Impacts of Thermal Processing, High Pressure, and CO2-Assisted High Pressure on Quality Characteristics and Shelf Life of Durian Fruit Puree

Abstract

1. Introduction

2. Material and Methods

2.1. Preparation of DFP

2.2. Processing Conditions

2.3. Storage Condition

2.4. Microbial Counts

2.5. Detection of pH, Total Soluble Solids, and Color

2.6. Rheological Measurement

2.7. Determination of Sugar Component and Ascorbic Acid

2.8. Determination of Total Phenolic, Total Flavonoid and Total Carotenoid

2.9. Measurement of Antioxidant Capacity

2.9.1. 2,2-Diphenyl-2-Picryl-Hydrazyl (DPPH) Radical Scavenging Capacity

2.9.2. 2,2′-Azino-Bis (3-Ethylbenzothiazoline-6-Sulfonic Acid) (ABTS) Radical Scavenging Capacity

2.10. Statistical Analysis

3. Results and Discussion

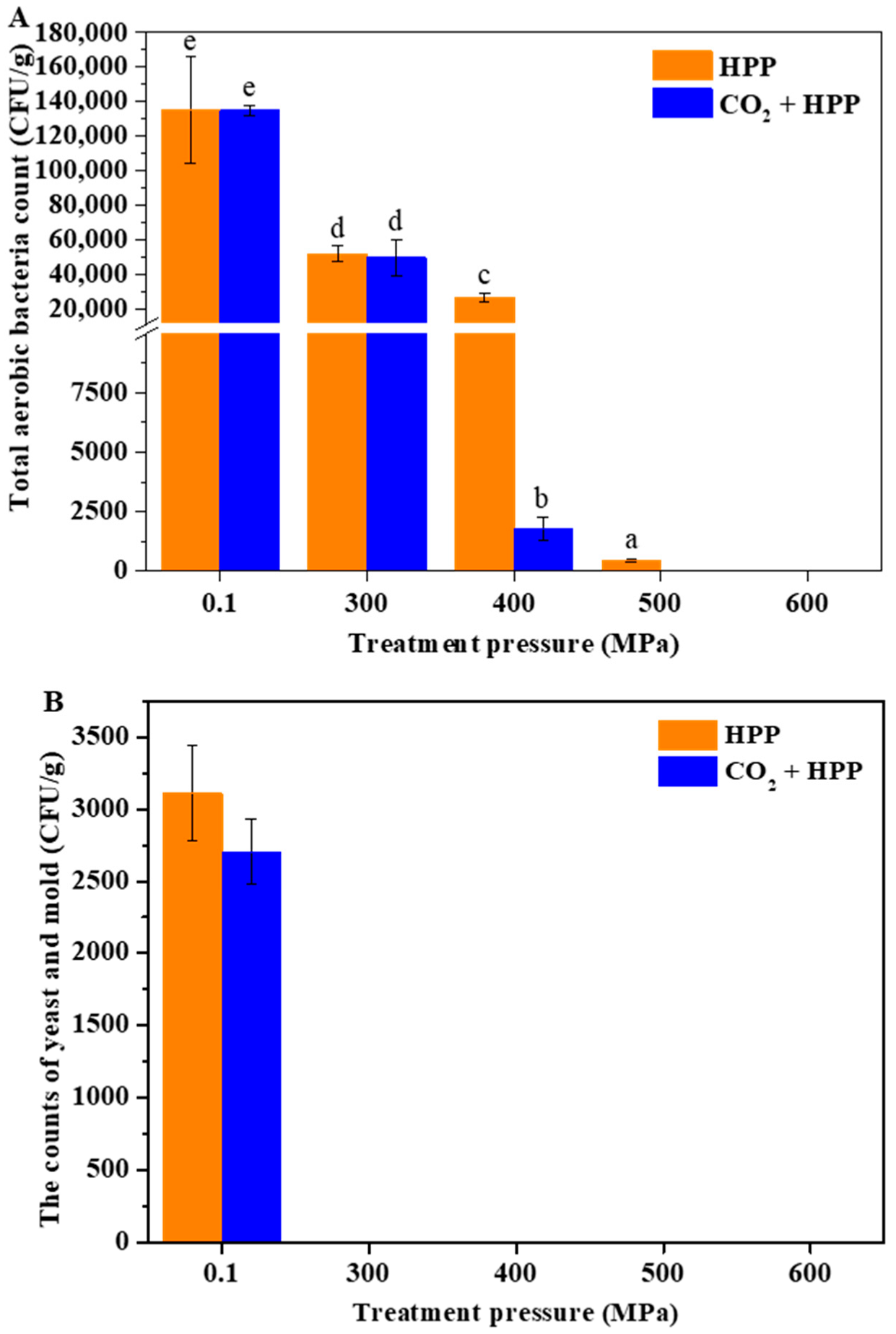

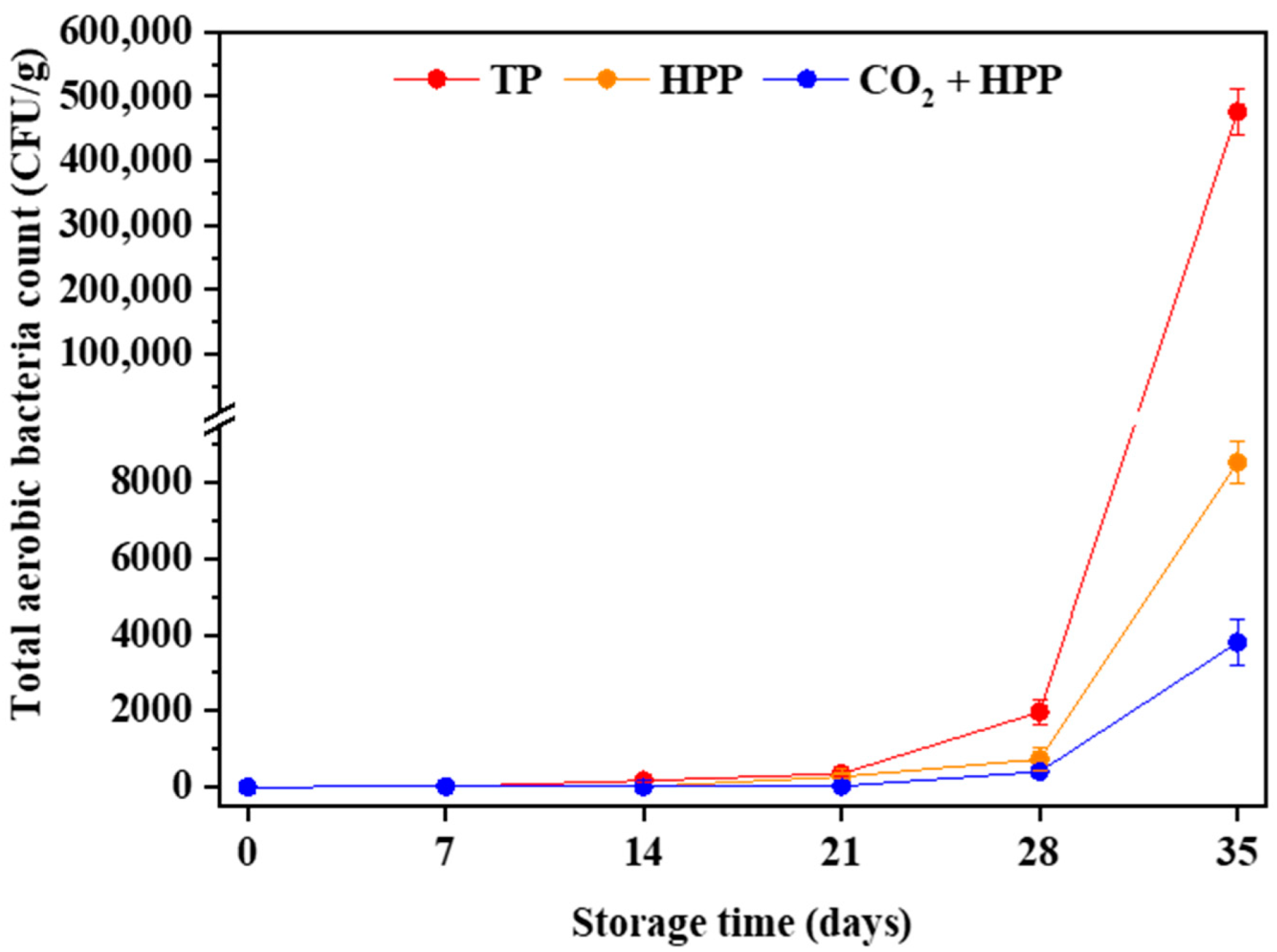

3.1. Influences of Different Treatments on Microbial Counts of DFP

3.2. Influences of Different Treatments on pH, Total Soluble Solids, and Sugars of DFP

