Amorphophallus konjac: Sensory Profile of This Novel Alternative Flour on Gluten-Free Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Sensory Analysis

2.3. Statistic Analysis

3. Results

3.1. Hedonic Scale Acceptance Test

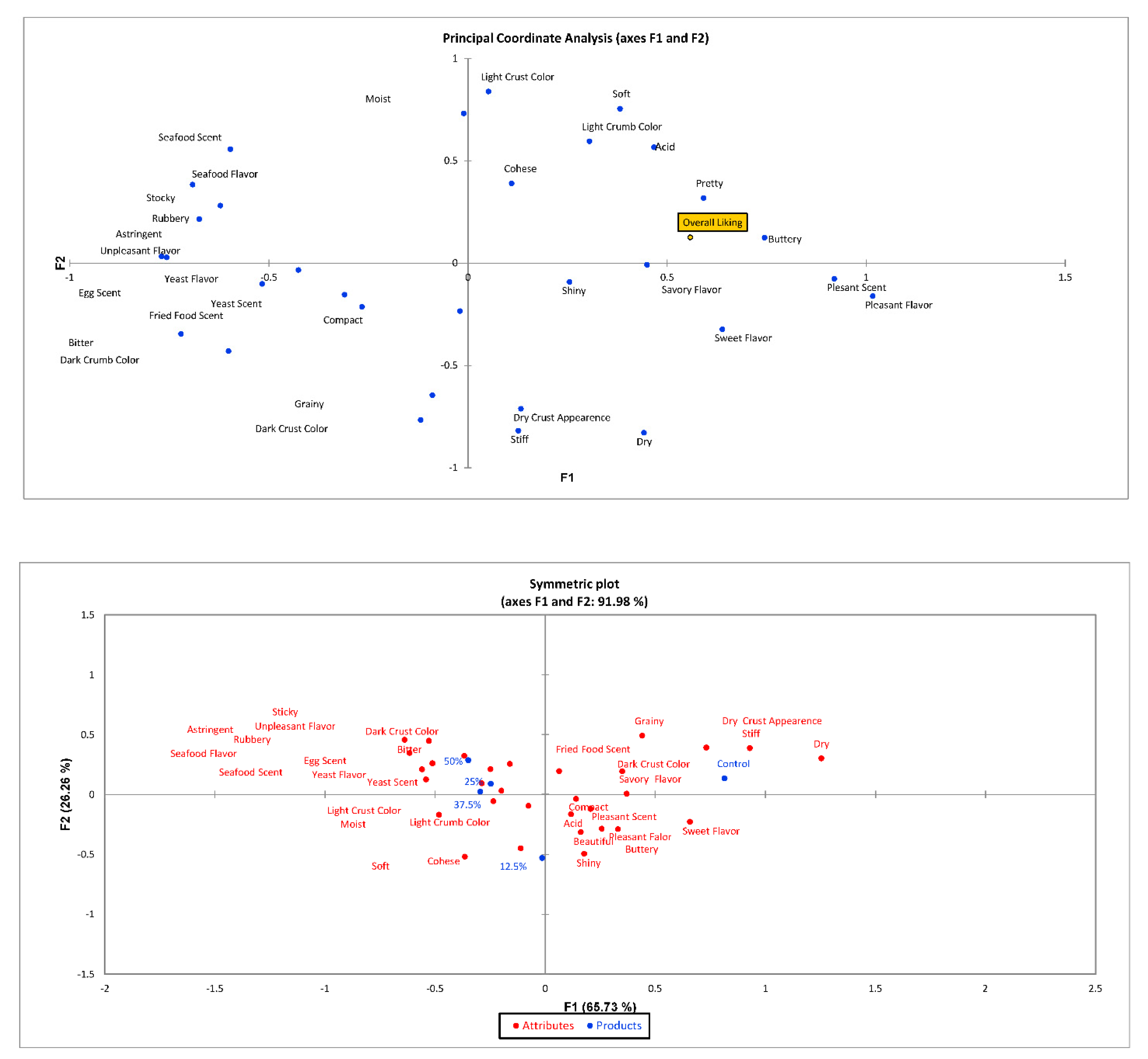

