Distribution and Quantification of Lactic Acid Enantiomers in Baijiu

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Samples

2.3. Sample Preparation

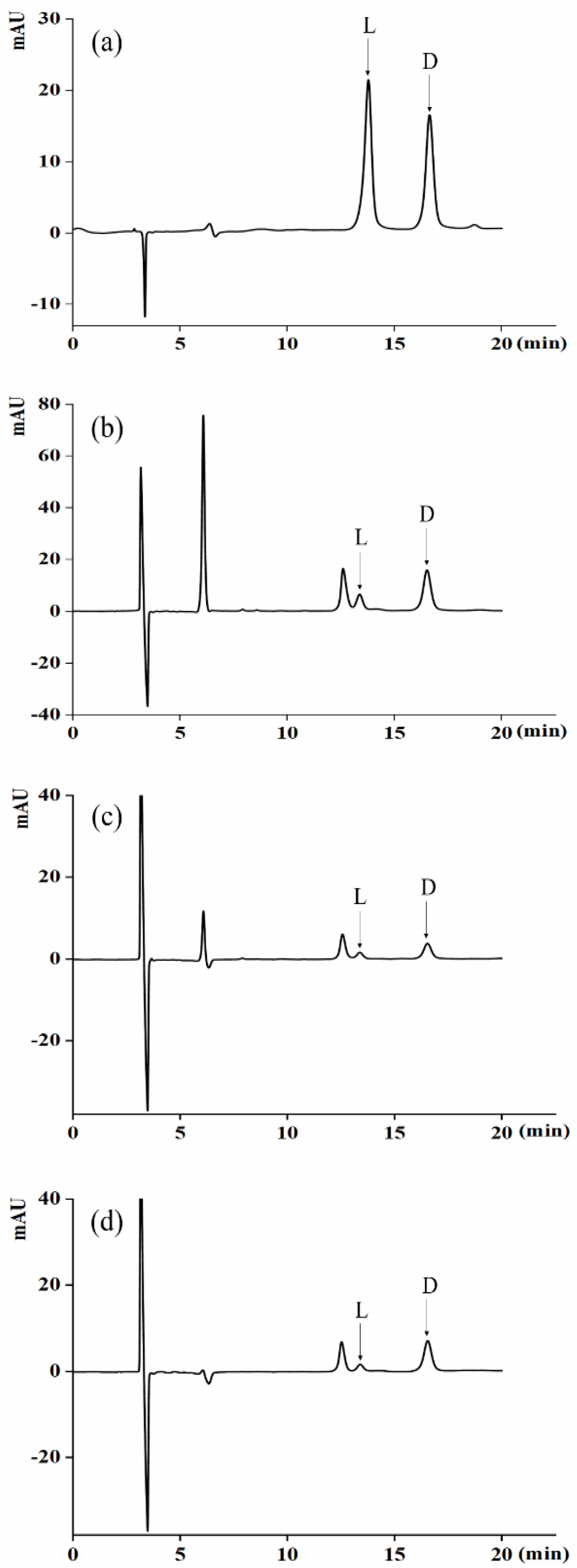

2.4. Isolation and Quantification of Lactic Acid Enantiomers by High Performance Liquid Chromatography

2.5. Recognition Thresholds

2.6. Statistical Analysis

3. Results and Discussion

3.1. Identification and Quantification of Lactic Acid Enantiomers in Chinese Baijiu by High Performance Liquid Chromatography

