3.1. Flat Bread Diversity in the Surveyed Area

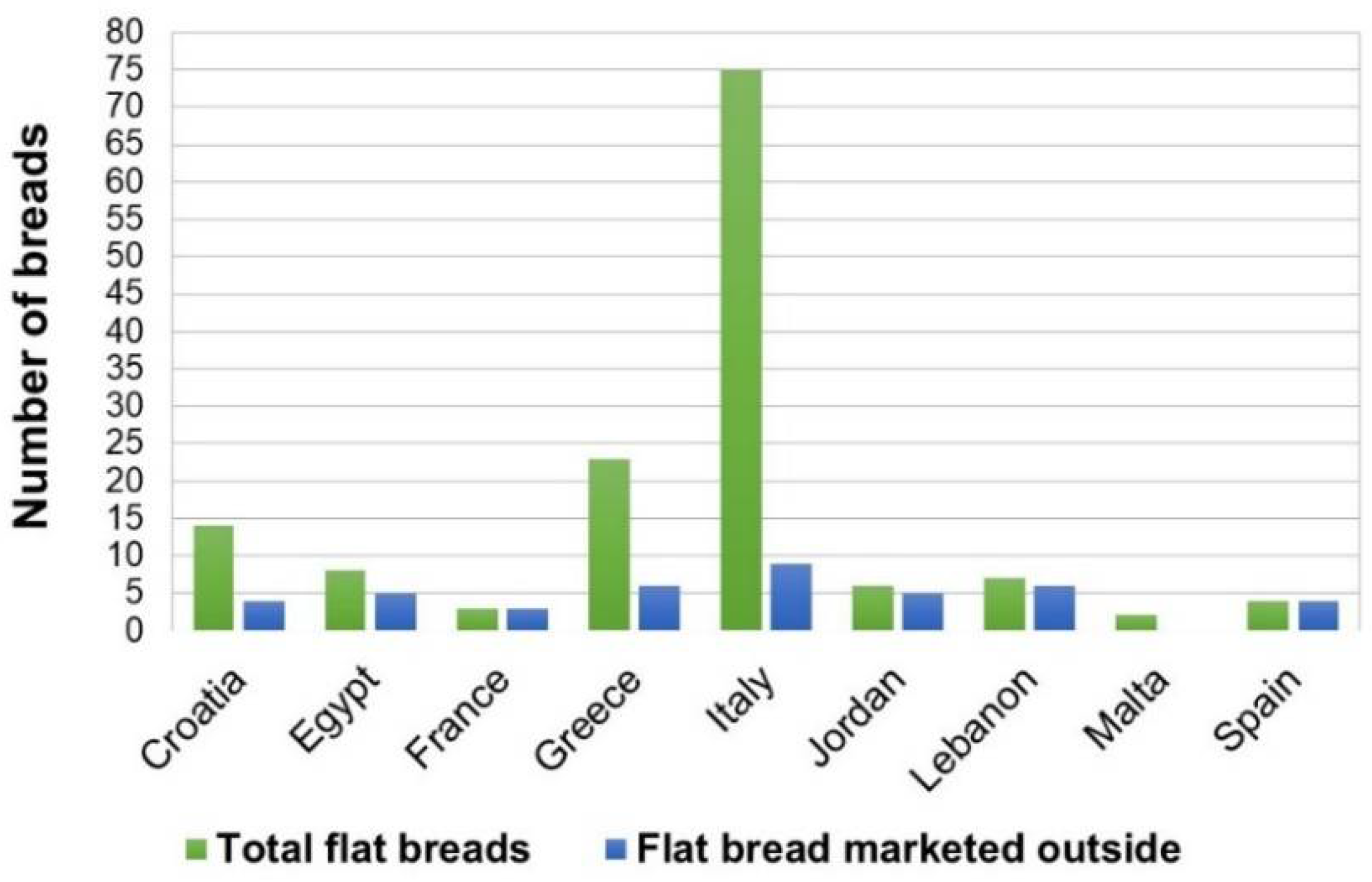

A total of 143 different flat bread types were found to be produced in the surveyed countries, distributed as follows: 14 from Croatia, 8 from Egypt, 3 from France, 23 from Greece, 75 from Italy, 6 from Jordan, 7 from Lebanon, 2 from Malta, and 5 from Spain (

Figure 1) [

16].

The high number of flat breads recorded in Italy was probably due to the existence of strong regional gastronomic differences within the Italian territory. Furthermore, the consolidated tendency to rediscover and keep alive the memory of small-scale, local, and traditional food products, included flat breads, finds its maximum expression in Italy, home of the Slow Food Foundation for Biodiversity [

17]. This trend, appreciated by modern consumers [

18,

19], aligns with the European policies for promoting traditional foods and protecting their origin [

20], and will be discussed more in depth in

Section 3.9.