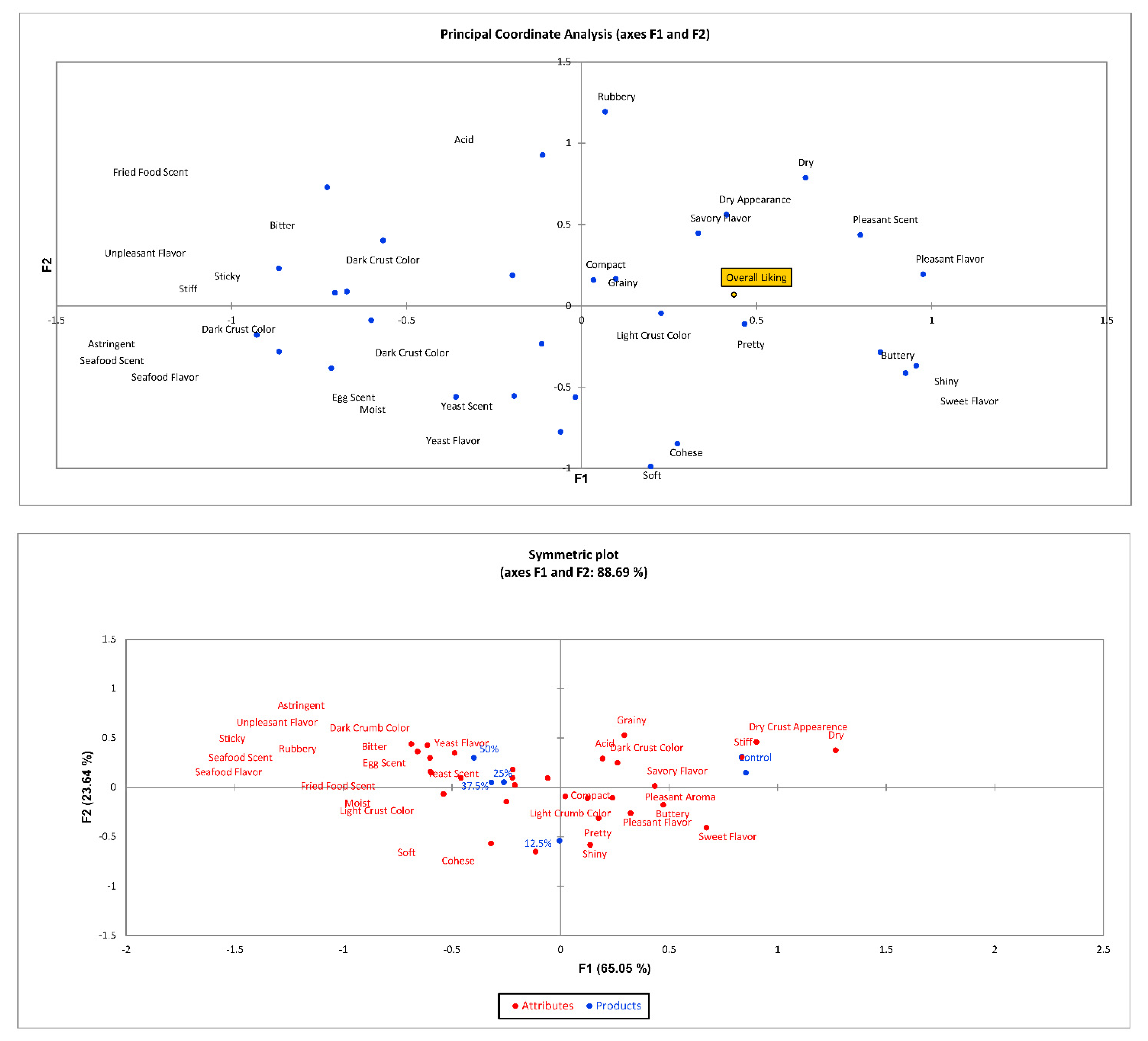

3.2. Check-All-That-Apply (CATA)

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statista Bread—Worldwide. 2020. Available online: https://www.statista.com/outlook/cmo/food/bread-cereal-products/bread/worldwide (accessed on 12 November 2021).

