Quality Properties of Dry-Aged Beef (Hanwoo Cattle) Crust on Pork Patties

Abstract

1. Introduction

2. Materials and Methods

2.1. Hanwoo Crust and Pork Pattie Preparation

2.2. Determination of the Proximate Composition

2.3. Determination of the pH Values

2.4. Determination of the Color of Samples

2.5. Determination of the Water-Holding Capacity (WHC)

2.6. Determination of the Cooking Yield

2.7. Determination of Viscosity

2.8. Determination of the Diameter and Thickness Reduction Ratio

2.9. Determination of the Shear Force

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

3.1. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on Proximate Composition

3.2. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on pH and Color

3.3. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on Water-Holding Capacity (WHC) and Cooking Yield

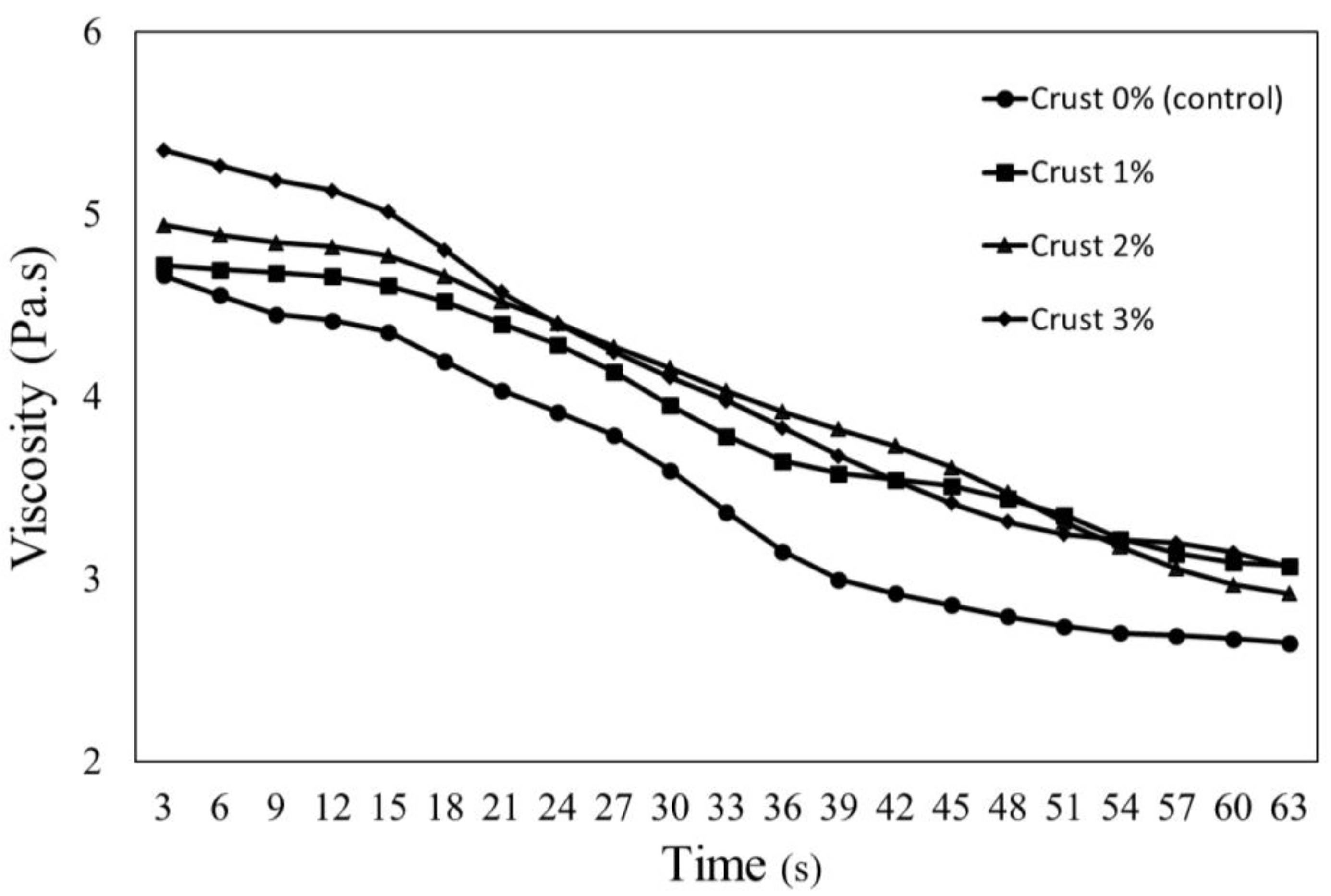

3.4. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on Viscosity

3.5. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on Diameter and Thickness Reduction Ratios