Another important factor is the different meaning that flat breads assume in different areas. In Italy these products are considered as a delicacy, admitting many variations on a regional basis, while in the areas where flat breads originated in the antiquity, i.e., Middle East [

1,

2] (Jordan and Lebanon, for this survey), or in closer countries, such as Egypt, they represent staple foods that are consumed daily, therefore are less affected by variations.

Flat breads can be classified into plain (further categorized into single- or double-layered), garnished (seasoned or stuffed), and fried.

Table 1 shows the occurrence of flat breads in the different categories through the surveyed countries. Garnished flat breads accounted for 46.2%, with a 27.3% contribution by Italy. These flat breads, prepared as specialties to be consumed occasionally, were seasoned or stuffed with several ingredients before baking. In Jordan and Egypt, instead, flat breads were only plain.

Among the plain types, the single-layered category, easier to be prepared, accounted for 35.7%. The double-layered (10.5%) are, instead, those characterized by the typical “pocket”, such as the Jordan

Kmaj [

21] (

Figure 2A), the Egyptian

Shamy and

Baladi [

22], and the common Arabic bread or

Khobz (

Khobz means “bread” in Arabic) (

Figure 2B), which are all known in western countries as “

Pita” bread.

The pocket is the visible result of the thermal expansion of the fermentation gas into a thin dough layer, which takes place during baking (

Figure 3).

Fried flat breads accounted for 7.7%. They were recorded in Italy (6 breads, namely Gnocco fritto, Crescenta fritta—also named Crescentina fritta—Pinzini ferraresi, Cresciolina, Pizza fritta, Pitt’ajima), Greece (4 breads: Pisia, Tiganopsomo, Sfakianopita and Fyllota), and Spain (one bread: Arepas Canarias).

Figure 4 shows, per each country, the number of flat bread types marketed outside the area of origin (town, subregion), compared to the total number flat breads produced in the country. In Italy, Greece, and Croatia, only a minority of flat breads were found to be marketed through the entire country, outside the area where they are originally produced and consumed, which was generally a very limited geographic area.

On the contrary, in countries such as Jordan, Lebanon, and Egypt, the distribution and consumption of flat breads was homogenous throughout the entire country and three flat breads from these countries were also exported abroad (namely the Egyptian Baladi and Shamy, and the Lebanese Khobz). These findings agreed with the different character, previously discussed, that flat breads assume in different areas: local specialties vs. national staple foods.

3.2. Flour Type and Quality

Refined soft wheat flour was widely used (67.4%) in the preparation of the surveyed flat breads (

Table 2).

Whole meal flour of soft wheat was used only in 5.1% of cases. Earlier studies, dating the late nineties, reported that flat breads were commonly made of wheat flour at high extraction levels [

4], so this flour has been progressively substituted by the refined one.

The use of durum wheat flour (more precisely, re-milled semolina) was reported in 13.7% of cases. Durum wheat cultivation is common in semiarid zones of the Mediterranean basin, and its use in bread making has been already reported [

23]. In fact, durum wheat breads (not flat), such as Altamura bread [

24] and Dittaino bread [

25], have been awarded by the Protected Designation of Origin (PDO) European Union (EU) mark for their peculiar characteristics, such as a compact and yellowish crumb (due to carotenoid pigments). Durum wheat whole meal represented an exception and was found only in the preparation of the Greek

Koulouri.

The use of corn refined flour accounted for 8.6%. In three cases it was subjected to thermal treatments: pre-cooked corn flour was recorded in the production of the Spanish

Arepa Canarias, and up to 30% extruded-cooked corn flour could be optionally added to soft wheat refined flour to prepare the Croatian flat breads

Pogača and

Kukuruzna miješana ciabatta (“corn composite

ciabatta”). The thermal treatment causes starch gelatinization, increasing dough viscosity [

26]. In the presence of wheat flour, this effect is not strictly needed because good viscoelasticity is ensured by gluten; however, the thermal treatment could be made also because it is able to slow down bread aging [

27,

28].

Corn has long been cultivated in the Canary islands and Eastern Europe, including Croatia [

29], so in the past the exclusive use of corn in the preparation of these breads could be hypothesized, explaining the need of pre-gelatinizing flour. The use of pre-cooked corn flour in the preparation of

Arepa Canarias, indeed, resembles the procedure adopted for its Venezuelan counterpart,

Arepa, which is made from corn only [

30]. Probably a return cultural contamination took place in the Canary islands following migrations to America, including Venezuela.

