Optimization of Roasted Green Tea Winnowing via Fluid–Solid Interaction Experiments and Simulations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Physical Properties of Materials

2.1.1. Determination of the Weight-to-Area Ratio

2.1.2. Density and Relative Composition

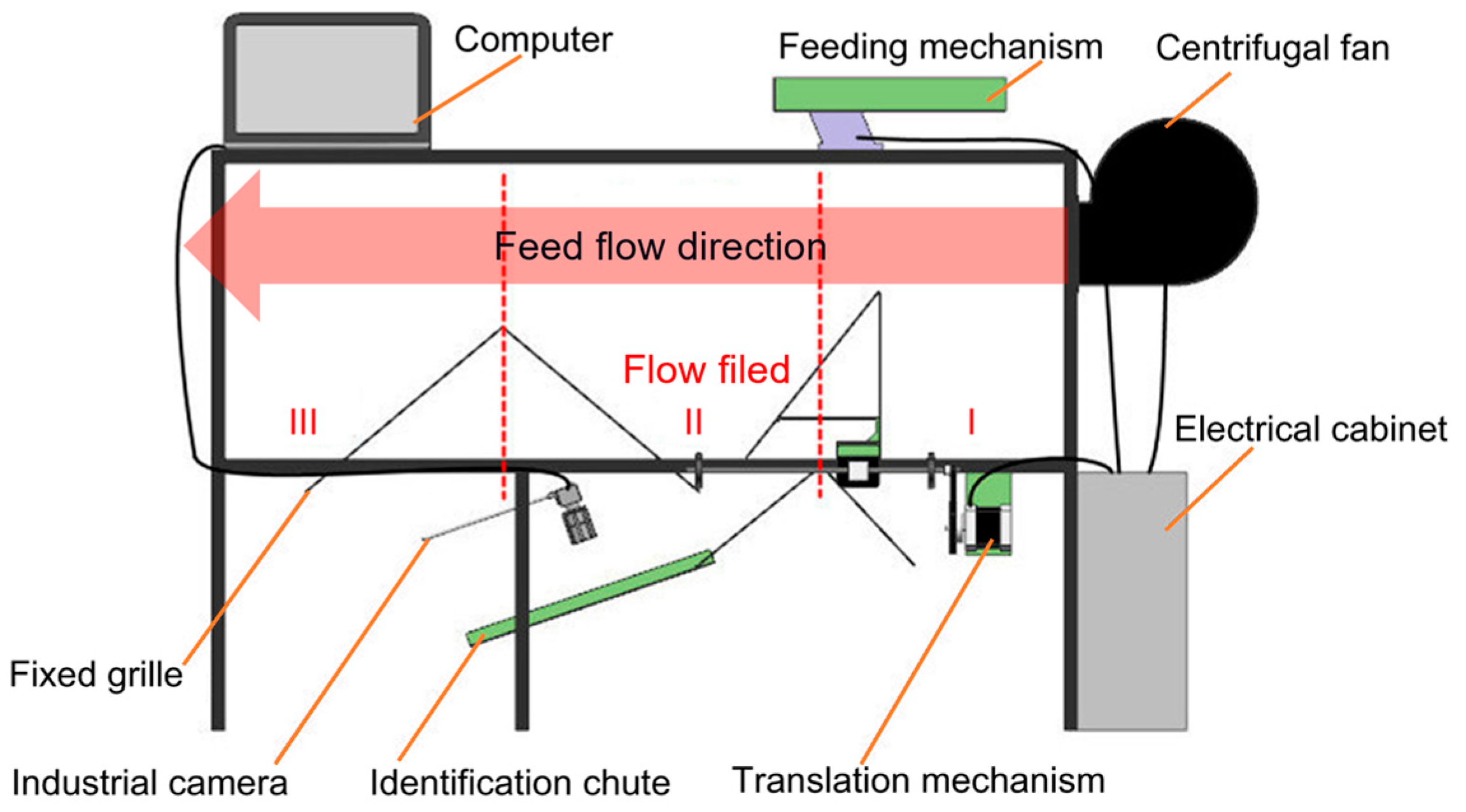

2.2. Working Principles

2.2.1. Adaptive Wind-Sorting Structure

2.2.2. Mathematical Modeling

2.3. Fluid–Solid Interaction Simulation

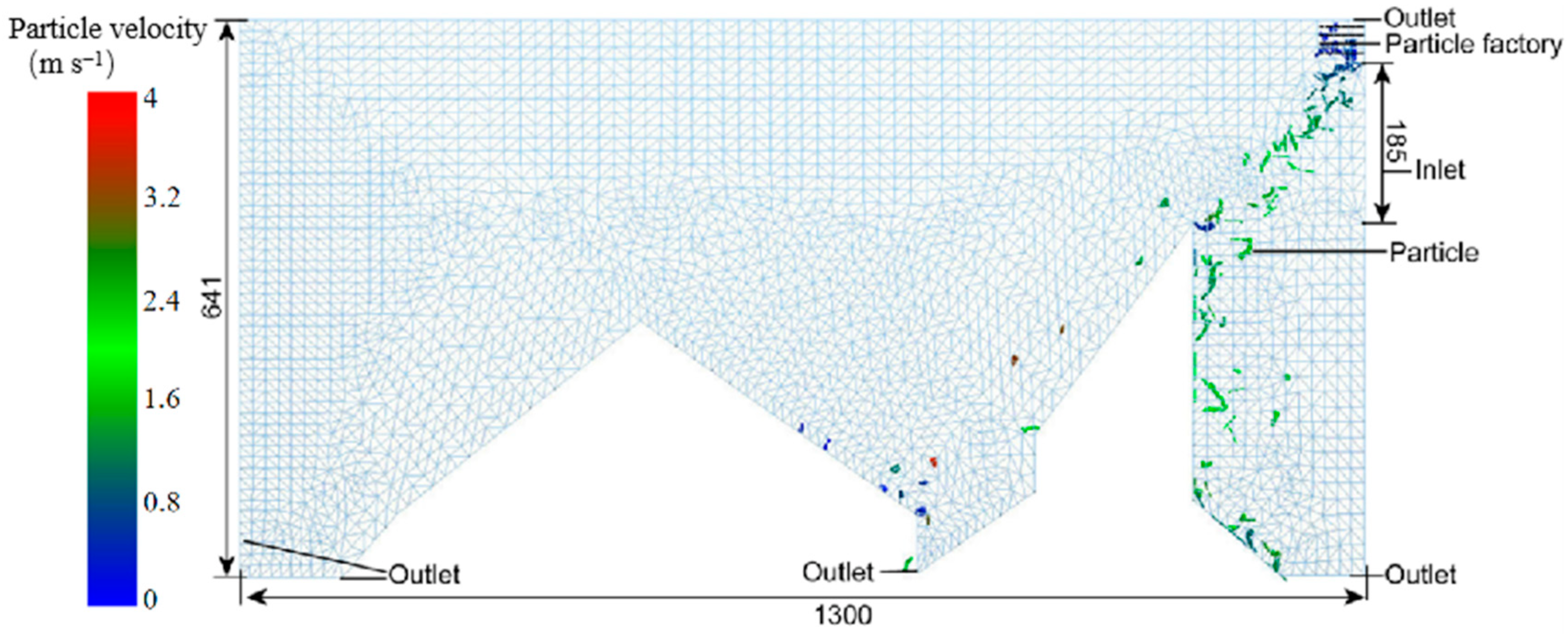

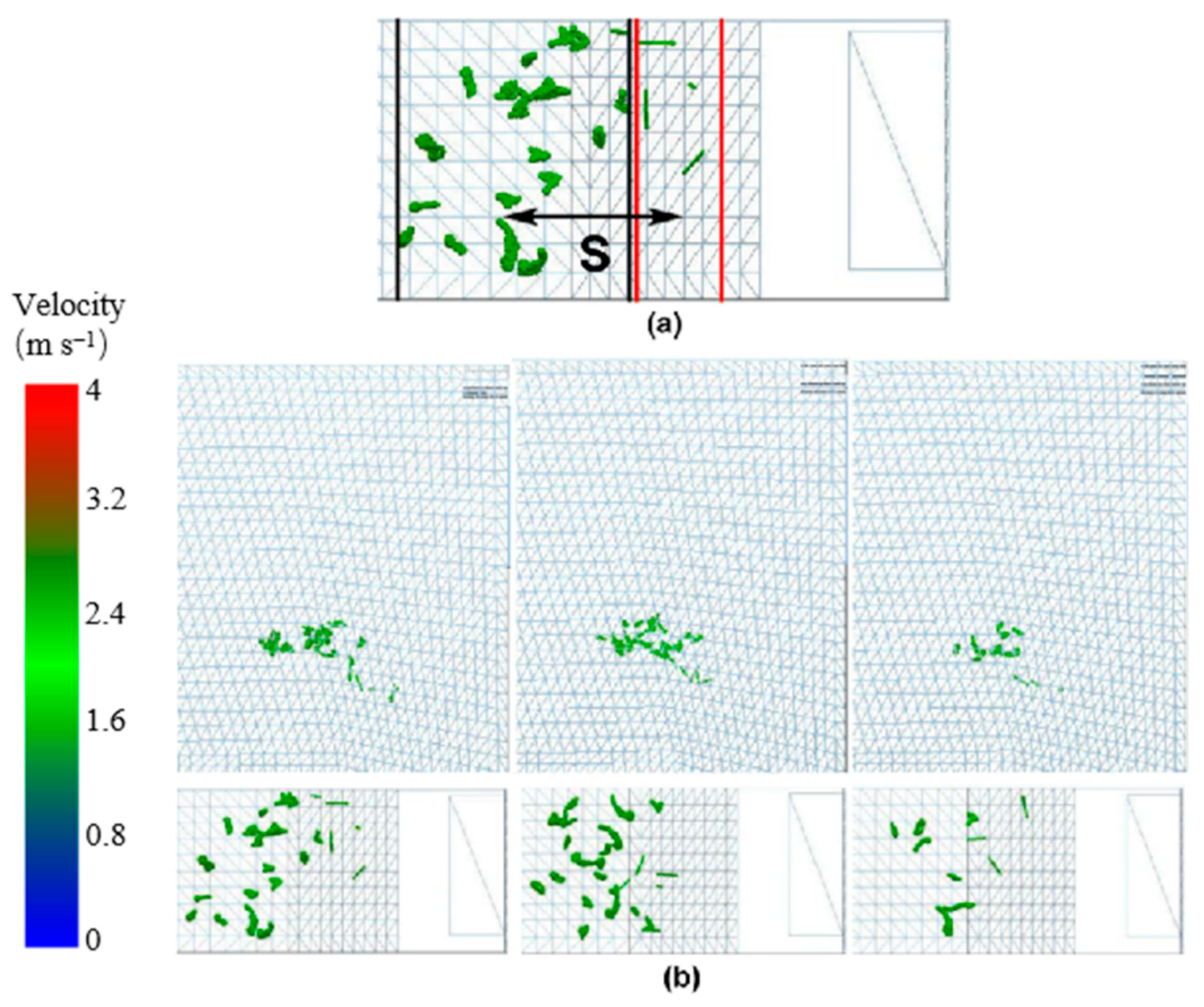

2.3.1. Particle and Flow Modeling

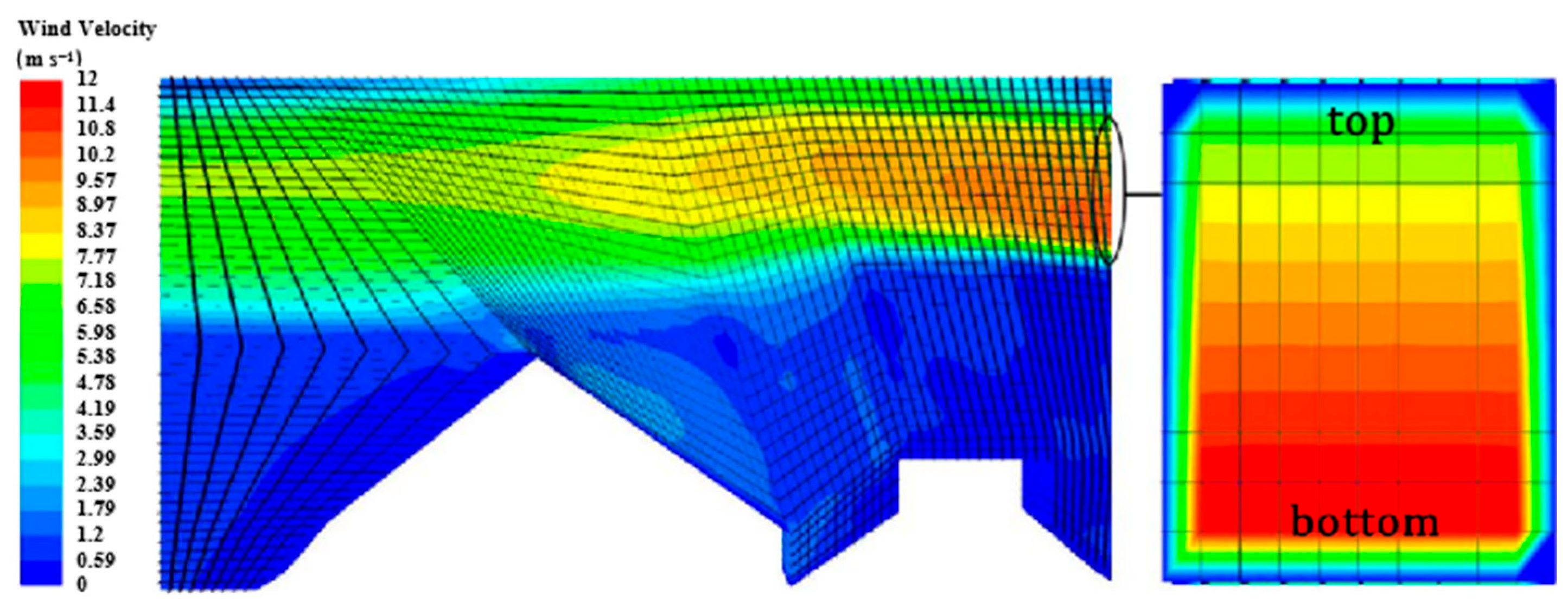

2.3.2. Optimal Design of Wind Field

2.3.3. Interaction Parameter Settings

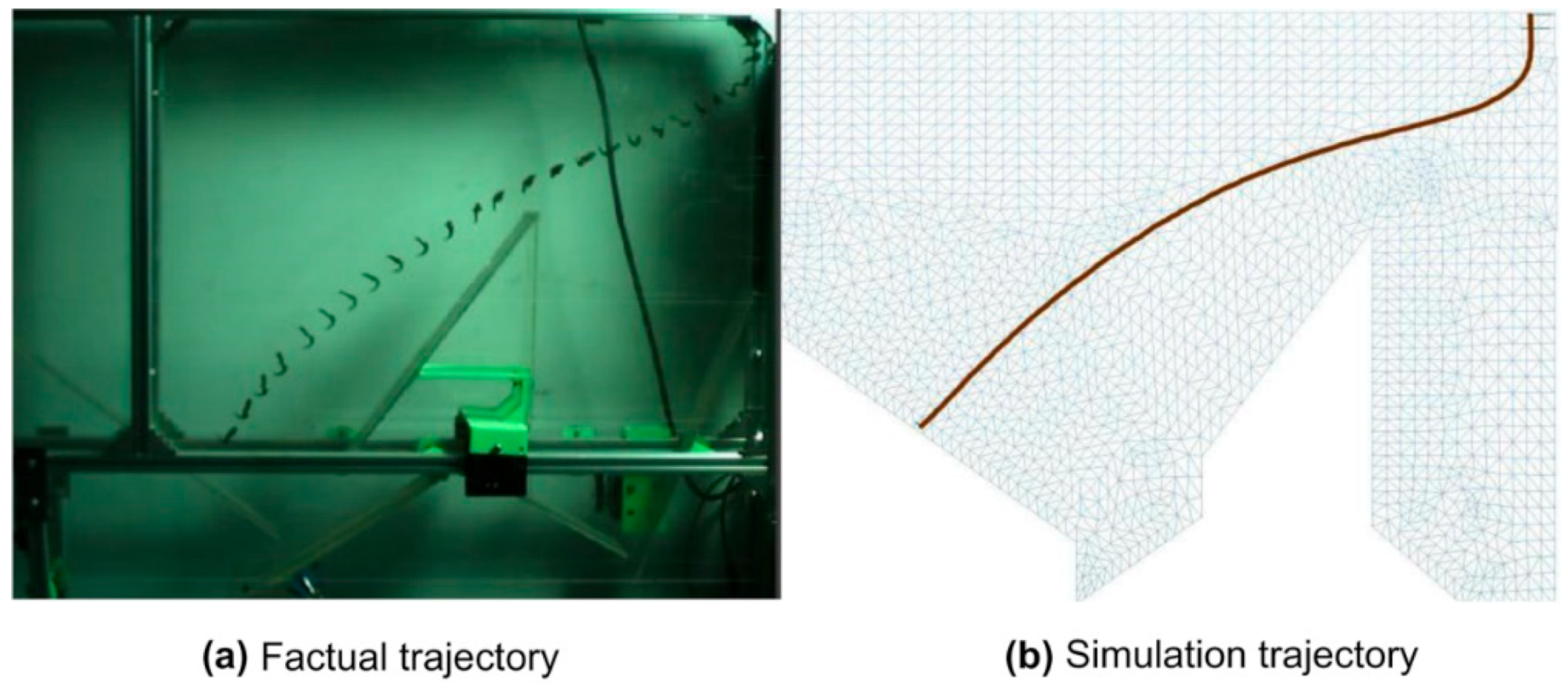

