Improving the Nutritional, Structural, and Sensory Properties of Gluten-Free Bread with Different Species of Microalgae

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Preparation of Doughs

2.2. Farinograph Mixing Properties

2.3. Fundamental Rheology-SAOS and Creep Recovery

2.4. Bread Technological Properties (Color, Volume, and Firmness)

2.5. Bread Nutritional Properties

2.6. Evaluation of Bioactivity in Breads

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Impact of Algal Biomass Addition on Dough Rheology

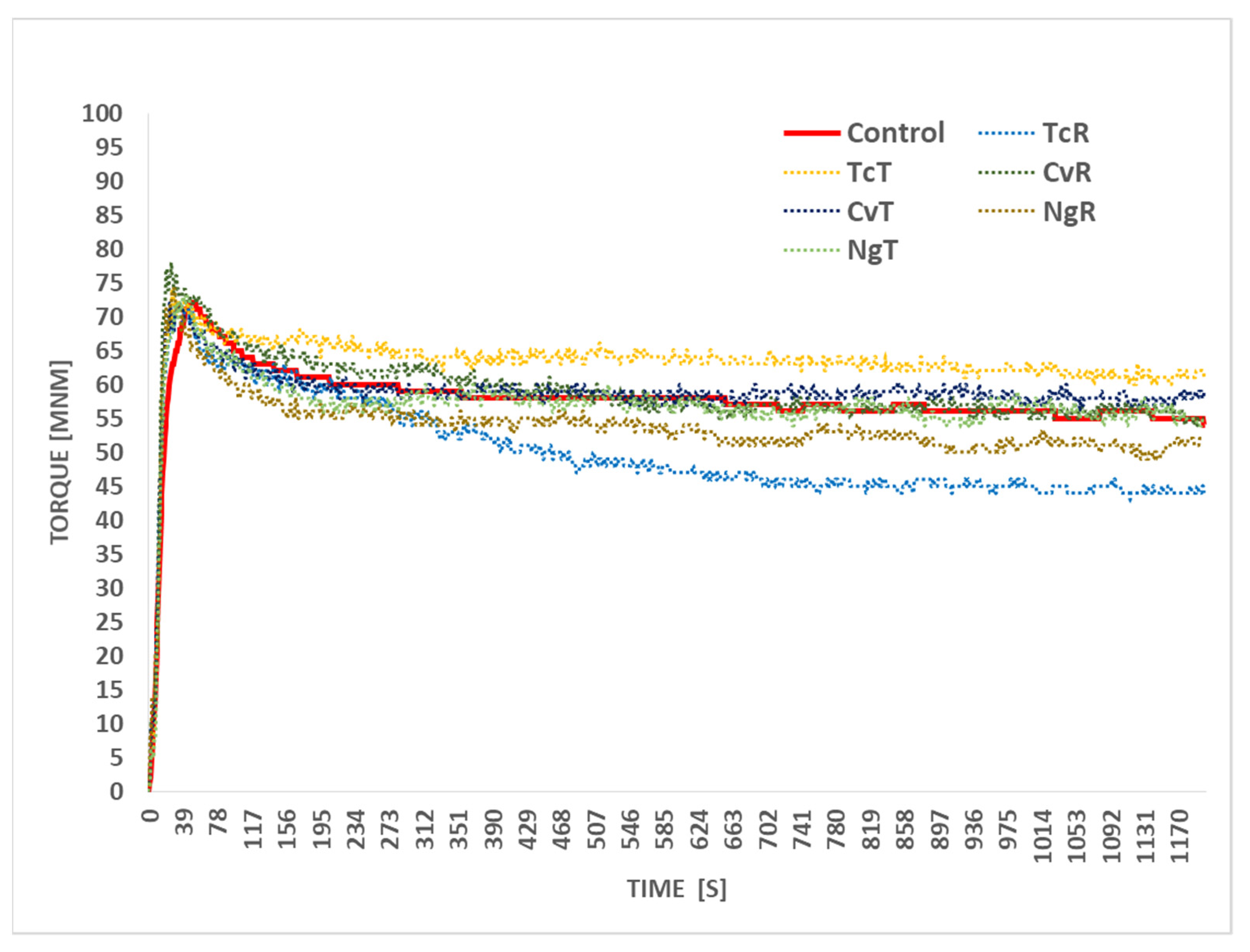

3.1.1. Empirical Methods

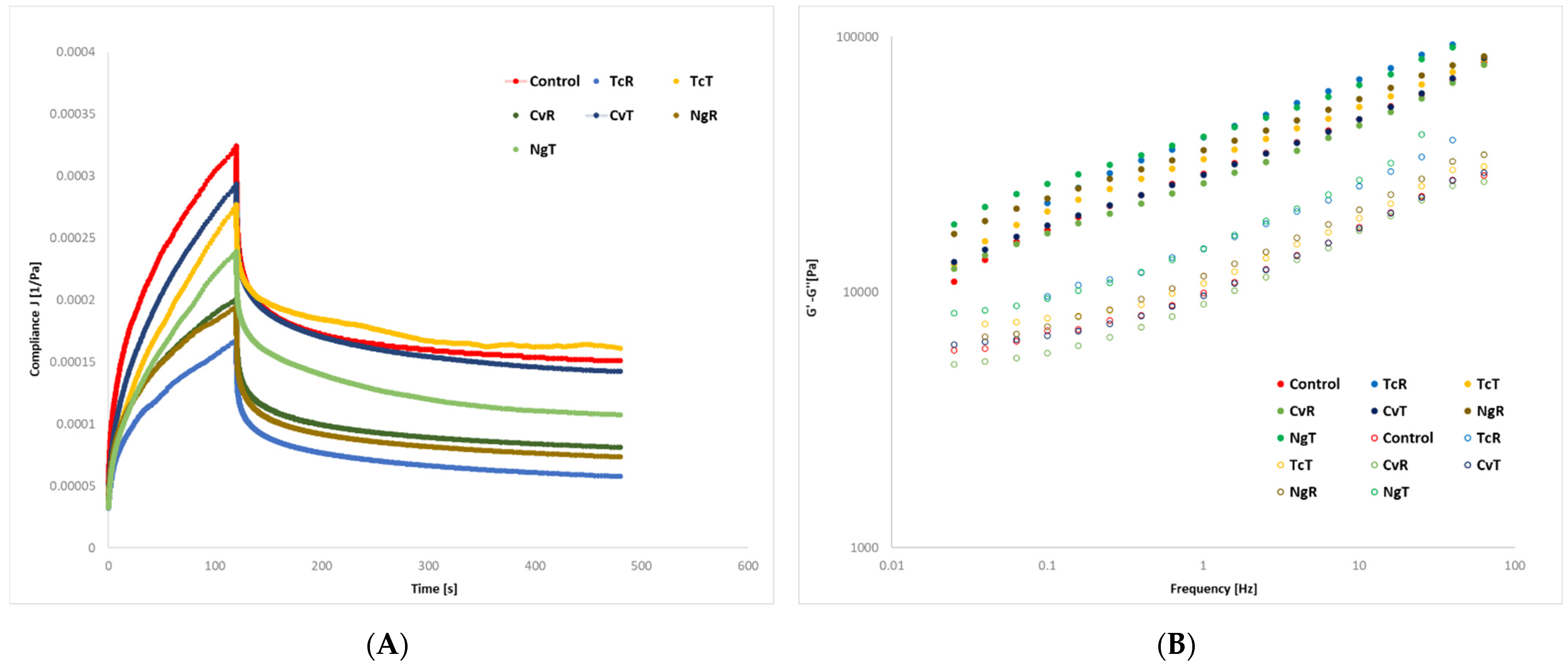

3.1.2. Fundamental Rheology-SOAS and Creep Recovery

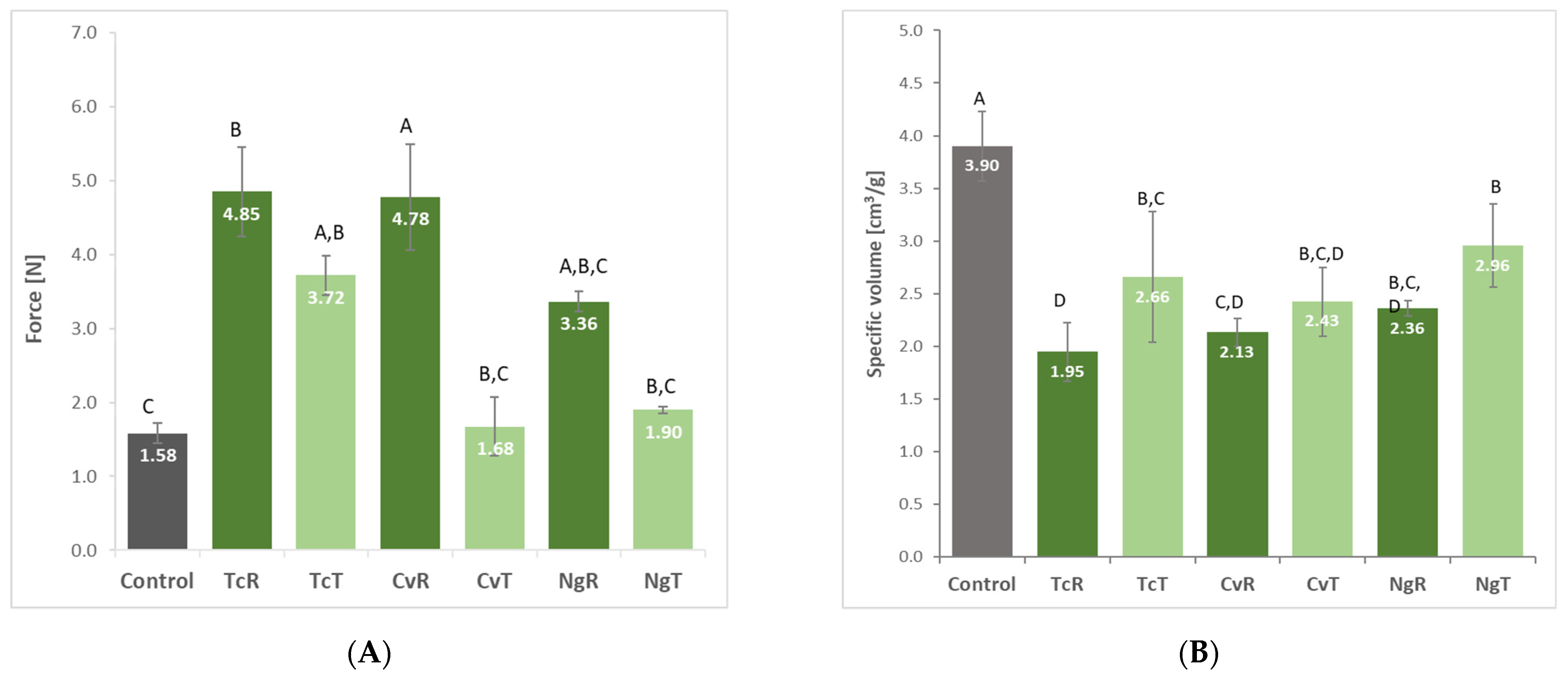

3.1.3. Nutritional and Technological Properties of the Bread

3.1.4. Combined Discussion on Biomass Nutritional Composition, Dough Rheology, and Consequential Baking Properties

3.1.5. Bioactivity in Bread (Phenols, Antioxidant Capacity, and Pigments)