Without a thermal pretreatment, instead, corn flour is used in the preparation of the Egyptian

Bataw and

Meraharah, as well as in the

Talo, a traditional bread from the Mungia subregion of Basque Countries. Interestingly, the latter has been associated by archeobotanists to an ancient flat bread of the same area, made of acorn [

31], which is being rediscovered recently for its high nutritional value [

32]. Corn flour can be used as an alternative to wheat flour in the Greek

Souvlakopita and

Plakopita, while

Bobota, which was the most consumed bread in Greece during the German-Italian occupation during World War II, was and is still made exclusively from corn flour [

16]. In Italy, corn flour is used to prepare the

Carchiola,

Torta al Testo,

Pizza di granone,

Pizza con farina di mais, and

Pizza di farinella bacolese. Only a very small amount of corn flour, about 5%, is mixed with wheat flour for preparing the Lebanese

Markouk.

Rye flour was found to be used in colder areas—to which is more adapted [

33]—such as the alpine Italian regions and part of Croatia. A mixture of rye and soft wheat flour, indeed, is used to prepare the Italian

Puccia ladina (typically consumed in the mountain huts of the Dolomites) and

Schüttelbrot. Rye flour is optionally added to soft wheat flour to prepare the Croatian

Pogača and

Kruh ispod peke (“bread under the lid”).

Like other commodities, cereals and particularly wheat, have long since become fully globalized. Egypt, for example, has become the world’s largest importer of wheat, exposing the country to significant vulnerabilities, not to mention that more than half of the consumption of wheat in the Mediterranean countries comes from Russia and Ukraine [

34]. The use of alternative flours should therefore be strengthened. Among them, sorghum flour was traditionally used to prepare the Egyptian

Khobz min el dorra al rafi’ah and

Zallut; however, these breads are now only prepared at home for family consumption and not for commercial purposes, with a serious risk of losing their knowledge.

Pulses, though nutritionally valuable, with an amino acid profile complementary to that of cereals, are underrepresented. Chickpea flour is used only in the Italian

Farinata, a typical street food from Liguria region with variants in Tuscany and Piedmont [

35]. However, the addition of pulse flours to bakery products, including flat bread, has been the object of a rising attention in the recent years [

36,

37,

38,

39].

Chestnut flour is used for preparing the Italian

Neccio. Besides their high antioxidant activity, chestnuts are rich in minerals, polyunsaturated fatty acids, fiber, and vitamins [

40]. In Italy, indeed, this crop has an important economic value [

41] and specific chestnut cultivars (Carpinese, Pontecosi, Capannaccia, and Morona) grown in the Garfagnana subregion of Tuscany are used to prepare the flour named “

Farina di Neccio della Garfagnana” which has been recognized as a PDO food product. According to tradition, before milling, the chestnuts are dried in small stone buildings named “

metati”, where a hearth on the ground floor heats and dries the chestnuts placed on the upper floor [

42].

Regarding the quality of flours used for flat breads, a limited technical knowledge was observed in all the surveyed countries, especially (but not exclusively) for the most artisanal productions. Consequently, this information often remained undefined in the database (where “not specified” is indicated), reaching 71.6% of missing data, which was the highest percentage among all collected data. Where information on the quality features was available, protein and gluten content and gluten quality were the most frequently reported. For refined wheat flour the quality parameters generally were: protein content ≥ 9%, wet gluten content ≥ 25%, alveograph W ≥ 180 × 10

−4 J, and P/L ≤ 1. For

Pizza Napoletana Traditional Specialty Guaranteed (STG) more detailed quality information was available: dry gluten 9.5–11%, alveograph W 220–380 × 10

−4 J, P/L 0.50–070, water absorption 55–62%, farinograph stability 4–12 min, farinograph drop off of consistency ≤60 Brabender Units [

43]. For corn flour only protein content ≥7% was reported.

It should be mentioned that data collection at bakers faced obstacles related to the COVID-19 pandemic restrictions and to the successive flour shortage following the Ukraine crisis. The economic value of bread and its scarcity have always important social repercussions, as evidenced by past and recent history. Bread availability provides a sense of security, while the lack of bread can be the cause of violent social movements. For example, in Lebanon, where the COVID-19 pandemic economic loss overlapped with a pre-existing crisis [

44], further wheat shortage exacerbated the situation, making wheat and bread availability an extremely hot topic. Especially small producers suffered from the financial crisis on full blow, which took its toll on their sales to the point that they cannot afford even proper maintenance for their equipment. A similar situation was observed in Egypt and Jordan [

45,

46]. At various levels, lockdown-related economic losses and flour shortage were common to all countries, making bakers not really inclined to cooperate with the interviews. These issues were reduced, but not totally solved, with the help of local associations of bakers which introduced the researchers, or relying on direct knowledge with them.

3.3. Additional Ingredients

Though many plain flat breads (54.3%) did not contain any lipid, olive oil was used in 19 cases, 10 of which were characterized by the use of the extra virgin category (

Table 3).

Two flat breads included sunflower oil in their formulation, and three were prepared with lard, namely the Italian

Piadina Romagnola,

Crescentina di Modena, and

Torta al testo, whose official technical sheets [

8,

47,

48,

49], however, report also the possibility to use olive oil. The use of lard is traditional in the area of origin of these three flat breads, which is approximately the same area of

Prosciutto di Parma PDO ham and is characterized by the presence of numerous pig farms.

