Application of Emulsion Gels as Fat Substitutes in Meat Products

Abstract

:1. Introduction

2. Emulsion Gel

2.1. A Basic Introduction of Emulsion Gel

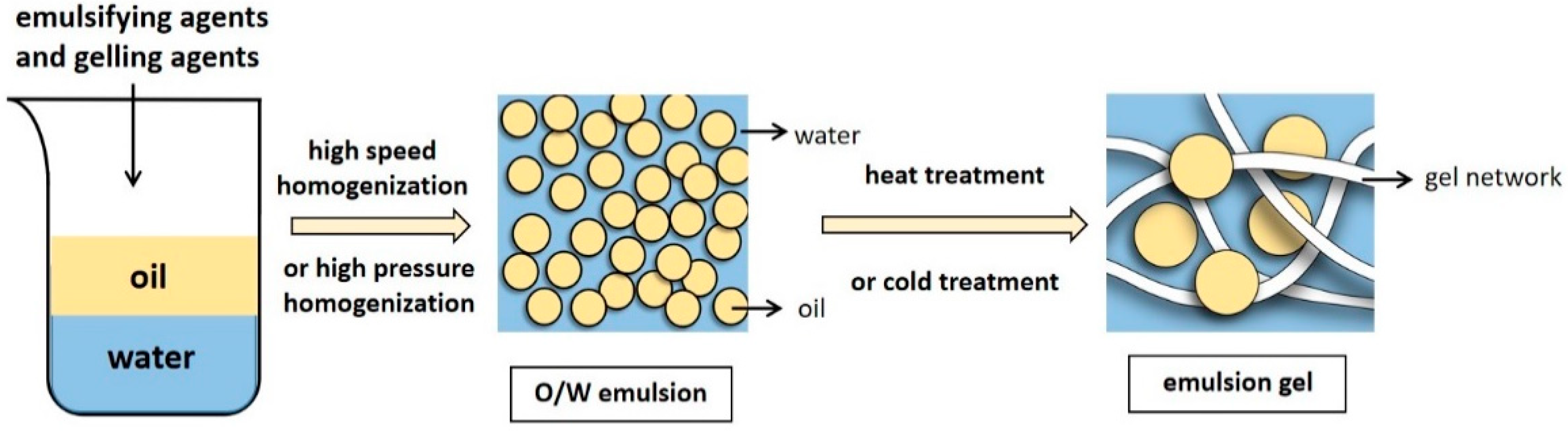

2.2. Preparation of the Emulsion Gel

3. The Application of Emulsion Gels as a Fat Replacement

3.1. Preparation of the Emulsion Gel

3.1.1. The Gelation Mechanism and Influencing Factors

3.1.2. Protein-Based Emulsion Gels as Fat Substitutes in Meat Products

- (1)

- Reducing the fat content and improving the fatty acid profile

- (2)

- Structured liquid oils

- (3)

- The introduction of functional ingredients and application of new technologies

3.2. Polysaccharide-Based Emulsion Gels

3.2.1. Gelation Mechanism and Influencing Factors

3.2.2. Polysaccharide-Based Emulsion Gels as Fat Substitutes in Meat Products

- (1)

- Reducing the fat content and improving the fatty acid profile

- (2)

- Structured liquid oils

- (3)

- The development of fat cube substitutes

- (4)

- The introduction of functional components

3.3. Protein–Polysaccharide Composite-Based Emulsion Gels

3.3.1. The Gelation Mechanism and Influencing Factors

3.3.2. Protein–Polysaccharide Composite-Based Emulsion Gels as Fat Substitutes in Meat Products

- (1)

- Reducing the fat content and improving the fatty acid profile

- (2)

- The development of fat cube substitutes

- (3)

- The application of cereal flour as a composite matrix emulsion gel

- (4)

- Changes in the sensory properties of products caused by different substitution ratios

| The Matrix Type | Oil | Protein | Polysaccharide | Gel Method | The Application of Fat Substitutes | References |

|---|---|---|---|---|---|---|

| Protein-based | Olive oil | SPI, SC | - | TG induction | Pork backfat in Frankfurters | [85] |

| Olive oil, linseed oil, fish oil | SPI, SC | - | TG induction | Technical applicability in different meat products | [49] | |

| Olive oil, linseed oil, fish oil | SPI, SC | - | TG induction | Pork backfat in Frankfurters | [48] | |

| Olive oil, linseed oil, fish oil | SPI, SC | - | TG induction | Pork backfat in Frankfurters | [47] | |

| Olive oil, chia oil | SPI | - | Gelatin was used as a gelling agent | Pork fat in functional fermented meat products (fuet) | [41] | |

| Canola oil | SPI | - | Adding hydrophobically modified biosurfactants (acetylated starch, OSA starch, EHEC, and DS inulin) | Low-fat meat product simulant constructed by 3D printing | [54,55] | |

| Olive oil | SPI | - | Gelling agent based on alginate | Fat in Frankfurters and research on the development of meat products rich in polyphenols | [53] | |

| Canola oil, sal fat, or mixtures thereof | SPI | TG induction | Fat in salami-type sausage | [86] | ||

| Polysaccharide-based | Olive oil, linseed oil, fish oil | - | Konjac glucomannan, i-carrageenan, pre-gelled corn starch | Ca(OH)2 induction | Pork backfat in low-fat pork liver pâté | [65] |

| Olive oil, linseed oil, fish oil | - | Konjac flour, pre-gelled corn starch | Ca(OH)2 induction | Pork backfat in dry fermented sausage | [66] | |

| Olive oil, linseed oil, fish oil | - | Konjac flour, pre-gelled corn starch | Ca(OH)2 induction | Pork backfat in Frankfurters | [67] | |

| Olive oil | - | Konjac flour, i- carrageenan, pre-gelled corn starch | Ca(OH)2 induction | Beef fat in fresh sausage (Merguez) | [87] | |

| Olive oil, linseed oil, fish oil | - | Konjac flour, pre-gelled corn starch, ι- carrageenan | Ca(OH)2 induction | Pork fat in dry-fermented sausage | [68] | |

| Linseed oil | - | Carrageenan | Cooling after heating | Part of the fat in Bologna sausage | [88] | |

| Sunflower oil | - | Carrageenan | Cooling after heating | Pork backfat in burger patties | [33] | |

| Soybean oil | - | Aloe gel | Cooling after heating | Fat in low-fat meat emulsion | [89] | |

| Linseed oil | - | κ-carrageenan | Cooling after heating | Pork backfat in dry-fermented sausage | [64] | |

| Algae oil | - | κ-carrageenan | Cold induction | Fat in beef patties | [90] | |

| Linseed oil | - | inulin | pork gelatin was used as a gelling agent | Pork backfat in dry-fermented sausage | [91] | |