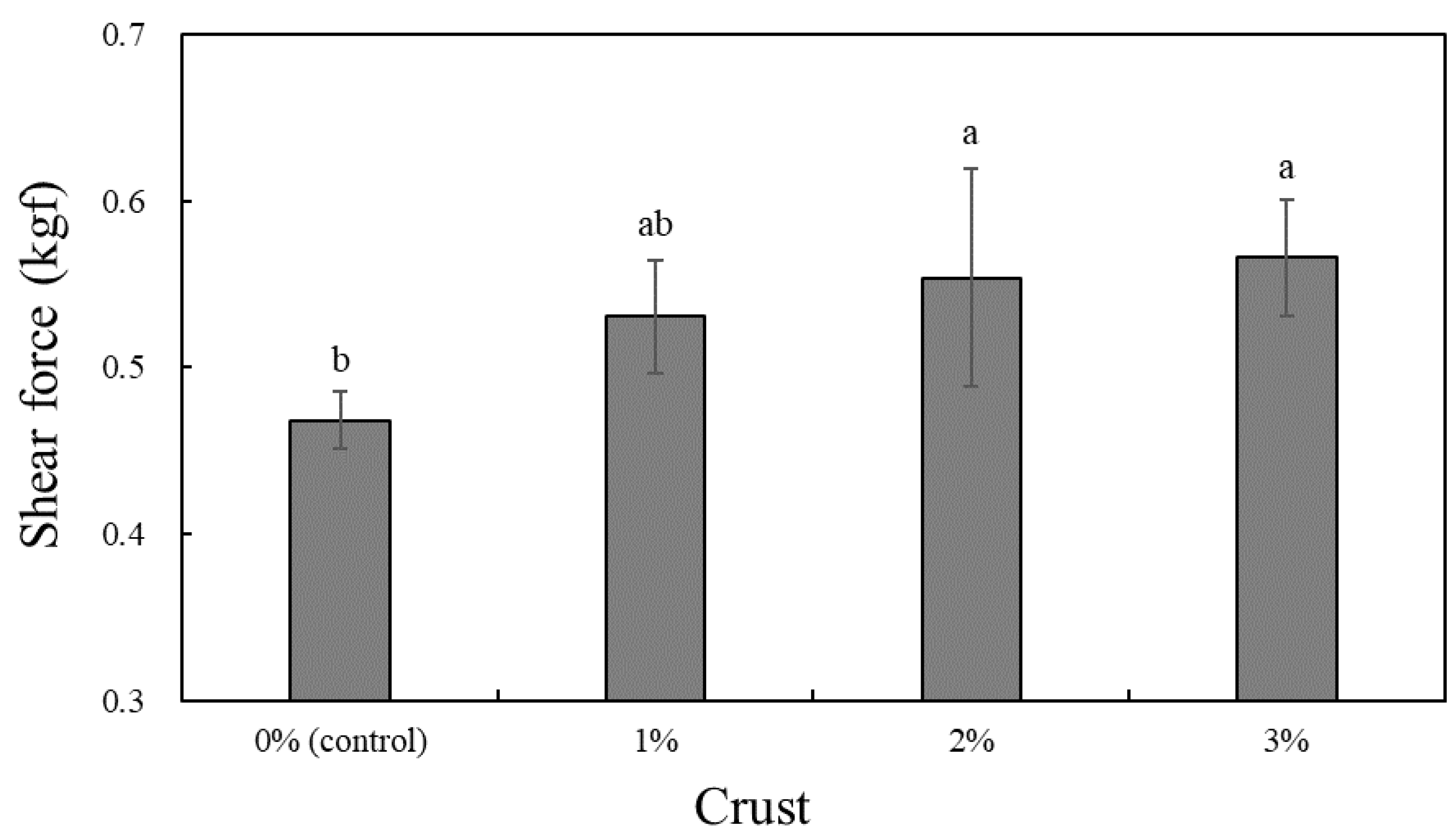

3.6. Effect of Lyophilized Crust Derived from Dry-Aged Beef (Hanwoo) Supplementation on Shear Force

3.7. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cho, S.; Kang, S.M.; Ahn, D.; Kim, Y.; Lee, E.; Ba, H.V.; Kim, Y.; Seong, P.; Kim, J.; Park, B. Effect of dry aging condition on yield, microbial growth and storage stability of bottom round muscle from Hanwoo beef. Ann. Anim. Resour. Sci. 2018, 29, 106–114. [Google Scholar] [CrossRef]

- Kim, J.H.; Cho, S.H.; Seong, P.N.; Hah, K.H.; Kim, H.K.; Park, B.Y.; Lee, J.M.; Kim, D.H.; Ahn, C.N. Effect of aging temperature and time on the meat quality of longissimus muscle from Hanwoo steer. Korean J. Food Sci. Anim. 2007, 27, 171–178. [Google Scholar] [CrossRef]

- Smith, R.D.; Nicholson, K.L.; Nicholson, J.D.W.; Harris, K.B.; Miller, R.K.; Griffin, D.B.; Savell, J.W. Dry versus wet aging of beef: Retail cutting yields and consumer palatability evaluations of steaks from US Choice and US Select short loins. Meat Sci. 2008, 79, 631–639. [Google Scholar] [CrossRef]

- Laville, E.; Sayd, T.; Morael, M.; Blinet, S.; Chambon, C.; Lepetit, J.; Renand, G.; Hocquette, J.G. Proteome changes during meat aging in tough and tender beef suggest the improtance of apoptosis and protein solubility for beef aging and tenderization. J. Agric. Food Chem. 2009, 57, 10755–10764. [Google Scholar] [CrossRef]