However, besides the obvious nutritional and health implications related to the reduction of saturated fatty acids, the substitution of lard with olive oil (possibly extra virgin olive oil), could eventually overcome religious restrictions for pork-derived ingredients.

All the garnished flat breads contained vegetable oils or lard. Vegetable oils, when specified, were represented by olive, sunflower, or rapeseed oil, and their blends (

Table 4). Greek, Italian, and French garnished flat breads were prepared with olive oil, and in particular extra virgin olive oil was used in the Italian

Focaccia di Recco and

Pizza Napoletana STG, agreeing with their official technical sheet [

43,

50]. Sunflower oil was used in the Croatian

Rudarska greblica and

Zlevanka, as well as in the

Poljički soparnik, where, however, it was used in 50:50 mixture with olive oil. The French

Flammekueche, of Alsatian origin (with German influence), was prepared with rapeseed oil. Lard, instead, was used in two Croatian (

Rudarska greblica and

Zlevanka) and ten Italian garnished flat breads (

Gnocco ingrassato,

Focaccia Novese,

Focaccia di Voltri,

Crescia d’la stacciola,

Crescia brusca,

Pizza a scannatur di Carbone,

Scarcedda,

Pizza con i cingoli di maiale,

Pizza con le sfrigole,

Crescenta bolognese).

During kneading and baking several reactions take place, including lipid oxidation. Studies carried out in several types of Italian

focaccia have shown that the level of oxidation may change by varying the type of toppings, with moist ingredients able to mitigate the rise of temperature during baking, thus exposing the lipid fraction to a less severe heat stress [

8].

Excluding oils and fats, the garnished flat breads contain also other ingredients which impart them well-defined and recognizable sensory characteristics and, by varying in nature and quantity, differentiate them into a myriad of nuanced variations. These ingredients are used to stuff or season the dough before baking, and their combination generates a pleasant palatability which makes the final product become much more than a staple food. The additional ingredients can be of plant and/or animal origin. The plant-based ones, which include spices, various vegetables, cereals, or seeds, accounted for 40.5%, while the sum of the ingredients having animal origin (dairy products, eggs, cured meat, canned fish, and meat) totalized 59.5%. Cured meat includes several charcuterie products such as salami and ham, while fresh meat is typically pork meat, added for example to Italian Pizza a scannatur di Carbone prepared on the day of the pig slaughter.

3.4. Leavening

Leavening agents were: compressed bakers’ yeast (

Saccharomyces cerevisiae) (55.8%), sourdough (16.7%), and baking powder (9.0%), while 18.6% flat breads were unleavened (

Table 5).

Sourdough, indeed, despite being the most traditional leavening method in the past, has overtime been partly replaced by compressed yeast, which is easier to handle and reduces leavening times. However, there is a renewed interest by consumers toward sourdough-leavened flat breads, also based on research results that prove nutritional and qualitative improvements, such as a reduction of phytic acid in whole meal flat breads [

51], an increase of selenium bioavailability [

52], and improved shelf life [

53], texture and sensory properties [

54,

55].

More “modern” leavening aids, such as baking soda, are used in the Italian flat breads Piadina Romagnola, Crostolo, Torta al Testo, Pizza scima, Gnocco fritto, Crescenta fritta, in the Croatian Pogaca z oreji and Zlevanka, and in the Greek Plakopita (Pita bread baked on a stone). In the preparation of Crescentina di Modena baking soda can be used as an alternative to the most used compressed yeast. Similarly, the Egyptian Shamy bread is leavened with baking powder as an alternative to compressed yeast. In three Jordan breads (Mashrouh, Tannur, and Taboun), instead, baking soda is used together with compressed yeast.

Among the unleavened flat breads there is an Italian one whose multiple names all remind the absence of fermentation: “Pizza azzima” (which is the original name, literally meaning “unleavened pizza” in Italian), and its naming variations “Pizza ascima”, “Pizza scive” and “Pizza scime”. Another unleavened Italian flat bread, similar to the former, is the “Pitt’ajima”, whose name is also clearly related to the original “Pizza azzima”.

The Egyptian

Shamsi bread (whose name derives from the Arabic word “

shams”, meaning “sun”), instead, is a leavened one. Its leavening phase is interesting from the ethnographic point of view, because traditionally it takes place with the help of sun heat, i.e., open air, under the direct sunlight [

16] (

Figure 5).

This bread is decorated by making three crescent-shaped cuts, that form three angles as the dough rises. Coptic Christians, instead, make four cuts to obtain a roughly cross-shaped loaf [

56] (

Figure 6).

3.5. Baking

When specified, the declared baking temperatures were <250 °C (50.3%), between 250 and 300 °C (7%), and >300 °C (28.7%) (

Table 6).

