Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances

Abstract

1. Introduction

2. Numerical Methods in the Produce Cold Chain Management

2.1. Effect of Loading Conditions on Stacked Fibreboard Cartons in the Distribution Chain

2.2. The Influence of Vent Design of Fibreboard Cartons on Produce Precooling Management

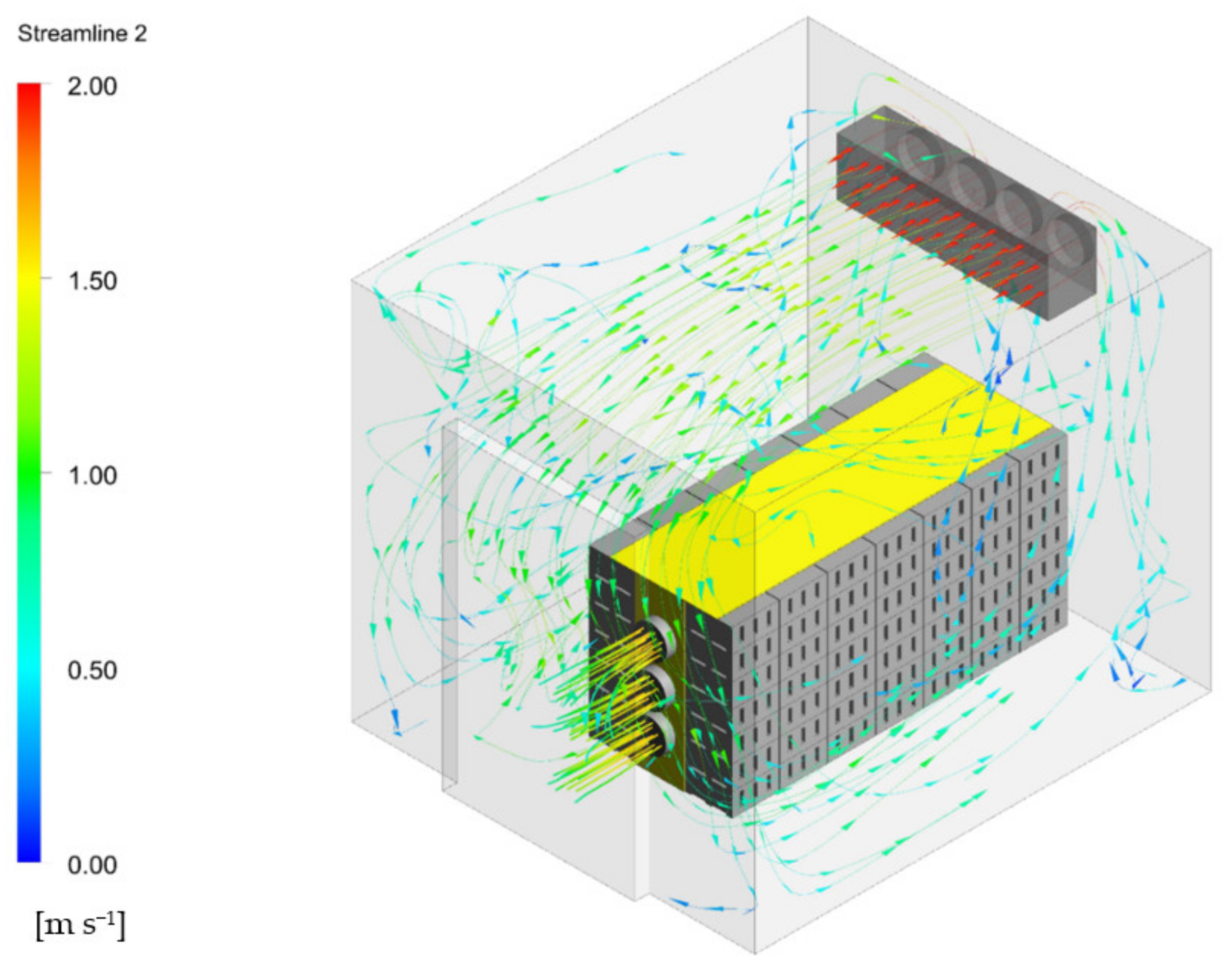

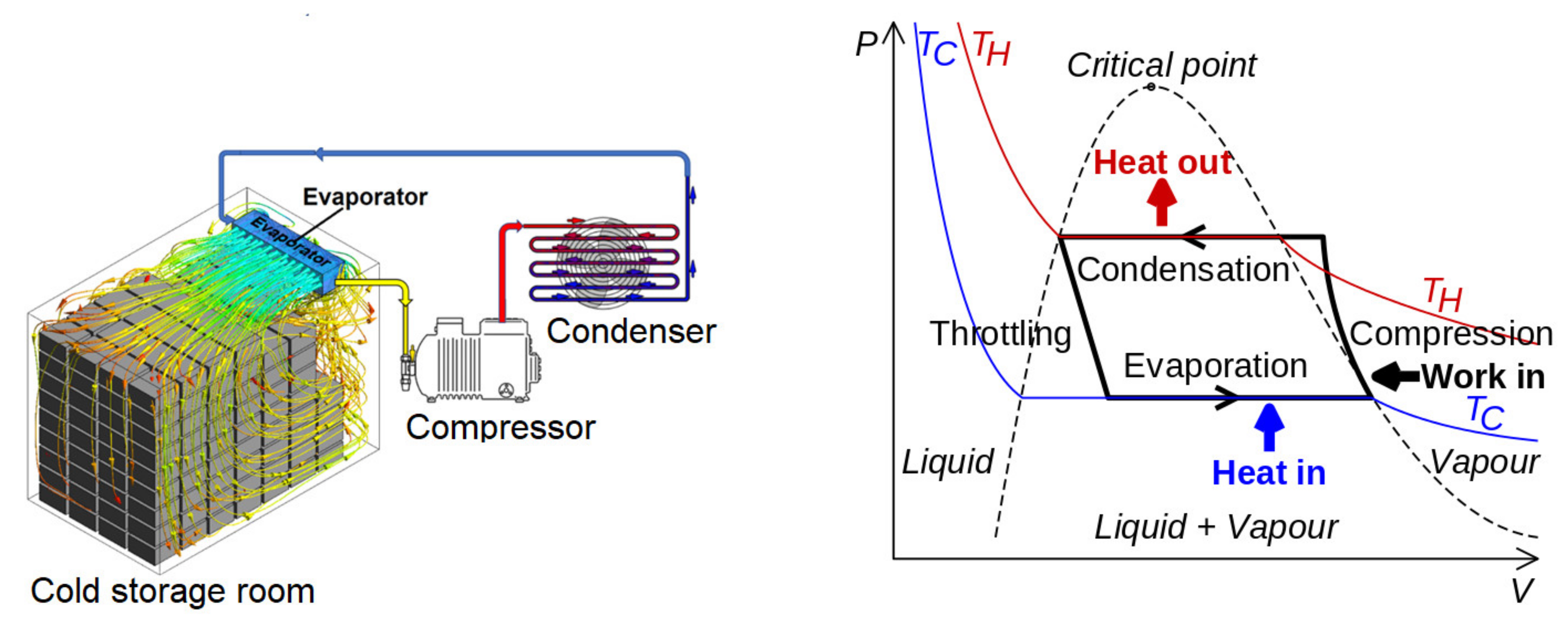

2.3. Cold Storage Room

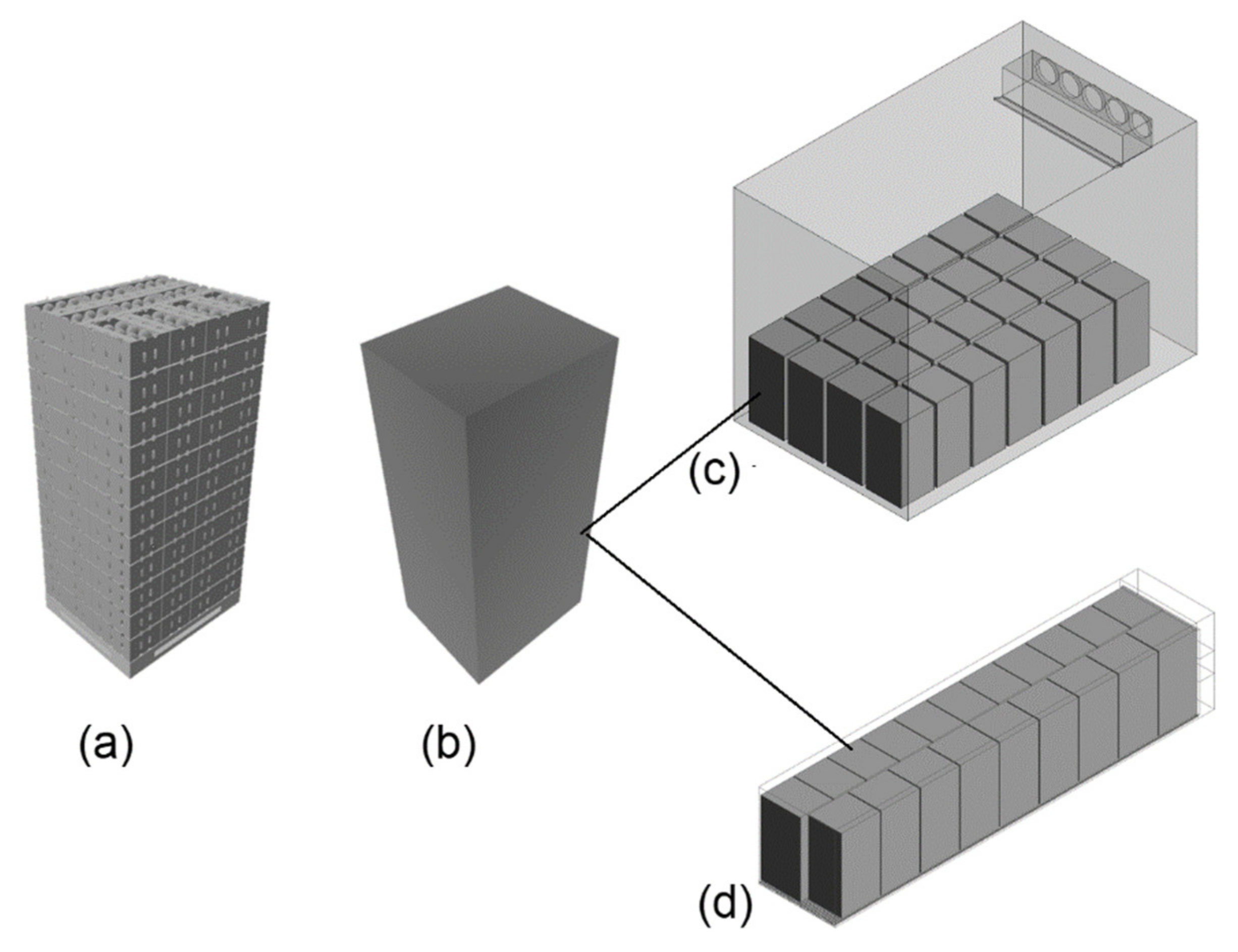

2.4. Reefer Container

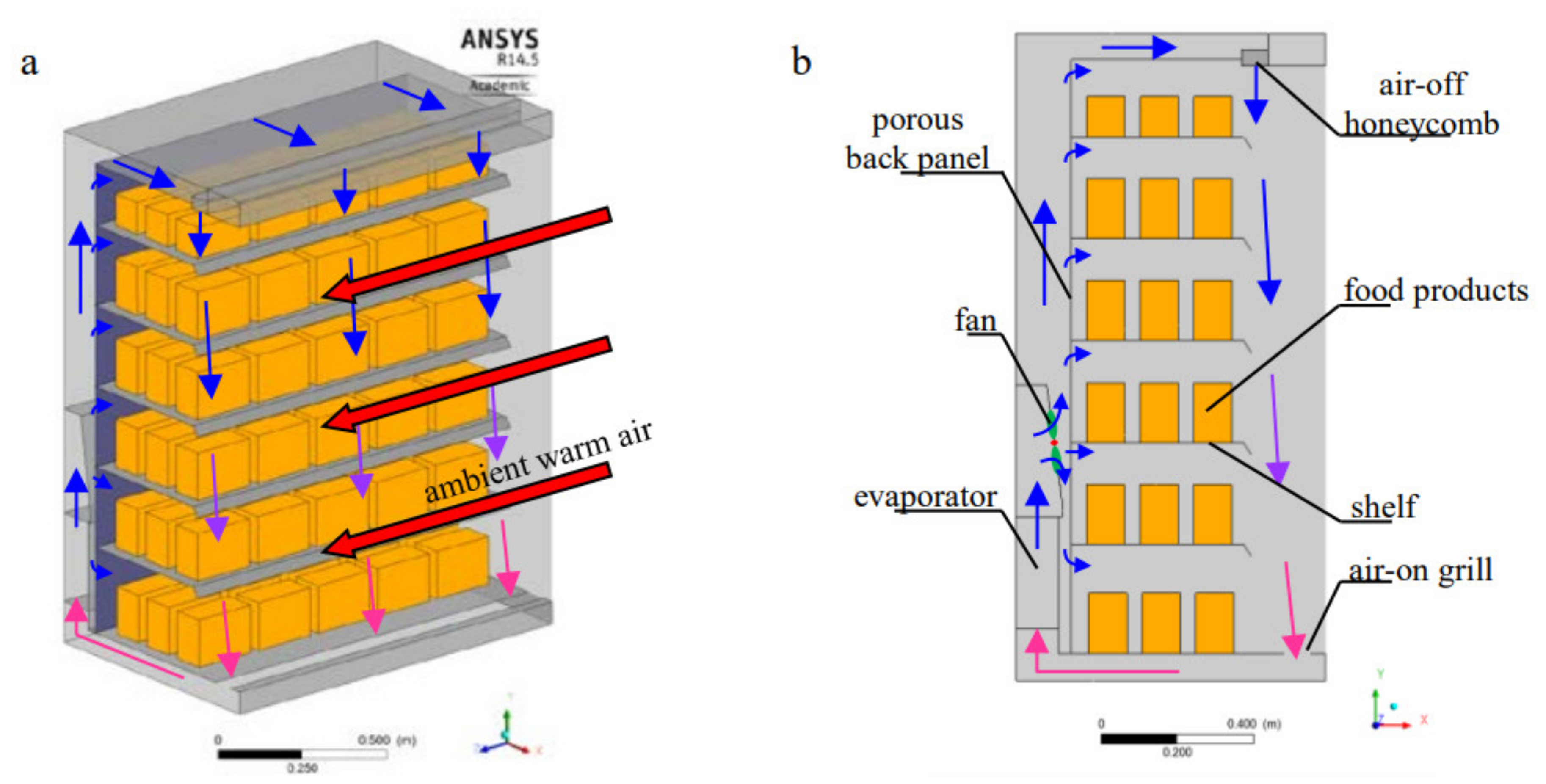

2.5. Refrigerated Display Cabinets

2.6. Objectives of Mathematical Modeling in the Fruit Cold Chain

3. Computational Fluid Dynamics in the Produce Cold Chain

3.1. CFD Solution Procedures

3.1.1. Problem Formulation

3.1.2. Geometry and Flow Domain

3.1.3. Establishing the Boundary and Initial Conditions

3.1.4. Mesh Generation

3.1.5. Pre-Processing

3.1.6. Simulation and Post-Processing

3.2. Overview of CFD Software

4. Notable CFD Studies

4.1. Airflow and Temperature Distribution during Precooling of Produce

| Fruit | Model Geometry | Numerical Technique | Objectives | Result | Reference |

|---|---|---|---|---|---|

| Pomegranate | Pallet | FVM in CFX | Redesigning the vent holes of packaging. | The new vent hole design enabled 14.4% faster cooling and lowered the airflow resistance by 6.5%. | [13] |

| Apple | Pallet | FVM on Open FOAM | Assessing thermal heterogeneity and the associated differences in quality. | Without precooling, about 23% more quality loss was found than with precooling. | [14,43,47,48] |

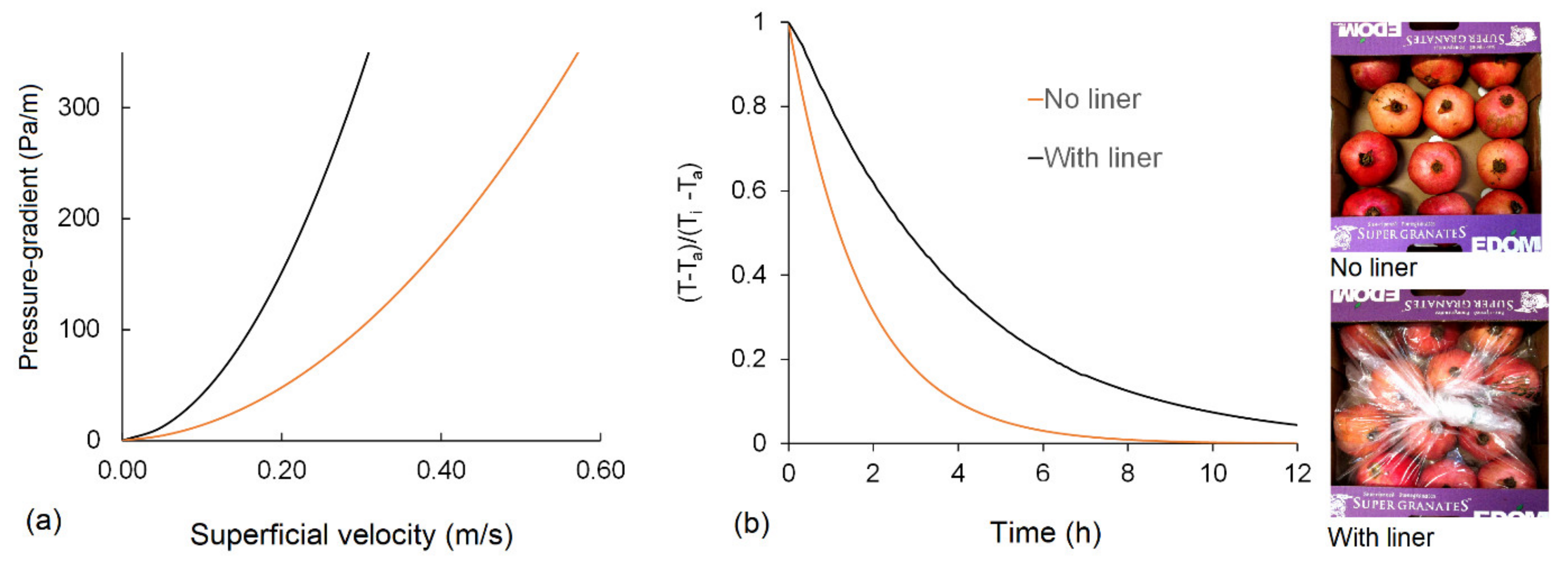

| Pomegranate | Pallet and single layer | FVM in CFX | Analyzing the effect of package design on the rate and uniformity of cooling. | A cooling rate difference of 30% was observed between two commercial package designs. Plastic lining increased the average 7/8th cooling time by threefold. | [13] |

| Apple | Single fruit, | FVM in Fluent | Studying the effect of air inflow velocities on the apple temperature distribution during forced convection cooling. | Cooling rate increases significantly with air inflow velocity up to 2.5 m/s; any further increase resulted in a relatively low increase in cooling rate. | [55] |

| Apple | Single package | FVM in Fluent | To evaluate the cooling performances, energy usages, and fruit quality (chilling injury and mass loss) of an existing container and a newly developed container. | A new package with improved cooling performance was proposed. For all existing package designs, the optimal air inflow velocities lay in the range 0.4–1 m/s (or 3–5 L s−1kg−1). | [62] |

| Apple | Pallet | FVM in Fluent | Evaluate cooling rate and uniformity, energy efficiency, and fruit quality (including chilling injury and mass loss). | For all existing package designs, the optimal air-inflow velocities lay in the range 0.4–1 m/s (or 3–5 L s−1 kg−1). | [63] |

| Kiwifruit | Single layer out of a pallet | FVM in Fluent | To determine the optimum pressure drop and cooling airflow rate for improved cooling rate, energy usage, and process throughput. | A pressure drop of 100 Pa with a corresponding cooling airflow rate of 0.25 L kg−1 s−1 was proposed as the optimal operating point. | [56] |