3.3. Influence of Different Treatments on Color Parameters of DFP

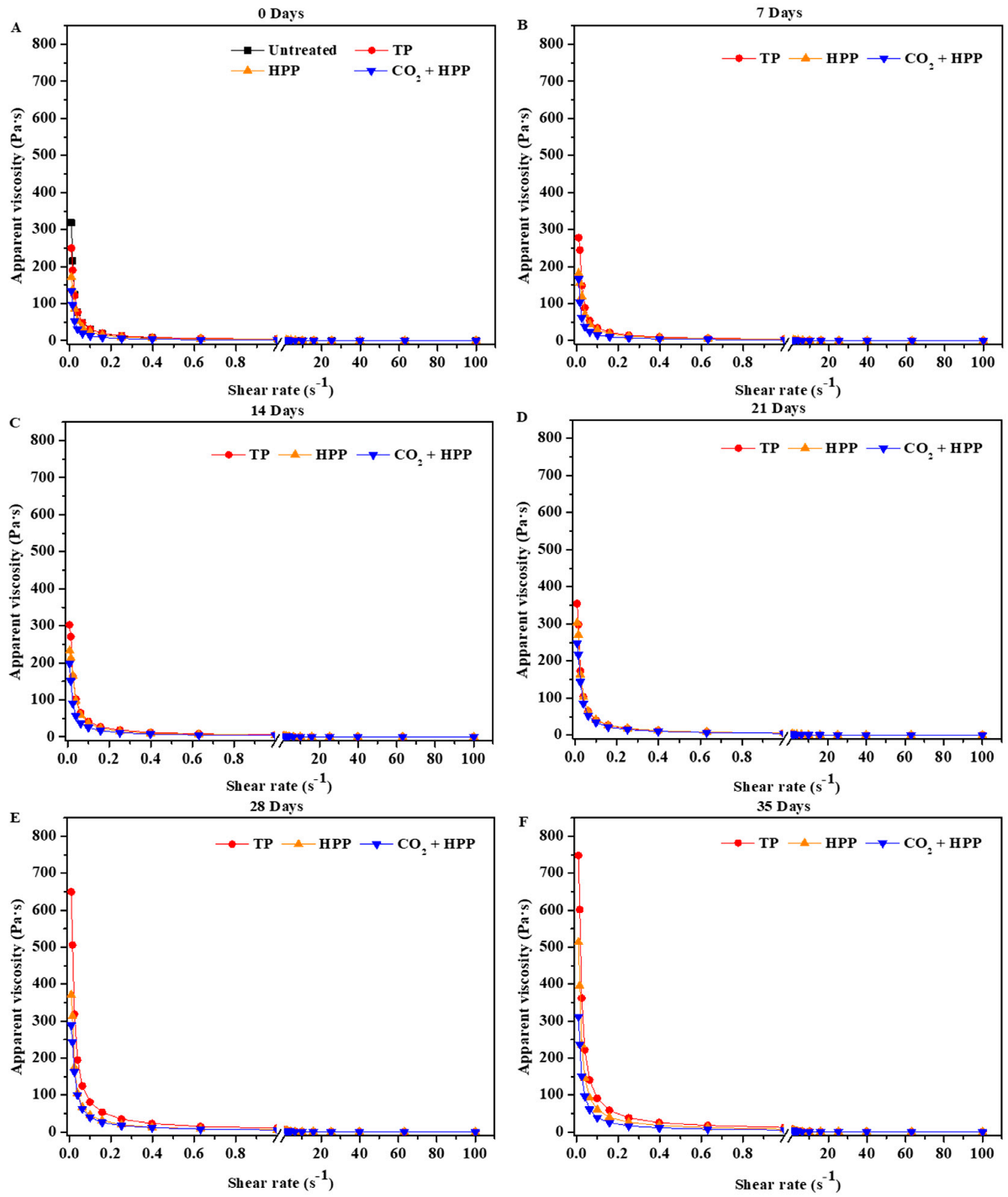

3.4. Influence of Different Treatments on Apparent Viscosity of DFP

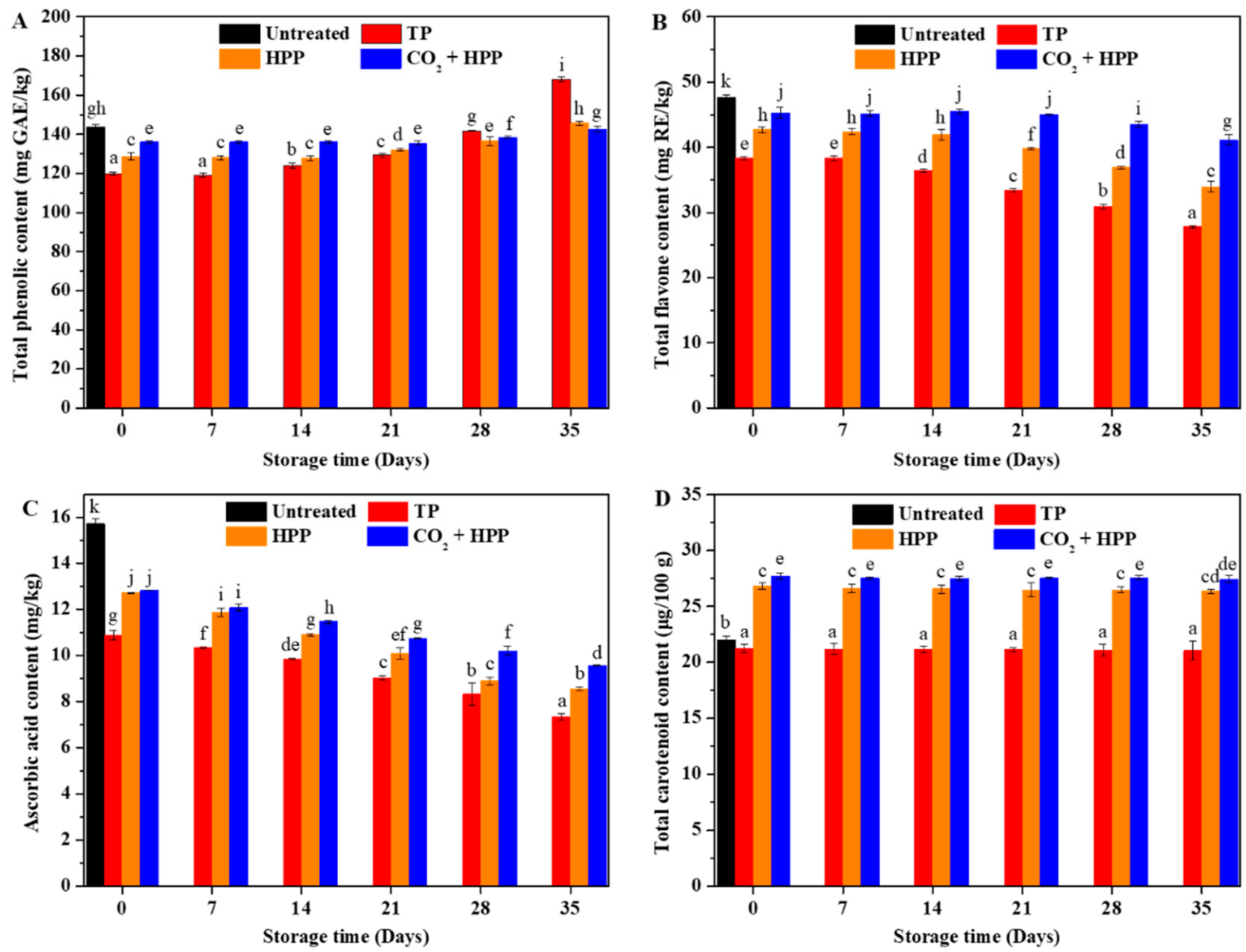

3.5. Influence of Different Treatments on Bioactive Compounds of DFP

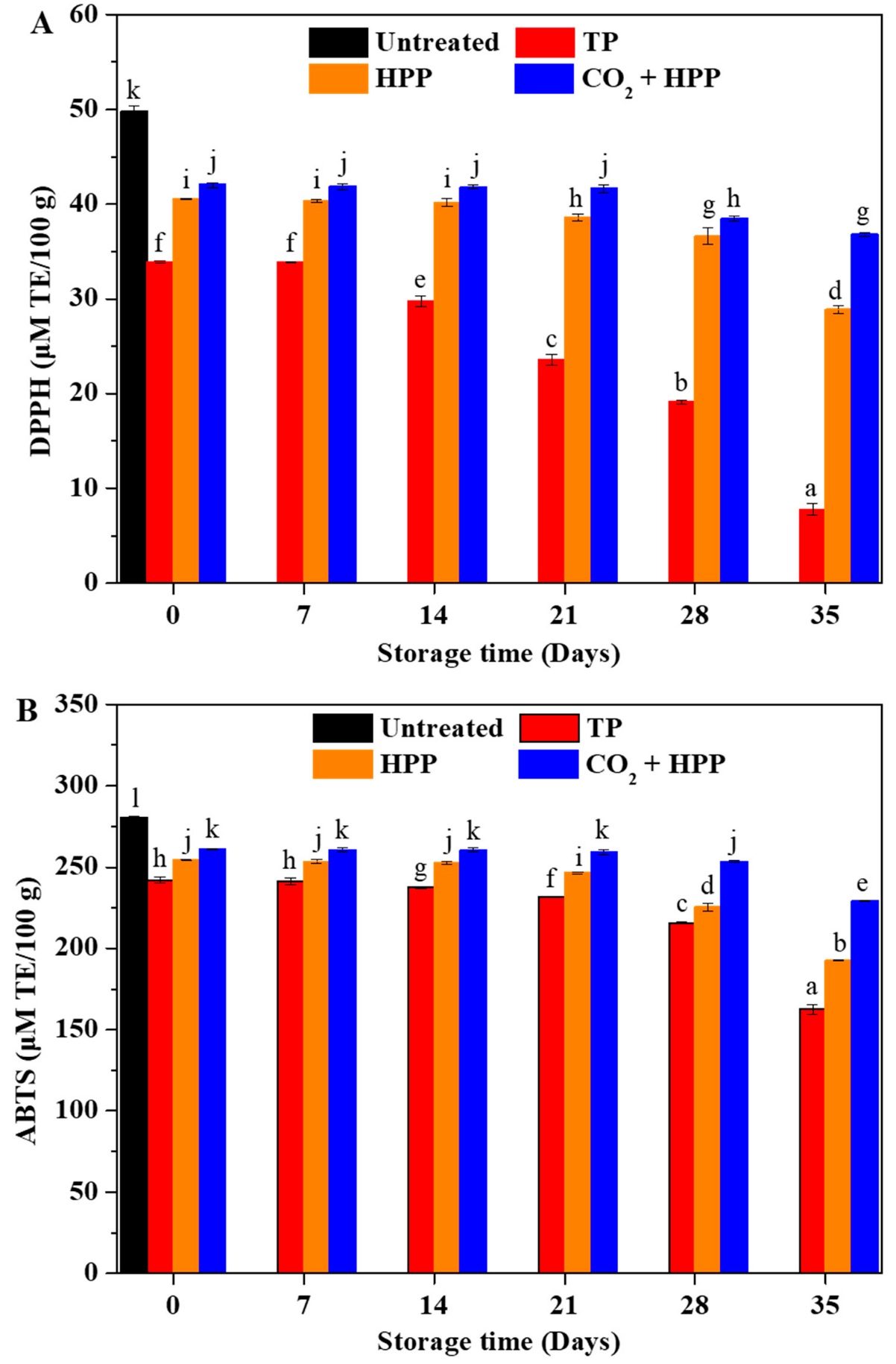

3.6. Influence of Different Treatments on Antioxidant Ability of DFP

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohd Ali, M.; Hashim, N.; Aziz, S.A.; Lasekan, O. Exploring the chemical composition, emerging applications, potential uses, and health benefits of durian: A review. Food Control 2020, 113, 107189. [Google Scholar] [CrossRef]

- Manshor, M.R.; Anuar, H.; Nur Aimi, M.N.; Ahmad Fitrie, M.I.; Wan Nazri, W.B.; Sapuan, S.M.; El-Shekeil, Y.A.; Wahit, M.U. Mechanical, thermal and morphological properties of durian skin fibre reinforced PLA biocomposites. Mater. Des. 2014, 59, 279–286. [Google Scholar] [CrossRef]