- Dashdorj, D.; Tripathi, V.K.; Cho, S.; Kim, Y.; Hwang, I. Dry aging of beef; Review. J. Anim. Sci. Technol. 2016, 58, 20. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Choe, J.; Kim, M.; Kim, H.C.; Yoon, J.W.; Jo, C. Role of moisture evaporation in the taste attributes of dry- and wet-aged beef determined by chemical and electronic tongue analyses. Meat Sci. 2019, 151, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Gorraiz, C.; Beriain, M.J.; Chasco, J.; Insausti, K. Effect of aging time on volatile compounds, odor, and flavor of cooked beef from Pirenaica and Friesian bulls and heifers. J. Food Sci. 2002, 67, 916–922. [Google Scholar] [CrossRef]

- Choe, J.; Park, B.; Lee, H.J.; Jo, C. Potential antioxidant and angiotensin i-converting enzyme inhibitory activity in crust of dry-aged beef. Sci. Rep. 2020, 10, 7883. [Google Scholar] [CrossRef]

- Park, B.; Yong, H.I.; Choe, J.; Jo, C. Utilization of the crust from dry-aged beef to enhance flavor of beef patties. Korean J. Food Sci. Anim. 2018, 38, 1019–1028. [Google Scholar] [CrossRef]

- Jung, I.C.; Park, H.S.; Choi, Y.J.; Park, S.S.; Kim, M.J.; Park, K.S. The effect of adding lotus root and leaf powder on the quality characteristics of cooked pork patties. Korean J. Food Cook. Sci. 2011, 27, 783–791. [Google Scholar] [CrossRef][Green Version]

- Choi, Y.J.; Park, K.S.; Jung, I.C. Quality characteristics of ground pork meat containing hot water extract from dandelion (Taraxacum officinale). J. East Asian Soc. Diet. Life 2015, 25, 651–659. [Google Scholar] [CrossRef]

- Choi, Y.S.; Jeon, K.H.; Park, J.D.; Sung, J.M.; Seo, D.H.; Ku, S.K.; Oh, N.S.; Kin, Y.B. Comparison of pork patties quality characteristics with various binding agents. Korean J. Food Cook. Sci. 2015, 31, 588–595. [Google Scholar] [CrossRef]