| Canola oil | - | κ-carrageenan | Cooling after heating | Fat in beef batter | [42] | |

| Microalgal oil | - | κ-carrageenan | Cold induction | Fat in beef patties | [70] | |

| Chia oil, linseed oil | - | κ-carrageenan | Heat induction | Pork backfat in low-fat burgers | [92] | |

| Pre-emulsified olive oil | - | Jerusalem artichoke powder | Heat induction | Pork back fat in Harbin dry sausages | [93] | |

| Corn germ oil | - | Konjac flour, κ-carrageenan, barley β glucan | Heat induction | Pork backfat in Harbin dry sausages (cube fat substitute) | [63] | |

| Canola oil, olive oil | - | κ-carrageenan | Carrageenan was used as a gelling agent. | Pork backfat in beef burgers | [94] | |

| Protein–polysaccharide composite-based | Olive oil | Chia powder (protein 22%) | Chia powder (dietary fiber 30.2%) | Three different cold-gelling agents: MTG and caseinate; sodium alginate, CaSO4, and pyrophosphate; gelatin | Pork backfat in low-fat Frankfurters | [78] |

| Olive oil | Gelatin | Inulin | Gelatin and inulin were used as gel agent | Beef fat in model system meat emulsion | [83] | |

| Olive oil | Chia powder | Chia powder | Gelling agent based on alginate | Pork backfat in low-fat Frankfurters | [35] | |

| Olive oil | Chia powder | Chia powder | Gelling agent based on alginate | Pork backfat in low-fat Frankfurters | [95] | |

| Olive oil | Gelatin | Inulin | Cooling after heating | Beef fat in chicken patties | [82] | |

| Linseed oil | Gelatin | Inulin | Cooling after heating | Beef fat in the model system meat emulsion | [96] | |

| Olive oil | Gelatin | Inulin | Cooling after heating | Beef fat in model turkey breast emulsion | [97] | |

| Olive oil | Chia powder, oat bran (protein 20%) | Chia powder, oat bran (dietary fiber 44%) | Gelling agent based on alginate | Fat in low-fat fresh sausage (longaniza) | [79] | |

| Soybean oil | SPI, SC | Carrageenan, pectin, inulin | Heat induction | Pork backfat in meat products develops functional emulsion gels | [37] | |

| Camellia oil | SC | κ-carrageenan | Cold induction | Pork fat in low-fat Harbin sausage | [98] | |

| Soybean oil | SPI, SC | Chia powder, inulin, carrageenan | Heat induction | Pork backfat in Bologna sausage | [39] | |

| Soybean oil | SPI | κ-carrageenan, ι-carrageenan, inulin, | Heat induction | Pork backfat in low-fat Frankfurter sausage | [51] | |

| Canola oil | Pork skin (protein 37.7% ± 0.9) | bamboo fiber, inulin, polydextrose, α-cyclodextrin | Cooling after heating | Pork backfat in emulsified meat products | [75] | |

| Olive oil | Chia mucilage, | Chia mucilage | Gelling agent based on alginate | Pork backfat in Bologna sausage | [99] | |

| Soybean oil | SPI | Inulin, carrageenan | Carrageenan was used as a gelling agent | Pork backfat in Bologna sausage | [100] | |

| Olive oil | Chia mucilage, whey protein, collagen | Chia mucilage | Six gelling agents (sodium alginate, collagen, whey protein, carboxymethylcellulose, TG, and carrageenan) | Pork backfat in emulsified meat products | [101] | |

| Black cumin oil, flaxseed oil | SC, gelatin | Inulin | Cooling after heating | Beef fat in functional fresh chicken sausages | [102] | |

| Peanut oil, linseed oil | Egg white albumin, gelatin | Inulin | Heating induction and cold induction were used, respectively | Beef fat in fermented beef sausage | [103] | |

| Olive oil | Chia mucilage, whey protein, collagen | Chia mucilage | Gelling agent based on alginate and collagen | Beef fat in fermented beef sausage | [104] | |

| Walnut oil | Cocoa bean shell flour (protein 17.13 g/100 g), gelatin | Cocoa bean shell flour (dietary fiber 61.18 g/100 g) | Gelatin was used as a gelling agent | Beef fat in fermented beef sausage | [77] | |

| Peanut oil, linseed oil | Egg white powder, gelatin | Chicory inulin | Gelatin was used as a gelling agent, cooling after heating | Beef fat in emulsified sausage | [84] | |

| Olive oil | Chia powder, oat bran | Chia powder, oat bran | Gelling agent based on alginate | Pork backfat in healthy fresh meat products (longanizas) | [80] | |

| Sunflower oil | SPI | Konjac glucomannan | Heat induction | Development of plant-based fish ball analogs | [76] | |

| Coconut oil | SPI | Konjac glucomannan | TG induction, heat induction | Simulated natural pork fat (3D structures) | [46] | |

| Soybean oil | SPI | Curdlan | Heat induction | Simulated pork backfat | [105] |

4. The Application of Double Emulsions for Fat Replacement

4.1. The Mechanism and Influencing Factors of Double Emulsions as Fat Substitutes

4.2. The Application of Double Emulsions in the Food Industry

4.2.1. The Application of Double Emulsions as Fat Substitutes in Meat Products

- (1)

- The application of double emulsions to reduce fat and improve fatty acid composition

- (2)

- The examination of the oxidation stability

- (3)

- Adding functional components via double emulsions

4.2.2. Examination of the Gelled Double Emulsion as a Fat Substitute

| W1 | O | W2 | Lipophilic Surfactant | Hydrophilic Emulsifiers | Research Content | References |

|---|---|---|---|---|---|---|

| NaCl | Olive oil | SC, whey protein concentrate, NaCl | Polyglycerol polyricinoleate (PGPR) | Whey protein concentrate, SC | Evaluates the effect of using double emulsion as a strategy to improve the fat content in meat model systems. | [113] |

| NaCl | Olive oil or pork lard | NaCl, SC | PGPR | SC | Possibility of food-grade double emulsion as a low-fat food ingredient in the meat industry. | [126] |

| NaCl, SC, Hxt | Chia oil | NaCl, SC | PGPR | SC | Antioxidant effect of double emulsion containing Hxt in the W1 as a fat substitute in a cooked meat system. | [115] |

| NaCl | Olive oil | NaCl, SC | PGPR | SC | Double emulsion replaces beef fat in a model beef emulsion system. | [109] |

| NaCl | Perilla oil, rendered pork backfat | NaCl, SC | PGPR | SC | Double emulsion replaces pork backfat in Frankfurters. | [112] |

| Native beetroot juice | Sunflower oil | Whey protein isolate | PGPR | Whey protein isolate | Double emulsion replaces pork backfat in the meat system and its effect on color improvement. | [114] |

