Effect of Maltodextrin on the Physicochemical Properties and Cooking Performance of Sweet Potato Starch Noodles

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Preparation of Maltodextrin Introduced Sweet Potato Starch (SPS-MD) Noodles

2.3. Fourier Transform Infrared Spectroscopy

2.4. Powder X-ray Diffraction Measurement

2.5. Cooking Quality

2.6. Texture Profile Analysis (TPA)

2.7. Pasting Properties

2.8. Thermal Properties

2.9. Gel Structure Morphology

2.10. Interaction Force Test

2.11. Statistical Analysis

3. Results and Discussion

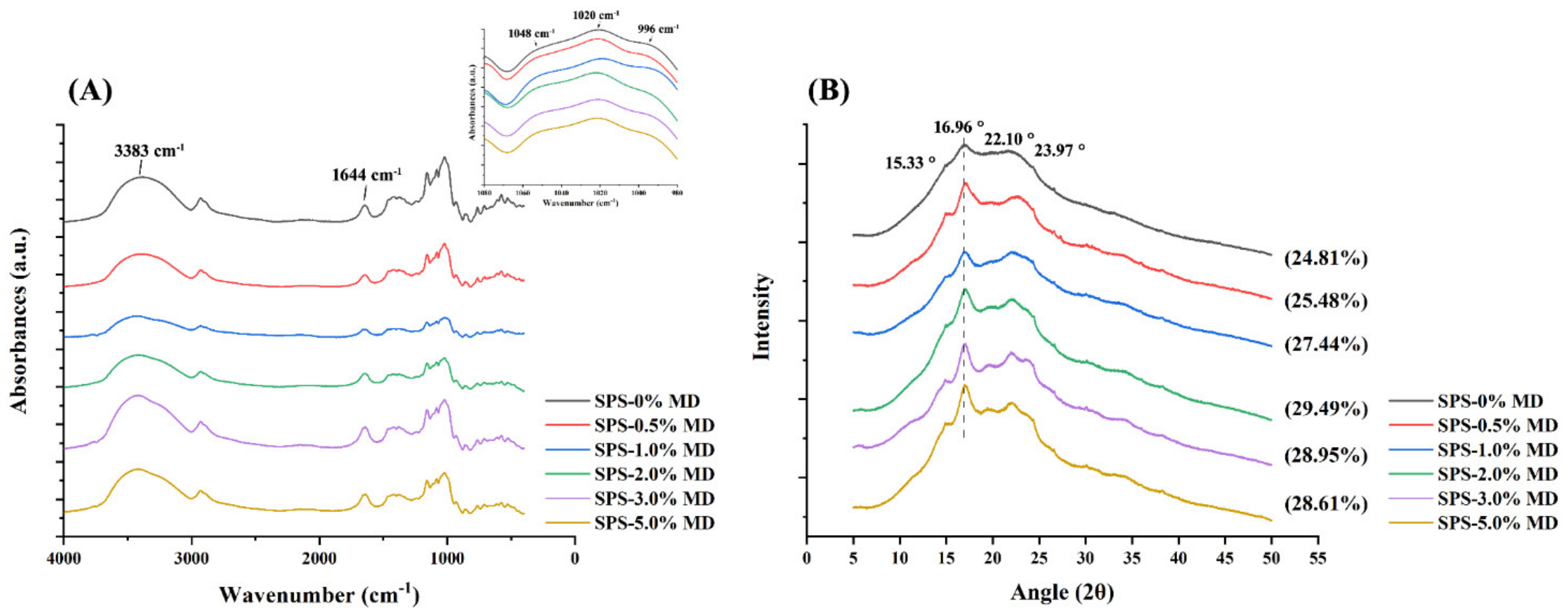

3.1. FTIR Analysis

3.2. XRD Analysis

3.3. Analysis of Cooking and Texture Properties

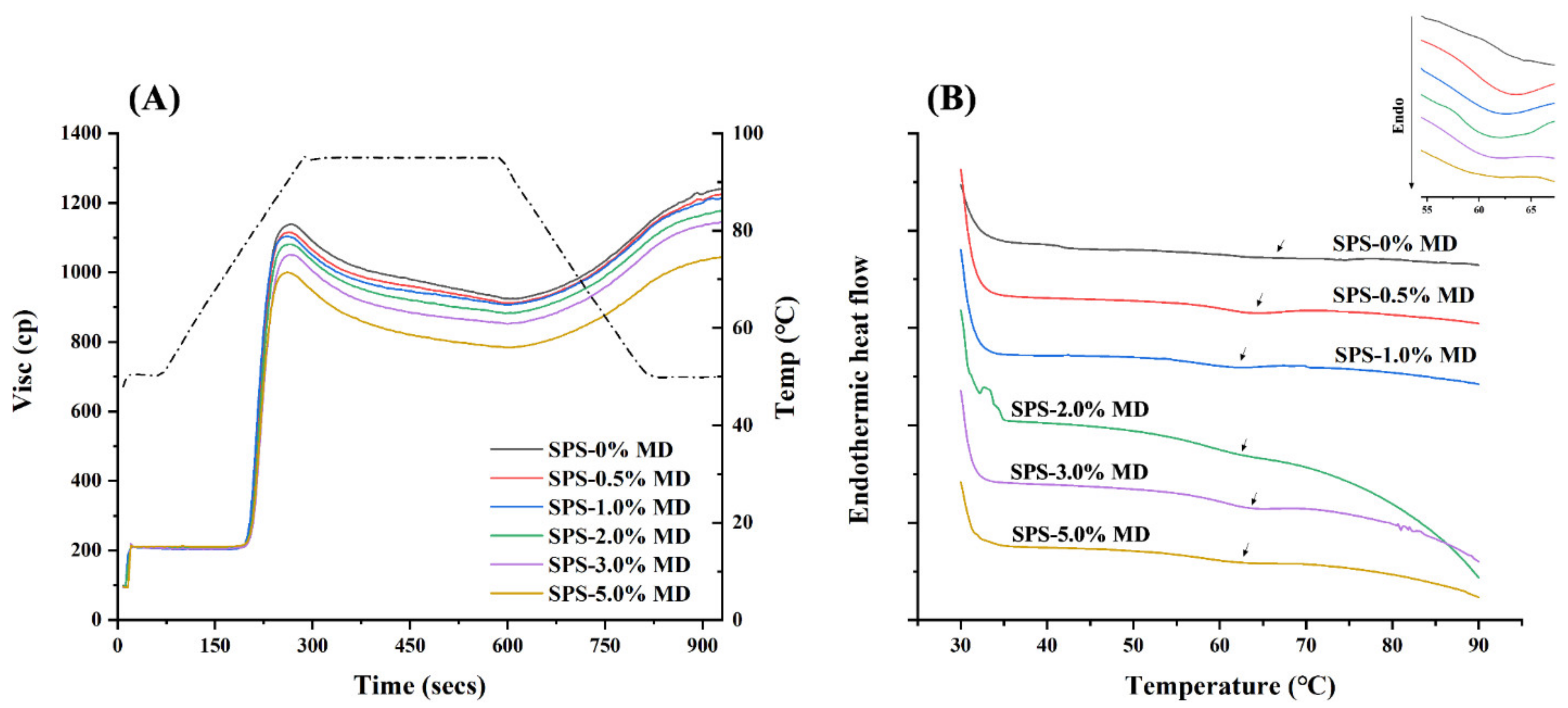

3.4. RVA Pasting Profiles

3.5. Thermal Properties

3.6. SEM Analysis

3.7. Interactions between Sweet Potato Starch and Maltodextrin

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chandla, N.K.; Saxena, D.C.; Singh, S. Processing and evaluation of heat moisture treated (HMT) amaranth starch noodles; An inclusive comparison with corn starch noodles. J. Cereal Sci. 2017, 75, 306–313. [Google Scholar] [CrossRef]