- Barbut, S.; Wood, J.; Marangoni, A. Potential use of organogels to replace animal fat in comminuted meat products. Meat Sci. 2016, 122, 155–162. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.E.; Chin, K.B. Antioxidant activities of brussels sprouts powder and its application to pork patties on the physicochemical properties and antioxidant activity during refrigerated storage. J. Korean Soc. Food Sci. Nutr. 2018, 47, 733–741. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, G.W.; Jeong, H.G. Development of tteokgalbi added with red pepper seed powder. J. Korean Soc. Food Sci. Nutr. 2016, 45, 255–260. [Google Scholar] [CrossRef]

- Jeong, H.G.; Kim, H.Y. Development of tteokgalbi added pig skin gelatine powder. J. Korean Soc. Food Sci. Nutr. 2016, 45, 1147–1152. [Google Scholar] [CrossRef]

- Joo, S.Y.; Choi, H.Y. Antioxidant activity and quality characteristics of pork patties added with saltwort (Salicornia herbacea L.) powder. J. Korean Soc. Food Sci. Nutr. 2014, 43, 1189–1196. [Google Scholar] [CrossRef][Green Version]

- Jung, H.O.; Lee, J.J. Quality and srorage characteristics of pork Teokgalbi with added rosemary (Rosemarinus officinalis) extract powder. Korean J. Community Living Sci. 2016, 27, 509–520. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 19th ed.; AOAC International: Gaithersburg, MD, USA, 2012; p. 931. [Google Scholar]

- Cabling, M.M.; Kang, H.S.; Lopez, B.M.; Jang, M.; Kim, H.S.; Nam, K.C.; Nam, J.G.; Choi, J.G.; Seo, K.S. Estimation of genetic associations between production and meat quality traits in duroc pigs. Asian-Australas. J. Anim. Sci. 2015, 28, 1061–1065. [Google Scholar] [CrossRef]

- Campbell, R.E.; Hunt, M.C.; Levis, P.; Chambers, E. Dry-aging effects on palatability of beef longissimus muscle. J. Food Sci. 2001, 66, 196–199. [Google Scholar] [CrossRef]

- Lee, C.W.; Lee, S.H.; Min, Y.; Lee, S.; Joo, C.; Jung, S. Quality improvement of strip loin from Hanwoo with low quality grade by dry aging. Korean J. Food Nutr. 2015, 28, 415–421. [Google Scholar] [CrossRef]

- Abdullah, N.; Wahab, N.; Saruan, N.; Matias-Peralta, H.M.; Xavier, N.R.; Muhammad, N.; Talip, B.A.; Bakar, M.F.A. Effect of replacing coconut milk with almond milk in spicy coconut gravy on its sensorial, nutritional and physical properties. Mater. Today-Proc. 2018, 5, 21919–21925. [Google Scholar] [CrossRef]

- Park, S.Y.; Seol, K.H.; Kim, H.Y. Effect of dry-aged beef crust levels on quality properties of brown sauce. Food Sci. Anim. Resour. 2020, 40, 699–709. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.S.; Jang, A.; Jin, S.K.; Lee, M.; Jo, C. Effect of marination with mixed salt and kiwi juice and cooking methods on the quality of pork loin-based processed meat product. J. Korean Soc. Food Sci. Nutr. 2008, 37, 217–222. [Google Scholar] [CrossRef][Green Version]

- Forrest, J.C.; Aberle, E.D.; Hedrick, H.B.; Judge, M.D.; Merkel, R.A. Principles of Meat Processing. In Principles of Meat Science; Schweigert, B.S., Ed.; WH Freeman and Co: New York, NY, USA, 1975; pp. 190–226. [Google Scholar]

- Kim, M.; Choe, J.; Lee, H.J.; Yoon, Y.; Yoon, S.; Jo, C. Effects of aging and aging method on physicochemical and sensory traits of different beef cuts. Food Sci. Anim. Resour. 2019, 39, 54–64. [Google Scholar] [CrossRef]

- Mancini, R.A.; Hunt, M.C. Current research in meat color. Meat Sci. 2005, 71, 100–121. [Google Scholar] [CrossRef]

- Young, O.A.; West, J. Meat Color. In Meat Science and Applications; Hui, Y.H., Nio, W.K., Rogers, R.W., Young, O.A., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 39–70. [Google Scholar]