| Citrus | Single layer out of a pallet | FVM in Fluent | To analyze the cooling rate and energy usage of existing container designs and new container designs. | The different containers were ranked with respect to their performances in cooling rate, cooling uniformity. and energy consumption. | [14] |

| Strawberries | Single layer out of a pallet | FEM in COMSOL Multiphysics | To assess the performance of a new package and cooling system for the precooling of strawberries. | Improvements were made in the uniformity of cooling of strawberry and reduced the fruit decay. | [61] |

| Apple | Single package | FVM in Fluent | To study the effect of vent shape, vent distribution, and stacking pattern on the cooling quality. | Vertical oblong-shaped vent and triangular vent distribution could improve the longitudinal and lateral airflow. | [67] |

| Artificial, Spherical Plastic Ball Citrus | Single package to half a pallet | FVM in Fluent | To study the effect of package vent design on airflow and heat transfer. | A 7% vent area proportion is optimum. | [59,60] |

4.2. CFD Models Analysing Cold Storage Room

| Fruit | Numerical Technique | Objectives | Result | Reference |

|---|---|---|---|---|

| Apple | FVM ANSYS in Fluent | To investigate the effectiveness of postharvest storage fungicide fogging systems. | The effect of airflow rates and different bin handling parameters on fungicide particles’ flow and deposition were obtained. | [69] |

| NA | FVM ANSYS in CFX | To analyze the aerodynamic sealing of doorways of refrigerated rooms. | The sealing efficiency was estimated for different situations. | [70] |

| Citrus | FVM ANSYS in Fluent | To investigate the cooling performance of a partially loaded cold store in the cooling process. | Effect of loading pattern on the cooling process was established. | [71] |

| Dates | FVM ANSYS in Fluent | To define the suitable precooling conditions leading to homogeneous storage temperature inside the room. | A new cold storeroom design was proposed using specific aerodynamic air deflector profiles. | [72] |

| Table Grapes | FVM ANSYS in Fluent | To analyze the effects of the packaging components (bunch carry bag and plastic liners) and box stacking on airflow, heat, and mass transfer. | The presence of the carry bag increased the half and 7/8th cooling time by 61.09% and 97.34%, respectively. | [59,60] |

| NA | FVM ANSYS in Fluent | To evaluate the air infiltration rate through sliding doors. | Air temperature difference between spaces affected the air infiltration. For this case study, the infiltration rate increased by 0.012 m3 s −1 per K of air temperature difference. | [73] |

| Apple Fruit | FVM ANSYS in CFX | To analyze the 1-MCP distribution in commercial cool storerooms: porous medium model application. | New index to visualize heterogeneity in time was presented. | [68] |

| Apple Fruit | FVM ANSYS in CFX | To analyze energy- and cost-saving alternatives. | The study showed that the air circulation fan is the major source of heat load. Hence, an attempt to reduce energy costs should first consider reducing the fan operation time. | [15] |