In the past, flat breads were baked only in wood-burning ovens, at very high temperatures, above 300 °C. Nowadays, the adopted baking temperature tends to be lower, below 250 °C, due to greater awareness on the risks related to the formation of thermal contaminants, such as polycyclic aromatic hydrocarbons (PAHs) [

10,

57] and acrylamide [

58].

Besides the modern electric or gas ovens (belt conveyor tunnel ovens or batch ovens), several traditional baking systems are still used in the preparation of flat breads. This survey recorded 16 different traditional ways to bake flat bread (

Table 7).

The method that most resembles the way flat breads were probably baked in antiquity was recorded for the Jordanian Arbood, the traditional bread of the Bedouins. This bread is prepared in the easiest possible way, i.e., unleavened and baked under hot ashes (a very rational way to cook, when an oven is not available). A fire is lit in a sandy area and, after the wood has burned, the dough disc is placed over hot ashes and covered with other ashes. During baking, bread is turned with the help of a stick, to cook evenly on both sides.

Another simple baking tool is a metal grill placed on the embers. The one used for baking the Italian

Carchiola, named

r’ticula, has a pivot in the center, so that it can be turned without removing it from the embers of the fireplace. The convex circular metal griddle (named

Saj in Middle East and Egypt and

Satsi in Greece) (

Figure 7) is used in a similar way to the metal grills, being placed on the embers. It has a large diameter, approximately 50 cm, and it is suitable to bake very large flat breads such as the Jordan

Shrak (also named

Saaj bread from its baking system) and

Mashrouh and the similar Lebanese

Markouk (named also

Saj bread).

The most traditional types of oven are those which retained the greatest differences among countries, being tightly related to local history and habits. Basically, two main baking systems were observed: baking plates (originally made of raw clay or terracotta, but nowadays generally substituted by iron cast), either coupled with lids or not, and vertical ovens: tannūr (transcribed also as tannur or tannour; pl. tananir) and tabūn (or tabun, taboun; pl. tawabeen).

Baking plates, i.e., large, open and shallow vessels, have been documented for cooking food in various contexts—temporal, spatial, and cultural, in parts of Europe and the eastern Mediterranean [

59]. Late Neolithic baking pans of the Balkans (early 5th millennium B.C.) and the subsequent baking plates of central Europe (late 5th and early 4th millennia B.C.), are small- and medium-sized flat trays interpreted as being used for baking bread [

60]. Furthermore, baking trays (25–40 cm diameter) with elaborate molded rims, appear in Syria during the Early Bronze Age (3200–2000 B.C.) and are found throughout the Levant during the Middle (2000–1600 B.C.) and Late Bronze Ages (1600–1100 B.C.). They are interpreted as vessels used on special occasions for baking bread or flat pies [

61].

Baking lids have a documented ancient root in the Roman

testum. Indeed, Cato reports in the

Liber de agri cultura (chapters 74 and 75) that bread and other foods were baked “

sub testum”, i.e., on the hearth and under a terracotta lid named

testum [

62]. Instead, terracotta baking plates to be placed on the embers, named

testelli (sing.

testello), were reported in the Middle Age in central-northern Italy [

62]. The influence of the original Latin word on the name “

Testo” given to the terracotta plate with a terracotta lid traditionally used to bake the Italian

Testarolo Pontremolese and

Torta al Testo is evident, as is the influence on the name of the corresponding flat breads.

Another naming similarity is between

tigella (pl.

tigelle), the terracotta plate used to bake the

Crescentina di Modena (which is very often named also

tigella, after its baking system), and

taguella, the typical flat bread prepared by the Touareg of Central Sahara [

63]. The

tigella terracotta plate derives its name from the Latin verb

tegere, meaning “to cover”, because the traditional way of cooking the

Crescentina di Modena involved to place the dough on the red-hot

tigella, to cover it with another

tigella, and to stack several of them in the fireplace. Chestnut or walnut leaves were used to avoid the direct contact of the dough with terracotta, as well as to flavor it and keep it clean from the ash.

Tannur and

tabun, instead, are vertical ovens [

2]. The

tannur consists of a truncated conical structure (

Figure 8).

Archeological remains of these ovens are widespread in the Middle East, Central Asia, northern India, North Africa, and along the Mediterranean coasts [

2]. The

tannur is still used in the rural areas of the Middle East, particularly in Syria and Iraq, whereas it disappeared in Egypt, where it was used until the 19th century [

64].

Embedded in the masonry, which acts as a workbench to prepare the dough and lay the bread loaves for cooling, the

tannur is placed in a slightly inclined position to facilitate the introduction of food to be baked, including bread, through the circular opening at the top, or “mouth” [

2]. The dough discs are rapidly pressed onto the inner walls of

tannur with the aid of a “bread cushion” or directly by hand. The adhesion to the vertical walls can be helped by wetting the surface of the dough discs just before slapping them into the oven [

2]. After about 1–2 min of cooking, the bread is taken out by metal tongs. The vertical ovens, such as all wood-burning ovens, reach very high temperatures, exceeding 300 °C.

