Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch

Abstract

1. Introduction

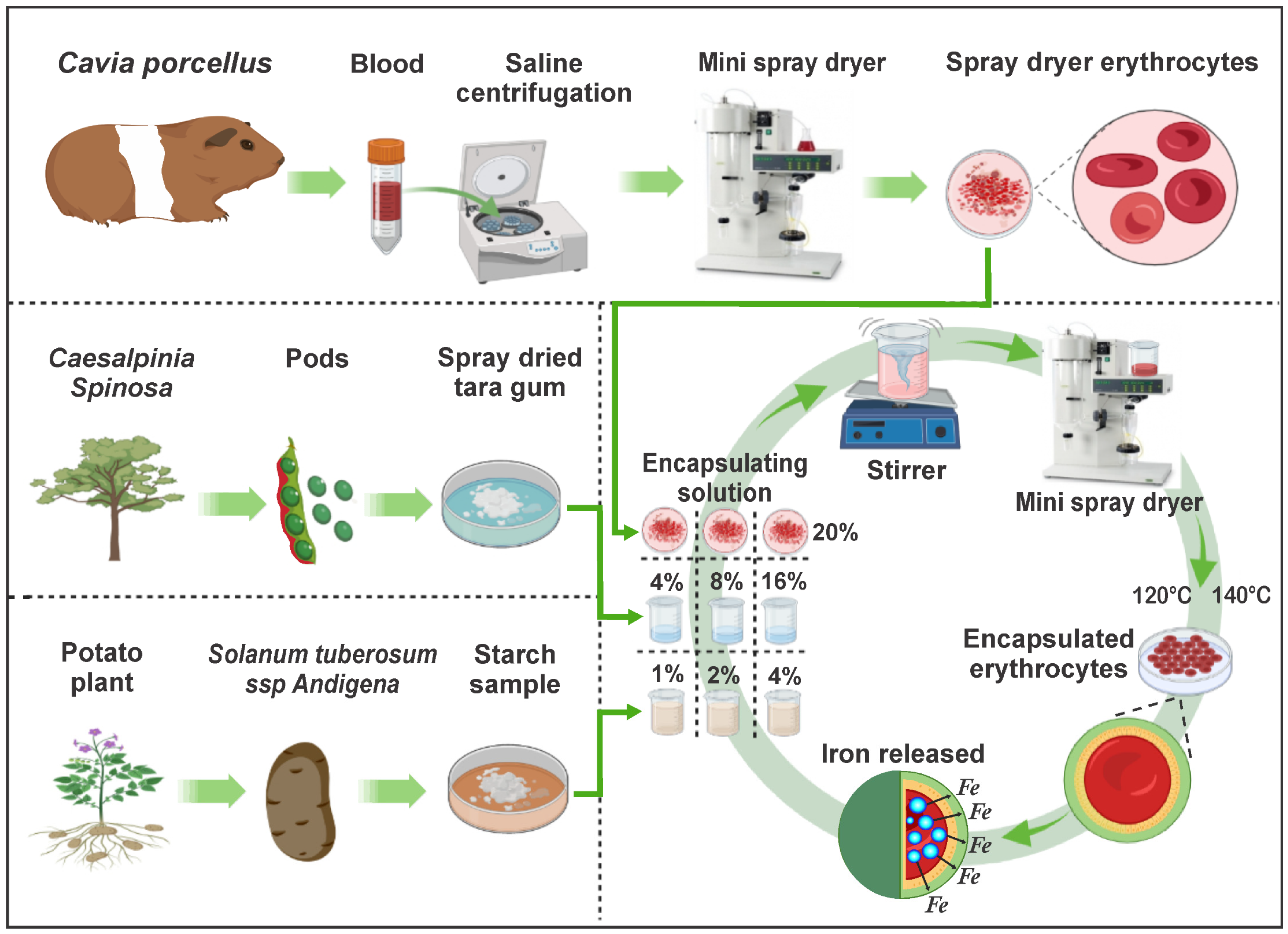

2. Materials and Methods

2.1. Materials

2.2. Obtaining Spray-Dried Erythrocytes

2.3. Obtaining Spray-Dried Tara Gum

2.4. Obtaining Starch from Native Potatoes

2.5. Erythrocytes Encapsulation

2.6. Iron Content

2.7. Moisture, Water Activity (Aw) and Bulk Density

2.8. Solubility

2.9. Hygroscopicity

2.10. Yield of Encapsulation

2.11. Color

2.12. Total Organic Carbon

2.13. SEM-EDX Analysis

2.14. Particle Size and ζ Potential

2.15. FTIR Analysis

2.16. Thermal Analysis

2.17. In Vitro Bioavailability

2.18. Statistical Analysis

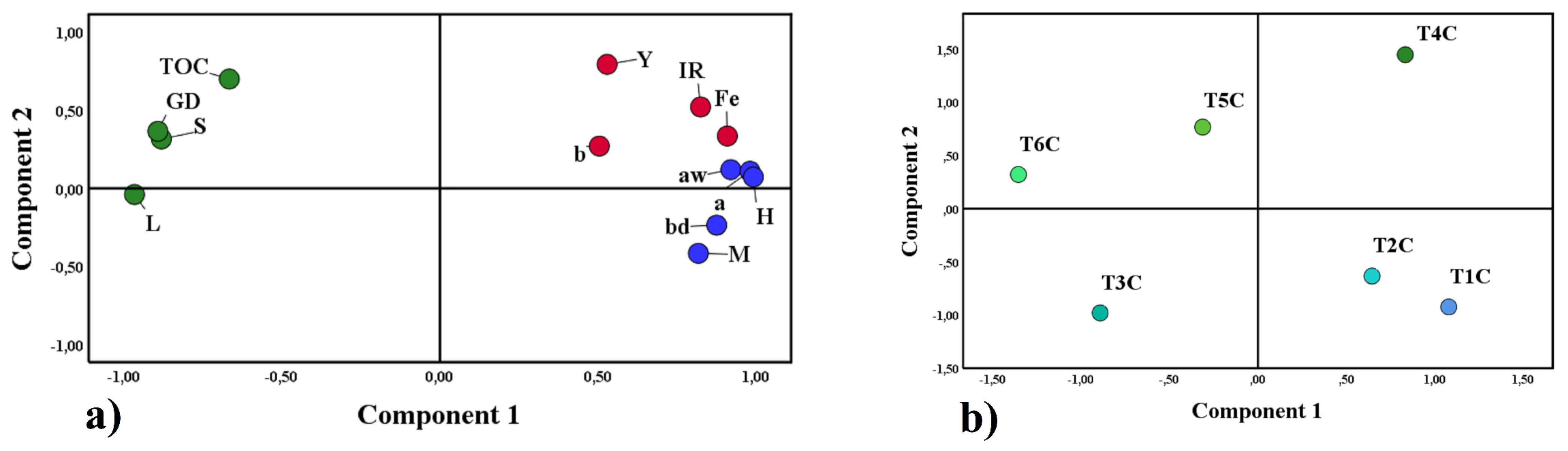

3. Results and Discussion

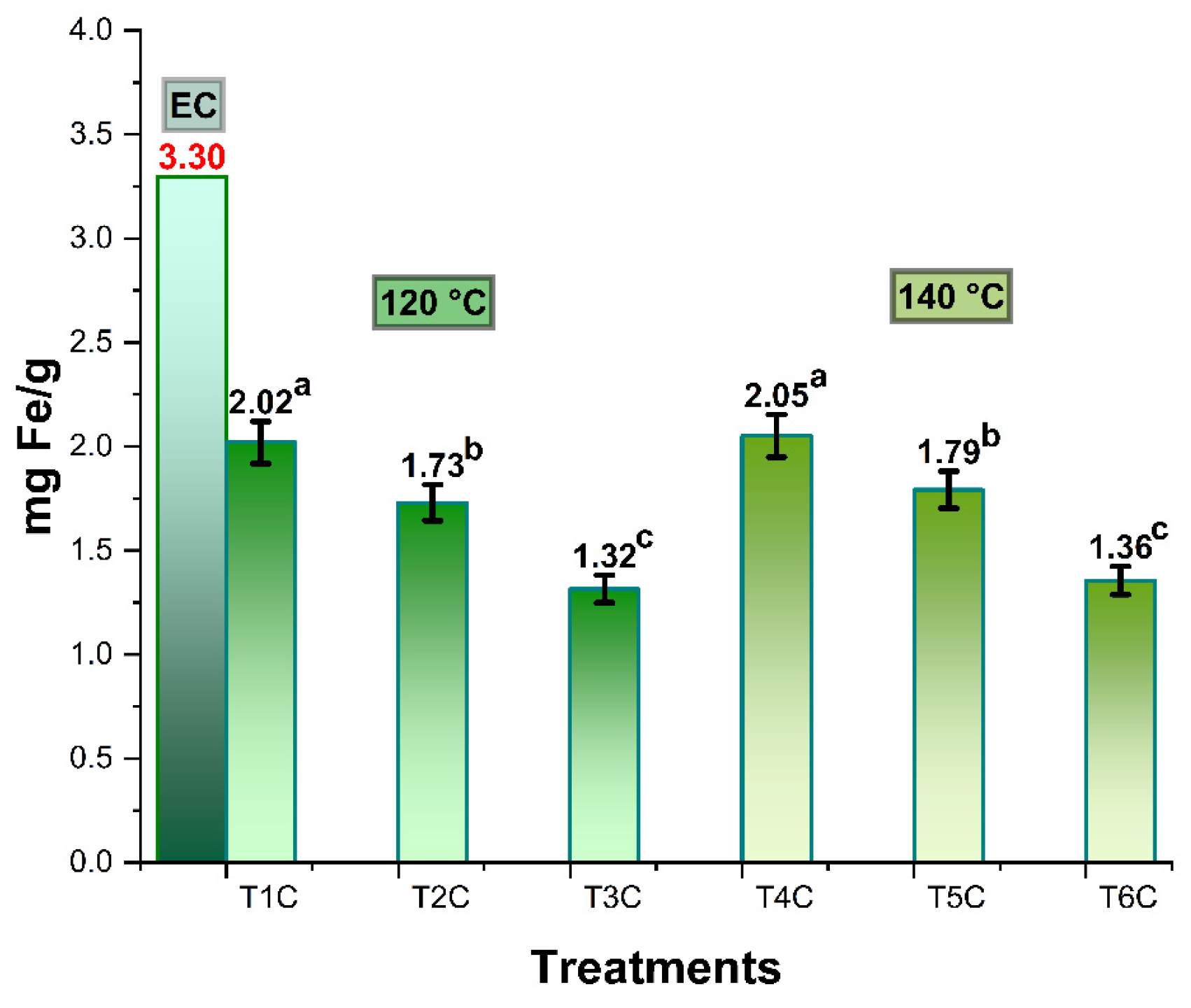

3.1. Iron Content

3.2. Moisture, Water Activity (Aw) and Bulk Density

3.3. Solubility and Hygroscopicity

3.4. Yield of Encapsulation and Color

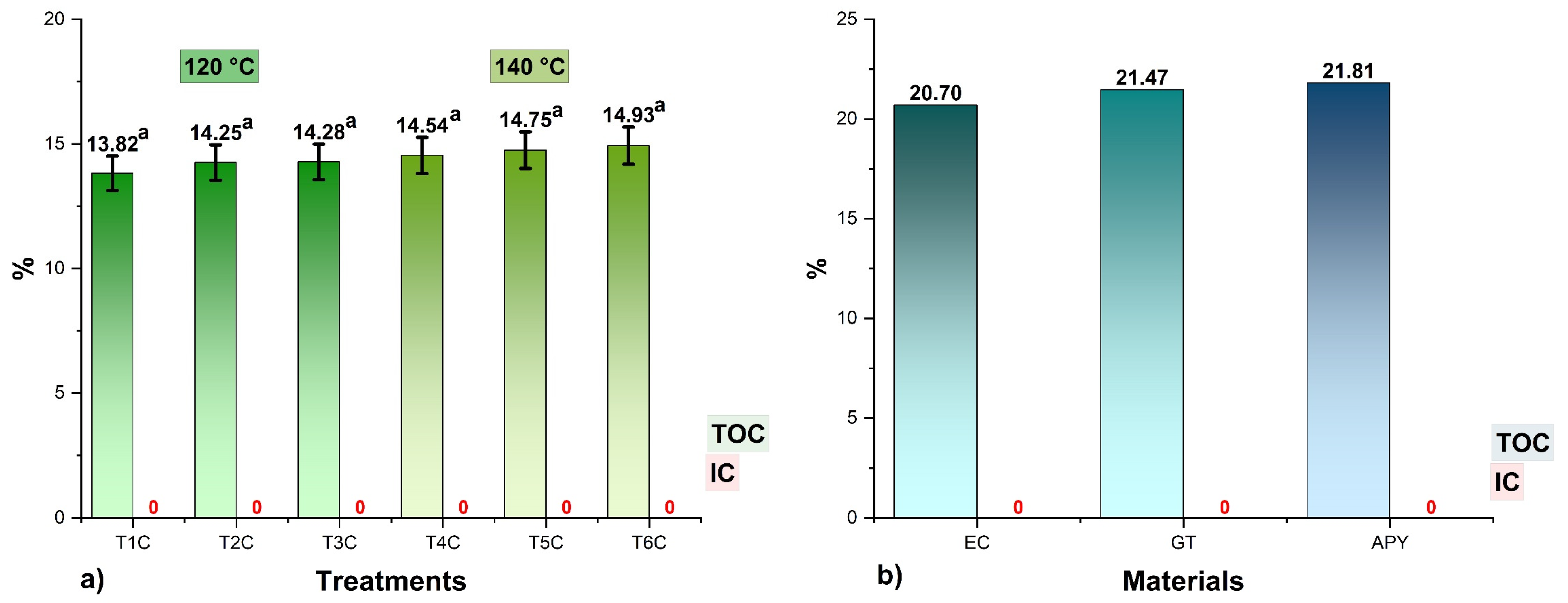