2.4. Simulation and Experimental Error Analysis

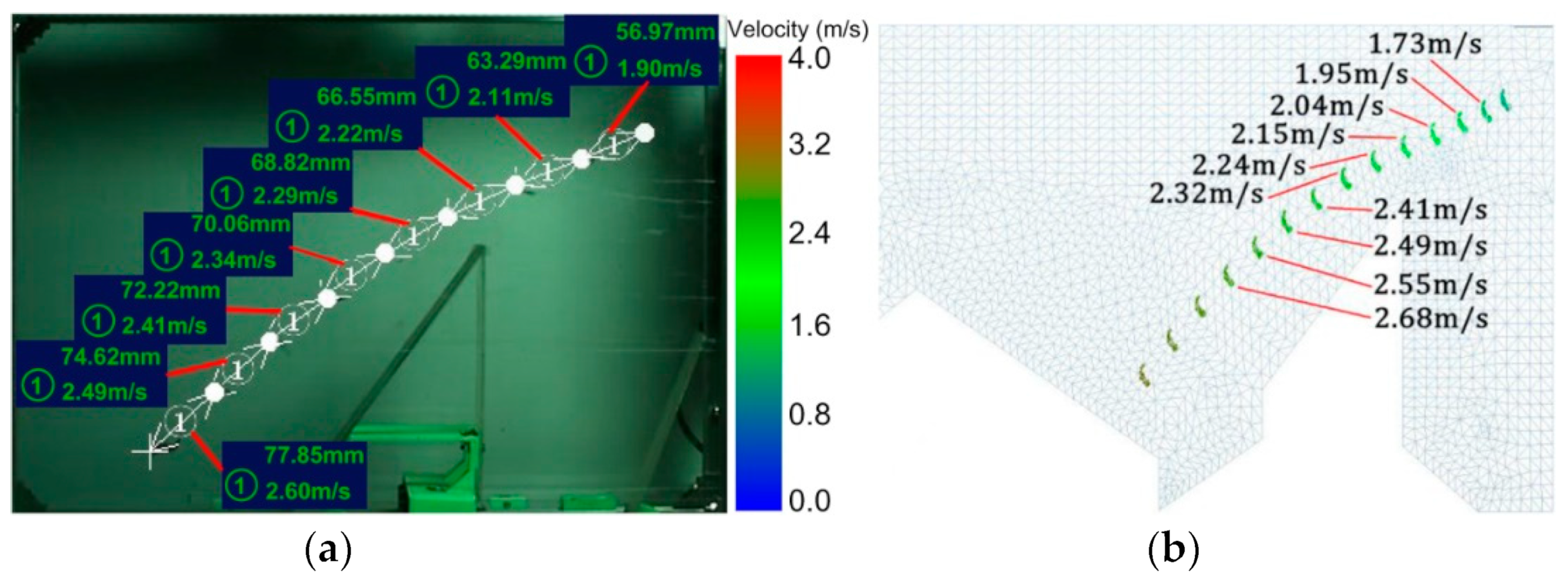

2.4.1. Comparison between Tea Material Trajectories in Simulation and Experiments

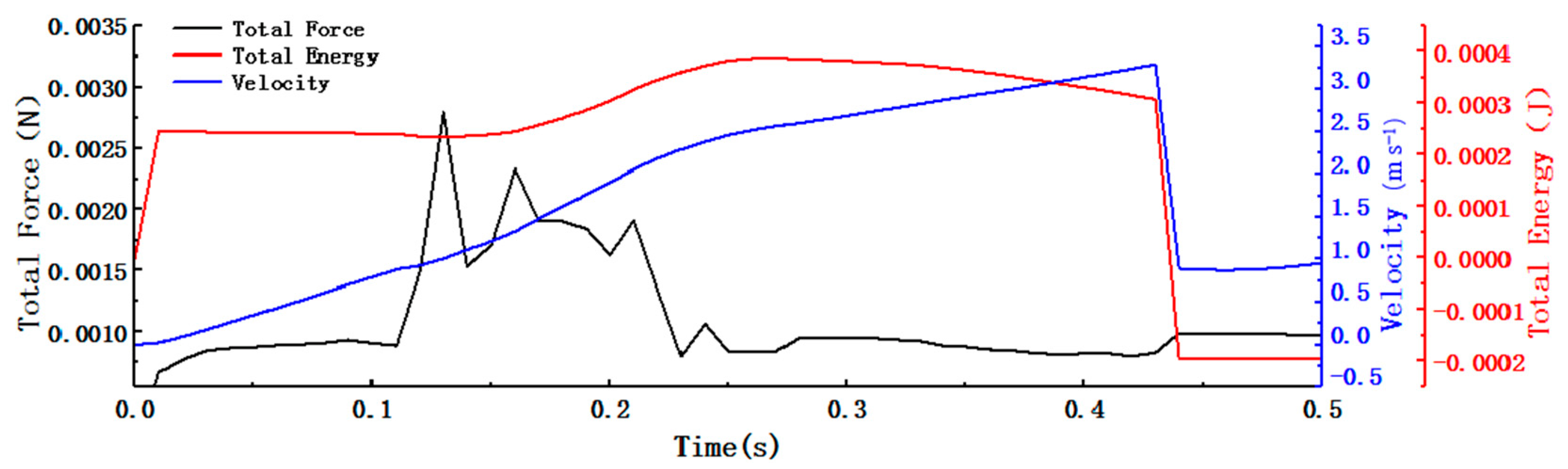

2.4.2. Speed Change of Tea Material

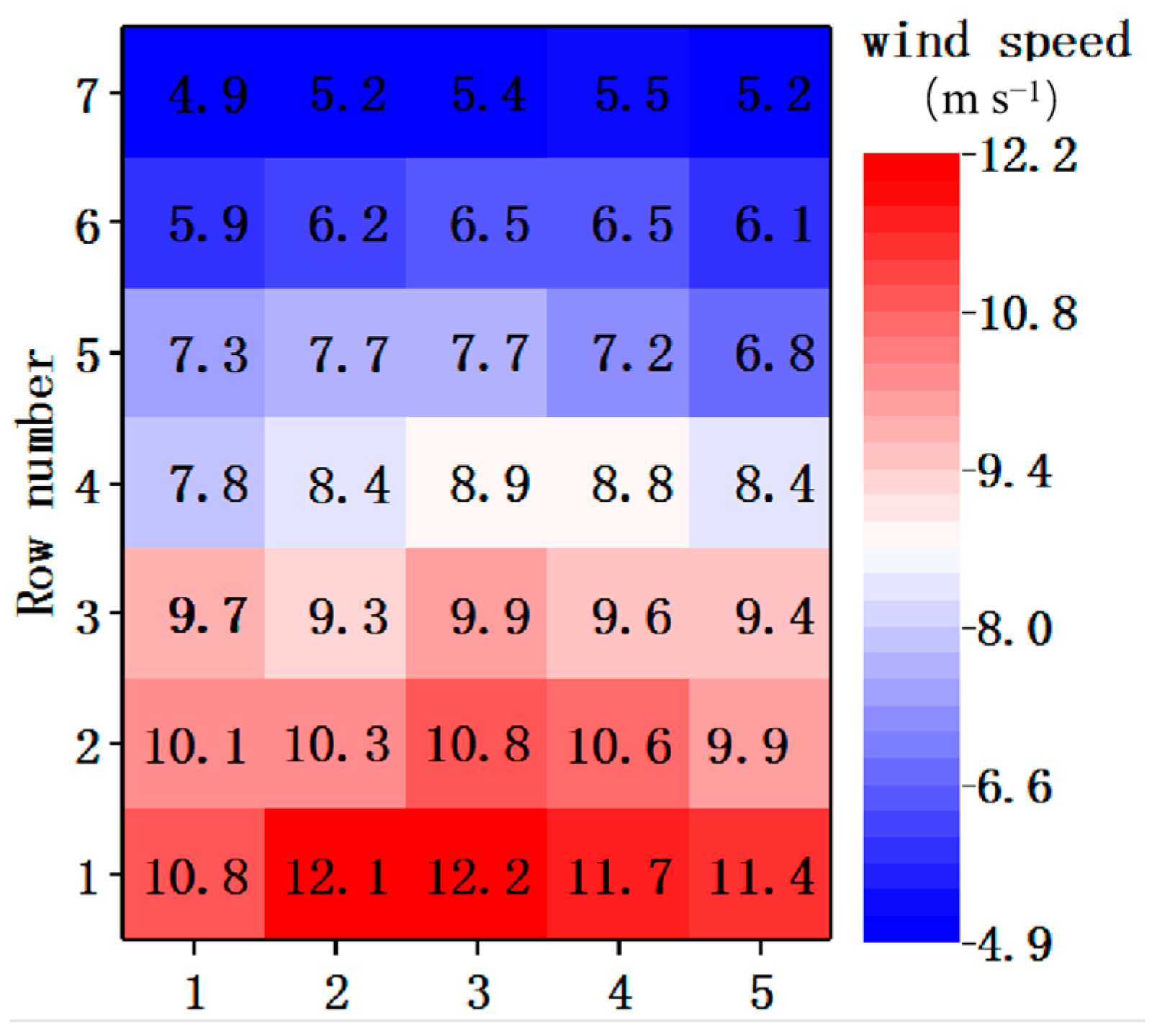

2.4.3. Comparison of Simulated and Experimental Wind Speed Inlet

3. Results and Discussion

3.1. Evaluation Indicators

3.1.1. Drift Limit Velocity

3.1.2. Drag Force Difference

3.1.3. Discrete Degree

3.2. Analysis of Simulation Results and Discussion

3.2.1. Orthogonal Experiments

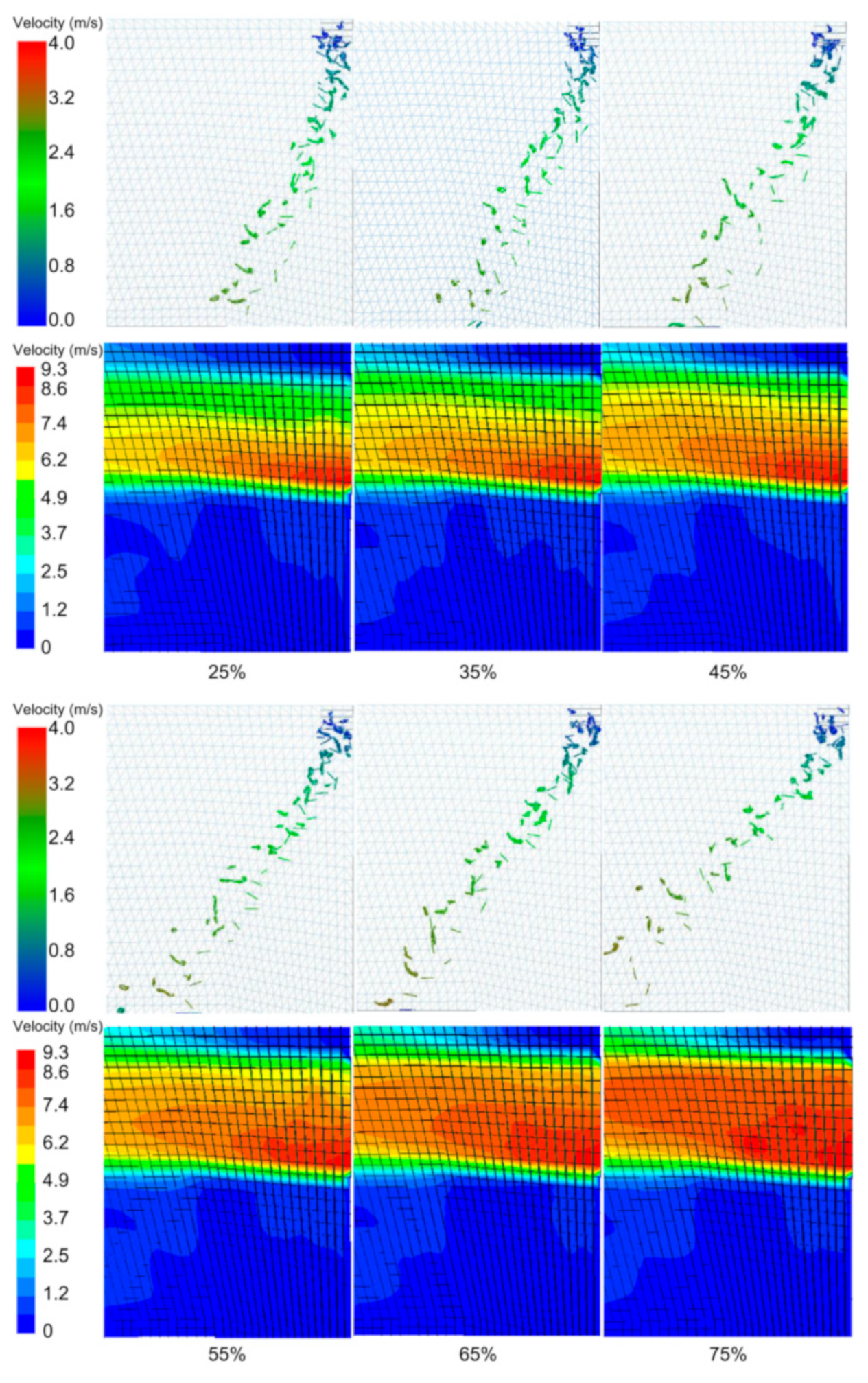

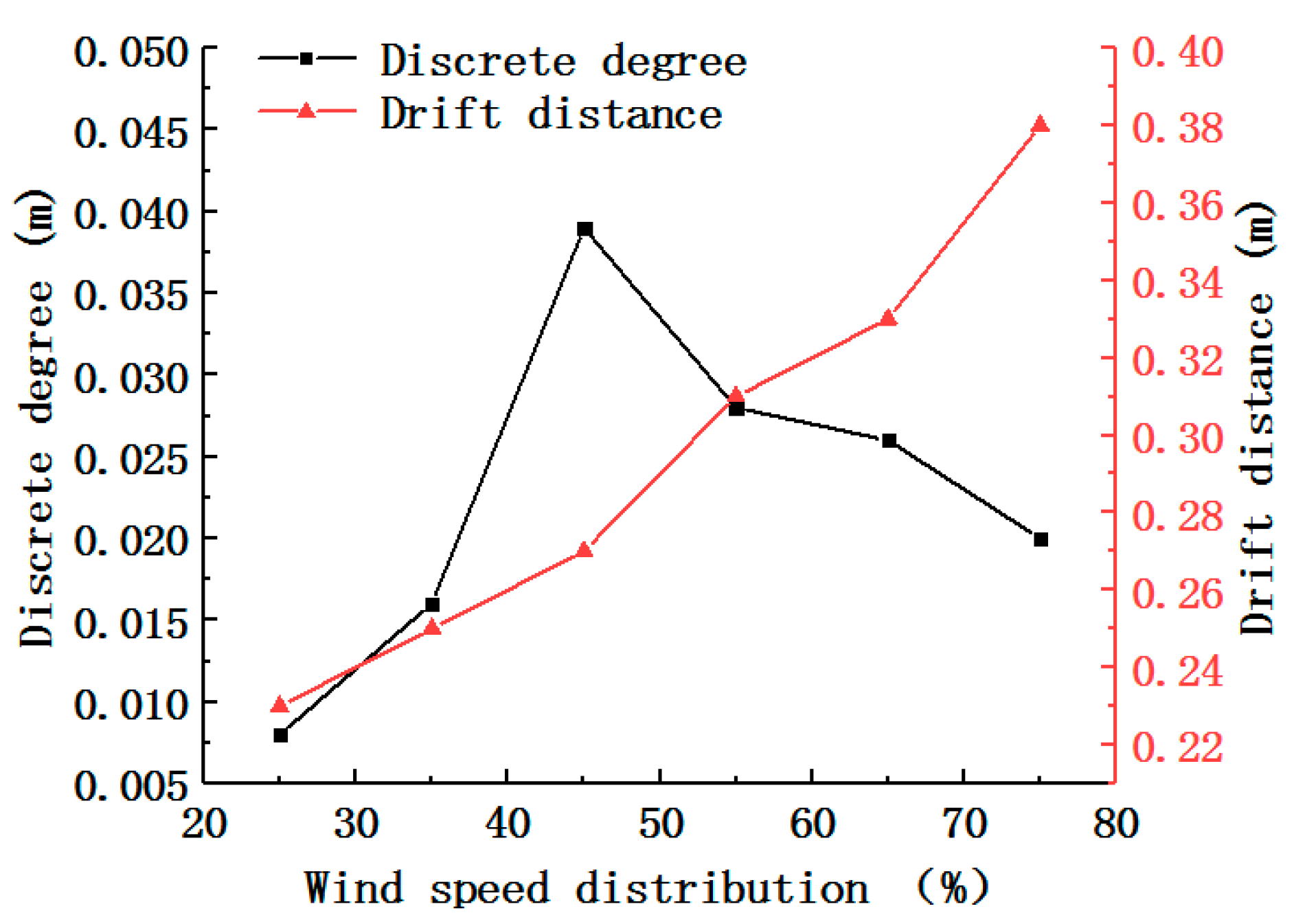

3.2.2. Wind Speed Distribution Experiment