The

tabun, instead, has an upper opening as the

tannur, but has an “igloo” shape, wider than tall [

2] (

Figure 9). This kind of oven, of Palestinian origin, is present in Jordan also due to large presence in this country of Palestinian refugees [

46,

65,

66,

67]. It is used in a different way than

tannur because, instead of slapping onto the inner walls, the loaves are placed on the oven floor, next to the embers, usually on a layer of hot pebbles [

2]. During baking, the top opening of the oven is closed with a metal lid.

The wood-fired refractory stone oven, dome-shaped, was present in all the surveyed countries, but with a different “perception”. In countries such as Italy, for instance, the presence of a wood-fired refractory stone oven (“forno a legna”) in a pizzeria is perceived very positively and attracts customers.

On the contrary, the traditional “furn fallahi” (farmer oven) used to bake the Bataw bread in the rural areas of Egypt is perceived as obsolete and has been almost abandoned (although it will likely make a comeback due to the sharp rise in the price of gas following the current Ukraine crisis).

3.6. Bread Characteristics

Regarding size and shape (

Table 8), 50 breads had a diameter between 10 and 40 cm, while seven breads were larger than 40 cm: the Italian

Borlengo and

Testarolo, the Croatian

Poljički soparnik, the Jordan

Saaj (or

Shrak) and

Mashrouh, the Lebanese

Saj (or

Markouk) and

Khobz. Only one bread was smaller than 10 cm, namely the Italian

Crescentina di Modena. Not all flat breads are circular: 34.2% of them were oval or rectangular.

An important quality characteristic of flat breads was golden color (45.4%). Moreover, texture was relevant, which should be crunchy (12.2%) for the hard flat bread types and soft (14.1%) for those pliable and rollable (

Table 9).

In the marketing classification, bread is included in the group of products of frequently purchased products, characterized by short shelf life and subject to high risk of waste [

15,

68,

69]. The shelf life of flat breads ranged from shorter than 3 days (58%), between 3 and 7 days (27.3%) and up to one year (9.1%) in case of hard, dry flat breads (

Table 10). Hard breads were obtained by means of a two-step baking: the first to cook and the second to dry them. Traditionally, this procedure was typical of breads to be carried during the transhumance of sheep [

2]. These flat breads were the Croatian

Mlinci (meaning “Mills”) and

Zagorski mlinci, the Egyptian

Bataw and

Merahrah, the Greek

Fylla Perek, the Italian

Pane Carasau,

Schuttelbrot,

Guttiau,

Pistoccu,

Zichi and

Puccia ladina, the Lebanese

Mullat al smeed and the Spanish

Torta Cenceña (or

Torta de Gazpacho Manchego). The latter only shares its name with the cold vegetable soup named

gazpacho consumed during the summer mainly in the Andalusia region.

Gazpacho Manchego, indeed, is a game meat stew from the Castilla La Mancha region, traditionally eaten with unleavened bread cakes. Its most peculiar ingredient is the unleavened bread cake (

Torta Cenceña) which, originally, was the plate for

Gazpacho Manchego.

In 5.6% of cases the shelf life was not specified because the product was prepared at a very small scale level and marketed unpackaged.

Studies showed that modified atmosphere packaging (40% carbon dioxide and 60% nitrogen), coupled with an oxygen absorbent sachet, prolonged the shelf life of

pita bread up to 28 days [

70]. Alternatively, sodium propionate (0.3%) can be added [

71]. Innovative solutions for extending the shelf life of bread are under study, such as ethanol and/or essential oil emitters, antimicrobial films, nanopackaging, biodegradable and renewable packaging, and edible coatings [

72].

3.7. Artisanal vs. Industrial Breads

Typically, the surveyed flat breads showed an artisanal character (82%) (

Figure 10). Those produced at industrial level accounted for 7%, and were:

Piadina (Italy),

Kmaj (Jordan),

Mlinci and

Kukuruzna miješana ciabatta (Croatia),

Souvlakopita (

Pita bread) (Greece),

Baladi and

Shami bread (Egypt),

Khobz (Arabic bread) (Lebanon). Another 11% was produced either way.

The Egyptian Bataw, which was the most traditional farmer bread in Egypt, can be considered a case study. It was not standardized, being made in a different way in different places. Farmers could prepare Bataw bread with wheat, corn, or mixture of these flours (the most common option), with or without fenugreek. Furthermore, this kind of bread was produced either in soft form or, to prolong shelf life, in hard, dry form.