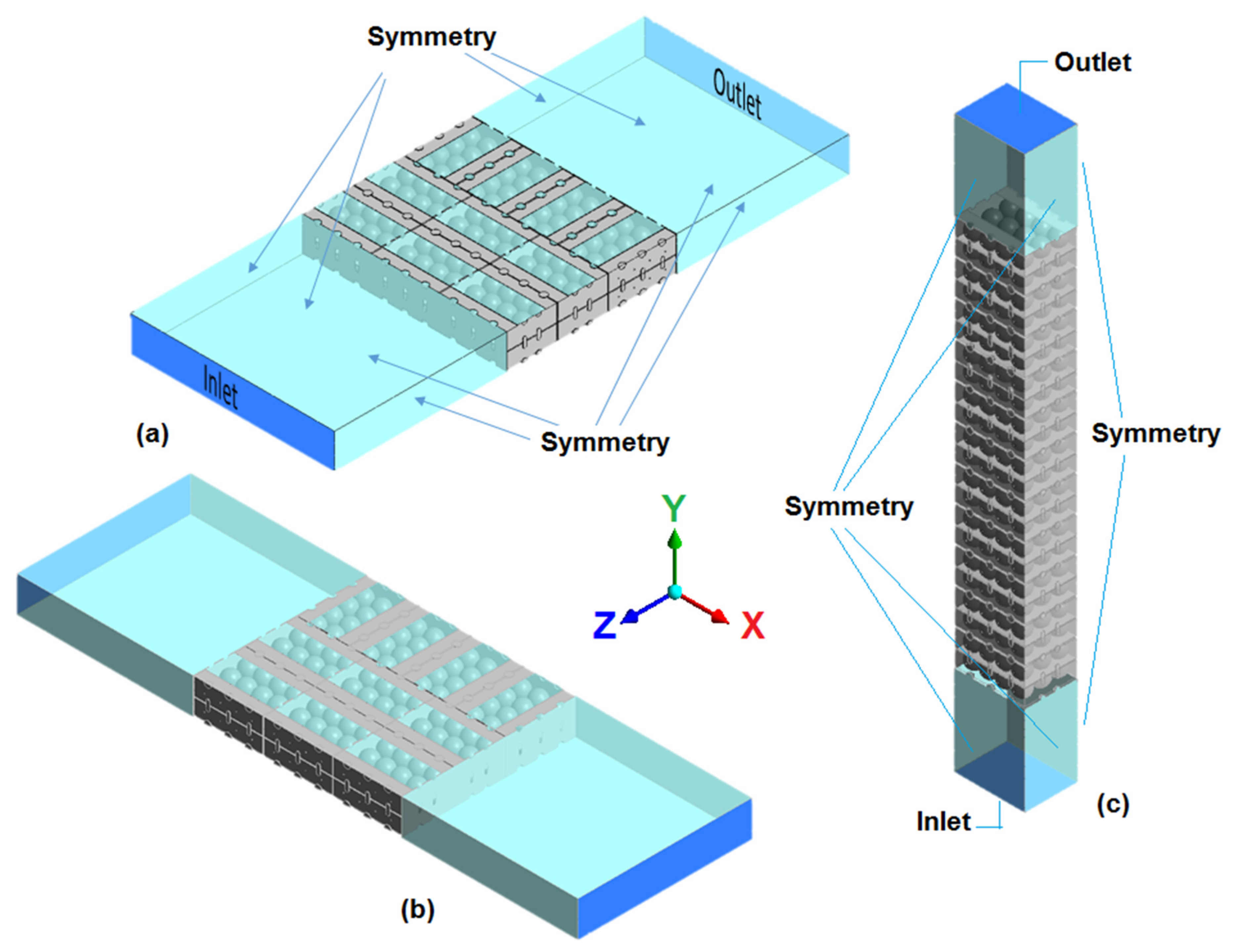

4.3. Refrigerated Container (Reefer)

4.4. Moisture Distribution in Cold Storage Room

4.5. Modeling Produce Quality

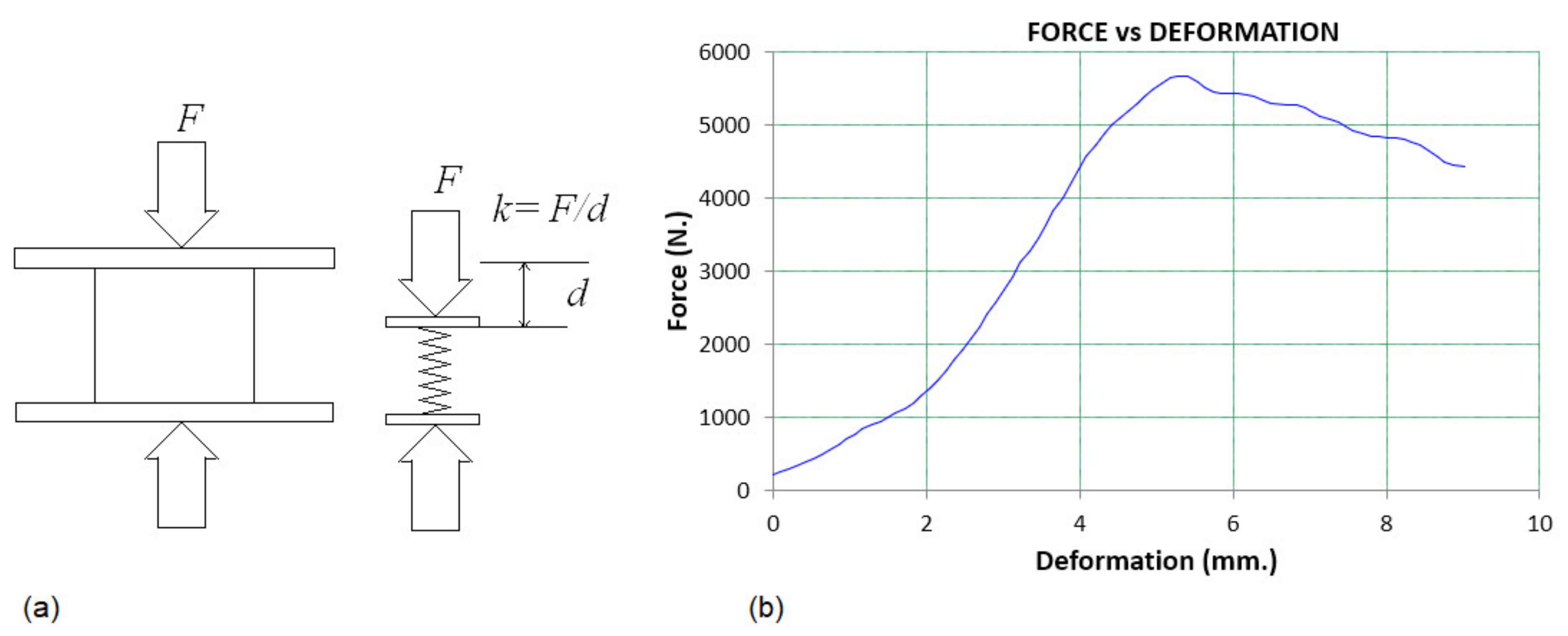

5. Mechanical Strength of Corrugated Fiberboard Cartons in the Produce Cold Chain

5.1. Compression Strength

5.2. Impact Strength

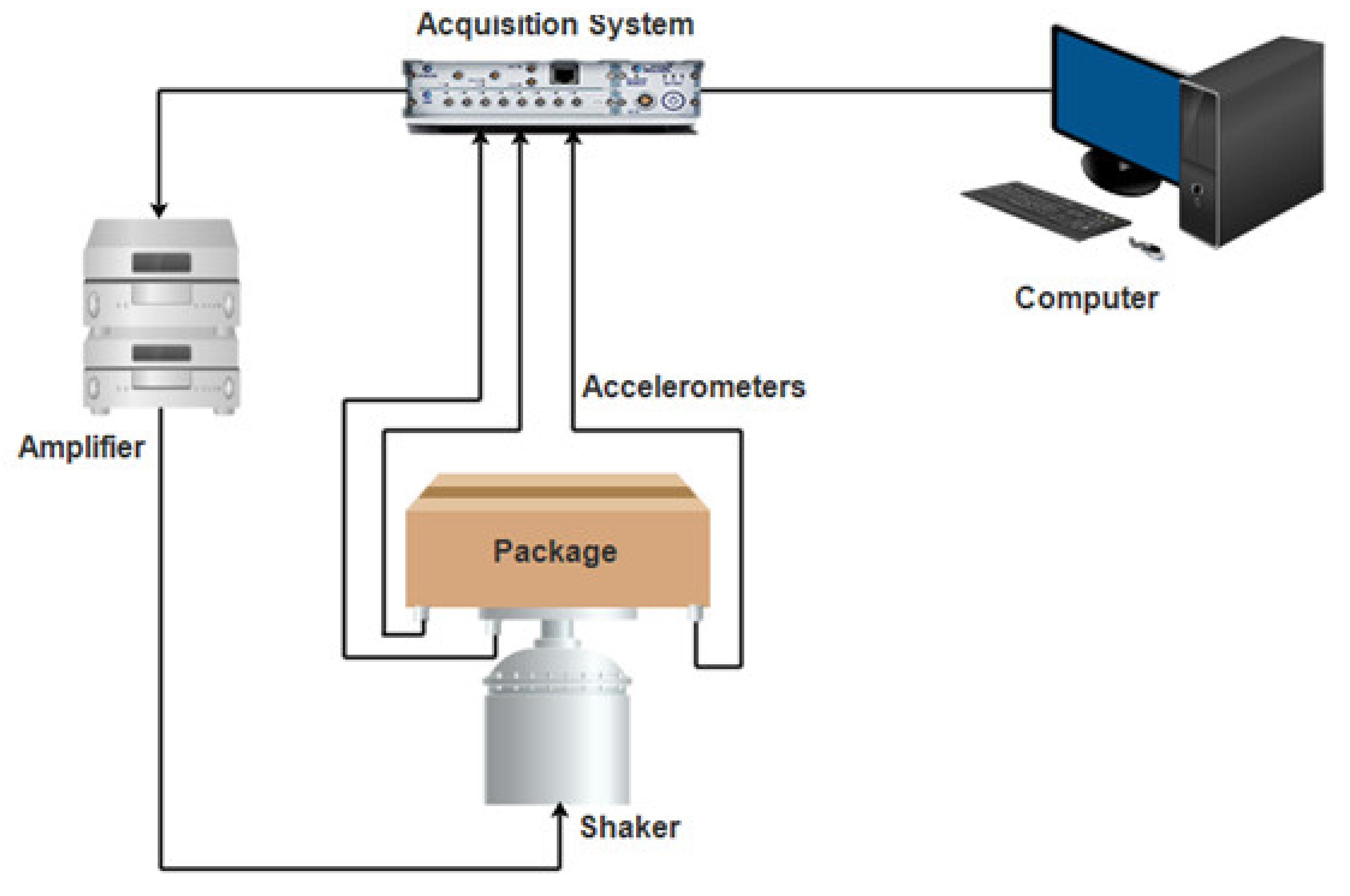

5.3. Vibration Strength

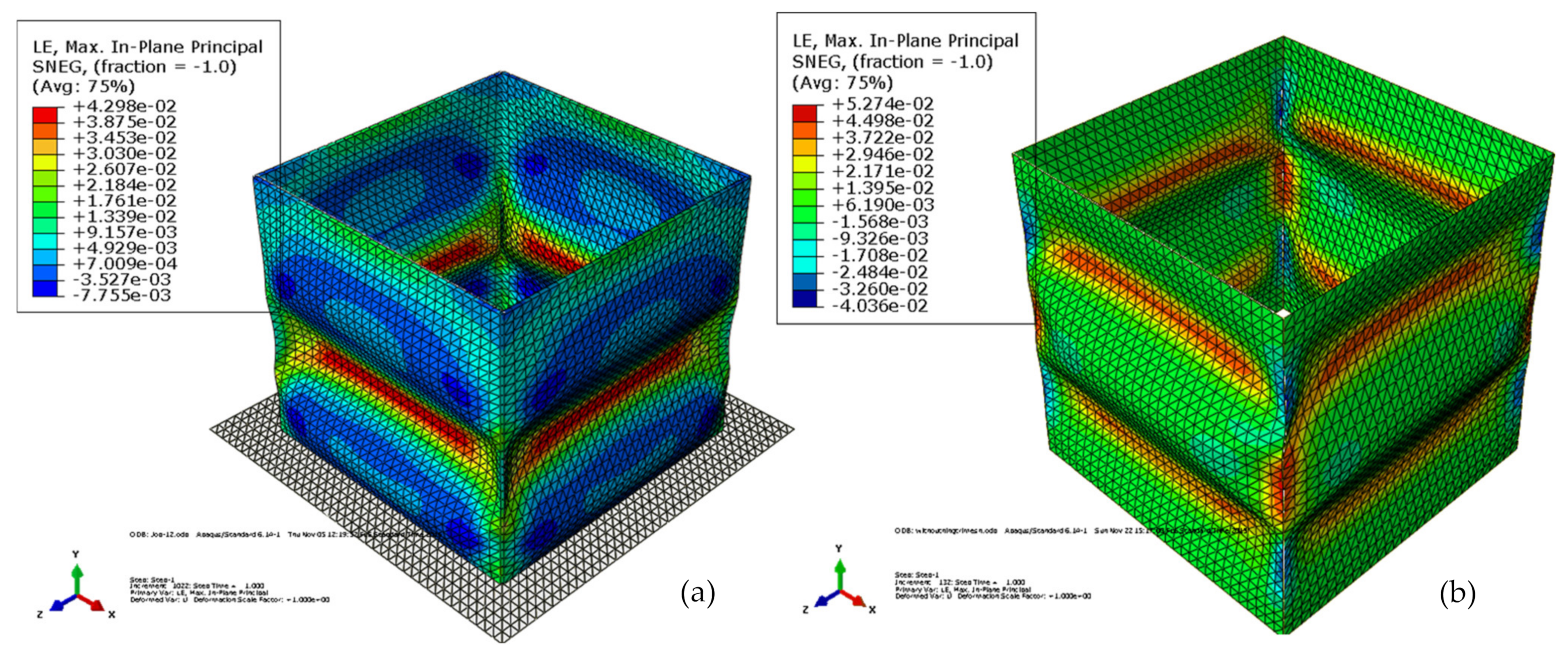

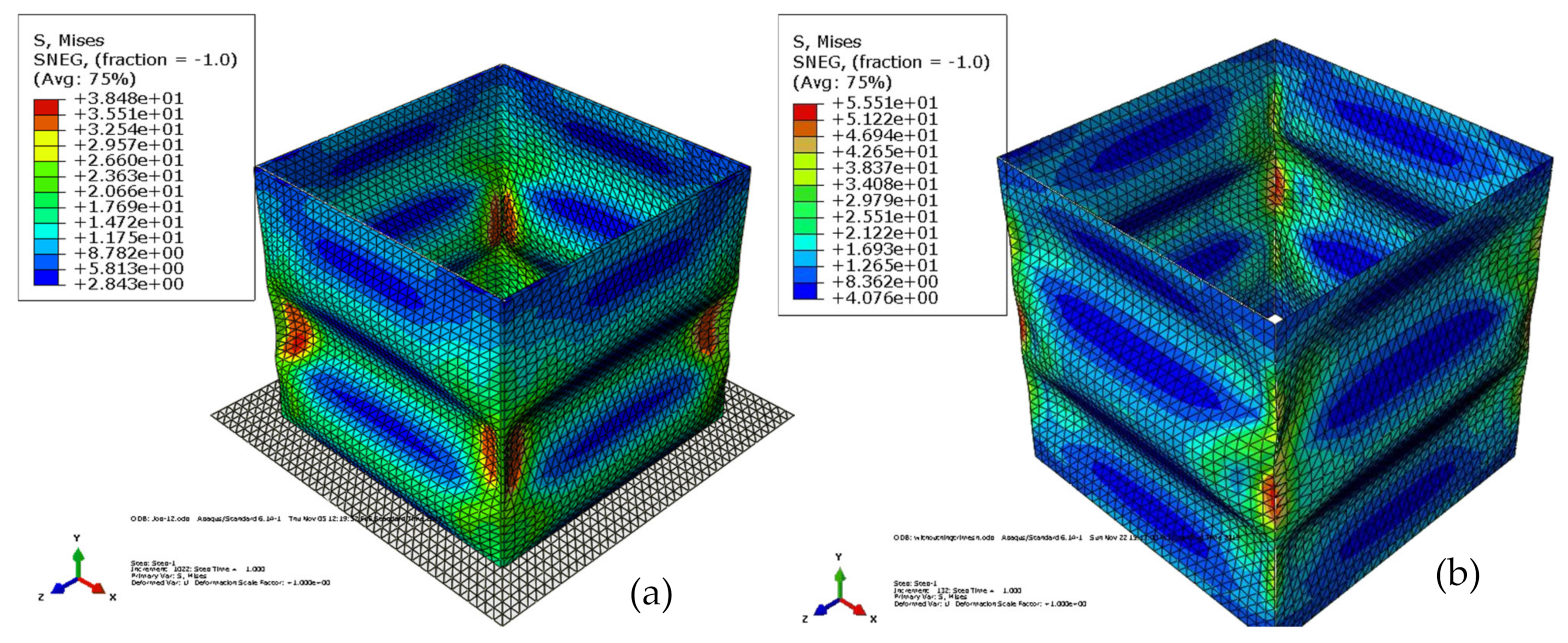

5.4. Modeling the Mechanical Strength of CFCs

6. Model Validation

7. Future Prospects for Computational Thermo-Mechanical Analysis in Fruit Cold Chains

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majeed, Y.; Zhang, J.; Zhang, X.; Fu, L.; Karkee, M.; Zhang, Q.; Whiting, M.D. Apple Tree Trunk and Branch Segmentation for Automatic Trellis Training Using Convolutional Neural Network Based Semantic Segmentation. IFAC-PapersOnLine 2018, 51, 75–80. [Google Scholar] [CrossRef]

- Wu, C.; He, L.; Du, X.; Chen, S.; Ni, K. 3D reconstruction of Chinese hickory tree for dynamics analysis. Biosyst. Eng. 2014, 119, 69–79. [Google Scholar] [CrossRef]

- Duga, A.T.; Ruysenc, K.; Dekeyserb, D.; Nuyttensb, D.; Bylemansc, D.; Nicolaia, B.M.; Verbovena, P. CFD based analysis of the effect of wind in orchard spraying. Chem. Eng. Trans. 2015, 44, 1–6. [Google Scholar]

- Karkee, M.; Adhikari, B.; Amatya, S.; Zhang, Q. Identification of pruning branches in tall spindle apple trees for automated pruning. Comput. Electron. Agric. 2014, 103, 127–135. [Google Scholar] [CrossRef]

- Karkee, M.; Adhikari, B. A Method for Three-Dimensional Reconstruction of Apple Trees for Automated Pruning. Trans. ASABE 2015, 58, 565–574. [Google Scholar] [CrossRef]

- Prusinkiewicz, P.; Lindenmayer, A. The Algorithmic Beauty of Plants; Springer Science and Business Media LLC: New York, NY, USA, 1990. [Google Scholar]

- Parra-Coronado, A.; Fischer, G.; Camacho-Tamayo, J.H. Model of pre-harvest quality of pineapple guava fruits (Acca sellowiana (O. berg) burret) as a function of weather conditions of the crops. Bragantia 2017, 76, 177–186. [Google Scholar] [CrossRef]

- Orlandini, S.; Moriondo, M.; Cappellini, P.; Ferrari, P. Analysis and modelling of apple fruit growth. Acta Hortic. 1999, 137–146. [Google Scholar] [CrossRef]