| NaCl | Olive oil | Egg white powder, NaCl | PGPR | Egg white powder | Double emulsion replacement of beef fat in meat emulsion in the model system. | [116] |

| Hxt | Perilla oil | SC, gelatin, MTG | PGPR | SC | Gelled double emulsion replaces pork backfat in pork patties and its applicability as an n-3 PUFA and hydroxytyramol delivery system. | [117] |

| Olive leaf extract | Olive oil, linseed oil, fish oil | NaCl, SC | PGPR | SC | W1 contains double emulsion olive leaf extract to replace pork backfat in the meat system. | [127] |

| NaCl, bromelain | Canola oil | Tween® 80 | PGPR | Tween® 80 | Effect of bromelain liberated or embedded in the double emulsion on the eating palatability of pork loin. | [128] |

| NaCl | Olive oil | SC, whey protein concentrate, NaCl | PGPR | Whey protein concentrate, SC | Evaluates the effect of using double emulsion as a strategy to improve the fat content in meat model systems. | [119] |

| Gellan gum, CaCl2 | Refined pork oil | SC | PGPR | SC | Development of low-fat emulsified sausages using G/O/W double emulsion. | [123] |

5. Summary and Prospects

- (1)

- Emulsion gels are suitable as fat substitutes

- (2)

- The development of solid cube fat mimetics

- (3)

- The development of double emulsions and gelled double emulsions as fat replacers

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siri-Tarino, P.W.; Chiu, S.; Bergeron, N.; Krauss, R.M. Saturated Fats Versus Polyunsaturated Fats Versus Carbohydrates for Cardiovascular Disease Prevention and Treatment. Annu. Rev. Nutr. 2015, 35, 517–543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Calder, P.C. Functional Roles of Fatty Acids and Their Effects on Human Health. J. Parenter. Enter. Nutr. 2015, 39, 18S–32S. [Google Scholar] [CrossRef] [PubMed]

- Geremias-Andrade, I.M.; Souki, N.; Moraes, I.C.F.; Pinho, S.C. Rheological and mechanical characterization of curcumin-loaded emulsion-filled gels produced with whey protein isolate and xanthan gum. LWT-Food Sci. Technol. 2017, 86, 166–173. [Google Scholar] [CrossRef]

- Valsta, L.M.; Tapanainen, H.; Mannisto, S. Meat fats in nutrition. Meat Sci. 2005, 70, 525–530. [Google Scholar] [CrossRef] [PubMed]

- Houston, D.K.; Ding, J.; Lee, J.S.; Garcia, M.; Kanaya, A.M.; Tylavsky, F.A.; Newman, A.B.; Visser, M.; Kritchevsky, S.B.; Hlth, A.B.C.S. Dietary fat and cholesterol and risk of cardiovascular disease in older adults: The Health ABC Study. Nutr. Metab. Carbiovasc. Dis. 2011, 21, 430–437. [Google Scholar] [CrossRef] [Green Version]

- Colmenero, F.J. Relevant factors in strategies for fat reduction in meat products. Trends Food Sci. Technol. 2000, 11, 56–66. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F. Healthier lipid formulation approaches in meat-based functional foods. Technological options for replacement of meat fats by non-meat fats. Trends Food Sci. Technol. 2007, 18, 567–578. [Google Scholar] [CrossRef] [Green Version]

- Bishop, D.J.; Olson, D.G.; Knipe, C.L. Pre-emulsified corn oil, pork fat, or added moisture affect quality of reduced fat bologna quality. J. Food Sci. 1993, 58, 484–487. [Google Scholar] [CrossRef]

- Lang, Z.; Yingying, H.; Hussain Badar, I.; Xiufang, X.; Baohua, K.; Qian, C. Prospects of artificial meat: Opportunities and challenges around consumer acceptance. Trends Food Sci. Technol. 2021, 116, 434–444. [Google Scholar] [CrossRef]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effects of fatty acids on meat quality: A review. Meat Sci. 2004, 66, 21–32. [Google Scholar] [CrossRef]

- Dreher, J.; Blach, C.; Terjung, N.; Gibis, M.; Weiss, J. Formation and characterization of plant-based emulsified and crosslinked fat crystal networks to mimic animal fat tissue. J. Food Sci. 2020, 85, 421–431. [Google Scholar] [CrossRef] [PubMed]

- Dreher, J.; Weissmuller, M.; Herrmann, K.; Terjung, N.; Gibis, M.; Weiss, J. Influence of protein and solid fat content on mechanical properties and comminution behavior of structured plant-based lipids. Food Res. Int. 2021, 145, 110416. [Google Scholar] [CrossRef] [PubMed]

- Yuqing, Z.; Xing, C.; McClements, D.J.; Liqiang, Z.; Wei, L. pH-, ion- and temperature-dependent emulsion gels: Fabricated by addition of whey protein to gliadin-nanoparticle coated lipid droplets. Food Hydrocoll. 2018, 77, 870–878. [Google Scholar] [CrossRef]

- Dickinson, E. Colloid science of mixed ingredients. Soft Matter 2006, 2, 642–652. [Google Scholar] [CrossRef]

- Dickinson, E. Food colloids research: Historical perspective and outlook. Adv. Colloid Interface Sci. 2011, 165, 7–13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pintado, T.; Ruiz-Capillas, C.; Jimenez-Colmenero, F.; Carmona, P.; Herrero, A.M. Oil-in-water emulsion gels stabilized with chia (Salvia hispanica L.) and cold gelling agents: Technological and infrared spectroscopic characterization. Food Chem. 2015, 185, 470–478. [Google Scholar] [CrossRef]

- Dickinson, E. Emulsion gels: The structuring of soft solids with protein-stabilized oil droplets. Food Hydrocoll. 2012, 28, 224–241. [Google Scholar] [CrossRef]

- Lin, D.Q.; Kelly, A.L.; Miao, S. Preparation, structure-property relationships and applications of different emulsion gels: Bulk emulsion gels, emulsion gel particles, and fluid emulsion gels. Trends Food Sci. Technol. 2020, 102, 123–137. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Salcedo-Sandoval, L.; Bou, R.; Cofrades, S.; Herrero, A.M.; Ruiz-Capillas, C. Novel applications of oil-structuring methods as a strategy to improve the fat content of meat products. Trends Food Sci. Technol. 2015, 44, 177–188. [Google Scholar] [CrossRef] [Green Version]

- Dickinson, E.; Evison, J.; Gramshaw, J.W.; Schwope, D. Flavour release from a protein-stabilized water-in-oil emulsion. Food Hydrocoll. 1994, 8, 63–67. [Google Scholar] [CrossRef]

- Dickinson, E. Stabilising emulsion-based colloidal structures with mixed food ingredients. J. Sci. Food Agric. 2013, 93, 710–721. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, E. Flocculation of protein-stabilized oil-in-water emulsions. Colloid Surf. B-Biointerfaces 2010, 81, 130–140. [Google Scholar] [CrossRef] [PubMed]