3.5. Total Organic Carbon

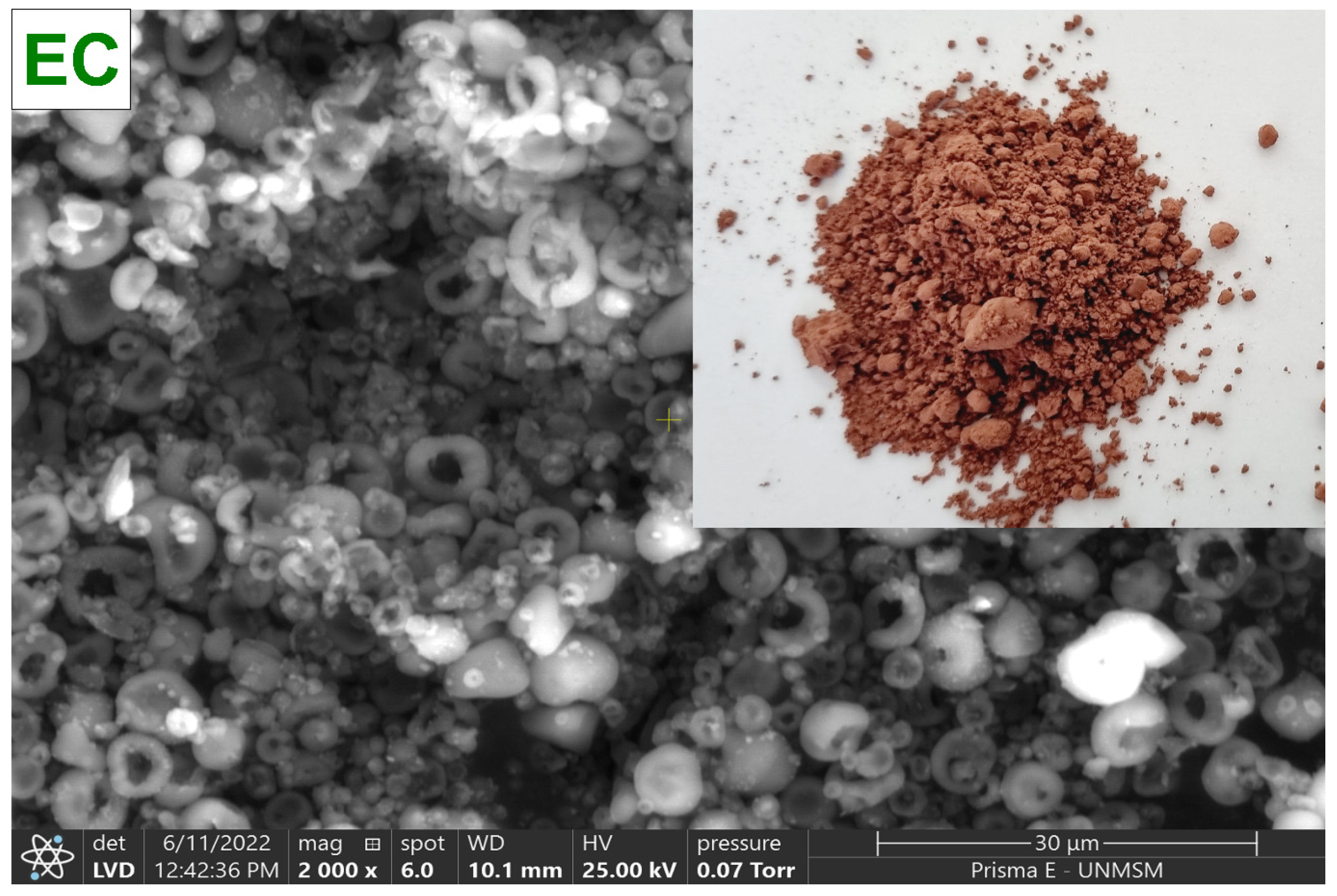

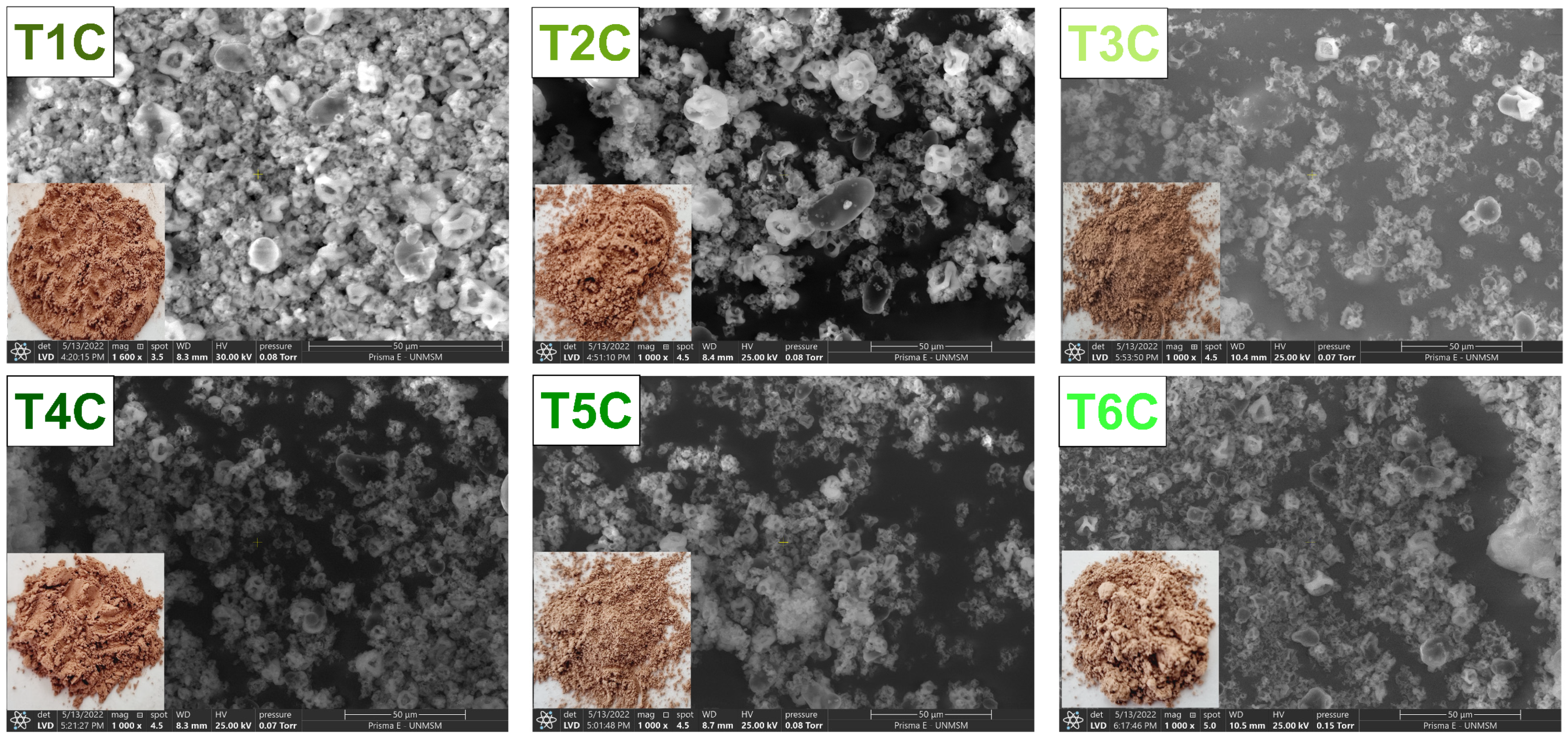

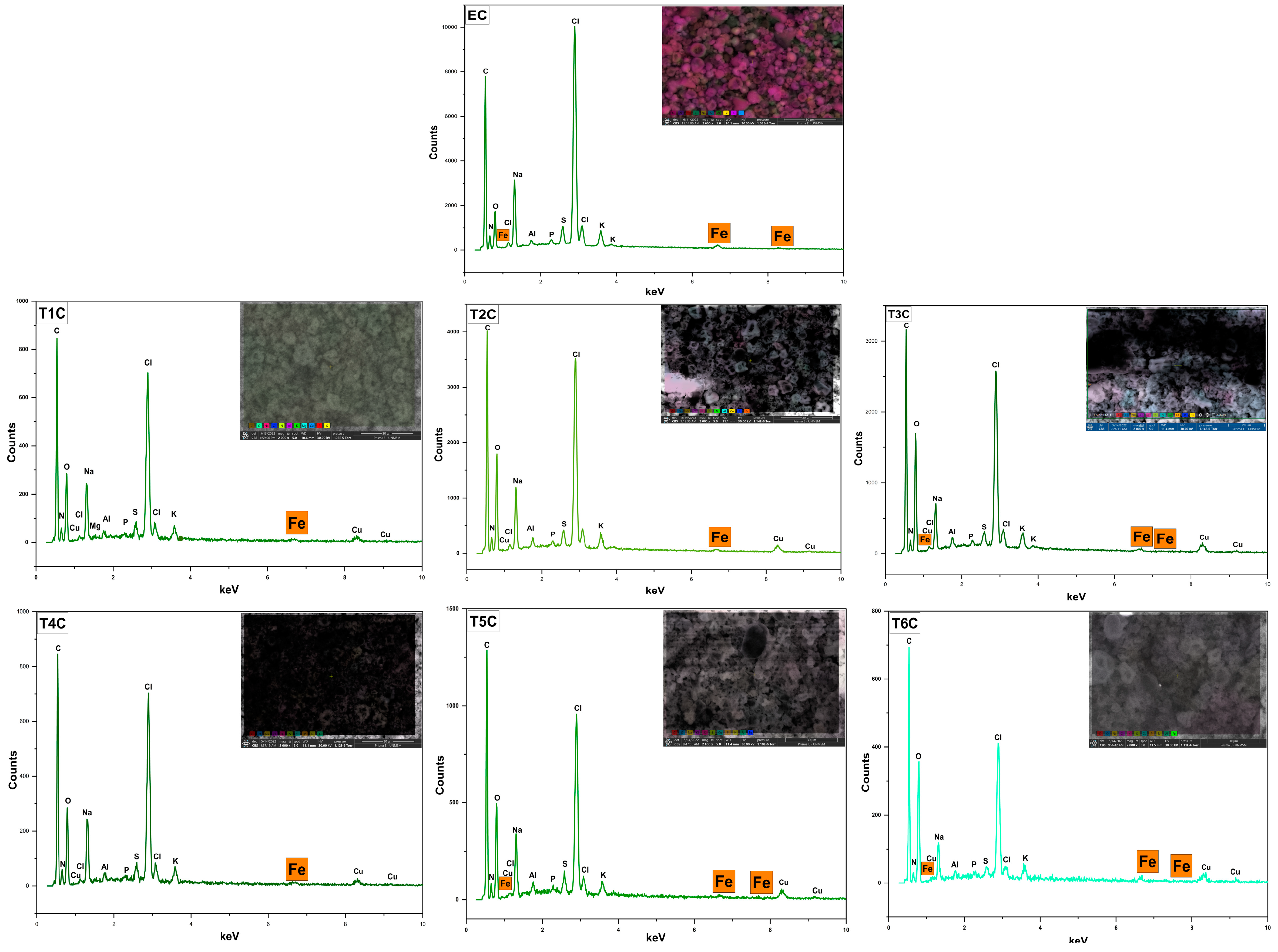

3.6. SEM-EDX Analysis

3.7. Particle Size and ζ Potential

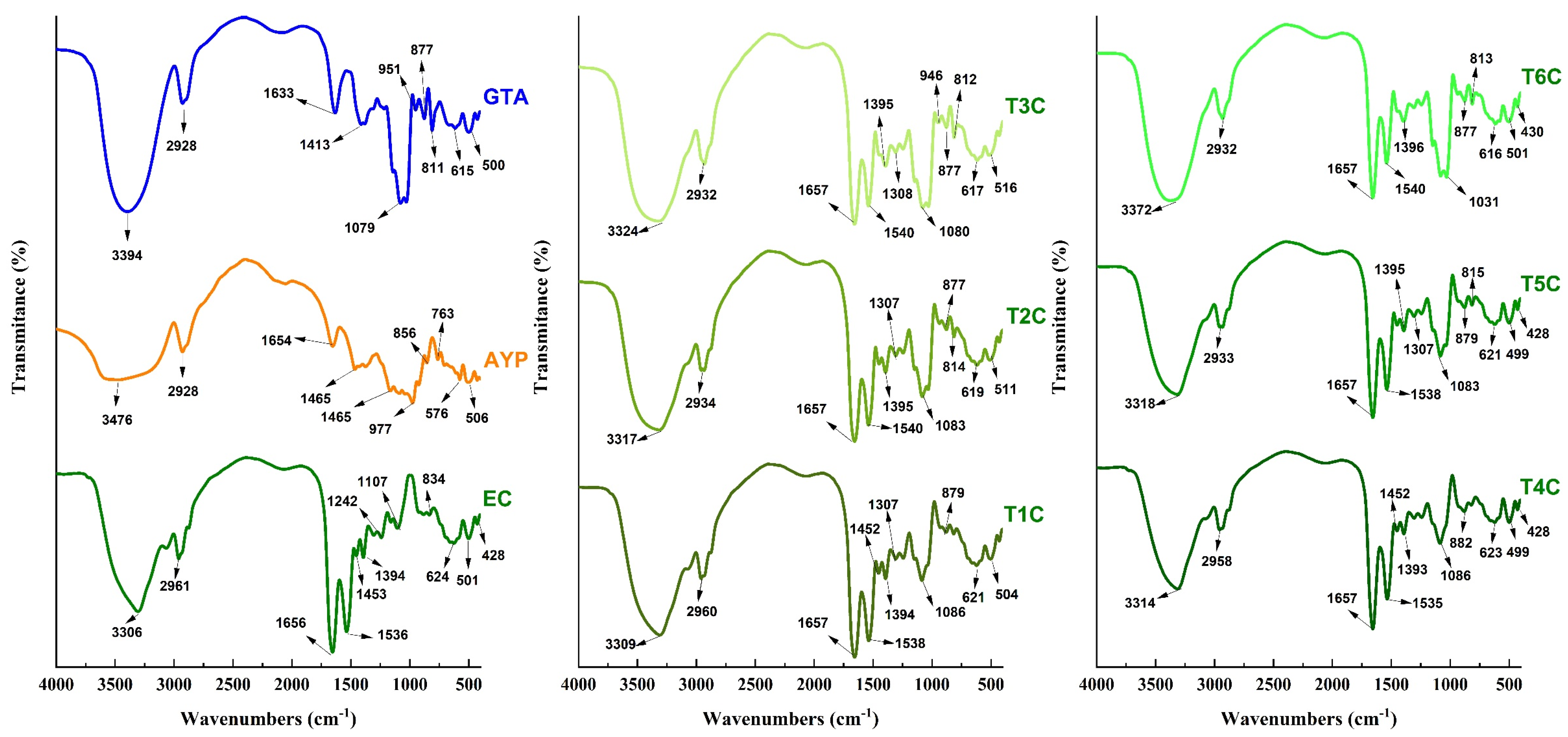

3.8. FTIR Analysis

3.9. Thermal Analysis

3.10. In Vitro Bioavailability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abe, E.; Fuwa, T.J.; Hoshi, K.; Saito, T.; Murakami, T.; Miyajima, M.; Ogawa, N.; Akatsu, H.; Hashizume, Y.; Hashimoto, Y. Expression of Transferrin Protein and Messenger RNA in Neural Cells from Mouse and Human Brain Tissue. Metabolites 2022, 12, 594. [Google Scholar] [CrossRef]

- Xu, S.; Ma, L.; Li, H.; Wang, X.; Wu, M.; Jing, J.; Chen, X.; Lan, R.; Tang, W.; Zhu, Y. Iron Supplementation Is Associated with Improvement of Motor Development, Hemoglobin Level, and Weight in Preterm Infants during the First Year of Life in China. Nutrients 2022, 14, 2624. [Google Scholar] [CrossRef]