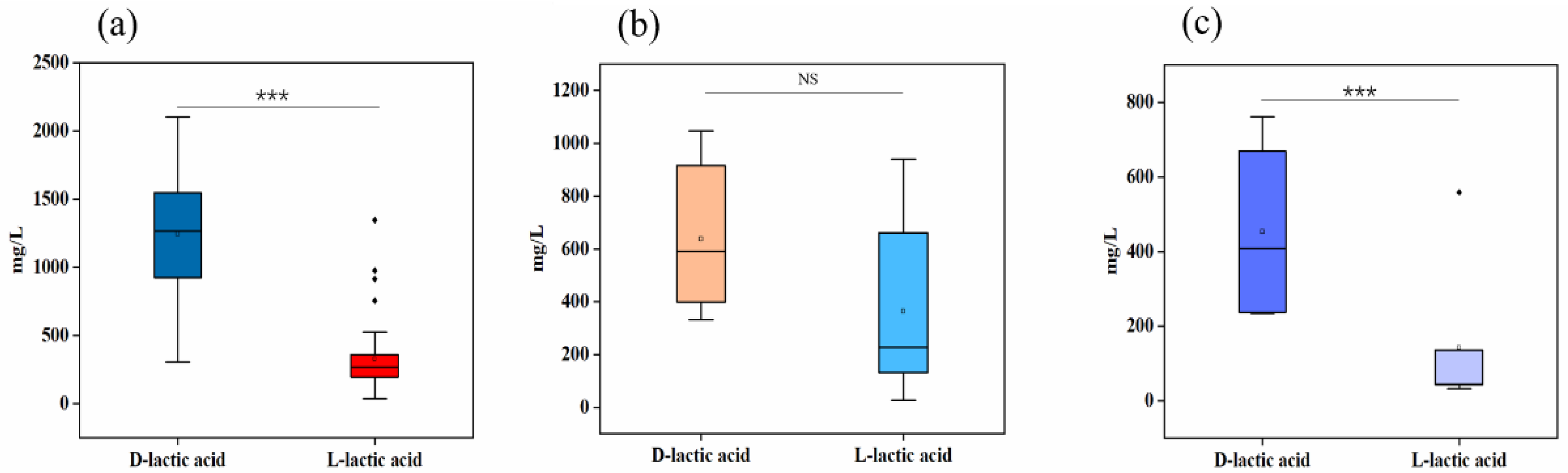

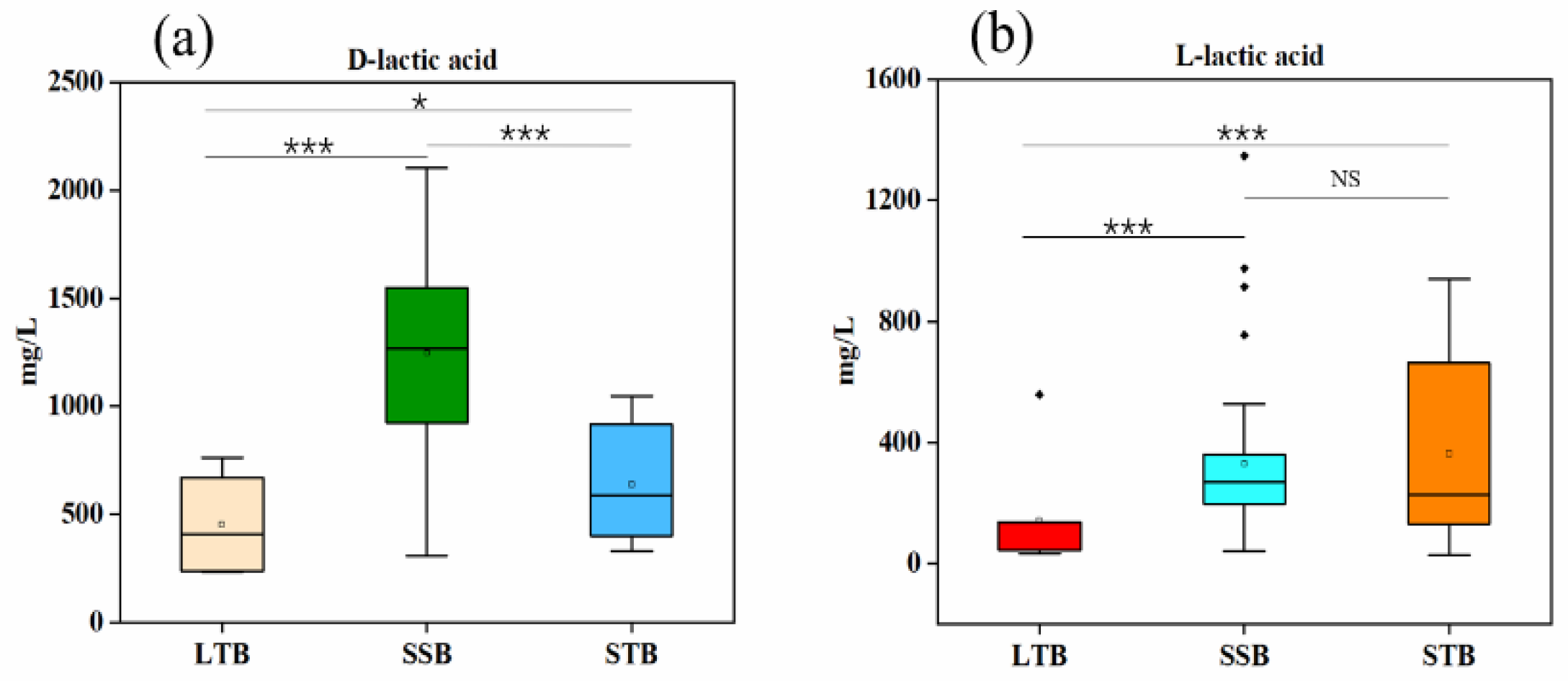

3.2. Comparison of Lactic Acid Enantiomers in Different Aromatic Baijiu

3.3. Comparison of Lactic Acid Enantiomers in Different Types of Baijiu

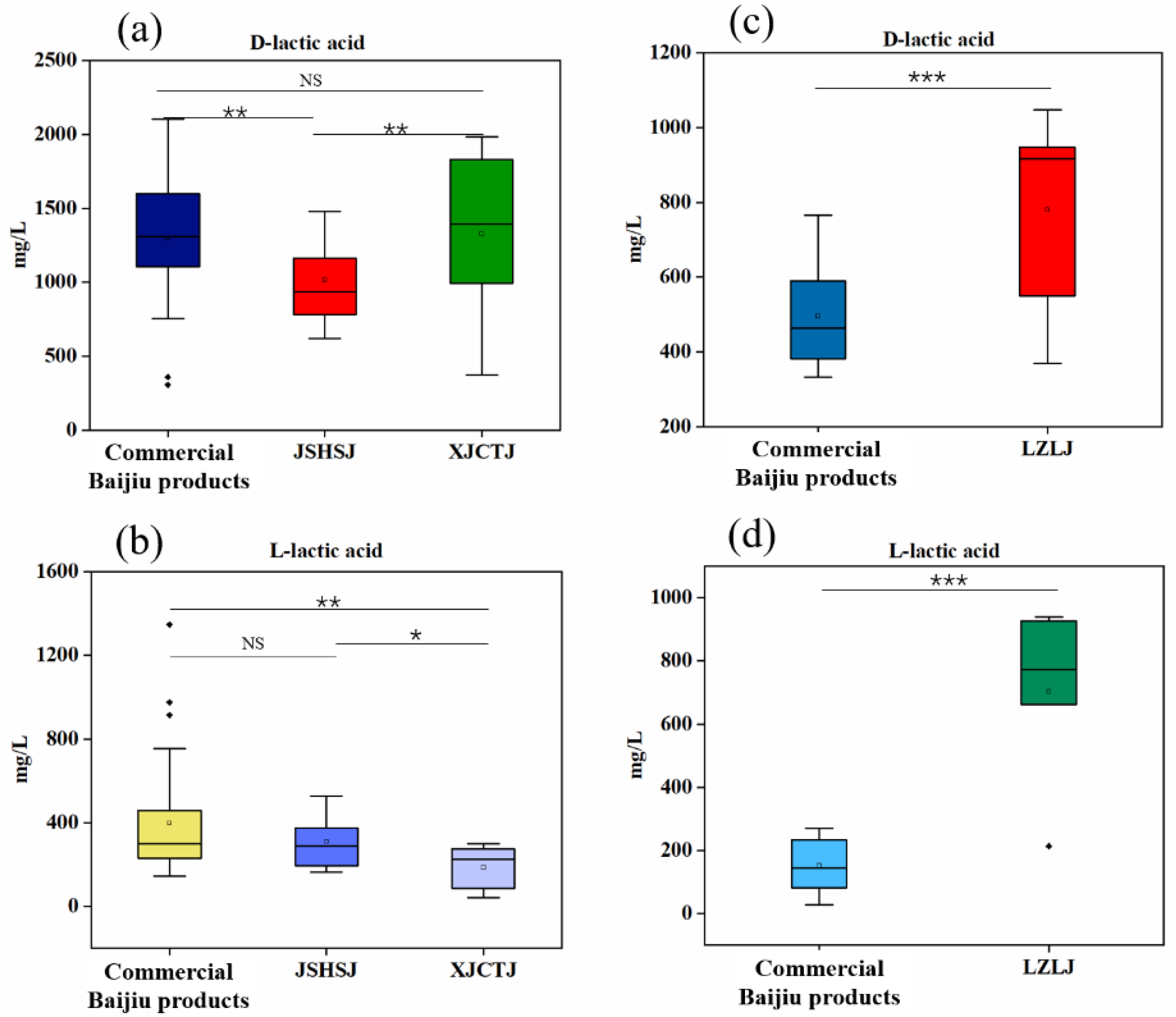

3.4. Analysis of Lactic Acid Enantiomers in Vintage Baijiu

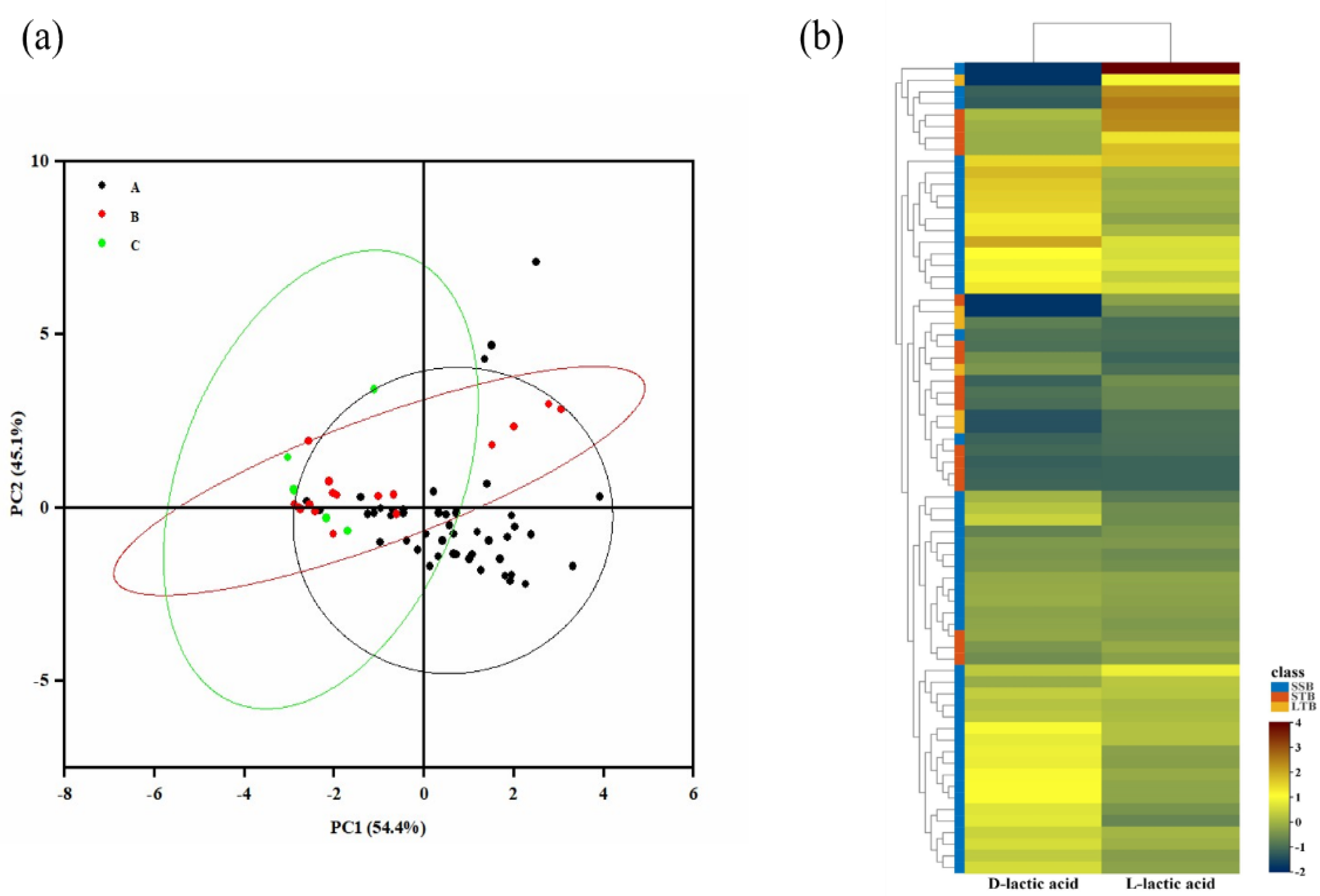

3.5. Principal Component Analysis and Heatmap Analysis of Lactic Acid Enantiomers in Baijiu

3.6. Recognition Thresholds and Taste Activity Value Analysis of Lactic Acid Isomers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, M.Y.; Yang, J.G.; Zhao, Q.S.; Zhang, K.Z.; Su, C. Research progress on flavor compounds and microorganisms of maotai flavor baijiu. J. Food Sci. 2018, 84, 6–18. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.J.; Fan, W.L.; Xu, Y. Characterization of the key odorants in light aroma type chinese liquor by gas chromatography-olfactometry, quantitative measurements, aroma recombination, and omission studies. J. Agr. Food Chem. 2014, 62, 5796–5804. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.W.; Kong, J.L.; Xiao, Z.B.; Chen, F.; Ma, N.; Zhu, J.C. Characterization of odor-active compounds of various Chinese “Wuliangye” liquors by gas chromatography-olfactometry, gas chromatography-mass spectrometry and sensory evaluation. Int. J. Food Prop. 2017, 20, S735–S745. [Google Scholar] [CrossRef]

- Niu, Y.W.; Chen, X.M.; Xiao, Z.B.; Ma, N.; Zhu, J.C. Characterization of aroma-active compounds in three Chinese Moutai liquors by gas chromatography-olfactometry, gas chromatography-mass spectrometry and sensory evaluation. Nat. Prod. Res. 2017, 31, 938–944. [Google Scholar] [CrossRef] [PubMed]