- Dickinson, E.; Radford, S.J.; Golding, M. Stability and rheology of emulsions containing sodium caseinate: Combined effects of ionic calcium and non-ionic surfactant. Food Hydrocoll. 2003, 17, 211–220. [Google Scholar] [CrossRef]

- Dickinson, E.; Chen, J.S. Heat-set whey protein emulsion gels: Role of active and inactive filler particles. J. Dispers. Sci. Technol. 1999, 20, 197–213. [Google Scholar] [CrossRef]

- Aiqian, Y.; Taylor, S. Characterization of cold-set gels produced from heated emulsions stabilized by whey protein. Int. Dairy J. 2009, 19, 721–727. [Google Scholar] [CrossRef]

- Mao, L.K.; Roos, Y.H.; Miao, S. Study on the Rheological Properties and Volatile Release of Cold-Set Emulsion-Filled Protein Gels. J. Agric. Food Chem. 2014, 62, 11420–11428. [Google Scholar] [CrossRef]

- Xi, Z.W.; Liu, W.; McClements, D.J.; Zou, L.Q. Rheological, structural, and microstructural properties of ethanol induced cold-set whey protein emulsion gels: Effect of oil content. Food Chem. 2019, 291, 22–29. [Google Scholar] [CrossRef]

- Jie, Y.; Yong, W.; Dong, L.; Li-jun, W. Freeze-thaw stability and rheological properties of soy protein isolate emulsion gels induced by NaCl. Food Hydrocoll. 2022, 123, 107113. [Google Scholar] [CrossRef]

- Zhu, Q.M.; Wu, F.F.; Saito, M.; Tatsumi, E.; Yin, L.J. Effect of magnesium salt concentration in water-in-oil emulsions on the physical properties and microstructure of tofu. Food Chem. 2016, 201, 197–204. [Google Scholar] [CrossRef] [Green Version]

- Luisa, A.; Gaspar, C.; de Goes-Favoni, S.P. Action of microbial transglutaminase (MTGase) in the modification of food proteins: A review. Food Chem. 2015, 171, 315–322. [Google Scholar] [CrossRef]

- Mao, Y.; Fu, L.; Chuan-He, T. Properties and microstructure of transglutaminase-set soy protein-stabilized emulsion gels. Food Res. Int. 2013, 52, 409–418. [Google Scholar] [CrossRef]

- Tang, C.H.; Luo, L.J.; Liu, F.; Chen, Z. Transglutaminase-set soy globulin-stabilized emulsion gels: Influence of soy beta-conglycinin/glycinin ratio on properties, microstructure and gelling mechanism. Food Res. Int. 2013, 51, 804–812. [Google Scholar] [CrossRef]

- Poyato, C.; Astiasaran, I.; Barriuso, B.; Ansorena, D. A new polyunsaturated gelled emulsion as replacer of pork back-fat in burger patties: Effect on lipid composition, oxidative stability and sensory acceptability. LWT-Food Sci. Technol. 2015, 62, 1069–1075. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, S.; Bhattacharya, S. Food Gels: Gelling Process and New Applications. Crit. Rev. Food Sci. Nutr. 2012, 52, 334–346. [Google Scholar] [CrossRef]

- Herrero, A.M.; Ruiz-Capillas, C.; Pintado, T.; Carmona, P.; Jimenez-Colmenero, F. Infrared spectroscopy used to determine effects of chia and olive oil incorporation strategies on lipid structure of reduced-fat frankfurters. Food Chem. 2017, 221, 1333–1339. [Google Scholar] [CrossRef]

- Tang, C.H.; Chen, L.; Foegeding, E. Mechanical and Water-Holding Properties and Microstructures of Soy Protein Isolate Emulsion Gels Induced by CaCl2, Glucono-δ-lactone (GDL), and Transglutaminase: Influence of Thermal Treatments before and/or after Emulsification. J. Agric. Food Chem. 2011, 59, 4071–4077. [Google Scholar] [CrossRef]

- Paglarini, C.D.S.; Furtado, G.D.F.; Biachi, J.P.; Silva Vidal, V.A.; Martini, S.; Soares Forte, M.B.; Cunha, R.L.; Rodrigues Pollonio, M.A. Functional emulsion gels with potential application in meat products. J. Food Eng. 2018, 222, 29–37. [Google Scholar] [CrossRef]

- Perr Ec Hil, F.A.; Cunha, R.L. Stabilization of multilayered emulsions by sodium caseinate and κ-carrageenan. Food Hydrocoll. 2013, 30, 606–613. [Google Scholar] [CrossRef]

- Paglarini, C.D.; Furtado, G.D.; Honorio, A.R.; Mokarze, L.; Vidal, V.A.D.; Ribeiro, A.P.B.; Cunha, R.L.; Pollonio, M.A.R. Functional emulsion gels as pork back fat replacers in Bologna sausage. Food Struct. 2019, 20, 100105. [Google Scholar] [CrossRef]

- Baune, M.C.; Schroeder, S.; Witte, F.; Heinz, V.; Terjung, N. Analysis of protein-network formation of different vegetable proteins during emulsification to produce solid fat substitutes. J. Food Meas. Charact. 2021, 15, 2399–2416. [Google Scholar] [CrossRef]

- Pintado, T.; Cofrades, S. Quality Characteristics of Healthy Dry Fermented Sausages Formulated with a Mixture of Olive and Chia Oil Structured in Oleogel or Emulsion Gel as Animal Fat Replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef] [PubMed]

- Alejandre, M.; Astiasaran, I.; Ansorena, D.; Barbut, S. Using canola oil hydrogels and organogels to reduce saturated animal fat in meat batters. Food Res. Int. 2019, 122, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Herrero, A.M.; Ruiz-Capillas, C. Novel lipid materials based on gelling procedures as fat analogues in the development of healthier meat products. Curr. Opin. Food Sci. 2021, 39, 1–6. [Google Scholar] [CrossRef]

- Dreher, J.; Blach, C.; Terjung, N.; Gibis, M.; Weiss, J. Influence of Protein Content on Plant-Based Emulsified and Crosslinked Fat Crystal Networks to Mimic Animal Fat Tissue. Food Hydrocoll. 2020, 106, 105864. [Google Scholar] [CrossRef]

- Herz, E.; Herz, L.; Dreher, J.; Gibis, M.; Ray, J.; Pibarot, P.; Schmitt, C.; Weiss, J. Influencing factors on the ability to assemble a complex meat analogue using a soy-protein-binder. Innov. Food Sci. Emerg. Technol. 2021, 73, 102806. [Google Scholar] [CrossRef]