- Wang, Y.; Ye, F.; Liu, J.; Zhou, Y.; Lei, L.; Zhao, G. Rheological nature and dropping performance of sweet potato starch dough as influenced by the binder pastes. Food Hydrocoll. 2018, 85, 39–50. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Mukesh. Studies on noodle quality of potato and rice starches and their blends in relation to their physicochemical, pasting and gel textural properties. LWT Food Sci. Technol. 2010, 43, 1289–1293. [Google Scholar] [CrossRef]

- Kasunmala, I.G.G.; Navaratne, S.B.; Wickramasinghe, I. Effect of process modifications and binding materials on textural properties of rice noodles. Int. J. Gastron. Food Sci. 2020, 21, 100217. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, L.; Bian, X.; Guo, K.; Zhou, L.; Wei, C. Characterization and comparative study of starches from seven purple sweet potatoes. Food Hydrocoll. 2018, 80, 168–176. [Google Scholar] [CrossRef]

- Wang, H.; Xu, K.; Ma, Y.; Liang, Y.; Zhang, H.; Chen, L. Impact of ultrasonication on the aggregation structure and physicochemical characteristics of sweet potato starch. Ultrason. Sonochem. 2020, 63, 104868. [Google Scholar] [CrossRef]

- Feng, Y.-Y.; Mu, T.-H.; Zhang, M.; Ma, M.-M. Effects of ionic polysaccharides and egg white protein complex formulations on dough rheological properties, structure formation and in vitro starch digestibility of wet sweet potato vermicelli. Int. J. Biol. Macromol. 2020, 149, 1170–1179. [Google Scholar] [CrossRef]

- Yang, S.; Shan, C.-S.; Xu, Y.-Q.; Jin, L.; Chen, Z.-G. Dissimilarity in sensory attributes, shelf life and spoilage bacterial and fungal microbiota of industrial-scale wet starch noodles induced by different preservatives and temperature. Food Res. Int. 2021, 140, 109980. [Google Scholar] [CrossRef]

- Xiang, Z.; Ye, F.; Zhou, Y.; Wang, L.; Zhao, G. Performance and mechanism of an innovative humidity-controlled hot-air drying method for concentrated starch gels: A case of sweet potato starch noodles. Food Chem. 2018, 269, 193–201. [Google Scholar] [CrossRef]

- Obadi, M.; Xu, B. Review on the physicochemical properties, modifications, and applications of starches and its common modified forms used in noodle products. Food Hydrocoll. 2021, 112, 106286. [Google Scholar] [CrossRef]

- Ren, Y.; Rong, L.; Shen, M.; Liu, W.; Xiao, W.; Luo, Y.; Xie, J. Interaction between rice starch and Mesona chinensis Benth polysaccharide gels: Pasting and gelling properties. Carbohyd. Polym. 2020, 240, 116316. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Qin, L.; Chen, T.; Yu, Q.; Chen, Y.; Xiao, W.; Ji, X.; Xie, J. Modification of starch by polysaccharides in pasting, rheology, texture and in vitro digestion: A review. Int. J. Biol. Macromol. 2022, 207, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Kaur, L.; Singh, J.; Singh, N. Effect of glycerol monostearate on the physico-chemical, thermal, rheological and noodle making properties of corn and potato starches. Food Hydrocoll. 2005, 19, 839–849. [Google Scholar] [CrossRef]

- Javaid, A.B.; Xiong, H.; Xiong, Z.; Soomro, A.H.; Zia-ud-Din; Ahmad, I.; Nawaz, A.; Ullah, I. Effects of xanthan gum on cooking qualities, texture and microstructures of fresh potato instant noodles. J. Food Meas. Charact. 2018, 12, 2453–2460. [Google Scholar] [CrossRef]