- Salarikia, A.; Ashtiani, S.-H.M.; Golzarian, M.R.; Mohammadinezhad, H. Finite element analysis of the dynamic behavior of pear under impact loading. Inf. Process. Agric. 2017, 4, 64–77. [Google Scholar] [CrossRef]

- Opara, U.L.; Pathare, P. Bruise damage measurement and analysis of fresh horticultural produce—A review. Postharvest Biol. Technol. 2014, 91, 9–24. [Google Scholar] [CrossRef]

- Kabas, O.; Vlăduţ, V. Determination of Drop-Test Behavior of a Sample Peach Using Finite Element Method. Int. J. Food Prop. 2014, 18, 2584–2592. [Google Scholar] [CrossRef]

- Mukama, M.; Ambaw, A.; Opara, U.L. A virtual prototyping approach for redesigning the vent-holes of packaging for handling pomegranate fruit—A short communication. J. Food Eng. 2020, 270, 109762. [Google Scholar] [CrossRef]

- Ambaw, A.; Mukama, M.; Opara, U. Analysis of the effects of package design on the rate and uniformity of cooling of stacked pomegranates: Numerical and experimental studies. Comput. Electron. Agric. 2017, 136, 13–24. [Google Scholar] [CrossRef]

- Defraeye, T.; Lambrecht, R.; Delele, M.A.; Tsige, A.A.; Opara, U.L.; Cronjé, P.; Verboven, P.; Nicolai, B. Forced-convective cooling of citrus fruit: Cooling conditions and energy consumption in relation to package design. J. Food Eng. 2014, 121, 118–127. [Google Scholar] [CrossRef]

- Ambaw, A.; Bessemans, N.; Gruyters, W.; Gwanpua, S.G.; Schenk, A.; De Roeck, A.; Delele, M.A.; Verboven, P.; Nicolai, B.M. Analysis of the spatiotemporal temperature fluctuations inside an apple cool store in response to energy use concerns. Int. J. Refrig. 2016, 66, 156–168. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Analysis of airflow and heat transfer inside fruit packed refrigerated shipping container: Part I—Model development and validation. J. Food Eng. 2017, 203, 58–68. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Analysis of airflow and heat transfer inside fruit packed refrigerated shipping container: Part II—Evaluation of apple packaging design and vertical flow resistance. J. Food Eng. 2017, 203, 83–94. [Google Scholar] [CrossRef]

- Roşca, R.; Ţenu, I.; Cârlescu, P. Food Chilling Methods and CFD Analysis of a Refrigeration Cabinet as a Case Study; IntechOpen: London, UK, 2017. [Google Scholar]

- Chaomuang, N.; Flick, D.; Laguerre, O. Experimental and numerical investigation of the performance of retail refrigerated display cabinets. Trends Food Sci. Technol. 2017, 70, 95–104. [Google Scholar] [CrossRef]