- Yablonskiy, D.A.; Wen, J.; Kothapalli, S.V.; Sukstanskii, A.L. In vivo evaluation of heme and non-heme iron content and neuronal density in human basal ganglia. Neuroimage 2021, 235, 118012. [Google Scholar] [CrossRef]

- Zheng, J.; Liu, J.; Yang, W. Association of Iron-Deficiency Anemia and Non-Iron-Deficiency Anemia with Neurobehavioral Development in Children Aged 6–24 Months. Nutrients 2021, 13, 3423. [Google Scholar] [CrossRef]

- Stanevičienė, I.; Šulinskienė, J.; Sadauskienė, I.; Liekis, A.; Ruzgaitė, A.; Naginienė, R.; Baranauskienė, D.; Šimakauskienė, V.; Krušnauskas, R.; Vieželienė, D.J.A.B.M. Effect of Selenium on the Iron Homeostasis and Oxidative Damage in Brain and Liver of Mice. Antioxidants 2022, 11, 1216. [Google Scholar] [CrossRef]

- Piórecka, B.; Koczur, K.; Cichocki, R.; Jagielski, P.; Kawalec, P. Socio-Economic Factors Influencing the Use of Dietary Supplements by Schoolchildren from Małopolska Voivodship (Southern Poland). Int. J. Environ. Res. Public Health 2022, 19, 7826. [Google Scholar] [CrossRef]

- Nairz, M.; Weiss, G. Iron in infection and immunity. Mol. Asp. Med. 2020, 75, 100864. [Google Scholar] [CrossRef]

- Skolmowska, D.; Głąbska, D. Analysis of heme and non-heme iron intake and iron dietary sources in adolescent menstruating females in a national polish sample. Nutrients 2019, 11, 1049. [Google Scholar] [CrossRef]

- Zhu, Z.; Wu, F.; Lu, Y.; Wu, C.; Wang, Z.; Zang, J.; Guo, C.; Jia, X.; Yao, J.; Peng, H. Total and nonheme dietary iron intake is associated with metabolic syndrome and its components in Chinese men and women. Nutrients 2018, 10, 1663. [Google Scholar] [CrossRef]

- Cian, R.E.; Proaño, J.L.; Salgado, P.R.; Mauri, A.N.; Drago, S.R. High iron bioaccessibility from co-microencapsulated iron/ascorbic acid using chelating polypeptides from brewers’ spent grain protein as wall material. LWT 2021, 139, 110579. [Google Scholar] [CrossRef]

