Microbiological Characteristics, Antimicrobial and Antioxidant Activities of Drinking Yoghurt. J. Agric. Sci. 2018, 24, 153–161. [Google Scholar]

- Chatterjee, G.; Das, S.; Das, R.S.; Des, A.B. Development of green tea infused chocolate yoghurt and evaluation of its nutritive value and storage stability. Progress Nutr. 2018, 20, 237–245. [Google Scholar] [CrossRef]

- Bulut, M.; Tunçtürk, Y.; Alwazeer, D. Effect of fortification of set-type yoghurt with different plant extracts on its physicochemical, rheological, textural and sensory properties during storage. Int. J. Dairy Technol. 2021, 74, 723–736. [Google Scholar] [CrossRef]

- Rahmani, F.; Gandomi, H.; Noori, N.; Faraki, A.; Farzaneh, M. Microbial, physiochemical and functional properties of probiotic yogurt containing Lactobacillus acidophilus and Bifidobacterium bifidum enriched by green tea aqueous extract. Food Sci. Nutr. 2021, 9, 5536–5545. [Google Scholar] [CrossRef]

- EFSA Panel on Dietetic Products, Nutrition and Allergies (NDA). Scientific Opinion on the substantiation of a health claim related to “native chicory inulin” and maintenance of normal defecation by increasing stool frequency pursuant to Article 13.5 of Regulation (EC) No 1924/2006. EFSA J. 2015, 13, 3951. [Google Scholar] [CrossRef] [Green Version]

- Lin, T.Y. Influence of lactic cultures, linoleic acid and fructo-oligosaccharides on conjugated linoleic acid concentration in non-fat set yogurt. Aust. J. Dairy Technol. 2003, 58, 11–14. [Google Scholar]

- Staffolo, M.D.; Bertola, N.; Martino, M. Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int. Dairy J. 2004, 14, 263–268. [Google Scholar] [CrossRef]

- Guven, M.; Yaser, K.; Karaca, O.; Hayaloglu, A. The effect of inulin as a fat replacer on the quality of set-type low-fat yogurt manufacture. Int. J. Dairy Technol. 2005, 58, 180–184. [Google Scholar] [CrossRef]

- Kip, P.; Meyer, D.; Jellema, R.H. Inulins improve sensoric and textural properties of low-fat yoghurts. Int. Dairy J. 2006, 16, 1098–1103. [Google Scholar] [CrossRef]

- Brennan, C.S.; Tudorica, C.M. Carbohydrate-based fat replacers in the modification of the rheological, textural and sensory quality of yoghurt: Comparative study of the utilisation of barley beta-glucan, guar gum and inulin. Int. J. Food Sci. Technol. 2008, 43, 824–833. [Google Scholar] [CrossRef]

- Paseephol, T.; Small, D.M.; Sherkat, F. Rheology and texture of set yogurt as affected by inulin addition. J. Text. Stud. 2008, 39, 617–634. [Google Scholar] [CrossRef]

- Guggisberg, D.; Cuthbert-Steven, J.; Piccinali, P.; Bütikofer, U.; Eberhard, P. Rheological, microstructural and sensory characterization of low-fat and whole milk set yoghurt as influenced by inulin addition. Int. Dairy J. 2009, 19, 107–115. [Google Scholar] [CrossRef]

- Świąder, K.; Florowska, A.; Konisiewicz, Z. The Sensory Quality and the Textural Properties of Functional Oolong Tea-Infused Set Type Yoghurt with Inulin. Foods 2021, 10, 1242. [Google Scholar] [CrossRef]

- ISO 13299:2016. Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. Available online: https://www.iso.org/standard/58042.html (accessed on 20 November 2021).

- ISO 8586:2012. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. Available online: https://www.iso.org/standard/45352.html (accessed on 20 November 2021).

- ISO 8589:2007/AMD 1:2014. Sensory Analysis—General Guidance for the Design of Test Rooms (Amd 1: 2014). Available online: https://www.iso.org/standard/36385.html (accessed on 20 November 2021).