- Huang, L.; Ren, Y.; Li, H.; Zhang, Q.; Wang, Y.; Cao, J.; Liu, X. Create Fat Substitute From Soybean Protein Isolate/Konjac Glucomannan: The Impact of the Protein and Polysaccharide Concentrations Formulations. Front. Nutr. 2022, 9, 843832. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Solas, M.T.; Triki, M.; Jimenez-Colmenero, F. Low-fat frankfurters formulated with a healthier lipid combination as functional ingredient: Microstructure, lipid oxidation, nitrite content, microbiological changes and biogenic amine formation. Meat Sci. 2011, 89, 65–71. [Google Scholar] [CrossRef] [Green Version]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Jimenez-Colmenero, F. Healthier lipid combination as functional ingredient influencing sensory and technological properties of low-fat frankfurters. Eur. J. Lipid Sci. Technol. 2010, 112, 859–870. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Cofrades, S.; Ruiz-Capillas, C.; Solas, M.T.; Jiménez-Colmenero, F. Healthier lipid combination oil-in-water emulsions prepared with various protein systems: An approach for development of functional meat products. Eur. J. Lipid Sci. Technol. 2010, 112, 791–801. [Google Scholar] [CrossRef]

- Farjami, T.; Madadlou, A. An overview on preparation of emulsion-filled gels and emulsion particulate gels. Trends Food Sci. Technol. 2019, 86, 85–94. [Google Scholar] [CrossRef]

- Paglarini, C.d.S.; Martini, S.; Pollonio, M.A.R. Using emulsion gels made with sonicated soy protein isolate dispersions to replace fat in frankfurters. LWT-Food Sci. Technol. 2019, 99, 453–459. [Google Scholar] [CrossRef]

- Freire, M.; Cofrades, S.; Perez-Jimenez, J.; Gomez-Estaca, J.; Jimenez-Colmenero, F.; Bou, R. Emulsion gels containing n-3 fatty acids and condensed tannins designed as functional fat replacers. Food Res. Int. 2018, 113, 465–473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pintado, T.; Munoz-Gonzalez, I.; Salvador, M.; Ruiz-Capillas, C.; Herrero, A.M. Phenolic compounds in emulsion gel-based delivery systems applied as animal fat replacers in frankfurters: Physico-chemical, structural and microbiological approach. Food Chem. 2021, 340, 128095. [Google Scholar] [CrossRef] [PubMed]

- Shahbazi, M.; Jager, H.; Chen, J.S.; Ettelaie, R. Construction of 3D printed reduced-fat meat analogue by emulsion gels. Part II: Printing performance, thermal, tribological, and dynamic sensory characterization of printed objects. Food Hydrocoll. 2021, 121, 107054. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jager, H.; Ettelaie, R.; Chen, J.S. Construction of 3D printed reduced-fat meat analogue by emulsion gels. Part I: Flow behavior, thixotropic feature, and network structure of soy protein-based inks. Food Hydrocoll. 2021, 120, 106967. [Google Scholar] [CrossRef]

- van den Berg, L.; Rosenberg, Y.; van Boekel, M.; Rosenberg, M.; van de Velde, F. Microstructural features of composite whey protein/polysaccharide gels characterized at different length scales. Food Hydrocoll. 2009, 23, 1288–1298. [Google Scholar] [CrossRef]

- Le, X.T.; Rioux, L.E.; Turgeon, S.L. Formation and functional properties of protein-polysaccharide electrostatic hydrogels in comparison to protein or polysaccharide hydrogels. Adv. Colloid Interface Sci. 2017, 239, 127–135. [Google Scholar] [CrossRef]

- Yousefi, M.; Khorshidian, N.; Hosseini, H. An overview of the functionality of inulin in meat and poultry products. Nutr. Food Sci. 2018, 48, 819–835. [Google Scholar] [CrossRef]

- Coorey, R.; Tjoe, A.; Jayasena, V. Gelling Properties of Chia Seed and Flour. J. Food Sci. 2014, 79, E859–E866. [Google Scholar] [CrossRef]

- Gao, X.-Q.; Kang, Z.-L.; Zhang, W.G.; Li, Y.P.; Zhou, G.-H. Combination of κ-Carrageenan and Soy Protein Isolate Effects on Functional Properties of Chopped Low-Fat Pork Batters During Heat-Induced Gelation. Food Bioprocess Technol. 2015, 8, 1524–1531. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Fernández-López, J.; Pérez-Lvarez, J.; Viuda-Martos, M. Gelled Emulsions Based on Amaranth Flour with Hemp and Sesame Oils. Proceedings 2021, 70, 98. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Triki, M.; Herrero, A.M.; Rodriguez-Salas, L.; Jimenez-Colmenero, F. Konjac gel as pork backfat replacer in dry fermented sausages: Processing and quality characteristics. Meat Sci. 2012, 92, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.X.; Zhao, J.H.; Li, X.; Liu, Q.; Kong, B.H. Composite Gel Fabricated with Konjac Glucomannan and Carrageenan Could Be Used as a Cube Fat Substitute to Partially Replace Pork Fat in Harbin Dry Sausages. Foods 2021, 10, 1460. [Google Scholar] [CrossRef] [PubMed]

- Alejandre, M.; Poyato, C.; Ansorena, D.; Astiasaran, I. Linseed oil gelled emulsion: A successful fat replacer in dry fermented sausages. Meat Sci. 2016, 121, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Pando, G.; Cofrades, S.; Rodriguez-Salas, L.; Jimenez-Colmenero, F. A healthier oil combination and konjac gel as functional ingredients in low-fat pork liver pate. Meat Sci. 2011, 88, 241–248. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Triki, M.; Herrero, A.M.; Rodriguez-Salas, L.; Ruiz-Capillas, C. Healthy oil combination stabilized in a konjac matrix as pork fat replacement in low-fat, PUFA-enriched, dry fermented sausages. LWT-Food Sci. Technol. 2013, 51, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Salcedo-Sandoval, L.; Cofrades, S.; Perez, C.R.C.; Solas, M.T.; Jimenez-Colmenero, F. Healthier oils stabilized in konjac matrix as fat replacers in n-3 PUFA enriched frankfurters. Meat Sci. 2013, 93, 757–766. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Rodriguez-Salas, L.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Chilled storage characteristics of low-fat, n-3 PUFA-enriched dry fermented sausage reformulated with a healthy oil combination stabilized in a konjac matrix. Food Control 2013, 31, 158–165. [Google Scholar] [CrossRef]

- Campagnol, P.C.B.; dos Santos, B.A.; Wagner, R.; Terra, N.N.; Pollonio, M.A.R. Amorphous cellulose gel as a fat substitute in fermented sausages. Meat Sci. 2012, 90, 36–42. [Google Scholar] [CrossRef]