- Song, X.B.; Zhu, L.; Jing, S.; Li, Q.; Ji, J.; Zheng, F.P.; Zhao, Q.Z.; Sun, J.Y.; Chen, F.; Zhao, M.M.; et al. Insights into the role of 2-Methyl-3-furanthiol and 2-Furfurylthiol as markers for the differentiation of chinese light, strong, and soy sauce aroma types of baijiu. J. Agr. Food Chem. 2020, 68, 7946–7954. [Google Scholar] [CrossRef]

- Xu, H.; Dai, Y.F.; Qiu, S.Y.; Sun, B.G.; Zeng, X.Y. Distribution and quantification of 1,2-Propylene glycol enantiomers in baijiu. Foods 2021, 10, 3039. [Google Scholar] [CrossRef]

- John, R.P.; Nampoothiri, K.M.; Pandey, A. Fermentative production of lactic acid from biomass: An overview on process developments and future perspectives. Appl. Microbiol. Biot. 2007, 74, 524–534. [Google Scholar] [CrossRef]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Recent advances in lactic acid production by microbial fermentation processes. Biotechnol. Adv. 2013, 31, 877–902. [Google Scholar] [CrossRef]

- Vijayakumar, J.; Aravindan, R.; Viruthagiri, T. Recent trends in the production, purification and application of lactic acid. Chem. Biochem. Eng. Q. 2008, 2, 245–264. [Google Scholar]

- Pohanka, M. D-Lactic acid as a metabolite: Toxicology, diagnosis, and detection. Biomed. Res. Int. 2020, 2020, 3419034. [Google Scholar] [CrossRef]

- Ding, X.M.; Lin, S.H.; Weng, H.B.; Liang, J.Y. Separation and determination of the enantiomers of lactic acid and 2-hydroxyglutaric acid by chiral derivatization combinedwith gas chromatography and mass spectrometry. J. Sep. Sci. 2018, 41, 2576–2584. [Google Scholar] [CrossRef] [PubMed]