3.1.6. Bread Color and Sensorial Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Meerts, M.; Cardinaels, R.; Oosterlinck, F.; Courtin, C.M.; Moldenaers, P. The Interplay Between the Main Flour Constituents in the Rheological Behaviour of Wheat Flour Dough. Food Bioprocess Technol. 2017, 10, 249–265. [Google Scholar] [CrossRef] [Green Version]

- Martínez, M.M.; Gómez, M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 2017, 197, 78–86. [Google Scholar] [CrossRef]

- Horstmann, S.W.; Lynch, K.M.; Arendt, E.K. Starch Characteristics Linked to Gluten-Free Products. Foods 2017, 6, 29. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Lu, F.; Li, Z.; Zhao, L.; Han, C. Recent developments in gluten-free bread baking approaches: A review. Food Sci. Technol. 2017, 37, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Ronda, F.; Pérez-Quirce, S.; Angioloni, A.; Collar, C. Impact of viscous dietary fibres on the viscoelastic behaviour of gluten-free formulated rice doughs: A fundamental and empirical rheological approach. Food Hydrocoll. 2013, 32, 252–262. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Diprat, A.B.; Silveira Thys, R.C.; Rodrigues, E.; Rech, R. Chlorella sorokiniana: A new alternative source of carotenoids and proteins for gluten-free bread. LWT 2020, 134, 109974. [Google Scholar] [CrossRef]

- Villanueva, M.; Abebe, W.; Collar, C.; Ronda, F. Tef [Eragrostis tef (Zucc.) Trotter] variety determines viscoelastic and thermal properties of gluten-free dough and bread quality. LWT 2021, 135, 110065. [Google Scholar] [CrossRef]

- Bernaerts, T.M.M.; Gheysen, L.; Foubert, I.; Hendrickx, M.E.; Van Loey, A.M. The potential of microalgae and their biopolymers as structuring ingredients in food: A review. Biotechnol. Adv. 2019, 37, 107419. [Google Scholar] [CrossRef] [PubMed]

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I.; Raymundo, A. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998. [Google Scholar] [CrossRef]