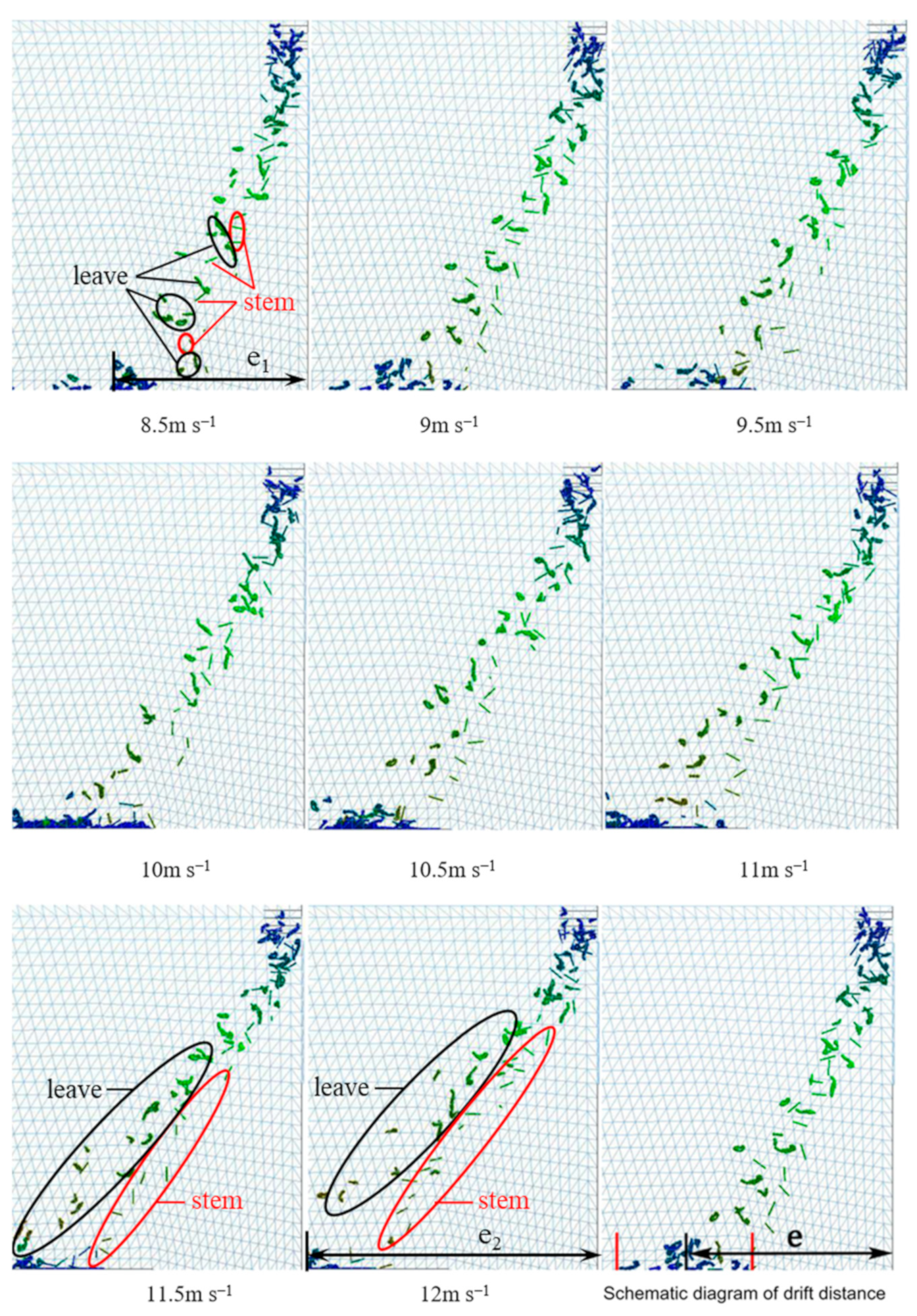

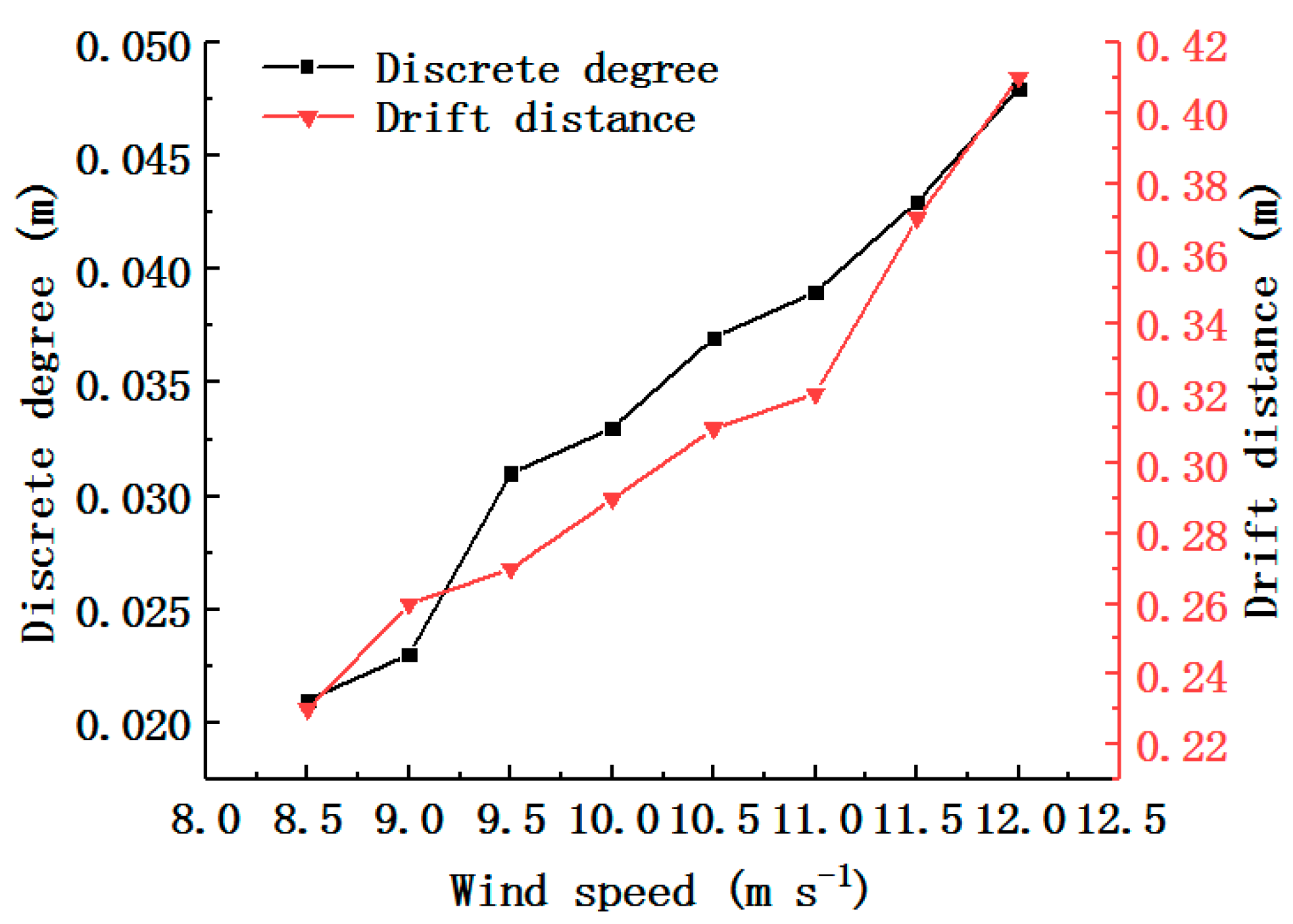

3.2.3. Wind Speed Experiment

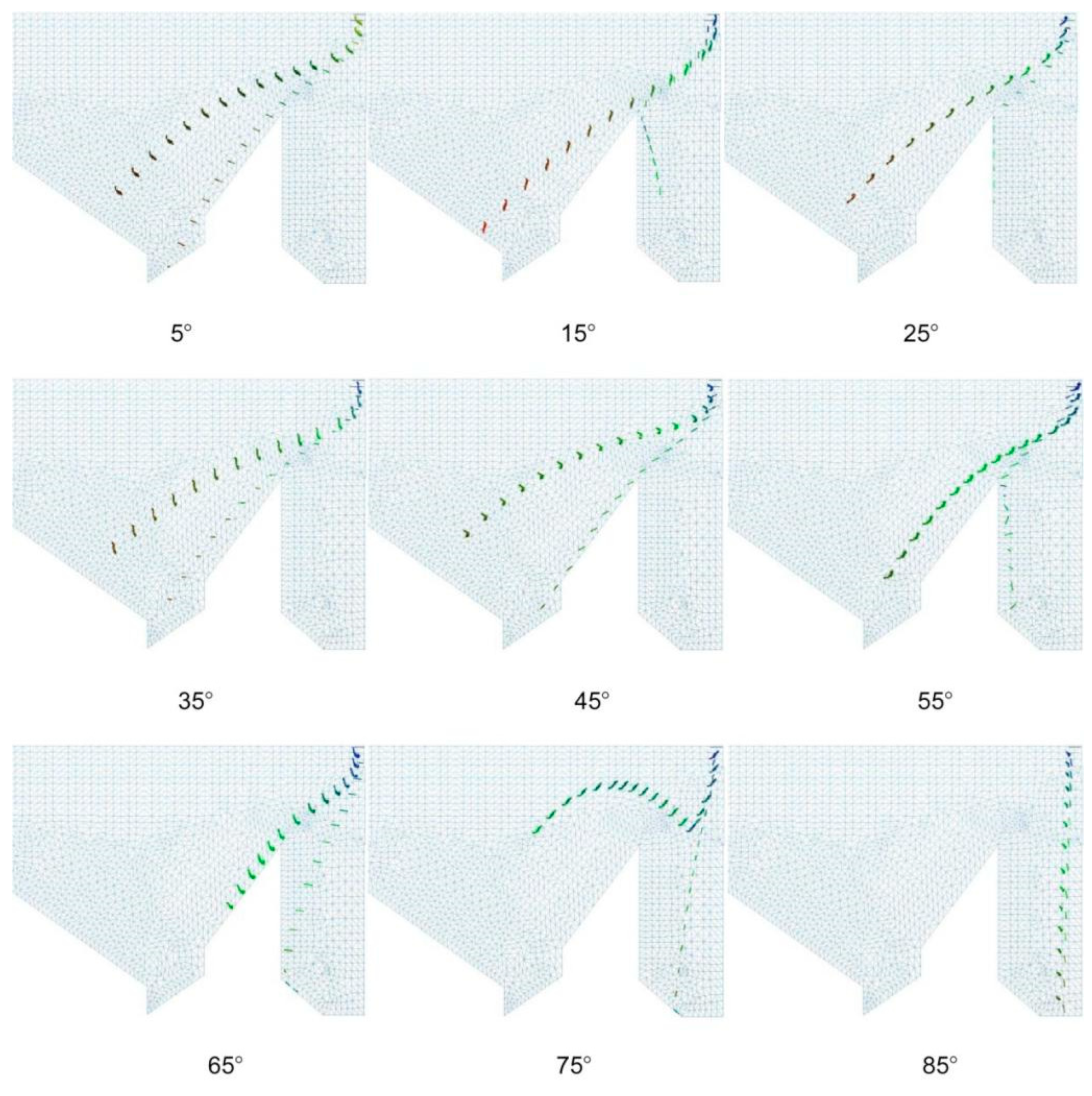

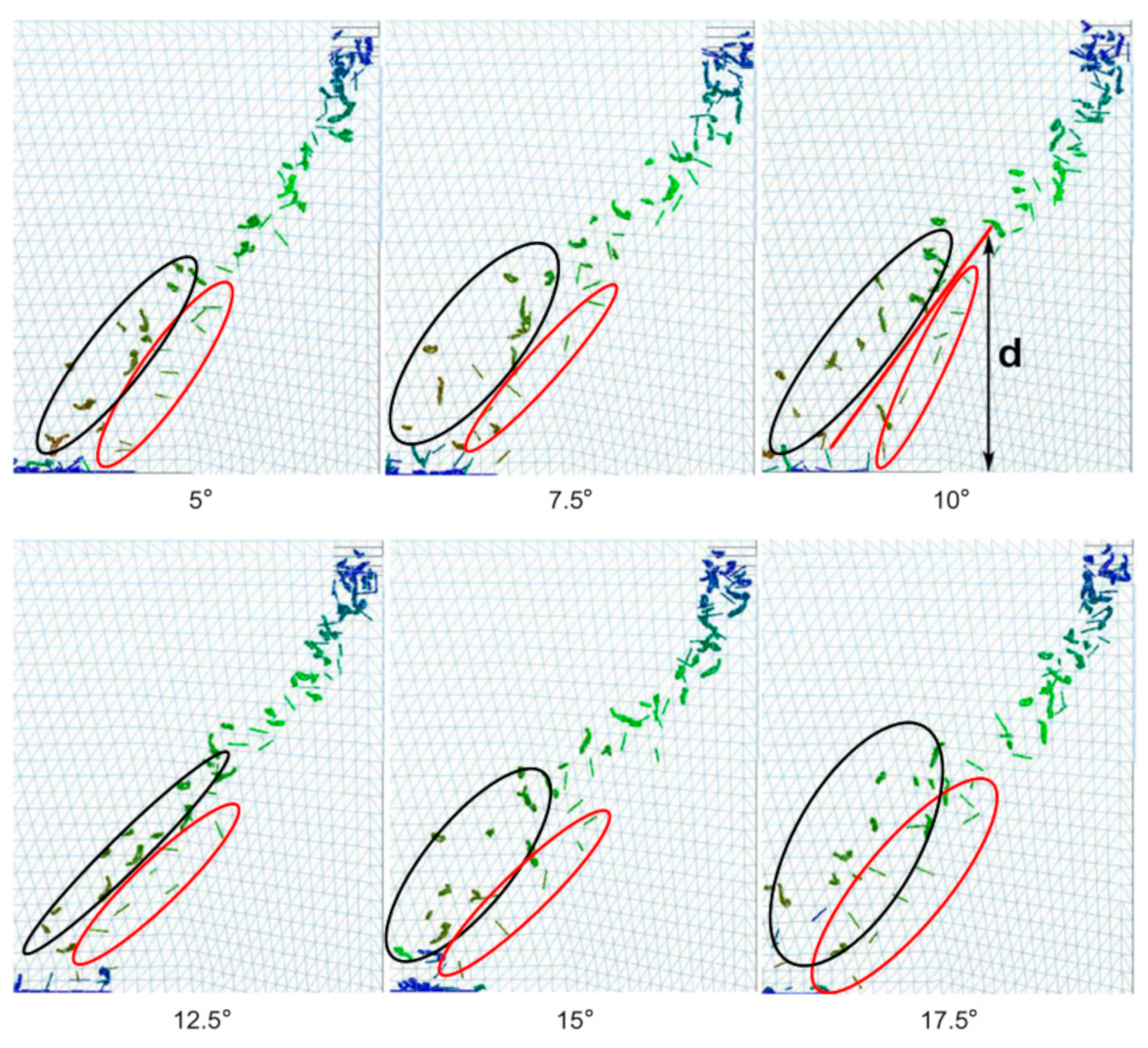

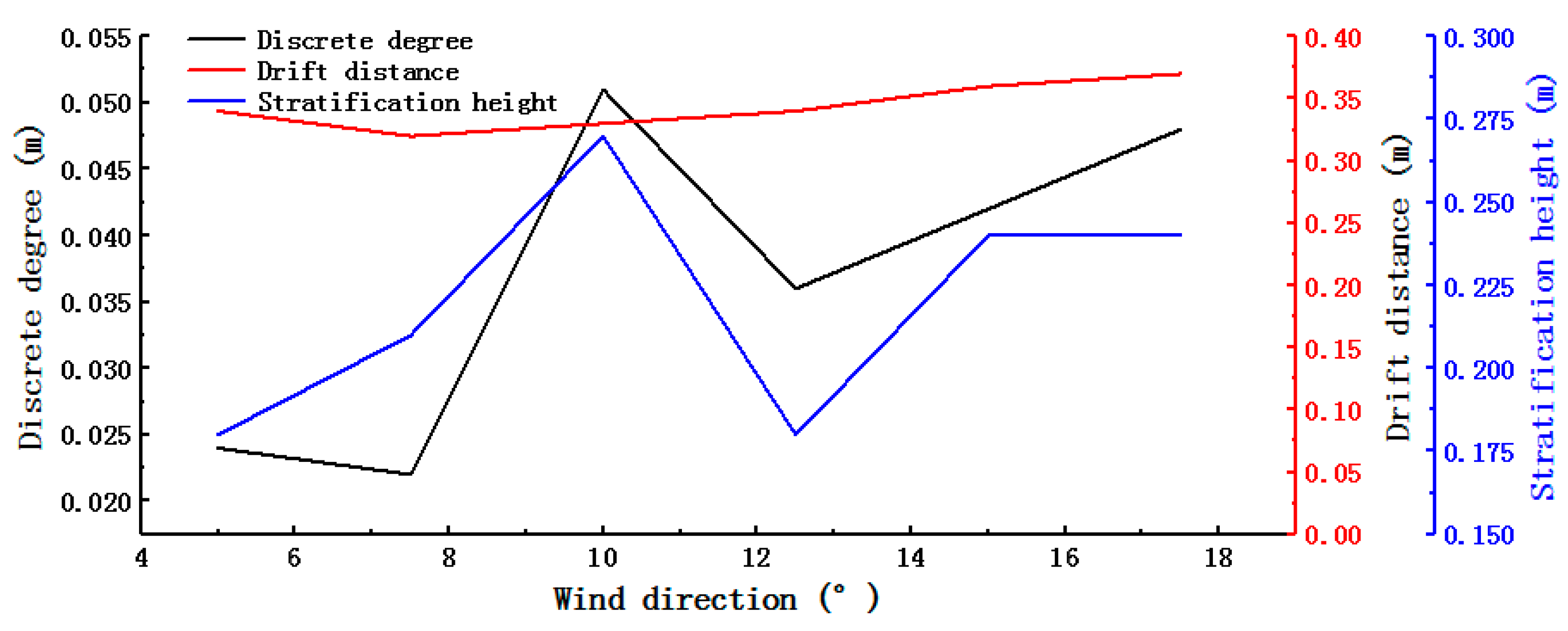

3.2.4. Wind Direction Experiment

3.2.5. Experimental Results and Discussion

4. Conclusions

- (a)

- The weight-to-area ratio (W/A) has a significant effect on airflow distribution and tea movement. An increase in the difference between the weight-to-area ratio of tea stems and leaves can make the stratification of leaves and stems more obvious.

- (b)

- The wind speed distribution (45%) design of the wind speed inlet can improve the pulling effect of the tea materials. The design