- Ho, L.H.; Bhat, R. Exploring the potential nutraceutical values of durian (Durio zibethinus L.)—An exotic tropical fruit. Food Chem. 2015, 168, 80–89. [Google Scholar] [CrossRef]

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45. [Google Scholar] [CrossRef]

- Soni, A.; Smith, J.; Thompson, A.; Brightwell, G. Microwave-induced thermal sterilization—A review on history, technical progress, advantages and challenges as compared to the conventional methods. Trends Food Sci. Technol. 2020, 97, 433–442. [Google Scholar] [CrossRef]

- Jiménez-Sánchez, C.; Lozano-Sánchez, J.; Segura-Carretero, A.; Fernández-Gutiérrez, A. Alternatives to conventional thermal treatments in fruit-juice processing. Part 1: Techniques and applications. Crit. Rev. Food Sci. 2017, 57, 501–523. [Google Scholar] [CrossRef]

- Yi, J.; Kebede, B.T.; Hai Dang, D.N.; Buvé, C.; Grauwet, T.; Van Loey, A.; Hu, X.; Hendrickx, M. Quality change during high pressure processing and thermal processing of cloudy apple juice. LWT-Food Sci. Technol. 2017, 75, 85–92. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, L.; Pan, X.; Lao, F.; Liao, X.; Wu, J. Alterations of phenolic compounds in red raspberry juice induced by high-hydrostatic-pressure and high-temperature short-time processing. Innov. Food Sci. Emerg. 2021, 67, 102569. [Google Scholar] [CrossRef]

- Xu, X.; Deng, J.; Luo, D.; Bao, Y.; Liao, X.; Gao, H.; Wu, J. Comparative study of high hydrostatic pressure and high temperature short time processing on quality of clear and cloudy Se-enriched kiwifruit juices. Innov. Food Sci. Emerg. Technol. 2018, 49, 1–12. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Wang, Y.; Zhao, F.; Sun, Z.; Liao, X. Quality comparison of carrot juices processed by high-pressure processing and high-temperature short-time processing. Innov. Food Sci. Emerg. Technol. 2016, 33, 135–144. [Google Scholar] [CrossRef]

- Wu, W.; Xiao, G.; Yu, Y.; Xu, Y.; Wu, J.; Peng, J.; Li, L. Effects of high pressure and thermal processing on quality properties and volatile compounds of pineapple fruit juice. Food Control 2021, 130, 108293. [Google Scholar] [CrossRef]