- Huang, T.; Qi, H.; Zhang, S.H.; Ren, L.; Zhai, Q.H.; Zhu, R.X.; Guo, L.; Zhang, Z.B. Study on the changing law of acetic acid and lactic acid in Xifeng liquor daqu and fermented grains. Brewing 2021, 48, 45–49. [Google Scholar]

- Wang, M.H. Determination of lactic acid and acetic acid in different aromatic Baijiu by ultra performance liquid chromatography. J. Food Saf. 2021, 75–76. [Google Scholar] [CrossRef]

- Zhuang, J.Y.; Fang, Y.F.; Hou, Z.Z.; Zhou, F.M. Study on the pretreatment and determination methods of lactic acid in chi-flavor chinese spirits. Food Ind. 2017, 38, 291–294. [Google Scholar]

- Yang, F.; Zhang, Q.L.; Liu, Y.F.; Li, J.H.; Wang, L.; Chen, J. Lactic acid biosynthesis pathways and important genes of Lactobacillus panis L7 isolated from the Chinese liquor brewing microbiome. Food Biosci. 2020, 36, 100627. [Google Scholar] [CrossRef]

- Chen, Q.; Luo, Z.; Liao, Q.J.; Li, Y.H.; An, M.Z. Detection and Analytical Method of Lactic Acid in Baijiu; Brewing Science and Technology: Guiyang, China, 2021; pp. 115–118. [Google Scholar]

- Yin, X.; Yoshizaki, Y.; Kurazono, S.; Sugimachi, M.; Takeuchi, H.; Han, X.; Okutsu, K.; Futagami, T.; Tamaki, H.; Takamine, K. Characterization of Flavor Compounds in Rice-flavor Baijiu, a Traditional Chinese Distilled Liquor, Compared with Japanese Distilled Liquors, awamori and kome-shochu. Food Sci. Technol. Res. 2020, 26, 411–422. [Google Scholar] [CrossRef]