- Ren, Y.; Jiang, L.; Wang, W.; Xiao, Y.; Liu, S.; Luo, Y.; Shen, M.; Xie, J. Effects of Mesona chinensis Benth polysaccharide on physicochemical and rheological properties of sweet potato starch and its interactions. Food Hydrocoll. 2020, 99, 105371. [Google Scholar] [CrossRef]

- Feng, Y.-Y.; Mu, T.-H.; Zhang, M.; Ma, M.-M. Effects of different polysaccharides and proteins on dough rheological properties, texture, structure and in vitro starch digestibility of wet sweet potato vermicelli. Int. J. Biol. Macromol. 2020, 148, 1–10. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, H.; McClements, D.J.; Zhang, Z.; Zhang, R.; Jin, Z.; Tian, Y. Effect of dietary fibers on the structure and digestibility of fried potato starch: A comparison of pullulan and pectin. Carbohyd. Polym. 2019, 215, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Sciarini, L.S.; Bustos, M.C.; Vignola, M.B.; Paesani, C.; Salinas, C.N.; Pérez, G.T. A study on fibre addition to gluten free bread: Its effects on bread quality and in vitro digestibility. J. Food Sci. Technol. 2017, 54, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Ye, F.; Lei, L.; Zhou, S.; Zhao, G. Fabricating low glycaemic index foods: Enlightened by the impacts of soluble dietary fibre on starch digestibility. Trends Food Sci. Techol. 2022, 122, 110–122. [Google Scholar] [CrossRef]

- Jang, A.; Kim, J.Y.; Lee, S. Rheological, thermal conductivity, and microscopic studies on porous-structured noodles for shortened cooking time. LWT 2016, 74, 1–6. [Google Scholar] [CrossRef]

- Xu, X.; Gao, C.; Xu, J.; Meng, L.; Wang, Z.; Yang, Y.; Shen, X.; Tang, X. Hydration and plasticization effects of maltodextrin on the structure and cooking quality of extruded whole buckwheat noodles. Food Chem. 2022, 374, 131613. [Google Scholar] [CrossRef]

- Churio, O.; Valenzuela, C. Development and characterization of maltodextrin microparticles to encapsulate heme and non-heme iron. LWT 2018, 96, 568–575. [Google Scholar] [CrossRef]

- Kaul, S.; Kaur, K.; Mehta, N.; Dhaliwal, S.S.; Kennedy, J.F. Characterization and optimization of spray dried iron and zinc nanoencapsules based on potato starch and maltodextrin. Carbohyd. Polym. 2022, 282, 119107. [Google Scholar] [CrossRef]

- Li, S.; Ye, F.; Zhou, Y.; Lei, L.; Zhao, G. Rheological and textural insights into the blending of sweet potato and cassava starches: In hot and cooled pastes as well as in fresh and dried gels. Food Hydrocoll. 2019, 89, 901–911. [Google Scholar] [CrossRef]

- Zhou, Y.; Cao, H.; Hou, M.; Nirasawa, S.; Tatsumi, E.; Foster, T.J.; Cheng, Y. Effect of konjac glucomannan on physical and sensory properties of noodles made from low-protein wheat flour. Food Res. Int. 2013, 51, 879–885. [Google Scholar] [CrossRef]

- Zheng, Y.; Yin, X.; Kong, X.; Chen, S.; Xu, E.; Liu, D.; Ogawa, Y.; Ye, X.; Tian, J. Introduction of chlorogenic acid during extrusion affects the physicochemical properties and enzymatic hydrolysis of rice flour. Food Hydrocoll. 2021, 116, 106652. [Google Scholar] [CrossRef]

- Warren, F.J.; Gidley, M.J.; Flanagan, B.M. Infrared spectroscopy as a tool to characterise starch ordered structure—A joint FTIR–ATR, NMR, XRD and DSC study. Carbohyd. Polym. 2016, 139, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Li, M.; Zhang, S.; Jiang, Y.; Lv, Y.; Liu, J.; Liu, Q.; Zhu, Y.; Zhang, H. Effect of epigallocatechin gallate on the gelatinisation and retrogradation of wheat starch. Food Chem. 2019, 294, 209–215. [Google Scholar] [CrossRef]