- Huertas, R.; Allwood, J.W.; Hancock, R.D.; Stewart, D. Iron and zinc bioavailability in common bean (Phaseolus vulgaris) is dependent on chemical composition and cooking method. Food Chem. 2022, 387, 132900. [Google Scholar] [CrossRef]

- Kondaiah, P.; Palika, R.; Mashurabad, P.; Yaduvanshi, P.S.; Sharp, P.; Pullakhandam, R. Effect of zinc depletion/repletion on intestinal iron absorption and iron status in rats. J. Nutr. Biochem. 2021, 97, 108800. [Google Scholar] [CrossRef]

- Polonifi, A.; Politou, M.; Kalotychou, V.; Xiromeritis, K.; Tsironi, M.; Berdoukas, V.; Vaiopoulos, G.; Aessopos, A. Iron metabolism gene expression in human skeletal muscle. Blood Cells Mol. Dis. 2010, 45, 233–237. [Google Scholar] [CrossRef]

- Blanco-Rojo, R.; Vaquero, M.P. Iron bioavailability from food fortification to precision nutrition. A review. Innov. Food Sci. Emerg. Technol. 2019, 51, 126–138. [Google Scholar] [CrossRef]

- Piskin, E.; Cianciosi, D.; Gulec, S.; Tomas, M.; Capanoglu, E. Iron Absorption: Factors, Limitations, and Improvement Methods. ACS Omega 2022, 7, 20441–20456. [Google Scholar] [CrossRef]

- Kandasamy, S.; Naveen, R. A review on the encapsulation of bioactive components using spray-drying and freeze-drying techniques. J. Food Process Eng. 2022, 3, e14059. [Google Scholar] [CrossRef]

- Wilson, R.J.; Hui, Y.; Whittaker, A.K.; Zhao, C.-X. Facile bioinspired synthesis of iron oxide encapsulating silica nanocapsules. J. Colloid Interface Sci. 2021, 601, 78–84. [Google Scholar] [CrossRef]

- Naktinienė, M.; Eisinaitė, V.; Keršienė, M.; Jasutienė, I.; Leskauskaitė, D.J.L. Emulsification and gelation as a tool for iron encapsulation in food-grade systems. LWT 2021, 149, 111895. [Google Scholar] [CrossRef]

- Bamidele, O.P.; Emmambux, M.N. Encapsulation of bioactive compounds by “extrusion” technologies: A review. Crit. Rev. Food Sci. Nutr. 2021, 61, 3100–3118. [Google Scholar] [CrossRef]

- Wang, L.; Clardy, A.; Hui, D.; Wu, Y. Physiochemical properties of encapsulated bitter melon juice using spray drying. Bioact. Carbohydr. Diet. Fibre 2021, 26, 100278. [Google Scholar] [CrossRef]

- Barick, K.; Tripathi, A.; Dutta, B.; Shelar, S.B.; Hassan, P. Curcumin encapsulated casein nanoparticles: Enhanced bioavailability and anticancer efficacy. J. Pharm. Sci. 2021, 110, 2114–2120. [Google Scholar] [CrossRef] [PubMed]

- Parra Huertas, R.A. Food microencapsulation: A review. Rev. Fac. Nac. Agron. Medellín 2010, 63, 5669–5684. [Google Scholar]

- Herrera, E.; Petrusan, J.-I.; Salvá-Ruiz, B.; Novak, A.; Cavalcanti, K.; Aguilar, V.; Heinz, V.; Smetana, S. Meat Quality of Guinea Pig (Cavia porcellus) Fed with Black Soldier Fly Larvae Meal (Hermetia illucens) as a Protein Source. Sustainability 2022, 14, 1292. [Google Scholar] [CrossRef]

- Dalle Zotte, A.; Cullere, M. Carcass traits and meat quality of rabbit, hare, guinea pig and capybara. In More than Beef, Pork and Chicken–The Production, Processing, and Quality Traits of Other Sources of Meat for Human Diet; Springer: Cham, Switzerland, 2019; pp. 167–210. [Google Scholar]

- Sánchez-Macías, D.; Cevallos-Velastegui, L.; Nuñez-Valle, D.; Morales-delaNuez, A. First report of postmortem pH evolution and rigor mortis in guinea pigs. Livest. Sci. 2019, 229, 22–27. [Google Scholar] [CrossRef]

- Carpentier, J.; Conforto, E.; Chaigneau, C.; Vendeville, J.-E.; Maugard, T. Microencapsulation and controlled release of α-tocopherol by complex coacervation between pea protein and tragacanth gum: A comparative study with arabic and tara gums. Innov. Food Sci. Emerg. Technol. 2022, 77, 102951. [Google Scholar] [CrossRef]

- Khlestkin, V.; Erst, T.; Igoshin, A.; Rozanova, I.; Khlestkina, E. Meta-Analysis of Genetic Factors for Potato Starch Phosphorylation. Agronomy 2022, 12, 1343. [Google Scholar] [CrossRef]

- Churio, O.; Valenzuela, C. Development and characterization of maltodextrin microparticles to encapsulate heme and non-heme iron. LWT 2018, 96, 568–575. [Google Scholar] [CrossRef]

- Yuan, L.; Geng, L.; Ge, L.; Yu, P.; Duan, X.; Chen, J.; Chang, Y. Effect of iron liposomes on anemia of inflammation. Int. J. Pharm. 2013, 454, 82–89. [Google Scholar] [CrossRef]

- Horwitz, W. Official Methods of Analysis of AOAC International. Volume I, Agricultural Chemicals, Contaminants, Drugs/Edited by William Horwitz; AOAC International: Gaithersburg, MD, USA, 2010. [Google Scholar]

- Kaul, S.; Kaur, K.; Mehta, N.; Dhaliwal, S.S.; Kennedy, J.F. Characterization and optimization of spray dried iron and zinc nanoencapsules based on potato starch and maltodextrin. Carbohydr. Polym. 2022, 282, 119107. [Google Scholar] [CrossRef]

- Churio, O.; Pizarro, F.; Valenzuela, C. Preparation and characterization of iron-alginate beads with some types of iron used in supplementation and fortification strategies. Food Hydrocoll. 2018, 74, 1–10. [Google Scholar] [CrossRef]

- Hu, S.; Lin, S.; He, X.; Sun, N. Iron delivery systems for controlled release of iron and enhancement of iron absorption and bioavailability. Crit. Rev. Food Sci. Nutr. 2022, 7, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Durán, E.; Villalobos, C.; Churio, O.; Pizarro, F.; Valenzuela, C. Encapsulación de hierro: Otra estrategia para la prevención o tratamiento de la anemia por deficiencia de hierro. Rev. Chil. Nutr. 2017, 44, 234–243. [Google Scholar] [CrossRef][Green Version]

- Romita, D.; Cheng, C.K.; Diosady, L.L. Microencapsulation of Ferrous Fumarate for the Production of Salt Double Fortified with Iron and Iodine. Int. J. Food Eng. 2011, 7, 1–16. [Google Scholar] [CrossRef]

- Gupta, C.; Chawla, P.; Arora, S.; Tomar, S.; Singh, A. Iron microencapsulation with blend of gum arabic, maltodextrin and modified starch using modified solvent evaporation method–Milk fortification. Food Hydrocoll. 2015, 43, 622–628. [Google Scholar] [CrossRef]

- Banjare, I.S.; Gandhi, K.; Sao, K.; Sharma, R. Optimization of spray-drying conditions for the preparation of whey protein concentrate–iron complex using response surface methodology. Int. J. Food Prop. 2019, 22, 1411–1424. [Google Scholar] [CrossRef]

- Gulmez, H.B.; Eroglu, E.; Topuz, A. Spray Drying Encapsulation of Minerals. In Spray Drying Encapsulation of Bioactive Materials; CRC Press: Boca Raton, FL, USA, 2021; pp. 171–182. [Google Scholar]

- Valenzuela, C.; Hernández, V.; Morales, M.S.; Neira-Carrillo, A.; Pizarro, F. Preparation and characterization of heme iron-alginate beads. LWT Food Sci. Technol. 2014, 59, 1283–1289. [Google Scholar] [CrossRef]