- Sun, J.Y.; Li, Q.Y.; Luo, S.Q.; Zhang, J.L.; Huang, M.Q.; Chen, F.; Zheng, F.P.; Sun, S.T.; Li, H.H. Characterization of key aroma compounds in Meilanchun sesame flavor style Baijiu by application of aroma extract dilution analysis, quantitative measurements, aroma recombination, and omission/addition experiments. Rsc. Adv. 2018, 8, 23757–23767. [Google Scholar] [CrossRef]

- Kodama, S.; Yamamoto, A.; Matsunaga, A.; Matsui, K.; Nakagomi, K.; Hayakawa, K. Behaviors of d-and l-Lactic Acids during the Brewing Process of Sake (Japanese Rice Wine). J. Agr. Food Chem. 2002, 50, 767–770. [Google Scholar] [CrossRef]

- Buglass, A.J.; Lee, S.H. Sequential analysis of malic acid and both enantiomers of lactic acid in wine using a high-performance liquid chromatographic column-switching procedure. J. Chromatogr. Sci. 2001, 39, 453–458. [Google Scholar] [CrossRef][Green Version]

- Buglass, A.J.; Lee, S.H. Elimination of amino acid interferences in the chiral ligand-exchange chromatographic analysis of lactic acid enantiomers in wine. J. Chromatogr. Sci. 2000, 38, 207–210. [Google Scholar] [CrossRef][Green Version]

- Jiang, F.; Zhao, Z.Y.; Nie, Y.; Li, Q.L.; Liu, S.; Wang, H.Y. Chiral Separation and Determination of l- and d-Lactic Acid in Baijiu by High-Performance Liquid Chromatography; Brewing Science and Technology: Guiyang, China, 2019; pp. 93–97. [Google Scholar]

- Liu, D.M.; Wu, H.; Yu, Y.G.; Li, X.F.; Guo, W.J.; Zeng, W.J. Chiral separation and determination of l-lactic acid and d-lactic acid in Pickles by high performance liquid chromatography. Mod. Food Sci. Technol. 2007, 23, 74–76. [Google Scholar] [CrossRef]

- Nanjo, Y.; Yano, T.; Hayashi, R.; Yao, T. Optically specific detection of D- and L-lactic acids by a flow-injection dual biosensor system with on-line microdialysis sampling. Anal. Sci. 2006, 22, 1135–1138. [Google Scholar] [CrossRef] [PubMed][Green Version]

- National Standard of the People’s Republic of China. GB/T 33406-2016. Guidelines for Determination of Liquor Flavor Substances Threshold. China Standards Press: Beijing, China, 2016. [Google Scholar]

- National Standard of the People’s Republic of China. GB/T 22366-2008. Sensory Analysis-Methodology-General Guidance for Measuring Odour, Flavour and Taste Detection Thresholds by a Three-Alternative Forced-Choice (3-AFC) Procedure. China Standards Press: Beijing, China, 2008. [Google Scholar]

- Wang, L.H.; Zhu, L.; Zheng, F.P.; Zhang, F.G.; Shen, C.H.; Gao, X.J.; Sun, B.G.; Huang, M.Q.; Li, H.H.; Chen, F. Determination and comparison of flavor (retronasal) threshold values of 19 flavor compounds in Baijiu. J. Food Sci. 2021, 86, 2061–2074. [Google Scholar] [CrossRef] [PubMed]

- National Standard of the People’s Republic of China. GB 2023-2003. Food Additive-Lactic Acid. China Standards Press: Beijing, China, 2003. [Google Scholar]

- Zheng, X.W.; Han, B.Z. Baijiu, Chinese liquor: History, classification and manufacture. J. Ethn. Foods 2016, 3, 19–25. [Google Scholar] [CrossRef]

- Song, X.B.; Wang, G.N.; Zhu, L.; Zheng, F.P.; Ji, J.; Sun, J.Y.; Li, H.H.; Huang, M.Q.; Zhao, Q.Z.; Zhao, M.M.; et al. Comparison of two cooked vegetable aroma compounds, dimethyl disulfide and methional, in Chinese Baijiu by a sensory-guided approach and chemometrics. LWT 2021, 146, 111427. [Google Scholar] [CrossRef]

- Jin, G.Y.; Zhu, Y.; Xu, Y. Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 2017, 63, 18–28. [Google Scholar] [CrossRef]

- Huang, S.; Xue, Y.; Yu, B.; Wang, L.; Zhou, C.; Ma, Y. A review of the recent developments in the bioproduction of polylactic acid and its precursors optically pure lactic acids. Molecules 2021, 26, 6446. [Google Scholar] [CrossRef]

- Pang, X.N.; Chen, C.; Huang, X.N.; Yan, Y.Z.; Chen, J.Y.; Han, B.Z. Influence of indigenous lactic acid bacteria on the volatile flavor profile of light-flavor Baijiu. LWT 2021, 147, 111540. [Google Scholar] [CrossRef]

- Clément, H.; Prost, C.; Chiron, H.; Ducasse, M.B.; Della Valle, G.; Courcoux, P.; Onno, B. The effect of organic wheat flour by-products on sourdough performances assessed by a multi-criteria approach. Food Res. Int. 2018, 106, 974–981. [Google Scholar] [CrossRef]

- Wang, S.; Wu, Q.; Nie, Y.; Wu, J.; Xu, Y. Construction of synthetic microbiota for reproducible flavor compound metabolism in chinese Light-Aroma-Type liquor produced by Solid-State fermentation. Appl. Environ. Microbiol. 2019, 85, e03090-18. [Google Scholar] [CrossRef]