- Nunes, M.C.; Fernandes, I.; Vasco, I.; Sousa, I.; Raymundo, A. Tetraselmis chuii as a Sustainable and Healthy Ingredient to Produce Gluten-Free Bread: Impact on Structure, Colour and Bioactivity. Foods 2020, 9, 579. [Google Scholar] [CrossRef]

- Lafarga, T. Effect of microalgal biomass incorporation into foods: Nutritional and sensorial attributes of the end products. Algal Res. 2019, 41, 101566. [Google Scholar] [CrossRef]

- Kulkarni, S.; Nikolov, Z. Process for selective extraction of pigments and functional proteins from Chlorella vulgaris. Algal Res. 2018, 35, 185–193. [Google Scholar] [CrossRef]

- Habashy, N.H.; Abu Serie, M.M.; Attia, W.E.; Abdelgaleil, S.A.M. Chemical characterization, antioxidant and anti-inflammatory properties of Greek Thymus vulgaris extracts and their possible synergism with Egyptian Chlorella vulgaris. J. Funct. Foods 2018, 40, 317–328. [Google Scholar] [CrossRef]

- Sikiru, A.B.; Arangasamy, A.; Alemede, I.C.; Guvvala, P.R.; Egena, S.S.A.; Ippala, J.R.; Bhatta, R. Chlorella vulgaris supplementation effects on performances, oxidative stress and antioxidant genes expression in liver and ovaries of New Zealand White rabbits. Heliyon 2019, 5, e02470. [Google Scholar] [CrossRef] [Green Version]

- AECOSAN. Report of the Scientific Committee of the Spanish Agency for Consumer Affairs, Food Safety and Nutrition (AECOSAN) on a Request for Initial Assessment for Marketing of the Dried Marine Microalgae Tetraselmis chuii in Food Supplements under Regulation (EC) No 258/97 on Novel Foods and Novel Food Ingredients; AECOSAN. 2017. Available online: https://zenodo.org/record/1248575file:///D:/%E4%B8%8B%E8%BD%BD/TETRASEMILS_CHUII_SUPPLEMENTS%20(1).pdf (accessed on 22 December 2021).

- Schwenzfeier, A.; Wierenga, P.A.; Gruppen, H. Isolation and characterization of soluble protein from the green microalgae Tetraselmis Sp. Bioresour. Technol. 2011, 102, 9121–9127.19. [Google Scholar] [CrossRef]

- Tibbetts, S.M.; Whitney, C.G.; MacPherson, M.J.; Bhatti, S.; Banskota, A.H.; Stefanova, R.; McGinn, P.J. Biochemical characterization of microalgal biomass from freshwater species isolated in Alberta, Canada for animal feed applications. Algal Res. 2015, 11, 435–447. [Google Scholar] [CrossRef] [Green Version]

- Zanella, L.; Vianello, F. Microalgae of the genus Nannochloropsis: Chemical composition and functional implications for human nutrition. J. Funct. Foods 2020, 68, 103919. [Google Scholar] [CrossRef]

- Molino, A.; Martino, M.; Larocca, V.; Di Sanzo, G.; Spagnoletta, A.; Marino, T.; Karatza, D.; Iovine, A.; Mehariya, S.; Musmarra, D. Eicosapentaenoic Acid Extraction from Nannochloropsis gaditana Using Carbon Dioxide at Supercritical Conditions. Marine Drugs 2019, 17, 132. [Google Scholar] [CrossRef] [Green Version]

- Kent, M.; Welladsen, H.M.; Mangott, A.; Li, Y. Nutritional Evaluation of Australian Microalgae as Potential Human Health Supplements. PLoS ONE 2015, 10, e0118985. [Google Scholar] [CrossRef] [PubMed]

- Caporgno, M.P.; Mathys, A. Trends in Microalgae Incorporation into Innovative Food Products With Potential Health Benefits. Front. Nutr. 2018, 5, 58. [Google Scholar] [CrossRef] [PubMed]

- Qazi, W.M.; Ballance, S.; Kousoulaki, K.; Uhlen, A.K.; Kleinegris, D.M.M.; Skjånes, K.; Rieder, A. Protein Enrichment of Wheat Bread with Microalgae: Microchloropsis gaditana, Tetraselmis chui and Chlorella vulgaris. Foods 2021, 10, 3078. [Google Scholar] [CrossRef] [PubMed]

- Kirsten, W.J. Automatic methods for the simultaneous determination of carbon, hydrogen, nitrogen, and sulfur, and for sulfur alone in organic and inorganic materials. Anal. Chem. 1979, 51, 1173–1179. [Google Scholar] [CrossRef]

- Beltrão Martins, R.; Gouvinhas, I.; Nunes, M.C.; Alcides Peres, J.; Raymundo, A.; Barros, A.I.R.N.A. Acorn Flour as a Source of Bioactive Compounds in Gluten-Free Bread. Molecules 2020, 25, 3568. [Google Scholar] [CrossRef] [PubMed]

- Norma Portuguesa. Cereais e Derivados-Determinação do teor de Matéria Gorda Total. 1991. Available online: http://www.esa.ipsantarem.pt/Norma_IPQ_homepage_206.pdf (accessed on 22 December 2021).