- Alejandre, M.; Ansorena, D.; Calvo, M.I.; Cavero, R.Y.; Astiasaran, I. Influence of a gel emulsion containing microalgal oil and a blackthorn (Prunus spinosa L.) branch extract on the antioxidant capacity and acceptability of reduced-fat beef patties. Meat Sci. 2019, 148, 219–222. [Google Scholar] [CrossRef]

- Schmitt, C.; Sanchez, C.; Desobry-Banon, S.; Hardy, J. Structure and technofunctional properties of protein-polysaccharide complexes: A review. Crit. Rev. Food Sci. Nutr. 1998, 38, 689–753. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Huang, X.; Wang, L.J.; Li, D.; Adhikari, B. Effect of flaxseed gum on the rheological properties of peanut protein isolate dispersions and gels. LWT-Food Sci. Technol. 2016, 74, 528–533. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Wang, L.J.; Adhikari, B. The effect of addition of flaxseed gum on the emulsion properties of soybean protein isolate (SPI). J. Food Eng. 2011, 104, 56–62. [Google Scholar] [CrossRef]

- Bi, C.H.; Chi, S.Y.; Wang, X.Y.; Alkhatib, A.; Huang, Z.G.; Liu, Y. Effect of flax gum on the functional properties of soy protein isolate emulsion gel. LWT-Food Sci. Technol. 2021, 149, 111846. [Google Scholar] [CrossRef]

- dos Santos, M.; Ozaki, M.M.; Ribeiro, W.O.; Paglarini, C.D.; Vidal, V.A.S.; Campagnol, P.C.B.; Pollonio, M.A.R. Emulsion gels based on pork skin and dietary fibers as animal fat replacers in meat emulsions: An adding value strategy to byproducts. LWT-Food Sci. Technol. 2020, 120, 108895. [Google Scholar] [CrossRef]

- Ran, X.L.; Lou, X.W.; Zheng, H.Q.; Gu, Q.Y.; Yang, H.S. Improving the texture and rheological qualities of a plant-based fishball analogue by using konjac glucomannan to enhance crosslinks with soy protein. Innov. Food Sci. Emerg. Technol. 2022, 75, 102910. [Google Scholar] [CrossRef]

- Botella-Martinez, C.; Lucas-Gonzalez, R.; Lorenzo, J.M.; Santos, E.M.; Rosmini, M.; Sepulveda, N.; Teixeira, A.; Sayas-Barbera, E.; Perez-Alvarez, J.A.; Fernandez-Lopez, J.; et al. Cocoa Coproducts-Based and Walnut Oil Gelled Emulsion as Animal Fat Replacer and Healthy Bioactive Source in Beef Burgers. Foods 2021, 10, 2706. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Ruiz-Capillas, C.; Triki, M.; Carmona, P.; Jimenez-Colmenero, F. Effects of emulsion gels containing bioactive compounds on sensorial, technological, and structural properties of frankfurters. Food Sci. Technol. Int. 2016, 22, 132–145. [Google Scholar] [CrossRef] [Green Version]

- Pintado, T.; Herrero, A.M.; Jimenez-Colmenero, F.; Cavalheiro, C.P.; Ruiz-Capillas, C. Chia and oat emulsion gels as new animal fat replacers and healthy bioactive sources in fresh sausage formulation. Meat Sci. 2018, 135, 6–13. [Google Scholar] [CrossRef]

- Pintado, T.; Ruiz-Capillas, C.; Jimenez-Colmenero, F.; Herrero, A.M. Impact of Culinary Procedures on Nutritional and Technological Properties of Reduced-Fat Longanizas Formulated with Chia (Salvia hispanica L.) or Oat (Avena sativa L.) Emulsion Gel. Foods 2020, 9, 1847. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Emulsion gels as potential fat replacers delivering beta-glucan and healthy lipid content for food applications. J. Food Sci. Technol. 2016, 53, 4336–4347. [Google Scholar] [CrossRef] [Green Version]

- Serdaroglu, M.; Nacak, B.; Karabiyikoglu, M. Effects of Beef Fat Replacement with Gelled Emulsion Prepared with Olive Oil on Quality Parameters of Chicken Patties. Korean, J. Food Sci. Anim. Resour. 2017, 37, 376–384. [Google Scholar] [CrossRef] [Green Version]

- Serdaroglu, M.; Nacak, B.; Karablykoglu, M.; Keser, G. Effects of Partial Beef Fat Replacement with Gelled Emulsion on Functional and Quality Properties of Model System Meat Emulsions. Korean J. Food Sci. Anim. Resour. 2016, 36, 744–751. [Google Scholar] [CrossRef] [Green Version]

- Nacak, B.; Ozturk-Kerimoglu, B.; Yildiz, D.; Cagindi, O.; Serdaroglu, M. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci. 2021, 176, 9. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Herrero, A.; Pintado, T.; Solas, M.T.; Ruiz-Capillas, C. Influence of emulsified olive oil stabilizing system used for pork backfat replacement in frankfurters. Food Res. Int. 2010, 43, 2068–2076. [Google Scholar] [CrossRef]

- Dreher, J.; Konig, M.; Herrmann, K.; Terjung, N.; Gibis, M.; Weiss, J. Varying the amount of solid fat in animal fat mimetics for plant-based salami analogues influences texture, appearance and sensory characteristics. LWT-Food Sci. Technol. 2021, 143, 111140. [Google Scholar] [CrossRef]

- Triki, M.; Herrero, A.M.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Effect of preformed konjac gels, with and without olive oil, on the technological attributes and storage stability of merguez sausage. Meat Sci. 2013, 93, 351–360. [Google Scholar] [CrossRef]

- Poyato, C.; Ansorena, D.; Berasategi, I.; Navarro-Blasco, I.; Astiasaraan, I. Optimization of a gelled emulsion intended to supply omega-3 fatty acids into meat products by means of response surface methodology. Meat Sci. 2014, 98, 615–621. [Google Scholar] [CrossRef] [Green Version]

- Kumar, Y.; Kairam, N.; Ahmad, T.; Yadav, D.N. Physico chemical, microstructural and sensory characteristics of low-fat meat emulsion containing aloe gel as potential fat replacer. Int. J. Food Sci. Technol. 2016, 51, 309–316. [Google Scholar] [CrossRef]

- Alejandre, M.; Passarini, D.; Astiasaran, I.; Ansorena, D. The effect of low-fat beef patties formulated with a low-energy fat analogue enriched in long-chain polyunsaturated fatty acids on lipid oxidation and sensory attributes. Meat Sci. 2017, 134, 7–13. [Google Scholar] [CrossRef]