- Kuanyshev, N.; Ami, D.; Signori, L.; Porro, D.; Morrissey, J.P.; Branduardi, P. Assessing physio-macromolecular effects of lactic acid on Zygosaccharomyces bailiicells during microaerobic fermentation. FEMS Yeast Res. 2016, 16, fow058. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Du, H.; Zhang, Y.; Xu, Y. Unraveling core functional microbiota in traditional Solid-State fermentation by High-Throughput amplicons and metatranscriptomics sequencing. Front. Microbiol. 2017, 8, 1294. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Sugimachi, M.; Yoshizaki, Y.; Yin, X.; Han, X.L.; Okutsu, K.; Futagami, T.; Tamaki, H.; Takamine, K. Correlation between key aroma and manufacturing processes of rice-flavor baijiu and awamori, Chinese and Japanese traditional liquors. Food Biosci. 2021, 44, 101375. [Google Scholar] [CrossRef]

- Hang, Y.D. Direct fermentation of corn to l(+)-lactic acid by Rhizopus oryzae. Biotechnol. Lett. 1989, 11, 299–300. [Google Scholar] [CrossRef]

- Yanez, R.; Moldes, A.B.; Alonso, J.L.; Parajo, J.C. Production of D(-)-lactic acid from cellulose by simultaneous saccharification and fermentation using Lactobacillus coryniformis subsp. Torquens. Biotechnol. Lett. 2003, 25, 1161–1164. [Google Scholar] [CrossRef]

- Blandine, N.C.; Quentin, S.; Lauriane, S.; Nicolas, D.; Thierry, B.; Pierre, W.; Denis, D.; Axel, M. How stereochemistry influences the taste of wine isolation, characterization and sensory evaluation of lyoniresinol stereoisomers. Anal. Chim. Acta 2015, 888, 191–198. [Google Scholar]

- Lytra, G.; Tempere, S.; de Revel, G.; Barbe, J. Distribution and organoleptic impact of ethyl 2-Methylbutanoate enantiomers in wine. J. Agr. Food Chem. 2014, 62, 5005–5010. [Google Scholar] [CrossRef]

- Gammacurta, M.; Tempere, S.; Marchand, S.; Moine, V.; De Revel, G. Ethyl 2-hydroxy-3-methylbutanoate enantiomers: Quantitation and sensory evaluation in wine. OENO One 2018, 52, 57–65. [Google Scholar] [CrossRef]

| No. | Compounds | Linearity (mg/L) | R2 | RSD (%) | Recovery Rate (%) | LOD (mg/L) |