- Romão, B.; Botelho, R.B.A.; Alencar, E.R.; da Silva, V.S.N.; Pacheco, M.T.B.; Zandonadi, R.P. Chemical Composition and Glycemic Index of Gluten-Free Bread Commercialized in Brazil. Nutrients 2020, 12, 2234. [Google Scholar] [CrossRef]

- Calvo-Lerma, J.; Crespo-Escobar, P.; Martínez-Barona, S.; Fornés-Ferrer, V.; Donat, E.; Ribes-Koninckx, C. Differences in the Macronutrient and Dietary Fibre Profile of Gluten-Free Products as Compared to Their Gluten-Containing Counterparts. Eur. J. Clin. Nutr. 2019, 73, 930–936. [Google Scholar] [CrossRef] [PubMed]

- Lamacchia, C.; Camarca, A.; Picascia, S.; Di Luccia, A.; Gianfrani, C. Cereal-Based Gluten-Free Food: How to Reconcile Nutritional and Technological Properties of Wheat Proteins with Safety for Celiac Disease Patients. Nutrients 2014, 6, 575–590. [Google Scholar] [CrossRef] [PubMed]

- Zandonadi, R.P.; Botelho, R.B.A.; Araújo, W.M.C. Psyllium as a Substitute for Gluten in Bread. J. Am. Diet. Assoc. 2009, 109, 1781–1784. [Google Scholar] [CrossRef] [PubMed]

- Capriles, V.A.J. Effects of Prebiotic Inulin-Type Fructans on Structure, Quality, Sensory Acceptance and Glycemic Response of Gluten-Free Breads Food & Function. Food Funct. 2013, 4, 104–110. [Google Scholar] [CrossRef] [PubMed]

- Sabanis, D.; Lebesi, D.; Tzia, C. Effect of Dietary Fibre Enrichment on Selected Properties of Gluten-Free Bread. LWT Food Sci. Technol. 2009, 42, 1380–1389. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. The Impact of Resistant Starch on Characteristics of Gluten-Free Dough and Bread. Food Hydrocoll. 2009, 23, 988–995. [Google Scholar] [CrossRef]

- Zhong, L.; Liu, E.; Yang, C.; Jin, S.; Diao, Y.; Hu, Z. High Embryogenic Ability and Regeneration from Floral Axis of Amorphophallus konjac (Araceae). Open Life Sci. 2017, 12, 34–41. [Google Scholar] [CrossRef]

- Zhou, Y.; Cao, H.; Hou, M.; Nirasawa, S.; Tatsumi, E.; Foster, T.J.; Cheng, Y. Effect of Konjac Glucomannan on Physical and Sensory Properties of Noodles Made from Low-Protein Wheat Flour. Food Res. Int. 2013, 51, 879–885. [Google Scholar] [CrossRef]

- He, Y.; Guo, J.; Ren, G.; Cui, G.; Han, S.; Liu, J. Effects of Konjac Glucomannan on the Water Distribution of Frozen Dough and Corresponding Steamed Bread Quality. Food Chem. 2020, 330, 127243. [Google Scholar] [CrossRef]

- Impaprasert, R.; Piyarat, S.; Sophontanakij, N.; Sakulnate, N.; Paengkanya, S.; Borompichaichartkul, C.; Srzednicki, G. Rehydration and Textural Properties of Dried Konjac Noodles: Effect of Alkaline and Some Gelling Agents. Horticulturae 2017, 3, 20. [Google Scholar] [CrossRef]

- Sutrisno, A.; Yuwono, S.S.; Ikarini, I. Effect of Glucomannan and Xanthan Gum Proportion on the Physical and Sensory Characteristic of Gluten-Free Bread. IOP Conf. Ser. Earth Environ. Sci. 2021, 924, 012028. [Google Scholar] [CrossRef]