- Ambigaipalan, P.; Hoover, R.; Donner, E.; Liu, Q. Retrogradation characteristics of pulse starches. Food Res. Int. 2013, 54, 203–212. [Google Scholar] [CrossRef]

- Bernardino-Nicanor, A.; Acosta-García, G.; Güemes-Vera, N.; Montañez-Soto, J.L.; de los Ángeles Vivar-Vera, M.; González-Cruz, L. Fourier transform infrared and Raman spectroscopic study of the effect of the thermal treatment and extraction methods on the characteristics of ayocote bean starches. J. Food Sci. Technol. 2017, 54, 933–943. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Dhital, S.; Shan, C.-S.; Zhang, M.-N.; Chen, Z.-G. Ordered structural changes of retrograded starch gel over long-term storage in wet starch noodles. Carbohyd. Polym. 2021, 270, 118367. [Google Scholar] [CrossRef]

- Saberi, B.; Vuong, Q.; Chockchaisawasdee, S.; Golding, J.; Scarlett, C.; Stathopoulos, C. Mechanical and Physical Properties of Pea Starch Edible Films in the Presence of Glycerol: Properties of Pea Starch Edible Films. J. Food Process. Pres. 2016, 40, 1339–1351. [Google Scholar] [CrossRef]

- Li, H.; Jin, Z.; Xu, X. Design and optimization of an efficient enzymatic extrusion pretreatment for Chinese rice wine fermentation. Food Control 2013, 32, 563–568. [Google Scholar] [CrossRef]

- Dong, H.; Vasanthan, T. Effect of phosphorylation techniques on structural, thermal, and pasting properties of pulse starches in comparison with corn starch. Food Hydrocoll. 2020, 109, 106078. [Google Scholar] [CrossRef]

- Chen, L.; Tong, Q.; Ren, F.; Zhu, G. Pasting and rheological properties of rice starch as affected by pullulan. Int. J. Biol. Macromol. 2014, 66, 325–331. [Google Scholar] [CrossRef] [PubMed]

- Song, J.Y.; Kim, Y.C.; Shin, M. Textural properties and structures of wheat and maize starch-gum mixed gels during storage. Food Sci. Biotechnol. 2008, 17, 20–25. [Google Scholar] [CrossRef]

- Yin, X.; Zheng, Y.; Kong, X.; Cao, S.; Chen, S.; Liu, D.; Ye, X.; Tian, J. RG-I pectin affects the physicochemical properties and digestibility of potato starch. Food Hydrocoll. 2021, 117, 106687. [Google Scholar] [CrossRef]

- Xie, J.; Ren, Y.; Xiao, Y.; Luo, Y.; Shen, M. Interactions between tapioca starch and Mesona chinensis polysaccharide: Effects of urea and NaCl. Food Hydrocoll. 2021, 111, 106268. [Google Scholar] [CrossRef]

- Lopez-Rubio, A.; Flanagan, B.M.; Gilbert, E.P.; Gidley, M.J. A novel approach for calculating starch crystallinity and its correlation with double helix content: A combined XRD and NMR study. Biopolymers 2008, 89, 761–768. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Chen, Z.; Yu, Q.; Feng, W. Impact of binding interaction characteristics on physicochemical, structural, and rheological properties of waxy rice flour. Food Chem. 2018, 266, 551–556. [Google Scholar] [CrossRef]

- Li, J.; Jiao, A.; Deng, L.; Rashed, M.M.A.; Jin, Z. Porous-structured extruded instant noodles induced by the medium temperature α-amylase and its effect on selected cooking properties and sensory characteristics. Int. J. Food Sci. Technol. 2018, 53, 2265–2272. [Google Scholar] [CrossRef]