- Park, J.W. A Study on the Quality Property of Pork Patties Supplemented by Concentrated Soy Protein (CSP). Master’s Thesis, Chung-Ang University, Seoul, Korea, 2011; pp. 4–15. [Google Scholar]

- Mittal, G.S.; Usborne, W.R. Meat emulsion extenders. Food Technol. 1985, 39, 121–130. [Google Scholar]

- Eshtiachi, M.N.; Stute, R.; Knorr, D. High-pressure and freesing pretreatment effects on drying, rehydraion, texture and color of green beans, carrots and potatoes. J. Food Sci. 1994, 59, 1168–1170. [Google Scholar] [CrossRef]

- Choi, J.H.; Yong, H.I.; Ku, S.K.; Kim, T.K.; Choi, Y.S. The qyality characteristics of pork patties according to the replacement of mealworm (Tenebrio molitor L.). Korean J. Food Cook. Sci. 2019, 35, 441–449. [Google Scholar] [CrossRef]

- Yang, H.D. Quality of Meat. In Meat Science, 1st ed.; Yang, H.D., Ed.; Sunjin Publishing: Gyeonggi-do, Korea, 2018; pp. 167–172. [Google Scholar]

- June, J.H.; Yoon, J.Y.; Kim, H.S. A study on the development of ‘hodojook’. J. Korean Soc. Food Cult. 1998, 13, 509–518. [Google Scholar]

- Hamm, R. On the rheology of minced meat. J. Texture Stud. 1975, 6, 281–296. [Google Scholar] [CrossRef]

- Kim, H.W.; Choi, J.H.; Choi, Y.S.; Han, D.J.; Kim, H.Y.; Lee, M.A.; Shim, S.Y.; Kim, C.J. Effect of wheat fiber and isolated soy protein on the quality characteristics of frankfurter type sausages. Korean J. Food Sci. Anim. Resour. 2009, 29, 475–481. [Google Scholar] [CrossRef]

- Brown, L.M.; Zayas, J.F. Corn germ protein flour as an extender in broiled patties. J. Food Sci. 1990, 55, 888–892. [Google Scholar] [CrossRef]

- Berry, B.W.; Leddy, K.F. Effects of freezing rate, frozen storage temperature and storage time on tenderness values of beef patties. J. Food Sci. 1989, 54, 291–296. [Google Scholar] [CrossRef]

- Lu, G.H.; Chen, T.C. Application of egg white and plasma powders as muscle food binding agents. J. Food Eng. 1999, 42, 147–151. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, D.S. Quality characteristics of hamburger patties adding with Tofu powder. Culin. Sci. Hosp. Res. 2014, 20, 28–40. [Google Scholar]

- Choi, Y.S.; Lee, M.A.; Jeong, J.Y.; Choi, J.H.; Han, D.J.; Lee, E.S.; Kim, C.J. Effects of wheat fiber on the quality of meat batter. Korean J. Food Sci. Anim. 2007, 27, 22–28. [Google Scholar] [CrossRef]

- Song, H.I.; Moon, K.I.; Moon, Y.H.; Jung, I.C. Quality and storage of hamburger during low temperature storage. Korean J. Food Sci. Anim. Resour. 2000, 20, 72–78. [Google Scholar]

- Moon, Y.H.; Kang, S.J.; Hyon, J.S.; Kang, H.G.; Jung, I.C. Comparison of the palatability related with characteristics of beef carcass grade B2 and D. J. Korean Soc. Food Sci. Nutr. 2001, 30, 1152–1157. [Google Scholar]

| Ingredients (%) | Crust (%) | ||||

|---|---|---|---|---|---|

| 0 (Control) | 1 | 2 | 3 | ||

| Main | Pork lean meat | 70 | 70 | 70 | 70 |

| Pork back fat | 15 | 15 | 15 | 15 | |

| Ice | 15 | 15 | 15 | 15 | |

| Additives | NPS (1) | 1.2 | 1.2 | 1.2 | 1.2 |

| Sugar | 1 | 1 | 1 | 1 | |

| Garlic powder | 0.5 | 0.5 | 0.5 | 0.5 | |

| Onion powder | 0.5 | 0.5 | 0.5 | 0.5 | |

| Crust | 0 | 1 | 2 | 3 | |

| Traits | Crust (%) | |||

|---|---|---|---|---|

| 0 (Control) | 1 | 2 | 3 | |

| Moisture (%) | 62.38 ± 0.67 a | 59.09 ± 1.66 b | 58.17 ± 0.11 b | 57.67 ± 0.23 b |