- Moore, M.M.; Schober, T.J.; Dockery, P.; Arendt, E.K. Textural Comparison of Gluten-Free and Wheat-Based Doughs, Batters and Breads. Cereal Chem. 2004, 81, 567–575. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lee, J.H.; Lee, S.K. Effects of Hydrocolloids on Quality Characteristics of Bread with Rice Flour. J. Korean Soc. Food Sci. Nutr. 2016, 45, 1324–1332. [Google Scholar] [CrossRef]

- Laignier, F.; Akutsu, R.; Maldonade, I.R.; Pacheco, M.T.B.; Silva, V.S.N.; Mendonça, M.A.; Zandonadi, R.P.; Raposo, A.; Botelho, R.B.A. Amorphophallus konjac: A Novel Alternative Flour on Gluten-Free Bread. Foods 2021, 10, 1206. [Google Scholar] [CrossRef] [PubMed]

- Aguiar, L.A.; Rodrigues, D.B.; Queiroz, V.A.V.; Melo, L.; Pineli, L.D.L.D.O. Comparison of Two Rapid Descriptive Sensory Techniques for Profiling and Screening of Drivers of Liking of Sorghum Breads. Food Res. Int. 2020, 131, 108999. [Google Scholar] [CrossRef] [PubMed]

- Villanueva, N.D.M.; Petenate, A.J.; Da Silva, M.A.A.P. Performance of the Hybrid Hedonic Scale as Compared to the Traditional Hedonic, Self-Adjusting and Ranking Scales. Food Qual. Prefer. 2005, 16, 691–703. [Google Scholar] [CrossRef]

- Moskowitz, H.R. Product Testing and Sensory Evaluation of Foods: Marketing and R&D Approaches; Food and Nutrition Press: Westport, CO, USA, 1983; ISBN 0917678168/9780917678165. [Google Scholar]

- Delgado-Nieblas, C.I.; Zazueta-Morales, J.J.; Aguilar-Palazuelos, E.; Jacobo-Valenzuela, N.; Aguirre-Tostado, F.S.; Carrillo-López, A.; Ruiz-Armenta, X.A.; Telis-Romero, J. Physical, Microstructural and Sensory Characteristics of Extruded and Microwave-Expanded Snacks Added with Dehydrated Squash. Rev. Mex. Ing. Química 2018, 17, 805–821. [Google Scholar] [CrossRef]

- Lim, J. Hedonic Scaling: A Review of Methods and Theory. Food Qual. Prefer. 2011, 22, 733–747. [Google Scholar] [CrossRef]

- Dutcosky, S.D. Análise Sensorial de Alimentos, 5th ed.; Champagnat-Pucpress: Curitiba, Brazil, 2019; Volume 1, ISBN 9788554945473. [Google Scholar]

- Sawaya, A.L.; Filgueiras, A. “Abra a Felicidade”? Implicações Para o Vício Alimentar. Estud. Avançados 2013, 27, 53–70. [Google Scholar] [CrossRef]

- Kim, H.Y.; Hwang, S.H.; Lee, J.H. Effect of Fermented Vinegar on the Reduction in Trimethylamine in Konjac Glucomannan Gel. Appl. Biol. Chem. 2017, 60, 281–285. [Google Scholar] [CrossRef]

- Takigami, S. Konjac Mannan. In Handbook of Hydrocolloids, 2nd ed.; Woodhead Publishing: Sawston, UK, 2009; pp. 889–901. [Google Scholar] [CrossRef]

- Bourne, M.C. Food Texture & Viscosity: Concept and Measuremente; Elsevier: Amsterdam, The Netherlands, 2002; pp. 1–415. [Google Scholar]