- Lerche, D.; Sobisch, T. Direct and accelerated characterization of formulation stability. J. Dispers. Sci. Technol. 2011, 32, 1799–1811. [Google Scholar] [CrossRef]

- Mokrzycki, W.; Tatol, M. Colour difference ∆E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Lee, S.M.; Lee, H.S.; Kim, K.H.; Kim, K.O. Sensory characteristics and consumer acceptability of decaffeinated green teas. J. Food Sci. 2009, 74, S135–S141. [Google Scholar] [CrossRef]

- Tamime, A.Y. Fermented Milks; Blackwell Science Ltd.: Oxford, UK, 2006. [Google Scholar]

- Cui, B.; Lu, Y.M.; Tan, C.P.; Wang, G.Q.; Li, G.H. Effect of cross-linked acetylated starch content on the structure and stability of set yoghurt. Food Hydrocoll. 2014, 35, 576–582. [Google Scholar] [CrossRef]

- Ozdal, T.; Capanoglu, E.; Altay, F. A review on protein-phenolic interactions and associated changes. Food Res. Int. 2013, 51, 954–970. [Google Scholar] [CrossRef]

- Najgebauer-Lejko, D.; Witek, M.; Żmudziński, D. Changes in the viscosity, textural properties, and water status in yogurt gel upon supplementation with green and, Pu-erh teas. J. Dairy Sci. 2020, 103, 11039–11049. [Google Scholar] [CrossRef]

- Dönmez, Ö.; Mogol, B.A.; Gökmen, V. Syneresis and rheological behaviors of set yogurt containing green tea and green coffee powders. J. Dairy Sci. 2017, 100, 901–907. [Google Scholar] [CrossRef]

- Salvador, A.; Fiszman, S.M. Textural and Sensory Characteristics of Whole and Skimmed Flavored Set-Type Yogurt During Long Storage. J. Dairy Sci. 2004, 87, 4033–4041. [Google Scholar] [CrossRef] [Green Version]

- Phillips, G.O.; Williams, P.A. Handbook of Hydrocolloid; CRC Press: Washington, DC, USA, 2000. [Google Scholar]

- Harbourne, N.; Jacquier, J.C.; O’Riordan, D. Effects of addition of phenolic compounds on the acid gelation of milk. Int. Dairy J. 2011, 21, 185–191. [Google Scholar] [CrossRef]

- Armoskaite, V.; Ramanaukiene, K.; Maruska, A.; Razukas, A.; Dagilyte, A.; Baranuskas, A.; Bredis, V. The analysis of quality and antioxidant activity of green tea extracts. J. Med. Plants Res. 2011, 5, 811–816. [Google Scholar]

- Karaaslan, M.; Ozden, M.; Vardin, H.; Turkoglu, H. Phenolic fortification of yogurt using grape and callus extracts. LWT 2011, 44, 1065–1072. [Google Scholar] [CrossRef]

- Najgebauer-Lejko, D. Effect of green tea supplementation on the microbiological, antioxidant, and sensory properties of probiotic milks. Dairy Sci. Technol. 2014, 94, 327–339. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, K.; Zhou, H.M.; Zhu, K.X.; Guo, X.N.; Peng, W. Increasing the physicochemical stability of stored green tea noodles: Analysis of the quality and chemical components. Food Chem. 2019, 278, 333–341. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.J.; Lucey, J.A. Formation and physical properties of yogurt. Asian-Aust. J. Anim. Sci. 2010, 23, 1127–1136. [Google Scholar] [CrossRef]

- Da Silva, D.F.; Junior, N.N.T.; Gomes, R.G.; dos Santos Pozza, M.S.; Britten, M.; Matumoto-Pintro, P.T. Physical, microbiological and rheological properties of probiotic yogurt supplemented with grape extract. J. Food Sci. Technol. 2017, 54, 1608–1615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, D. Effect of Fuzhuan brick-tea addition on the quality and antioxidant activity of skimmed set-type yoghurt. Int. J. Dairy Technol. 2018, 71, 22–33. [Google Scholar] [CrossRef]

- Delikanli, B.; Ozcan, T. Effects of various whey proteins on the physicochemical and textural properties of set type nonfat yoghurt. Int. J. Dairy Technol. 2014, 67, 495–503. [Google Scholar] [CrossRef]