- Fadiji, T.; Berry, T.M.; Coetzee, C.; Opara, U.L. Mechanical design and performance testing of corrugated paperboard packaging for the postharvest handling of horticultural produce. Biosyst. Eng. 2018, 171, 220–244. [Google Scholar] [CrossRef]

- Berry, T.; Ambaw, A.; Defraeye, T.; Coetzee, C.; Opara, U.L. Moisture adsorption in palletised corrugated fibreboard cartons under shipping conditions: A CFD modelling approach. Food Bioprod. Process. 2019, 114, 43–59. [Google Scholar] [CrossRef]

- Pathare, P.; Opara, U.L. Structural design of corrugated boxes for horticultural produce: A review. Biosyst. Eng. 2014, 125, 128–140. [Google Scholar] [CrossRef]

- Pathare, P.B.; Berry, T.M.; Opara, U.L. Changes in moisture content and compression strength during storage of ventilated corrugated packaging used for handling apples. Packag. Res. 2016, 1, 1–6. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Opara, U.L. Analysis of the creep behaviour of ventilated corrugated paperboard packaging for handling fresh produce—An experimental study. Food Bioprod. Process. 2019, 117, 126–137. [Google Scholar] [CrossRef]

- Maheshwari, T.; Shenoy, R. A Study of the Effect of Squareness of the Corrugated Box on its Box Compression Strength. Int. J. Latest Technol. Eng. Manag. Appl. Sci. 2017, 6, 26–28. [Google Scholar]

- Rudawska, A.; Čuboňova, N.; Pomarańska, K.; Stančeková, D.S.; Gola, A. Technical and Organizational Improvements of Packaging Production Process. Adv. Sci. Technol. Res. J. 2016, 10, 182–192. [Google Scholar] [CrossRef]

- Fadiji, T.; Ambaw, A.; Coetzee, C.; Berry, T.M.; Opara, U.L. Application of finite element analysis to predict the mechanical strength of ventilated corrugated paperboard packaging for handling fresh produce. Biosyst. Eng. 2018, 174, 260–281. [Google Scholar] [CrossRef]

- Velloso, N.S.; Costa, A.L.G.; Magalhães, R.R.; Santos, F.L.; De Andrade, E.T. The Finite Element Method Applied to Agricultural Engineering: A Review. Curr. Agric. Res. J. 2018, 6, 286–299. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Berry, T.M.; Ambaw, A.; Opara, U.L. The efficacy of finite element analysis (FEA) as a design tool for food packaging: A review. Biosyst. Eng. 2018, 174, 20–40. [Google Scholar] [CrossRef]

- Cook, R.D.; Malkus, D.S.; Plesha, M.E.; Witt, R.J. Concepts and Applications of Finite Element Analysis, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Lufu, R.; Ambaw, A.; Opara, U.L. The contribution of transpiration and respiration processes in the mass loss of pomegranate fruit (cv. Wonderful). Postharvest Biol. Technol. 2019, 157, 110982. [Google Scholar] [CrossRef]

- Eastburn, D.M.; McElrone, A.J.; Bilgin, D.D. Influence of atmospheric and climatic change on plant-pathogen interactions. Plant Pathol. 2011, 60, 54–69. [Google Scholar] [CrossRef]

- Fraser, H. Forced-Air Cooling Systems for Fresh Ontario Fruits and Vegetables; Ontario Ministry of Agriculture, Food and Rural Affairs: Toronto, ON, Canada, 2014.

- Praeger, U.; Jedermann, R.; Sellwig, M.; Neuwald, D.A.; Hartgenbusch, N.; Borysov, M.; Truppel, I.; Scaar, H.; Geyer, M. Airflow distribution in an apple storage room. J. Food Eng. 2020, 269, 109746. [Google Scholar] [CrossRef]

- Elansari, A.M.; Fenton, D.L.; Callahan, C.W. Precooling. In Postharvest Technology of Perishable Horticultural Commodities; Woodhead Publishing: Cambridge, MA, USA, 2019; pp. 161–207. [Google Scholar]

- Hardenburg, R.E.; Wright, R.C.; Rose, D.H.; Watada, A.E.; Whiteman, T.M.; Wang, C.Y. The Commercial Storage of Fruits, Vegetables, and Florist and Nursery Stocks; Agriculture Handbook, No. 66; US Department of Agriculture, Agricultural Research Service: Washington, DC, USA, 1986.

- Mukama, M.; Ambaw, A.; Berry, T.M.; Opara, U.L. Energy usage of forced air precooling of pomegranate fruit inside ventilated cartons. J. Food Eng. 2017, 215, 126–133. [Google Scholar] [CrossRef]

- Shaheed, B.S.; Nayeem, M.; Rasheed, M.A. Design considerations for a cold storage unit. Int. J. Sci. Res. Sci. Eng. Technol. 2016, 2, 545–548. [Google Scholar]

- Wu, W.; Cronjé, P.; Verboven, P.; Defraeye, T. Unveiling how ventilated packaging design and cold chain scenarios affect the cooling kinetics and fruit quality for each single citrus fruit in an entire pallet. Food Packag. Shelf Life 2019, 21, 100369. [Google Scholar] [CrossRef]

- Martin, S.; Martin, J.; Lai, P. International container design regulations and ISO standards: Are they fit for purpose? Marit. Policy Manag. 2018, 46, 217–236. [Google Scholar] [CrossRef]

- Sun, J.; Tsamos, K.M.; Tassou, S. CFD comparisons of open-type refrigerated display cabinets with/without air guiding strips. Energy Procedia 2017, 123, 54–61. [Google Scholar] [CrossRef]

- Dyck, N.; Straatman, A.G. A new approach to digital generation of spherical void phase porous media microstructures. Int. J. Heat Mass Transf. 2015, 81, 470–477. [Google Scholar] [CrossRef]

- Gruyters, W.; Verboven, P.; Diels, E.; Rogge, S.; Smeets, B.; Ramon, H.; Defraeye, T.; Nicolaï, B.M. Modelling Cooling of Packaged Fruit Using 3D Shape Models. Food Bioprocess. Technol. 2018, 11, 2008–2020. [Google Scholar] [CrossRef]

- Elhalwagy, M.; Dyck, N.; Straatman, A.G. A Multi–Level Approach for Simulation of Storage and Respiration of Produce. Appl. Sci. 2019, 9, 1052. [Google Scholar] [CrossRef]

- Löhner, R. Recent Advances in Parallel Advancing Front Grid Generation. Arch. Comput. Methods Eng. 2014, 21, 127–140. [Google Scholar] [CrossRef]

- Liseikin, V.D. Grid Generation Methods; Springer: Berlin, Germany, 2017. [Google Scholar]

- Wu, W.; Beretta, C.; Cronje, P.; Hellweg, S.; Defraeye, T. Environmental trade-offs in fresh-fruit cold chains by combining virtual cold chains with life cycle assessment. Appl. Energy 2019, 254, 113586. [Google Scholar] [CrossRef]

- Wu, W.; Defraeye, T. Identifying heterogeneities in cooling and quality evolution for a pallet of packed fresh fruit by using virtual cold chains. Appl. Therm. Eng. 2018, 133, 407–417. [Google Scholar] [CrossRef]

- Marai, S.V.; Ferrari, E.; Civelli, R. Postharvest cold chain optimization of little fruits. In Proceedings of the COMSOL Conference, Milan, Italy, 10 October 2012. [Google Scholar]

- Li, Z.; Miao, F.; Andrews, J. Mechanical Models of Compression and Impact on Fresh Fruits. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1296–1312. [Google Scholar] [CrossRef] [PubMed]

- Ambaw, A.; Beaudry, R.; Bulens, I.; Delele, M.A.; Ho, Q.T.; Schenk, A.; Nicolaï, B.M.; Verboven, P.; Tsige, A.A. Modeling the diffusion—adsorption kinetics of 1-methylcyclopropene (1-MCP) in apple fruit and non-target materials in storage rooms. J. Food Eng. 2011, 102, 257–265. [Google Scholar] [CrossRef]

- Ho, Q.T.; Hertog, M.L.A.T.M.; Verboven, P.; Ambaw, A.; Rogge, S.; Verlinden, B.E.; Nicolaï, B.M. Down-regulation of respiration in pear fruit depends on temperature. J. Exp. Bot. 2018, 69, 2049–2060. [Google Scholar] [CrossRef]

- Retta, M.; Ho, Q.T.; Yin, X.; Verboven, P.; Berghuijs, H.N.; Struik, P.C.; Nicolaï, B.M. A two-dimensional microscale model of gas exchange during photosynthesis in maize (Zea mays L.) leaves. Plant Sci. 2016, 246, 37–51. [Google Scholar] [CrossRef]

- Nguyen, T.; Dresselaers, T.; Verboven, P.; D’Hallewin, G.; Culeddu, N.; Van Hecke, P.; Nicolaï, B. Finite element modelling and MRI validation of 3D transient water profiles in pears during postharvest storage. J. Sci. Food Agric. 2006, 86, 745–756. [Google Scholar] [CrossRef]

- Han, J.W.; Badía-Melis, R.; Yang, X.T.; Ruiz-Garcia, L.; Qian, J.P.; Zhao, C.J. CFD simulation of airflow and heat transfer during forced-air precooling of apples. J. Food Process Eng. 2017, 40, e12390. [Google Scholar] [CrossRef]

- O’Sullivan, J.L.; Ferrua, M.J.; Love, R.; Verboven, P.; Nicolaï, B.; East, A. Forced-air cooling of polylined horticultural produce: Optimal cooling conditions and package design. Postharvest Biol. Technol. 2017, 126, 67–75. [Google Scholar] [CrossRef]

- Guo, J.; Wei, X.; Li, B.; Cao, Y.; Han, J.; Yang, X.; Lü, E. Characteristic analysis of humidity control in a fresh-keeping container using CFD model. Comput. Electron. Agric. 2020, 179, 105816. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Delele, M.A.; Defraeye, T.; Tijskens, E.; Schenk, A.; Nicolai, B.M. CFD Modelling of the 3D Spatial and Temporal Distribution of 1-methylcyclopropene in a Fruit Storage Container. Food Bioprocess. Technol. 2013, 6, 2235–2250. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.E.K.; Getahun, S.T.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part I: Model development and validation. Postharvest Biol. Technol. 2013, 86, 536–545. [Google Scholar] [CrossRef]

- Delele, M.; Ngcobo, M.; Getahun, S.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part II: Effect of package design. Postharvest Biol. Technol. 2013, 86, 546–555. [Google Scholar] [CrossRef]

- Ferrua, M.; Singh, R. Improved airflow method and packaging system for forced-air cooling of strawberries. Int. J. Refrig. 2011, 34, 1162–1173. [Google Scholar] [CrossRef]

- Han, J.-W.; Qian, J.-P.; Zhao, C.-J.; Yang, X.-T.; Fan, B.-L. Mathematical modelling of cooling efficiency of ventilated packaging: Integral performance evaluation. Int. J. Heat Mass Transf. 2017, 111, 386–397. [Google Scholar] [CrossRef]

- Han, J.-W.; Zhao, C.-J.; Qian, J.-P.; Ruiz-Garcia, L.; Zhang, X. Numerical modeling of forced-air cooling of palletized apple: Integral evaluation of cooling efficiency. Int. J. Refrig. 2018, 89, 131–141. [Google Scholar] [CrossRef]