- Rios, M.B.; Iriondo-DeHond, A.; Iriondo-DeHond, M.; Herrera, T.; Velasco, D.; Gómez-Alonso, S.; Callejo, M.J.; del Castillo, M.D. Effect of Coffee Cascara Dietary Fiber on the Physicochemical, Nutritional and Sensory Properties of a Gluten-Free Bread Formulation. Molecules 2020, 25, 1358. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, L.V. Análise Sensorial Na Indústria de Alimentos. Rev. Inst. Laticínios Cândido Tostes 2009, 64, 1–14. [Google Scholar]

- Oliver, P.; Cicerale, S.; Pang, E.; Keast, R. Check-All-That-Applies as an Alternative for Descriptive Analysis to Establish Flavors Driving Liking in Strawberries. J. Sens. Stud. 2018, 33, e12316. [Google Scholar] [CrossRef]

- Ares, G.; Jaeger, S.R. Check-All-That-Apply (CATA) Questions with Consumers in Practice: Experimental Considerations and Impact on Outcome. In Rapid Sensory Profiling Techniques; Woodhead Publishing: Sawston, UK, 2015; pp. 227–245. ISBN 9781782422488. [Google Scholar]

| Amorphophallus konjac (AK) Flour (% of Flour Replacement) | Appearance | Flavor | Aroma | Texture | Global Acceptance |

|---|---|---|---|---|---|

| 0 | 7.28 ± 1.81 b | 7.15 ± 1.74 a | 7.07 ± 1.65 a | 5.60 ± 2.14 a | 6.78 ± 1.77 b |

| 12.5 | 8.09 ± 1.85 a | 7.36 ± 1.55 a | 6.95 ± 1.80 a | 7.39 ± 1.45 b | 7.53 ± 1.22 a |

| 25 | 6.67 ± 1.72 bc | 5.40 ± 2.03 b | 5.70 ± 1.88 b | 5.47 ± 2.04 a | 5.66 ± 1.80 c |

| 37.5 | 7.19 ± 1.64 b | 5.57 ± 2.14 b | 6.13 ± 1.97 b | 5.64 ± 2.04 a | 5.82 ± 1.99 c |

| 50 | 6.46 ± 1.89 c | 4.65 ± 2.07 c | 5.64 ± 1.99 b | 4.92 ± 2.20 a | 5.07 ± 1.99 c |

| Gluten-Free Bread Consumers (% of Acceptance) | |||||

|---|---|---|---|---|---|

| Amorphophallus konjac (AK) Flour (% of Flour Replacement) | Appearance % | Flavor % | Aroma % | Texture % | Global Acceptance % |