|---|---|---|---|---|---|---|

| 1 | D-lactic acid | 20–800 | 0.9997 | 0.53–1.45% | 94.78–106.99% | 1.594 |

| 2 | L-lactic acid | 20–800 | 0.9985 | 2.03–4.16% | 94.16–101.90% | 1.188 |

| Sample | D-Lactic Acid (mg/L) | L-Lactic Acid (mg/L) | ee | D:L |

|---|---|---|---|---|

| SSB (soy sauce aroma-type Baijiu) | ||||

| LM | 1545.93 ± 22.83 | 244.83 ± 1.62 | 72.66% | 86:14 |

| JSHSJ1 | 756.08 ± 2.39 | 144.92 ± 1.78 | 67.83% | 84:16 |

| JSHSJ2 | 857.13 ± 2.11 | 219.10 ± 3.98 | 59.28% | 80:20 |

| JSJ | 1119.18 ± 7.23 | 153.90 ± 5.21 | 75.82% | 88:12 |

| ZJ1 | 1855.91 ± 3.03 | 295.78 ± 3.96 | 72.51% | 86:14 |

| ZJ2 | 2103.84 ± 5.79 | 473.05 ± 6.93 | 63.29% | 82:18 |

| DYT1 | 1173.98 ± 19.78 | 220.02 ± 4.37 | 68.43% | 84:16 |

| DYT2 | 1598.53 ± 4.65 | 405.37 ± 6.25 | 59.54% | 80:20 |

| GT1 | 1234.13 ± 9.05 | 303.94 ± 7.34 | 60.48% | 80:20 |

| GT2 | 1193.68 ± 7.89 | 359.96 ± 13.14 | 53.66% | 77:23 |

| GT3 | 1104.49 ± 4.86 | 318.02 ± 1.80 | 55.29% | 78:22 |

| XJYZ | 1232.18 ± 5.16 | 150.60 ± 7.87 | 78.22% | 89:11 |

| QHL | 1567.41 ± 24.85 | 457.44 ± 8.86 | 54.82% | 77:23 |

| MT43 | 1673.00 ± 9.16 | 238.07 ± 4.20 | 75.08% | 88:12 |

| MT53 | 1700.58 ± 5.81 | 318.85 ± 1.61 | 68.42% | 84:16 |

| XJ1988 | 1308.86 ± 2.21 | 287.37 ± 0.89 | 63.99% | 82:18 |

| QJ1H1 | 1525.75 ± 5.11 | 351.01 ± 2.72 | 62.59% | 81:19 |

| DYT3 | 1452.59 ± 8.58 | 229.17 ± 0.38 | 72.75% | 86:14 |

| MTWZJ | 1529.40 ± 3.69 | 267.83 ± 3.66 | 70.20% | 85:15 |

| LJ | 1803.99 ± 6.59 | 755.38 ± 1.17 | 40.97% | 70:30 |

| MTCX | 359.08 ± 1.13 | 914.22 ± 1.01 | 43.60% | 28:72 |

| QJ1H2 | 1698.16 ± 28.78 | 471.82 ± 19.2 | 56.51% | 78:22 |

| TCSP | 306.75 ± 6.11 | 975.31 ± 14.03 | 52.15% | 24:76 |

| GZJSJ1 | 880.63 ± 2.28 | 196.79 ± 4.16 | 64.86% | 82:18 |

| GZJSJ2 | 923.32 ± 5.81 | 236.53 ± 2.86 | 69.93% | 85:15 |

| JSHSJ39 | 1162.00 ± 7.21 | 525.74 ± 6.90 | 37.70% | 69:31 |

| JSHSJ34 | 936.50 ± 4.53 | 373.89 ± 0.32 | 42.93% | 71:29 |

| JSHSJ23 | 1480.00 ± 7.78 | 485.68 ± 1.41 | 50.58% | 75:25 |

| JSHSJ17 | 1420.00 ± 9.90 | 350.79 ± 1.47 | 60.38% | 80:20 |

| JSHSJ15 | 1153.50 ± 6.79 | 331.12 ± 1.09 | 55.39% | 77:23 |

| JSHSJ9 | 620.00 ± 6.36 | 181.60 ± 0.91 | 54.69% | 76:24 |

| JSHSJ6 | 776.50 ± 8.77 | 194.01 ± 0.71 | 60.02% | 79:21 |

| JSHSJ5 | 934.50 ± 4.10 | 232.13 ± 1.09 | 60.20% | 80:20 |

| JSHSJ4 | 902.50 ± 9.90 | 245.38 ± 0.11 | 57.25% | 78:22 |

| JSHSJ3 | 781.25 ± 0.78 | 163.13 ± 0.68 | 65.45% | 83:17 |

| XJCT2010 | 1296.49 ± 1.38 | 239.06 ± 4.89 | 68.86% | 84:16 |

| XJCT2011 | 1830.78 ± 9.39 | 277.89 ± 1.65 | 73.64% | 87:13 |

| XJCT 2012 | 1547.23 ± 3.04 | 246.89 ± 4.60 | 72.48% | 86:14 |

| XJCT 2013 | 995.24 ± 1.38 | 85.23 ± 3.83 | 84.22% | 92:8 |

| XJCT 2014 | 1891.19 ± 4.45 | 273.68 ± 5.49 | 74.72% | 87:13 |

| XJCT 2015 | 1985.58 ± 11.34 | 300.89 ± 6.36 | 73.68% | 87:13 |

| XJCT 2016 | 496.49 ± 9.98 | 41.12 ± 1.27 | 84.70% | 92:8 |

| XJCT 2017 | 371.77 ± 12.62 | 40.30 ± 0.99 | 80.44% | 90:10 |

| XJCT2018 | 1374.47 ± 7.73 | 180.61 ± 4.36 | 76.77% | 88:12 |

| XJCT2019 | 1395.83 ± 14.52 | 128.67 ± 5.29 | 83.12% | 92:8 |

| XJCT2020 | 1436.31 ± 11.25 | 224.72 ± 7.69 | 72.94% | 86:14 |

| STB (strong aroma-type Baijiu) | ||||

| LZLJTOUQU | 483.60 ± 12.63 | 130.08 ± 1.08 | 57.61% | 79:21 |

| LZLJTQ1 | 449.23 ± 0.55 | 128.18 ± 0.57 | 55.60% | 78:22 |

| LZLJTQ2 | 356.10 ± 1.48 | 157.90 ± 3.06 | 38.56% | 69:31 |

| LZLJER | — | 235.50 ± 0.51 | — | — |

| MZDQ | 331.75 ± 2.19 | — | — | — |

| JNC | 478.13 ± 11.38 | 27.11 ± 3.23 | 89.27% | 95:5 |

| WLY | 407.70 ± 0.45 | 35.02 ± 1.79 | 84.18% | 92:8 |

| GJ1573 | 764.67 ± 1.85 | 268.99 ± 0.29 | 47.95% | 74:26 |

| SJF | 695.54 ± 7.93 | 228.43 ± 2.40 | 50.56% | 74:26 |

| LZLJ2012 | 370.00 ± 2.12 | — | — | — |

| LZLJ2013 | 389.83 ± 0.73 | — | — | — |

| LZLJ2014 | 933.88 ± 8.87 | 661.25 ± 0.21 | 17.09% | 59:41 |

| LZLJ2015 | 1048.00 ± 11.46 | 939.83 ± 0.23 | 5.44% | 54:46 |

| LZLJ2016 | 708.90 ± 1.81 | — | — | — |

| LZLJ2017 | 900.70 ± 1.07 | 213.35 ± 0.24 | 61.70% | 81:19 |

| LZLJ2018 | 932.63 ± 6.97 | 772.00 ± 2.12 | 9.42% | 56:44 |

| LZLJ2019 | 960.98 ± 0.13 | 926.00 ± 2.26 | 1.85% | 51:49 |

| LTB (light aroma-type Baijiu) | ||||

| FPLJ | — | 135.28 ± 2.79 | — | — |

| FJZC1988 | — | 558.33 ± 3.06 | — | — |

| LBFJ | 760.90 ± 9.45 | 43.76 ± 0.99 | 89.12% | 95:5 |

| FJQH20 | 576.55 ± 13.51 | 31.81 ± 1.27 | 89.54% | 95:5 |

| FJQXMR | 240.80 ± 7.23 | 43.27 ± 0.99 | 69.54% | 85:15 |

| FJBF | 234.42 ± 9.45 | 45.99 ± 2.39 | 67.20% | 84:16 |

| Average Concentration ± Standard Deviation (mg/L) | ||||

|---|---|---|---|---|

| Category | Number of Samples | D | L | D/L |

| Soy sauce aroma-type | ||||

| Commercial Baijiu products | 26 | 1300.18 ± 447.40 | 397.54 ± 289.81 | 78:22 ± 16.16 |