- Alemán, M.; Bou, R.; Polo, J.; Rodríguez, C.; Tres, A.; Codony, R.; Guardiola, F. Co-spray-drying of a heme iron ingredient to decrease its pro-oxidant effect in lipid-containing foods. Eur. J. Lipid Sci. Technol. 2015, 118, 195–207. [Google Scholar] [CrossRef]

- Pateiro, M.; Gómez, B.; Munekata, P.E.; Barba, F.J.; Putnik, P.; Kovačević, D.B.; Lorenzo, J.M. Nanoencapsulation of promising bioactive compounds to improve their absorption, stability, functionality and the appearance of the final food products. Molecules 2021, 26, 1547. [Google Scholar] [CrossRef]

- Gupta, C.; Chawla, P.; Arora, S. Development and evaluation of iron microencapsules for milk fortification. CyTA J. Food 2015, 13, 116–123. [Google Scholar] [CrossRef]

- Moslemi, M.; Hosseini, H.; Erfan, M.; Mortazavian, A.M.; Fard, R.M.N.; Neyestani, T.R.; Komeyli, R. Characterisation of spray-dried microparticles containing iron coated by pectin/resistant starch. Int. J. Food Sci. Technol. 2014, 49, 1736–1742. [Google Scholar] [CrossRef]

- Rezvankhah, A.; Emam-Djomeh, Z.; Askari, G. Encapsulation and delivery of bioactive compounds using spray and freeze-drying techniques: A review. Dry. Technol. 2020, 38, 235–258. [Google Scholar] [CrossRef]

- Arenas-Jal, M.; Suñé-Negre, J.; García-Montoya, E. An overview of microencapsulation in the food industry: Opportunities, challenges, and innovations. Eur. Food Res. Technol. 2020, 246, 1371–1382. [Google Scholar] [CrossRef]

- Premi, M.; Sharma, H. Effect of different combinations of maltodextrin, gum arabic and whey protein concentrate on the encapsulation behavior and oxidative stability of spray dried drumstick (Moringa oleifera) oil. Int. J. Biol. Macromol. 2017, 105, 1232–1240. [Google Scholar] [CrossRef] [PubMed]

- Ruengdech, A.; Siripatrawan, U. Improving encapsulating efficiency, stability, and antioxidant activity of catechin nanoemulsion using foam mat freeze-drying: The effect of wall material types and concentrations. LWT 2022, 162, 113478. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; da Silva, V.M.; Durigon, A.; Hubinger, M.D.; Laurindo, J.B. Production of mango powder by spray drying and cast-tape drying. Powder Technol. 2017, 305, 447–454. [Google Scholar] [CrossRef]

- Tuyen, C.K.; Nguyen, M.H.; Roach, P.D. Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. J. Food Eng. 2010, 98, 385–392. [Google Scholar] [CrossRef]

- Ricci, A.; Mejia, J.A.A.; Versari, A.; Chiarello, E.; Bordoni, A.; Parpinello, G.P. Microencapsulation of polyphenolic compounds recovered from red wine lees: Process optimization and nutraceutical study. Food Bioprod. Process. 2022, 132, 1–12. [Google Scholar] [CrossRef]

- Chng, G.Y.V.; Chang, L.S.; Pui, L.P. Effects of maltodextrin concentration and inlet temperature on the physicochemical properties of spray-dried kuini powder. Asia Pac. J. Mol. Biol. Biotechnol. 2020, 28, 113–131. [Google Scholar] [CrossRef]

- Mahdi Jafari, S.; Masoudi, S.; Bahrami, A. A Taguchi approach production of spray-dried whey powder enriched with nanoencapsulated vitamin D3. Dry. Technol. 2019, 37, 2059–2071. [Google Scholar] [CrossRef]

- Salum, P.; Berktas, S.; Cam, M.; Erbay, Z. Enzyme-modified cheese powder production: Influence of spray drying conditions on the physical properties, free fatty acid content and volatile compounds. Int. Dairy J. 2022, 125, 105241. [Google Scholar] [CrossRef]

- de Barros Fernandes, R.V.; Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532. [Google Scholar] [CrossRef] [PubMed]

- Wardhani, D.H.; Wardana, I.N.; Ulya, H.N.; Cahyono, H.; Kumoro, A.C.; Aryanti, N. The effect of spray-drying inlet conditions on iron encapsulation using hydrolysed glucomannan as a matrix. Food Bioprod. Process. 2020, 123, 72–79. [Google Scholar] [CrossRef]

- Desai, S.; Prajapati, V.; Chandarana, C. Chemistry, Biological Activities, and Uses of Tara Gum. In Gums, Resins and Latexes of Plant Origin: Chemistry, Biological Activities and Uses; Springer: Cham, Switzerland, 2022; pp. 1–24. [Google Scholar]

- Furuta, T.; Neoh, T.L. Microencapsulation of food bioactive components by spray drying: A review. Dry. Technol. 2021, 39, 1800–1831. [Google Scholar] [CrossRef]

- Samborska, K.; Poozesh, S.; Barańska, A.; Sobulska, M.; Jedlińska, A.; Arpagaus, C.; Malekjani, N.; Jafari, S.M. Innovations in spray drying process for food and pharma industries. J. Food Eng. 2022, 321, 110960. [Google Scholar] [CrossRef]

- Zbicinski, I.; Ciesielski, K.; Ge, B. Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review. Processes 2022, 10, 727. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Spray-drying of fruit and vegetable juices: Effect of drying conditions on the product yield and physical properties. Trends Food Sci. Technol. 2017, 63, 91–102. [Google Scholar] [CrossRef]

- Zhou, Z.; Langrish, T. Color formation and Maillard reactions during the spray drying process of skim milk and model systems. J. Food Process Eng. 2022, 45, e13936. [Google Scholar] [CrossRef]

- Woo, K.S.; Kim, H.Y.; Hwang, I.G.; Lee, S.H.; Jeong, H.S. Characteristics of the thermal degradation of glucose and maltose solutions. Prev. Nutr. Food Sci. 2015, 20, 102. [Google Scholar] [CrossRef]

- Chávez-Rodríguez, A.; López-Muraira, I.G.; Goméz-Leyva, J.F.; Luna-Solano, G.; Ortíz-Basurto, R.I.; Andrade-González, I. Optimization of Agave tequilana Weber var. Azul juice spray drying process. J. Chem. 2014, 2014, 915941. [Google Scholar] [CrossRef][Green Version]

- Choque-Quispe, D.; Mojo-Quisani, A.; Ligarda-Samanez, C.A.; Calla-Florez, M.; Ramos-Pacheco, B.S.; Zamalloa-Puma, L.M.; Peralta-Guevara, D.E.; Solano-Reynoso, A.M.; Choque-Quispe, Y.; Zamalloa-Puma, A. Preliminary Characterization of a Spray-Dried Hydrocolloid from a High Andean Algae (Nostoc sphaericum). Foods 2022, 11, 1640. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, T.; Li, J.; Pan, B.; Hu, Q.; Duan, M.; Zhang, X. Study on the Effect of Spray Drying Process on the Quality of Microalgal Biomass: A Comprehensive Biocomposition Analysis of Spray-Dried S. acuminatus Biomass. BioEnergy Res. 2022, 15, 320–333. [Google Scholar] [CrossRef]

- Halahlah, A.; Piironen, V.; Mikkonen, K.S.; Ho, T.M. Polysaccharides as wall materials in spray-dried microencapsulation of bioactive compounds: Physicochemical properties and characterization. Crit. Rev. Food Sci. Nutr. 2022, 2, 1–33. [Google Scholar] [CrossRef] [PubMed]

- Piñón-Balderrama, C.I.; Leyva-Porras, C.; Terán-Figueroa, Y.; Espinosa-Solís, V.; Álvarez-Salas, C.; Saavedra-Leos, M.Z. Encapsulation of active ingredients in food industry by spray-drying and nano spray-drying technologies. Processes 2020, 8, 889. [Google Scholar] [CrossRef]

- Chopde, S.; Datir, R.; Deshmukh, G.; Dhotre, A.; Patil, M.; Research, F. Nanoparticle formation by nanospray drying & its application in nanoencapsulation of food bioactive ingredients. J. Agric. 2020, 2, 100085. [Google Scholar] [CrossRef]