| 0 | 81.39 | 95.34 | 86.05 | 60.46 | 83.72 |

| 12.5 | 95.35 | 90.70 | 76.75 | 88.37 | 93.03 |

| 25 | 72.09 | 48.84 | 55.81 | 58.14 | 67.44 |

| 37.5 | 93.02 | 55.81 | 65.12 | 55.81 | 67.44 |

| 50 | 76.75 | 41.86 | 48.84 | 37.21 | 48.84 |

| Gluten-free bread non-consumers (% of acceptance) | |||||

| 0 | 85.07 | 74.63 | 73.13 | 50.74 | 73.13 |

| 12.5 | 97.02 | 82.58 | 76.11 | 86.57 | 95.52 |

| 25 | 76.12 | 47.76 | 44.77 | 50.75 | 49.25 |

| 37.5 | 80.60 | 50.74 | 61.19 | 55.22 | 56.71 |

| 50 | 61.19 | 29.85 | 49.25 | 37.31 | 38.81 |

| Attributes | Control | 12.5 | 25 | 37.5 | 50 | p-Values (Cochran’s Q) | |

|---|---|---|---|---|---|---|---|

| Appearance | Dark Crust Color | 18 ab | 42 c | 8 a | 13 a | 31 bc | <0.0001 |

| Dry Crust Appearence | 5 a | 60 c | 20 b | 9 ab | 16 ab | <0.0001 | |

| Light Crust Color | 56 bc | 33 a | 77 d | 74 cd | 42 ab | <0.0001 | |

| Light Crumb Color | 78 b | 59 a | 68 ab | 72 ab | 58 a | 0.003 | |

| Dark Crumb Color | 9 a | 7 a | 15 ab | 10 a | 30 b | <0.0001 | |

| Pretty | 66 c | 50 bc | 28 a | 33 ab | 25 a | <0.0001 | |

| Shiny | 10 a | 6 a | 6 a | 3 a | 1 a | 0.031 | |

| Aroma | Egg Scent | 6 a | 7 a | 14 a | 11 a | 13 a | 0.143 |

| Fried Food Scent | 6 a | 13 a | 12 a | 9 a | 10 a | 0.376 | |

| Seafood Scent | 13 b | 1 a | 16 b | 18 b | 26 b | <0.0001 | |

| Yeast Scent | 28 a | 30 a | 33 a | 29 a | 34 a | 0.152 | |

| Pleasant Scent | 65 bc | 77 c | 43 a | 49 ab | 35 a | <0.0001 | |

| Flavor | Seafood Flavor | 8 ab | 1 a | 14 b | 17 b | 21 b | <0.0001 |

| Yeast Flavor | 19 ab | 13 a | 34 b | 26 ab | 27 ab | 0.003 | |

| Unpleasant Flavor | 3 a | 6 a | 27 b | 34 b | 39 b | <0.0001 | |

| Pleasant Flavor | 80 b | 73 b | 37 a | 36 a | 28 a | <0.0001 | |

| Bitter | 2 a | 3 a | 4 a | 3 a | 5 a | 0.804 | |

| Sour | 2 a | 2 a | 1 a | 2 a | 1 a | 0.50 | |

| Sweet Flavor | 23 bc | 36 c | 4 a | 10 ab | 6 a | <0.0001 | |

| Astringent | 1 a | 1 a | 7 a | 9 a | 4 a | 0.011 | |

| Savory Flavor | 18 a | 34 b | 19 ab | 12 a | 11 a | <0.0001 | |

| Texture | Moist | 34 b | 1 a | 25 b | 34 b | 31 b | <0.0001 |

| Stiff | 2 a | 50 c | 15 b | 8 ab | 5 ab | <0.0001 | |

| Sticky | 6 a | 1 a | 26 b | 28 b | 49 c | <0.0001 | |

| Cohese | 15 a | 5 a | 7 a | 8 a | 5 a | 0.010 | |

| Rubbery | 10 a | 1 a | 57 b | 47 b | 53 b | <0.0001 | |

| Soft | 82 c | 3 a | 40 b | 39 b | 34 b | <0.0001 | |

| Compact | 21 a | 26 a | 22 a | 14 a | 15 a | 0.155 | |

| Buttery | 25 b | 26 b | 6 a | 16 ab | 8 a | <0.0001 | |

| Grainy | 2 a | 40 d | 9 ab | 15 bc | 24 cd | <0.0001 | |

| Dry | 8 a | 76 b | 9 a | 3 a | 6 a | <0.0001 |

| Attributes | Control | 12.5 | 25 | 37.5 | 50 | p-Values Cochran’s Q | |

|---|---|---|---|---|---|---|---|

| Appearence | Dark Crust Color | 7 a | 17 a | 4 a | 6 a | 14 a | 0.001 |

| Dry Crust Appearence | 1 a | 29 b | 8 a | 2 a | 6 a | <0.0001 | |

| Light Crust Color | 23 ab | 11 a | 29 b | 29 b | 12 a | <0.0001 | |