- Jemima Beryl Mohankumar, U.L.; Uma Maheswari, S. Total Phenolic Content of Organic and Conventionally Grown Gourd Vegetables. Indian J. Nutr. Diet. 2020, 57, 266–275. [Google Scholar]

- Sánchez-Moreno, C.; Larrauri, J.A.; Saura-Calixto, F. A procedure to measure the antiradical efficiency of polyphenols. J. Sci. Food Agric. 1998, 76, 270–276. [Google Scholar] [CrossRef]

- Maadane, A.; Merghoub, N.; Ainane, T.; El Arroussi, H.; Benhima, R.; Amzazi, S.; Bakri, Y.; Wahby, I. Antioxidant activity of some Moroccan marine microalgae: Pufa profiles, carotenoids and phenolic content. J. Biotechnol. 2015, 215, 13–19. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Creep-recovery parameters of gluten-free batter and crumb properties of bread prepared from pregelatinised cassava starch, sorghum and selected proteins. Int. J. Food Sci. Technol. 2009, 44, 2493–2499. [Google Scholar] [CrossRef]

- Coultate, T.P. Food: The Chemistry of Its Components, 4th ed.; Royal Society of Chemistry: London, UK, 2002. [Google Scholar]

- Martignier, A.; Filella, M.; Pollok, K.; Melkonian, M.; Bensimon, M.; Barja, F.; Langenhorst, F.; Jaquet, J.M.; Ariztegui, D. Marine and freshwater micropearls: Biomineralization producing strontium-rich amorphous calcium carbonate inclusions is widespread in the genus Tetraselmis (Chlorophyta). Biogeosciences 2018, 15, 6591–6605. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.C.; Sun, X.S. Creep-Recovery of Wheat Flour Doughs and Relationship to Other Physical Dough Tests and Breadmaking Performance. Cereal Chem. 2002, 79, 567–571. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Dough rheology and bread quality of wheat–chickpea flour blends. Ind. Crops Prod. 2012, 36, 196–202. [Google Scholar] [CrossRef]

- Qazi, W.M.; Ballance, S.; Uhlen, A.K.; Kousoulaki, K.; Haugen, J.-E.; Rieder, A. Protein enrichment of wheat bread with the marine green microalgae Tetraselmis chuii–Impact on dough rheology and bread quality. LWT 2021, 143, 111115. [Google Scholar] [CrossRef]

- Pareyt, B.; Finnie, S.M.; Putseys, J.A.; Delcour, J.A. Lipids in bread making: Sources, interactions, and impact on bread quality. J. Cereal Sci. 2011, 54, 266–279. [Google Scholar] [CrossRef]

- BeMiller, J.N. 9—Hydrocolloids, in Gluten-Free Cereal Products and Beverages; Arendt, E.K., Bello, F.D., Eds.; Academic Press: San Diego, CA, USA, 2008; pp. 203–215. [Google Scholar]

- Ahlborn, G.J.; Pike, O.A.; Hendrix, S.B.; Hess, W.M.; Huber, C.S. Sensory, Mechanical, and Microscopic Evaluation of Staling in Low-Protein and Gluten-Free Breads. Cereal Chem. 2005, 82, 328–335. [Google Scholar] [CrossRef]

- Machu, L.; Misurcova, L.; Vavra Ambrozova, J.; Orsavova, J.; Mlcek, J.; Sochor, J.; Jurikova, T. Phenolic Content and Antioxidant Capacity in Algal Food Products. Molecules 2015, 20, 1118–1133. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verardo, V.; Glicerina, V.; Cocci, E.; Frenich, A.G.; Romani, S.; Caboni, M.F. Determination of free and bound phenolic compounds and their antioxidant activity in buckwheat bread loaf, crust and crumb. LWT 2018, 87, 217–224. [Google Scholar] [CrossRef]

- Patra, M.; Salonen, E.; Terama, E.; Vattulainen, I.; Faller, R.; Lee, B.W.; Holopainen, J.; Karttunen, M. Under the influence of alcohol: The effect of ethanol and methanol on lipid bilayers. Biophys. J. 2006, 90, 1121–1135. [Google Scholar] [CrossRef] [Green Version]