- Glisic, M.; Baltic, M.; Glisic, M.; Trbovic, D.; Jokanovic, M.; Parunovic, N.; Dimitrijevic, M.; Suvajdzic, B.; Boskovic, M.; Vasilev, D. Inulin-based emulsion-filled gel as a fat replacer in prebiotic- and PUFA-enriched dry fermented sausages. Int. J. Food Sci. Technol. 2019, 54, 787–797. [Google Scholar] [CrossRef]

- Heck, R.T.; Saldana, E.; Lorenzo, J.M.; Correa, L.P.; Fagundes, M.B.; Cichoski, A.J.; de Menezes, C.R.; Wagner, R.; Campagnol, P.C.B. Hydrogelled emulsion from chia and linseed oils: A promising strategy to produce low-fat burgers with a healthier lipid profile. Meat Sci. 2019, 156, 174–182. [Google Scholar] [CrossRef]

- Zhu, Y.L.; Guo, L.P.; Tang, W.T.; Yang, Q.L. Beneficial effects of Jerusalem artichoke powder and olive oil as animal fat replacers and natural healthy compound sources in Harbin dry sausages. Poult. Sci. 2020, 99, 7147–7158. [Google Scholar] [CrossRef]

- Dias, M.F.; Guimaraes, A.S.; Benevenuto, A.A.; Silva, V.R.O.; Fontes, P.R.; Ramos, A.D.S.; Ramos, E.M. Canola and olive oil gelled emulsions as pork fat replacers in beef burgers. Br. Food J. 2022, 124, 50–60. [Google Scholar] [CrossRef]

- Pintado, T.; Herrero, A.M.; Jimenez-Colmenero, F.; Ruiz-Capillas, C. Strategies for incorporation of chia (Salvia hispanica L.) in frankfurters as a health-promoting ingredient. Meat Sci. 2016, 114, 75–84. [Google Scholar] [CrossRef]

- Serdarolu, M.; Çağındı, Ö.; Öztürk, B.; Karabykolu, M. Effects of using gelled emulsion prepared with linseed oil on oxidative stability and fatty acid composition of model system meat emulsions. In Proceedings of the 63rd International Congress of Meat Science and Technology, Cork, Ireland, 13–18 August 2017. [Google Scholar]

- Serdaroglu, M.; Ozturk, B. Use of olive oil-in-water gelled emulsions in model turkey breast emulsions. In Proceedings of the 59th International-Meat-Industry Conference (MEATCON), Zlatibor, Serbia, 1–4 October 2017. [Google Scholar]

- Wang, X.X.; Xie, Y.Y.; Li, X.M.; Liu, Y.; Yan, W.J. Effects of partial replacement of pork back fat by a camellia oil gel on certain quality characteristics of a cooked style Harbin sausage. Meat Sci. 2018, 146, 154–159. [Google Scholar] [CrossRef]

- Camara, A.; Geraldi, M.V.; Okuro, P.K.; Marostica, M.R.; da Cunha, R.L.; Pollonio, M.A.R. Satiety and in vitro digestibility of low saturated fat Bologna sausages added of chia mucilage powder and chia mucilage-based emulsion gel. J. Funct. Food. 2020, 65, 103753. [Google Scholar] [CrossRef]

- Paglarini, C.D.; Vidal, V.A.S.; Ozaki, M.M.; Ribeiro, A.P.B.; Bernardinelli, O.D.; Camara, A.; Herrero, A.M.; Ruiz-Capillas, C.; Sabadini, E.; Pollonio, M.A.R. Inulin gelled emulsion as a fat replacer and fiber carrier in healthier Bologna sausage. Food Sci. Tecgnol. Int. 2022, 28, 3–14. [Google Scholar] [CrossRef]

- Camara, A.; Okuro, P.K.; Santos, M.; Paglarini, C.D.; da Cunha, R.L.; Ruiz-Capillas, C.; Herrero, A.M.; Pollonio, M.A.R. Understanding the role of chia (Salvia Hispanica L.) mucilage on olive oil-based emulsion gels as a new fat substitute in emulsified meat products. Eur. Food Res. Technol. 2020, 246, 909–922. [Google Scholar] [CrossRef]

- Kavusan, H.S.; Serdaroglu, M.; Nacak, B.; Ipek, G. An Approach to Manufacture of Fresh Chicken Sausages Incorporated with Black Cumin and Flaxseed Oil in Water Gelled Emulsion. Food Sci. Anim. Resour. 2020, 40, 426–443. [Google Scholar] [CrossRef]

- Ozturk-Kerimoglu, B.; Kavusan, H.S.; Gurel, D.B.; Cagindi, O.; Serdaroglu, M. Cold-set or hot-set emulsion gels consisted of a healthy oil blend to replace beef fat in heat-treated fermented sausages. Meat Sci. 2021, 176, 108461. [Google Scholar] [CrossRef]

- Camara, A.K.F.I.; Ozaki, M.M.; Santos, M.; Vidal, V.A.S.; Ribeiro, W.O.; Paglarini, C.d.S.; Bernardinelli, O.D.; Sabadini, E.; Pollonio, M.A.R. Olive oil-based emulsion gels containing chia (Salvia hispanica L.) mucilage delivering healthy claims to low-saturated fat Bologna sausages. Food Struct. 2021, 28, 100187. [Google Scholar] [CrossRef]

- Cui, B.; Mao, Y.Y.; Liang, H.S.; Li, Y.; Li, J.; Ye, S.X.; Chen, W.X.; Li, B. Properties of soybean protein isolate/curdlan based emulsion gel for fat analogue: Comparison with pork backfat. Int. J. Biol. Macromol. 2022, 206, 481–488. [Google Scholar] [CrossRef]

- Ozturk-Kerimoglu, B.; Kara, A.; Urgu-Ozturk, M.; Serdaroglu, M. A new inverse olive oil emulsion plus carrot powder to replace animal fat in model meat batters. LWT-Food Sci. Technol. 2021, 135, 110044. [Google Scholar] [CrossRef]

- Estrada-Fernandez, A.G.; Roman-Guerrero, A.; Jimenez-Alvarado, R.; Lobato-Calleros, C.; Alvarez-Ramirez, J.; Vernon-Carter, E.J. Stabilization of oil-in-water-in-oil (O1/W/O2) Pickering double emulsions by soluble and insoluble whey protein concentrate-gum Arabic complexes used as inner and outer interfaces. J. Food Eng. 2018, 221, 35–44. [Google Scholar] [CrossRef]

- Chung, C.; McClements, D.J. Structure-function relationships in food emulsions: Improving food quality and sensory perception. Food Struct. 2014, 1, 106–126. [Google Scholar] [CrossRef]

- Serdaroglu, M.; Ozturk, B.; Urgu, M. Emulsion characteristics, chemical and textural properties of meat systems produced with double emulsions as beef fat replacers. Meat Sci. 2016, 117, 187–195. [Google Scholar] [CrossRef]