| Light Crumb Color | 29 a | 28 a | 24 a | 27 a | 19 b | 0.066 | |

| Dark Crumb Color | 4 ab | 2 a | 7 ab | 4 ab | 15 b | <0.0001 | |

| Pretty | 27 b | 21 a | 11 a | 13 a | 10 a | <0.0001 | |

| Shiny | 2 a | 1 a | 2 a | 0 a | 0 a | 0.406 | |

| Aroma | Egg Scent | 2 a | 2 a | 3 a | 0 a | 3 a | 0.532 |

| Fried Food Scent | 3 a | 3 a | 6 a | 5 a | 4 a | 0.519 | |

| Seafood Scent | 6 ab | 0 a | 9 ab | 9 ab | 13 b | 0.001 | |

| Yeast Scent | 11 a | 8 a | 12 a | 13 a | 13 a | 0.639 | |

| Pleasant Scent | 25 b | 32 c | 17 a | 18 a | 13 d | <0.0001 | |

| Flavor | Seafood Flavor | 5 ab | 0 a | 11 b | 11 b | 11 b | 0.001 |

| Yeast Flavor | 7 a | 2 a | 10 a | 10 a | 12 a | 0.038 | |

| Unpleasant Flavor | 1 a | 1 a | 8 ab | 13 b | 12 b | <0.0001 | |

| Pleasant Flavor | 31 b | 32 b | 13 a | 13 a | 11 a | <0.0001 | |

| Bitter | 1 a | 1 a | 3 a | 0 a | 2 a | 0.406 | |

| Sour | 0 a | 1 a | 1 a | 1 a | 0 a | 0.736 | |

| Sweet Flavor | 10 ab | 12 b | 1 a | 3 ab | 1 ab | <0.0001 | |

| Astringent | 0 a | 0 a | 3 a | 4 a | 3 a | 0.083 | |

| Savory Flavor | 6 ab | 13 b | 7 ab | 4 ab | 3 a | 0.003 | |

| Texture | Moist | 11 b | 0 a | 10 b | 13 b | 13 b | 0.001 |

| Stiff | 2 a | 20 b | 6 ab | 4 a | 2 a | <0.0001 | |

| Sticky | 3 ab | 0 a | 9 ab | 10 b | 15 b | <0.0001 | |

| Cohese | 5 a | 1 a | 1 a | 1 a | 2 a | 0.056 | |

| Rubbery | 5 a | 1 a | 22 b | 20 b | 21 b | <0.0001 | |

| Soft | 32 c | 2 a | 16 b | 12 ab | 12 ab | <0.0001 | |

| Compact | 8 a | 9 a | 8 a | 6 a | 4 a | 0.573 | |

| Buttery | 7 a | 11 a | 3 a | 6 a | 1 a | 0.013 | |

| Grainy | 1 a | 14 b | 3 ab | 6 b | 11 b | 0.000 | |

| Dry | 2 a | 30 b | 3 a | 2 a | 2 a | <0.0001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laignier, F.; Akutsu, R.d.C.d.A.; Lima, B.R.d.; Zandonadi, R.P.; Raposo, A.; Saraiva, A.; Botelho, R.B.A. Amorphophallus konjac: Sensory Profile of This Novel Alternative Flour on Gluten-Free Bread. Foods 2022, 11, 1379. https://doi.org/10.3390/foods11101379

Laignier F, Akutsu RdCdA, Lima BRd, Zandonadi RP, Raposo A, Saraiva A, Botelho RBA. Amorphophallus konjac: Sensory Profile of This Novel Alternative Flour on Gluten-Free Bread. Foods. 2022; 11(10):1379. https://doi.org/10.3390/foods11101379

Chicago/Turabian StyleLaignier, Fernanda, Rita de Cássia de Almeida Akutsu, Bernardo Romão de Lima, Renata Puppin Zandonadi, António Raposo, Ariana Saraiva, and Raquel Braz Assunção Botelho. 2022. "Amorphophallus konjac: Sensory Profile of This Novel Alternative Flour on Gluten-Free Bread" Foods 11, no. 10: 1379. https://doi.org/10.3390/foods11101379

APA StyleLaignier, F., Akutsu, R. d. C. d. A., Lima, B. R. d., Zandonadi, R. P., Raposo, A., Saraiva, A., & Botelho, R. B. A. (2022). Amorphophallus konjac: Sensory Profile of This Novel Alternative Flour on Gluten-Free Bread. Foods, 11(10), 1379. https://doi.org/10.3390/foods11101379