- Chua, E.T.; Schenk, P.M. A biorefinery for Nannochloropsis: Induction, harvesting, and extraction of EPA-rich oil and high-value protein. Bioresour. Technol. 2017, 244, 1416–1424. [Google Scholar] [CrossRef] [Green Version]

- García-Segovia, P.; Pagán-Moreno, M.J.; Lara, I.; Martínez-Monzó, J. Effect of microalgae incorporation on physicochemical and textural properties in wheat bread formulation. J. Food Sci. Technol. Int. 2017, 23, 437–447. [Google Scholar] [CrossRef]

| Bread Ingredients (g/100 g) | Control | TcR | TcT | CvR | CvT | NgR | NgT |

|---|---|---|---|---|---|---|---|

| Buckwheat flour Provida | 46 | 44.2 | 44.2 | 44.2 | 44.2 | 44.2 | 44.2 |

| Rice flourEspiga | 31 | 29.8 | 29.8 | 29.8 | 29.8 | 29.8 | 29.8 |

| Potato starchGlobo | 23 | 22.1 | 22.1 | 22.1 | 22.1 | 22.1 | 22.1 |

| Microalgae biomass replacement | 0 | 4 | 4 | 4 | 4 | 4 | 4 |

| Sunflower oil, Fula (in relation to flour) | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| HPMC, Dupont (in relation to flour) | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 |

| Instant dried yeast, Fermipan (in relation to flour) | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Commercial salt (in relation to flour) | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 | 1.8 |

| Commercial sugar (in relation to flour) | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 | 2.8 |

| Macronutrients (algae biomass) | |||||||

| Proteins (total amino acids) | 42.1 ± 0.1 | 59.5 ± 0.2 | 47.8 ± 1.1 | 58.8 ± 0.3 | 43.3 ± 1.5 | 61.7 ± 2.8 | |

| Lipids | 13.8 | 0.3 | 15.7 | 0.6 | 21.4 | 0.4 | |

| Ash | 16.0 ± 0.1 | 16.7 ± 0.1 | 6.7 ± 0.6 | 8.2 ± 0.0 | 7 ± 1.1 | 7.4 ± 0.1 | |

| Dietary fibers | 8.9 ± 0.8 | 15.1 ± 2.2 | 13.8 ± 0.5 | 19.0 ± 0.6 | 12.2 ± 0.6 | 21.8 ± 0.8 | |

| GF Dough | WA (%) | Peak (mN.m) | Torque (600 s) | Torque (1200 s) | DDT (s) | DS (s) | Dough Softening (mN.m) |

|---|---|---|---|---|---|---|---|

| Control | 75.0 | 69.3 ± 2.7 | 52.5 cd ± 3.6 | 50.7 cd ± 4.1 | 43.6 a ± 8.8 | 28.2 a ± 4.5 | 17.8 ab ± 6.4 |

| TcR | 74.5 | 70.0 ± 5.5 | 48.3 d ± 1.2 | 44.3 d ± 0.5 | 52.0 a ± 3.5 | 22.2 a ± 9.2 | 20.0 a ± 5.9 |

| TcT | 75.5 | 70.6 ± 2.3 | 65.6 a ± 5.3 | 63.2 a ± 2.8 | 51.0 a ± 4.2 | 24.0 a ± 0.0 | 6.3 c ± 1.2 |

| CvR | 75.5 | 72.8 ± 2.2 | 56.2 bc ± 1.9 | 56.5 bc ± 3.2 | 51.0 a ± 5.4 | 26.4 a ± 3.3 | 14.0 bc ± 4.2 |

| CvT | 75.3 | 70.4 ± 2.8 | 57.7 bcd ± 6.3 | 54.0 bc ± 6.1 | 47.1 a ± 5.4 | 24.0 a ± 0.0 | 13.6 bc ± 3.9 |

| NgR | 75.3 | 68.7 ± 2.5 | 51.3 cd ± 4.6 | 53.8 cd ± 3.1 | 50.2 a ± 13.3 | 30.0 a ± 10.0 | 16.0 bc ± 2.8 |

| NgT | 75.5 | 72.2 ± 2.2 | 61.2 d ± 2.7 | 58.2 ab ± 4.1 | 45.0 a ± 6.0 | 24.0 a ± 0.0 | 11.0 bc ± 2.4 |