- Cetinkaya, T.; Altay, F.; Ceylan, Z. A new application with characterized oil-in-water-in-oil double emulsions: Gelatin-xanthan gum complexes for the edible oil industry. LWT-Food Sci. Technol. 2021, 138, 8. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F. Potential applications of multiple emulsions in the development of healthy and functional foods. Food Res. Int. 2013, 52, 64–74. [Google Scholar] [CrossRef]

- Freire, M.; Bou, R.; Cofrades, S.; Solas, M.T.; Jimenez-Colmenero, F. Double emulsions to improve frankfurter lipid content: Impact of perilla oil and pork backfat. J. Sci. Food Agric. 2016, 96, 900–908. [Google Scholar] [CrossRef]

- Cofrades, S.; Antoniou, I.; Solas, M.T.; Herrero, A.M.; Jimenez-Colmenero, F. Preparation and impact of multiple (water-in-oil-in-water) emulsions in meat systems. Food Chem. 2013, 141, 338–346. [Google Scholar] [CrossRef] [PubMed]

- Eisinaite, V.; Juraite, D.; Schroen, K.; Leskauskaite, D. Food-grade double emulsions as effective fat replacers in meat systems. J. Food Eng. 2017, 213, 54–59. [Google Scholar] [CrossRef]

- Cofrades, S.; Santos-Lopez, J.A.; Freire, M.; Benedi, J.; Sanchez-Muniz, F.J.; Jimenez-Colmenero, E. Oxidative stability of meat systems made with W1/O/W2 emulsions prepared with hydroxytyrosol and chia oil as lipid phase. LWT-Food Sci. Technol. 2014, 59, 941–947. [Google Scholar] [CrossRef]

- Ozturk, B.; Urgu, M.; Serdaroglu, M. Egg white powder-stabilised multiple (water-in-olive oil-in-water) emulsions as beef fat replacers in model system meat emulsions. J. Sci. Food Agric. 2017, 97, 2075–2083. [Google Scholar] [CrossRef]

- Freire, M.; Cofrades, S.; Serrano-Casas, V.; Pintado, T.; Jimenez, M.J.; Jimenez-Colmenero, F. Gelled double emulsions as delivery systems for hydroxytyrosol and n-3 fatty acids in healthy pork patties. J. Food Sci. Technol. 2017, 54, 3959–3968. [Google Scholar] [CrossRef]

- Poyato, C.; Navarro-Blasco, I.; Calvo, M.I.; Cavero, R.Y.; Astiasaran, I.; Ansorena, D. Oxidative stability of O/W and W/O/W emulsions: Effect of lipid composition and antioxidant polarity. Food Res. Int. 2013, 51, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Kumar, Y.; Kumar, V. Effects of double emulsion (W1/O/W2) containing encapsulated Murraya koenigii berries extract on quality characteristics of reduced-fat meat batter with high oxidative stability-ScienceDirect. LWT-Food Sci. Technol. 2020, 127, 109365. [Google Scholar] [CrossRef]

- Guzman-Diaz, D.A.; Trevino-Garza, M.Z.; Rodriguez-Romero, B.A.; Gallardo-Rivera, C.T.; Amaya-Guerra, C.A.; Baez-Gonzalez, J.G. Development and Characterization of Gelled Double Emulsions Based on Chia (Salvia hispanica L.) Mucilage Mixed with Different Biopolymers and Loaded with Green Tea Extract (Camellia sinensis). Foods 2019, 8, 677. [Google Scholar] [CrossRef] [Green Version]

- Perez-Moral, N.; Watt, S.; Wilde, P. Comparative study of the stability of multiple emulsions containing a gelled or aqueous internal phase. Food Hydrocoll. 2014, 42, 215–222. [Google Scholar] [CrossRef]

- Sebben, D.A.; MacWilliams, S.V.; Yu, L.; Spicer, P.T.; Bulone, V.; Krasowska, M.; Beattie, D.A. Influence of Aqueous Phase Composition on Double Emulsion Stability and Colour Retention of Encapsulated Anthocyanins. Foods 2022, 11, 34. [Google Scholar] [CrossRef]

- Yan, Z.; Xu, W.; Han, C.; Fazheng, R.; Zuowen, L.; Pengjie, W.; Xiaofei, L. Application of gel-in-oil-in-water double emulsions as a pork oil replacer in emulsified sausage. J. Food Process. Preserv. 2022, 46, e16333. [Google Scholar] [CrossRef]

- Molet-Rodriguez, A.; Martin-Belloso, O.; Salvia-Trujillo, L. Formation and Stabilization of W1/O/W2 Emulsions with Gelled Lipid Phases. Molecules 2021, 26, 312. [Google Scholar] [CrossRef] [PubMed]

- Benna-Zayani, M.; Kbir-Ariguib, N.; Trabelsi-Ayadi, M.; Grossiord, J.L. Stabilisation of W/O/W double emulsion by polysaccharides as weak gels. Colloid Surf. A Physicochem. Eng. Asp. 2008, 316, 46–54. [Google Scholar] [CrossRef]

- Bou, R.; Cofrades, S.; Jiménez-Colmenero, F. Properties of W1/O/W2 Emulsions as Potential Fat Replacers in Meat Products. In Proceedings of the International Congress of Meat Science and Technology, Izmir, Turkey, 18–23 August 2013. [Google Scholar]

- Robert, P.; Zamorano, M.; Gonzalez, E.; Silva-Weiss, A.; Cofrades, S.; Gimenez, B. Double emulsions with olive leaves extract as fat replacers in meat systems with high oxidative stability. Food Res. Int. 2019, 120, 904–912. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shin, H.; Kim, H.T.; Choi, M.J.; Ko, E.Y. Effects of Bromelain and Double Emulsion on the Physicochemical Properties of Pork Loin. Food Sci. Anim. Resour. 2019, 39, 888–902. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Huang, L.; Zhang, Y.; Li, H.; Zhao, D.; Cao, J.; Liu, X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods 2022, 11, 1950. https://doi.org/10.3390/foods11131950

Ren Y, Huang L, Zhang Y, Li H, Zhao D, Cao J, Liu X. Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods. 2022; 11(13):1950. https://doi.org/10.3390/foods11131950

Chicago/Turabian StyleRen, Yuqing, Lu Huang, Yinxiao Zhang, He Li, Di Zhao, Jinnuo Cao, and Xinqi Liu. 2022. "Application of Emulsion Gels as Fat Substitutes in Meat Products" Foods 11, no. 13: 1950. https://doi.org/10.3390/foods11131950

APA StyleRen, Y., Huang, L., Zhang, Y., Li, H., Zhao, D., Cao, J., & Liu, X. (2022). Application of Emulsion Gels as Fat Substitutes in Meat Products. Foods, 11(13), 1950. https://doi.org/10.3390/foods11131950