- Rudra, S.G.; Nath, P.; Kaur, C.; Basu, S. Rheological, storage stability and sensory profiling of low-fat yoghurt fortified with red capsicum carotenoids and inulin. J. Food Processing Preserv. 2017, 41, e13067. [Google Scholar] [CrossRef]

- Moghadam, B.E.; Keivaninahr, F.; Fouladi, M.; Mokarram, R.R.; Nazemi, A. Inulin addition to yoghurt: Prebiotic activity, health effects and sensory properties. Int. J. Dairy Technol. 2019, 72, 183–198. [Google Scholar] [CrossRef]

- Arango, O.; Trujillo, A.J.; Castillo, M. Influence of fat substitution by inulin on fermentation process and physical properties of set yoghurt evaluated by an optical sensor. Food Bioprod. Processing 2020, 124, 24–32. [Google Scholar] [CrossRef]

- Glibowski, P.; Gałązka, A. Effect of shear forces on textural properties of inulin gels. Acta Agrophys. 2009, 13, 67–76. [Google Scholar]

| Sample | Yield Stress [Pa] | Texture | |

|---|---|---|---|

| Firmness [N] | Adhesiveness [Ns] | ||

| C | 127.2 a ± 6.7 | 0.817 a ± 0.111 | −0.048 b ± 0.007 |

| C1 | 182.3 d ± 7.7 | 1.136 bc ± 0.068 | −0.078 ab ± 0.009 |

| G | 154.9 bc ± 9.7 | 0.950 ab ± 0.105 | −0.104 a ± 0.011 |

| G1 | 149.5 ab ± 16.5 | 0.923 ab ± 0.115 | −0.101 a ± 0.010 |

| G2 | 176.8 cd ± 7.7 | 1.058 b ± 0.036 | −0.105 a ± 0.028 |

| G3 | 189.9 d ± 7.2 | 1.302 c ± 0.058 | −0.087 ab ± 0.013 |

| Sample | Color Parameters | Instability Index | |||

|---|---|---|---|---|---|

| L* | a* | b* | ΔE | ||

| C | 89.80 c ± 0.59 | −1.31 a ± 0.06 | 9.52 a ± 0.22 | - | 0.517 a ± 0.022 |

| C1 | 90.47 c ± 0.13 | −1.20 a ± 0.04 | 10.17 a ± 0.15 | 0.97 ± 0.43 | 0.618 b ± 0.018 |

| G | 84.42 b ± 0.19 | 0.78 b ± 0.21 | 15.69 b ± 0.77 | 8.47 ± 0.52 | 0.705 c ± 0.021 |

| G1 | 85.41 b ± 0.47 | 0.90 b ± 0.25 | 15.91 b ± 0.30 | 1.40 ± 0.59 | 0.702 c ± 0.025 |

| G2 | 82.35 a ± 0.10 | 0.97 b ± 0.05 | 15.15 b ± 0.07 | 2.24 ± 0.39 | 0.706 c ± 0.012 |

| G3 | 82.35 a ± 0.62 | 1.01 b ± 0.44 | 15.45 b ± 0.73 | 2.47 ± 0.82 | 0.725 c ± 0.030 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świąder, K.; Florowska, A. The Sensory Quality and the Physical Properties of Functional Green Tea-Infused Yoghurt with Inulin. Foods 2022, 11, 566. https://doi.org/10.3390/foods11040566

Świąder K, Florowska A. The Sensory Quality and the Physical Properties of Functional Green Tea-Infused Yoghurt with Inulin. Foods. 2022; 11(4):566. https://doi.org/10.3390/foods11040566

Chicago/Turabian StyleŚwiąder, Katarzyna, and Anna Florowska. 2022. "The Sensory Quality and the Physical Properties of Functional Green Tea-Infused Yoghurt with Inulin" Foods 11, no. 4: 566. https://doi.org/10.3390/foods11040566

APA StyleŚwiąder, K., & Florowska, A. (2022). The Sensory Quality and the Physical Properties of Functional Green Tea-Infused Yoghurt with Inulin. Foods, 11(4), 566. https://doi.org/10.3390/foods11040566