| Protein (%) | 21.20 ± 0.25 c | 23.02 ± 0.15 b | 23.33 ± 0.51 ab | 23.80 ± 0.12 a |

| Fat (%) | 14.67 ± 0.58 c | 16.50 ± 0.71 b | 17.67 ± 0.58 b | 19.33 ± 0.58 a |

| Ash (%) | 1.46 ± 0.25 b | 1.79 ± 0.10 a | 1.74 ± 0.09 a | 1.78 ± 0.04 a |

| Traits | Crust (%) | |||||

|---|---|---|---|---|---|---|

| 0 (Control) | 1 | 2 | 3 | |||

| pH | Uncooked | 6.14 ± 0.01 a | 6.13 ± 0.01 b | 6.09 ± 0.01 c | 6.08 ± 0.01 d | |

| Cooked | 6.31 ± 0.01 a | 6.31 ± 0.01 a | 6.27 ± 0.01 b | 6.25 ± 0.01 c | ||

| Color | Uncooked | CIE L* | 62.70 ± 1.27 a | 60.65 ± 1.63 ab | 59.50 ± 0.28 b | 57.65 ± 0.49 b |

| CIE a* | 3.80 ± 0.01 b | 4.0 ± 0.14 b | 4.35 ± 0.07 b | 5.40 ± 0.71 a | ||

| CIE b* | 14.20 ± 0.01 a | 13.60 ± 0.14 b | 11.60 ± 0.14 c | 11.25 ± 0.21 c | ||

| Cooked | CIE L* | 67.53 ± 0.51 a | 63.43 ± 0.42 b | 62.75 ± 0.07 bc | 62.50 ± 0.00 c | |

| CIE a* | 4.00 ± 0.28 b | 4.15 ± 0.21 b | 4.75 ± 0.21 b | 5.85 ± 0.49 a | ||

| CIE b* | 13.45 ± 0.35 | 12.40 ± 0.14 | 12.20 ± 0.42 | 11.50 ± 1.70 | ||

| Traits | Crust (%) | |||

|---|---|---|---|---|

| 0 (Control) | 1 | 2 | 3 | |

| Color | 8.00 ± 0.93 b | 8.75 ± 0.93 ab | 9.38 ± 0.74 a | 9.38 ± 0.74 a |

| Flavor | 8.13 ± 0.83 b | 8.63 ± 0.52 bc | 9.25 ± 0.46 ab | 9.50 ± 1.07 a |

| Tenderness | 9.00 ± 0.76 | 9.25 ± 0.46 | 9.13 ± 0.83 | 8.88 ± 0.64 |

| Juiciness | 8.38 ± 0.52 b | 9.00 ± 0.53 ab | 9.13 ± 0.64 a | 9.00 ± 0.76 ab |

| Overall acceptability | 8.00 ± 0.93 b | 8.81 ± 0.53 a | 9.44 ± 0.50 a | 9.38 ± 0.92 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-A.; Kim, H.-Y.; Seol, K.-H. Quality Properties of Dry-Aged Beef (Hanwoo Cattle) Crust on Pork Patties. Foods 2022, 11, 2191. https://doi.org/10.3390/foods11152191

Lee J-A, Kim H-Y, Seol K-H. Quality Properties of Dry-Aged Beef (Hanwoo Cattle) Crust on Pork Patties. Foods. 2022; 11(15):2191. https://doi.org/10.3390/foods11152191

Chicago/Turabian StyleLee, Jeong-Ah, Hack-Youn Kim, and Kuk-Hwan Seol. 2022. "Quality Properties of Dry-Aged Beef (Hanwoo Cattle) Crust on Pork Patties" Foods 11, no. 15: 2191. https://doi.org/10.3390/foods11152191

APA StyleLee, J.-A., Kim, H.-Y., & Seol, K.-H. (2022). Quality Properties of Dry-Aged Beef (Hanwoo Cattle) Crust on Pork Patties. Foods, 11(15), 2191. https://doi.org/10.3390/foods11152191