| JSHSJ Vintage Baijiu (5–41) | 10 | 1016.68 ± 281.63 | 308.35 ± 127.07 | 76:24 ± 4.26 |

| XJCTJ Vintage Baijiu (1–11) | 11 | 1329.22 ± 527.87 | 185.37 ± 96.46 | 88:12 ± 2.80 |

| Strong aroma-type | ||||

| Commercial Baijiu products | 9 | 495.84 ± 155.38 | 151.40 ± 98.26 | 80:20 ± 9.72 |

| LZLJ Vintage Baijiu (2–9) | 8 | 780.62 ± 264.98 | 702.49 ± 427.18 | 60:40 ± 11.99 |

| Light aroma-type | ||||

| Commercial Baijiu products | 6 | 453.17 ± 260.05 | 143.07 ± 206.94 | 90:10 ± 6.08 |

| Compounds | Recognition Threshold (mg/L) | Flavor Characteristics |

|---|---|---|

| D-lactic acid | 194.18 | sour taste |

| L-lactic acid | 98.19 | sour taste |

| Sample | D-Lactic Acid | L-Lactic Acid |

|---|---|---|

| SSB (soy sauce aroma-type Bai-jiu) | ||

| LM | 8 | 2 |

| JSHSJ1 | 4 | 1 |

| JSHSJ2 | 4 | 2 |

| JSJ | 6 | 2 |

| ZJ1 | 10 | 3 |

| ZJ2 | 11 | 5 |

| DYT1 | 6 | 2 |

| DYT2 | 8 | 4 |

| GT1 | 6 | 3 |

| GT2 | 6 | 4 |

| GT3 | 6 | 3 |

| XJYZ | 6 | 2 |

| QHL | 8 | 5 |

| MT43 | 9 | 2 |

| MT53 | 9 | 3 |

| XJ1988 | 7 | 3 |

| QJ1H1 | 8 | 4 |

| DYT3 | 7 | 2 |

| MTWZJ | 8 | 3 |

| LJ | 9 | 8 |

| MTCX | 2 | 9 |

| QJ1H2 | 9 | 5 |

| TCSP | 2 | 10 |

| GZJSJ1 | 5 | 2 |

| GZJSJ2 | 5 | 2 |

| JSHSJ39 | 6 | 5 |

| JSHSJ34 | 5 | 4 |

| JSHSJ23 | 8 | 5 |

| JSHSJ17 | 7 | 4 |

| JSHSJ15 | 6 | 3 |

| JSHSJ9 | 3 | 2 |

| JSHSJ6 | 4 | 2 |

| JSHSJ5 | 5 | 2 |

| JSHSJ4 | 5 | 2 |

| JSHSJ3 | 4 | 2 |

| XJCT 2010 | 7 | 2 |

| XJCT 2011 | 9 | 3 |

| XJCT 2012 | 8 | 3 |

| XJCT 2013 | 5 | 1 |

| XJCT 2014 | 10 | 3 |

| XJCT 2015 | 10 | 3 |

| XJCT 2016 | 3 | <1 |

| XJCT 2017 | 2 | <1 |

| XJCT2018 | 7 | 2 |

| XJCT2019 | 7 | 1 |

| XJCT2020 | 7 | 2 |

| STB (strong aroma-type Baijiu) | ||

| LZLJTOUQU | 2 | 1 |

| LZLJTQ1 | 2 | 1 |

| LZLJTQ2 | 2 | 2 |

| LZLJER | — | 2 |

| MZDQ | 2 | — |

| JNC | 2 | — |

| WLY | 2 | — |

| GJ1573 | 4 | 3 |

| SJF | 4 | 2 |

| LZLJ2012 | 2 | — |

| LZLJ2013 | 2 | — |

| LZLJ2014 | 5 | 7 |

| LZLJ2015 | 5 | 10 |

| LZLJ2016 | 4 | — |

| LZLJ2017 | 5 | 2 |

| LZLJ2018 | 5 | 8 |

| LZLJ2019 | 5 | 9 |

| LTB (light aroma-type Baijiu) | ||

| FPLJ | — | 1 |

| FJZC1988 | — | 6 |

| LBFJ | 4 | <1 |

| FJQH20 | 3 | <1 |

| FJQXMR | 1 | <1 |

| FJBF | 1 | <1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Qiu, S.; Dai, Y.; Wu, Y.; Zeng, X. Distribution and Quantification of Lactic Acid Enantiomers in Baijiu. Foods 2022, 11, 2607. https://doi.org/10.3390/foods11172607

Xu H, Qiu S, Dai Y, Wu Y, Zeng X. Distribution and Quantification of Lactic Acid Enantiomers in Baijiu. Foods. 2022; 11(17):2607. https://doi.org/10.3390/foods11172607

Chicago/Turabian StyleXu, Hao, Shuyi Qiu, Yifeng Dai, Yuangen Wu, and Xiangyong Zeng. 2022. "Distribution and Quantification of Lactic Acid Enantiomers in Baijiu" Foods 11, no. 17: 2607. https://doi.org/10.3390/foods11172607

APA StyleXu, H., Qiu, S., Dai, Y., Wu, Y., & Zeng, X. (2022). Distribution and Quantification of Lactic Acid Enantiomers in Baijiu. Foods, 11(17), 2607. https://doi.org/10.3390/foods11172607