| GF Dough | Je(1/Pa) | Jv(1/Pa) | Jmax(1/Pa) | η0 × 10−5 (Pa.s) | G’ = K’ (Pa.sn’) | G” = K” (Pa.sn”) | n’ | n” |

|---|---|---|---|---|---|---|---|---|

| Control | 1.8 a ± 0.2 | 2.1 a ± 0.2 | 3.8 a ± 0.4 | 8.1 b ± 0.2 | 30,395 b ± 2778 | 11,962 abc ± 1165 | 0.23 | 0.22 |

| TcR | 1.0 c ± 0.1 | 0.9 b ± 0.1 | 1.9 c ± 0.2 | 13.4 a ± 0.0 | 35,659 ab ± 5222 | 13,274 ab ± 1979 | 0.21 | 0.23 |

| TcT | 1.2 abc ± 0.3 | 1.1 b ± 0.5 | 2.3 bc ± 0.7 | 12.4 ab ± 0.5 | 33,759 b ± 5386 | 11,787 bc ± 1373 | 0.22 | 0.19 |

| CvR | 1.2 abc ± 0.1 | 1.0 ab ± 0.1 | 2.1 abc ± 0.1 | 12.1 ab ± 0.1 | 27,438 b ± 891 | 10,212 c ± 220 | 0.22 | 0.21 |

| CvT | 1.3 ab ± 0.2 | 1.4 ab ± 0.3 | 2.7 ab ± 0.5 | 9.1 ab ± 0.3 | 29,544 b ± 3826 | 11,331 bc ± 929 | 0.23 | 0.21 |

| NgR | 1.1 bc ± 0.1 | 1.0 ab ± 0.2 | 2.1 bc ± 0.2 | 12.5 ab ± 0.4 | 35,239 ab ± 8464 | 12,769 abc ± 2979 | 0.23 | 0.23 |

| NgT | 1.2 bc ± 0.5 | 1.2 ab ± 0.7 | 2.4 bc ± 1.1 | 11.1 ab ± 0.4 | 39,945 a ± 6624 | 14,373 a ± 2430 | 0.22 | 0.20 |

| GF Bread | Moisture | Protein (N× 6.25) | Fat | Ash | * Carbohydrate | Energy Kcal/100 g |

|---|---|---|---|---|---|---|

| Control | 44.96 a ± 1.17 | 6.28 e ± 0.04 | 3.63 a ± 0.58 | 1.47 c ± 0.00 | 43.66 | 232.19 |

| TcR | 43.18 a ± 1.96 | 7.29 c ± 0.04 | 4.00 a ± 0.35 | 1.81 a ± 0.03 | 42.95 | 236.96 |

| TcT | 43.91 a ± 2.21 | 7.35 bc ± 0.10 | 3.59 a ± 0.53 | 1.80 a ± 0.00 | 43.35 | 235.11 |

| CvR | 44.41 a ± 1.93 | 7.29 c ± 0.04 | 4.02 a ± 0.35 | 1.60 bc ± 0.05 | 42.68 | 236.06 |

| CvT | 43.04 a ± 0.80 | 7.87 a ± 0.06 | 3.59 a ± 0.73 | 1.65 b ± 0.00 | 44.69 | 239.19 |

| NgR | 43.60 a ± 1.25 | 7.16 d ± 0.07 | 4.55 a ± 0.17 | 1.62 b ± 0.04 | 43.07 | 241.87 |

| NgT | 44.51 a ± 1.69 | 7.44 b ± 0.01 | 3.96 a ± 0.57 | 1.61 bc ± 0.02 | 42.49 | 235.36 |

| GF Bread | K | Ca | Mg | P | S | Fe | Cu | Zn | Mn |

|---|---|---|---|---|---|---|---|---|---|

| Control | 199.2 ± 2.7 | 6.4 ± 0.1 | 56.4 ± 0.6 | 140.0 ± 1.6 | 70.0 ± 0.2 | 2.6 ± 0.1 | 0.1 ± 0.0 | 0.9 ± 0.0 | 0.5 ± 0.0 |

| TcR | 223.7 ± 1.8 | 67.5 ± 1.6 | 68.6 ± 1.2 | 164.6 ± 0.3 | 104.3 ± 0.4 | 4.8 ± 0.4 | 0.2 ± 0.0 | 1.0 ± 0.0 | 0.7 ± 0.0 |

| TcT | 201.6 ± 0.5 | 88.7 ± 0.3 | 64.1 ± 0.1 | 173.3 ± 0.4 | 103.8 ± 0.8 | 5.5 ± 0.2 | 0.1 ± 0.0 | 1.0 ± 0.0 | 0.8 ± 0.0 |