- Nalbandi, H.; Seiiedlou, S.; Ghasemzadeh, H.R.; Rangbar, F. Innovative Parallel Airflow System for forced-air cooling of strawberries. Food Bioprod. Process. 2016, 100, 440–449. [Google Scholar] [CrossRef]

- Berry, T.M.; Fadiji, T.; Defraeye, T.; Opara, U.L. The role of horticultural carton vent hole design on cooling efficiency and compression strength: A multi-parameter approach. Postharvest Biol. Technol. 2017, 124, 62–74. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Verboven, P.; Opara, U.L.; Nicolai, B. Exploring ambient loading of citrus fruit into reefer containers for cooling during marine transport using computational fluid dynamics. Postharvest Biol. Technol. 2015, 108, 91–101. [Google Scholar] [CrossRef]

- Lu, L.-X.; Chen, X.-Q.; Wang, J. Modelling and Thermal Analysis of Tray-layered Fruits inside Ventilated Packages during Forced-air Precooling. Packag. Technol. Sci. 2016, 29, 105–119. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Delele, M.A.; Defraeye, T.; Tijskens, E.; Schenk, A.; Verlinden, B.E.; Opara, U.L.; Nicolaï, B.M.; Tsige, A.A. CFD-Based Analysis of 1-MCP Distribution in Commercial Cool Store Rooms: Porous Medium Model Application. Food Bioprocess. Technol. 2013, 7, 1903–1916. [Google Scholar] [CrossRef]

- Delele, M.; Vorstermans, B.; Creemers, P.; Tsige, A.; Tijskens, E.; Schenk, A.; Opara, U.; Nicolaï, B.; Verboven, P. CFD model development and validation of a thermonebulisation fungicide fogging system for postharvest storage of fruit. J. Food Eng. 2012, 108, 59–68. [Google Scholar] [CrossRef]

- Gonçalves, J.C.; Costa, J.; Figueiredo, A.R.A.; Lopes, A. Study of the aerodynamic sealing of a cold store—Experimental and numerical approaches. Energy Build. 2012, 55, 779–789. [Google Scholar] [CrossRef]

- Tanaka, F.; Konishi, Y.; Kuroki, Y.; Hamanaka, D.; Uchino, T. The use of CFD to improve the performance of a partially loaded cold store. J. Food Process. Eng. 2012, 35, 874–880. [Google Scholar] [CrossRef]

- Ghiloufi, Z.; Khir, T. 3D CFD modelling of the airflow and heat transfer in cold room filled with Dates. Int. J. Nutr. Food Eng. 2018, 12, 349–353. [Google Scholar]

- Carneiro, R.; Gaspar, P.; Silva, P. 3D and transient numerical modelling of door opening and closing processes and its influence on thermal performance of cold rooms. Appl. Therm. Eng. 2017, 113, 585–600. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Shinoda, T. The effect of solar radiation on the energy consumption of refrigerated container. Case Stud. Therm. Eng. 2018, 12, 687–695. [Google Scholar] [CrossRef]

- Kan, A.; Hu, J.; Guo, Z.; Meng, C.; Chao, C. Impact of Cargo Stacking Modes on Temperature Distribution Inside Marine Reefer Containers. Int. J. Air-Cond. Refrig. 2017, 25, 1750020. [Google Scholar] [CrossRef]

- Yildiz, T. CFD Characteristics of Refrigerated Trailers and Improvement of Airflow for Preserving Perishable Foods. Logistics 2019, 3, 11. [Google Scholar] [CrossRef]

- Jiang, T.; Xu, N.; Luo, B.; Deng, L.; Wang, S.; Gao, Q.; Zhang, Y. Analysis of an internal structure for refrigerated container: Improving distribution of cooling capacity. Int. J. Refrig. 2020, 113, 228–238. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Shinoda, T. Energy efficiency on the reefer container storage yard; an analysis of thermal performance of installation roof shade. Energy Rep. 2020, 6, 686–692. [Google Scholar] [CrossRef]

- Budiyanto, M.A.; Suheriyanto, N. Analysis of the Effect of Inlet Velocity on Cooling Speed in a Refrigerated Container using CFD simulations. CFD Lett. 2020, 12, 55–62. [Google Scholar] [CrossRef]

- Issa, S.; Lang, W. Airflow simulation inside reefer containers. In Dynamics in Logistics; Springer Science and Business Media LLC: New York, NY, USA, 2016; pp. 303–311. [Google Scholar]

- Robertson, G.L. Food Packaging: Principles and Practice; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Dermesonlouoglou, E.K.; Pourgouri, S.; Taoukis, P.S. Kinetic study of the effect of the osmotic dehydration pre-treatment to the shelf life of frozen cucumber. Innov. Food Sci. Emerg. Technol. 2008, 9, 542–549. [Google Scholar] [CrossRef]

- Tsironi, T.; Salapa, I.; Taoukis, P. Shelf life modelling of osmotically treated chilled gilthead seabream fillets. Innov. Food Sci. Emerg. Technol. 2009, 10, 23–31. [Google Scholar] [CrossRef]

- Frank, B. Corrugated Box Compression—A Literature Survey. Packag. Technol. Sci. 2013, 27, 105–128. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.P.; Saha, K. Effect of horizontal offset on vertical compression strength of stacked corrugated fiberboard boxes. J. Appl. Packag. Res. 2011, 5, 131–143. [Google Scholar]

- Fadiji, T.; Coetzee, C.; Opara, U.L. Compression strength of ventilated corrugated paperboard packages: Numerical modelling, experimental validation and effects of vent geometric design. Biosyst. Eng. 2016, 151, 231–247. [Google Scholar] [CrossRef]

- Allaoui, S.; Aboura, Z.; Benzeggagh, M. Effects of the environmental conditions on the mechanical behaviour of the corrugated cardboard. Compos. Sci. Technol. 2009, 69, 104–110. [Google Scholar] [CrossRef]

- Pathare, P.B.; Berry, T.M.; Opara, U.L. Experimental investigation of compression strength of ventilated corrugated citrus packaging. Packag. Res. 2017, 2, 22–27. [Google Scholar] [CrossRef][Green Version]

- Singh, J.; Olsen, E.; Singh, S.P.; Manley, J.; Wallace, F. The effect of ventilation and hand holes on loss of compression strength in corrugated boxes. J. Appl. Packag. Res. 2008, 2, 227–238. [Google Scholar]

- Hussain, S.; Coffin, D.W.; Todoroki, C. Investigating Creep in Corrugated Packaging. Packag. Technol. Sci. 2017, 30, 757–770. [Google Scholar] [CrossRef]

- Åslund, P.E.; Hägglund, R.; Carlsson, L.A.; Isaksson, P. Modeling of global and local buckling of corrugated board panels loaded in edge-to-edge compression. J. Sandw. Struct. Mater. 2014, 16, 272–292. [Google Scholar] [CrossRef]

- Park, J.; Kim, G.; Kim, H.; Kwon, S.; Mitusoka, M.; Inoue, E.; Okayasu, T. Characteristics of Vibration Transmissibility for Corrugated Paperboard. J. Fac. Agric. Kyushu Univ. 2011, 56, 327–333. [Google Scholar] [CrossRef]

- Csavajda, P.; Böröcz, P.; Mojzes, Á.; Molnár, B. The effect of creasing lines on the compression strength of adjustable height corrugated boxes. J. Appl. Packag. Res. 2017, 9, 15–22. [Google Scholar]

- Kueh, C.S.L.; Dahm, K.; Emms, G.; Wade, K.; Bronlund, J.E. Digital image correlation analysis of vertical strain for corrugated fiberboard box panel in compression. Packag. Technol. Sci. 2019, 32, 133–141. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.J.; Opara, U.L. Evaluating the displacement field of paperboard packages subjected to compression loading using digital image correlation (DIC). Food Bioprod. Process. 2020, 123, 60–71. [Google Scholar] [CrossRef]

- Jarimopas, B.; Singh, S.P.; Sayasoonthorn, S.; Singh, J. Comparison of package cushioning materials to protect post-harvest impact damage to apples. Packag. Technol. Sci. 2007, 20, 315–324. [Google Scholar] [CrossRef]

- Kılıçkan, A.; Güner, M. Physical properties and mechanical behaviour of olive fruits (Olea europaea L.) under compression loading. J. Food Eng. 2008, 87, 222–228. [Google Scholar] [CrossRef]

- Opara, U.L.; Fadiji, T. Compression damage susceptibility of apple fruit packed inside ventilated corrugated paperboard package. Sci. Hortic. 2018, 227, 154–161. [Google Scholar] [CrossRef]

- Rodriguez, K.C.; Ornelas-Paz, J.D.J.; Ibarra-Junquera, V.; Toto, M.C.; Jain, A.; Prakash, A. Effects of Fruit Position in Standard Place Pack Cartons and Gamma Irradiation on the Postharvest Quality of ‘Barnfield’ Navel Oranges. Food Bioprocess. Technol. 2018, 11, 2153–2163. [Google Scholar] [CrossRef]

- Rojas-Argudo, C.; Palou, L.; Bermejo, A.; Cano, A.; del Río, M.A.; González-Mas, M.C. Effect of X-ray irradiation on nutritional and antifungal bioactive compounds of ‘Clemenules’ clementine mandarins. Postharvest Biol. Technol. 2012, 68, 47–53. [Google Scholar] [CrossRef]

- Mazidi, M.; Sadrnia, H.; Khojastehpour, M. Evaluation of orange mechanical damage during packaging by study of changes in firmness. Int. Food Res. J. 2016, 23, 899–903. [Google Scholar]

- Obenland, D.; Collin, S.; Sievert, J.; Fjeld, K.; Doctor, J.; Arpaia, M.L. Commercial packing and storage of navel oranges alters aroma volatiles and reduces flavor quality. Postharvest Biol. Technol. 2008, 47, 159–167. [Google Scholar] [CrossRef]

- Rojas-Argudo, C.; Del Río, M.Á.; Montesinos-Herrero, C.; Palou, L. Effects of CO2 and O2 shocks at high temperature on postharvest quality of cold-stored citrus fruit. Int. J. Food Sci. Technol. 2010, 45, 2062–2070. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T.; Grabski, J.K. Estimation of the Compressive Strength of Corrugated Cardboard Boxes with Various Openings. Energies 2021, 14, 155. [Google Scholar] [CrossRef]

- Saha, K.; Messner, S.; Dizon, J.; Chhajed, N.; Singh, J. Influence of fiberboard container design on compression bulge displacement. J. Appl. Packag. Res. 2020, 12, 93–106. [Google Scholar]

- Gong, G.; Liu, Y.; Fan, B.; Sun, D. Deformation and compressive strength of corrugated cartons under different indentation shapes: Experimental and simulation study. Packag. Technol. Sci. 2020, 33, 215–226. [Google Scholar] [CrossRef]

- Gok, B.Y.; Akpinar, D. Investigation of Strength and Migration of Corrugated Cardboard Boxes. Hittite J. Sci. Eng. 2020, 7, 163–168. [Google Scholar] [CrossRef]

- Pyryev, Y.; Zwierzyński, T.; Kibirkštis, E.; Gegeckienė, L.; Vaitasius, K. Model to predict the top-to-bottom compressive strength of folding cartons. Nord. Pulp Pap. Res. J. 2019, 34, 117–127. [Google Scholar] [CrossRef]

- Kobayashi, T. Numerical Simulation for Compressive Strength of Corrugated Fiberboard Box. Jpn. TAPPI J. 2019, 73, 793–800. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Berry, T.M.; Opara, U.L. Investigating the role of geometrical configurations of ventilated fresh produce packaging to improve the mechanical strength—Experimental and numerical approaches. Food Packag. Shelf Life 2019, 20, 100312. [Google Scholar] [CrossRef]