can reduce the falling distance of tea leaves. Tea leaves can be quickly dispersed when entering the flow field, which promotes the improvement of wind-sorting accuracy.

- (c)

- When the wind speed is 12 m/s, wind speed distribution is 45%, and wind direction is 10°, the drift distance, stratification height, and dispersion of tea materials all reach desirable levels. More tea stems fell in one zone, and the tea and stems distinction reached the maximum.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, G.Y.; Meng, X.; Gan, R.Y.; Zhao, C.N.; Liu, Q.; Feng, Y.B.; Li, S.; Wei, X.L.; Atanasov, A.G.; Corke, H.; et al. Health functions and related molecular mechanisms of tea components: An update review. Int. J. Mol. Sci. 2019, 20, 6196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, Z.; Huang, Y.; Ouyang, T.; Luo, K.; Qin, K.; Sun, Y.; Cao, C. Design and Test of Precise Regulation System for Process Parameters of Double-Layer Tea Winnowing Machine. Agriculture 2022, 12, 1584. [Google Scholar] [CrossRef]

- Wang, Q.M. Simulation and Improvement of Structure on the Flow Field of Tea Winnowing Machine Based on FLUENT. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2017. [Google Scholar]

- Wang, R.Y. Numerical Simulations of Gas-Solid Coupling Mechanism of Flexible Flaky Materials and Experimental Studies of the Sorting Equipment for Machine-Plucked Fresh Tea Leaves. Ph.D. Thesis, Zhejiang Sci-Tech University, Hangzhou, China, 2020. [Google Scholar]