- Baldelli, A.; Wells, S.; Pratap-Singh, A. Impact of product formulation on spray-dried microencapsulated zinc for food fortification. Food Bioprocess Technol. 2021, 14, 2286–2301. [Google Scholar] [CrossRef]

- Bordón, M.G.; Alasino, N.P.X.; Villanueva-Lazo, Á.; Carrera-Sánchez, C.; Pedroche-Jiménez, J.; del Carmen Millán-Linares, M.; Ribotta, P.D.; Martínez, M.L. Scale-up and optimization of the spray drying conditions for the development of functional microparticles based on chia oil. Food Bioprod. Process. 2021, 130, 48–67. [Google Scholar] [CrossRef]

- Caruana, R.; Montalbano, F.; Zizzo, M.G.; Puleio, R.; Caldara, G.; Cicero, L.; Cassata, G.; Licciardi, M. Enhanced anticancer effect of quercetin microparticles formulation obtained by spray drying. Int. J. Food Sci. Technol. 2022, 57, 2739–2746. [Google Scholar] [CrossRef]

- de Moura, S.C.S.R.; Schettini, G.N.; Gallina, D.A.; Dutra Alvim, I.; Hubinger, M.D. Microencapsulation of hibiscus bioactives and its application in yogurt. J. Food Process. Preserv. 2022, 46, e16468. [Google Scholar] [CrossRef]

- Dueik, V.; Diosady, L.L. Microencapsulation of iron in a reversed enteric coating using spray drying technology for double fortification of salt with iodine and iron. J. Food Process Eng. 2017, 40, e12376. [Google Scholar] [CrossRef]

- Lisboa, H.M.; Duarte, M.E.; Cavalcanti-Mata, M.E. Modeling of food drying processes in industrial spray dryers. Food Bioprod. Process. 2018, 107, 49–60. [Google Scholar] [CrossRef]

- Deshmukh, R.; Wagh, P.; Naik, J. Solvent evaporation and spray drying technique for micro-and nanospheres/particles preparation: A review. Dry. Technol. 2016, 34, 1758–1772. [Google Scholar] [CrossRef]

- Arpagaus, C.; John, P.; Collenberg, A.; Rütti, D. Nanocapsules formation by nano spray drying. In Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Elsevier: Amsterdam, The Netherlands, 2017; pp. 346–401. [Google Scholar]

- Han, J.; Fitzpatrick, J.; Cronin, K.; Maidannyk, V.; Miao, S. Breakage behaviour and functionality of spray-dried agglomerated model infant milk formula: Effect of proteins and carbohydrates content. Food Chem. 2022, 391, 133179. [Google Scholar] [CrossRef] [PubMed]

- Nandiyanto, A.B.D.; Okuyama, K. Progress in developing spray-drying methods for the production of controlled morphology particles: From the nanometer to submicrometer size ranges. Adv. Powder Technol. 2011, 22, 1–19. [Google Scholar] [CrossRef]

- Asghari-Varzaneh, E.; Shahedi, M.; Shekarchizadeh, H. Iron microencapsulation in gum tragacanth using solvent evaporation method. Int. J. Biol. Macromol. 2017, 103, 640–647. [Google Scholar] [CrossRef] [PubMed]

- Mikol, V.; Vincendon, P.; Eriani, G.; Hirsch, E.; Giegé, R. Diagnostic of protein crystallization by dynamic light scattering; an application to an aminoacyl-tRNA synthetase. J. Cryst. Growth 1991, 110, 195–200. [Google Scholar] [CrossRef]

- Ferrari, C.C.; Germer, S.P.M.; de Aguirre, J.M. Effects of spray-drying conditions on the physicochemical properties of blackberry powder. Dry. Technol. 2012, 30, 154–163. [Google Scholar] [CrossRef]

- Schramm, L.L. Emulsions, Foams, Suspensions, and Aerosols: Microscience and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Kumar, A.; Dixit, C.K. Methods for characterization of nanoparticles. In Advances in Nanomedicine for the Delivery of Therapeutic Nucleic Acids; Elsevier: Amsterdam, The Netherlands, 2017; pp. 43–58. [Google Scholar]

- Thielbeer, F.; Donaldson, K.; Bradley, M. Zeta potential mediated reaction monitoring on nano and microparticles. Bioconjug. Chem. 2011, 22, 144–150. [Google Scholar] [CrossRef]

- Nandiyanto, A.B.D.; Oktiani, R.; Ragadhita, R. How to read and interpret FTIR spectroscope of organic material. Indones. J. Sci. Technol. 2019, 4, 97–118. [Google Scholar] [CrossRef]

- Santiago-Adame, R.; Medina-Torres, L.; Gallegos-Infante, J.; Calderas, F.; González-Laredo, R.; Rocha-Guzmán, N.; Ochoa-Martínez, L.; Bernad-Bernad, M. Spray drying-microencapsulation of cinnamon infusions (Cinnamomum zeylanicum) with maltodextrin. LWT-Food Sci. Technol. 2015, 64, 571–577. [Google Scholar] [CrossRef]

- Ghayempour, S.; Montazer, M.; Rad, M.M. Tragacanth gum as a natural polymeric wall for producing antimicrobial nanocapsules loaded with plant extract. Int. J. Biol. Macromol. 2015, 81, 514–520. [Google Scholar] [CrossRef]

- Santos, M.B.; Isabel, I.C.A.; Garcia-Rojas, E.E. Ultrasonic depolymerization of aqueous tara gum solutions: Kinetic, thermodynamic and physicochemical properties. J. Sci. Food Agric. 2022, 2, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Li, X.; Yang, P.; Liu, H.; Kong, L.; Yu, X. Microencapsulation of Fe2+ in Spray-Dried Lactose for Improved Bioavailability. Bioinorg. Chem. Appl. 2021, 2021, 5840852. [Google Scholar] [CrossRef]

- Medina-Torres, L.; Calderas, F.; Ramírez, D.M.N.; Herrera-Valencia, E.E.; Bernad, M.J.B.; Manero, O. Spray drying egg using either maltodextrin or nopal mucilage as stabilizer agents. J. Food Sci. Technol. 2017, 54, 4427. [Google Scholar] [CrossRef] [PubMed]

- Castro-López, C.; Espinoza-González, C.; Ramos-González, R.; Boone-Villa, V.D.; Aguilar-González, M.A.; Martínez-Ávila, G.C.; Aguilar, C.N.; Ventura-Sobrevilla, J.M. Spray-drying encapsulation of microwave-assisted extracted polyphenols from Moringa oleifera: Influence of tragacanth, locust bean, and carboxymethyl-cellulose formulations. Food Res. Int. 2021, 144, 110291. [Google Scholar] [CrossRef] [PubMed]

- Kaur, R.; Kaur, K. Effect of processing on color, rheology and bioactive compounds of different sweet pepper purees. Plant Foods Hum. Nutr. 2020, 75, 369–375. [Google Scholar] [CrossRef]

- Singh, A.P.; Siddiqui, J.; Diosady, L.L. Characterizing the pH-dependent release kinetics of food-grade spray drying encapsulated iron microcapsules. Food Bioprocess Technol. 2018, 11, 435–446. [Google Scholar] [CrossRef]

- Pratap-Singh, A.; Leiva, A. Double fortified (iron and zinc) spray-dried microencapsulated premix for food fortification. LWT 2021, 151, 112189. [Google Scholar] [CrossRef]

- Li, Y.O. Development of Microencapsulation-Based Technologies for Micronutrient Fortification in Staple Foods for Developing Countries; University of Toronto: Toronto, ON, Canada, 2009. [Google Scholar]

- Barbosa, B.S.T.; Garcia-Rojas, E.E. Double emulsions as delivery systems for iron: Stability kinetics and improved bioaccessibility in infants and adults. Curr. Res. Food Sci. 2022, 5, 718–725. [Google Scholar] [CrossRef]