- del Rosario García-Mateos, M.; Quiroz-González, B.; Corrales-García, J.; Ybarra-Moncada, M.C.; Leyva-Ruelas, G. Ozone-high hydrostatic pressure synergy for the stabilization of refrigerated pitaya (Stenocereus pruinosus) juice. Innov. Food Sci. Emerg. Technol. 2019, 56, 102187. [Google Scholar] [CrossRef]

- Duong, T.; Balaban, M.; Perera, C.; Bi, X. Microbial and sensory rffects of combined high hydrostatic pressure and dense phase carbon dioxide process on feijoa puree. J. Food Sci. 2015, 80, E2478–E2485. [Google Scholar] [CrossRef]

- Zhao, L.; Qin, X.; Wang, Y.; Ling, J.; Shi, W.; Pang, S.; Liao, X. CO2-assisted high pressure processing on inactivation of Escherichia coli and Staphylococcus aureus. J. CO2 Util. 2017, 22, 53–62. [Google Scholar] [CrossRef]

- Duong, T.; Balaban, M.; Perera, C. Effects of combined high hydrostatic pressure and dense phase carbon dioxide on the activity, structure and size of polyphenoloxidase. J. Food Sci. 2015, 80, E2486–E2494. [Google Scholar] [CrossRef] [PubMed]