- Santana, R.F.; Bonomo, R.C.F.; Gandolfi, O.R.R.; Rodrigues, L.B.; Santos, L.S.; dos Santos Pires, A.C.; de Oliveira, C.P.; da Costa Ilhéu Fontan, R.; Veloso, C.M. Characterization of starch-based bioplastics from jackfruit seed plasticized with glycerol. J. Food Sci. Technol. 2018, 55, 278–286. [Google Scholar] [CrossRef] [PubMed]

- von Borries-Medrano, E.; Jaime-Fonseca, M.R.; Aguilar-Méndez, M.A. Tapioca starch-galactomannan systems: Comparative studies of rheological and textural properties. Int. J. Biol. Macromol. 2018, 122, 1173–1183. [Google Scholar] [CrossRef] [PubMed]

| Sample | Cooking Behavior | Texture Parameters | ||||||

|---|---|---|---|---|---|---|---|---|

| Dry Matter Content (g/100g) | Swelling Index (%) | Cooking Loss (%) | Hardness (g) | Elasticity (mm) | Chewiness (g) | IR Ratio 1048/1020 | IR Ratio 1020/996 | |

| SPS-0% MD | 90.85 ± 1.47 a | 445.16 ± 20.60 b | 3.80 ± 0.50 b | 940.12 ± 37.25 d | 0.90 ± 0.02 ab | 728.17 ± 66.01 d | 0.878 ± 0.00 c | 1.115 ± 0.00 b |

| SPS-0.5% MD | 90.39 ± 2.22 a | 451.41 ± 17.56 ab | 1.47 ± 0.15 c | 1133.17 ± 84.08 c | 0.91 ± 0.03 ab | 894.05 ± 85.48 c | 0.869 ± 0.00 c | 1.162 ± 0.01 b |

| SPS-1.0% MD | 90.82 ± 2.03 a | 457.77 ± 23.83 ab | 2.14 ± 0.30 c | 1339.17 ± 52.85 b | 0.92 ± 0.02 a | 1079.70 ± 59.16 ab | 0.906 ± 0.00 ab | 1.061 ± 0.00 c |

| SPS-2.0% MD | 90.45 ± 1.74 a | 457.66 ± 11.16 ab | 2.16 ± 0.35 c | 1583.92 ± 89.09 a | 0.89 ± 0.03 ab | 1160.61 ± 92.52 a | 0.921 ± 0.00 a | 1.142 ± 0.01 b |

| SPS-3.0% MD | 90.78 ± 1.37 a | 460.04 ± 3.63 ab | 3.63 ± 0.28 b | 1511.83 ± 47.92 a | 0.89 ± 0.02 ab | 1132.53 ± 95.30 ab | 0.914 ± 0.01 a | 1.262 ± 0.03 a |

| SPS-5.0% MD | 90.8 ± 1.42 a | 474.74 ± 15.61 a | 4.69 ± 0.17 a | 1362.22 ± 117.86 b | 0.89 ± 0.01 b | 1047.57 ± 68.80 b | 0.889 ± 0.00 bc | 1.269 ± 0.01 a |

| Sample | Peak Visc (cps) | Through Visc (cps) | Breakdown (cps) | Final Visc (cps) | Setback (cps) |

|---|---|---|---|---|---|

| SPS-0% MD | 1137.8 ± 11.75 a | 924.0 ± 5.90 a | 214.2 ± 7.47 ab | 1233.8 ± 8.61 a | 310.6 ± 7.91 a |

| SPS-0.5% MD | 1122.8 ± 4.62 b | 914.2 ± 6.27 b | 206.4 ± 7.00 bc | 1223.4 ± 12.08 ab | 309.4 ± 9.65 a |

| SPS-1.0% MD | 1108.4 ± 5.82 c | 910.2 ± 5.19 b | 197.8 ± 9.56 c | 1210.2 ± 10.57 b | 299.8 ± 5.74 ab |

| SPS-2.0% MD | 1080.4 ± 9.83 d | 881.6 ± 9.65 c | 197.6 ± 5.57 c | 1179.0 ± 12.47 c | 295.4 ± 10.09 ab |