- Zhong, J.; Hang, J.H.; Yang, T.; Zhang, X.; Zhao, Z.F. Optimization study of tea winnowing machine. J. Tea Sci. 2013, 33, 576–583. [Google Scholar]

- Zhu, Z.N.; Zhao, Z.F.; Zhong, J.; Zhou, R.G.; Zhang, X. Study on parameter optimization of centrifugal and continuous dewatering of tea leaves based on numerical simulation of multiphase flow. J. Tea Sci. 2017, 37, 280–289. [Google Scholar]

- Zhao, Z.F.; Ren, C.; Zheng, J.S.; Zhong, J.; Xie, B.J. Study on the relationship between work efficiency of spherical tea frying equipment and tea formation. J. Tea Sci. 2018, 38, 527–536. [Google Scholar]

- Li, B.; Li, W.N.; Bo, X.B.; Zhang, Z.Z. Research on screening rate of fresh tea leaves classifier based on EDEM. J. Tea Sci. 2019, 39, 484–494. [Google Scholar]

- Yu, W.J.; Wu, R.M.; Li, H.; Pei, G.; Jin, S.F.; Hang, C.Q.; Zhu, R.Z.; Yang, P.X.; Xiong, A.H. The numerical simulation on temperature field inside the radiation de-enzyme machine based on FLUENT-EDEM coupling. Food Mach. 2019, 35, 104–109. [Google Scholar]

- Cao, M.L.; Yang, Y.J.; Wu, C.Y.; Cai, C.G. A novel micro-spiral pneumatic selection system for the separation of fresh tea leaves. Int. J. Food Eng. 2021, 17, 595–608. [Google Scholar] [CrossRef]

- Yu, K.J.; Shao, C.P. Wind tunnel investigation of the aerodynamic characteristics of purple wisteria compound leaves. Chin J. Theor. Appl. Mech. 2019, 51, 245–262. [Google Scholar]