- Wen, J.; Ma, L.; Xu, Y.; Wu, J.; Yu, Y.; Peng, J.; Tang, D.; Zou, B.; Li, L. Effects of probiotic litchi juice on immunomodulatory function and gut microbiota in mice. Food Res. Int. 2020, 137, 109433. [Google Scholar] [CrossRef]

- Wisutiamonkul, A.; Promdang, S.; Ketsa, S.; van Doorn, W.G. Carotenoids in durian fruit pulp during growth and postharvest ripening. Food Chem. 2015, 180, 301–305. [Google Scholar] [CrossRef]

- Zou, Y.; Yu, Y.; Cheng, L.; Li, L.; Zou, B.; Wu, J.; Zhou, W.; Li, J.; Xu, Y. Effects of curcumin-based photodynamic treatment on quality attributes of fresh-cut pineapple. LWT-Food Sci. Technol. 2021, 141, 110902. [Google Scholar] [CrossRef]

- Tan, P.; Ng, S.; Tan, T.; Chong, G.; Tan, C. Shelf life determination of durian (Durio zibethinus) paste and pulp upon highpressure processing. Food Res. 2018, 3, 221–230. [Google Scholar] [CrossRef]

- Wang, L.; Pan, J.; Xie, H.; Yang, Y.; Lin, C. Inactivation of Staphylococcus aureus and Escherichia coli by the synergistic action of high hydrostatic pressure and dissolved CO2. Int. J. Food Microbiol. 2010, 144, 118–125. [Google Scholar] [CrossRef]

- Peñas, E.; Frias, J.; Gómez, R.R.; Vidal-Valverde, C. High hydrostatic pressure can improve the microbial quality of sauerkraut during storage. Food Control 2010, 21, 524–528. [Google Scholar] [CrossRef]

- Li, W.; Pan, J.; Xie, H.; Yang, Y.; Zhou, D.; Zhu, Z. Pasteurization of fruit juices of different pH values by combined high hydrostatic pressure and carbon dioxide. J. Food Prot. 2012, 75, 1873–1877. [Google Scholar]

- Mukhopadhyay, S.; Sokorai, K.; Ukuku, D.; Fan, X.; Juneja, V. Effect of high hydrostatic pressure processing on the background microbial loads and quality of cantaloupe puree. Food Res. Int. 2017, 91, 55–62. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Zhang, X.; Zhao, L.; Wang, Y.; Liao, X. Potential of high-pressure processing and high-temperature/short-time thermal processing on microbial, physicochemical and sensory assurance of clear cucumber juice. Innov. Food Sci. Emerg. Technol. 2016, 34, 51–58. [Google Scholar] [CrossRef]

- Ma, X.J.; Gao, J.Y.; Tong, P.; Li, X.; Chen, H.B. Tracking the behavior of Maillard browning in lysine/arginine–sugar model systems under high hydrostatic pressure. J. Sci. Food Agric. 2017, 97, 5168–5175. [Google Scholar] [CrossRef]

- Elizondo-Montemayor, L.; Hernández-Brenes, C.; Ramos-Parra, P.A.; Moreno-Sánchez, D.; Nieblas, B.; Rosas-Pérez, A.M.; Lamadrid-Zertuche, A.C. High hydrostatic pressure processing reduces the glycemic index of fresh mango puree in healthy subjects. Food Funct. 2015, 6, 1352–1360. [Google Scholar] [CrossRef]

- Puente-Díaz, L.; Spolmann, O.; Nocetti, D.; Zura-Bravo, L.; Lemus-Mondaca, R. Effects of infrared-assisted refractance window™ drying on the drying kinetics, microstructure, and color of physalis fruit purée. Foods 2020, 9, 343. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, Y.; Li, Z.; Xie, X.; Gong, E.S.; Tian, J.; Si, X.; Wang, Y.; Gao, N.; Shu, C.; et al. Effects of high hydrostatic pressure and thermal processing on anthocyanin content, polyphenol oxidase and β-glucosidase activities, color, and antioxidant activities of blueberry (Vaccinium Spp.) puree. Food Chem. 2021, 342, 128564. [Google Scholar] [CrossRef]

- Zhou, L.; Bi, X.; Xu, Z.; Yang, Y.; Liao, X. Effects of high-pressure CO2 processing on flavor, texture, and color of foods. Crit. Rev. Food Sci. 2015, 55, 750–768. [Google Scholar] [CrossRef]

- Usmani, Z.; Sharma, M.; Sudheer, S.; Gupta, V.K.; Bhat, R. Engineered microbes for pigment production using waste biomass. Curr. Genom. 2020, 21, 80–95. [Google Scholar] [CrossRef]

- Klug, T.V.; Martínez-Sánchez, A.; Gómez, P.A.; Collado, E.; Aguayo, E.; Artés, F.; Artés-Hernández, F. Improving quality of an innovative pea puree by high hydrostatic pressure. J. Sci. Food Agric. 2017, 97, 4362–4369. [Google Scholar] [CrossRef] [PubMed]