- Vítězová, M.; Jančiková, S.; Dordević, D.; Vítěz, T.; Elbl, J.; Hanišáková, N.; Jampílek, J.; Kushkevych, I. The possibility of using spent coffee grounds to improve wastewater treatment due to respiration activity of microorganisms. Appl. Sci. 2019, 9, 3155. [Google Scholar] [CrossRef]

| Treatments | Temperature | SST | EC | APY | GTA |

|---|---|---|---|---|---|

| °C | % | % | % | % | |

| T1C | 120 | 25 | 20 | 4 | 1 |

| T2C | 30 | 20 | 8 | 2 | |

| T3C | 40 | 20 | 16 | 4 | |

| T4C | 140 | 25 | 20 | 4 | 1 |

| T5C | 30 | 20 | 8 | 2 | |

| T6C | 40 | 20 | 16 | 4 |

| Moisture (%) | Aw | Bulk Density | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ± | SD | CV | ± | SD | CV | ± | SD | CV | ||||

| EC | 11.30 | ± | 0.44 | 3.85 | 0.43 | ± | 0.002 | 0.35 | 0.23 | ± | 0.007 | 2.92 |

| T1C | 8.61 | ± | 0.09 a | 1.03 | 0.40 | ± | 0.003 a | 0.63 | 0.24 | ± | 0.001 a | 0.30 |

| T2C | 6.86 | ± | 0.07 b | 0.96 | 0.41 | ± | 0.003 b | 0.62 | 0.24 | ± | 0.002 a | 1.13 |

| T3C | 4.85 | ± | 0.12 c | 2.43 | 0.35 | ± | 0.001 c | 0.33 | 0.22 | ± | 0.001 b | 0.41 |

| T4C | 5.69 | ± | 0.05 a | 0.96 | 0.40 | ± | 0.001 a | 0.29 | 0.24 | ± | 0.003 a | 1.09 |

| T5C | 5.52 | ± | 0.18 a | 3.31 | 0.38 | ± | 0.002 b | 0.40 | 0.20 | ± | 0.003 b | 1.29 |

| T6C | 4.73 | ± | 0.11 b | 2.32 | 0.36 | ± | 0.001 c | 0.16 | 0.17 | ± | 0.005 c | 3.04 |

| Solubility (%) | Hygroscopicity (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| ± | SD | CV | ± | SD | CV | |||

| EC | 72.08 | ± | 0.47 | 0.65 | 36.66 | ± | 0.59 | 1.60 |

| T1C | 43.22 | ± | 0.83 a | 1.92 | 32.94 | ± | 1.20 a | 3.65 |

| T2C | 44.27 | ± | 2.76 a | 6.23 | 30.13 | ± | 1.39 b | 4.62 |

| T3C | 49.74 | ± | 2.54 b | 5.11 | 22.56 | ± | 1.26 c | 5.59 |

| T4C | 45.11 | ± | 1.06 a | 2.36 | 31.95 | ± | 0.60 a | 1.88 |

| T5C | 55.21 | ± | 4.84 b | 8.77 | 26.03 | ± | 1.48 b | 5.71 |

| T6C | 57.18 | ± | 1.20 b | 2.10 | 22.05 | ± | 0.86 c | 3.91 |

| Yield | Color | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | L | a | b | |||||||||||||

| ± | SD | CV | ± | SD | CV | ± | SD | CV | ± | SD | CV | |||||

| GT | 12.31 | ± | 0.64 | 5.22 | 91.02 | ± | 0.06 | 0.07 | 0.06 | ± | 0.01 | 10.19 | 3.52 | ± | 0.05 | 1.34 |

| APY | 12.34 | ± | 0.22 | 1.78 | 92.69 | ± | 0.07 | 0.07 | −0.16 | ± | 0.01 | −6.25 | 1.66 | ± | 0.03 | 1.51 |

| EC | 29.18 | ± | 1.19 | 4.06 | 39.37 | ± | 0.26 | 0.65 | 15.18 | ± | 0.08 | 0.49 | 21.45 | ± | 0.08 | 0.36 |

| T1C | 52.73 | ± | 0.79 a | 1.49 | 54.17 | ± | 0.12 a | 0.23 | 9.82 | ± | 0.06 a | 0.56 | 18.99 | ± | 0.06 a | 0.29 |

| T2C | 49.32 | ± | 0.93 b | 1.88 | 53.88 | ± | 0.16 a | 0.29 | 9.61 | ± | 0.07 b | 0.75 | 19.68 | ± | 0.01 b | 0.03 |

| T3C | 47.84 | ± | 1.39 b | 2.92 | 59.38 | ± | 0.18 b | 0.30 | 7.20 | ± | 0.10 c | 1.34 | 19.12 | ± | 0.06 c | 0.30 |

| T4C | 58.73 | ± | 1.30 a | 2.21 | 54.37 | ± | 0.06 a | 0.10 | 9.90 | ± | 0.02 a | 0.23 | 20.22 | ± | 0.09 a | 0.46 |

| T5C | 53.29 | ± | 1.11 a | 2.09 | 56.40 | ± | 0.06 b | 0.11 | 8.61 | ± | 0.05 b | 0.52 | 18.50 | ± | 0.01 b | 0.06 |

| T6C | 50.33 | ± | 3.80 a | 7.55 | 61.38 | ± | 0.02 c | 0.03 | 6.38 | ± | 0.02 c | 0.33 | 18.96 | ± | 0.03 c | 0.18 |

| Treatments | NICOMP Distribution | Gaussian Distribution | ζ Potential (mV) | ||||

|---|---|---|---|---|---|---|---|

| Peak | Size (nm) | % | SD | CV | |||

| T1C | 1 | 541.6 | 100.0 | 817.1 | 67.98 | 8.32 | −0.40 |

| T2C | 1 | 677.0 | 100.0 | 1076.8 | 82.05 | 7.62 | −0.83 |

| T3C | 1 | 122.0 | 6.1 | 1595.5 | 115.67 | 7.25 | −1.79 |

| 2 | 188.3 | 9.9 | |||||

| 3 | 902.5 | 84.0 | |||||

| T4C | 1 | 900.2 | 100.0 | 1331.8 | 121.64 | 8.26 | −2.19 |

| T5C | 1 | 902.8 | 100.0 | 1472.7 | 104.81 | 7.87 | −8.60 |

| T6C | 1 | 39.8 | 1.2 | 1672.2 | 132.27 | 7.91 | −9.17 |

| 2 | 199.3 | 23.0 | |||||

| 3 | 903.7 | 75.8 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ligarda-Samanez, C.A.; Moscoso-Moscoso, E.; Choque-Quispe, D.; Palomino-Rincón, H.; Martínez-Huamán, E.L.; Huamán-Carrión, M.L.; Peralta-Guevara, D.E.; Aroni-Huamán, J.; Arévalo-Quijano, J.C.; Palomino-Rincón, W.; et al. Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch. Foods 2022, 11, 2107. https://doi.org/10.3390/foods11142107

Ligarda-Samanez CA, Moscoso-Moscoso E, Choque-Quispe D, Palomino-Rincón H, Martínez-Huamán EL, Huamán-Carrión ML, Peralta-Guevara DE, Aroni-Huamán J, Arévalo-Quijano JC, Palomino-Rincón W, et al. Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch. Foods. 2022; 11(14):2107. https://doi.org/10.3390/foods11142107

Chicago/Turabian StyleLigarda-Samanez, Carlos A., Elibet Moscoso-Moscoso, David Choque-Quispe, Henry Palomino-Rincón, Edgar L. Martínez-Huamán, Mary L. Huamán-Carrión, Diego E. Peralta-Guevara, Jimmy Aroni-Huamán, José C. Arévalo-Quijano, Wilbert Palomino-Rincón, and et al. 2022. "Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch" Foods 11, no. 14: 2107. https://doi.org/10.3390/foods11142107

APA StyleLigarda-Samanez, C. A., Moscoso-Moscoso, E., Choque-Quispe, D., Palomino-Rincón, H., Martínez-Huamán, E. L., Huamán-Carrión, M. L., Peralta-Guevara, D. E., Aroni-Huamán, J., Arévalo-Quijano, J. C., Palomino-Rincón, W., Cruz, G. D. l., Ramos-Pacheco, B. S., Muñoz-Saenz, J. C., & Muñoz-Melgarejo, M. (2022). Microencapsulation of Erythrocytes Extracted from Cavia porcellus Blood in Matrices of Tara Gum and Native Potato Starch. Foods, 11(14), 2107. https://doi.org/10.3390/foods11142107