- Chengmao, C.; Kun, L.; Meile, P.; Zhengmin, W.; Guangzong, L.; Zheng, L. Experiment on winnowing mechanism and winnowing performance of hickory material. Trans. Chin. Soc. Agric. Mach. 2019, 50, 105–112. [Google Scholar]

- Hu, H.; Zhou, Z.; Wu, W.; Yang, W.; Li, T.; Chang, C.; Ren, W.; Lei, X. Distribution characteristics and parameter optimisation of an air-assisted centralised seed-metering device for rapeseed using a CFD-DEM coupled simulation. Biosyst. Eng. 2021, 208, 246–259. [Google Scholar] [CrossRef]

- Zhou, M.M.; Kuang, S.B.; Xiao, F.; Luo, K.; Yu, A.B. CFD-DEM analysis of hydraulic conveying bends: Interaction between pipe orientation and flow regime. Powder Technol. 2021, 392, 619–631. [Google Scholar] [CrossRef]

- Dai, F.; Song, X.F.; Guo, W.J.; Zhao, W.Y.; Zhang, F.W.; Zhang, S.L. Simulation and test on separating cleaning process of flax threshing material based on gas-solid coupling theory. Int. J. Agric. Biol. Eng. 2020, 13, 73–81. [Google Scholar] [CrossRef]

- Zambra, C.E.; Puente-Díaz, L.; Ah-Hen, K.; Rosales, C.; Hernandez, D.; Lemus-Mondaca, R. Experimental and numerical study of a turbulent air-drying process for an ellipsoidal fruit with volume changes. Foods 2022, 11, 1880. [Google Scholar] [CrossRef]

- Beaumont, F.; Liger-Belair, G.; Polidori, G. Computational Fluid Dynamics (CFD) as a Tool for Investigating Self-Organized Ascending Bubble-Driven Flow Patterns in Champagne Glasses. Foods 2020, 9, 972. [Google Scholar] [CrossRef]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed motion characteristics and seeding performance of a centralised seed metering system for rapeseed investigated by DEM simulation and bench testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, K.; Tian, X.; Kou, M.; Wu, S.; Shen, Y. Influence of burden profile on gas-solid distribution in COREX shaft furnace with center gas supply by CFD-DEM model. Powder Technol. 2021, 392, 672–679. [Google Scholar] [CrossRef]

- Yang, T. Numerical Simulation of Tea Winnowing and Optimal Design of Winnowing Machine. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2012. [Google Scholar]

- Li, W.N.; Song, Y.Y.; Li, B. Simulation test of double-pan roasting machine based on EDEM. Food Mach. 2019, 35, 90–95. [Google Scholar]

- Puderbach, V.; Schmidt, K.; Antonyuk, S. A coupled CFD-DEM model for resolved simulation of filter cake formation during solid-liquid separation. Processes 2021, 9, 826. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, T.; Qiao, X.; Zhong, J.; Ou, C.J.; Wang, S.F.; Zhao, Z.F. Study on effect of air inlet flow field on the tea particles drift distance and quality of wind-selecting. J. Tea Sci. 2013, 33, 60–66. [Google Scholar]

| Material Type | Density (kg m−3) | Relative Composition (%) | Weight-to-Area Ratio (kg m−2) | Length (mm) | Width (mm) |

|---|---|---|---|---|---|

| Stem | 455 | 5.2 | 0.56–0.79 | 15–40 | 1–3 |

| Large leaves | 232 | 36.4 | 0.35–0.66 | 28–33 | 6–10 |

| Compact leaves | 250 | 22.2 | 0.64–1 | 15–23 | 3–5.5 |

| Tattered leaves | 34.1 | ||||

| Dust, foam | 2.1 |

| Parameters | Steel | Tea Leaves | Tea Stems | |

|---|---|---|---|---|

| EDEM | Poisson’s ratio | 0.25 | 0.4 | 0.4 |

| Density (kg m−3) | 2500 | 232/250 | 455 | |

| Shear modulus (Pa) | 1 × 108 | 2.7 × 106 | ||

| Restitution coefficient (with particles) | 0.5 | 0.36 | 0.36 | |

| Static friction coefficient (with particles) | 0.8 | 0.1 | 0.1 | |

| Rolling friction coefficient (with particles) | 0.6 | 0.7 | 0.7 | |

| Time step (s) | 0.000001 | |||

| FLUENT | Fluid | Air | ||

| Inlet velocity function | Vy = b−ky | |||

| Time step (s) | 0.00001 | |||

| Levels | Wind Speed Distribution | Airflow Direction (°) | Airflow Velocity (m s−1) |

|---|---|---|---|

| 1 | 25% | 10 | 10 |

| 2 | 50% | 15 | 12 |

| 3 | 75% | 20 | 14 |

| No. | Wind Speed Distribution | Airflow Direction (°) | Airflow Velocity (m s−1) | Drift Limiting Velocity (m s−1) | Drag Force Difference (N) | Discrete Degree (m) |

|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 2.9 | 0.00165 | −0.01 |

| 2 | 1 | 2 | 2 | 2.8 | 0.00075 | 0.0059 |

| 3 | 1 | 3 | 3 | 2.8 | 0.002 | 0.034 |

| 4 | 2 | 1 | 2 | 3.1 | 0.00189 | 0.028 |

| 5 | 2 | 2 | 3 | 3.3 | 0.00189 | 0.061 |

| 6 | 2 | 3 | 1 | 2.8 | 0.00121 | −0.005 |

| 7 | 3 | 1 | 3 | 4.1 | 0.00125 | 0.02 |

| 8 | 3 | 2 | 1 | 3.2 | 0.00176 | 0.042 |

| 9 | 3 | 3 | 2 | 3.3 | 0.002 | 0.067 |

| Drift limiting velocity | K1 | 2.833 | 3.367 | 2.967 | ||

| K2 | 3.067 | 3.1 | 3.067 | |||

| K3 | 3.533 | 2.967 | 3.4 | |||

| R | 0.7 | 0.4 | 0.433 | |||

| Primary and secondary factors B > C > A; optimal parameter combination B3C1A1 | ||||||

| Drag force difference | K1 | 0.001 | 0.002 | 0.002 | ||

| K2 | 0.002 | 0.001 | 0.002 | |||

| K3 | 0.002 | 0.002 | 0.002 | |||

| R | 0.001 | 0.001 | 0 | |||

| Primary and secondary factors A = B > C; optimal parameter combination A2B1C1 | ||||||

| Discrete degree | K1 | 0.01 | 0.015 | 0.009 | ||

| K2 | 0.028 | 0.036 | 0.034 | |||

| K3 | 0.045 | 0.032 | 0.041 | |||

| R | 0.035 | 0.021 | 0.032 | |||

| Primary and secondary factors A > C > B; optimal parameter combination A3C3B2 | ||||||

| Parameter | Values | |||||||

|---|---|---|---|---|---|---|---|---|

| Wind speed distribution | 25% | 35% | 45% | 55% | 65% | 75% | ||

| Airflow velocity | 8.5 | 9 | 9.5 | 10 | 10.5 | 11 | 11.5 | 12 |

| Airflow direction | 5 | 7.5 | 10 | 12.5 | 15 | 17.5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, K.; Cao, C.; Wu, Z.; Zhang, X.; An, M. Optimization of Roasted Green Tea Winnowing via Fluid–Solid Interaction Experiments and Simulations. Foods 2022, 11, 3271. https://doi.org/10.3390/foods11203271

Luo K, Cao C, Wu Z, Zhang X, An M. Optimization of Roasted Green Tea Winnowing via Fluid–Solid Interaction Experiments and Simulations. Foods. 2022; 11(20):3271. https://doi.org/10.3390/foods11203271

Chicago/Turabian StyleLuo, Kun, Chengmao Cao, Zhengmin Wu, Xuechen Zhang, and Minhui An. 2022. "Optimization of Roasted Green Tea Winnowing via Fluid–Solid Interaction Experiments and Simulations" Foods 11, no. 20: 3271. https://doi.org/10.3390/foods11203271

APA StyleLuo, K., Cao, C., Wu, Z., Zhang, X., & An, M. (2022). Optimization of Roasted Green Tea Winnowing via Fluid–Solid Interaction Experiments and Simulations. Foods, 11(20), 3271. https://doi.org/10.3390/foods11203271