| CvR | 218.6 ± 1.2 | 8.0 ± 0.2 | 62.6 ± 0.1 | 166.5 ± 1.3 | 94.7 ± 0.3 | 2.9 ± 0.1 | 0.2 ± 0.0 | 0.9 ± 0.0 | 0.6 ± 0.0 |

| CvT | 220.4 ± 2.2 | 9.2 ± 0.2 | 69.8 ± 0.8 | 183.4 ± 2.7 | 108.7 ± 1.0 | 3.8 ± 0.2 | 0.2 ± 0.0 | 1.0 ± 0.0 | 0.7 ± 0.0 |

| NgR | 202.4 ± 2.8 | 10.1 ± 0.1 | 63.1 ± 0.2 | 162.1 ± 2.6 | 94.0 ± 2.0 | 3.3 ± 0.0 | 0.1 ± 0.0 | 1.0 ± 0.0 | 0.6 ± 0.0 |

| NgT | 202.3 ± 3.2 | 14.0 ± 0.1 | 68.7 ± 0.4 | 173.8 ± 0.6 | 99.8 ± 0.4 | 2.8 ± 0.0 | 0.1 ± 0.0 | 1.1 ± 0.0 | 0.7 ± 0.0 |

| 15% RDV * (mg) | 300.0 | 120.0 | 56.3 | 105.0 | NM | 2.1 | 0.2 | 1.5 | 0.3 |

| Crumb | Crust | |||||||

|---|---|---|---|---|---|---|---|---|

| GF Bread | L* | a* | b* | ∆E | L* | a* | b* | ∆E |

| Control | 67.53 a ± 1.8 | 2.46 ab ± 0.2 | 12.08 a ± 1.3 | 49.93 a ± 2.6 | 11.10 a ± 0.8 | 19.78 a ± 2.7 | ||

| TcR | 34.99 d ± 3.6 | −0.23 ab ± 0.2 | 10.24 cd ± 1.9 | 32.7 | 36.32 b ± 4.5 | 1.07 c ± 0.8 | 8.52 cd ± 2.7 | 20.3 |

| TcT | 51.07 c ± 3.7 | 0.05 ab ± 0.0 | 11.40 c ± 1.5 | 16.6 | 41.62 ab ± 4.5 | 5.56 b ± 0.5 | 12.74 abcd ± 2.5 | 12.2 |

| CvR | 35.75 d ± 4.7 | −0.75 b ± 0.1 | 8.83 b ± 2.5 | 32.1 | 35.54 b ± 3.3 | 0.71 c ± 0.5 | 6.08 d ± 1.0 | 22.4 |

| CvT | 52.28 bc ± 2.9 | 1.71 a ± 0.4 | 15.21 a ± 2.4 | 15.6 | 46.19 ab ± 5.5 | 5.99 b ± 0.4 | 15.74 abc ± 3.1 | 7.5 |

| NgR | 37.22 d ± 4.1 | −0.60 ab ± 0.3 | 14.05 ab ± 3.0 | 30.5 | 35.51 b ± 5.7 | 1.40 c ± 0.1 | 9.47 bcd ± 3.3 | 20.2 |

| NgT | 60.99 ab ± 4.7 | 2.70 a ± 0.3 | 14.83 a ± 1.8 | 7.1 | 47.15 ab ± 6.1 | 9.28 a ± 1.0 | 17.76 ab ± 3.8 | 3.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qazi, M.W.; de Sousa, I.G.; Nunes, M.C.; Raymundo, A. Improving the Nutritional, Structural, and Sensory Properties of Gluten-Free Bread with Different Species of Microalgae. Foods 2022, 11, 397. https://doi.org/10.3390/foods11030397

Qazi MW, de Sousa IG, Nunes MC, Raymundo A. Improving the Nutritional, Structural, and Sensory Properties of Gluten-Free Bread with Different Species of Microalgae. Foods. 2022; 11(3):397. https://doi.org/10.3390/foods11030397

Chicago/Turabian StyleQazi, Muhammad Waqas, Inês Gonçalves de Sousa, Maria Cristiana Nunes, and Anabela Raymundo. 2022. "Improving the Nutritional, Structural, and Sensory Properties of Gluten-Free Bread with Different Species of Microalgae" Foods 11, no. 3: 397. https://doi.org/10.3390/foods11030397

APA StyleQazi, M. W., de Sousa, I. G., Nunes, M. C., & Raymundo, A. (2022). Improving the Nutritional, Structural, and Sensory Properties of Gluten-Free Bread with Different Species of Microalgae. Foods, 11(3), 397. https://doi.org/10.3390/foods11030397