These findings demonstrate that the formulation of

Bataw bread, a traditional product made mostly on a family basis, depends on the local availability of raw materials and personal preference of the family. However, this bread is currently not as widely consumed as in the past, mostly due to the subsidization of another bread, namely

Baladi bread. It should be considered that in Egypt, bread consumption is one of the highest in the world, so bread subsidies have a strong influence on consumer choice [

34]. Likely, changes in lifestyle and increasing urbanization may further enhance the abandonment of

Bataw breadmaking. Therefore, there is a concrete risk of losing the memory and knowledge behind this kind of bread. This happens continuously to many food products, everywhere, but since bread is much more than simply a nutritious food, being linked to identity and local knowledge [

3], abandoning a certain type of artisanal bread, in favor of a more industrialized one, is a phenomenon with important cultural repercussions.

Besides the Bataw, other breads which were found to be made on a family basis were the Egyptian Zallut, Khobz min el dorra al rafi’ah, Farasheeh, and Merahrah; the Jordan Arbood; the Lebanese Mishtah el jreesh and Mullat al smeed; the Italian Carchiola, Puccia alla spasa and Pitt’ajima; the Greek Lambropsomo, Christopsomo, Spargana tou Christou and Vasilopita trifti (whose cultural importance and ethnographical aspects are highlighted in the next paragraph).

3.8. Specific Consumption Patterns

The analysis of data also provided a cultural view of flat breads within each country. Preferences for food, including bread, are influenced by culture, family habits, traditions, religious believes, and income [

68]. One of the characteristics of contemporary consumer behavior and habits is that people often purchase products (including food products) not because they are “used for something”, but because they symbolize something, as described by Solomon et al. [

73] and Jones [

74]. The role a product plays in people’s lives, indeed, extends beyond the practical functions it fulfils. Bread is a “soul food” and is the symbolic food

par excellence, to be treated with the respect due to what it represents.

A strong link has been observed between the consumption of a specific flat bread type and certain periods of the year having a religious meaning, highlighting the iconic nature of cooking and eating [

74]. The Greek

Lambropsomo (Easter Bread) and

Lagana are related to Easter [

16]. The

Lambropsomo is prepared by intertwining three long cylinders of dough, symbolizing the Holy Trinity, and on the surface of the dough four hard-boiled red-colored eggs are placed, which remind the blood of Jesus Christ. The

Lagana is specifically consumed on Clean Monday (

Kathari Deutera), i.e., on the first day of Lent of the Eastern Christianity, when sinful attitudes and non-fasting foods are left behind. That day is also named “Ash Monday”, by analogy with Ash Wednesday (the day when the Western Churches begin Lent). In Greece, the

Christopsomo is the typical Christmas Bread, eaten on Christmas’ eve. The surface of this bread is decorated with a cross of dough and walnuts in shell [

16]. The latter symbolizes rebirth and are believed to bring prosperity to the family. Moreover, the Greek

Spargana tou Christou is related to Christmas. The name of these very thin pancakes, prepared during Christmas lent, literally means “The swaddling clothes of Jesus” [

16]. The

Vasilopita trifti or “New year’s bread”, instead, is a traditional Greek bread served at midnight on New Year’s Eve to celebrate the life of Saint Basil of Caesarea (

Agios Vasilis), who is Santa Claus according to Greek Christmas traditions [

16]. After baking, a coin is inserted through the base of the bread, and whoever finds it is said to be granted luck for the rest of the year.

In Croatia, Zagorski mlinci are traditionally eaten with turkey at Christmas and New Year. Moreover, Poljički soparnik is known as the “poor man’s dish” because it was always prepared on fasting days (All Saints’ day or Good Friday) and holidays such as Christmas.

The Lebanese

Mishtah el jreesh, now become a rare bread prepared only at home, is particularly associated with the Muslim month of Ramadan, for breaking the fast, while the

Mullat al smeed, another rare Lebanese bread, was traditionally brought during the

Hajj (pilgrimage to Mecca) because of its long shelf life (being dried) but, as travel times became shorter,

Mullat al smeed began to disappear [

75]. The meat variant of

Manouche, instead, called

Lahem b aajin (or “meat in dough”), is a “go to” meal for funerals and condolences in certain regions of Lebanon.

In Italy, the Sardinian double-layered flat bread

Spianata was traditionally prepared in a decorated version for weddings, by using a special stamp named

pintadera. The Italian

Borlengo was typically consumed at Carnival, so its name is related to the Italian word “

burla”, meaning “joke” [

16]. The

Pizza a scannatur di Carbone, instead, was prepared on the day of the pig slaughter which, in the past, represented an important day, to be celebrated as a collective rite ending with a common lunch for those who helped in the slaughter [

16].

3.9. Promoting the Tradition

The application of quality schemes to flat breads deserves a specific discussion. As a way for promoting the most traditional and artisanal foods, several quality marks have been set up. This action is aimed at keeping their knowledge alive, reducing the erosion of food diversity, which is a modern problem induced by the globalization of food products.