| SPS-3.0% MD | 1056.6 ± 3.44 e | 859.0 ± 6.23 d | 197.2 ± 5.04 c | 1143.8 ± 18.70 d | 285.2 ± 13.42 b |

| SPS-5.0% MD | 1001.6 ± 3.77 f | 782.6 ± 3.61 e | 218.4 ± 5.92 a | 1038.2 ± 14.43 e | 255.8 ± 10.91 c |

| Sample | ΔH (J/g) | To (°C) | Tp (°C) | Tc (°C) |

|---|---|---|---|---|

| SPS-0% MD | 2.55 ± 0.6 b | 57.96 ± 0.54 ab | 64.31 ± 0.14 a | 70.62 ± 0.89 a |

| SPS-0.5% MD | 6.08 ± 0.29 a | 58.27 ± 0.02 ab | 63.77 ± 0.07 a | 69.47 ± 0.33 ab |

| SPS-1.0% MD | 6.01 ± 0.54 a | 55.36 ± 1.54 b | 61.78 ± 0.35 b | 67.61 ± 0.48 c |

| SPS-2.0% MD | 6.31 ± 0.11 a | 56.17 ± 0.28 ab | 61.53 ± 0.24 b | 67.97 ± 0.4 bc |

| SPS-3.0% MD | 6.23 ± 0.37 a | 56.68 ± 1.01 ab | 60.95 ± 1.69 b | 67.55 ± 1.49 c |

| SPS-5.0% MD | 5.64 ± 0.52 a | 56.94 ± 0.28 ab | 60.42 ± 0.26 b | 64.56 ± 0.43 d |

| Sample | K (Pa·sn) | n | R2 |

|---|---|---|---|

| SPS-2% MD | 56.79 ± 0.77 a | 0.12 ± 0 e | 0.96 |

| SPS-2% MD-0.2M NaCl | 31.60 ± 1.92 c | 0.23 ± 0.02 d | 0.98 |

| SPS-2% MD-0.6M NaCl | 45.98 ± 1.60 b | 0.29 ± 0 c | 0.98 |

| SPS-2% MD-1.0M NaCl | 55.03 ± 0.42 a | 0.27 ± 0 c | 0.99 |

| SPS-2% MD-0.2M Urea | 27.25 ± 1.69 d | 0.22 ± 0.01 d | 0.95 |

| SPS-2% MD-0.6M Urea | 10.15 ± 0.82 e | 0.34 ± 0.02 b | 0.95 |

| SPS-2% MD-1.0M Urea | 5.18 ± 0.06 f | 0.41 ± 0.01 a | 0.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Zhang, W.; Zhang, Z.; Shen, S.; Lu, G.; Wu, W. Effect of Maltodextrin on the Physicochemical Properties and Cooking Performance of Sweet Potato Starch Noodles. Foods 2022, 11, 4082. https://doi.org/10.3390/foods11244082

Hu W, Zhang W, Zhang Z, Shen S, Lu G, Wu W. Effect of Maltodextrin on the Physicochemical Properties and Cooking Performance of Sweet Potato Starch Noodles. Foods. 2022; 11(24):4082. https://doi.org/10.3390/foods11244082

Chicago/Turabian StyleHu, Weiwei, Wen Zhang, Zhiguo Zhang, Shengfa Shen, Guoquan Lu, and Weicheng Wu. 2022. "Effect of Maltodextrin on the Physicochemical Properties and Cooking Performance of Sweet Potato Starch Noodles" Foods 11, no. 24: 4082. https://doi.org/10.3390/foods11244082

APA StyleHu, W., Zhang, W., Zhang, Z., Shen, S., Lu, G., & Wu, W. (2022). Effect of Maltodextrin on the Physicochemical Properties and Cooking Performance of Sweet Potato Starch Noodles. Foods, 11(24), 4082. https://doi.org/10.3390/foods11244082