- Böröcz, P. Measurement and Analysis of Deformation Shapes on Corrugated Cardboard Logistical Boxes Under Static and Dynamic Compression. Acta Tech. Jaurinensis 2015, 8, 320. [Google Scholar] [CrossRef][Green Version]

- Wei, Z.; Hua, G.J.; Zhao, D.J. Testing Research of Aspect Ratio on Corrugated Box Compression Strength. Appl. Mech. Mater. 2011, 48–49, 1213–1216. [Google Scholar] [CrossRef]

- Poustis, J. Corrugated fiberboard packaging. In Paper and Paperboard Packaging Technology; Kirwan, M.J., Ed.; Wiley-Blackwell: Oxford, UK, 2005; pp. 317–372. [Google Scholar]

- Eagleton, D.G. Creep Properties of Corrugated Fibreboard Containers for Produce in Simulated Road Transport Environment. Ph.D. Thesis, Victoria University of Technology, Melbourne, VIC, Australia, 1995. [Google Scholar]

- Lu, F.; Ishikawa, Y.; Kitazawa, H.; Satake, T. Impact damage to apple fruits in commercial corrugated fiberboard box packaging evaluated by the pressure-sensitive film technique. J. Food Agric. Environ. 2010, 8, 218–222. [Google Scholar]

- Fadiji, T.; Coetzee, C.; Pathare, P.; Opara, U.L. Susceptibility to impact damage of apples inside ventilated corrugated paperboard packages: Effects of package design. Postharvest Biol. Technol. 2016, 111, 286–296. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R.; Enshaei, H. Assessment and Characterizing Mechanical Damage in Packaged Bananas in the Post-harvest Supply Chain. In MATEC Web of Conferences, Proceedings of the 2019 7th International Conference on Traffic and Logistic Engineering (ICTLE 2019), Paris, France, 21–23 August 2019; EDP Sciences: Les Ulis, France, 2019; Volume 296, p. 02004. [Google Scholar]

- Fernando, I.; Fei, J.; Stanley, R.; Enshaei, H. Measurement and evaluation of the effect of vibration on fruits in transit—Review. Packag. Technol. Sci. 2018, 31, 723–738. [Google Scholar] [CrossRef]

- Fernando, I.; Fei, J.; Stanley, R.; Rouillard, V. Evaluating packaging performance for bananas under simulated vibration. Food Packag. Shelf Life 2020, 23, 100428. [Google Scholar] [CrossRef]

- Dunno, K. Experimental evaluation of techniques designed to reduce vibration simulation test time. J. Appl. Packag. Res. 2014, 6, 1–10. [Google Scholar] [CrossRef]

- Berardinelli, A.; Donati, V.; Giunchi, A.; Guarnieri, A.; Ragni, L. Damage to pears caused by simulated transport. J. Food Eng. 2005, 66, 219–226. [Google Scholar] [CrossRef]

- Idah, P.A.; Gana, Y.M.; Ogbonnaya, C.; Morenikeji, O.O. Simulated transport damage study on fresh tomato (Lycopersicon esculentum) fruits. CIGR J. 2012, 14, 119–126. [Google Scholar]

- Kipp, W. Accelerated random vibration with time-history shock. In Proceedings of the IOPP 2001 Annual Membership Meeting, San Jose, CA, USA, 29 March 2001. [Google Scholar]

- Jarimopas, B.; Singh, S.P.; Saengnil, W. Measurement and analysis of truck transport vibration levels and damage to packaged tangerines during transit. Packag. Technol. Sci. 2005, 18, 179–188. [Google Scholar] [CrossRef]

- Bernad, C.; Laspalas, A.; González, D.; Núñez, J.L.; Buil, F. Transport vibration laboratory simulation: On the necessity of multiaxis testing. Packag. Technol. Sci. 2010, 24, 1–14. [Google Scholar] [CrossRef]

- ASTM. Packaging and Shipping Container Standards; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ISTA. ISTA—2017 Resource Book; International Safe Transit Association: East Lansing, MI, USA, 2017. [Google Scholar]

- Konya, T.; Kainuma, H.; Fujioka, O.; Tanaka, H. Development and Adaptability of Individual Packaging Containers for Strawberries. Jpn. Agric. Res. Q. 2016, 50, 183–186. [Google Scholar] [CrossRef]

- Soleimani, B.; Ahmadi, E. Measurement and analysis of truck vibration levels as a function of packages locations in truck bed and suspension. Comput. Electron. Agric. 2014, 109, 141–147. [Google Scholar] [CrossRef]

- Vursavuş, K.K.; Özgüven, F. Determining the effects of vibration parameters and packaging method on mechanical damage in golden delicious apples. Turk. J. Agric. For. 2004, 28, 311–320. [Google Scholar]

- Fadiji, T.; Coetzee, C.; Chen, L.; Chukwu, O.; Opara, U.L. Susceptibility of apples to bruising inside ventilated corrugated paperboard packages during simulated transport damage. Postharvest Biol. Technol. 2016, 118, 111–119. [Google Scholar] [CrossRef]

- Rouillard, V.; Sek, M.A.; Crawford, S. The dynamic behaviour of stacked shipping units during transport. Part 1: Model validation. Packag. Technol. Sci. 2004, 17, 237–247. [Google Scholar] [CrossRef]

- Çakmak, B.; Alayunt, F.N.; Akdeniz, R.C.; Aksoy, U.; Can, H.Z. Assessment of the quality losses of fresh fig fruits during transportation. J. Agric. Sci. 2010, 16, 180–193. [Google Scholar]

- Shahbazi, F.; Rajabipour, A.; Mohtasebi, S.; Rafie, S. Simulated in-transit vibration damage to watermelons. J. Agric. Sci. Technol. 2010, 12, 23–34. [Google Scholar]

- Tabatabaekoloor, R.; Hashemi, S.J.; Taghizade, G. Vibration damage to kiwifruits during road transportation. Int. J. Agric. Sci. Food Technol. 2013, 4, 467–474. [Google Scholar]

- Wei, X.; Xie, D.; Mao, L.; Xu, C.; Luo, Z.; Xia, M.; Zhao, X.; Han, X.; Lu, W. Excess water loss induced by simulated transport vibration in postharvest kiwifruit. Sci. Hortic. 2019, 250, 113–120. [Google Scholar] [CrossRef]

- Wasala, W.; Dharmasena, D.; Dissanayake, T.; Thilakarathne, B. Vibration simulation testing of banana bulk transport packaging systems. Trop. Agric. Res. 2015, 26, 355. [Google Scholar] [CrossRef]

- Lin, M.; Chen, J.; Chen, F.; Zhu, C.; Wu, D.; Wang, J.; Chen, K. Effects of cushioning materials and temperature on quality damage of ripe peaches according to the vibration test. Food Packag. Shelf Life 2020, 25, 100518. [Google Scholar] [CrossRef]

- Khodaei, M.; Seiiedlou, S.; Sadeghi, M. The evaluation of vibration damage in fresh apricots during simulated transport. Res. Agric. Eng. 2019, 65, 112–122. [Google Scholar] [CrossRef]

- Rostampour, V.; Motlagh, A.M. Evaluation of the bruising susceptibility of apple in transport conditions. Bulg. J. Agric. Sci. 2018, 24, 902–908. [Google Scholar]

- La Scalia, G.; Enea, M.; Micale, R.; Corona, O.; Settanni, L. Damage to strawberries caused by simulated transport. Int. J. Biol. Biomol. Agric. Food Biotechnol. Eng. 2015, 9, 1139–1144. [Google Scholar]

- Chaiwong, S.; Bishop, C.F. Effect of vibration damage on the storage quality of ’Elsanta’ strawberry. Aust. J. Crop Sci. 2015, 9, 859–864. [Google Scholar]

- Chonhenchob, V.; Singh, S.P. A comparison of corrugated boxes and reusable plastic containers for mango distribution. Packag. Technol. Sci. 2003, 16, 231–237. [Google Scholar] [CrossRef]

- Chonhenchob, V.; Sittipod, S.; Swasdee, D.; Rachtanapun, P.; Singh, S.P.; Singh, J.A. Effect of truck vibration during transport on damage to fresh produce shipments in Thailand. Ind. Technol. 2009, 6, 27–38. [Google Scholar]

- Coffin, D.W. Some observations towards improved predictive models for box compression strength. TAPPI J. 2015, 14, 537–545. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.; Verboven, P.; Nicolai, B. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. Trends Food Sci. Technol. 2015, 44, 201–225. [Google Scholar] [CrossRef]

- Kueh, C.; Navaranjan, N.; Duke, M. The effect of in-plane boundary conditions on the post-buckling behaviour of rectangular corrugated paperboard panels. Comput. Struct. 2012, 104–105, 55–62. [Google Scholar] [CrossRef]

- Marek, A.; Garbowski, T. Homogenization of sandwich panels. Comput. Ass. Met. Eng. Sci. 2015, 22, 39–50. [Google Scholar]

- Starke, M.M. Material and Structural Modelling of Corrugated Paperboard Packaging. Master’s Thesis, Stellenbosch University, Stellenbosch, South Africa, 2020. [Google Scholar]

- Biancolini, M. Evaluation of equivalent stiffness properties of corrugated board. Compos. Struct. 2005, 69, 322–328. [Google Scholar] [CrossRef]

- Biancolini, M.E.; Brutti, C.; Porziani, S. Corrugated board containers design methods. Int. J. Comput. Mater. Sci. Surf. Eng. 2010, 3, 143. [Google Scholar] [CrossRef]

- Biancolini, M.E.; Brutti, C. Numerical and experimental investigation of the strength of corrugated board packages. Packag. Technol. Sci. 2003, 16, 47–60. [Google Scholar] [CrossRef]

- Hammou, A.D.; Duong, P.T.M.; Abbes, B.; Makhlouf, M.; Guo, Y.-Q. Finite-element simulation with a homogenization model and experimental study of free drop tests of corrugated cardboard packaging. Mech. Ind. 2012, 13, 175–184. [Google Scholar] [CrossRef]

- Talbi, N.; Batti, A.; Ayad, R.; Guo, Y. An analytical homogenization model for finite element modelling of corrugated cardboard. Compos. Struct. 2009, 88, 280–289. [Google Scholar] [CrossRef]

- Zaheer, M.; Awais, M.; Rautkari, L.; Sorvari, J. Finite element analysis of paperboard package under compressional load. Procedia Manuf. 2018, 17, 1162–1170. [Google Scholar] [CrossRef]

- Luong, V.D.; Abbes, F.; Abbes, B.; Duong, P.T.M.; Nolot, J.-B.; Erre, D.; Guo, Y.-Q. Finite element simulation of the strength of corrugated board boxes under impact dynamics. In Proceedings of the International Conference on Advances in Computational Mechanics, Phu Quoc Island, Vietnam, 2–4 August 2017; Springer Nature: Singapore, 2017; pp. 369–380. [Google Scholar]

- Luong, V.; Bonnin, A.S.; Abbès, F.; Nolot, J.B.; Erre, D.; Abbès, B. Finite Element and Experimental Investigation on the Effect of Repetitive Shock in Corrugated Cardboard Packaging. J. Appl. Comput. Mech. 2021, 7, 820–830. [Google Scholar]

- Yoshihara, H. Influence of the specimen depth to length ratio and lamination construction on Young’s modulus and in-plane shear modulus of plywood measured by flexural vibration. BioResources 2012, 7, 1337–1351. [Google Scholar]