The EU Regulation No 1151/2012 [

20] provides the legal framework on quality schemes to protect the name of food and beverages having unique characteristics linked to their geographical origin as well as traditional know-how [

20]. These quality schemes include the PDO, granted to products whose production, processing, and preparation are entirely made within a particular geographical area; the Protected Geographical Indication (PGI), awarded to products for which at least one of the stages of production, processing or preparation takes place within a particular geographical area; the TSG, for products whose quality is not linked to a specific geographical area but is based on traditional processing methods or recipes. These quality marks are all recognizable by the presence of specific logos in the label of food and bring benefits to producers, who keep the exclusive right to use the protected name and usually get a premium price. At the same time, the consumers have a proof of heritage and tradition of food specialties they buy.

Many of the surveyed flat breads have been awarded of quality marks (

Table 11). Five were PGI (namely the Italian

Piadina Romagnola,

Focaccia di Recco and

Schuttelbrot dell’Alto Adige, as well as the Croatian

Poljički soparnik’ and

Zagorski mlinci) and one was TSG (the

Pizza Napoletana). Furthermore, being the “art” of the Neapolitan pizza-makers (

pizzaiuoli napoletani) globally renowned, it has been inscribed on the Representative List of the Intangible Cultural Heritage of Humanity by the United Nations Educational, Scientific and Cultural Organization (UNESCO). Similarly, “the culinary art and culture of flattened sourdough flat bread

Ftira”, was added by the UNESCO to the same list, being a key part of the cultural heritage of the inhabitants of the Maltese archipelago.

According to the Slow Food Foundation for Biodiversity, Slow Food Presidia should be good tasting, sustainably produced, should have a local and social dimension, and represent a sense of place. This recognition requires that producers join a project to safeguard biodiversity and form a community. Two flat breads of this survey were Slow Food presidia, i.e., the Italian Testarolo Pontremolese and the Spanish Talo.

In Croatia, the quality schemes “Intangible cultural goods” (awarded by the Ministry of Culture, of the Republic of Croatia), and “Croatian quality” (by the Croatian Chamber of Commerce) applied to Pogača z oreji and Pogača, respectively.

The “

Denominazione Comunale di Origine” (DeCO, meaning “Municipal Designation of Origin”), instead, is granted by the Italian Municipalities to recognize, promote, and protect high quality artisanal agri-food products indigenous to their municipal territory. Two Italian breads were DeCO, while the remarkable number of 63 were

Prodotti Agroalimentari Tradizionali (PAT, meaning “Traditional Agri-food Products”), which is another (more prestigious) Italian recognition awarded by the Italian Ministry of Agriculture to foods prepared according to traditional processing systems, homogeneous in the geographic area and consolidated through a period of time not inferior to 25 years (

Table 12).

A list of PAT is released yearly, with new entries and eventually deletions for products which have been upgraded to PDO, PGI, or TSG [

76]. PAT flat breads were homogeneously distributed throughout the country.

Rare breads, instead, prepared only by the household cooks for family consumption and not for sale, were surveyed by the Slow Food Foundation for Biodiversity within the “Ark of Taste” project. These breads were the Egyptian

Zallut,

Khobz min el dorra al rafi’ah, Farasheeh, and

Merahrah [

77], the Lebanese

Mishtah el jreesh and

Mullat al smeed [

75], the Jordan

Arbood [

78] and the Italian breads reported in

Table 13. The Ark of Taste project is aimed at keeping alive small-scale quality productions tightly linked to local culture, history and tradition [

79,

80].

It is indeed fundamental to draw attention to these local rare foods which are at risk of extinction, to prevent the reduction of food and cultural biodiversity. The Egyptian

Shamsi bread, for example, which was another rare bread, has recently increased its popularity and has now gained certain market, as proved by the large number of webpages released by searching its name in Google. A possible means for keeping alive these food products is also to show their production to the tourists, who are attracted by local traditions, such as for the Jordan

Arbood bread. This bread is typically baked for tourists enjoying the Wadi Rum tours. In this way, the promotion of traditional foods can generate an income to the local communities [

81].

Another means to enhance the knowledge of rare flat breads is represented by the food blogs which attract the interest of many people prompt by the will of learning new recipes and rediscovering old ones. These tools, as well as YouTube videos, or even Wikipedia, easily carry the information also far from the area of origin. For example, the Italian breads inserted in the Ark of Taste (namely Carchiola, Pizza scime—or Pizza scive, Pizza ascima, Pizza azzima—Pitt’ajima, Pizza a fiamma, Puccia alla spasa and Puccia ladina) are all the object of several blogs and are mentioned in Wikipedia pages, with Carchiola having its own entry.

In Lebanon, instead, the popular garnished flat bread Manouche is the object of the “World Manoucheh Day”, on November 2nd, though this bread has not an official quality label yet.