- Ollé, D.; Baron, A.; Lozano, Y.F.; Brillouet, J.M. Enzymatic degradation of cell wall polysaccharides from mango (Mangifera indica L.) puree. J. Agric. Food Chem. 2000, 48, 2713–2716. [Google Scholar] [CrossRef]

- Bhat, B.; Bajaj, B.K. Hypocholesterolemic and bioactive potential of exopolysaccharide from a probiotic Enterococcus faecium K1 isolated from kalarei. Bioresour. Technol. 2018, 254, 264–267. [Google Scholar] [CrossRef] [PubMed]

- Lima, M.C.; Paiva de Sousa, C.; Fernandez-Prada, C.; Harel, J.; Dubreuil, J.D.; de Souza, E.L. A review of the current evidence of fruit phenolic compounds as potential antimicrobials against pathogenic bacteria. Microb. Pathog. 2019, 130, 259–270. [Google Scholar] [CrossRef]

- Patras, A.; Brunton, N.; Da Pieve, S.; Butler, F.; Downey, G. Effect of thermal and high pressure processing on antioxidant activity and instrumental colour of tomato and carrot purées. Innov. Food Sci. Emerg. Technol. 2009, 10, 16–22. [Google Scholar] [CrossRef]

- Wang, F.; Du, B.L.; Cui, Z.W.; Xu, L.P.; Li, C.Y. Effects of high hydrostatic pressure and thermal processing on bioactive compounds, antioxidant activity, and volatile profile of mulberry juice. Food Sci. Technol. Int. 2017, 23, 119–127. [Google Scholar] [CrossRef]

- Hurtado, A.; Guàrdia, M.D.; Picouet, P.; Jofré, A.; Bañón, S.; Ros, J.M. Shelf-life extension of multi-vegetables smoothies by high pressure processing compared with thermal treatment. Part II: Retention of selected nutrients and sensory quality. J. Food Process. Preserv. 2019, 43, e14210. [Google Scholar] [CrossRef]

- Polydera, A.C.; Stoforos, N.G.; Taoukis, P.S. Comparative shelf life study and vitamin C loss kinetics in pasteurised and high pressure processed reconstituted orange juice. J. Food Eng. 2003, 60, 21–29. [Google Scholar] [CrossRef]

- Swami Hulle, N.R.; Srinivasa Rao, P. Effect of high pressure and thermal processing on quality changes of aloe vera-litchi mixed beverage (ALMB) during storage. J. Food Sci. Tech. 2016, 53, 359–369. [Google Scholar] [CrossRef][Green Version]

- González-Cebrino, F.; García-Parra, J.; Contador, R.; Tabla, R.; Ramírez, R. Effect of high-pressure processing and thermal treatment on quality attributes and nutritional compounds of “Songold” plum purée. J. Food Sci. 2012, 77, C866–C873. [Google Scholar] [CrossRef]

- Silva, K.D.R.R.; Sirasa, M.S.F. Antioxidant properties of selected fruit cultivars grown in Sri Lanka. Food Chem. 2018, 238, 203–208. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, A.; Farid, M.; Silva, F.V.M. Strawberry puree processed by thermal, high pressure, or power ultrasound: Process energy requirements and quality modeling during storage. Food Sci. Technol. Int. 2016, 23, 293–309. [Google Scholar] [CrossRef] [PubMed]

| Treatments | Storage Time (Days) | pH | Total Soluble Solid (°Brix) | Sugar Component (g/kg) | Color Parameter | |||

|---|---|---|---|---|---|---|---|---|

| Fructose | Glucose | Sucrose | L | b | ||||

| Untreated | 0 | 6.82 ± 0.02 i | 9.01 ± 0.03 c | 9.42 ± 0.02 l | 8.47 ± 0.10 k | 7.97 ± 0.18 a | 69.98 ± 0.27 j | 20.38 ± 0.27 h |

| TP | 0 | 6.57 ± 0.02 g | 9.86 ± 0.04 gh | 5.65 ± 0.06 e | 4.64 ± 0.06 e | 39.19 ± 1.58 g | 61.19 ± 0.14 g | 15.41 ± 0.26 e |

| 7 | 6.56 ± 0.01 g | 9.85 ± 0.04 g | 5.53 ± 0.11 e | 4.62 ± 0.01 e | 38.49 ± 0.12 g | 60.92 ± 0.36 g | 15.36 ± 0.23 e | |

| 14 | 6.36 ± 0.01 f | 9.71 ± 0.04 f | 5.30 ± 0.04 cd | 4.41 ± 0.01 d | 36.01 ± 0.11 f | 59.79 ± 0.16 f | 14.29 ± 0.18 d | |

| 21 | 6.15 ± 0.04 e | 9.48 ± 0.04 e | 5.11 ± 0.03 c | 4.20 ± 0.05 c | 32.67 ± 0.89 e | 58.84 ± 0.28 e | 13.56 ± 0.20 c | |

| 28 | 5.86 ± 0.05 d | 9.05 ± 0.05 c | 4.69 ± 0.07 b | 3.88 ± 0.12 b | 22.41 ± 3.78 c | 56.82 ± 0.20 c | 12.85 ± 0.14 b | |