- Fadiji, T.; Berry, T.; Coetzee, C.J.; Opara, L. Investigating the mechanical properties of paperboard packaging material for handling fresh produce under different environmental conditions: Experimental analysis and finite element modelling. J. Appl. Packag. Res. 2017, 9, 20–34. [Google Scholar]

- Pathare, P.; Opara, U.L.; Vigneault, C.; Delele, M.A.; Al-Said, F.A.-J. Design of Packaging Vents for Cooling Fresh Horticultural Produce. Food Bioprocess. Technol. 2012, 5, 2031–2045. [Google Scholar] [CrossRef]

- SIAM Working Group on CSE SWGoC. Graduate education in computational science and engineering. SIAM Rev. 2001, 43, 163–177. [Google Scholar] [CrossRef]

- Franklin, J. Computational Methods for Physics; Cambridge University Press (CUP): Cambridge, UK, 2013. [Google Scholar]

- Opara, L.U.; Zou, Q.; Opara, U.L. Sensitivity Analysis of a CFD Modelling System for Airflow and Heat Transfer of Fresh Food Packaging: Inlet Air Flow Velocity and Inside-Package Configurations. Int. J. Food Eng. 2007, 3, 1263. [Google Scholar] [CrossRef]

- Tanner, D.; Cleland, A.; Robertson, T.; Opara, L.; Opara, U.L. PH—Postharvest Technology: Use of Carbon Dioxide as a Tracer Gas for Determining In-package Airflow Distribution. J. Agric. Eng. Res. 2000, 77, 409–417. [Google Scholar] [CrossRef]

- Tanner, D.; Cleland, A.; Opara, L.; Robertson, T.; Opara, U.L. A generalised mathematical modelling methodology for design of horticultural food packages exposed to refrigerated conditions: Part 1, formulation. Int. J. Refrig. 2002, 25, 33–42. [Google Scholar] [CrossRef]

- Tanner, D.J.; Cleland, A.C.; Opara, L.U. A generalized mathematical modelling methodology for the design of horticultural food packages exposed to refrigerated conditions. Part 2. Heat transfer modelling and testing. Int. J. Refrig. 2002, 25, 43–53. [Google Scholar] [CrossRef]

- Zou, Q.; Opara, U.L.; McKibbin, R. A CFD modeling system for airflow and heat transfer in ventilated packaging for fresh foods: I. Initial analysis and development of mathematical models. J. Food Eng. 2006, 77, 1037–1047. [Google Scholar] [CrossRef]

- Zou, Q.; Opara, L.U.; McKibbin, R. A CFD modeling system for airflow and heat transfer in ventilated packaging for fresh foods: II. Computational solution, software development, and model testing. J. Food Eng. 2006, 77, 1048–1058. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Tchuenbou-Magaia, F. An extended finite element model for fracture mechanical response of tomato fruit. Postharvest Biol. Technol. 2021, 174, 111468. [Google Scholar] [CrossRef]

| Software Package | General Description | Postharvest Applications |

|---|---|---|

| COMSOL Multiphysics | Finite-element-based, solves various physics and engineering problems, especially coupled phenomena or multi-physics. Usually used for small uncomplicated systems. Possible to run 2D simulations. |

|

| ANSYS in Fluent | Finite-volume-based, the most versatile. Solves problems for multiphase flows, chemical reaction, viscous and turbulent, internal and external flows, flow-induced noise predictions, and heat transfer with and without radiation. Possible to run 2D simulations. |

|

| ANSYS in CFX | Finite-volume-based. Ansys, Inc. released the new release Ansys 2020 R2 on July 15, 2020. Can only run 3D simulations | |

| Open FOAM | Finite-volume-based numerical algorithms originally developed by the CFD research group at London’s Imperial College in the late 1980s. |

| Fruit | Numerical Technique | Objectives | Result | Reference |

|---|---|---|---|---|

| Citrus | FVM ANSYS in Fluent | Investigating a new cold chain protocol. | Ambient loading of fruit in reefer containers for cooling during long-haul marine transport. | [66] |

| N/A | FVM | Investigating the effect of the azimuth angle on energy consumption. | The introduction of installation of a roof shade at reefer container reduced energy consumption. | [74] |

| Apple | FVM ANSYS in CFX | Analyzing the air-corrugated carton moisture exchange phenomenon inside reefer containers. | The sealing efficiency was estimated for different situations, with the air circulation devices installed inside, outside, or on both sides of the door. | [21] |

| Citrus | FVM ANSYS in Fluent | Investigating the impact of cargo stacking methods on temperature distribution. | Non-uniformity of temperature distributions increases with stack height and stack length. | [75] |

| Table Grapes | FVM ANSYS in Fluent | Investigating the differences among refrigerated trailer models. | Reports significant differences among three airflow design models of refrigerated cargo systems. | [76] |

| Apple | FVM | Redesigning internal structure for improved cooling rate and uniformity. | Airflow velocity was improved by 5.24–425.04% and the cooling rate improved by 34.0% to 59.5%. | [77] |

| N/A | NA | Investigating the effect of inlet velocity variation on the cooling speed inside a refrigerated container. | The cooling speed difference between low-speed (4 m/s) and high-speed (10 m/s) fans was about 12 min. | [74,78,79] |

| Banana | FEM in COMSOL Multiphysics software | Evaluating airflow pattern in reefer container loaded with bananas. | Simulation results predicted the location of the hot spots. Moreover, it was found that the cooling distribution was improved by modification of the scheme for placing pallets in the container, the so-called chimney layout. | [80] |

| Apple | FVM ANSYS in Fluent | Investigating the cooling rate and cooling uniformity performances of commonly used ventilated packaging boxes. | The study demonstrated the significance of vent holes on the bottom face of packaging boxes and the potential energy-saving opportunities in refrigerated transport systems. | [16,17] |

| Problem | Approach | Software Package | Key Outputs | References |

|---|---|---|---|---|

| To estimate the static top-to-bottom compressive strength of corrugated packaging with different ventilation openings and holes. | Analytical-numerical approach validated with experimental data | Not applicable | For different hole sizes or locations in no-flap and flap boxes, the estimation error may be reduced up to three times, compared to the simple analytical approach. | [104] |

| To determine the influence of paperboard carton design on its bulging performance when under compression. | Experimental analysis | Not applicable | To a certain extent, regular slotted cartons with a 5-down footprint had higher compression bulge displacement on the short face with increasing carton height at ambient conditions. | [105] |

| To analyze the deformation and compressive strength of cartons with different indentation shapes. | Simulation and experimental methods | ANSYS Mechanical | Rhombus indentation and cross-indentation had the greatest influence on the compressive strength of cartons. | [106] |

| To investigate the strength of corrugated cardboard boxes. | Experimental analysis | Not applicable | As the paper weight increased, the strength of corrugated cardboard increased. | [107] |

| To propose an analytical model to deduce the compression force for corrugated paperboard packaging. | Mathematical model and experimental method | Not applicable | Analytical results compared with experimental showed a good correlation. | [108] |

| To determine the compression strength of different corrugated fiberboard boxes. | Nonlinear finite element analysis that considers geometric nonlinearity and material nonlinearity validated with experimental methods | MSC Marc | Boxes with a hand hole in their end panel had less compression strength than those without holes. | [109] |

| To investigate the effect of carton configuration on compression strength. | Nonlinear finite element analysis and experimental methods | MSC Marc | The compression strength of double-walled corrugated cartons (BC-flute) was higher than single-walled cartons (B- and C-flute). | [110] |

| To evaluate the compression strength of corrugated cartons at storage conditions. | Experimental analysis | Not applicable | The compression strength of the carton decreased with an increase in moisture content. | [23] |

| To study the effect of multiple creasing lines on the compression strength of corrugated cartons. | Experimental analysis | Not applicable | The carton compression strength decreased significantly due to additional creasing line(s). | [93] |

| To determine the effects of storage temperature on the moisture content and compression strength of two carton designs. | Experimental analysis | Not applicable | The compression strength of the “Supervent” carton with 34% more vent area was significantly lower than that of the “Standard” carton. | [88] |

| To study the effects of squareness on the compression strength of corrugated cartons. | Experimental analysis | Not applicable | Square cartons of any flute type performed better than rectangular cartons of the same perimeter and same materials. | [25] |

| To evaluate the effects of geometric parameters on carton compression strength. | Simulation and experimental methods | MSC Nastran | Vent number, area, orientation, and shape affected the compression strength of the carton. Rectangular vent holes better retained the carton strength. | [86] |

| To analyze possible deformation shapes of corrugated paperboard cartons under compression. | Experimental analysis | Not applicable | Varying skews with side walls bending in both convex and concave directions were observed during BCT. | [111] |

| To assess the effect of aspect ratio on corrugated carton compression strength. | Experimental analysis | Not applicable | The compression strength reached the maximum when the aspect ratio at 1.6. | [112] |

| Produce | Frequency (Hz) | Acceleration (g) | Duration (min) | Packaging Methods Used | Damage and Quality Evaluation | References |

|---|---|---|---|---|---|---|

| Fresh Fig | 3 | 0.06 | 30 | Polystyrene packaging boxes | Yes | [133] |

| 16 | 0.26 | 30 | Cardboard boxes | |||

| Watermelon | 7.5, 13 | 0.3, 0.7 | 30, 60 | Corrugated containers | Yes | [134] |

| Kiwifruit | 7.5, 13 | 0.3, 0.7 | N/A | Wooden bin | Yes | [135] |

| Kiwifruit | 20 | 0.9 | 300 | Foam-rubber cushion | Yes | [136] |

| Banana | 3.5 | 0.1 | 120 | Styrofoam sheets | Yes | [137] |

| Corrugated fiberboard boxes | ||||||

| Banana | PSD spectra | 0.36 | 180 | Corrugated cartons | Yes | [119] |

| Peaches | N/A | 0.56 | 90 | Polyurethane | Yes | [138] |

| Corrugated fiberboard boxes | ||||||

| Expandable polyethylene | ||||||

| Apricot | 17, 20 | 0.7 | 15, 30 | Reusable plastic containers | Yes | [139] |

| Apple | 9, 12, 15 | 0.9 | 240 | Corrugated paperboard cartons | Yes | [131] |

| Apple | 7.5, 10 13 | 0.3, 0.5, 0.7 | N/A | N/A | Yes | [140] |

| Strawberry | 9 | N/A | 2880 | Polyvinyl Chloride (PVC) containers | Yes | [141] |

| Crates made of cardboard | ||||||

| Strawberry | 3 | 0.4 | 0.83, 2.5 | Polyethylene terephthalate (PET) vented punnets | Yes | [142] |

| 4 | 0.8 | |||||

| 5 | 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ambaw, A.; Fadiji, T.; Opara, U.L. Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances. Foods 2021, 10, 1357. https://doi.org/10.3390/foods10061357

Ambaw A, Fadiji T, Opara UL. Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances. Foods. 2021; 10(6):1357. https://doi.org/10.3390/foods10061357

Chicago/Turabian StyleAmbaw, Alemayehu, Tobi Fadiji, and Umezuruike Linus Opara. 2021. "Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances" Foods 10, no. 6: 1357. https://doi.org/10.3390/foods10061357

APA StyleAmbaw, A., Fadiji, T., & Opara, U. L. (2021). Thermo-Mechanical Analysis in the Fresh Fruit Cold Chain: A Review on Recent Advances. Foods, 10(6), 1357. https://doi.org/10.3390/foods10061357

_Ambaw.png)