| 35 | 5.57 ± 0.02 a | 8.10 ± 0.01 a | 3.74 ± 0.10 a | 3.12 ± 0.15 a | 7.51 ± 0.10 a | 52.81 ± 0.33 a | 12.23 ± 0.10 a | |

| HPP | 0 | 6.64 ± 0.01 h | 9.99 ± 0.08 j | 7.19 ± 0.14 h | 5.15 ± 0.03 g | 34.80 ± 1.62 ef | 62.85 ± 0.49 hi | 16.40 ± 0.31 f |

| 7 | 6.63 ± 0.01 h | 9.94 ± 0.04 hij | 7.09 ± 0.09 h | 5.09 ± 0.08 g | 33.08 ± 0.90 e | 62.43 ± 0.61 h | 16.36 ± 0.33 f | |

| 14 | 6.63 ± 0.01 h | 9.93 ± 0.03 ghij | 7.01 ± 0.20 h | 5.06 ± 0.10 g | 32.81 ± 0.94 e | 62.23 ± 0.53 h | 16.16 ± 0.25 f | |

| 21 | 6.54 ± 0.01 g | 9.72 ± 0.03 f | 6.65 ± 0.10 g | 4.85 ± 0.02 f | 28.53 ± 0.20 d | 60.61 ± 0.05 g | 15.33 ± 0.17 e | |

| 28 | 6.12 ± 0.01 e | 9.30 ± 0.04 d | 6.17 ± 0.08 f | 4.67 ± 0.01 e | 22.01 ± 0.91 c | 58.20 ± 0.13 d | 14.55 ± 0.25 d | |

| 35 | 5.76 ± 0.03 c | 8.56 ± 0.04 b | 5.46 ± 0.03 de | 4.35 ± 0.02 cd | 15.12 ± 0.19 b | 55.66 ± 0.14 b | 13.18 ± 0.45 bc | |

| CO2 + HPP | 0 | 5.86 ± 0.01 d | 9.95 ± 0.04 ij | 9.18 ± 0.01 k | 7.75 ± 0.16 j | 35.02 ± 1.12 ef | 63.45 ± 0.73 i | 17.23 ± 0.13 g |

| 7 | 5.85 ± 0.01 d | 9.90 ± 0.07 ghij | 9.17 ± 0.15 k | 7.73 ± 0.21 j | 33.43 ± 1.22 e | 62.90 ± 0.35 hi | 17.13 ± 0.20 g | |

| 14 | 5.84 ± 0.04 d | 9.88 ± 0.08 ghi | 9.10 ± 0.20 k | 7.61 ± 0.20 j | 33.22 ± 1.40 e | 62.80 ± 0.20 h | 17.06 ± 0.08 g | |

| 21 | 5.83 ± 0.02 d | 9.89 ± 0.05 ghi | 9.07 ± 0.21 k | 7.58 ± 0.17 j | 32.73 ± 1.32 e | 62.73 ± 0.24 h | 17.04 ± 0.16 g | |

| 28 | 5.71 ± 0.01 b | 9.65 ± 0.03 f | 8.77 ± 0.02 j | 7.27 ± 0.01 i | 28.50 ± 0.43 d | 59.52 ± 0.50 f | 16.36 ± 0.32 f | |

| 35 | 5.59 ± 0.01 a | 9.27 ± 0.05 d | 8.14 ± 0.08 i | 6.61 ± 0.01 h | 21.27 ± 0.31 c | 57.61 ± 0.24 d | 15.53 ± 0.33 e | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bu, Z.; Luo, W.; Wei, J.; Peng, J.; Wu, J.; Xu, Y.; Yu, Y.; Li, L. Impacts of Thermal Processing, High Pressure, and CO2-Assisted High Pressure on Quality Characteristics and Shelf Life of Durian Fruit Puree. Foods 2022, 11, 2717. https://doi.org/10.3390/foods11172717

Bu Z, Luo W, Wei J, Peng J, Wu J, Xu Y, Yu Y, Li L. Impacts of Thermal Processing, High Pressure, and CO2-Assisted High Pressure on Quality Characteristics and Shelf Life of Durian Fruit Puree. Foods. 2022; 11(17):2717. https://doi.org/10.3390/foods11172717

Chicago/Turabian StyleBu, Zhibin, Wenshan Luo, Jiayin Wei, Jian Peng, Jijun Wu, Yujuan Xu, Yuanshan Yu, and Lu Li. 2022. "Impacts of Thermal Processing, High Pressure, and CO2-Assisted High Pressure on Quality Characteristics and Shelf Life of Durian Fruit Puree" Foods 11, no. 17: 2717. https://doi.org/10.3390/foods11172717

APA StyleBu, Z., Luo, W., Wei, J., Peng, J., Wu, J., Xu, Y., Yu, Y., & Li, L. (2022). Impacts of Thermal Processing, High Pressure, and CO2-Assisted High Pressure on Quality Characteristics and Shelf Life of Durian Fruit Puree. Foods, 11(17), 2717. https://doi.org/10.3390/foods11172717